Strategies for Biofouling Control: A Review from an Environmental Perspective of Innovation and Trends

Abstract

1. Introduction

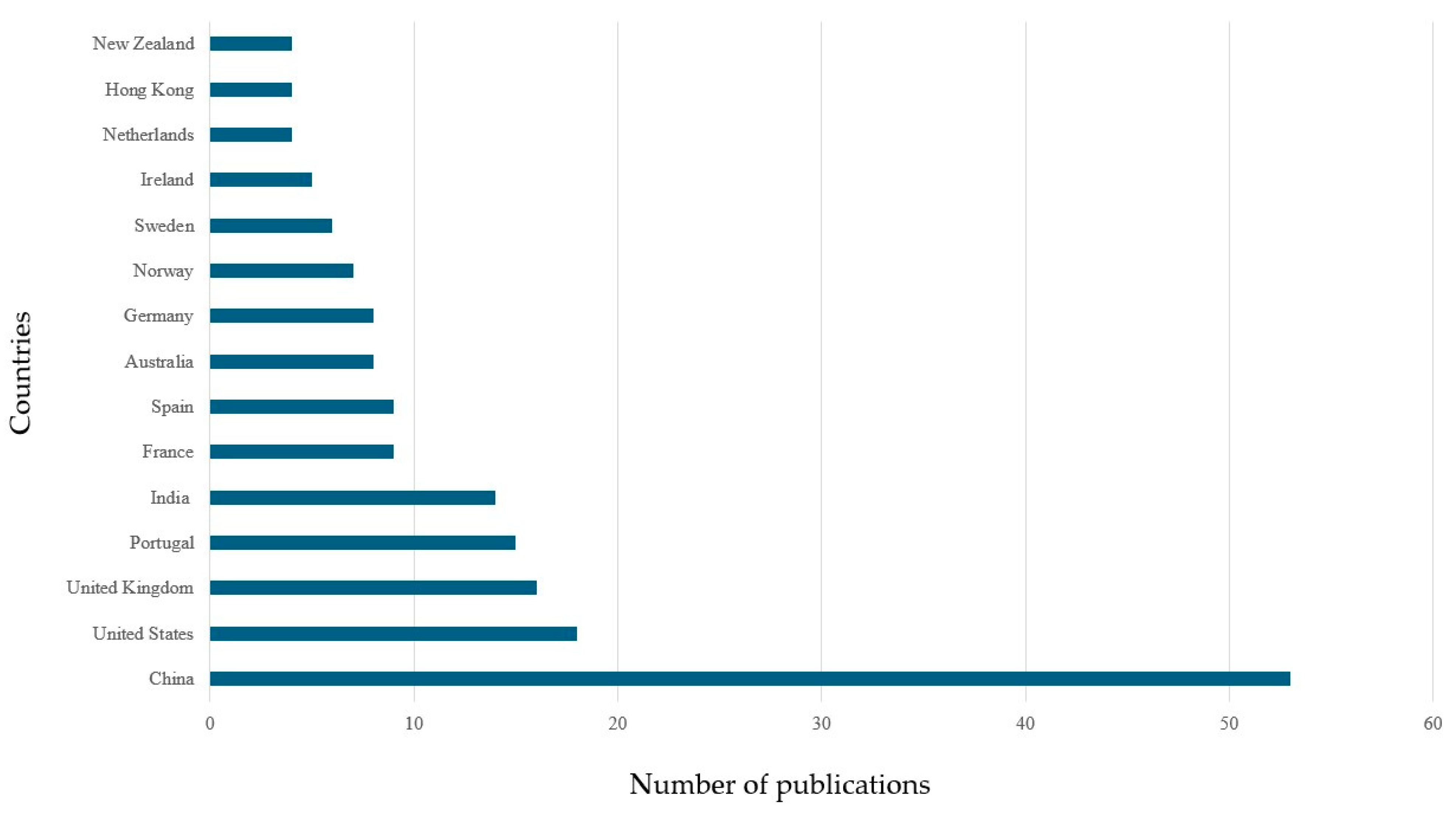

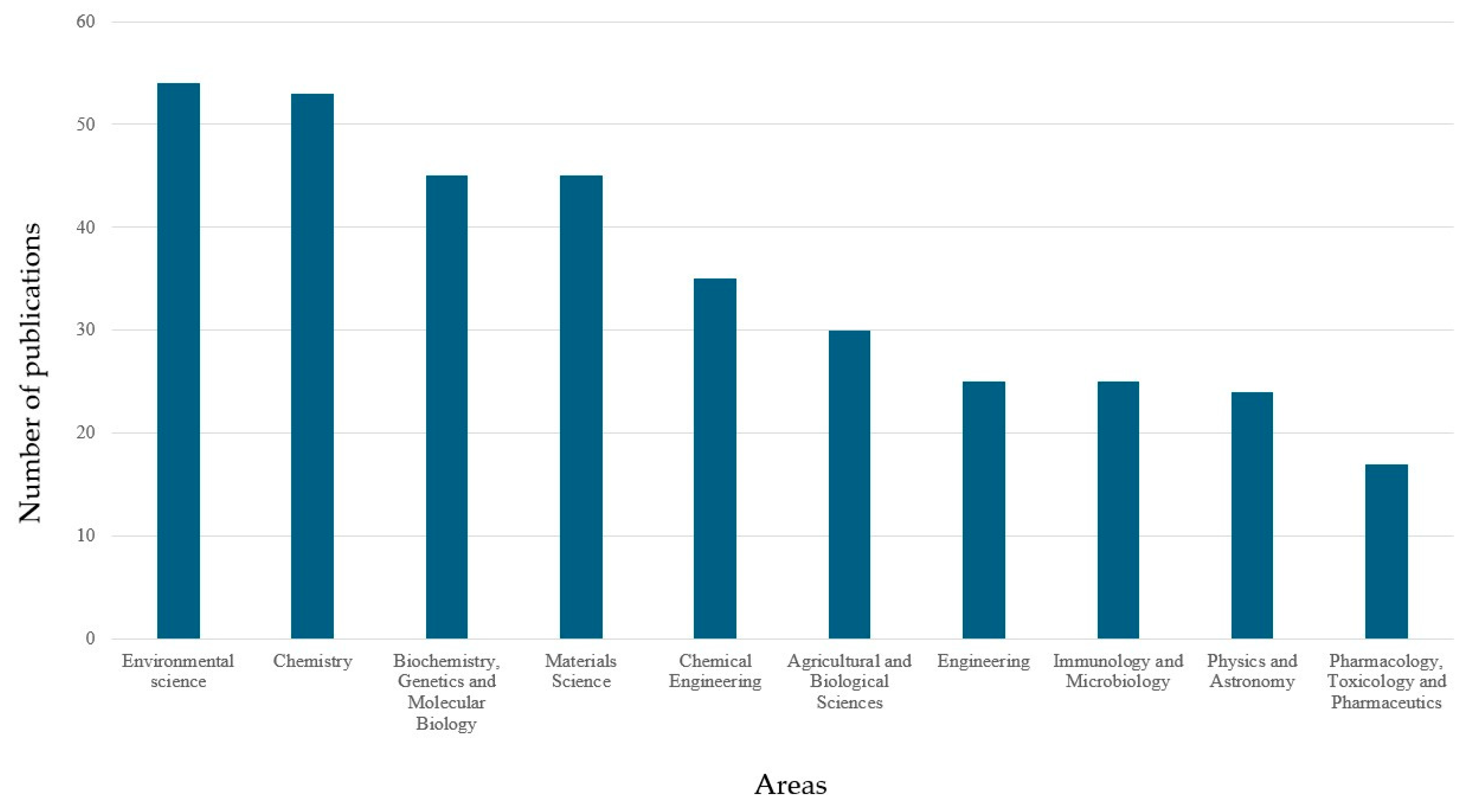

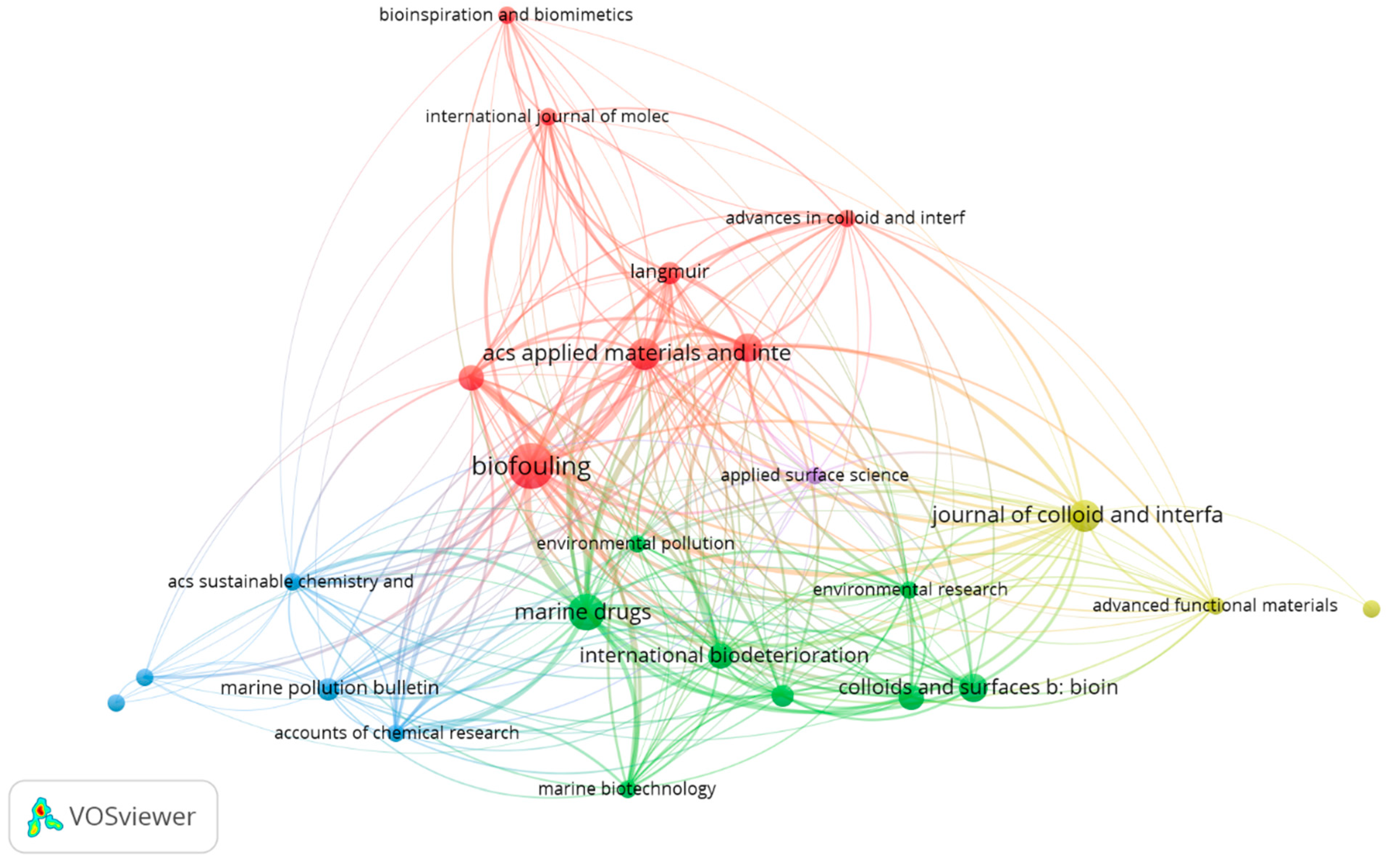

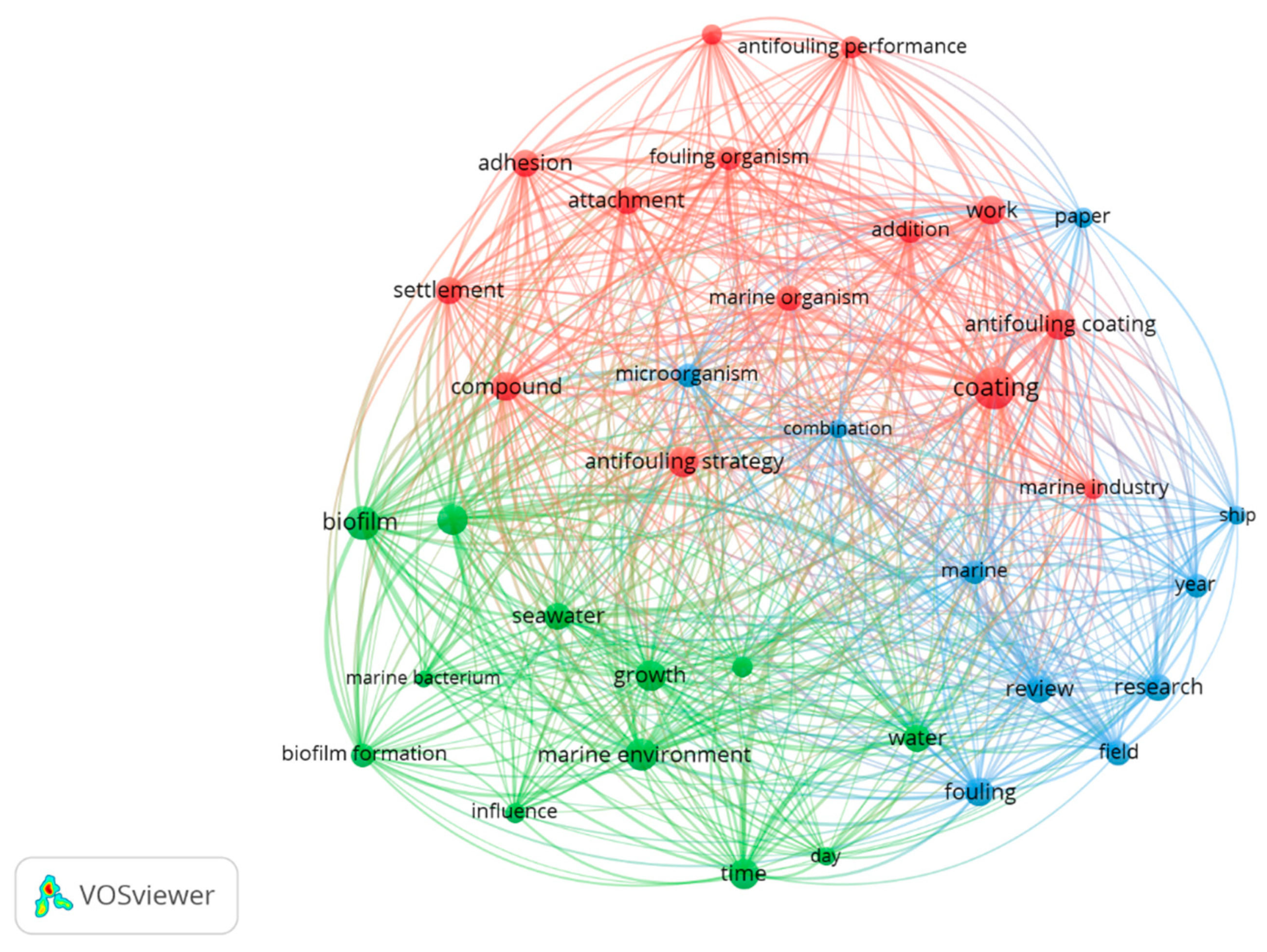

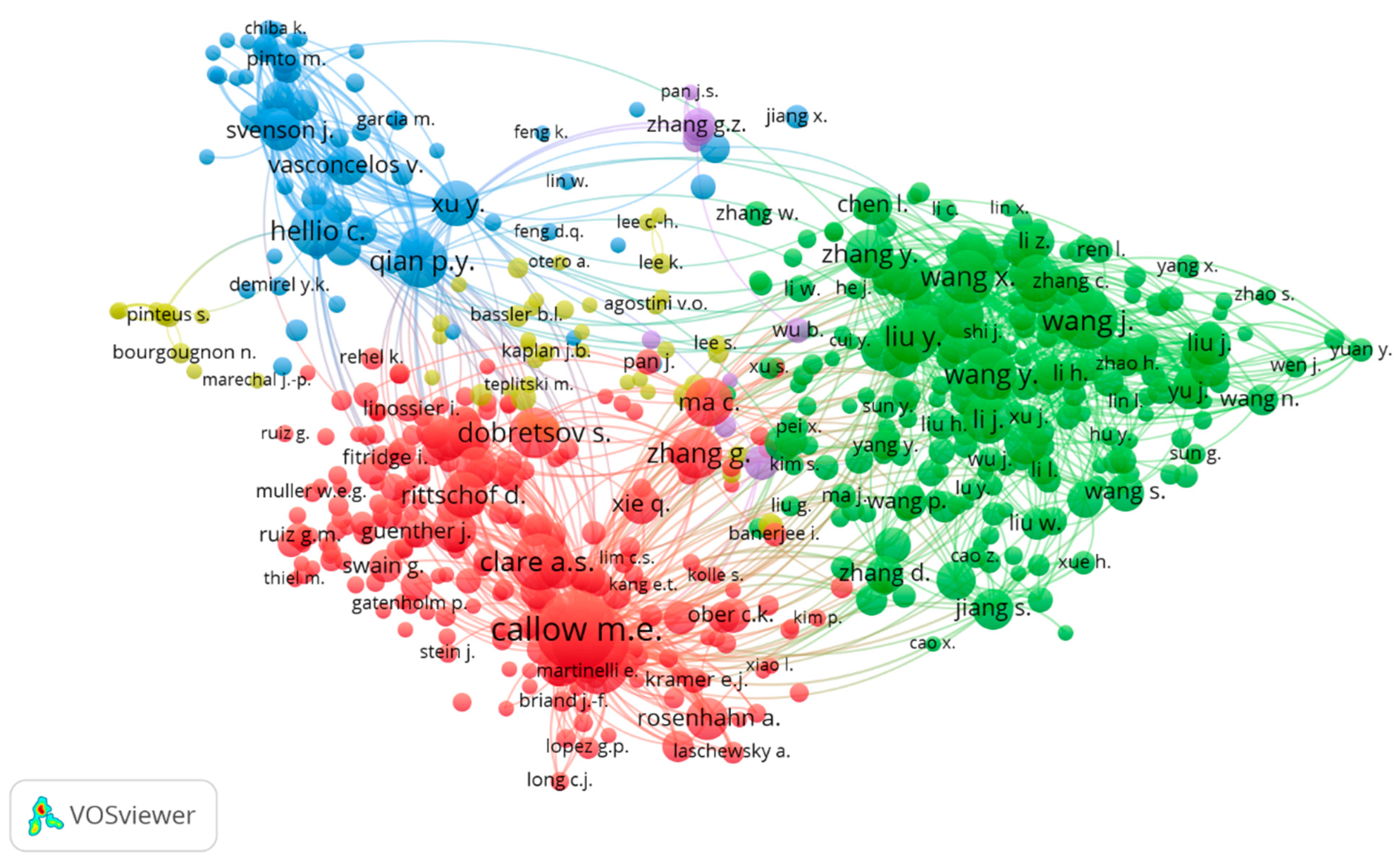

2. Integrative Bibliometric Review

Data Analysis and Visualization

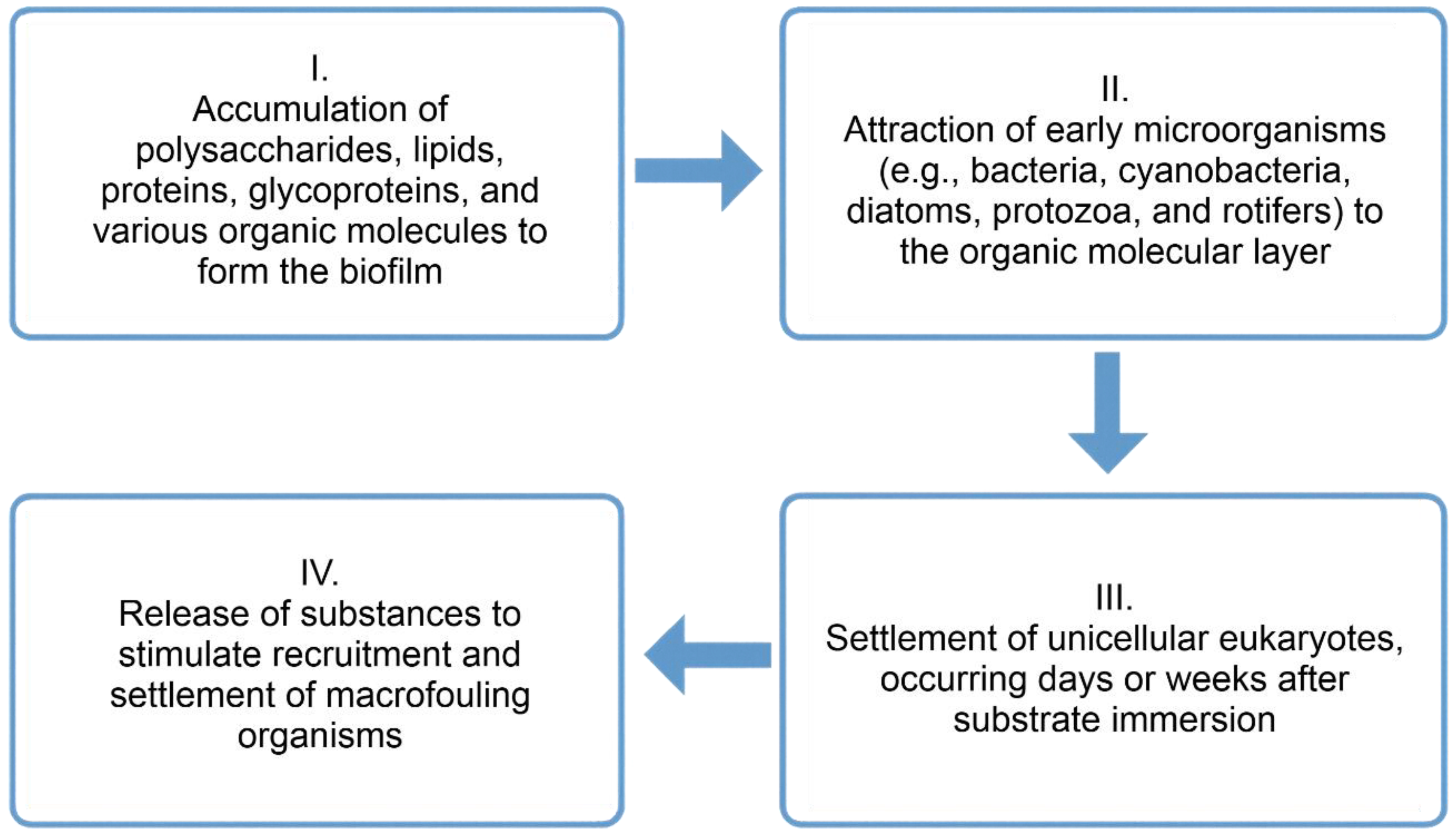

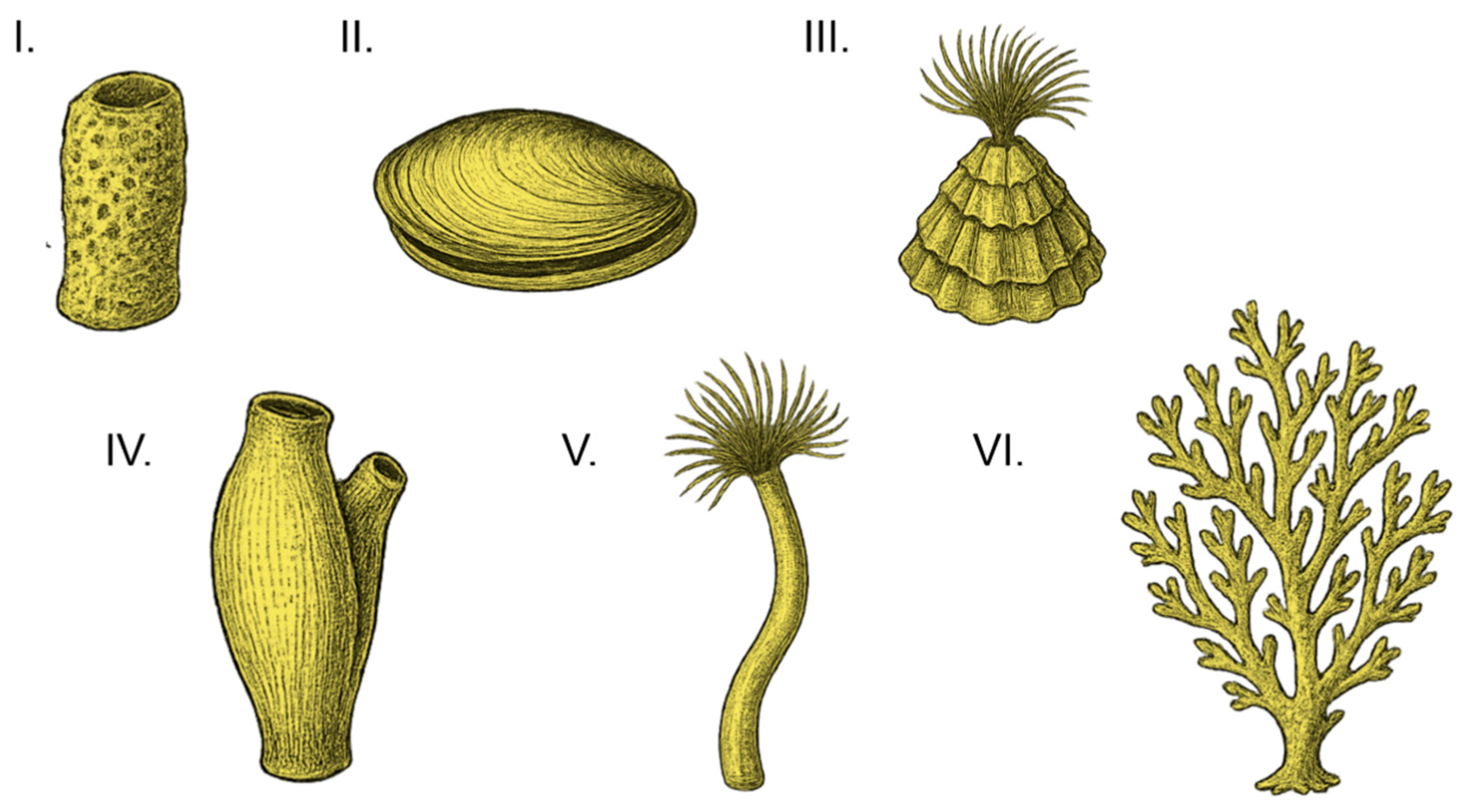

3. The Most Common Organisms on Marine Structures and Their Effects

4. Effective Strategies and Methods for Managing Biofouling

| Patent Title | Patent Number | Locality | Reference |

|---|---|---|---|

| System and method for cleaning of biofouling and pathogens and use of the system | WO2024151170 | NO * | [142] |

| Membrane treatment method and biofouling suppression method | WO2024128050 | JP * | [143] |

| Biofouling prevention system for vessel | WO2024117880 | KR * | [144] |

| Reduction of biofouling on watercraft | WO2024094622 | SE * | [145] |

| Mixed metal oxide coatings for protecting titanium alloys from biofouling | WO2024079222 | ES * | [146] |

| Photocatalytic surfaces for anti-biofouling | WO2024044665 | USA * | [147] |

| Roof coating resistant to biofouling | EP4519372 | EP * | [148] |

| Controlling biofouling in water purification | WO2023028503 | USA * | [149] |

| Biofouling preventing device for ships and method for manufacturing same | WO2022255578 | KR * | [150] |

| Underwater robot for removing marine biofouling from hulls of floating units, with system for containing and capturing waste | WO2022140831 | BR * | [151] |

| A marine system comprising an anti-biofouling light arrangement that includes a polarizing device | EP4103468 | EP * | [152] |

| Anti-biofouling in marine applications using uv light source | WO2021055500 | USA * | [153] |

| Marine biofouling prevention apparatus for seawater battery | WO2020013378 | KR * | [154] |

| Compositions for antifouling protection | JP2023126913 | JP * | [155] |

| Stainless steel coating with marine organism fouling resistance function and preparation method thereof | CN114150306 | CN * | [156] |

| Environment-friendly marine antifouling coating and preparation method thereof | CN112876984 | CN * | [157] |

| Integrated system for removing and treating marine biofouling on submerged metal surfaces | NZ802311 | NZ * | [158] |

| High-transmittance ultraviolet antifouling coating system with embedded ultraviolet led lamp beads and preparation method thereof | CN111117477 | CN * | [159] |

| Modular system for treating effluent from cleaning hulls of floating units | CA3203772 | CA * | [160] |

