Badminton Racket Coatings and Athletic Performance: Review Based on Functional Coatings

Abstract

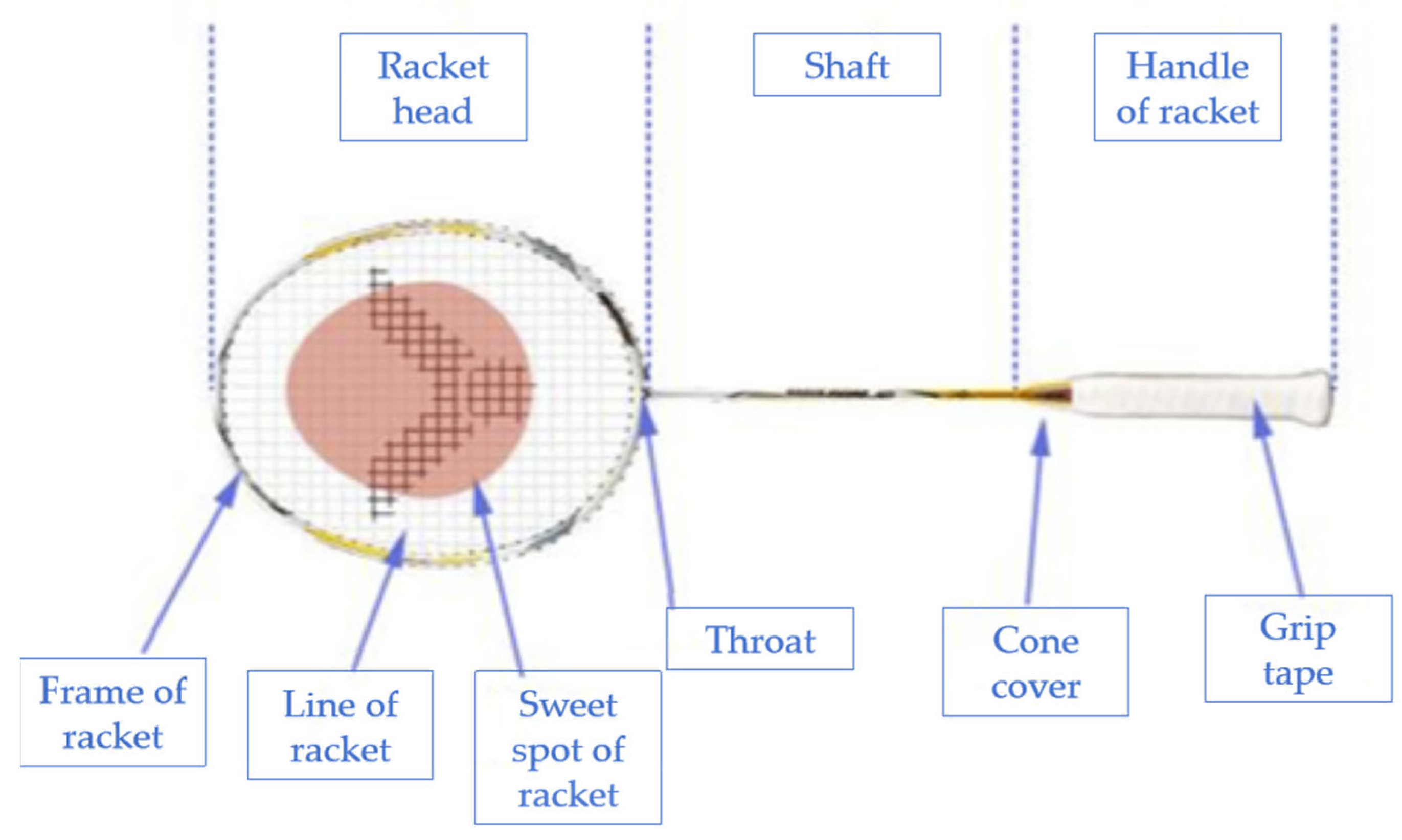

1. Introduction

2. Classification and Characteristics of Functional Coatings for Badminton Rackets

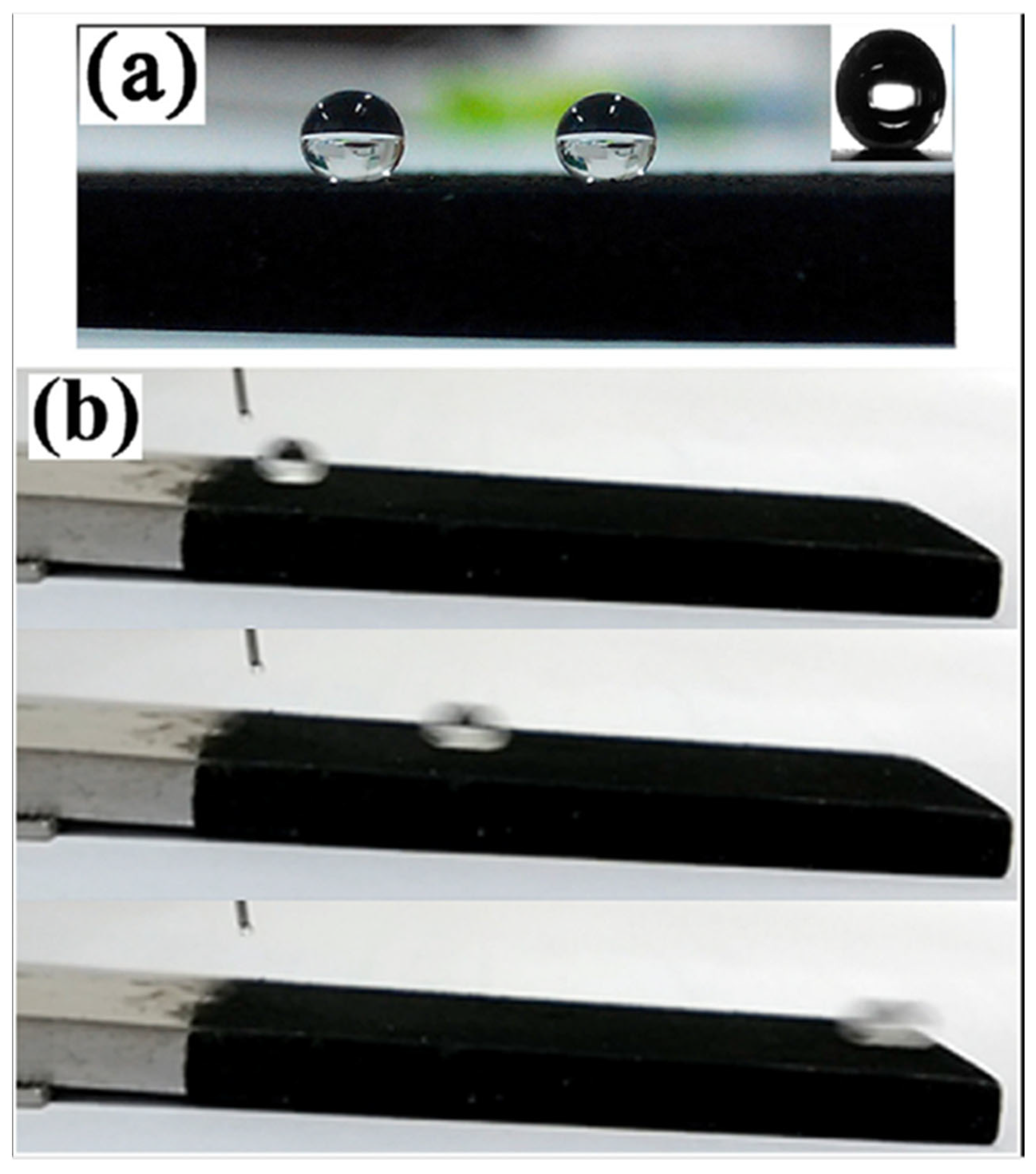

2.1. Superhydrophobic Coating

2.1.1. Enhanced Water and Ice Resistance for Sports Equipment

2.1.2. Superhydrophobic Mechanism and Coating Construction Technology

2.2. Anti-Scratch Coating

2.2.1. Necessity and Sources of Damage

2.2.2. Core Functions and Implementation Mechanisms

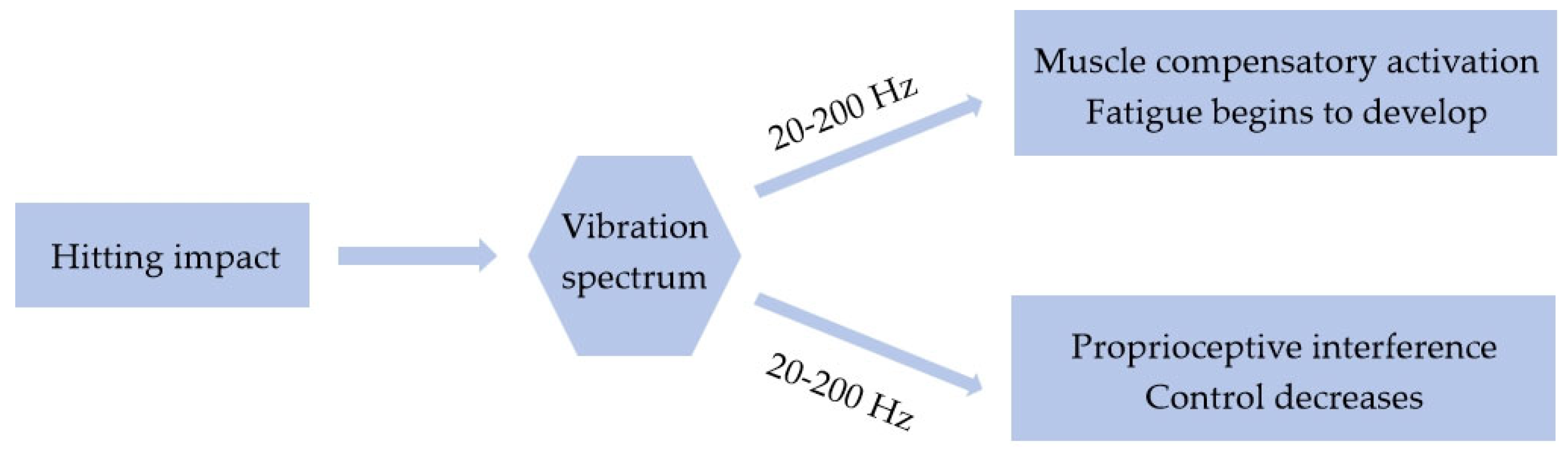

2.3. Vibration Damping Coatings

2.3.1. Sources of Vibration, Hazards, and the Necessity of Shock Absorption

2.3.2. Vibration Damping Mechanism and Coating Material Technology

2.4. Strength-Enhancing Coatings

2.4.1. Background of Strength Requirements

2.4.2. Strengthening Mechanisms and Coating Technology Approaches

3. Enhancement in Badminton Racket Performance by Coatings

3.1. Functional Coatings’ Systematic Enhancement in Badminton Racket Durability and Damage Resistance

3.1.1. Core Mechanisms and Synergistic Effects of Coatings in Enhancing Durability and Damage Resistance

3.1.2. Synergistic Effects and the Value of Multi-Layer Coating Systems

3.2. Optimization Effect of Functional Coatings on Badminton Racket Elasticity and Hitting Performance

3.2.1. Core Mechanism: How Coatings Intervene in the Energy Transfer Chain

