Experimental Study on the Anti-Erosion of the Exterior Walls of Ancient Rammed-Earth Houses in Yangjiatang Village, Lishui

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.3. Problem Statement and Objectives

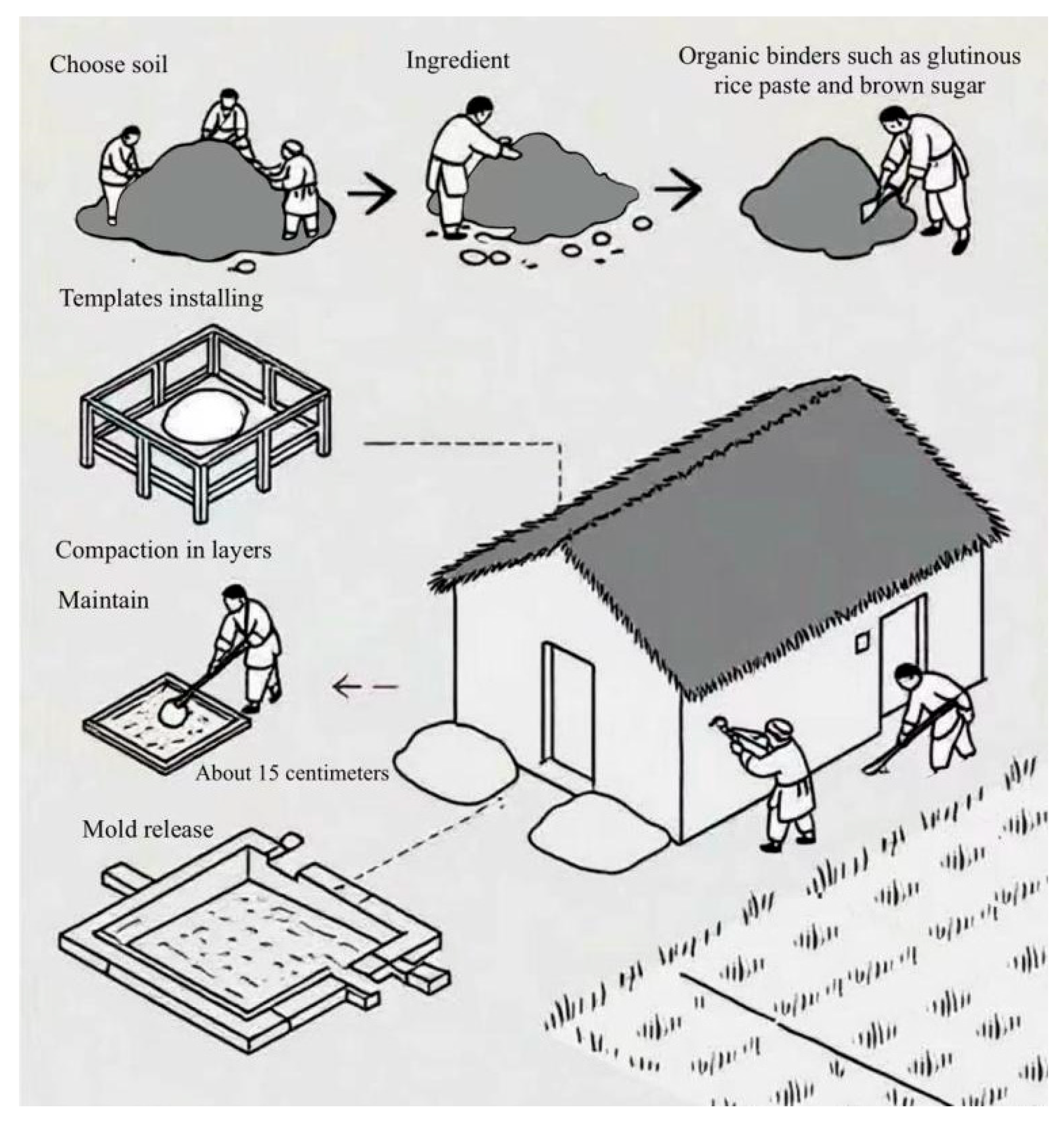

2. Materials and Methods