| Transparent nanowire architectures for marine anti-fouling | US20210262089 | USA * | [161] |

| Environment-friendly antifouling slow-release material as well as preparation method and application thereof | CN118085433 | CN * | [162] |

| Device and method for preventing biofouling of marine propellers | CN111498071 | CN * | [163] |

| Stratified poly dimethyl siloxane-epoxy coating possessing anticorrosive & foul release properties in a single coat and their method of preparation thereof | IN202111011420 | IN * | [164] |

| Antibacterial polytitanilazane coating composition and preparation method thereof | CN115558323 | CN * | [165] |

| Light emitting unit configured to be applied to surface area of marine object | CN112771309 | CN * | [166] |

| Apparatus and methods to prevent biofouling | US20210138519 | USA * | [167] |

| Process for biofouling cohibition in marine environments | US20210395900 | USA * | [168] |

| Biofouling prevention device for marine instrument | CN210146517 | CN * | [169] |

| Ocean system comprising device for preventing biofouling light comprising polarizing device | CN115087592 | CN * | [170] |

| Marine plastic pipeline with high impact resistance, high biofouling resistance and high wear resistance and preparation method thereof | CN112480520 | CN * | [171] |

| Biofouling prevention device | JP2024121088 | JP * | [172] |

| Sensor device | WO/2024/09499 | EP * | [173] |

| Method for producing a coating with low surface energy against biofouling | RU0002760600 | RU * | [174] |

| Biofouling prevention film structure formed on surface of ship structure | KR1020230066865 | KR * | [175] |

| A system for mitigating biofouling | SE2350663 | SE * | [176] |

| Biological fouling prevention coating as well as preparation method and application thereof | CN115521709 | CN * | [177] |

| Anti-fouling robot | WO/2022/268300 | WO * | [178] |

| 960 mpa grade ultrahigh-strength steel plate with marine fouling resistance and manufacturing method therefor | WO/2023/240850 | WO * | [18] |

| An apparatus for vessel drag reduction and planetary cooling | AU2023204574 | AU * | [179] |

| Preparation method of photocatalytic material composite micro-texture anti-microbial attachment surface | CN114985937 | CN * | [180] |

| Antifouling polymer and composition, polymerizable monomer, article, method for producing a medetomidine monomer and an antifouling polymer | BR1120230074541 A2 | BR * | [181] |

| Wet and dry synthesis process of lysoglycerophosphocholine compounds and their o-alkylated derivatives as biocidal additives in antifouling coatings | BR1020200200453 A2 | BR * | [182] |

| Antifouling composition and its use, antifouling paint and method for inhibiting marine biofouling | BR112021009728 7 A2 | BR * | [183] |