3.2.2. Quantitative Understanding and Boundaries of Coating Effects

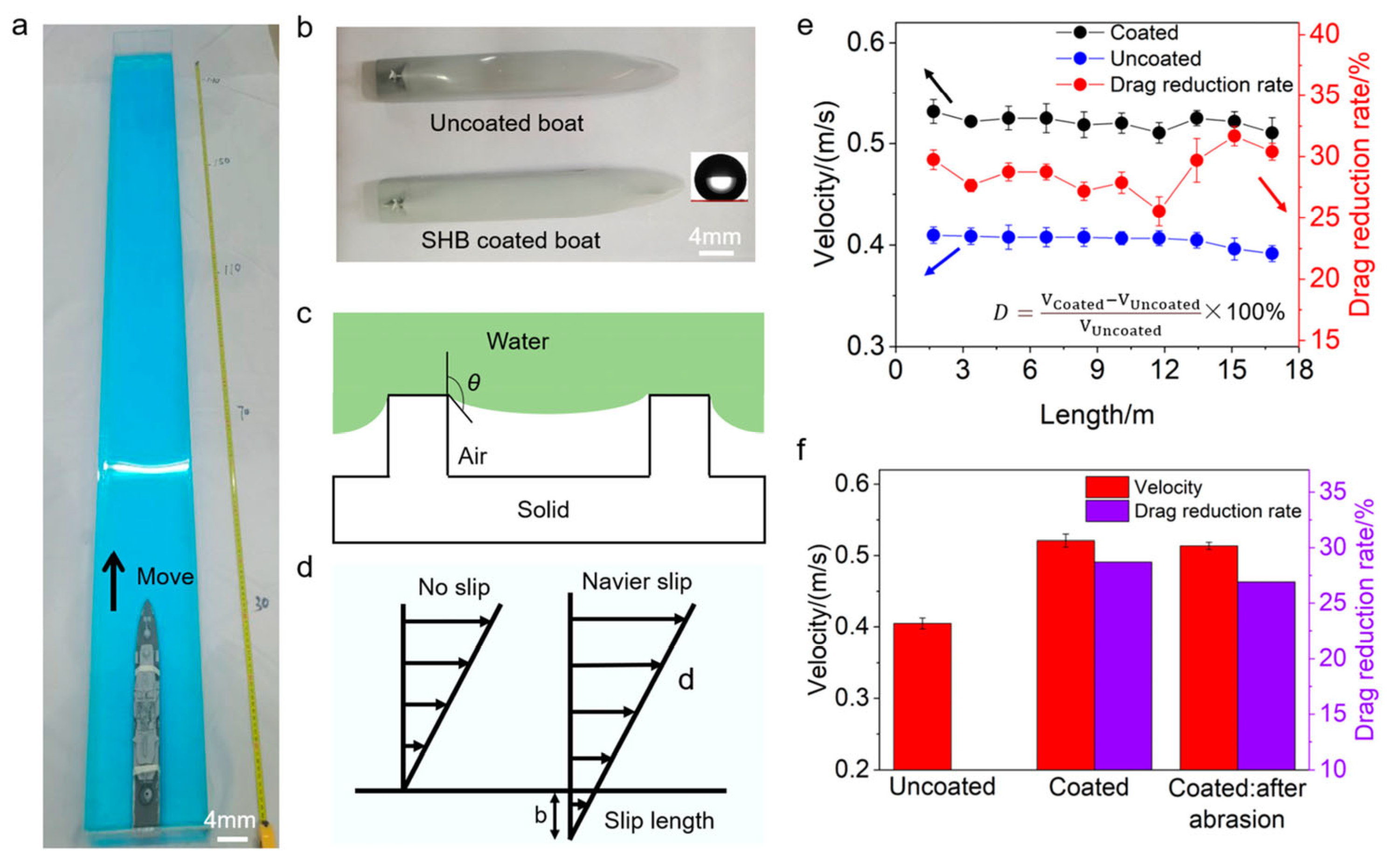

3.3. The Role of Functional Coatings in Reducing Air Resistance and Enhancing Swing Speed

3.3.1. Sources of Air Resistance and Core Determinants of Swing Speed

3.3.2. Core Mechanisms and Efficacy of Functional Coatings in Reducing Air Resistance

4. The Impact of Functional Coatings on Badminton Players’ Sports Performance

4.1. Player Control and Comfort

4.2. Potential and Indirect Effects on Sports Performance

4.3. The Enhancing Role of Coating Technology on Competitive Performance

5. Challenges in the Application of Functional Coatings in Badminton Rackets

5.1. Technical Feasibility and Cost Issues

5.1.1. Core Technical Feasibility Challenges

5.1.2. Complexity, Stability, and Scalability of Manufacturing Processes

5.1.3. Cost–Benefit Analysis and Key Market Adoption Constraints

5.1.4. Market Positioning and Consumer Acceptance

5.2. Environmental Protection and Sustainability

6. Summary and Future Outlook

6.1. Summary

6.2. Future Prospects

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahzadi, P.; Majeed, M.A.; Ibrahim, S.; Asif, S.; Kalsoom, R.; Hussain, I. Polymeric coating doped with nanomaterials for functional impact on different substrates. Sci. Rep. 2024, 14, 578. [Google Scholar] [CrossRef]

