Abstract

Potholes are typical scattered distresses on asphalt pavements, severely impairing traffic safety and pedestrian safety due to delayed repair time and secondary distress. Aiming to extend the service life of repaired potholes, this study develops a pothole repair technique characterized by repair materials with superior performance and adhesive materials with high bonding strength. Firstly, the mechanical analysis for repaired potholes was conducted via finite element simulation, and thereafter, corresponding technical measures were derived to prevent the recurrence of distress in repaired potholes. Secondly, according to the material composition of solvent-based cold-mix asphalt (SCMA) and emulsified-based cold-mix asphalt (ECMA), pavement performance testing methods were proposed to test and evaluate their forming strength, high-temperature stability, low-temperature crack resistance, and water stability. On this basis, interlayer shear tests, pull-out tests, and field pothole repair cases with varying repair materials and adhesive materials were conducted, and the interfacial bonding strengths with the old pavement were then compared to optimize the pothole re-pair technique. The results showed that (1) increasing the repair material modulus and interfacial friction coefficient reduces the pressure strain (σy) and pressure stress (εy), thereby decreasing the risk of secondary dis-tress; (2) ECMA exhibits superior pavement performance, with strength and rutting resistance 49.7%–64.6% higher than SCMA; (3) the combination of ECMA and WER-EA achieves the highest interfacial pull-out and shear strengths, with their values 76.7%–78.2% higher than SCMA+WER-EA); and (4) after 1 year of opening to traffic, potholes repaired with ECMA+WER-EA show minimal thickness loss of 0.2 cm and no aggregate peeling at the edges, thus being recommended as the optimal solution for repairing potholes. This study clarifies the secondary distress mechanism of repaired potholes and provides an optimal repair scheme (ECMA+WER-EA) for engineering applications.

1. Introduction

Potholes are typical distresses in asphalt pavements, characterized by localized, scattered defects that preclude centralized repair [1,2]. Under the combined action of vehicular loading and water infiltration, these isolated potholes progressively deepen and expand, accelerating the overall structural deterioration of the pavement system [3,4]. This resulting distress not only substantially reduces pavement service life but also generates significant traffic safety hazards, deteriorating both vehicular operating safety and ride comfort [5,6,7]. Therefore, routine pavement inspection and maintenance are essential, with timely pothole repair using appropriate techniques.

For large-scale and concentrated potholes, road authorities typically use hot mix asphalt (HMA) for repairing them, which yields repaired sections with performance comparable to the original pavement [8,9,10]. However, this hot repair technique exhibits inherent limitations, including stringent equipment requirements, high energy consumption and carbon emissions, pronounced seasonal dependency, and compromised compaction efficiency at low temperatures [11,12,13], which limits its suitability for timely, flexible repairs. Against this backdrop, cold-mix asphalt mixtures (CMA) have emerged as alternatives. CMA is a low-emission mixture produced by mixing diluted or emulsified asphalt with aggregates, mineral filler, and reinforcing agents at ambient temperature [14,15]. It offers advantages like convenient construction, low energy consumption, and environmental friendliness, making it widely used in pavement repair, especially for scattered potholes [16,17,18].

CMAs are categorized as solvent-based (SCMA) and emulsified-based (ECMA) cold mix asphalt based on the strength formation mechanisms and binders. SCMA commonly uses diesel, kerosene, or waste oil as diluents to reduce asphalt viscosity, thereby ensuring favorable workability during pothole repair operations [19,20]. As diluents volatilize, the SCMA progressively develops its structural strength and pavement performance, ultimately meeting the requirements of routine traffic loading [21,22,23]. For instance, Raheb et al. (2023) selected light oil as a diluent to reduce the viscosity of petroleum asphalt, together with recycled pavement materials as aggregates to develop an eco-friendly solvent-based cold mix asphalt mixture by optimizing grading types and adding additives [24]. To adjust the viscosity and workability of SCMA for repairing potholes, Xu et al. (2025) incorporated solvent naphtha (SN) as a diluent and polymerized methylene diphenyl diisocyanate (PMDI) as a polymer modifier to develop a novel self-curing active cold patch asphalt mixture, and they pointed out that the mixture containing 20% SN-PMDI with a 50:50 SN-to-PMDI ratio achieved favorable mechanical properties comparable to HMA [25]. ECMA typically utilizes emulsified asphalt as the binder, and subsequently, the demulsification process of emulsified asphalt contributes to the formation and development of its mechanical strength [26,27,28]. Ghafar et al. (2024) developed a cold-mix asphalt mixture using cationic emulsified asphalt as the binder and natural cup lump rubber for reinforcement and found that the modified CMA exhibited a 26% improvement in tensile properties, a 70% enhancement in rutting resistance, and a 10% increase in moisture damage resistance [29]. Shantharam et al. (2025) prepared cold stone matrix asphalt (CSMA) utilizing slow-setting emulsified asphalt as the binder, incorporating lime and natural cellulose fibers, which synergistically enhanced resistance to moisture damage and cracking, thereby demonstrating superior durability and making it particularly suitable for pothole repair in medium-to-high traffic volume road pavements [30]. Despite these advances, secondary distress persists, as SCMA retains residual diluents that weaken asphalt-aggregate adhesion, while ordinary ECMA lacks cohesion and adhesion to old pavements, and mismatched mechanical properties between repair materials and original structures further exacerbate failure risks [31].

Additionally, the long-term durability of pothole repairs depends not only on the performance properties of the repair materials but is also critically governed by the interfacial bonding strength between the newly applied repair material and the old pavement [32,33,34]. Crucially, this interfacial bonding strength is provided by the adhesive material, which integrates the repair material and old pavement into a monolithic structure, thereby mitigating distresses like moisture-induced erosion and pavement misalignment. When HMA and SCMA are employed for pothole repairs, emulsified asphalt is widely adopted as the adhesive material due to its excellent painting workability and favorable bonding strength. As for ECMA, its inherent cohesion allows the internal emulsified asphalt to bond ECMA and old pavement into a unified structure, eliminating the need for additional adhesive material during the pothole repair process. However, ordinary emulsified asphalt exhibits slower demulsification in low-temperature or humid environments, while investigations reveal that secondary damage after pothole repair predominantly occurs around the patch periphery [35,36,37,38]. Therefore, innovative development of interfacial adhesive materials is urgently needed to ensure their applicability for temporary pothole repairs while achieving extended service life.

To extend the service life of the repaired pothole and explore the secondary damage mechanism, finite element software was selected to conduct the mechanical analysis of the repaired potholes under different repair materials and interface bonding states; thus, technical measures to ensure long-term service of repaired potholes were proposed. Secondly, according to the material composition characteristics of HMA, SCMA, and ECMA, testing methods for their pavement performance were designed, and the tests were conducted along with performance evaluations. Furthermore, the interlayer shear and pull-out tests were carried out to measure the bonding strengths between the repair materials and the old pavement, and thereafter, the repair material and the corresponding adhesive material were optimized. Finally, field potholes were repaired with different repair materials and adhesive materials to evaluate and validate the pavement performance and bonding strength of the optimized pothole repair scheme.