5. Sustainable Approaches to Biofouling Control

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFS Convention | International Convention on the Control of Harmful Anti-fouling Systems on Ships |

| EPO | European Patent Office |

| INPI | Brazilian National Institute of Industrial Property |

| IPC | International Patent Classification |

| IMO | International Marine Organization |

| MARPOL | International Convention for the Prevention of Pollution from Ships |

| NPAs | Natural Product Antifoulants |

| TBT | Tributyltin |

| PDMS | Polydimethylsiloxane |

| PEG | Polyethylene glycol |

| RAFT | Reversible Addition–Fragmentation Chain Transfer |

| WIPO | World Intellectual Property Organization |

References

- Agostini, V.O.; Macedo, A.J.; Muxagata, E. O papel do biofilme bacteriano no acoplamento bentopelágico, durante o processo de bioincrustação. Rev. Lib. 2018, 19, 23–42. [Google Scholar] [CrossRef]

- Bae, S.; Ubagan, M.D.; Shin, S.; Kim, D.G. Comparison of recruitment patterns of sessile marine invertebrates according to substrate characteristics. Int. J. Environ. Res. Public Health 2022, 19, 1083. [Google Scholar] [CrossRef] [PubMed]

- Fitridge, I.; Dempster, T.; Guenther, J.; De Nys, R. The impact and control of biofouling in marine aquaculture: A review. Biofouling 2012, 28, 649–669. [Google Scholar] [CrossRef]

- Bagheri, M.; Mirbagheri, S.A. Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour. Technol. 2018, 258, 318–334. [Google Scholar] [CrossRef]

- Dobretsov, S.; Rittschof, D. Biofouling and Antifouling: Interactions between Microbes and Larvae of Invertebrates. Int. J. Mol. Sci. 2023, 24, 6531. [Google Scholar] [CrossRef]

- Romeu, M.J.; Mergulhão, F. Development of Antifouling Strategies for Marine Applications. Microorganisms 2023, 11, 1568. [Google Scholar] [CrossRef]

- Tyrrel, M.C.; Byers, J.E. Do artificial substrate favor nonindigenous fouling species over native species? J. Exp. Mar. Biol. Ecol. 2007, 342, 54–60. [Google Scholar] [CrossRef]

- Cunha, J.L.O.; Silva, S.L.; Batista, R.O.; Marques, B.C.D.; Coelho, D.C.L.; Silva, K.B. Monitoramento da bioincrustação em fitas gotejadoras aplicando água com distintas temperaturas e salinidades. Irriga 2020, 25, 1–13. [Google Scholar] [CrossRef]

- Lum, W.M.; Sakamoto, S.; Yuasa, K.; Takahashi, K.; Kuwata, K.; Kodama, T.; Katayama, T.; Leaw, C.P.; Lim, P.T.; Iwataki, M. Comparative effects of temperature and salinity on growth of four harmful Chattonella spp. (Raphidophyceae) from tropical Asian waters. Front. Mar. Sci. 2023, 10, 1–16. [Google Scholar] [CrossRef]

- Araújo, E.A.; Andrade, N.J.; Silva, L.H.M.; Carvalho, A.F.; Silva, C.A.S.; Ramos, A.M. Control of microbial adhesion as a strategy for food and bioprocess technology. Food Bioprocess Technol. 2010, 3, 321–332. [Google Scholar] [CrossRef]

- Zheng, S.; Bawazir, M.; Dhall, A.; Kim, H.; He, L.; Heo, J.; Hwang, G. Implication of Surface Properties, Bacterial Motility, and Hydrodynamic Conditions of Bacterial Surface Sensing and Their Initial Adhesion. Front. Bioeng. Biotechnol. 2021, 9, 643722. [Google Scholar] [CrossRef] [PubMed]

- Xavier, E.A.; Almeida, A.C.; Nogueira, M.M.; Vieira, L.M. Effects of substratum type and orientation on the recruitment of bryozoans in an artificial area of the Western Atlantic. Biofouling 2023, 39, 748–762. [Google Scholar] [CrossRef] [PubMed]

- Raw, J.L.; Miranda, N.A.; Perissinotto, R. Chemical cues released by heterospecific competitors: Behavioural responses of native and alien invasive aquatic gastropods. Aquat. Sci. 2015, 77, 655–666. [Google Scholar] [CrossRef]

- Vieira, E.A.; Flores, A.A.V.; Dias, G.M. Colonization history meets further niche processes: How the identity of founders modulates the way predation structure fouling communities. Oecologia 2021, 196, 1167–1178. [Google Scholar] [CrossRef]

- Somma, E.; Terlizzi, A.; Costantini, M.S.; Madeira, M.; Zupo, V. Global Changes Alter the Successions of Early Colonizers of Benthic Surfaces. J. Mar. Sci. Eng. 2023, 11, 1232. [Google Scholar] [CrossRef]

- Soroldoni, S.; Castro, Í.B.; Abreu, F.; Duarte, F.A.; Choueri, R.B.; Möller, O.O., Jr.; Fillmann, G.; Pinho, G.L.L. Antifouling paint particles: Sources, occurrence, composition and dynamics. Water Res. 2018, 137, 47–56. [Google Scholar] [CrossRef]

- Yu, X.; Wang, J.; Kou, M.; Shi, Z.; Young-Dong, Y. Research Progress and Prospect of Marine Antifouling Coatings. Stud. Soc. Sci. Res. 2023, 4, 152–157. [Google Scholar] [CrossRef]

- Liu, W.; Li, T.; Si, S.; Wang, C.; Zang, Y.; Wang, C.; Chaoyi, W.; Tao, A. 960 MPa Grade Ultrahigh-Strength Steel Plate with Marine Fouling Resistance and Manufacturing Method Therefor. WO Patent 2023240850, 21 December 2023. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2023240850&_cid=P20-MFWIQ7-32382-1 (accessed on 3 June 2025).

- Thouvenin, M.; Peron, J.J.; Langlois, V.; Guerin, P.; Langlois, J.Y.; Valee-Rehel, K. Formulation and antifouling activity of marine paints: A study by a statistically based experiments plan. Prog. Org. Coat. 2002, 44, 85–92. [Google Scholar] [CrossRef]

- Yebra, D.M.; Kiil, S.; Dam-Johasen, K. Antifouling technology—Past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog. Org. Coat. 2004, 50, 75–104. [Google Scholar] [CrossRef]

- Bers, V.; Wahl, M. The influence of natural surface microtopographies on fouling. Biofouling 2004, 20, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Barrios, C.A.; Xu, Q.; Cutright, T.; Newby, B.M.Z. Incorporating zosteric acid into silicone coatings to achieve its slow release while reducing fresh water bacterial attachment. Colloids Surf. B Biointerfaces 2005, 41, 83–93. [Google Scholar] [CrossRef]

- Hellio, C.; Maréchal, J.; Da Gama, B.; Pereira, R.; Clare, A. Natural marine products with antifouling activities. In Advances in Marine Antifouling Coatings and Technologies; Hellio, C., Yebra, D., Eds.; Woodhead Publishing: Cambridge, UK, 2009; pp. 572–622. [Google Scholar] [CrossRef]

- Trepos, R.; Cervin, G.; Hellio, C.; Pavia, H.; Stensen, W.; Stensvåg, K.; Svendsen, J.; Haug, T.; Svenson, J. Antifouling Compounds from the Sub-Arctic Ascidian Synoicum pulmonaria: Synoxazolidinones A and C, Pulmonarins A and B, and Synthetic Analogues. J. Nat. Prod. 2014, 77, 2105–2113. [Google Scholar] [CrossRef]

- Gittens, J.E.; Smith, T.J.; Suleiman, R.; Akid, R. Current and emerging environmentally-friendly systems for fouling control in the marine environment. Biotechnol. Adv. 2013, 31, 1738–1753. [Google Scholar] [CrossRef]

- Silva, E.R.; Ferreira, O.; Ramalho, P.A.; Azevedo, N.F.; Bayón, R.; Igartua, A.; Bordado, J.C.; Calhorda, M.J. Eco-friendly non-biocide-release coatings for marine biofouling prevention. Sci. Total Environ. 2019, 650, 2499–2511. [Google Scholar] [CrossRef]

- Gu, Y.; Yu, L.; Mou, J.; Wu, D.; Xu, M.; Zhou, P.; Ren, Y. Research strategies to develop environmentally friendly marine antifouling coatings. Mar. Drugs 2020, 18, 371. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Amini, S.; Kolle, S.; Petrone, L.; Ahanotu, O.; Sunny, S.; Sutanto, C.N.; Hoon, S.C.L.; Weaver, J.C.; Aizenberg, J.; Vogel, N.; et al. Preventing mussel adhesion using lubricant-infused materials. Science 2017, 357, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Li, J.; Mieszkin, S.; Di Fino, A.; Clare, A.S.; Callow, M.E.; Callow, J.A.; Grunze, M.; Rosenhahn, A.; Levkin, P.A. Slippery liquid-infused porous surfaces showing marine antibiofouling properties. ACS Appl. Mater. Interfaces 2013, 5, 10074–10080. [Google Scholar] [CrossRef] [PubMed]

- Bannister, J.; Sievers, M.; Bush, F.; Bloecher, N. Biofouling in marine aquaculture: A review of recent research and developments. Biofouling 2019, 35, 631–648. [Google Scholar] [CrossRef]

- Srinivasan, R.; Santhakumari, S.; Poonguzhali, P.; Geetha, M.; Dyavaiah, M.; Xiangmin, L. Bacterial biofilm inhibition: A focused review on recent therapeutic strategies for combating the biofilm mediated infections. Front. Microbiol. 2021, 12, 676458. [Google Scholar] [CrossRef]

- Braithwaite, R.A.; McEvoy, L.A. Marine biofouling on fish farms and its remediation. Adv. Mar. Biol. 2005, 47, 215–252. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, D.; Sun, S.; Li, T.; Sun, Y. Fabrication of slippery lubricant-infused porous surface with high underwater transparency for the control of marine biofouling. ACS Appl. Mater. Interfaces 2017, 9, 972–982. [Google Scholar] [CrossRef]

- Chen, L.; Duan, Y.; Cui, M.; Huang, R.; Su, R.; Qi, W.; He, Z. Biomimetic surface coatings for marine antifouling: Natural antifoulants, synthetic polymers and surface microtopography. Sci. Total Environ. 2021, 766, 144469. [Google Scholar] [CrossRef]

- Leonardi, A.K.; Ober, C.K. Polymer-based marine antifouling and fouling release surfaces: Strategies for synthesis and modification. Ann. Rev. Chem. Biomol. Eng. 2019, 10, 241–264. [Google Scholar] [CrossRef]

- Ferrari, M.; Benedetti, A. Superhydrophobic surfaces for applications in seawater. Adv. Colloid Interface Sci. 2015, 222, 291–304. [Google Scholar] [CrossRef]

- Nicklisch, S.C.; Waite, J.H. Mini-review: The role of redox in Dopa-mediated marine adhesion. Biofouling 2012, 28, 865–877. [Google Scholar] [CrossRef] [PubMed]

- Whelan, A.; Regan, F. Antifouling strategies for marine and riverine sensors. J. Environ. Monit. 2006, 8, 880–886. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Wei, Q.; Wu, C.; Zhang, X.; Xue, Q.; Zheng, T.; Cao, M. Superhydrophilicity and strong salt-affinity: Zwitterionic polymer grafted surfaces with significant potentials particularly in biological systems. Adv. Colloid Interface Sci. 2020, 278, 102141. [Google Scholar] [CrossRef] [PubMed]

- Rosenhahn, A.; Ederth, T.; Pettitt, M.E. Advanced Nanostructures for the Control of Biofouling: The FP6 EU Integrated Project AMBIO. Biointerphases 2008, 3, IR1–IR5. [Google Scholar] [CrossRef]

- Pinteus, S.; Lemos, M.F.L.; Alves, C.; Neugebauer, A.; Silva, J.; Thomas, O.P.; Botana, L.M.; Gaspar, H.; Pedrosa, R. Marine invasive macroalgae: Turning a real threat into a major opportunity-the biotechnological potential of Sargassum muticum and Asparagopsis armata. Algal Res. 2018, 34, 217–234. [Google Scholar] [CrossRef]

- Sun, W.; Feng, L.; Zhang, J.; Lin, K.; Wang, H.; Yan, B.; Feng, T.; Cao, M.; Liu, T.; Yuan, Y.; et al. Amidoxime group-anchored single cobalt atoms for anti-biofouling during uranium extraction from seawater. Adv. Sci. 2022, 9, 2105008. [Google Scholar] [CrossRef]

- Wu, S.; Wu, S.; Xing, S.; Wang, T.; Hou, J.; Zhao, Y.; Li, W. Research Progress of Marine Anti-Fouling Coatings. Coatings 2024, 14, 1227. [Google Scholar] [CrossRef]

- He, S.; Xue, Q.; Fu, Z.; Bao, L.; Li, K.; Zhang, G.; Zhang, H.; Qiu, T. Biofouling Community Dynamics on Nylon and Polyethylene Aquaculture Nets in the North Yellow Sea: Colonization Patterns and Mytilus edulis Mechanical Properties. Water 2025, 17, 1250. [Google Scholar] [CrossRef]