- Towler, H.; Mitchell, S.R.; King, M.A. Effects of racket moment of inertia on racket head speed, impact location and shuttlecock speed during the badminton smash. Sci. Rep. 2023, 13, 14060. [Google Scholar] [CrossRef]

- Kwan, M.; Rasmussen, J. The importance of being elastic: Deflection of a badminton racket during a stroke. J. Sports Sci. 2010, 28, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Phomsoupha, M.; Laffaye, G.; Cohen, C.; Clanet, C. How to use the elasticity of a badminton racket to increase its speed by 80%? Comput. Methods Biomech. Biomed. Eng. 2015, 18, 2028–2029. [Google Scholar] [CrossRef]

- Wang, T.; Yee Guan, N.; Amri, S.; Kamalden, T.F.; Gao, Z. Effects of resistance training on performance in competitive badminton players: A systematic review. Front. Physiol. 2025, 16, 1548869. [Google Scholar] [CrossRef]

- Goralczyk, A.; Savicheva, S.; Montazeri, R.; Fine, S.; Mayoussi, F.; Zhu, P.; Steffen, K.; Kotz-Helmer, F.; Helmer, D.; Rapp, B.E. Spray-Coating of Superhydrophobic Coatings for Advanced Applications. Adv. Eng. Mater. 2022, 25, 2201314. [Google Scholar] [CrossRef]

- He, S.; Chen, J.; Lu, Y.; Huang, S.; Feng, K. Enhanced waterproof performance of superhydrophobic SiO2/PDMS coating. Prog. Org. Coat. 2024, 197, 108845. [Google Scholar] [CrossRef]

- Han, S.; Wang, Y.; Wang, Q.; Han, L.; Han, G. Film-formation processes of polymer emulsions in polymer-cement waterproof coatings and their effect on coatings’ macroscopic properties. Constr. Build. Mater. 2024, 438, 137137. [Google Scholar] [CrossRef]