2. Materials and Methods

2.1. Matrails

2.1.1. Hot Mix Asphalt (HMA)

In hot repair techniques, SK70# asphalt was employed as the binder for hot mix asphalt (HMA). Higher-grade mix asphalts require elevated mixing and construction temperatures, which compromise the operational convenience for pothole repairing. SK70 # Asphalt was purchased from Nantong Tongsha Asphalt Technology Co., Ltd. (Nantong, China), and its basic performance indicators were tested as shown in Table 1. The coarse and fine aggregates in HMA are pyrochlore, and the mineral powder is limestone, with the gradation and asphalt content of AC-13 and 5.2%, respectively. The particle size distribution of the aggregates in the AC-13 gradation is shown in Table 2.

Table 1.

Basic performance indices of SK70# asphalt.

Table 2.

The gradation of AC-13 and LB-13.

2.1.2. Solvent-Based Cold Mix Asphalt Mixture (SCMA)

Solvent-based cold mix asphalt was prepared from solvent-based asphalt, aggregates, and mineral powder. Among them, solvent-based asphalt was composed of SK70# asphalt, diesel oil, tackifier, and anti-stripping agent, with the mixing ratio of 100:24:4:0.5. 0# diesel oil was selected as the diluent because of its similar polarity to asphalt [39]. Terpene resin T-100, purchased from Chongqing Haimu Transportation Technology Co., Ltd. (Chongqing, China), was used as the tackifier to enhance the mechanical strength and deformation resistance of SCMA. The anti-stripping agent, manufactured by Changzhou Yibao New Material Technology Co., Ltd. (Changzhou, China), was selected to improve the adhesion between solvent-based asphalt and aggregates, thereby improving the water damage resistance of SCMA. Similar to HMA, the SCMA utilizes pyrochlore as both coarse and fine aggregates, with limestone serving as the mineral filler. To achieve optimal pavement performance in SCMA, a gap-gradation aggregate structure was deliberately designed, and thereafter was named LB-13. The detailed particle size distributions of LB-13 are provided in Table 2. Subsequently, combined with the Tongji University empirical equation and the improved Marshall test method, the asphalt content of SCMA was determined to be 4.6%.

2.1.3. Emulsified Cold Mix Asphalt (ECMA)

Emulsified cold mix asphalt was prepared from WER-emulsified asphalt, aggregates, mineral powder, and a small amount of polypropylene fiber. Among them, WER-emulsified asphalt was modified with waterborne epoxy resin (WER) to enhance the cohesiveness and pavement performance of ECMA. The type of waterborne epoxy resin used in WER-EA is E-44, accounting for 6.5% mass of emulsified asphalt, and its supplier was Guangzhou Tongshangyun Chemical Co., Ltd. (Guangzhou, China). The general properties of WER-EA were tested as shown in Table 3. To enhance comparability, ECMA and SCMA used the same coarse and fine aggregates as well as mineral filler, with the aggregates being basalt and the mineral filler being limestone. Meanwhile, they also shared the same aggregate gradation type, both designated as LB-13. Additionally, polypropylene fiber with a length of 6 mm was incorporated as the reinforcing material at a dosage of 0.3% by weight of aggregates, consistent with the mix design in our prior study [31]. Combined with the improved Marshall test and scattering loss methods, the asphalt content of ECMA was 9%.

Table 3.

General properties of WER-EA.

2.1.4. Adhesive Materials

To ensure strong adhesion between the repairing materials and the old pavement structure, and to avoid the failure issue of pothole repair, an adhesive material is typically applied to its surrounding and bottom surfaces when using HMA and SCMA for repairing potholes. Emulsified asphalt is usually chosen as the adhesive material because it has excellent spreadability. In this study, the ordinary emulsified asphalt (EA) and waterborne epoxy emulsified asphalt (WER-EA) mentioned in Section 2.1.3 were selected as adhesive materials to verify the influence of the properties of bonding materials on the effectiveness of repairing potholes. Table 3 demonstrates the general properties of EA and WER-EA.

2.2. Finite Element Simulation

2.2.1. Road Structure and Material Parameters

Finite element simulation was used to construct pavement structures, and different sizes of potholes were excavated by cutting the road surface. A three-dimensional (3D) model of the pavement structure was developed using ABAQUS 6.14, and the software was provided by Dassault Systèmes, France. The pavement structure consists of the surface course, base course, and subgrade, with complex interfacial interactions among the layers. Referring to previous studies, when establishing the three-dimensional model of pavement structure with a repaired pothole, the interlayer contacts of the pavement structure follow the ideal elastic layer system theory. The structural layers were assumed to be continuous, homogeneous, and isotropic elastic materials, with corresponding material parameters defined by a linear elastic model expressed through elastic modulus (E) and Poisson ratio (μ) [40,41]. This assumption reduces computational complexity, allowing focus on interfacial mechanical responses. However, it may underestimate stress in low-temperature viscoelastic regimes where asphalt exhibits higher stiffness and overestimate stress in high-temperature regimes where creep behavior occurs, while a focus on short-term traffic load responses helps mitigate this bias. The constitutive equation of the linear elastic model is present in Formula (1). As for the repaired potholes, the interface contacts between the repairing materials and the surrounding as well as the bottom walls of the potholes were assumed to be continuous and bonded. In line with the Design Specification for Asphalt Pavement of Highways (JTG D20-2017) [42], the pavement structure and corresponding material properties were defined, with details summarized in Table 4. Additionally, to investigate the influence of different repairing materials on the mechanical response of the repaired structure, the elastic modulus of the repairing materials was set to 400, 800, 1200, 1600, and 2000 MPa, respectively.

Table 4.

Material properties of the pavement structure.

2.2.2. Model Geometric Dimensions and Load

Before pavement structure modeling, the geometric dimensions of pavement structure were optimized to balance computational efficiency and accuracy. Excessively large dimensions increase computational cost, whereas excessively small dimensions compromise result accuracy. Through trial calculations of various dimensions and combined with previous research, the final dimensions of pavement structure were set as X (4 m) × Y (3 m) × Z (4 m). The coordinate system is defined such that X represents the horizontal direction of the roadway, Y denotes the longitudinal direction, and Z corresponds to the direction of vehicular travel. The boundary conditions for the road model are specified as: no Z-direction displacement along both sides of the travel direction, no X-direction displacement perpendicular to both sides of the travel direction, and the bottom surface at a certain depth along the Y-direction of the roadbed was fixed, while the upper and lower layers of the road structure were assumed to be in complete contact. Specifically, X and Y-direction displacement constraints simulate lateral confinement from adjacent pavement, and the fixed subgrade bottom mimics the stiff underlying layer. This setup is consistent with the ideal elastic layer system theory as specified in JTG D20-2017.