- Wang, T.; Hou, J.; Wang, Y.; Feng, X.; Liu, X. Urushiol-Based Antimicrobial Coatings: Molecular Mechanisms, Structural Innovations, and Multifunctional Applications. Polymers 2025, 17, 1500. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, Q.; Zhang, Y.; Lu, G.; Liu, Y.; Tong, Y. Prevention and Control of Biofouling Coatings in Limnoperna fortunei: A Review of Research Progress and Strategies. Polymers 2024, 16, 3070. [Google Scholar] [CrossRef] [PubMed]

- Tian, W.; Jin, H.; Tian, L. Ideas Inspired by Nature to Combat Marine Biofouling and Corrosion. Coatings 2022, 12, 1434. [Google Scholar] [CrossRef]

- Gosens, J.; Hellsmark, H.; Kåberger, T.; Liu, L.; Sandén, B.A.; Wang, S.; Zhao, L. The limits of academic entrepreneurship: Conflicting expectations about commercialization and innovation in China’s nascent sector for advanced bio-energy technologies. Energy Res. Soc. Sci. 2018, 37, 1–11. [Google Scholar] [CrossRef]

- Shi, X.; Liang, H.; Li, Y. Review of Progress in Marine Anti-Fouling Coatings: Manufacturing Techniques and Copper- and Silver-Doped Antifouling Coatings. Coatings 2024, 14, 1454. [Google Scholar] [CrossRef]

- Li, L.; Hong, H.; Cao, J.; Yang, Y. Progress in Marine Antifouling Coatings: Current Status and Prospects. Coatings 2023, 13, 1893. [Google Scholar] [CrossRef]

- Ning, J.; Pang, S.; Arifin, Z.; Zhang, Y.; Epa, U.P.K.; Qu, M.; Zhao, J.; Zhen, F.; Chowdhury, A.; Guo, R.; et al. The Diversity of Artificial Intelligence Applications in Marine Pollution: A Systematic Literature Review. J. Mar. Sci. Eng. 2024, 12, 1181. [Google Scholar] [CrossRef]

- Tai, P.F. Why the Asian craze for publication? An examination from academic regime. In Research, Development, and Innovation in Asia Pacific Higher Education; Neubauer, D.E., Ed.; Palgrave Macmillan: New York, NY, USA, 2015; pp. 61–79. ISBN 978-1-137-51384-0. [Google Scholar]

- Patelli, A.; Cimini, G.; Pugliese, E.; Gabrielli, A. The scientific influence of nations on global scientific and technological development. J. Informetr. 2017, 11, 1229–1237. [Google Scholar] [CrossRef]

- Huang, J.; Li, W.; Huang, X.; Wang, Y.; Guo, L. Technology and innovation in China: A patent citation-based analysis. Sci. Techol. Soc. 2021, 26, 344–365. [Google Scholar] [CrossRef]

- Wahl, M.; Goecke, F.; Labes, A.; Dobretsov, S.; Weinberger, F. The second skin: Ecological role of epibiotic biofilms on marine organisms. Front. Microbiol. 2012, 3, 292. [Google Scholar] [CrossRef] [PubMed]

- Salta, M.; Chambers, L.; Wharton, J.; Wood, R.; Briand, J.F.; Blache, Y.; Stokes, K. Marine fouling organisms and their use in antifouling bioassays. In Proceedings of the EUROCORR; European Federation of Corrosion: Nice, France, 2009; pp. 6–9. [Google Scholar]

- Siboni, N.; Lidor, M.; Kramarsky-Winter, E.; Kushmaro, A. Conditioning film and initial biofilm formation on ceramics tiles in the marine environment. FEMS Microbiol. Lett. 2007, 274, 24–29. [Google Scholar] [CrossRef] [PubMed]

- Dobretsov, S. Inhibition and induction of marine biofouling by biofilms. In Marine and Industrial Biofouling; Flemming, H.C., Murthy, P.S., Venkatesan, R., Cooksey, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; p. 20. [Google Scholar]

- Satheesh, S.; Wesley, S. Biofilm development on acrylic coupons during the initial 24 hour period of submersion in a tropical coastal environment. Oceanol. Hydrobiol. Stud. 2010, 39, 27–38. [Google Scholar] [CrossRef]

- Wang, C.; Bao, W.Y.; Gu, Z.Q.; Li, Y.F.; Liang, X.; Ling, Y.; Cai, S.L.; Shen, H.D.; Yang, J.L. Larval settlement and metamorphosis of the mussel Mytilus coruscus in response to natural biofilms. Biofouling 2012, 28, 249–256. [Google Scholar] [CrossRef]

- Archana, S.; Sundaramoorthy, B.F.M. Review on impact of biofouling in aquafarm infrastructures. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2942–2953. [Google Scholar] [CrossRef]

- Wahl, M. Marine epibiosis I. Fouling and antifouling: Some basic aspects. Mar. Ecol. Prog. Ser. 1989, 58, 175–189. [Google Scholar] [CrossRef]

- Kavouras, J.H.; Maki, J.S. Effects of biofilms on zebra mussel postveliger attachment to artificial surfaces. Invertebr. Biol. 2003, 122, 138–151. [Google Scholar] [CrossRef]

- Rittschof, D.; Chai, C.; Teo, S.L.M.; Maki, J.S. Fouling and Its Next Generation Management: A Perspective. J. Agric. Mar. Sci. 2015, 20, 16–23. [Google Scholar] [CrossRef]

- Bhosle, N.B.; Garg, A.; Fernandes, L.; Citon, P. Dynamics of amino acids in the conditioning film developed on glass panels immersed in the surface seawaters of Dona Paula Bay. Biofouling 2005, 21, 99–107. [Google Scholar] [CrossRef]

- Stavridou, I.; Forzi, L. Biofilms: Friend or foe? Meeting report; June 2011. Virulence 2011, 2, 475–489. [Google Scholar] [CrossRef] [PubMed]

- Stoodley, P.; Sauer, K.; Davies, D.G.; Costerton, J.W. Biofilms as complex differentiated communities. Annu. Rev. Microbiol. 2002, 1, 187–209. [Google Scholar] [CrossRef]

- Anil, A.C.; Patil, J.S.; Mitbavkar, S.; DeCosta, P.M.; DeSilva, S.; Hegde, S.; Naik, R. Role of diatoms in marine biofouling. CSMCRI 2006, 1, 351–365. Available online: http://drs.nio.org/drs/handle/2264/810 (accessed on 8 June 2025).

- Mitbavkar, S.; Anil, A.C. Species interactions within a fouling diatom community: Roles of nutrients, initial inoculum and competitive strategies. Biofouling 2007, 23, 99–112. [Google Scholar] [CrossRef]

- Nagarkar, S.; Williams, G.A.; Subramanian, G.; Saha, S.K. Cyanobacteria-dominated biofilms: A high quality food resource for intertidal grazers. In Proceedings of the 2nd Asian Pacific Phycological Forum, Hong Kong, China, 21–25 June 1999; pp. 89–95. [Google Scholar]

- Roeselers, G.; Loosdrecht, M.V.; Muyzer, G. Phototrophic biofilms and their potential applications. J. Appl. Phycol. 2008, 20, 227–235. [Google Scholar] [CrossRef]

- Rossi, F.; De Philippis, R. Role of Cyanobacterial Exopolysaccharides in Phototrophic Biofilms and in Complex Microbial Mats. Life 2015, 5, 1218–1238. [Google Scholar] [CrossRef] [PubMed]

- Sawall, Y.; Richter, C.; Ramette, A. Effects of eutrophication, seasonality and macrofouling on the diversity of bacterial biofilms in equatorial coral reefs. PLoS ONE 2012, 7, e39951. [Google Scholar] [CrossRef]

- Patil, J.S.; Anil, A.C. Biofilm diatom community structure: Influence of temporal and substratum variability. Biofouling 2005, 21, 189–206. [Google Scholar] [CrossRef]

- Whalan, S.; Webster, N.S. Sponge larval settlement cues: The role of microbial biofilms in a warming ocean. Sci. Rep. 2014, 4, 4072. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.C.; Norton, T.A.; Hawkins, S.J. Physical stress and biological control regulate the producer—Consumer balance in intertidal biofilms. Ecology 2004, 85, 1372–1382. [Google Scholar] [CrossRef]

- Passarelli, C.; Meziane, T.; Thiney, N.; Boeuf, D.; Jesus, B.; Ruivo, M.; Jeanthon, C.; Hubas, C. Seasonal variations of the composition of microbial biofilms in sandy tidal flats: Focus of fatty acids, pigments and exopolymers. Estuar. Coast. Shelf Sci. 2007, 153, 29–37. [Google Scholar] [CrossRef]

- Costerton, J.W.; Lewandowski, Z.; Caldwell, D.E.; Korber, D.R.; LappinScott, H.M. Microbial biofilms. Annu. Rev. Microbiol. 1995, 49, 711–745. [Google Scholar] [CrossRef] [PubMed]

- McElroy, D.J.; Doblin, M.A.; Murphy, R.J.; Hochuli, D.F.; Coleman, R.A. A limited legacy effect of copper in marine biofilms. Mar. Pollut. Bull. 2016, 109, 117–127. [Google Scholar] [CrossRef]

- Guo, X.; Niu, Z.; Lu, D.; Feng, J.; Chen, Y.; Tou, F.; Liu, M.; Yang, Y. Bacterial community structure in the intertidal biofilm along the Yangtze Estuary, China. Mar. Pollut. Bull. 2017, 124, 314–320. [Google Scholar] [CrossRef] [PubMed]

- Maki, J.S.; Mitchell, R. Biofouling in the marine environment. In Encyclopedia of Environmental Microbiology; Bitton, G., Ed.; Wiley: New York, NY, USA, 2002; p. 3730. [Google Scholar] [CrossRef]

- Dobretsov, S. Marine biofilms. In Biofouling; Simone Dürr, S., Thomason, J.C., Eds.; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2009; p. 13. [Google Scholar] [CrossRef]

- Crisp, D.J. Overview of research on marine invertebrate larvae, 1940–1980. In Proceedings of the Symposium on Marine Biodeterioration, Uniformed Services University of Health Sciences, Bethesda, MD, USA, 20–23 April 1981; pp. 103–126. [Google Scholar]

- Haderlie, E.C. A brief overview of the effects of macrofouling. In Marine Biodeterioration: An Interdisciplinary Study; Costlow, J.D., Tipper, R.C., Eds.; Naval Institute Press: Annapolis, MD, USA, 1984; p. 163. ISBN 978-1-4615-9722-3. [Google Scholar]

- Clare, A.S.; Rittschof, D.J.; Gerhart, J.S.M. Molecular approaches to nontoxic antifouling. Invertebr. Reprod. Dev. 1992, 22, 67–76. [Google Scholar] [CrossRef]

- Christensen, A.M.; McDermott, J.J. Life-history and biology of the oyster crab, Pinnotheres ostreum Say. Biol. Bull. 1958, 114, 146–179. [Google Scholar] [CrossRef]

- Raman, S.; Kumar, R. Interfacial morphology and nanomechanics of cement of the barnacle, Amphibalanus reticulatus on metallic and non-metallic substrata. Biofouling 2011, 27, 569–577. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Jia, Y.; Sun, S.; Xu, Y.; Minsky, B.B.; Stuart, M.C.; Colfen, H.; Von Klitzing, R.; Guo, X. Mineral-enhanced polyacrylic acid hydrogel as an oyster-inspired organic–inorganic hybrid adhesive. ACS Appl. Mater. Interfaces 2018, 10, 10471–10479. [Google Scholar] [CrossRef]

- Rajagopal, S.; Nair, K.V.K.; Azariah, J.; Van der Velde, G.; Jenner, H.A. Chlorination and mussel control in the cooling conduits of a tropical coastal power station. Mar. Environ. Res. 1996, 41, 201–221. [Google Scholar] [CrossRef]

- Edyvean, R.G.; Videla, H.A. Biological corrosion. Interdiscip. Sci. Rev. 1991, 16, 267–282. [Google Scholar] [CrossRef]

- Neville, A.; Hodgkiess, T. Localised effects of macrofouling species on electrochemical corrosion of corrosion resistant alloys. Br. Corros. J. 2000, 35, 54–59. [Google Scholar] [CrossRef]

- Blackwood, D.J.; Lim, C.S.; Teo, S.L.; Hu, X.; Pang, J. Macrofouling induced localized corrosion of stainless steel in Singapore seawater. Corros. Sci. 2017, 129, 152–160. [Google Scholar] [CrossRef]

- Li, Y.; Ning, C. Latest research progress of marine microbiological corrosion and bio-fouling, and new approaches of marine anti-corrosion and anti-fouling. Bioact. Mater. 2019, 4, 189–195. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Huang, Y.; Wang, X.; Xu, Y.; Cai, F. Effects of oyster as macrofouling organism on corrosion mechanisms of a high-strength low-alloy steel. Corros. Sci. 2022, 207, 110580. [Google Scholar] [CrossRef]

- Ezgi, C.; Ozbalta, N. Optimization of heat exchanger cleaning cycle on a ship. J. Nav. Sci. Eng. 2012, 8, 33–46. [Google Scholar]

- Woods, C.M.; Floerl, O.; Jones, L. Biosecurity risks associated with in-water and shore-based marine vessel hull cleaning operations. Mar. Pollut. Bull. 2012, 64, 1392–1401. [Google Scholar] [CrossRef]

- Klijnstra, J.; Zhang, X.; van der Putten, S.; Röckmann, C. Technical Risks of Offshore Structures. In Aquaculture Perspective of Multi-Use Sites in the Open Ocean; Buck, B.H., Langan, R., Eds.; Springer: Cham, Switzerland, 2017; p. 404. [Google Scholar] [CrossRef]

- Azevedo, J.; Antunes, J.T.; Machado, A.M.; Vasconcelos, V.; Leao, P.N.; Froufe, E. Monitoring of biofouling communities in a Portuguese port using a combined morphological and metabarcoding approach. Sci. Rep. 2020, 10, 13461. [Google Scholar] [CrossRef] [PubMed]

- Mathew, N.T.; Kronholm, J.; Bertilsson, K.; Despeisse, M.; Johansson, B. Environmental and economic impacts of biofouling on marine and coastal heat exchangers. In EcoDesign and Sustainability II: Social Perspectives and Sustainability Assessment; Springer: Singapore, 2020; p. 661. [Google Scholar]

- Rao, T.S. Biofouling (Macro-Fouling) in Seawater Intake Systems. In Water-Formed Deposits; Elsevier: Amsterdam, The Netherlands, 2022; pp. 565–587. [Google Scholar] [CrossRef]

- Sell, D. Marine fouling. Proc. R. Soc. Edinb. Sect. B Biol. Sci. 1992, 100, 169–184. [Google Scholar] [CrossRef]

- Naser, H.A. Variability of marine macrofouling assemblages in a marina and a mariculture centre in Bahrain, Arabian Gulf. Reg. Stud. Mar. Sci. 2017, 16, 162–170. [Google Scholar] [CrossRef]

- Lezzi, M.; Del Pasqua, M.; Pierri, C.; Giangrande, A. Seasonal non-indigenous species succession in a marine macrofouling invertebrate community. Biol. Invasions 2018, 20, 937–961. [Google Scholar] [CrossRef]