- Ghezal, I.; Moussa, A.; Marzoug, I.B.; El-Achari, A.; Campagne, C.; Sakli, F. Evaluating the Mechanical Properties of Waterproof Breathable Fabric Produced by a Coating Process. Cloth. Text. Res. J. 2019, 37, 235–248. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Kan, L.; Shen, F.; Ling, H.; Wang, X. All-biomass-based eco-friendly waterproof coating for paper-based green packaging. Green Chem. 2022, 24, 7039–7048. [Google Scholar] [CrossRef]

- Yoon, S.-h.; Heo, N.-h.; An, K.-w.; Oh, S.-k. A Study on the Change in Properties by Using an Additive with Water-Soluble Rubber-Asphalt-Based Waterproof Coating Materials. Appl. Sci. 2022, 12, 4599. [Google Scholar] [CrossRef]

- Yu, S.S.; Zhang, S.; Xia, Z.W.; Liu, S.; Lu, H.J.; Zeng, X.T. Textured hybrid nanocomposite coatings for surface wear protection of sports equipment. Surf. Coat. Technol. 2016, 287, 76–81. [Google Scholar] [CrossRef]

- Li, H.; Yu, S. Fabrication and theoretical explanation of the superhydrophobic Cu Zn coating with dandelion-like CuO microstructure. J. Alloys Compd. 2017, 691, 195–205. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, X.; Ji, J.; Tao, T.; Zhang, T.; Xu, J.; Jiao, Y.; Liu, K. Underwater Drag Reduction and Buoyancy Enhancement on Biomimetic Antiabrasive Superhydrophobic Coatings. ACS Appl. Mater. Interfaces 2021, 13, 48270–48280. [Google Scholar] [CrossRef]

- Xu, Y.; An, K.; Wang, Y.; Sui, Y.; Tong, W.; Liu, H.; Qing, Y. Designing a Robust Ni–P/CeO2 Superhydrophobic Composite Coating for Synergistically Enhanced Corrosion Protection and Friction Reduction Performance. Langmuir 2024, 40, 16771–16782. [Google Scholar] [CrossRef] [PubMed]

- Emelyanenko, A.M.; Boinovich, L.B.; Bezdomnikov, A.A.; Chulkova, E.V.; Emelyanenko, K.A. Reinforced Superhydrophobic Coating on Silicone Rubber for Longstanding Anti-Icing Performance in Severe Conditions. ACS Appl. Mater. Interfaces 2017, 9, 24210–24219. [Google Scholar] [CrossRef]

- Domene-López, D.; Sarabia-Riquelme, R.; García-Quesada, J.C.; Martin-Gullon, I. Custom-Made Chemically Modified Graphene Oxide to Improve the Anti-Scratch Resistance of Urethane-Acrylate Transparent Coatings. Coatings 2019, 9, 408. [Google Scholar] [CrossRef]

- Ning, N.; Wang, S.; Zhang, Z.; Feng, Z.; Zheng, Z.; Yu, B.; Tian, M.; Zhang, L. Superhydrophobic coating with ultrahigh adhesive force and good anti-scratching on elastomeric substrate by thiol-ene click chemistry. Chem. Eng. J. 2019, 373, 318–324. [Google Scholar] [CrossRef]

- Karimi, L.S.; Amiri, S.; Zori, M.H. Synthesis and Characterization of Anti-Scratch and Anti-Corrosion Hybrid Nanocomposite Coatings Based on Sol-Gel Process. Silicon 2020, 13, 2195–2207. [Google Scholar] [CrossRef]

- Lei, F.; Yang, J.; Wu, B.; Chen, L.; Sun, H.; Zhang, H.; Sun, D. Facile design and fabrication of highly transparent and hydrophobic coatings on glass with anti-scratch property via surface dewetting. Prog. Org. Coat. 2018, 120, 28–35. [Google Scholar] [CrossRef]

- Joo, W.; Kim, Y.; Jang, S.; Kim, J.K. Antireflection coating with enhanced anti-scratch property from nanoporous block copolymer template. Thin Solid Film. 2011, 519, 3804–3808. [Google Scholar] [CrossRef]

- Ning, C.; Tang, G.; Yu, S.; Wu, H.; Zhou, J.; Zeng, B.; Wu, Y.; Cai, Z. Effect of laser shock peening on the properties of Cr coatings on Zr alloy surfaces. Surf. Coat. Technol. 2025, 511, 132252. [Google Scholar] [CrossRef]

- Nie, X.; Li, Y.; Tu, S.; Zhang, X.; Luo, S.; Li, Y.; Yang, Z.; He, W. Feasibility study of microscale laser shock processing without absorbing coating to improve high-cycle fatigue performance of DZ17G directionally solidified superalloy. J. Laser Appl. 2019, 31, 042007. [Google Scholar] [CrossRef]

- Acanfora, V.; Saputo, S.; Russo, A.; Riccio, A. A feasibility study on additive manufactured hybrid metal/composite shock absorbers. Compos. Struct. 2021, 268, 113958. [Google Scholar] [CrossRef]

- Liu, Z.-h.; Tao, R.; Luo, P.; Shu, X.; Ban, G.-d. Preparation and microwave absorbing property of carbon fiber/polyurethane radar absorbing coating. RSC Adv. 2017, 7, 46060–46068. [Google Scholar] [CrossRef]

- Safina, L.R.; Krylova, K.A.; Murzaev, R.T.; Shcherbinin, S.A.; Baimova, J.A. Graphene/Ni composite coating for enhanced strength of Ni surface. Surf. Interfaces 2024, 53, 105011. [Google Scholar] [CrossRef]

- Li, M.; Zhou, X.; Zhao, J.; Hong, Y.; Qu, S.; Wang, P. Enhancing the adhesive strength of solar reflective coatings via mechanical activation. Powder Technol. 2023, 422, 118433. [Google Scholar] [CrossRef]

- Liu, T.-H.; Chen, W.-H.; Shih, Y.; Lin, Y.-C.; Yu, C.; Shiang, T.-Y. Better position for the wearable sensor to monitor badminton sport training loads. Sports Biomech. 2021, 23, 503–515. [Google Scholar] [CrossRef] [PubMed]