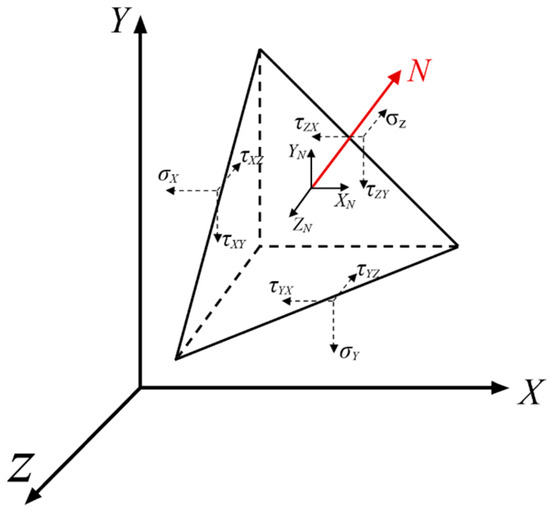

Additionally, practical engineering expertise and analytical expediency required that the pothole model dimensions be X (0.8 m) × Y (0.8 m) × Z (0.04 m) and X (0.8 m) × Y (0.8 m) × Z (0.1 m). The interfacial conditions between the newly repaired and old regions were configured to continuous contact (Tie) and bonding, with the friction coefficients (FC) being 0, 0.25, 0.5, 0.75 and 1, respectively. During the loading process, a standardized axle load of BZZ-100 was applied, resulting in a ground pressure of 0.7 MPa. After applying vehicle loads, the pavement structural units generate compressive stresses along three orthogonal axes and shear stresses across six distinct planes. The detailed stress state at any point of the road structure is illustrated in Figure 1.

Figure 1.

The stress state at any point of the road structure.

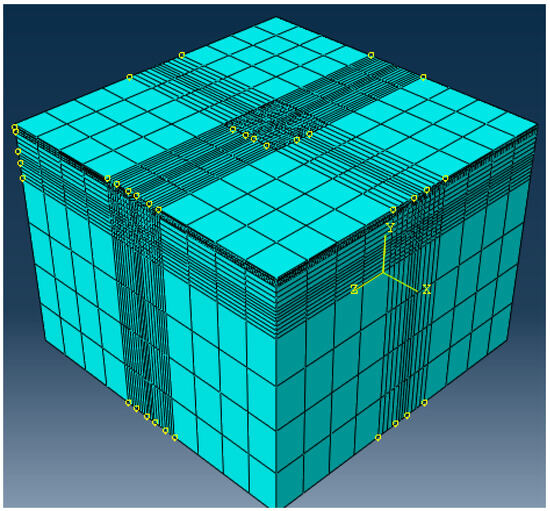

2.2.3. Mesh

The mesh division density influences both computational speed and accuracy of the simulation results. To reconcile the need for detailed stress analysis of the pavement structure with the need to minimize computational time, a variable mesh division strategy was implemented. In particular, the upper, middle and lower layers, along with the pothole regions, were subjected to denser division in three orthogonal directions. Conversely, the remaining sections of the model were meshed using a coarser, yet uniform, tetrahedral element configuration. The computational elements employed were C3D8R, and the resultant mesh configuration for the pavement structure is depicted in Figure 2.

Figure 2.

Grid division model for the pavement structure.

2.3. Experimental Methods

2.3.1. Pavement Performance Evaluation

The binders utilized in HMA, SCMA, and ECMA are SK70# asphalt, solvent-diluted asphalt, and water epoxy resin emulsified asphalt, respectively. These variations result in pronounced significant disparities in the formation and development processes of strength and pavement performance among the aforementioned repair materials. Furthermore, the different development mechanisms of strength and pavement performance also affect their evaluation methods and the service life of the repaired pothole. Therefore, it is necessary to summarize the methods for evaluating the strength, high-temperature rutting resistance, low-temperature cracking resistance, and water stability of these repair materials. The testing methods for the strength and pavement performance of HMA were based on the Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering (JTG E20-2011) [43].

The development of pavement performance for SCMA is accompanied by the volatilization of diluents. To ensure the maximum performance of the repair material, the evaporation process of the diluent was accelerated by high temperature. Therefore, when evaluating its strength, high-temperature rutting resistance, low-temperature cracking resistance, and water stability, the test procedures and temperatures specified in the JTG E20-2011 were modified. These modifications are manifested in Table 5. As for ECMA, its strength formation is accompanied by the demulsification of emulsified asphalt and the curing of water-based epoxy resin. Therefore, when evaluating its pavement performance, it is necessary to ensure that the emulsified asphalt is completely demulsified and the water-based epoxy resin is fully cured. The demulsification process of emulsified asphalt and the curing process of waterborne epoxy resin will be very fast under high temperatures. Accordingly, a high-temperature acceleration method was designed for testing the strength and pavement performance of ECMA, as shown in Table 5.

Table 5.

Summary of pavement performance evaluation methods for repair materials.

2.3.2. Bonding Strength of the Repairing Materials and the Original Road

Longer service life of repaired pothole not only relies on the repair materials with good performance, but also, more importantly, depends on the bonding strength between the repair materials and the existing pavement. If the bonding strength is insufficient, moisture will penetrate along the micro-cracks between the repair materials and the old pavement, leading to their separation and further causing the failure of the pothole repair. Therefore, when using HMA and SCMA to repair potholes, it is essential to apply adhesive materials on the surrounding and bottom areas of the cleaned potholes. Typically, emulsified asphalt is the primary adhesive material used for this purpose. Meanwhile, to verify the enhancing effect of water-based epoxy resin on the bonding strength of emulsified asphalt, the WER-EA mentioned above was selected for comparison, and interlayer shear tests and interlayer pull-out tests were used to evaluate the bonding strength between the new and old pavement structures.

- (1)

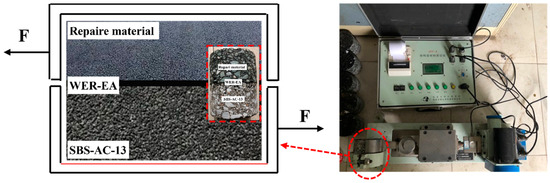

- Interlayer shear test

The interlayer shear test was used to evaluate the shear strength of the interface between the repair material and the old pavement, where the old pavement is made of SBS-AC-13 material. SBS-AC-13 material is an asphalt mixture modified by styrene butadiene styrene (SBS), with a gradation type of AC-13 and an asphalt content of 6.2%. The coarse aggregates in SBS-AC-13 material were basalt, while the fine aggregates were limestone. During the interlayer shear test, SBS-AC-13 rutting slabs were prepared under standard conditions, cleaned after curing and demolding, and then placed into self-made composite rutting molds. A specified amount of emulsified asphalt was applied to the slab surface, followed by filling the mold with repair material. After that, the mixture was rolled by 12 back-and-forth passes using a wheeled roller to form double-layer rutting slabs. After curing, the slabs were demolded and cored to obtain the cylindrical specimens with a height of 10 cm. The interlayer shear test procedure is illustrated in Figure 3, from which the horizontal shear force and the position of each material can be obtained.

Figure 3.

Interlayer shear test.