- Mineur, F.; Johnson, M.P.; Maggs, C.A. Macroalgal introductions by hull fouling on recreational vessels: Seaweeds and sailors. Environ. Manag. 2008, 42, 667–676. [Google Scholar] [CrossRef]

- Perkol-Finkel, S.; Shashar, N.; Barneah, O.; Ben-David-Zaslow, R.; Oren, U.; Reichart, T.; Yacobovich, T.; Yahel, G.; Yahel, R.; Benayahu, Y. Fouling reefal communities on artificial reefs: Does age matter? Biofouling 2005, 21, 127–140. [Google Scholar] [CrossRef]

- Nelson, M.L.; Craig, S.F. Role of the sea anemone Metridium senile in structuring a developing subtidal fouling community. Mar. Ecol. Prog. Ser. 2011, 421, 139–149. [Google Scholar] [CrossRef]

- Lim, S.C.; de Voogd, N.J.; Tan, K.S. Fouling sponges (Porifera) on navigation buoys from Singapore waters. Raffles Bull. Zool. 2009, 22, 41–58. [Google Scholar]

- Khalaman, V.V.; Komendantov, A.Y. Structure of fouling communities formed by Halichondria panicea (Porifera: Demospongiae) in the White Sea. Russ. J. Ecol. 2011, 42, 493–501. [Google Scholar] [CrossRef]

- Kremer, L.P.; Rocha, R.M. The role of Didemnum perlucidum F. Monniot, 1983 (Tunicata, Ascidiacea) in a marine fouling community. Aquat. Invasions 2011, 6, 441–449. [Google Scholar] [CrossRef]

- Lins, D.M.; Rocha, R.M. Cultivated brown mussel (Perna perna) size is reduced through the impact of three invasive fouling species in southern Brazil. Aquat. Invasions 2020, 15, 114–126. [Google Scholar] [CrossRef]

- Calder, D.; Carlton, J.T.; Larson, K.; Mallinson, J.J.; Choong, H.H.; Keith, I.; Ruiz, G. Hydroids (Cnidaria, Hydrozoa) from marine fouling assemblages in the Galápagos Islands, Ecuador. Aquat. Invasions 2019, 14, 21–58. [Google Scholar] [CrossRef]

- Ajala-Batista, L.; de Miranda, L.D.; Haddad, M.A. Diversity of estuarine and marine hydroids (Cnidaria, Hydrozoa) from subtropical ecosystems of Brazil. Mar. Biodivers. 2020, 50, 97. [Google Scholar] [CrossRef]

- Agostini, V.O.; Ozorio, C.P. Biofouling initial succession on offshore artificial substrate under subtropical conditions. An. Acad. Bras. Ciênc. 2022, 94, e20201357. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.C.C.; Xavier, E.A.; Gouveia, R.L.; Silva, A.K.P.; Fernandes, M.L.B. Balanomorpha Community of Confined Artificial Substrate in a Thermal Power Plant of Pernambuco, Brazil. Indian J. Appl. Res. 2018, 8, 76–78. Available online: https://www.worldwidejournals.com/indian-journal-of-applied-research-(IJAR)/file.php?val=October_2018_1538401838__154.pdf (accessed on 26 September 2025).

- Freitas, L.E.L.D.; Feitosa, C.V.; Araújo, M.E.D. Mangrove oyster (Crassostrea rhizophorae) (Guilding, 1928) farming areas as artificial reefs for fish: A case study in the state of Ceará, Brazil. Braz. J. Oceanogr. 2006, 54, 31–39. [Google Scholar] [CrossRef]

- Mansur, M.C.D.; Pereira, D.; dos Santos, C.P.; Bergonci, P.E.A.; Thormann, B.M.; Takeda, A.M. Colonização de substrato artificial pelo mexilhão dourado, Limnoperna fortunei (Dunker, 1857) (Bivalvia, Mytiloida, Mytilidae), no delta do rio Jacuí (RS, Brasil). Biotemas 2009, 22, 75–80. [Google Scholar] [CrossRef]

- Nedved, B.T.; Hadfield, M.G. Hydroides elegans (Annelida: Polychaeta): A model for biofouling research. In Marine and Industrial Biofouling; Flemming, H.C., Murthy, P.S., Venkatesan, R., Cooksey, K., Eds.; Springer Series on Biofilms; Springer: Berlin/Heidelberg, Germany, 2009; Volume 4, pp. 203–219. [Google Scholar] [CrossRef]

- Schwan, I.D.S.; Brasil, A.C.D.S.; Neves, D.; Dias, G.M. The invasive worm Hydroides elegans (Polychaeta–Serpulidae) in southeastern Brazil and its potential to dominate hard substrata. Mar. Biol. Res. 2016, 12, 96–103. [Google Scholar] [CrossRef]

- Subías-Baratau, A.; Sanchez-Vidal, A.; Di Martino, E.; Figuerola, B. Marine biofouling organisms on beached, buoyant and benthic plastic debris in the Catalan Sea. Mar. Pollut. Bull. 2022, 175, 113405. [Google Scholar] [CrossRef] [PubMed]

- Thiel, M.; Gutow, L. The ecology of rafting in the marine environment. I. The floating substrata. Oceanogr. Mar. Biol. 2004, 42, 181–264. [Google Scholar] [CrossRef]

- da Gama, B.A.; Santos, R.P.; Pereira, R.C. The effect of epibionts on the susceptibility of the red seaweed Cryptonemia seminervis to herbivory and fouling. Biofouling 2008, 24, 209–218. [Google Scholar] [CrossRef]

- Roberts, D.; Rittschof, D.; Holm, E.; Schmidt, A.R. Factors influencing initial larval settlement: Temporal, spatial and surface molecular components. J. Exp. Mar. Biol. Ecol. 1991, 150, 203–221. [Google Scholar] [CrossRef]

- Skinner, L.F.; Coutinho, R. Effect of microhabitat distribution and substrate roughness on barnacle Tetraclita stalactifera (Lamarck, 1818) settlement. Braz. Arch. Biol. Technol. 2005, 48, 109–113. [Google Scholar] [CrossRef]

- Bravo, M.; Astudillo, J.C.; Lancellotti, D.; Luna-Jorquera, G.; Valdivia, N.; Thiel, M. Rafting on abiotic substrata: Properties of floating items and their influence on community succession. Mar. Ecol. Prog. Ser. 2011, 439, 1–17. [Google Scholar] [CrossRef]

- Whalan, S.; Abdul Wahab, M.A.; Sprungala, S.; Poole, A.J.; De Nys, R. Larval settlement: The role of surface topography for sessile coral reef invertebrates. PLoS ONE 2015, 10, e0117675. [Google Scholar] [CrossRef]

- Delgado, A.; Richards, C.; Daly, P.; Power, S.; Briciu-Burghina, C.; Delauré, Y.; Regan, F. Assessment of Biofouling on Typical Marine Sensors Materials. In Proceedings of the OCEANS 2023-Limerick, Limerick, Ireland, 12 September 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Gizer, S.G.; Sahiner, N. The effect of sulphur on the antibacterial properties of succinic acid-Cu (II) and mercaptosuccinic acid-Cu (II) MOFs. Inorg. Chim. Acta 2021, 528, 120611. [Google Scholar] [CrossRef]

- Connell, S.D.; Glasby, T.M. Do urban structures influence local abundance and diversity of subtidal epibiota? A case study from Sydney Harbour, Australia. Mar. Environ. Res. 1999, 47, 373–387. [Google Scholar] [CrossRef]

- Shevalkar, M.; Mishra, A.; Meenambiga, S.S. A review on invasive species in marine biofouling. Res. J. Pharm. Technol. 2020, 13, 4517–4521. [Google Scholar] [CrossRef]

- Tian, M.; Xu, H.; Yao, L.; Wang, R. A biomimetic antimicrobial surface for membrane fouling control in reverse osmosis for seawater desalination. Desalination 2021, 503, 114954. [Google Scholar] [CrossRef]

- Venettacci, S.; Ponticelli, G.S.; Tagliaferri, F.; Guarino, S. Environmental and economic impact of an innovative biocide-free antifouling coating for naval applications. Materials 2023, 16, 748. [Google Scholar] [CrossRef] [PubMed]

- Vuong, P.; McKinley, A.; Kaur, P. Understanding biofouling and contaminant accretion on submerged marine structures. Npj Mater. Degrad. 2023, 7, 50. [Google Scholar] [CrossRef]

- Reise, K.; Buschbaum, C.; Büttger, H.; Wegner, K.M. Invading oysters and native mussels: From hostile takeover to compatible bedfellows. Ecosphere 2017, 8, e01949. [Google Scholar] [CrossRef]

- Montalto, V.; Mangano, M.C.; Sarà, G.; Mangano, C.; Rinaldi, A.; Ape, F.; Mirto, S. Functional role of biofouling linked to aquaculture facilities in Mediterranean enclosed locations. Aquac. Environ. Interact. 2020, 12, 11–22. [Google Scholar] [CrossRef]

- Marques, A.C.; Klôh, A.S.; Migotto, A.E.; Cabral, A.C.; Rigo, A.P.R.; Bettim, A.L.; Razzolini, M.L.; Matthews-Cascon, H.; Bardi, J.; Kremer, L.P.; et al. Rapid assessment survey for exotic benthic species in the São Sebastião Channel, Brazil. Lat. Am. J. Aquat. Res. 2013, 41, 265–285. [Google Scholar] [CrossRef]

- Xavier, E.A.; Almeida, A.C.; Vieira, L.M. The role of artificial habitats on fouling bryozoan fauna in the southwestern Atlantic. Mar. Pollut. Bull. 2021, 167, 112310. [Google Scholar] [CrossRef]

- Serrano, E.; Ribes, M.; Bolivar, M.; Coma, R. Fouling of a boat hull by the invasive zooxanthellate coral Oculina patagonica-could shipping be enhancing its unique large-scale spread? Mediter. Mar. Sci. 2023, 24, 76–86. [Google Scholar] [CrossRef]

- Faccioli, Y.E.D.S.; de Oliveira, K.W.; Campos-Guerra, J.M.; Converti, A.; Soares da Silva, R.D.C.F.; Sarubbo, L.A. Biosurfactants: Chemical properties, ecofriendly environmental applications, and uses in the industrial energy sector. Energies 2024, 17, 5042. [Google Scholar] [CrossRef]

- Karataş, A.R.; Kazak, H.; Akcan, A.T.; Akkaş, E.; Arık, M. A bibliometric mapping analysis of the literature on patent analysis. World Pat. Inf. 2024, 77, 102266. [Google Scholar] [CrossRef]

- Yang, W.; Wang, X. The impact of patent protection on technological innovation: A global value chain division of labor perspective. Technol. Forecast. Soc. Change 2024, 203, 123370. [Google Scholar] [CrossRef]

- Eilertsen, A.; Karlsen, K.; Haugereid, J. System and Method for Cleaning of Biofouling and Pathogens and Use of the System. WO Patent 2024151170, 18 July 2024. [Google Scholar]

- Shimpo, C.; Takahashi, J. Membrane Treatment Method and Biofouling Suppression Method. WO Patent 2024128050, 20 June 2024. [Google Scholar]

- Kim, Y.W. Biofouling Prevention System for Vessel. WO Patent 2024117880, 6 June 2024. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2024117880&_cid=P20-MFWJNA-62883-1 (accessed on 12 June 2025).

- Andersson, T. Reduction of Biofouling on Watercraft. WO Patent 2024094622, 10 May 2024. [Google Scholar]

- Samaniego, A.M. Mixed Metal Oxide Coatings for Protecting Titanium Alloys from Biofouling. ES WO Patent 2024079222, 18 April 2024. [Google Scholar]

- Feng, L.; Machado, C.J.; Park, K.C.K. Photocatalytic Surfaces for Anti-Biofouling. WO Patent 2024044665, 29 February 2024. [Google Scholar]

- Abramo, G.P.; Jayaraman, A.; Demarest, V.A.; Fabiny, W.J.; Repollet, P.H. Roof Coating Resistant to Biofouling. EP Patent 4519372, 12 March 2025. [Google Scholar]

- Samad, N.A. Controlling Biofouling in Water Purification. WO Patent 2023028503, 2 March 2023. [Google Scholar]

- Kim, J.W. Biofouling Preventing Device for Ships and Method for Manufacturing Same. WO Patent 2022255578, 8 December 2022. [Google Scholar]

- Barbosa, M.L.; Correia, E.S.; Rocha, L.S.N.; Almeida, E.S.; Meneses, M.S.; Jorge, C.E.S.; Oliveira, F.G.; Ledezma, L.C.M.; Silva, A.Q.; Oliveira, J.S.S.; et al. Underwater Robot for Removing Marine Biofouling from Hulls of Floating Units, with System for Containing and Capturing Waste. WO Patent 2022140831, 7 July 2022. [Google Scholar]

- Salters, B.A.; Hietbrink, R.B.; Niessen, E.M.J.; Marsman, A.W. A Marine System Comprising an Anti-Biofouling Light Arrangement That Includes a Polarizing Device. EP Patent 4103468, 21 December 2022. [Google Scholar]

- Hatch, M.; Fisher, J. Anti-Biofouling in Marine Applications Using UV Light Source. WO Patent 2021055500, 25 March 2021. [Google Scholar]

- Baek, S.J.; Seo, J.M. Marine Biofouling Prevention Apparatus for Seawater Battery. WO Patent 2020013378, 16 January 2020. [Google Scholar]

- Takashi, N.; Kappock, P.; Iwase, Y.; Schroeer, J.; Riegler, J.; Van Aken, P. Compositions for antifouling protection. JP Patent 2023126913A, 12 September 2023. [Google Scholar]

- Zhao, J.; Chunguang, Y.; Ke, Y.; Jiqiang, W.; Xinyu, C.; Tianying, X. Stainless steel coating with marine organism fouling resistance function and preparation method thereof. CN Patent 114150306, 08 March 2022. [Google Scholar]

- Tian, L.; Jin, H.; Wang, J.; Yin, Y.; Shang, Y.; Zhao, J.; Sun, J. Environment-friendly marine antifouling coating and preparation method thereof. CN Patent 112876984, 01 June 2021. [Google Scholar]

- Ligeiro Barbosa, M.L.; Correia, E.S.; Rocha, L.S.N.; Almeida, E.S.; Meneses, M.S.; Jorge, C.E.S.; Oliveira, F.G.; Ledezma, L.C.M.; Silva, A.Q.S.; Oliveira, J.R.S. Integrated System for Removing and Treating Marine Biofouling on Submerged Metal Surfaces. NZ Patent 802311, 28 July 2023. [Google Scholar]

- Liu, C.; Sun, J.; Duan, J. High-Transmittance Ultraviolet Antifouling Coating System with Embedded Ultraviolet LED Lamp Beads and Preparation Method Thereof. CN Patent 111117477, 8 May 2020. [Google Scholar]