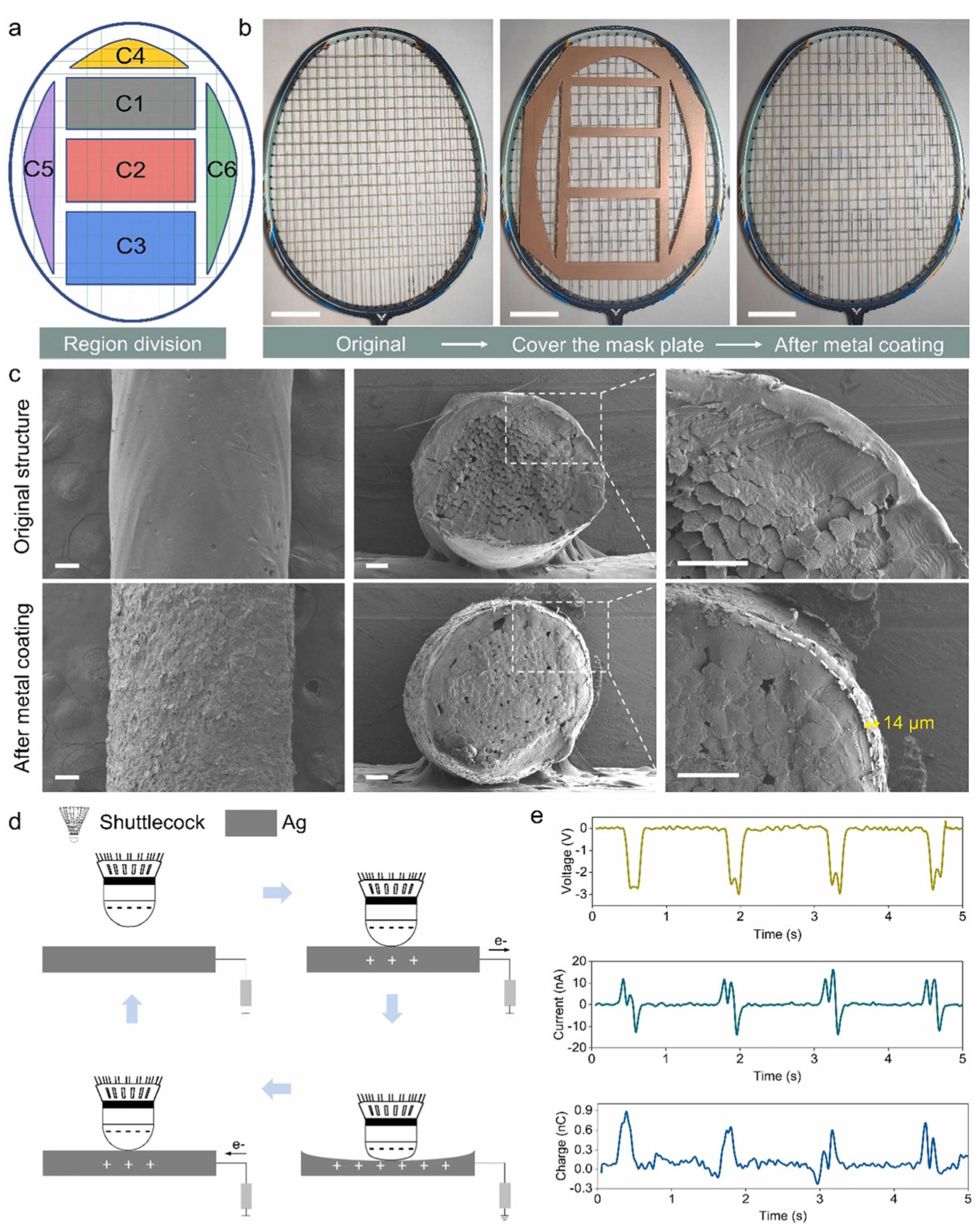

- Yuan, J.; Xue, J.; Liu, M.; Wu, L.; Cheng, J.; Qu, X.; Yu, D.; Wang, E.; Fan, Z.; Liu, Z.; et al. Self-powered intelligent badminton racket for machine learning-enhanced real-time training monitoring. Nano Energy 2024, 132, 110377. [Google Scholar] [CrossRef]

- Chang, J.Y. BST: Badminton Stroke-type Transformer for Skeleton-based Action Recognition in Racket Sports. arXiv 2025, arXiv:2502.21085. [Google Scholar] [CrossRef]

- Lee, S.H.; Ahn, Y.N.; Botu, V.; Stewart, R.J.; Oh, S.Y. Enhancement of Adhesion Strength of Perfluoroalkylpolyethers on Rough Glassy Silica for Antismudge Coatings. ACS Appl. Polym. Mater. 2019, 1, 2613–2621. [Google Scholar] [CrossRef]

- Li, L.; Zhu, J.; Zeng, Z. A sky-blue superhydrophobic coating and applications. Prog. Org. Coat. 2020, 147, 105863. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, X.; Zhao, L.; Hou, B. Transparent Superhydrophobic and Self-Cleaning Coating. Polymers 2024, 16, 1876. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Yang, Y.; Fang, Y.; Wang, H.; Wang, X.; Zhang, H.; Wang, H.; Cao, H.; Hou, J.; et al. Vibration behaviours of composite conical–cylindrical shells with damping coating: Theory and experiment. Thin-Walled Struct. 2024, 203, 112218. [Google Scholar] [CrossRef]

- Amadori, S.; Catania, G.; Casagrande, A. Experimental Evaluation and Modeling of the Damping Properties of Multi-Layer Coated Composites. Coatings 2018, 8, 53. [Google Scholar] [CrossRef]

- Yang, J.; Song, H.; Chen, D.; Zhang, Y. Free vibration and damping analysis of the cylindrical shell partially covered with equidistant multi-ring hard coating based on a unified Jacobi-Ritz method. Sci. Prog. 2021, 104, 00368504211032550. [Google Scholar] [CrossRef]

- Wen, M.; Jiang, B.; Duan, X.; Xiang, D. Research Progress on Microstructure, Mechanical Properties, and Strengthening Mechanisms of In Situ-Synthesized Ceramic-Reinforced Titanium Matrix Composite Coatings via Laser Cladding. Coatings 2025, 15, 815. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, J.; Pan, W.; Wang, W.; Tang, C. Research progress in surface strengthening technology of carbide-based coating. J. Alloys Compd. 2022, 905, 164062. [Google Scholar] [CrossRef]

- Li, Y.; Fu, H.; Ma, T.; Wang, K.; Yang, X.; Lin, J. Strengthening mechanisms in AlCoCrFeNiMo0.8–TiC composite coating based on first-principles calculations. J. Mater. Sci. 2023, 58, 13317–13334. [Google Scholar] [CrossRef]