- (2)

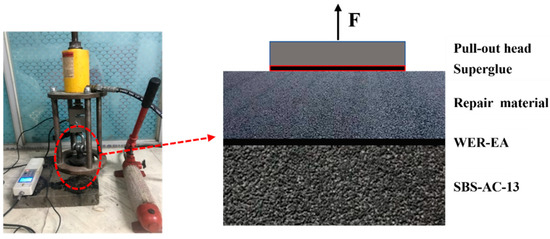

- Interlayer pull-out test

After preparing cylindrical specimens for the interlayer pull-out test, the upper surface of the repair material layer was carefully cleaned and uniformly coated with a suitable amount of superglue to ensure full adhesion of the pull-out head. After allowing the adhesive to cure and achieve sufficient bonding strength over 24 h, the interlayer pull-out test was conducted. The experimental setup for the interlayer pull-out test is illustrated in Figure 4, from which the vertical pull-out force and material positions can be obtained.

Figure 4.

Interlayer pull-out test.

2.3.3. Field Investigation

Intending to verify the repair effect of three repair materials on potholes and investigate the actual reinforcing contribution of water-based epoxy resin on the bond strength of emulsified asphalt. Six potholes were repaired using HMA, ECMA, and SCMA on the Xiyan expressway in August 2021. When using HMA, SCMA, and ECMA to repair potholes, the adhesive materials used were ordinary EA and WER-EA, with the paving mass of 0.4~0.5 kg/m2. During the pothole repair process, the loose sections around the potholes need to be cut off, and the bottom should be cleaned thoroughly and kept dry. After the potholes were repaired, standardized compaction procedures were carried out. Subsequently, one year after opening to traffic, each repaired pothole was inspected for thickness, loose material, and edge spalling. Thereafter, cylindrical specimens were drilled from the center of each repaired structure by a core drilling machine. These specimens were then cut into standard interlayer shear and pull-out specimens with a cutting machine, after which their shear strength and pull-out strength were tested (Figure 5).

Figure 5.

Examples of a repaired pothole and core sampling.

3. Results and Discussion

3.1. Finite Element Simulation

3.1.1. Influence of the Repairing Material Modulus

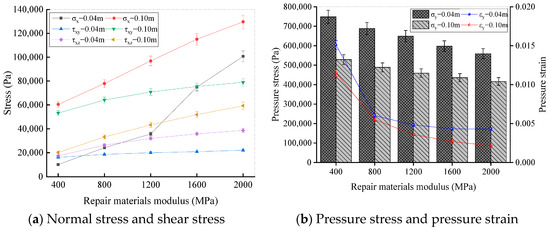

A higher elastic modulus often indicates that the material has larger mechanical properties. Therefore, the elastic modulus was used to indirectly characterize the mechanical properties of repair materials. Intending to investigate the influence of repair materials modulus on the mechanical response at the pothole repair interface, the pothole depths were set at 0.04 m and 0.1 m, respectively. While the elastic modulus of the repair materials was configured as E = 400 MPa, 800 MPa, 1200 MPa, 1600 MPa, and 2000 MPa. The interface between the repair materials and old pavement was set as a continuous bonding constraint (Tie). Finite element analyses were performed following the established modeling procedures, with results presented in Figure 6.

Figure 6.

Mechanical indices of the repaired potholes under different repairing material moduli.

Figure 6 demonstrates the mechanical indices of repaired potholes under different repairing material modulus, including maximum longitudinal interface normal stress (σx), maximum longitudinal interface shear stress (τxy and τxz), maximum pressure stress (σy), and corresponding pressure strain (εy) at the pothole bottom. It is worth noting that the elastic modulus of the repair material exhibits a significant influence on the mechanical indices of the repaired potholes. Specifically, as the elastic modulus increases, the values of σx, τxy, and τxz exhibit a gradual increasing trend. This phenomenon occurs because, when the interface contact state between old and new pavement is defined as a Tie constraint, these stresses are significantly influenced by the load distribution capacity of the repair material. Research has indicated that when the material properties are identical, higher modulus substances generally exhibit superior load distribution capacity. Therefore, as the modulus of the repair materials increases, the values of σx, τxy, and τxz at the longitudinal interface gradually increase. Given the Tie constraint at the old and new interface contact, the possibility of interfacial shear failure is relatively low. In this scenario, internal structural failure within the repaired structure should be considered, specifically compressive densification failure under applied loads.

As shown in Figure 6a, with an increase in elastic modulus, the values of pressure stress and strain at the pothole bottom gradually decrease, indicating that the ability of the repaired structure to resist traffic loads is gradually improving. For the repaired pothole with a depth of 10 cm, increasing the elastic modulus of the repair material from 400 MPa to 2000 MPa reduces the pressure stress from 528,783 Pa to 416,169 Pa and the pressure strain from 1.15 × 10−2 to 2.15 × 10−3, with the decrease of 21.3% and 81.3%, respectively. This demonstrates that the elastic modulus of repair materials directly influences the pothole repair effectiveness. To prevent secondary distress, repair materials with a higher elastic modulus should be selected in engineering practice.

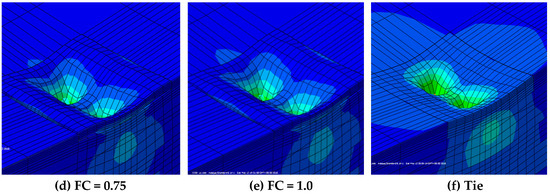

3.1.2. Influence of the Interface Contact State

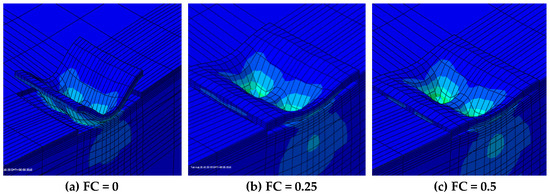

The bonding strength between the repaired structure and the original pavement directly influences pothole repair effectiveness. Insufficient bonding may cause the interface between new and old pavements to become a high-incidence zone for secondary distress. Therefore, investigating the influence of interlayer contact state on the mechanical indices of repaired potholes under traffic loading is essential. The interlayer friction coefficient serves as an indicator of contact states, where an increased friction coefficient signifies enhanced interlayer bonding strength. By changing the friction coefficient between the repaired pothole and old pavement, the mechanical indices of σx, τxy, τxz, σy, and εy under traffic loading were obtained and analyzed. During the mechanical analysis, the interlayer friction coefficient (FC) was set to 0, 0.25, 0.5, 0.75, and 1, respectively, as well as with a Tie constraint, while the modulus of the repair material was defined as 800 MPa. Finite element analyses were performed following the established modeling procedures, with results presented in Figure 7 and Figure 8.

Figure 7.

Deformation of the repaired potholes under different contact states.

Figure 8.

Mechanical indices of the repaired pothole under different contact states.