- Barbosa, M.L.; Correia, E.S.; Rocha, L.S.N.; Almeida, E.S.; Menezes, M.S.; Jorge, C.E.S.; Oliveira, F.G.; Ledezma, L.C.M.; Da Silva, A.Q.; Oliveira, J.R.S. Modular System for Treating Effluent from Cleaning Hulls of Floating Units. CA Patent 3203772, 7 July 2022. [Google Scholar]

- Dasgupta, N.P.; Wang, J.; Tuteja, A. Transparent Nanowire Architectures for Marine Anti-Fouling. U.S. Patent 20210262089, 26 August 2021. [Google Scholar]

- Yachen, C.; Wenjuan, J.; Hongzhi, L.; Yaqi, D.; Jihui, W. Environment-Friendly Antifouling Slow-Release Material as well as Preparation Method and Application Thereof. CN Patent 118085433, 7 August 2024. [Google Scholar]

- Ri, Q.; Qiu, Z.; Jin, Z. Dispositivo e Método para Prevenção de Bioincrustação de Hélices Marinhas. CN Patent 111498071, 7 August 2020. [Google Scholar]

- Pawar, S.S.; Naik, R.B.; Balasubramanian, K.; Malvankar, N.G.; Naik, R.S.; Rath, S.K.; Mahato, T.K. Stratified Poly Dimethyl Siloxane-Epoxy Coating Possessing Anticorrosive & Foul Release Properties in a Single Coat and Their Method of Preparation Thereof. IN Patent 202111011420, 18 November 2022. [Google Scholar]

- Tang, H.; Wang, Y.; Ye, Q.; Yu, Z.; Chen, Y.; Zhu, J.; Zhang, Y.; Li, G. Antibacterial Polytitanilazane Coating Composition and Preparation Method Thereof. CN Patent 115558323, 3 January 2023. [Google Scholar]

- Leijssen, J.J. Light Emitting Unit Configured to Be Applied to Surface Area of Marine Object. CN Patent 112771309, 7 May 2021. [Google Scholar]

- Woelk, E. Apparatus and Methods to Prevent Biofouling. U.S. Patent 20210138519, 13 May 2021. [Google Scholar]

- Kessel, R.; Carloni, C.; Coutinho, R.; Messano, L. Process for Biofouling Cohibition in Marine Environments. U.S. Patent 20210395900, 23 December 2021. [Google Scholar]

- Xiangfeng, K.; Zhongliang, S.; Qian, W.; Guangli, H.; Dongzhi, C.; Conggang, W.; Yan, L.; Xuan, C.; Qingpeng, L. Biofouling Prevention Device for Marine Instrument. CN Patent 210146517, 13 March 2020. [Google Scholar]

- Salters, B.A.; Hietbrink, R.B.; Niessen, E.M.J.; Marsman, A.W. Ocean System Comprising Device for Preventing Biofouling Light Comprising Polarizing Device. CN Patent 115087592, 20 September 2022. [Google Scholar]

- Shixiong, C.; Guoqiang, L.; Xianwei, H. Marine Plastic Pipeline with High Impact Resistance, High Biofouling Resistance and High Wear Resistance and Preparation Method Thereof. CN Patent 112480520, 12 March 2021. [Google Scholar]

- Yusuke, K. Biofouling Prevention Device. JP Patent 2024121088, 6 September 2024. [Google Scholar]

- Dürr, S.; Shaw, A.; Moejes, K.B. Sensor Device. WO Patent 2024094996, 10 May 2024. [Google Scholar]

- Baldaev, L.K.; Baldaev, S.L.; Mankovskij, S.A.; Kozlov, N.S.; Pavlov, A.Y.; Ishchenko, Y.N. Method for Producing a Coating with Low Surface Energy against Biofouling. RU Patent 0002760600, 29 November 2021. [Google Scholar]

- Jung, K.K.; Han, W.B.; Son, J.H. Biofouling Prevention Film Structure Formed on Surface of Ship Structure. KR Patent 1020230066865, 16 May 2023. [Google Scholar]

- Räftegård, V. A System for Mitigating Biofouling. SE Patent 2350663, 31 May 2023. [Google Scholar]

- Hongying, Y.; Dizhu, Y.; Xuzhou, J.; Donbai, S. Biological Fouling Prevention Coating as Well as Preparation Method and Application Thereof. CN Patent 115521709, 27 December 2022. [Google Scholar]

- Towson, J.D. Anti-Fouling Robot. WO Patent 2022268300, 29 December 2022. [Google Scholar]

- MacDonald, J. An Apparatus for Vessel Drag Reduction and Planetary Cooling. AU Patent 2023204574, 27 July 2023. [Google Scholar]

- Yi, P.; Hongyu, J.; Xiaoshuang, Y.; Jian, M.; Yong, F.; Jiawei, S.; Shengbo, Y. Preparation Method of Photocatalytic Material Composite Micro-Texture Anti-Microbial Attachment Surface. CN Patent 114985937, 2 September 2022. [Google Scholar]

- Isaksson, D.; Hoffmann, M. Polímero e Composição Anti-Incrustante, Monômero Polimerizável, Artigo, Método para Produzir um Monômero de Medetomidina e um Polímero Anti-Incrustante. BR Patent 1120230074541 A2, 23 May 2023. Available online: https://busca.inpi.gov.br/pePI/servlet/PatenteServletController?Action=detail&CodPedido=1699432&SearchParameter=BR%201120230074541%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20&Resumo=&Titulo= (accessed on 16 June 2025).

- Lopes, C.C.; Braga, E.F.; Lopes, R.S.C. Processo de Síntese por Via Úmida e Seca de Compostos Lisoglicerofosfocolinas e Seus Derivados O-Alquilados como Aditivos Biocidas em Revestimentos de Ação Anti-Incrustante. BR Patent 1020200200453 A2, 12 April 2022. Available online: https://busca.inpi.gov.br/pePI/servlet/PatenteServletController?Action=detail&CodPedido=1590395&SearchParameter=BR%201020200200453%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20&Resumo=&Titulo= (accessed on 21 June 2025).

- Nakae, T.; Kappock, P.; Iwase, Y.; Schröer, J.; Riegler, J.; Aken, P. Composição Anti-Incrustação e Seu Uso, Tinta para Pintura Anti-Incrustação e Método para Inibir Bioincrustação Marinha. BR Patent 1120210097287 A2, 17 August 2021. Available online: https://busca.inpi.gov.br/pePI/servlet/PatenteServletController?Action=detail&CodPedido=1612269&SearchParameter=BR%201120210097287%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20%20&Resumo=&Titulo= (accessed on 14 June 2025).

- Wang, Y. Has China Established a Green Patent System? Implementation of Green Principles in Patent Law. Sustainability 2022, 14, 11152. [Google Scholar] [CrossRef]

- Lakshmi, V.V.; Akondi, K.B. Control of biofouling in marine environment—Past, present and future. Int. J. Sci. Eng. Res. 2015, 6, 283–286. [Google Scholar]

- Zan, H. Research on the Impact of High-Tech Enterprise Certification Policy on Corporate Technological Innovation: An Empirical Study Based on Listed Company Data. Adv. Econ. Manag. Polit. Sci. 2024, 87, 9–23. [Google Scholar] [CrossRef]

- Sánchez, D.; García, S.; Ruiz, A.; Boullosa-Falces, D.; Esteban, G. Antifouling and Anticorrosive Prevention with Ceramic Coatings on Offshore Structures for Renewable Energy. In Proceedings of the 15th European Wave and Tidal Energy Conference (EWTEC 2023), Bilbao, Spain, 3–7 September 2023. [Google Scholar] [CrossRef]

- Satasiya, G.; Kumar, M.A.; Ray, S. Biofouling dynamics and antifouling innovations: Transitioning from traditional biocides to nanotechnological interventions. Environ. Res. 2025, 269, 120943. [Google Scholar] [CrossRef]

- Borges, M.N. Ciência, Tecnologia e Inovação para o Desenvolvimento do Brasil. Sci. Plena 2016, 12, 1–11. [Google Scholar] [CrossRef]

- Vasconcelos, C.R.D.; Silva, D.P.D. Intellectual property challenges for the roads of innovation in Brazil. Innov. Manag. Rev. 2019, 16, 185–192. [Google Scholar] [CrossRef]

- Silva, L.C.S.; Oliveira Lima, V. Innovation and Technology Transfer Policies in the Brazilian Public Sector. In Perspectives on Innovation and Technology Transfer in Managing Public Organizations; Silva, L., Ed.; IGI Global: Hershey, PA, USA, 2024. [Google Scholar] [CrossRef]

- Cavalcanti, M.; Neto, A.P. Inovação tecnológica no Brasil: Há uma pedra no meio do caminho. Liinc Rev. 2014, 10, 726–741. [Google Scholar] [CrossRef]

- Tulyakova, I.R.; Gregova, E.; Dengov, V.V. Assessment of Competitiveness of Shipbuilding Industry in Russia. NAŠE MORE Znan. Časopis Za More I Pomor. 2017, 64, 112–119. [Google Scholar] [CrossRef]

- Gizer, G.; Önal, U.; Manoj, K.R.; Sahiner, N. Biofouling and Mitigation Methods: A Review. Biointerface Res. Appl. Chem. 2022, 13, 185. [Google Scholar] [CrossRef]

- Miromanova, A.; Hovhannisyan, N. To Innovate or Not to Innovate: International Sanctions and Their Impact on Patenting of Target Countries. SSRN Prepr. 2025. [Google Scholar] [CrossRef]

- Hellio, C. The potential of marine biotechnology for the development of new antifouling solutions. Res. Paper 2010, 2, 35–41. [Google Scholar]

- Sommerscales, E.F.C.; Bergles, A.E. Enhancement of Heat Transfer and Fouling Mitigation. Adv. Heat Transf. 1997, 30, 197–253. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Wu, K.F.; Wang, Z.J.; Zhao, L.; Li, S.S. Fouling and cleaning of membrane-a literature review. J. Environ. Sci. 2000, 12, 241–251. [Google Scholar]

- Bott, T.R. Industrial Biofouling; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Cabot, C.G. Compositions and Method for Inhibiting Biofouling and Barnacle Growth on Substrates under Water. U.S. Patent 20170275473, 28 September 2017. [Google Scholar]

- Trueba, A.; Garcia, S.; Otero, F.M. Mitigation of biofouling using electromagnetic fields in tubular heat exchangers–condensers cooled by seawater. Biofouling 2014, 30, 95–103. [Google Scholar] [CrossRef] [PubMed]

- Müller-Steinhagen, H.; Malayeri, M.R.; Watkinson, A.P. Heat exchanger fouling: Mitigation and cleaning strategies. Heat Transf. Eng. 2011, 32, 189–196. [Google Scholar] [CrossRef]

- Peng, J.; Qiu, Y.; Gehr, R. Characterization of permanent fouling on the surfaces of UV lamps used for wastewater disinfection. Water Environ. Res. 2005, 77, 309–322. [Google Scholar] [CrossRef] [PubMed]

- Chatzikonstantinou, K.; Tzamtzis, N.; Pappa, A.; Liodakis, S. Membrane fouling control using high-frequency power vibration, in an SMBR pilot system—Preliminary studies. Desalin. Water Treat. 2016, 57, 11550–11560. [Google Scholar] [CrossRef]

- Benito, A.; Garcia, G.; Gonzalez-Olmos, R. Fouling reduction by UV-based pretreatment in hollow fiber ultrafiltration membranes for urban wastewater reuse. J. Membr. Sci. 2017, 536, 141–147. [Google Scholar] [CrossRef]

- Zhao, F.; Chu, H.; Zhang, Y.; Jiang, S.; Yu, Z.; Zhou, X.; Zhao, J. Increasing the vibration frequency to mitigate reversible and irreversible membrane fouling using an axial vibration membrane in microalgae harvesting. J. Membr. Sci. 2017, 529, 215–223. [Google Scholar] [CrossRef]

- Xing, J.; Liang, H.; Xu, S.; Chuah, C.J.; Luo, X.; Wang, T.; Wang, J.; Li, G.; Snyder, S.A. Organic matter removal and membrane fouling mitigation during algae-rich surface water treatment by powdered activated carbon adsorption pretreatment: Enhanced by UV and UV/chlorine oxidation. Water Res. 2019, 159, 283–293. [Google Scholar] [CrossRef]

- Baudequin, C.; Mai, Z.; Rakib, M.; Deguerry, I.; Severac, R.; Pabon, M.; Couallier, E. Removal of fluorinated surfactants by reverse osmosis–role of surfactants in membrane fouling. J. Membr. Sci. 2014, 458, 111–119. [Google Scholar] [CrossRef]

- Amjad, Z.; Koutsoukos, P.G.A. Current Review of Polymeric Dispersants and Their Practical Significance in Industrial Water Treatment. In Proceedings of the CORROSION 2019, Nashville, TN, USA, 24–28 March 2019. NACE-2019-12988. [Google Scholar]

- Silva, M.G.C.; Medeiros, A.O.; Almeida, D.G.; Silva, M.E.P.; Meira, H.M.; Sarubbo, L.A. Application of green surfactants to control barnacle recruitment. Reg. Stud. Mar. Sci. 2021, 45, 101–854. [Google Scholar] [CrossRef]

- Martensson, L.; Gunnarsson, F. Preventing Marine Biofouling by Inhibiting Adhesive Release from Barnacles. U.S. Patent 20060045864, 2 March 2006. [Google Scholar]

- Isaksson, D.; Mårtensson Lindblad, L. Use of the Enantiomer Dexmedetomidine as Inhibitor for Marine Biofouling of Surfaces. WO Patent 2015011178, 20 January 2015. [Google Scholar]

- Pereira, M.O.; Vieira, M.J.; Beleza, V.M.; Melo, L.F. Comparison of two biocides-carbamate and glutaraldehyde-in the control of fouling in pulp and paper industry. Environ. Technol. 2001, 22, 781–790. [Google Scholar] [CrossRef]

- Liu, M.; Chen, Q.; Wang, L.; Yu, S.; Gao, C. Improving fouling resistance and chlorine stability of aromatic polyamide thin-film composite RO membrane by surface grafting of polyvinyl alcohol (PVA). Desalination 2015, 367, 11–20. [Google Scholar] [CrossRef]

- Kasongo, G.; Steenberg, C.; Morris, B.; Kapenda, G.; Jacobs, N.; Aziz, M. Surface grafting of polyvinyl alcohol (PVA) cross-linked with glutaraldehyde (GA) to improve resistance to fouling of aromatic polyamide thin film composite reverse osmosis membranes using municipal membrane bioreactor effluent. Water Pract. Technol. 2019, 14, 614–624. [Google Scholar] [CrossRef]

- Paradas, W.C.; Filho, G.M.A. Are metals of antifouling paints transferred to marine biota. Braz. J. Oceanogr. 2007, 55, 51–56. [Google Scholar] [CrossRef]

- Joshi, M.; Mukherjee, A.; Misra, S.C.; Ramesh, U.S. Natural biocides in antifouling paints. Technol. Innovat. Shipbuild. 2013, 12, 1–11. [Google Scholar]