- Peng, W.; Sun, K.; Abdullah, R.; Zhang, M.; Chen, J.; Shi, J. Strengthening mechanisms of graphene coatings on Cu film under nanoindentation: A molecular dynamics simulation. Appl. Surf. Sci. 2019, 487, 22–31. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, W.; Xie, Q.; Sun, H.; Bai, P. Strengthening Mechanism of Nickel Coating in SLM Processed Ni@Al2O3–CoCrMo Composites. Met. Mater. Int. 2024, 30, 1687–1694. [Google Scholar] [CrossRef]

- Hu, S.; Huang, W.; Meng, F.; Lam, R.H.W.; Lau, D. Adhesion Strengthening Mechanism of Carbon Nanotube-Embedded Epoxy Composites: A Fracture-Based Approach. ACS Appl. Mater. Interfaces 2022, 14, 7221–7229. [Google Scholar] [CrossRef]

- King, M.; Towler, H.; Dillon, R.; McErlain-Naylor, S. A Correlational Analysis of Shuttlecock Speed Kinematic Determinants in the Badminton Jump Smash. Appl. Sci. 2020, 10, 1248. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, S.; He, Y.; Yan, S.; Fan, Y.; Li, Z.; Zhou, H.; Li, H.; Wei, K.; Gong, X.; et al. Enhancement of Corrosion and Wear Resistance of Ni–P Coatings Stems from the Synergistic Effects of Cr3C2 and Heat Treatment. Langmuir 2024, 40, 16400–16418. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Nguyen, T.A.; Nguyen, T.H. The Synergistic Effects of Sio2 Nanoparticles and Organic Photostabilizers for Enhanced Weathering Resistance of Acrylic Polyurethane Coating. J. Compos. Sci. 2020, 4, 23. [Google Scholar] [CrossRef]

- Jiang, T.; Song, L.; Zhang, B.; Zhang, H.; Wang, P.; Zhou, Y.; Fu, L.; Wang, Y.; Han, H.; Yu, H. Synergistic mechanism of MoS2 and PTFE in reinforcing epoxy-based composite coatings. Surf. Coat. Technol. 2025, 516, 132686. [Google Scholar] [CrossRef]

- Alberca, I.; Chénier, F.; Astier, M.; Combet, M.; Bakatchina, S.; Brassart, F.; Vallier, J.-M.; Pradon, D.; Watier, B.; Faupin, A. Impact of Holding a Badminton Racket on Spatio-Temporal and Kinetic Parameters During Manual Wheelchair Propulsion. Front. Sports Act. Living 2022, 4, 862760. [Google Scholar] [CrossRef]

- Ramasamy, Y.; Sundar, V.; Usman, J.; Razman, R.; Towler, H.; King, M.A. Relationships between Racket Arm Joint Moments and Racket Head Speed during the Badminton Jump Smash Performed by Elite Male Malaysian Players. Appl. Sci. 2022, 12, 880. [Google Scholar] [CrossRef]

- Che Hassan, M.F.; Mohd Rosli, M.U.; Mohd Redzuan, M.A. Material selection in a sustainable manufacturing practice of a badminton racket frame using Elimination and Choice Expressing Reality (ELECTRE) Method. J. Phys. Conf. Ser. 2018, 1020, 012012. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, L.; Li, X.; Ma, Y. A Study of Racket Weight Adaptation in Advanced and Beginner Badminton Players. Appl. Bionics Biomech. 2024, 2024, 8908294. [Google Scholar] [CrossRef] [PubMed]

- Touzard, P.; Lecomte, C.; Bideau, B.; Kulpa, R.; Fourel, L.; Fadier, M.; Cantin, N.; Martin, C. There is no rush to upgrade the tennis racket in young intermediate competitive players: The effects of scaling racket on serve biomechanics and performance. Front. Psychol. 2023, 14, 1104146. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.Q.J.; Robertson, S.; Komar, J. Quantifying performance in racket sports: The need for greater context. Int. J. Sports Sci. Coach. 2025, 20, 858–868. [Google Scholar] [CrossRef]

- Krizkova, S.; Tomaskova, H.; Tirkolaee, E.B. Sport Performance Analysis with a Focus on Racket Sports: A Review. Appl. Sci. 2021, 11, 9212. [Google Scholar] [CrossRef]

- Ding, C.; Soh, K.G.; Sun, H.; Roslan, S.; Cao, S.; Zhao, Y. Does mental fatigue affect performance in racket sports? A systematic review. BMC Sports Sci. Med. Rehabilit. 2024, 16, 179. [Google Scholar] [CrossRef]

- Alberca, I.; Chénier, F.; Watier, B.; Brassart, F.; Vallier, J.-M.; Faupin, A. Impact of holding a badminton racket on spatiotemporal parameters during manual wheelchair propulsion based on forward and backward propulsion. Disabil. Rehabil. Assist. Technol. 2025, 20, 1530–1538. [Google Scholar] [CrossRef]

- Sakamoto, M.; Ifuku, H. Experience-Dependent Modulation of Rubber Hand Illusion in Badminton Players. J. Sport Exerc. Psychol. 2022, 44, 14–22. [Google Scholar] [CrossRef]

- Li, Y. Simplified Beam Element Model of Badminton Batting Process Based on Motion Differential Equation. Complexity 2021, 2021, 2071282. [Google Scholar] [CrossRef]

- Tan, J.Q.J.; Chow, J.Y.; Komar, J. The utility of markerless motion capture for performance analysis in racket sports. Proc. Inst. Mech. Eng. Part. P J. Sports Eng. Technol. 2024. [Google Scholar] [CrossRef]

- Martínez-Gallego, R.; Sánchez-Alcaraz, B.; Vučković, G.; Ramón-Llin, J. Editorial: Multidisciplinary aspects and performance in racket sports. Front. Psychol. 2024, 15, 1427362. [Google Scholar] [CrossRef] [PubMed]

- Du, F. Racket, Rhythm, and Results: Assessment of Factors Leading to Transformation of Badminton Teaching Based on Intuitionistic Fuzzy Extended DEMATEL Method. IEEE Access 2025, 13, 89441–89451. [Google Scholar] [CrossRef]