Figure 7 presents the deformation clouds of the repaired pothole under different contact states. It can be seen that different interlayer contact states lead to distinct deformation responses in repaired potholes under vehicular loading. Under the Tie constraint state, the repaired pothole maintained integral bonding with the original pavement at the bottom and sidewalls, resulting in vertical deformation localized exclusively beneath the loading zone. As the FC values increased from 0 to 1, the vertical deformation of the repaired pothole occurred not only at the vehicle action position but also at its sides and bottom, accompanied by a progressive reduction in warping depth. This phenomenon correlates with the mechanical indices of the repaired pothole under different contact states, as shown in Figure 8. It is noteworthy that increasing the FC values progressively reduces the mechanical indices, with minimum stress and strain values occurring under the Tie constraint state. Specifically, when the FC values increased from 0 to 1, σy and εy decreased by 4.25% and 11.0%, respectively, with corresponding gradual reductions of the bucking depth on both sides of the repaired pothole. The relationship between σy, εy, and FC demonstrates that higher FC values simultaneously enhance both shear resistance at pothole edges and compressive capacity under vehicular loading. Additionally, it can also be found that pothole depth has little influence on the mechanical indices, with variations primarily manifested in deformation magnitude. Pothole with the depth of 0.1 m exhibits lower σx, τxy, τxz, σy, and εy values compared to the pothole with a depth of 0.04 m, which is mainly because of the gradual diffusion and dissipation of vehicular loads with increasing pothole depth.

In summary, increasing the modulus of repair material reduces the values of σy and εy, while elevating the interlayer friction coefficient (FC) decreases warping depth along the pothole sidewalls and bottom, as well as the mechanical indices. These indicate a gradual reduction in the probability of secondary distress occurrence in the repaired pothole. Moreover, when the interfacial contact state was the Tie constraint, the probability of secondary distress in the repaired pothole was minimized. Moreover, the optimal performance of the Tie constraint highlights that superior interfacial bonding, which can be achieved through adhesive materials, is critical for durability. This aligns with the findings of Zhang et al. (2022) [31] regarding interfacial reinforcement, further validating the importance of greater interfacial bonding in mitigating secondary distress. Therefore, to ensure the pothole repair effectiveness, the repair materials should possess high mechanical strength and strong bonding strength with the original pavement.

3.2. Pavement Performance of the Repair Materials

As concluded in Section 3.1.1, the mechanical indices of the repaired potholes are substantially influenced by the performance of the repair materials. Specifically, repair materials with a higher elastic modulus are more effective in mitigating the occurrence of secondary defects within the repaired potholes. Accordingly, based on the established testing method for the performance of repair materials, the strength, high-temperature rutting resistance, low-temperature cracking resistance, and water stability of HMA, SCMA, and ECMA were measured, and the results are shown in Figure 9.

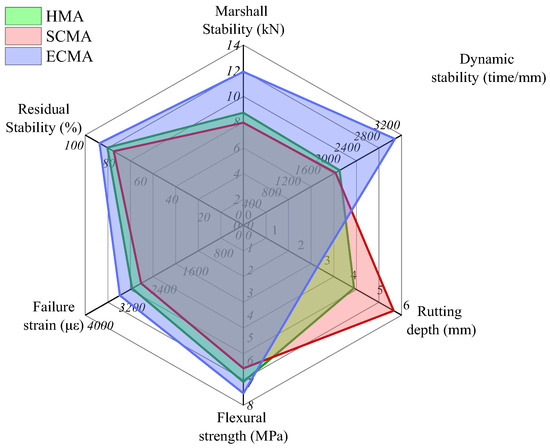

Figure 9.

Pavement performance of the repair materials.

Figure 9 presents the Marshall stability, dynamic stability, rutting depth, failure strain, residual stability, and tensile strength of the repair materials. Among these, dynamic stability and rutting depth serve as two key indicators for evaluating high-temperature rutting resistance, while failure strain and tensile strength are used to assess low-temperature cracking resistance. It can be observed that ECMA exhibits the best pavement performance, followed by HMA, while SCMA demonstrates the poorest pavement performance. Quantitatively, compared with the strength and high-temperature deformation resistance of SCMA, those of ECMA increased by 49.7% and 64.6%, respectively, while those of HMA increased by 9.8% and 4.5%, respectively. In terms of low-temperature crack resistance and water stability, comparative analysis reveals that ECMA demonstrates superior performance relative to SCMA, with respective increases of 20.7% and 9.6%, while HMA exhibits increases of 8.7% and 3.6% in the two properties, respectively.

SCMA utilizes diesel as a diluent to reduce the viscosity of base asphalt. Although the use of tackifier and high-temperature curing to accelerate the evaporation of diesel has been adopted to ensure the adhesive properties of asphalt binder, a portion of diesel remained within the asphalt matrix due to its complete miscibility with the asphalt phase. These residual diluents impaired the adhesion between dilute asphalt and aggregates by disrupting interfacial bonding mechanisms. Concurrently, prolonged exposure to elevated temperatures induces thermo-oxidative aging of the asphalt matrix, compromising its polymer network integrity. Therefore, SCMA exhibits lower strength, water stability, and high-temperature rutting resistance. As for the ECMA, its pavement performance was enhanced through modification with waterborne epoxy resin (WER) and polypropylene fiber. After curing, epoxy resin forms a thermosetting three-dimensional network structure within the asphalt matrix, which significantly enhances the interfacial adhesion of emulsified asphalt [44,45]. This network chemically bonds with polar molecules in asphalt while physically interlocking with aggregate pores, thereby tightly integrating asphalt, polypropylene fibers, and aggregates. In addition, polyethylene fibers can stabilize and increase the proportion of structural asphalt after the demulsification of emulsified asphalt, thereby enhancing the cohesion of asphalt mixtures. More importantly, when the mixture was subjected to external loads, the polyethylene fibers also served as bridging elements that enhanced internal cohesion, thus improving both deformation resistance and crack resistance.

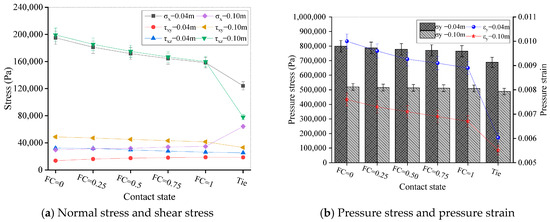

3.3. Bonding Strength of the Repaired Pothole with the Old Pavement

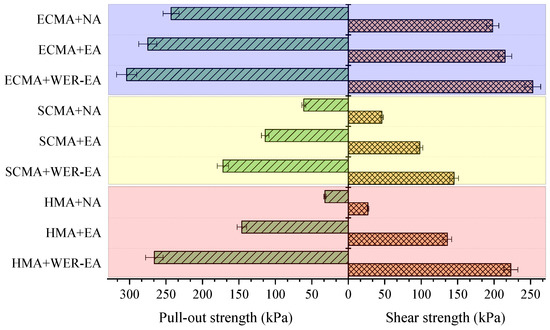

The interfacial bonding strengths between different repair materials and old pavement are shown in Figure 10, along with the influence of adhesive materials on them. In the figure, ECMA, HMA, and SCMA denote the types of repair materials; WER-EA and EA represent the types of adhesive materials, while NA indicates non-adhesive paving material. It can be observed that both repair materials and adhesive materials exert a significant influence on the interfacial bonding strength between the repaired pothole with the old pavement. Taking the pothole repair with HMA as an example, the pull-out strength and shear strength achieved by using EA were 4.56 times and 5.04 times those obtained without any adhesive material, respectively, while these values were further increased by 8.31% and 8.63% when WER-EA is adopted as the adhesive material. This indicates that the utilization of adhesive materials significantly enhanced the bonding strength between repair materials and the old pavement, and the incorporation of WER exerts a further promoting effect on improving the bonding strength. Emulsified asphalt is a liquid substance that can penetrate into repair materials and old pavement structures. After demulsification and curing, it can effectively bond the new and old pavement structures together, which is the main reason why it is commonly used as a tack coat in pavement structures [37,46]. After curing, waterborne epoxy resin (WER) forms a three-dimensional network structure with extremely strong adhesion characteristics, which can enhance the adhesion of emulsified asphalt and thereby improve the shear strength and tensile strength of the interfacial layer. Therefore, all test groups using WER-EA as the adhesive material exhibited the highest shear strength and pull-out strength.