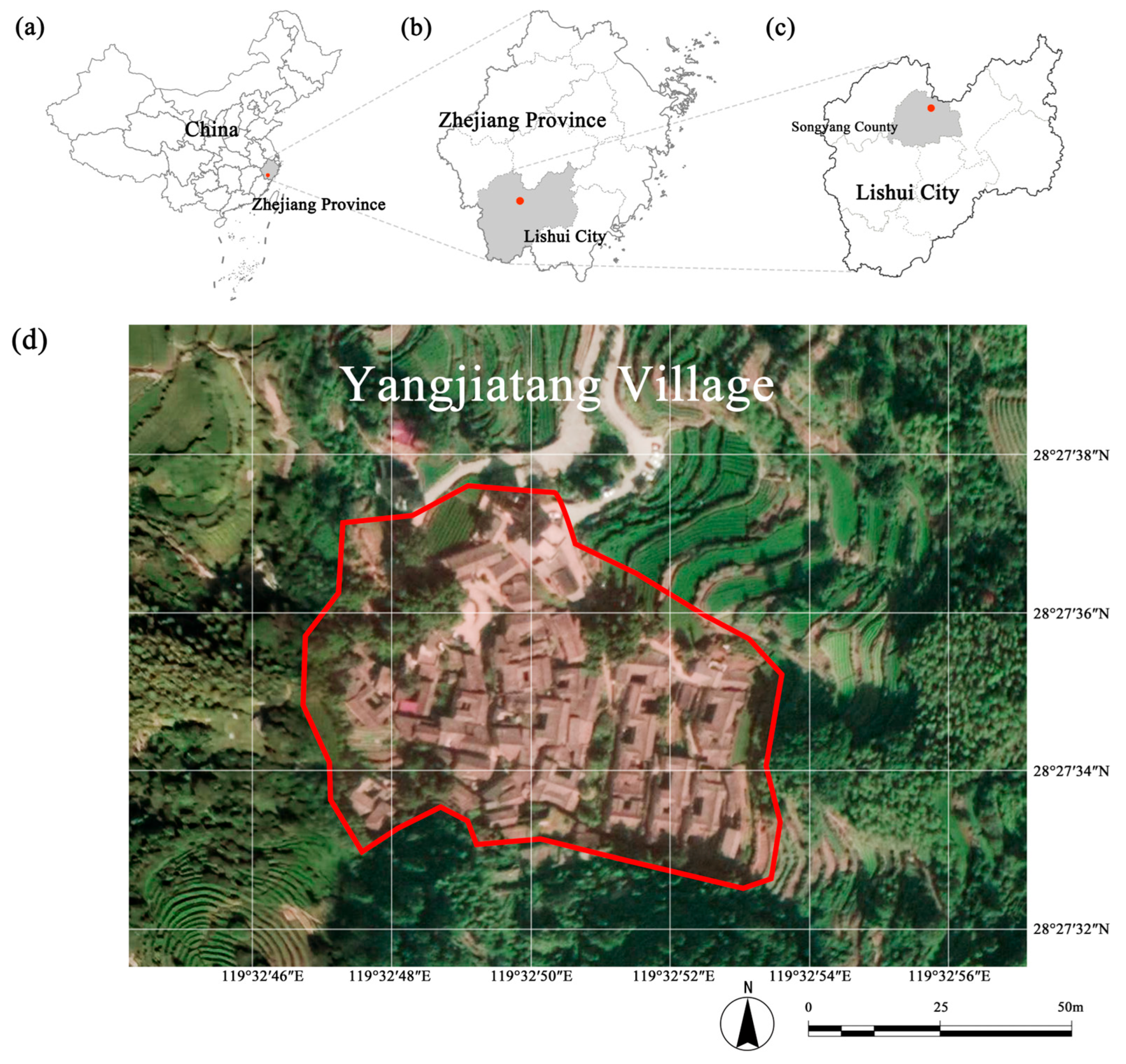

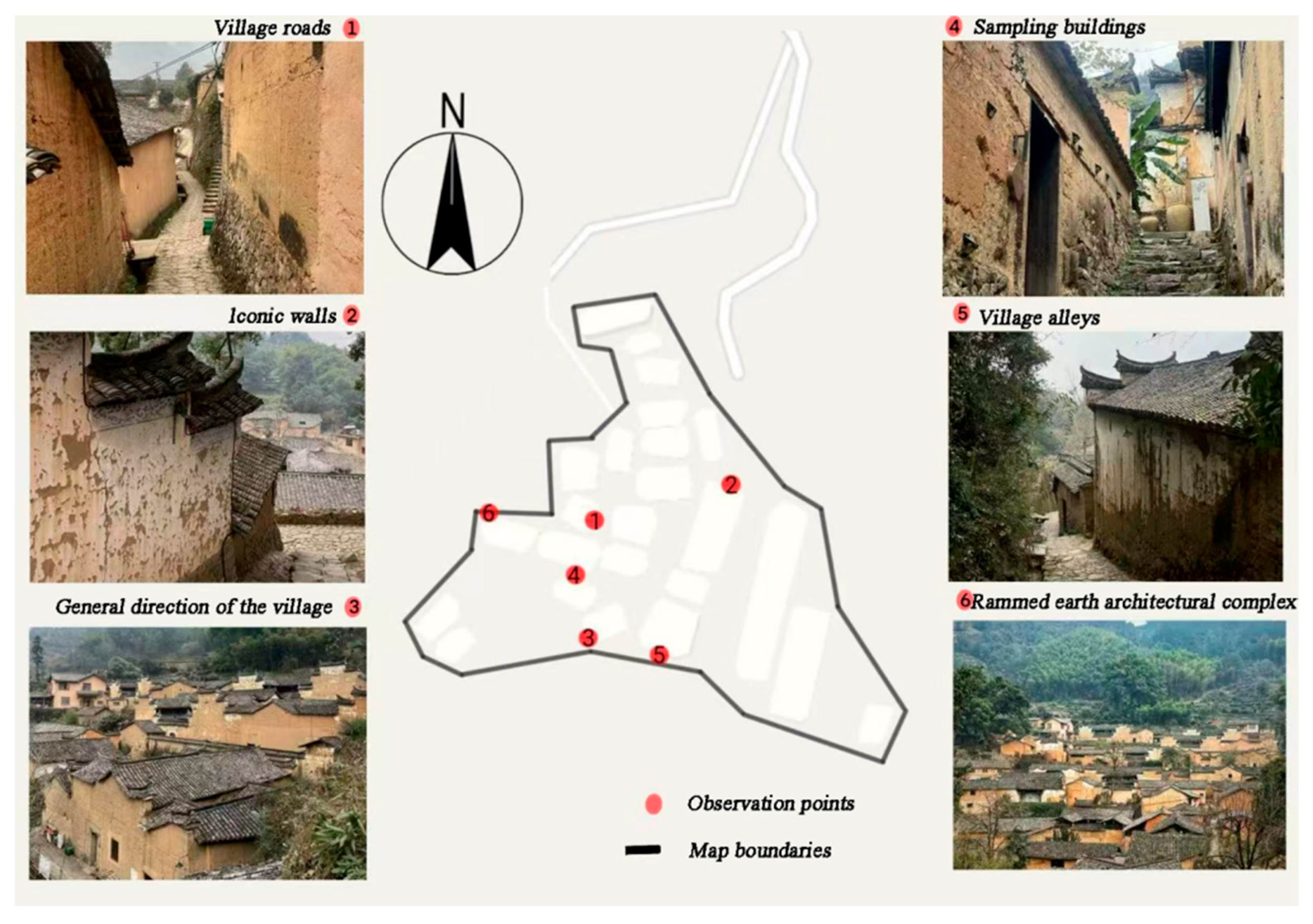

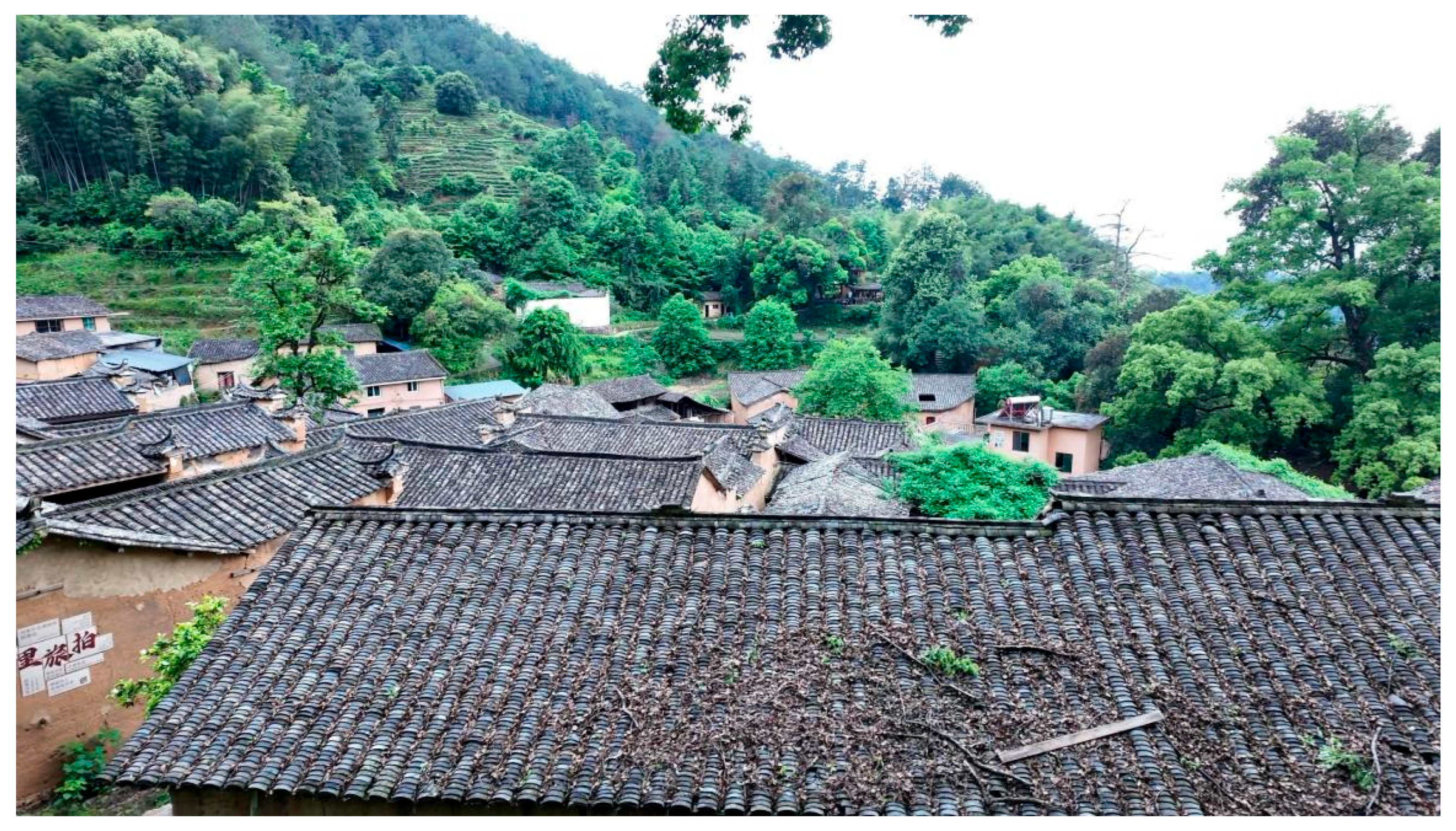