- Malwanage, K.T.; Senadheera, V.V.; Dassanayake, T.L. Effect of balance training on footwork performance in badminton: An interventional study. PLoS ONE 2022, 17, e0277775. [Google Scholar] [CrossRef] [PubMed]

- Le Mansec, Y.; Perez, J.; Rouault, Q.; Doron, J.; Jubeau, M. Impaired Performance of the Smash Stroke in Badminton Induced by Muscle Fatigue. Int. J. Sports Physiol. Perform. 2020, 15, 52–59. [Google Scholar] [CrossRef]

- Chiu, Y.-L.; Tsai, C.-L.; Sung, W.-H.; Tsai, Y.-J. Feasibility of Smartphone-Based Badminton Footwork Performance Assessment System. Sensors 2020, 20, 6035. [Google Scholar] [CrossRef]

- Ramasamy, Y.; Usman, J.; Sundar, V.; Towler, H.; King, M. Kinetic and kinematic determinants of shuttlecock speed in the forehand jump smash performed by elite male Malaysian badminton players. Sports Biomech. 2021, 23, 582–597. [Google Scholar] [CrossRef]

- Tan, K.J.Z.; Goh, W.X.; Boey, D.; Aziz, L.; Ozaki, H.; Nakashima, H.; Sim, D.; Lee, M.J.C. Impact of a new synthetic shuttlecock on badminton performance and player perception. Proc. Inst. Mech. Eng. Part. P J. Sports Eng. Technol. 2025. [Google Scholar] [CrossRef]

- Wong, T.K.K.; Ma, A.W.W.; Liu, K.P.Y.; Chung, L.M.Y.; Bae, Y.-H.; Fong, S.S.M.; Ganesan, B.; Wang, H.-K. Balance control, agility, eye–hand coordination, and sport performance of amateur badminton players. Medicine 2019, 98, e14134. [Google Scholar] [CrossRef]

- Kwan, M.; Andersen, M.S.; Cheng, C.-L.; Tang, W.-T.; Rasmussen, J. Investigation of high-speed badminton racket kinematics by motion capture. Sports Eng. 2010, 13, 57–63. [Google Scholar] [CrossRef]

- Liu, Y.; Abdullah, B.B.; Abu Saad, H.B. Effects of high-intensity interval training on strength, speed, and endurance performance among racket sports players: A systematic review. PLoS ONE 2024, 19, e0295362. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z. Aerodynamic Characteristics and Trajectory Analysis of Badminton Shuttlecocks. Acta Bioeng. Biomech. 2024, 26. [Google Scholar] [CrossRef] [PubMed]

- Osondu, H.A.A.; Akinola, S.A.; Shoko, T.; Pillai, S.K.; Sivakumar, D. Coating properties, resistance response, molecular mechanisms and anthracnose decay reduction in green skin avocado fruit (‘Fuerte’) coated with chitosan hydrochloride loaded with functional compounds. Postharvest. Biol. Technol. 2022, 186, 111812. [Google Scholar] [CrossRef]

- Upadhyay, A.; Lucia, L.; Pal, L. Functional barrier and recyclable packaging materials through microfibrillated cellulose bilayer composite coatings. Carbohydr. Polym. 2025, 359, 123592. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Tang, P.; Su, Y.; Lin, S.; Dai, M.; Zhang, C.; Zou, J.; Shi, Q. Effect of Y-doping on the microstructural evolution and oxidation resistance of NiAlHf coatings at 1200 °C. Ceram. Int. 2023, 49, 35123–35134. [Google Scholar] [CrossRef]

- Loiseau-Taupin, M.; Ruffault, A.; Slawinski, J.; Delabarre, L.; Bayle, D. Effects of Acute Physical Fatigue on Gaze Behavior and Performance During a Badminton Game. Front. Sports Act. Living 2021, 3, 725625. [Google Scholar] [CrossRef]

- Amaro, C.M.; Nolasco, S.; Roseiro, L.; Amaro, A.M.; Castro, M.A. sEMG Analysis of Upper Limb Muscles during Backhand Smash Using Badminton Rackets of Different Stiffness. Appl. Sci. 2022, 12, 9483. [Google Scholar] [CrossRef]

- Lambert, C.; Banerjee, M.; Ritzmann, R.; Lachmann, D.; Wolfarth, B.; Grim, C.; Shafizadeh, S.; Geßlein, M.; Peters, N.; Reinert, N. Epidemiology of injuries in racket sports: A cross-sectional study of specific injuries within one olympic cycle. BMC Sports Sci. Med. Rehabil. 2025, 17, 95. [Google Scholar] [CrossRef]

- van de Water, T.; Huijgen, B.; Faber, I.; Elferink-Gemser, M. Assessing Cognitive Performance in Badminton Players: A Reproducibility and Validity Study. J. Hum. Kinet. 2017, 55, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Hennig, E.M. Influence of Racket Properties on Injuries and Performance in Tennis. Exerc. Sport Sci. Rev. 2007, 35, 62–66. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Wang, C.; Bi, Y.; Chen, L. Effect of Integrative Neuromuscular Training for Injury Prevention and Sports Performance of Female Badminton Players. BioMed Res. Int. 2021, 2021, 5555853. [Google Scholar] [CrossRef]

- Jaworski, J.; Lech, G.; Żak, M.; Witkowski, K.; Piepiora, P. Relationships between selected indices of postural stability and sports performance in elite badminton players: Pilot study. Front. Psychol. 2023, 14, 1110164. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Sun, M. Motion recognition technology of badminton players in sports video images. Future Gener. Comput. Syst. 2021, 124, 381–389. [Google Scholar] [CrossRef]

- Jaworski, J.; Żak, M. The Structure of Morpho-Functional Conditions Determining the Level of Sports Performance of Young Badminton Players. J. Hum. Kinet. 2015, 47, 215–223. [Google Scholar] [CrossRef]

- Kosack, M.H.; Staiano, W.; Folino, R.; Hansen, M.B.; Lønbro, S. The Acute Effect of Mental Fatigue on Badminton Performance in Elite Players. Int. J. Sports Physiol. Perform. 2020, 15, 632–638. [Google Scholar] [CrossRef]