Figure 10.

Interfacial bonding strength under different repair materials.

Regarding the quantitative influence of repair materials on bonding strength, by taking WER-EA as an example, compared with SCMA, the pull-out strength and shear strength formed by using ECMA increased by 76.74% and 74.48%, respectively, while those formed by using HMA improved by 54.65% and 53.79% respectively. This indicates that under the condition of using an appropriate adhesive material, the bonding strength between repair materials and the old pavement ranks as ECMA > HMA > SCMA. SCMA contains a large amount of diesel oil with slow volatility, which may impair the penetration of emulsified asphalt and form a weak layer between repair materials and old pavement structures, thus resulting in lower bonding strength. However, ECMA utilizes the WER-EA as the adhesive material, which ensures that the adhesive material can fully penetrate into the repair material. After this portion of liquid demulsified and cured, it forms a reinforced bonding layer, thus resulting in higher bonding strength. This superior penetration and curing effect of WER-EA in ECMA aligns with Peng et al. (2024) [47], who highlighted WER-EA’s capacity to form robust bonding layers by integrating with repair materials. In contrast, SCMA’s residual diesel not only hinders emulsified asphalt penetration but also weakens interfacial cohesion, further validating ECMA as the optimal choice for enhancing old-new pavement bonding.

In summary, when using HMA and SCMA to repair potholes, adhesive materials with strong adhesiveness should be applied at the interface to ensure effective bonding between the repair materials and the old pavement. However, due to its excellent permeability and adhesiveness, ECMA can be used without applying adhesive materials or with only a small amount applied.

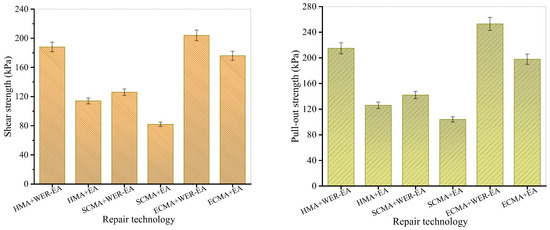

3.4. Survey Result Analysis

The survey results of repaired potholes, including the thickness, appearance, and interfacial bonding strength of core samples with different repair techniques, are exhibited in Table 6 and Figure 11. As shown in Table 6, one year after opening to traffic, the repaired structures exhibited a reduction in thickness relative to the surface layer by 4 cm. Specifically, the thickness reduction of SCMA was the largest, at 0.3 cm, while the thickness reduction of HMA was the smallest, at only 0.1 cm. HMA exhibits high cohesion at ambient temperature. After high-temperature compaction, its thickness is less affected by traffic loads under ambient temperature conditions, consequently exhibiting minimal thickness loss. In contrast, the formation of strength in SCMA is accompanied by the release of diluents. During this process, the mixture was gradually compacted, resulting in a certain reduction in thickness. As for ECMA, its strength is basically fully developed on the day of pothole repair because of its rapid demulsification and curing rate. Moreover, the added polypropylene fibers and water epoxy resin can also enhance their deformation resistance. Visibly, partial aggregate peeling was observed at the edges of the repaired pothole using the SCMA+EA technique. This phenomenon likely resulted from insufficient penetration of emulsified asphalt into the SCMA mixture, leading to inadequate interfacial bonding between the repair material and the old pavement.

Table 6.

Survey results of repaired potholes after opening to traffic for 1 year.

Figure 11.

Interfacial bonding strength of core samples with different repair techniques.

As shown in Figure 11, the ECMA+WER-ER repair technique exhibits high interfacial bonding strength. Compared with SCMA and HMA, which also used WER-EA as the adhesive material, its shear strength increased by 61.90% and 8.51%, respectively, while its pull-out strength increased by 78.17% and 17.68%, respectively. This indicates that in practical pothole repair cases, the ECMA+WER-EA repair technique still exhibits strong application potential. Additionally, by comparing the laboratory interfacial bonding strength and field survey results under the same type of repair technique, as presented in Figure 10 and Figure 11, it can be observed that the bonding strength from laboratory tests is larger than that from core sampling tests.

Specifically, taking the ECMA+WER-EA repair technique as an example, the shear strength obtained from the survey core sampling test decreased by 19.37% compared to the laboratory test, while the pull-out strength decreased by 32.90%. There are interconnected pores within the asphalt mixture (HMA, SCMA, and ECMA), and some rainwater may permeate along these pores into the contact area between the repair material and the old pavement structure, forming weak areas between the two structures and causing a loss of interfacial bonding strength. Additionally, repeated vehicular loads may trigger microcrack initiation at the interface. Over time, these microcracks propagate, causing cumulative damage to the bonding interface and further reducing load-bearing capacity. However, laboratory tests have not taken this practical scenario into account.

4. Conclusions

In this study, finite element simulation, laboratory experiments, and field tests are used to explore the secondary distress mechanism of repaired potholes and optimize repair schemes. The main conclusions are as follows:

- (1)

- Increasing the repair material modulus reduces the pressure strain (εy) and pressure stress (σy) of repaired potholes: for 10 cm deep potholes, increasing the modulus from 400 MPa to 2000 MPa decreases σy by 21.3% and εy by 81.3%. Elevating the interfacial friction coefficient (FC) from 0 to 1 reduces σy by 4.25% and εy by 11.0%, and the Tie constraint minimizes secondary distress probability.

- (2)

- To avoid distress recurrence, repair materials must have high deformation resistance, and the interface between repair materials and old pavement must have superior bonding strength.

- (3)

- ECMA exhibits excellent road performance, with strength and rutting resistance improved by 49.7%–64.6% compared to SCMA. This enhancement is attributed to the three-dimensional network induced by epoxy resin and polypropylene fiber reinforcement. In contrast, the performance of SCMA is compromised due to reduced cohesion caused by residual diesel and thermal aging.

- (4)

- Both repair materials and adhesive materials significantly affect the interfacial bonding strength between the repair material and old pavement, with ECMA+WER-EA exhibiting the highest pull-out strength and shear strength. This is attributed to the sufficient penetration of WER-EA into repair material and old pavement, as well as the high cohesive force of epoxy resin.