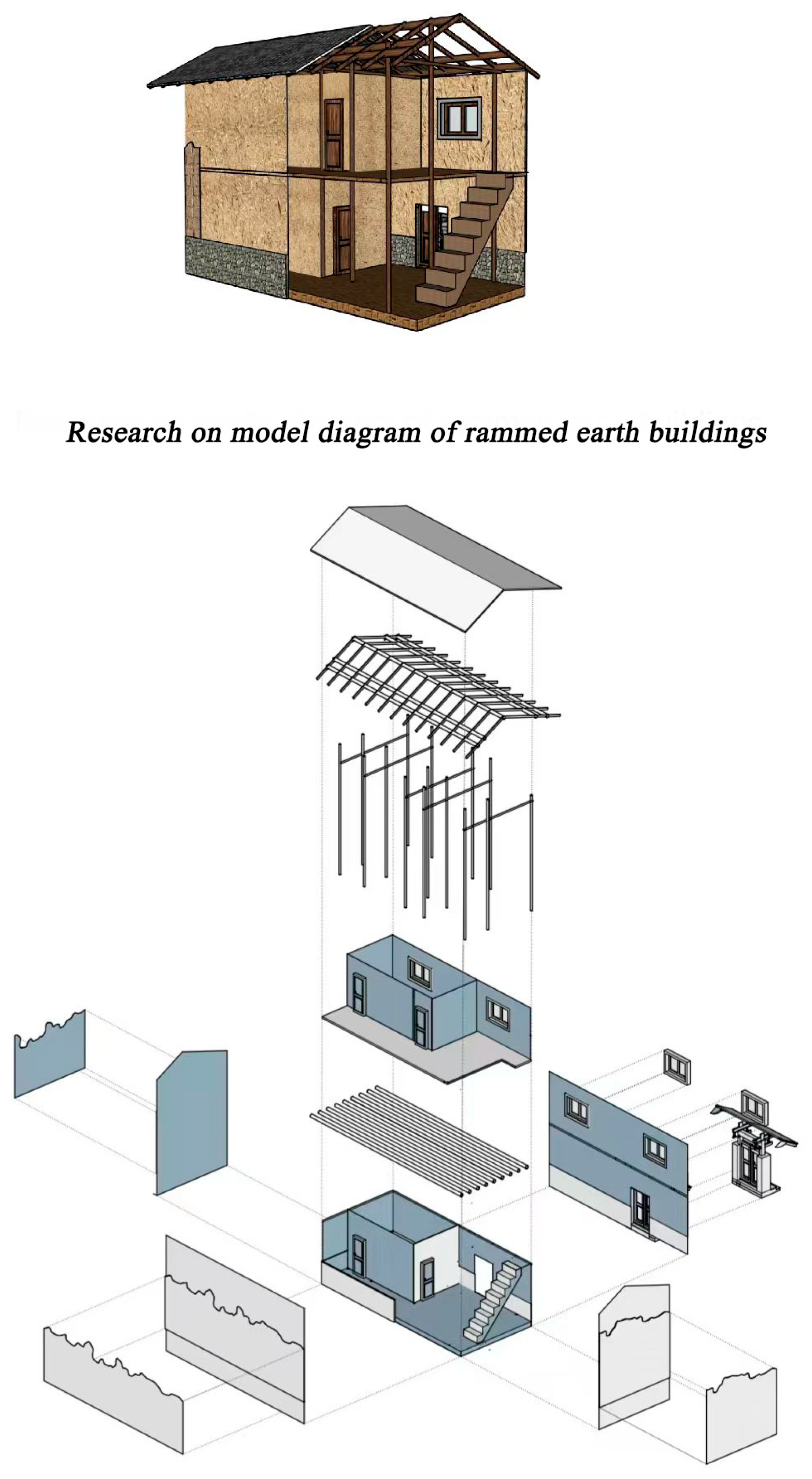

2.1. Study Area: Yangjiatang Village in Lishui City