- Fong, S.-M.; Ng, L.-K.; Ma, W.-W.; Wang, H.-K.; Bae, Y.-H.; Yam, T.-T.; Kam, W.-K.; Chung, W.-Y. Effects of kinesiology taping on shoulder girdle muscle activity and sports performance during badminton forehand overhead strokes in amateur badminton players with shoulder impingement syndrome. J. Sports Med. Phys. Fit. 2019, 59, 994–1000. [Google Scholar] [CrossRef]

- Zheng, Y.-J.; Wang, W.-C.; Chen, Y.-Y.; Chiu, W.-H.; Chen, R.; Lo, C.-Y. Wearable and wireless performance evaluation system for sports science with an example in badminton. Sci. Rep. 2022, 12, 16855. [Google Scholar] [CrossRef]

- Chang, C.-L.; Gan, Y.-C.; Pan, C.-Y.; Tseng, Y.-T.; Wang, T.-C.; Tsai, C.-L. Neurocognitive performance of badminton players at different competitive levels in visuospatial attention tasks. Exp. Brain Res. 2024, 242, 1933–1946. [Google Scholar] [CrossRef]

- Zhang, Y.; Leng, B. Performance of Elite Women’s Singles Badminton Players: The Influence of Left-Handed Players. J. Hum. Kinet. 2023, 92, 239–249. [Google Scholar] [CrossRef]

- Ma, S.; Soh, K.G.; Japar, S.B.; Liu, C.; Luo, S.; Mai, Y.; Wang, X.; Zhai, M. Effect of core strength training on the badminton player’s performance: A systematic review & meta-analysis. PLoS ONE 2024, 19, e0305116. [Google Scholar] [CrossRef]

- Ghorpade, O.S.; Rizvi, M.R.; Sharma, A.; Almutairi, H.J.; Ahmad, F.; Hasan, S.; Shaik, A.R.; Seyam, M.K.; Uddin, S.; Nanjan, S.; et al. Enhancing physical attributes and performance in badminton players: Efficacy of backward walking training on treadmill. BMC Sports Sci. Med. Rehabil. 2024, 16, 170. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Fernandez, J.; Loturco, I.; Hernández-Davó, J.; Nakamura, F.; García-Tormo, V.; Álvarez-Dacal, F.; Martinez-Maseda, J.; García-López, J. On-Court Change of Direction Test: An Effective Approach to Assess COD Performance in Badminton Players. J. Hum. Kinet. 2022, 82, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Xue, W.; Soh, K.G.; Liu, H.; Xu, F.; Sun, M.; Li, J.; Shi, X.; Wang, X. Effects of physical training programs on healthy badminton players’ performance: A systematic review and meta-analysis. BMC Sports Sci. Med. Rehabil. 2025, 17, 189. [Google Scholar] [CrossRef]

- Jaworski, J.; Żak, M.; Lech, G.; Bujas, P.; Żak, S.; Tchórzewski, D. Somatic and functional compensations in junior badminton players. Hum. Mov. 2018, 19, 26–33. [Google Scholar] [CrossRef]

- Hülsdünker, T.; Rentz, C.; Ruhnow, D.; Käsbauer, H.; Strüder, H.K.; Mierau, A. The Effect of 4-Week Stroboscopic Training on Visual Function and Sport-Specific Visuomotor Performance in Top-Level Badminton Players. Int. J. Sports Physiol. Perform. 2019, 14, 343–350. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Huang, Y.; Zhou, Z.; Leng, B.; Gong, W.; Cui, Y.; Bao, D. The Effect of 6-Week Combined Balance and Plyometric Training on Change of Direction Performance of Elite Badminton Players. Front. Psychol. 2021, 12, 684964. [Google Scholar] [CrossRef] [PubMed]

| Failure Types | Cause of Formation | Technical Countermeasures |

|---|---|---|

| Mechanical Wear and Peeling | String Friction/Ball Impact | Organic-Inorganic Hybrid Reinforcement Coating Toughness |

| Chemical degradation | UV/sweat pH | UV absorber + acid-alkali resistant monomer |

| Loss of interfacial adhesion | Thermal and humidity cycling stress | Plasma substrate activation pretreatment |

| Coating Types | Control Influence Mechanism | Performance Correlation |

|---|---|---|

| Shock-Absorbing Coating | Suppressing 100–500 Hz high-frequency vibrations enhances proprioceptive clarity | Success rate of net shots improvement |

| Anti-scratch coating | Maintaining constant friction coefficient ensures spin control | Reduced error range in slice drop shot placement |

| Strength-enhancing coating | Reducing frame deformation (≤0.8 mm) improves power transmission linearity. | Narrowing the range of fluctuations in the initial velocity of the kill shot |

| Coating Combinations | Ball Control Stability | Physiological Fatigue Effects | Applicable Scenarios |

|---|---|---|---|

| Scratch-resistant + Shock Absorption | Enhancement | Extension | Multi-shot offense and defense |

| Enhanced strength + superhydrophobic | Improvement | Extension | High humidity environment |

| Full-function multi-layer coating | Enhancement | Extension | Major Events |

| Player Typ | Core Requirements | Coating Technology Solutions | Typical Performance Enhancement Scenarios |

|---|---|---|---|

| Professional players | Ultimate control precision | Thin-layer high-damping shock absorption + nano scratch resistance | Crucial point stability, extreme environment adaptability |

| Amateur enthusiasts | Comfort first | Thick-layer medium damping vibration reduction | Technical movement fault tolerance rate, fatigue delay |

| Youth | Injury Protection | Full-frame enhanced strength + high-toughness interface layer | Injury prevention, fundamental movement patterning |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Huang, G. Badminton Racket Coatings and Athletic Performance: Review Based on Functional Coatings. Coatings 2025, 15, 1186. https://doi.org/10.3390/coatings15101186

Tian H, Huang G. Badminton Racket Coatings and Athletic Performance: Review Based on Functional Coatings. Coatings. 2025; 15(10):1186. https://doi.org/10.3390/coatings15101186

Chicago/Turabian StyleTian, Houwei, and Guoyuan Huang. 2025. "Badminton Racket Coatings and Athletic Performance: Review Based on Functional Coatings" Coatings 15, no. 10: 1186. https://doi.org/10.3390/coatings15101186

APA StyleTian, H., & Huang, G. (2025). Badminton Racket Coatings and Athletic Performance: Review Based on Functional Coatings. Coatings, 15(10), 1186. https://doi.org/10.3390/coatings15101186