- (5)

- Repair and adhesive materials significantly affect interfacial bonding strength. ECMA+WER-EA achieves the highest pull-out strength and shear strength, with 76.74% and 74.48% higher than SCMA+WER-EA. This is attributed to the sufficient penetration of WER-EA into repair material and old pavement, as well as the high cohesive force of epoxy resin. The incompletely volatilized diesel contained in SCMA forms a weak layer between the repair material and old pavement, thereby reducing the interfacial bonding strength.

- (6)

- One year after opening to traffic, potholes repaired using the ECMA+WER-EA technique exhibit minimal thickness loss (0.2 cm) and the highest interfacial bonding strength. ECMA is recommended as the repair material, with WER-EA as the interfacial adhesive material.

Author Contributions

W.Z.: Methodology and writing—original draft preparation. S.Z.: Writing—review and editing. K.Z.: Supervision and funding acquisition. Z.L.: Visualization and investigation. Y.S.: Resources and software. B.D.: Data Curation and validation. All authors have read and agreed to the published version of the manuscript.

Funding

The study is supported by Key Project of Natural Science Research of Anhui Provincial Department of Education (2023AH052853, 2022AH052823), Postdoctoral research project in Anhui Province (2024C929), the Provincial Natural Science Foundation of Anhui (1908085QE217), the Natural Science Research Project of Fuyang Normal University (2024FSKJ15ZD), the Key Project of the Youth Talent Fund at Fuyang Normal University (rcxm202511), and the Scientific Research Project of Fuyang Normal University (2023KYQD0031). The authors gratefully acknowledge their financial support.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or codes that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ouma, Y.O.; Hahn, M. Pothole detection on asphalt pavements from 2D-colour pothole images using fuzzy c-means clustering and morphological reconstruction. Autom. Constr. 2017, 83, 196–211. [Google Scholar] [CrossRef]

- Faisal, A.; Gargoum, S. Cost-effective LiDAR for pothole detection and quantification using a low-point-density approach. Autom. Constr. 2025, 172, 106006. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H. Asphalt pavement pothole repair with recycled material and preheating: Laboratory and field evaluation. J. Clean. Prod. 2024, 434, 140410. [Google Scholar] [CrossRef]

- Roman-Garay, M.; Rodriguez-Rangel, H.; Hernandez-Beltran, C.B.; Lepej, P.; Arreygue-Rocha, J.E.; Morales-Rosales, L.A. Architecture for pavement pothole evaluation using deep learning, machine vision, and fuzzy logic. Case Stud. Constr. Mater. 2025, 22, e04440. [Google Scholar] [CrossRef]

- Talha, S.A.; Nazzal, M.D.; Abbas, A.; Mansour, M. Survival Analysis and Cost Effectiveness of Winter Pothole Patching Techniques. J. Transp. Eng. Part B-Pavements 2023, 149, 04023018. [Google Scholar] [CrossRef]

- Zhang, K.; Xiong, J.; Ruiz, C.; Zhang, J. Design and performance assessment of sustainable road pothole patching materials using waste cooking oil, plastic, and reclaimed asphalt pavement. Constr. Build. Mater. 2024, 429, 136426. [Google Scholar] [CrossRef]

- Mehta, S.; Yusuf, A.B.; Ghafari, S. Data-driven framework for pothole repair automation using unmanned ground vehicle fleets. Autom. Constr. 2025, 174, 106176. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Zhang, W.; Liu, G.; Dai, L. Investigation of thermal asphalt mastic and mixture to repair potholes. Constr. Build. Mater. 2019, 201, 286–294. [Google Scholar] [CrossRef]

- Byzyka, J.; Rahman, M.; Chamberlain, D.A.; Malieva, M. Performance enhancement of asphalt patch repair with innovative heating strategy. Proc. Inst. Civ. Eng.–Transp. 2019, 175, 300–309. [Google Scholar] [CrossRef]

- Bruno, M.; Tataranni, P.; Sangiorgi, C. Experimental application of fully recycled asphalt concretes produced with chemical additives for patch pavement rehabilitation. Constr. Build. Mater. 2023, 363, 129807. [Google Scholar] [CrossRef]

- Byzyka, J.; Rahman, M.; Chamberlain, D.A. An innovative asphalt patch repair pre–heating method using dynamic heating. Constr. Build. Mater. 2018, 188, 178–197. [Google Scholar] [CrossRef]

- Wang, T.; Dra, Y.A.S.S.; Cai, X.; Cheng, Z.; Zhang, D.; Lin, Y.; Yu, H. Advanced cold patching materials (CPMs) for asphalt pavement pothole rehabilitation: State of the art. J. Clean. Prod. 2022, 366, 133001. [Google Scholar] [CrossRef]

- Wang, X.; Ma, B.; Su, W.; Tao, J.; Shi, H.; Si, W. Design and laboratory performance of reactive cold patching materials containing epoxy/unsaturated polyester blends. Constr. Build. Mater. 2023, 377, 131152. [Google Scholar] [CrossRef]

- Boateng, K.A.; Tuffour, Y.A.; Agyeman, S.; Boadu, F. Potential improvements in montmorillonite-nanoclay-modified Cold-Mix Asphalt. Case Stud. Constr. Mater. 2022, 17, e01331. [Google Scholar] [CrossRef]

- Chu, F.; Li, Q.; Sun, C.; Luo, Y.; Li, J.; Feng, J.; Zhang, H. Investigation on the pavement performance and application of cold mix emulsified asphalt mixture in the surface layer. J. Clean. Prod. 2025, 507, 145542. [Google Scholar] [CrossRef]

- Geng, L.; Xu, Q.; Yu, X.; Jiang, C.; Zhang, Z.; Li, C. Laboratory performance evaluation of a cold patching asphalt material containing cooking waste oil. Constr. Build. Mater. 2020, 246, 117637. [Google Scholar] [CrossRef]

- Boateng, K.A.; Tuffour, Y.A.; Obeng-Atuah, D.; Agyeman, S. Quality of cold-mix asphalt in bituminous pavement maintenance in Ghana: Preliminary indications. Case Stud. Constr. Mater. 2021, 15, e00769. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, X.; Cheng, Z.; Shen, D.; Tan, J.; Xie, S.; Zhang, C.; Sun, G.; Xu, Y.; Xu, C. Road performance of cold repaired asphalt mixture with new green maintenance materials. Case Stud. Constr. Mater. 2024, 21, e03959. [Google Scholar] [CrossRef]

- Guo, W.; Zhao, S.; Tian, W.; Li, Y.; Zhu, Y.; Chen, W. Analysis of viscoelastic rheological properties and storage stability of solvent cold patching asphalt. J. Mol. Liq. 2024, 411, 125754. [Google Scholar] [CrossRef]

- Pei, Z.; Yi, J.; Fan, L.; Yu, W.; Hai, B.; Feng, D. Analysis of the trend in evolution of multilevel mechanical properties of solvent-based cold mixed liquid asphalt and mixture. Constr. Build. Mater. 2022, 335, 127476. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Y.; Li, J.; Zhang, Y.; Qian, G. Optimization design of cold patching asphalt liquid based on performance experiments and statistical methods. Constr. Build. Mater. 2023, 391, 131881. [Google Scholar] [CrossRef]