2.2. Field Survey and Sample Collection

2.3. Analysis Methods and Process

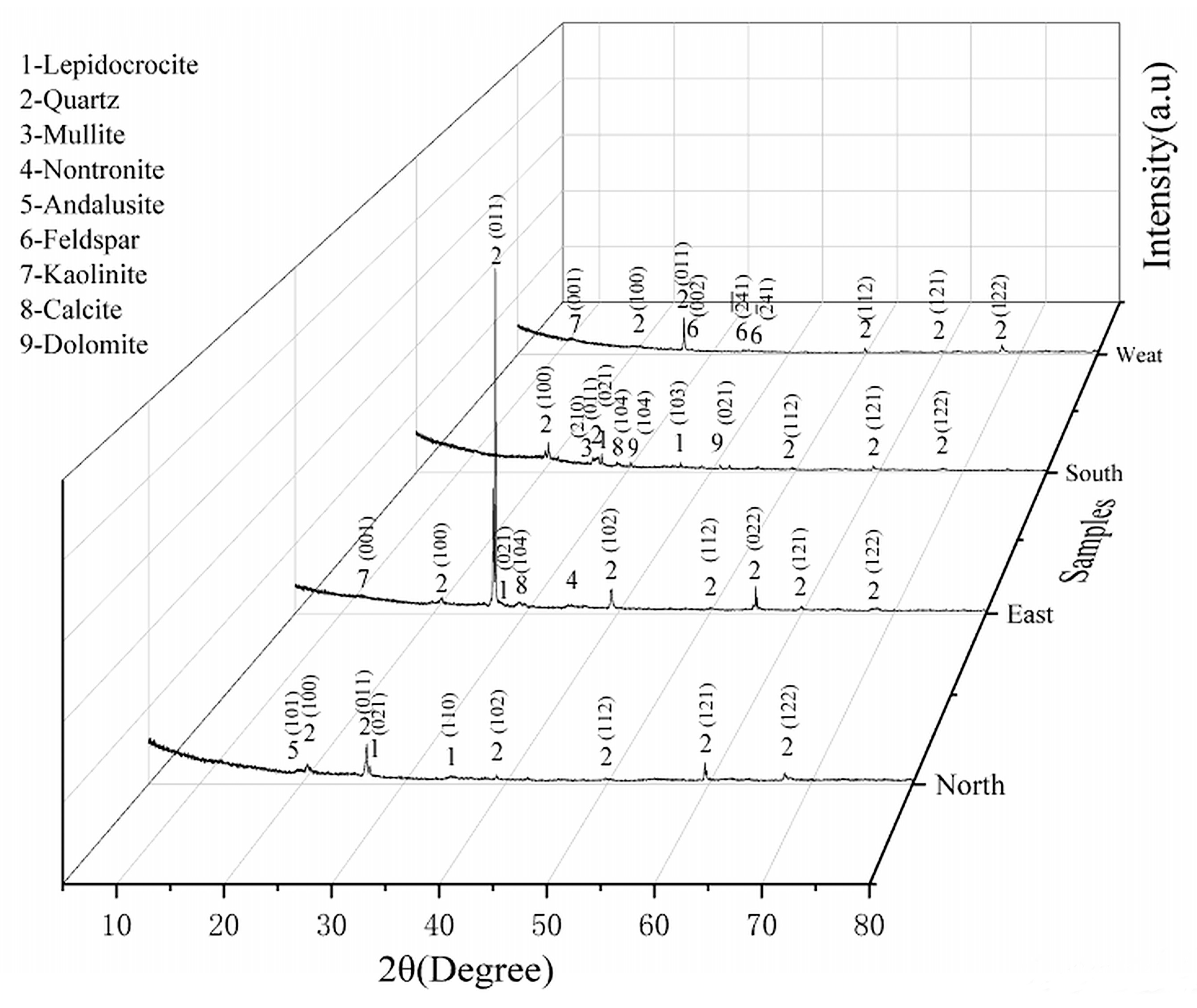