- Campos, B.G.; Figueiredo, J.; Perina, F.; Abessa, D.M.D.S.; Loureiro, S.; Martins, R. Occurrence, effects and environmental risk of antifouling biocides (EU PT21): Are marine ecosystems threatened? Crit. Rev. Environ. Sci. Technol. 2022, 52, 3179–3210. [Google Scholar] [CrossRef]

- Zheng, J.; Lin, C.; Duan, D. Method for Preparing Ulva pertusa Kjellm Extract for Marine Antifoulant. CN Patent 101564050, 28 October 2009. [Google Scholar]

- Characklis, W.G. Bioengineering report: Fouling biofilm development: A process analysis. Biotechnol. Bioeng. 1981, 23, 1923–1960. [Google Scholar] [CrossRef]

- Dobretsov, S.; Dahms, H.U.; Qian, P.Y. Inhibition of biofouling by marine microorganisms and their metabolites. Biofouling 2006, 22, 43–54. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, P.; Yu, S.; Li, D.; Cao, S. Inhibition of common fouling organisms in mariculture by epiphytic bacteria from the surfaces of seaweeds and invertebrates. Acta Ecol. Sin. 2009, 29, 222–226. [Google Scholar] [CrossRef]

- Zuo, Y.; Shao, Y.; Wang, L.; Sun, Y.; An, Y.; Jiang, L.M.; Yu, N.; Hao, R.; Zhou, C.; Tá, J.; et al. Simultaneous sludge minimization and membrane fouling mitigation in membrane bioreactors by using a microaerobic-Settling pretreatment module. J. Environ. Manag. 2023, 328, 116977. [Google Scholar] [CrossRef]

- Al-Amoudi, A.; Lovitt, R.W. Fouling strategies and the cleaning system of NF membranes and factors affecting cleaning efficiency. J. Membr. Sci. 2007, 303, 4–28. [Google Scholar] [CrossRef]

- Krause, S.; Zimmermann, B.; Meyer-Blumenroth, U.; Lamparter, W.; Siembida, B.; Cornel, P. Enhanced membrane bioreactor process without chemical cleaning. Water Sci. Technol. 2010, 61, 2575–2580. [Google Scholar] [CrossRef] [PubMed]

- Erol, E.; Cansoy, C.E.; Aybar, O.Ö. Assessment of the impact of fouling on vessel energy efficiency by analyzing ship automation data. Appl. Ocean Res. 2020, 105, 102418. [Google Scholar] [CrossRef]

- Hellio, C.; Yebra, D. (Eds.) Advances in Marine Antifouling Coatings and Technologies; Elsevier: Cambridge, UK, 2009. [Google Scholar]

- Sullivan, T.; O’Callaghan, I. Recent developments in biomimetic antifouling materials: A review. Biomimetics 2020, 5, 58. [Google Scholar] [CrossRef]

- Banerjee, S.; Das, A.; Das, R.; Bhattacharjee, C. Mesoporous Mg–Al–Ti Composite oxide incorporated mixed matrix ultrafiltration membrane with superior multi-heavy metal removal capacity, anti-fouling & anti-microbial property. J. Membr. Sci. 2024, 703, 122836. [Google Scholar] [CrossRef]

- Ramotowski, T.S. Method and Apparatus for Preventing Biofouling of Surfaces. U.S. Patent 8309625, 13 November 2012. [Google Scholar]

- Epstein, N. Thinking about Heat Transfer Fouling: A 5 × 5 Matrix. Heat Transf. Eng. 1983, 4, 43–56. [Google Scholar] [CrossRef]

- Panchal, C.B.; Knudsen, J.G. Mitigation of water fouling: Technology status and challenges. Adv. Heat Transf. 1998, 31, 431–474. [Google Scholar] [CrossRef]

- Kazi, S.N. Fouling and fouling mitigation on heat exchanger surfaces. Fouling and fouling mitigation on heat exchanger surfaces. In Heat Exchangers-Basics Design Applications; Mitrović, J., Ed.; Intechopen: Berlin, Germany, 2012; p. 600. [Google Scholar] [CrossRef]

- Albuquerque Filho, L.H.; Casagrande, M.D.T.; Almeida, M.S.d.S.; Costa, W.G.S.; Santana, P.R.L.d. Mechanical Performance and Life Cycle Assessment of Soil Stabilization Solutions for Unpaved Roads from Northeast Brazil. Sustainability 2024, 16, 9850. [Google Scholar] [CrossRef]

- Poohphajai, F.; Gubenšek, A.; Černoša, A.; Butina Ogorelec, K.; Rautkari, L.; Sandak, J.; Sandak, A. Bioinspired Living Coating System for Wood Protection: Exploring Fungal Species on Wood Surfaces Coated with Biofinish during Its Service Life. Coatings 2024, 14, 430. [Google Scholar] [CrossRef]

- Lee, S.; Shon, H.K.; Hong, S. Dewatering of activated sludge by forward osmosis (FO) with ultrasound for fouling control. Desalination 2017, 421, 79–88. [Google Scholar] [CrossRef]

- Fortunato, H.F.; Figueira, R.M.; de Souza, R.F.; Theodoro Junior, N.; Mello, V.B. Artificial intelligence as an ally to assess and manage the golden mussel (Limnoperna fortunei (Dunker, 1857)) bioinvasion. Aquat. Sci. 2025, 87, 53. [Google Scholar] [CrossRef]

- Zeidan, G.C.; Boehs, G. Assessment of tributyltin contamination based on imposex in Stramonita rustica (Mollusca: Gastropoda) along southern Bahia coast, northeastern Brazil. Braz. J. Biol. 2017, 77, 185–190. [Google Scholar] [CrossRef]

- Goldeberg, E.D. TBT: An environmental dilemma. Environ. Sci. Policy Sustain. Dev. 1986, 28, 17–44. [Google Scholar] [CrossRef]

- Kotrikla, A. Environmental management aspects for TBT antifouling wastes from the shipyards. J. Environ. Manag. 2009, 90, S77–S85. [Google Scholar] [CrossRef] [PubMed]

- Selim, M.S.; El-Safty, S.A.; Shenashen, M.A.; Higazy, S.A.; Elmarakbi, A. Progress in biomimetic leverages for marine antifouling using nanocomposite coatings. J. Mater. Chem. B 2020, 8, 3701–3732. [Google Scholar] [CrossRef]

- Alonso Felipe, J.V. Evaluation of the Effects of Biocides in Antifouling Coatings (AF Coatings) on Marine Ecosystems. Master’s Thesis, E.T.S.I. Minas, Universidad Politécnica de Madrid, Madrid, Spain, 2011. [Google Scholar]

- Elia, A.C.; Magara, G.; Pastorino, P.; Zaccaroni, A.; Caldaroni, B.; Andreini, R.; Righetti, M.; Silvi, M.; Dörr, A.J.M.; Prearo, M. Ecotoxicity in Hyriopsis bialatus of copper and zinc biocides used in metal-based antifouling paints. Environ. Sci. Pollut. Res. 2022, 29, 18245–18258. [Google Scholar] [CrossRef]

- Ferreira, A.M.P.; Matos, J.M.; Silva, L.K.; Viana, J.L.M.; Freitas, M.S.D.; Amarante Júnior, O.P.; Franco, T.C.R.S.; Brito, N.M. Assessing the spatiotemporal occurrence and ecological risk of antifouling biocides in a Brazilian estuary. Environ. Sci. Pollut. Res. 2024, 31, 3572–3581. [Google Scholar] [CrossRef]

- Paz-Villarraga, C.A.; Castro, Í.B.; Fillmann, G. Biocides in antifouling paint formulations currently registered for use. Environ. Sci. Pollut. Res. 2022, 29, 30090–30101. [Google Scholar] [CrossRef]

- International Maritime Organization. Resolution A.774(18), Guidelines for Preventing the Introduction of Unwanted Aquatic Organisms and Pathogens from Ships’ Ballast Water and Sediment Discharges; Adopted by the 18th Assembly; IMO: London, UK, 4 November 1993. [Google Scholar]

- International Maritime Organization. Resolution A.868(20): Guidelines for the Control and Management of Ships’ Ballast Water to Minimize the Transfer of Harmful Aquatic Organisms and Pathogens; Adopted by the 20th Assembly; IMO: London, UK, 27 November 1997. [Google Scholar]

- Riadh, M. Preventing Marine Pollution through MARPOL: Enhancing Protection for Coastal Ecosystems and Mangroves. Collab. Eng. Dly. Book Ser. 2024, 2, 125–130. [Google Scholar] [CrossRef]

- Horiguchi, T. Ecotoxicological Impacts of Organotins: An Overview. In Biochemical and Biological Effects of Organotins, 1st ed.; Pagliarani, A., Trombetti, F., Ventrella, V., Eds.; Bentham Science Publishers: Sharjah, United Arab Emirates, 2012; pp. 3–24. [Google Scholar] [CrossRef]

- Muadtrap, M.; Thiramanas, R.; Crespy, D. Amphiphilic materials for advanced antifouling and anticorrosion coatings. Prog. Org. Coat. 2025, 207, 109391. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Y.; Tang, Z.; Zhang, C.; Wu, J.; Wu, B. Surface Reconstruction of Silicone-Based Amphiphilic Polymers for Mitigating Marine Biofouling. Polymers 2024, 16, 1570. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Do, J.; Kang, S.M. Polydopamine-Mediated, Amphiphilic Poly (Carboxybetaine Methacrylamide-r-Trifluoroethyl Methacrylate) Coating with Resistance to Marine Diatom Adhesion and Silt Adsorption. Adv. Mater. Interfaces 2024, 11, 2300871. [Google Scholar] [CrossRef]

- Callow, J.A.; Callow, M.E. Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat. Commun. 2011, 2, 244. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Zhou, S.; Luo, H.; Wu, L.; Gao, W.; Yang, J. Temperature-dependent phase-segregation behavior and antifouling performance of UV-curable methacrylated PDMS/PEG coatings. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1612–1623. [Google Scholar] [CrossRef]

- Chen, Y.; Song, Q.; Zhao, J.; Gong, X.; Schlaad, H.; Zhang, G. Betulin-constituted multiblock amphiphiles for broad-spectrum protein resistance. ACS Appl. Mater. Interfaces 2018, 10, 6593–6600. [Google Scholar] [CrossRef] [PubMed]

- Tian, S.; Zhang, J.; Liu, S.; Li, J.; Pu, J.; Hao, Y.; Ying, G.; Xue, Q.; Lu, G. An Integrated Anti-Fouling and Anti-Corrosion Coating Enabled by RGO/AgNPs and Amphiphilic Networks. Engineering 2024, 42, 223–234. [Google Scholar] [CrossRef]

- Li, Y.; Liao, J.; Zhang, H.; Tang, X.; Zhong, S.; Yu, Y.; Li, Q. Super-structural 2D ultrathin carbon nitride/acrylate boron silane polymer with multi-function for enhancing antifouling performance. J. Coat. Technol. Res. 2021, 18, 1051–1064. [Google Scholar] [CrossRef]

- Benda, J.; Stafslien, S.; Vanderwal, L.; Finlay, J.A.; Clare, A.S.; Webster, D.C. Surface modifying amphiphilic additives and their effect on the fouling-release performance of siloxane-polyurethane coatings. Biofouling 2021, 37, 309–326. [Google Scholar] [CrossRef]

- Yan, D.; Lin, J.; Zhang, B.; Zhang, S.; Ling, S.; Song, J. Drag reduction and antifouling of a spontaneous fast moving air film. J. Mater. Chem. A 2024, 30, 19268–19276. [Google Scholar] [CrossRef]

- Lin, J.; Wang, X.; Wang, H.; Sun, Z.; Yan, D.; Song, J. High drag reduction by spontaneous capture and transportation of bubbles. Nanoscale 2025, 17, 10892–10900. [Google Scholar] [CrossRef]

- Yan, D.; Lu, Y.; Lin, J.; Li, W.; Song, J. Enhancing water transportation capacity by asymmetrical patterned surface with super-wettability. Appl. Phys. Lett. 2024, 125, 071601. [Google Scholar] [CrossRef]

- Pu, X.; Li, G.; Huang, H. Preparation, anti-biofouling and drag-reduction properties of a biomimetic shark skin surface. Biol. Open 2016, 5, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Rostami, S.; Garipcan, B. Evolution of antibacterial and antibiofouling properties of sharkskin-patterned surfaces. Surf. Innov. 2022, 10, 165–190. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, L.; Zang, D.; Guo, X.; Liu, M. Designing bioinspired anti-biofouling surfaces based on a superwettability strategy. Small 2017, 13, 1503334. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.H.; Cho, S.H.; Zhang, H.; Zhao, M.; Zacharia, N.S. Slippery liquid-infused porous surfaces (SLIPS) using layer-by-layer polyelectrolyte assembly in organic solvent. Langmuir 2018, 34, 4722–4731. [Google Scholar] [CrossRef]

- Richards, C.; Slaimi, A.; O’Connor, N.E.; Barrett, A.; Kwiatkowska, S.; Regan, F. Bio-inspired Surface Texture Modification as a Viable Feature of Future Aquatic Antifouling Strategies: A Review. Int. J. Mol. Sci. 2020, 21, 5063. [Google Scholar] [CrossRef]

- Subbaiyan, R.; Ganesan, A.; Varadharajan, V. Bioprospecting and exploration of the natural antifouling approaches against marine foulers. J. Pure Appl. Microbiol. 2023, 17, 1374–1390. [Google Scholar] [CrossRef]

- Acervado, M.S.; Puentes, C.; Carreño, K.; León, J.G.; Stupak, M.; García, M.; Pérez, M.; Blustein, G. Antifouling paints based on marine natural products from Colombian Caribbean. Int. Biodeterior. Biodegrad. 2013, 83, 97–104. [Google Scholar] [CrossRef]

- Aldred, N.; Phang, I.Y.; Conlan, S.L.; Clare, A.S.; Vancso, G.J. The effects of a serine protease, Alcalase®, on the adhesives of barnacle cyprids (Balanus amphitrite). Biofouling 2008, 24, 97–107. [Google Scholar] [CrossRef] [PubMed]

- Pettitt, M.E.; Henry, S.L.; Callow, M.E.; Callow, J.A.; Clare, A.S. Activity of commercial enzymes on settlement and adhesion of cypris larvae of the barnacle Balanus amphitrite, spores of the green alga Ulva linza, and the diatom Navicula perminuta. Biofouling 2004, 20, 299–311. [Google Scholar] [CrossRef] [PubMed]

- Ashbridge, Z.; Fielden, S.D.; Leigh, D.A.; Pirvu, L.; Schaufelberger, F.; Zhang, L. Knotting matters: Orderly molecular entanglements. Chem. Soc. Rev. 2022, 51, 7779–7809. [Google Scholar] [CrossRef]

- Cappitelli, F.; Salvadori, O.; Albanese, D.; Villa, F.; Sorlini, C. Cyanobacteria cause black staining of the National Museum of the American Indian Building, Washington, DC, USA. Biofouling 2012, 28, 257–266. [Google Scholar] [CrossRef]