- Vassaux, S.; Havel, M.; Lesueur, D.; Van Rompu, J.; Geisler, F.; Pouget, S. Development of a novel infrared methodology to assess the degree of blending in cold and warm recycled asphalt mixtures incorporating a bituminous or bio-based virgin binder. Constr. Build. Mater. 2023, 403, 133103. [Google Scholar] [CrossRef]

- Chen, L.; Yu, W.; Zhang, W.; Wang, W.; Dai, G.; Zhu, J.; Chen, X.; Zhao, X. A BWM-TOPSIS based multi-criteria decision-making framework for design of cold patching asphalt binder. Case Stud. Constr. Mater. 2025, 22, e04806. [Google Scholar] [CrossRef]

- Raheb, H.; Federico, A.; Felice, G. The effect of using flux oil and RAP on the performance of pavement cold mix patching materials. Transp. Res. Procedia 2023, 69, 616–622. [Google Scholar] [CrossRef]

- Xu, X.; Gong, K.; Sreeram, A.; Tan, Z. A novel self-curing active cold patch asphalt mixture: Performance evaluation and mechanism analysis. Case Stud. Constr. Mater. 2025, 22, e04629. [Google Scholar] [CrossRef]

- Xu, O.; Li, Y.; Xu, R.; Liu, Y.; Dong, Y. Performance evaluation of waterborne epoxy resin modified emulsified asphalt mixtures for asphalt pavement pothole repair. Constr. Build. Mater. 2022, 325, 126709. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Guo, H.; Xu, X.; Wang, X.; Zhang, B.; Liu, J.; Wan, C. Steel slag aggregate property improvement in cold mixed asphalt mixtures through surface modification treatment. J. Clean. Prod. 2024, 477, 143889. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Chu, F.; Li, J.; Feng, J.; Du, P. A polymeric cationic asphalt emulsifier for low-carbon and renewable pavements: Investigating its dual effects of modification and emulsification on asphalt. Constr. Build. Mater. 2025, 487, 142132. [Google Scholar] [CrossRef]

- Ghafar, S.A.; Warid, M.N.M.; Hassan, N.A.; Jattak, Z.A.; Radwan, A.A.M. Mechanical performance of cold mix asphalt containing cup lump rubber as a sustainable bio-modifier. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 424–440. [Google Scholar] [CrossRef]

- Shantharam, A.; Kataware, A.V. Study on design and performance evaluation of cold stone matrix asphalt-A high performance cold mix asphalt. Constr. Build. Mater. 2025, 487, 142062. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, M.; Liu, X.; Ju, J.; Dong, C. Preparation of Emulsified Type Cold-Mix Asphalt with Waterborne Epoxy Resin and Polypropylene Fiber for Pothole Repair. J. Mater. Civ. Eng. 2022, 34, 0004389. [Google Scholar] [CrossRef]

- Liu, F.; Wang, B.; Zhou, C.; Chen, Z.; Fan, C. Investigating the interfacial vertical shear behavior of BFPMPC mortar and cement concrete with pothole repair. J. Build. Eng. 2024, 97, 110992. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H. Hydro-mechanical analysis of water-induced pothole patch failure in asphalt pavement. Constr. Build. Mater. 2024, 413, 134767. [Google Scholar] [CrossRef]

- Zhang, W.; Zuo, S.; Zhang, K.; Luo, Y.; Zhu, L. Investigation of the interfacial bonding of new and old pavement materials for pothole applications: Bonding materials optimization, mechanical properties and structural performance. Constr. Build. Mater. 2024, 425, 135983. [Google Scholar] [CrossRef]

- Wu, S.; Tahri, O.; Spell, C.; Adkins, I. Case study: Characterization of short-term field aged asphalt binders in cold mix asphalt pavement. Constr. Build. Mater. 2022, 324, 126643. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, J.; Kong, W.; Hu, Y. Review of emulsified asphalt modification mechanisms and performance influencing factors. J. Road Eng. 2023, 3, 141–155. [Google Scholar] [CrossRef]

- Xu, W.; Yuan, J.; Qiu, X.; Zheng, K.; Xiao, S.; Ye, Y.; Yang, Q. Exploring the bonding and debonding behaviors of emulsified asphalt-aggregate interface using molecular dynamic simulation and binder bonding strength test. Appl. Surf. Sci. 2025, 700, 163236. [Google Scholar] [CrossRef]

- Wang, C.; Fan, Z.; Wang, Z.; Yu, J.; Chen, Q.; Fu, H. Multi-component waterborne polymer modifiers for road emulsified asphalt: Modular design, mechanism of action and performance evaluation. J. Clean. Prod. 2025, 513, 145740. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.; Zhao, Q. Laboratory Performance Evaluation of a Waterborne Epoxy Modified Asphalt Mixture with Styrene-Butadiene Rubber for Cold Patching Applications. J. Mater. Civ. Eng. 2022, 34, 0004242. [Google Scholar] [CrossRef]

- Liu, Q.; Pei, J.; Wang, Z.; Hu, D.; Huang, G.; Meng, Y.; Lyu, L.; Zheng, F. Analysis of tire-pavement interaction modeling and rolling energy consumption based on finite element simulation. Constr. Build. Mater. 2024, 425, 136101. [Google Scholar] [CrossRef]

- Meng, Y.; Zheng, F.; Pei, J.; Liu, Q.; Hu, D.; Wen, Y.; Kingan, M. Study on tire-road air pumping noise characteristics based on computational fluid dynamics (CFD) and acoustic finite element simulation. Constr. Build. Mater. 2025, 488, 142181. [Google Scholar] [CrossRef]

- JTG D20; Design Specification for Asphalt Pavement of Highways. JTG: Beijing, China, 2017. (In Chinese)

- JTG E20; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. JTG: Beijing, China, 2011. (In Chinese)

- Tian, J.; Luo, S.; Lu, Q.; Liu, S. Effects of Epoxy Resin Content on Properties of Hot Mixing Epoxy Asphalt Binders. J. Mater. Civ. Eng. 2022, 34, 04022145. [Google Scholar] [CrossRef]

- Song, W.; Chen, D.; Wu, H.; Wu, Z.; Wada, S.A.; Yuan, H. Preparation and performance characterization of waterborne epoxy resin modified asphalt emulsion for tack coat. J. Clean. Prod. 2024, 475, 143715. [Google Scholar] [CrossRef]

- Kong, L.; Su, S.; Wang, Z.; Wu, P.; Zhang, Y.; Chen, Z.; Ren, D.; Ai, C. Microscale mechanism and key factors of waterborne epoxy resin emulsified asphalt enhancing interlayer bonding performance and shear resistance of bridge deck pavement. Constr. Build. Mater. 2024, 419, 135570. [Google Scholar] [CrossRef]

- Peng, Y.; Miao, J.; Yu, X.; Yang, Y.; Yang, Q.; Kong, L.; Wang, W.; Chen, Y.; Liang, F.; Ao, T. The effect of anionic emulsifiers’ diversity and manufacturing processes on the stability and mechanical properties of the water-based epoxy-emulsified asphalt. Sci. Rep. 2024, 14, 22268. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).