- Rolin, C.; Inkster, R.; Laing, J.; McEvoy, L. Regrowth and biofouling in two species of cultivated kelp in the Shetland Islands, UK. J. Appl. Phycol. 2017, 29, 2351–2361. [Google Scholar] [CrossRef]

- Szewczyk, P. The role of nanotechnology in improving marine antifouling coatings. Zesz. Nauk. Akad. Morskiej Szczecinie 2010, 24, 118–123. [Google Scholar]

- Liu, X.; Zhou, J.; Bai, X.; Cao, P. Research Progress on New Environmentally Friendly Antifouling Coatings in Marine Settings: A Review. Biomimetics 2023, 8, 200. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L.; Zhang, Y.; Wang, D.; Guo, J.; Zhang, M.; Li, Y. The performance of electrode ultrafiltration membrane bioreactor in treating cosmetics wastewater and its anti-fouling properties. Environ. Res. 2022, 206, 112629. [Google Scholar] [CrossRef]

- El-Wahab, H.A.; Al-Shareef, H.F. Novel antifouling paint formulation based on Ca2Cr2O5 and CaMnO3 NPs as a protective pigment. Sci. Rep. 2024, 14, 24474. [Google Scholar] [CrossRef]

- Holmström, C.; Kjelleberg, S. Marine Pseudoalteromonas species are associated with higher organisms and produce biologically active extracellular agents. FEMS Microbiol. Ecol. 1999, 30, 285–293. [Google Scholar] [CrossRef] [PubMed]

- Holmström, C.; Egan, S.; Franks, A.; McCloy, S.; Kjelleberg, S. Antifouling activities expressed by marine surface associated Pseudoalteromonas species. FEMS Microbiol. Ecol. 2002, 41, 47–58. [Google Scholar] [CrossRef] [PubMed]

- Maréchal, J.P.; Hellio, C. Challenges for the development of new non-toxic antifouling solutions. Int. J. Mol. Sci. 2009, 10, 4623–4637. [Google Scholar] [CrossRef] [PubMed]

- Kalinovskaya, N.I.; Ivanova, E.P.; Alexeeva, Y.V.; Gorshkova, N.M.; Kuznetsova, T.A.; Dmitrenok, A.S.; Nicolau, D.V. Low-molecular-weight, biologically active compounds from marine Pseudoalteromonas species. Curr. Microbiol. 2004, 48, 441–446. [Google Scholar] [CrossRef]

- Muhammad, A.; Kashere, M.A. Neem, Azadirachta indica L.(A. Juss): An eco-friendly botanical insecticide for managing farmers’ insects pest problems-a review. FUDMA J. Sci. 2020, 4, 484–491. [Google Scholar] [CrossRef]

- Mancillas-Salas, S.; Ledón-Smith, J.Á.; Pérez-Álvarez, M.; Cadenas-Pliego, G.; Mata-Padilla, J.M.; Andrade-Guel, M.; Esparza-González, S.C.; Vargas-Gutiérrez, G.; Sierra-Gómez, U.A.; Saucedo-Salazar, E.M. Nanostructured Copper Selenide Coatings for Antifouling Applications. Polymers 2024, 16, 489. [Google Scholar] [CrossRef]

- Maria, V.L.; Barreto, A. Ecotoxicity Assessment of Nanomaterials: Latest Advances and Prospects. Nanomaterials 2024, 14, 326. [Google Scholar] [CrossRef]

- Boros, B.-V.; Ostafe, V. Evaluation of Ecotoxicology Assessment Methods of Nanomaterials and Their Effects. Nanomaterials 2020, 10, 610. [Google Scholar] [CrossRef] [PubMed]

- Perina, F.; Ottoni, C.; Santos, J.; Santos, V.; Silva, M.; Campos, B.; Fontes, M.; Santana, D.; Maia, F.; Abessa, D.; et al. Marine Hazard Assessment of Soluble and Nanostructured Forms of the Booster Biocide DCOIT in Tropical Waters. Water 2023, 15, 1185. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Z.; Xu, Z.; Li, Y. Mini-Review of Biofilm Interactions with Surface Materials in Industrial Piping System. Membranes 2023, 13, 125. [Google Scholar] [CrossRef]

- Sánchez, M.C.; Alonso-Español, A.; Ribeiro-Vidal, H.; Alonso, B.; Herrera, D.; Sanz, M. Relevance of Biofilm Models in Periodontal Research: From Static to Dynamic Systems. Microorganisms 2021, 9, 428. [Google Scholar] [CrossRef]

- AlSawaftah, N.; Abuwatfa, W.; Darwish, N.; Husseini, G.A. A Review on Membrane Biofouling: Prediction, Characterization, and Mitigation. Membranes 2022, 12, 1271. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Wu, Y.; Liu, Y. Design and Application of Antifouling Bio-Coatings. Polymers 2025, 17, 793. [Google Scholar] [CrossRef]

- Faria, S.I.; Teixeira-Santos, R.; Romeu, M.J.; Morais, J.; Jong, E.d.; Sjollema, J.; Vasconcelos, V.; Mergulhão, F.J. Unveiling the Antifouling Performance of Different Marine Surfaces and Their Effect on the Development and Structure of Cyanobacterial Biofilms. Microorganisms 2021, 9, 1102. [Google Scholar] [CrossRef]

- Lee, M.-S.; Hussein, H.R.; Chang, S.-W.; Chang, C.-Y.; Lin, Y.-Y.; Chien, Y.; Yang, Y.-P.; Kiew, L.-V.; Chen, C.-Y.; Chiou, S.-H.; et al. Nature-Inspired Surface Structures Design for Antimicrobial Applications. Int. J. Mol. Sci. 2023, 24, 1348. [Google Scholar] [CrossRef] [PubMed]

- Suprobo, Y.; Riyanto, R.; Herawati, S. Sustainable biofouling mitigation: Advancing maritime efficiency and environmental protection. J. Pendidik. Biol. Indones. 2025, 11, 208–217. [Google Scholar] [CrossRef]

- Zhou, J. Composite Coating for Preventing Marine Biofouling and Spraying Method Thereof. WO Patent 2012136127, 11 October 2012. [Google Scholar]

- Tian, L.; Jin, E.; Ke, Q.; Shang, Y.; Li, Y.; Sun, H.; Liu, Y.; Ren, L. Method for Preventing Marine Biofouling by Using Principle of Harmonic Vibration. U.S. Patent 20170158876, 8 June 2017. [Google Scholar]

- Chang-Lun, S.; Xiao-Feng, M.; Mei-Yan, W. A kind of nitrogenous compound and preparation method thereof and application as marine antifoulant. CN Patent 108658975A, 16 October 2018. [Google Scholar]

- Wang, L.; Lin, C. Preparation Method of Self-Polishing Enzyme-Based Antifouling Paint. CN Patent 104774519, 15 July 2015. [Google Scholar]

- Ren, X. Novel Antifouling Agent Composite Paint Applied to a Soluble Antifouling Paint. CN Patent 104710936A, 17 June 2015. [Google Scholar]

- Qian, P.; Huang, X.; Xu, Y.; Zhang, Y.; Wong, Y.H.; Yin, Y.; Han, Z. Use of Amide Compounds for Preventing Marine Biofouling. U.S. Patent 20140044810, 13 February 2014. [Google Scholar]

- Salamanca, C.E.R. Bacterial Product from Marine Origin, Useful for Preventing the Macro and Micro Biofouling Caused by Macroalgae and Marine Invertebrates. EP Patent 1811848, 1 August 2007. [Google Scholar]

- Messersmith, P.B.; Lee, H.; Statz, A.R.; Lee, B.P.; Dalsin, J.L.; Sherman, D. Surface Independent, Surface-Modifying, Multifunctional Coatings and Applications Thereof. U.S. Patent 20100330025, 30 December 2010. [Google Scholar]

- Claes, M.; Bonduel, D.; Dubois, P.; Beigbeder, A.; Devalckenaere, M. Anti-Adhesive and Anti-Static Composition. EP Patent 1914277A1, 23 April 2008. [Google Scholar]

- Vladkova, T.G.; Dineff, P.D.; Zlatanov, I.Y.; Kathioli, S.; Ramasammy, V.; Vasudeva, P.S.M. Composition Coating for Biofouling Protection. WO Patent 2008074102, 26 June 2008. [Google Scholar]

- Hannah, J.; Hartshorne, R.S.; Neser, D.; Tustin, G.J. Systems and Methods for Marine Anti-Fouling. AU Patent 2010329601, 5 July 2019. [Google Scholar]

- Hartshorne, R.S.; Tustin, G.J.; Westwood, J.F.; Gahlings, S.A. Systems and Methods for Marine Anti-Fouling. U.S. Patent 20120321809, 20 December 2012. [Google Scholar]

- Lee, C.G.; Kim, K.M.; Lim, S.M.; Lee, Y.W.; Park, H.W.; Jeong, I.J.; Park, J.H. Fotobiorreator Marinho Flutuante. KR Patent 1019589380000, 15 March 2019. [Google Scholar]

- Becker, A.T.; Stiblo, G.K. Paint Coating. RU Patent 0002648082, 22 March 2018. [Google Scholar]

- Grozea, C.M.; Walker, G.C. Nanostructured Block Copolymer Films for Inhibition of Marine Organism Attachment to Surfaces. WO Patent 2010045728, 29 April 2010. [Google Scholar]

- Grozea, C.M.; Walker, G.C. Block Copolymer Morphology Trapping in Thin Films Using Low Temperature Treatment and Annealing for Inhibition of Marine Organism Attachment to Surfaces. U.S. Patent 20110104452, 5 May 2011. [Google Scholar]

- Lobe, H.; Knapp, J.; Das, A.K.; Moffat, G. Optically Clear Biofouling Resistant Compositions and Methods for Marine Instruments. U.S. Patent 20100278771, 4 November 2010. [Google Scholar]

- Lee, H. Multiscale Microdevices with Nanopillars for Chronically Implanted Devices. U.S. Patent 20190313955, 17 September 2019. [Google Scholar]

- Tsuruta, N.; Yamashita, M.; Shinohara, H.; Hamada, K.; Fukutomi, T.; Furusawa, H.; Takizawa, M.; Yoshikawa, Y.; Nakamura, M. Anti-Biofouling Agent, Anti-Fouling Coating, Anti-Fouling Treatment Method, and Anti-Foulingly Treated Material. WO Patent 2007116912, 18 October 2007. [Google Scholar]

- Suzuki, S.; Tomoya, N.; Takeshi, H.; Kazuko, A.; Naoki, K. Adhesive Tape for Preventing Aquatic Biofouling. JP Patent 2018048331, 29 March 2018. [Google Scholar]

- Letchford, G. Improved Process of Preventing Marine Bio-Foul. AU Patent 2012100045, 2 February 2012. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=AU181568567&_cid=P20-MFWKDZ-85176-1 (accessed on 26 June 2025).

- Gopalan, S.; Pitchai, V.; Seeni, P. An Apparatus for the Prevention of Biofouling. IN Patent 2162/DEL/2006—Concession 267686, 25 April 2008. [Google Scholar]

- Zheng, J.; Cunguo, L.; Zhenghui, Q.; Ri, Q. Cathode Probe for Electrochemical Monitoring of Microscopic Biofouling, Real-Time and In-Situ Electrochemical Monitoring Device and Method for Microscopic Biofouling. CN Patent 109030603, 18 December 2018. [Google Scholar]

- Kuik, S.H.; Chew, T.T.; Chew, H.H.; Chua, C.Y. System and Method of Ballast Water Treatment with Continuous Biofouling Control. EP Patent 2890610, 8 July 2015. [Google Scholar]

- Otvalko, Z.A.; Railkin, A.I.; Tverdov, A.I.; Korotkov, S.I.; Fomin, S.E.; Rudakova, E.V. Method for Protection From Biofouling. RU Patent 0002588253, 31 March 2015. Available online: https://patentscope.wipo.int/search/en/detail.jsf?docId=RU174259979&_cid=P21-MG9N42-86954-1 (accessed on 27 June 2025).

- Kee-Rong, W.; Yu-Tsuen, S.; Chung-Hsuang, H.; Jiing-Kae, W.; Chiung-Wei, Y.; Shun-Hsyung, C. Apparatus Using an Electro-Catalytic Coating to Reduce Ship’s Friction and Prevent Biofouling. U.S. Patent 20140331912, 13 November 2014. [Google Scholar]

- Nyberg-Swenson, B.A. A Method and a Surface Treatment Agent for Preventing Biofouling on Surfaces Under Water. EP Patent 1578874, 28 September 2005. [Google Scholar]

- Shilova, O.A.; Railkin, A.I.; Efimova, L.N.; Shevchenko, V.Y. Coating Composition for Protecting Underwater Surfaces from Biofouling. RU Patent 0002606777, 10 January 2017. [Google Scholar]

- Salters, B.A. Dithered Marine UV Reflective Coating with Color. IN Patent 201847002494, 30 March 2018. [Google Scholar]

- Matveev, V.A.; Kolesnik, G.V. Coating for Protecting the Submerged Surface of Ships Against Biofouling. WO Patent 2009113893, 17 September 2009. [Google Scholar]

- Jinwei, Z.; Cunguo, L.; Deyu, L.; Zhiyong, S.; Li, W. A kind of preparation method of hydrophilic and hydrophobic interactive distribution microstructure surface. CN Patent 109337105, 15 February 2019. [Google Scholar]

- Pelzer, R.; Wöhrle, I. Non-Toxic Coating Composition, Methods of Use Thereof and Articles Protected from Attachment of Biofouling Organisms. NZ Patent 542883, 21 December 2007. [Google Scholar]

- Guo, X.; Su, X.; Hao, D. Hydrogel Capable of Being used for Marine Antifouling, Preparation Method and Uses Thereof. CN Patent 110358006, 22 October 2019. [Google Scholar]

- Koob, T.J. Method of Preventing Biofouling Using an Anti-Fouling bio-Hydrogel Composition. U.S. Patent 8603452, 10 December 2013. [Google Scholar]

- Van Delden, M. Device for protecting a protected surface against soiling. CN Patent 110214057, 6 September 2019. [Google Scholar]

- Hietbrink, R.B.; Salters, B.A. Marine Cable Device Configured to Prevent Fouling. RU Patent 0002695939, 29 July 2019. [Google Scholar]

- Ober, C.K.; Weinman, C.J.; Park, D.; Handlin, D.L. Coatings to Prevent Biofouling of Surfaces. U.S. Patent 20120244369, 27 September 2012. [Google Scholar]

- Kem, W.R.; Soti, F.; Rittschof, D. Materials and Methods for Inhibiting Fouling of Surfaces Exposed to Aquatic Environments. U.S. Patent 20050159454, 21 July 2005. [Google Scholar]

- Gallardo, M.; Maurel, S.; Pale, M.; Courtois, A.; Thollas, B. Process for Preventing the Formation of Biofouling on Material in Contact with an Aqueous Medium. EP Patent 3411443, 12 December 2018. [Google Scholar]