2.3.1. X-Ray Diffraction (XRD) Analysis

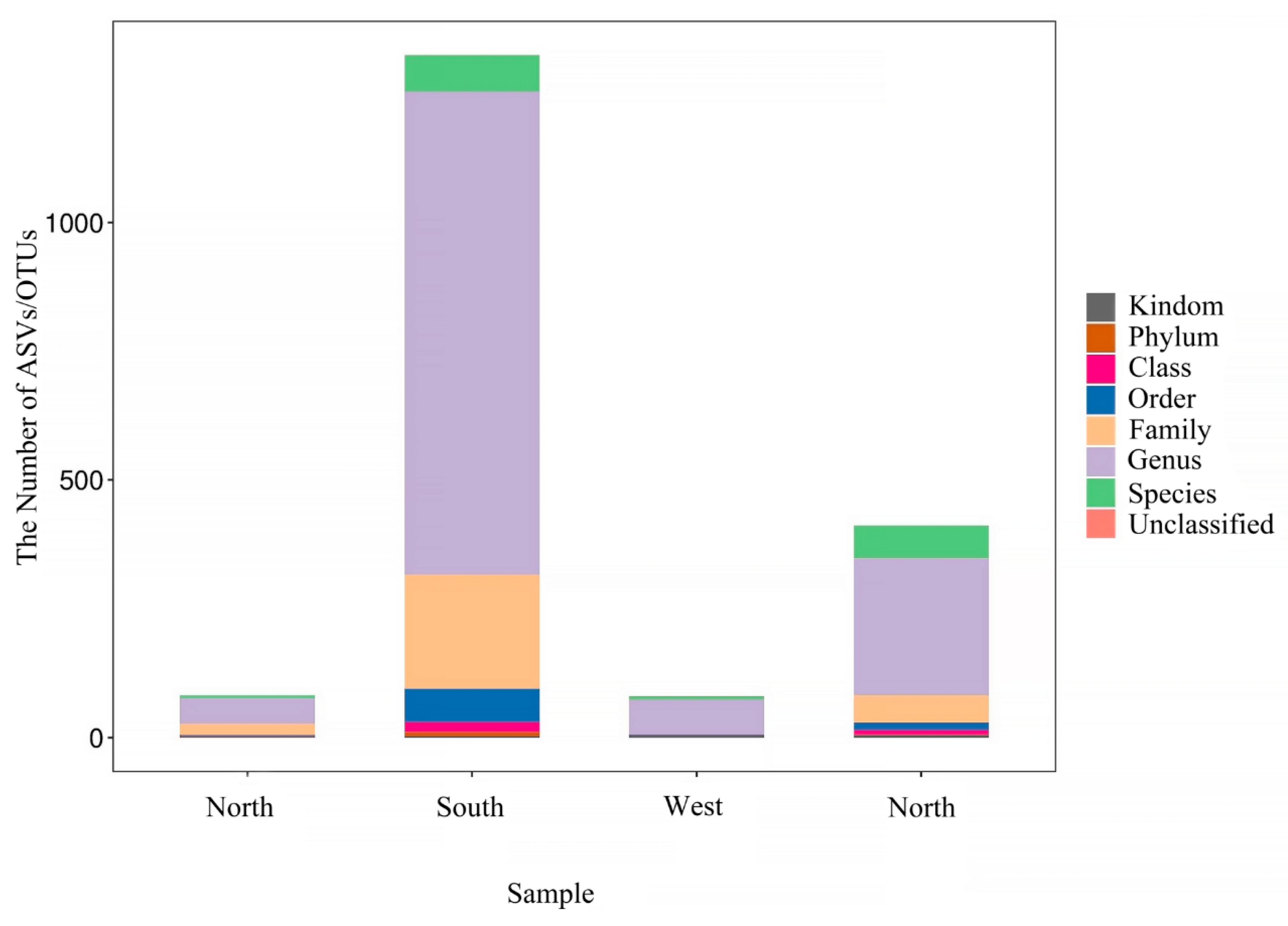

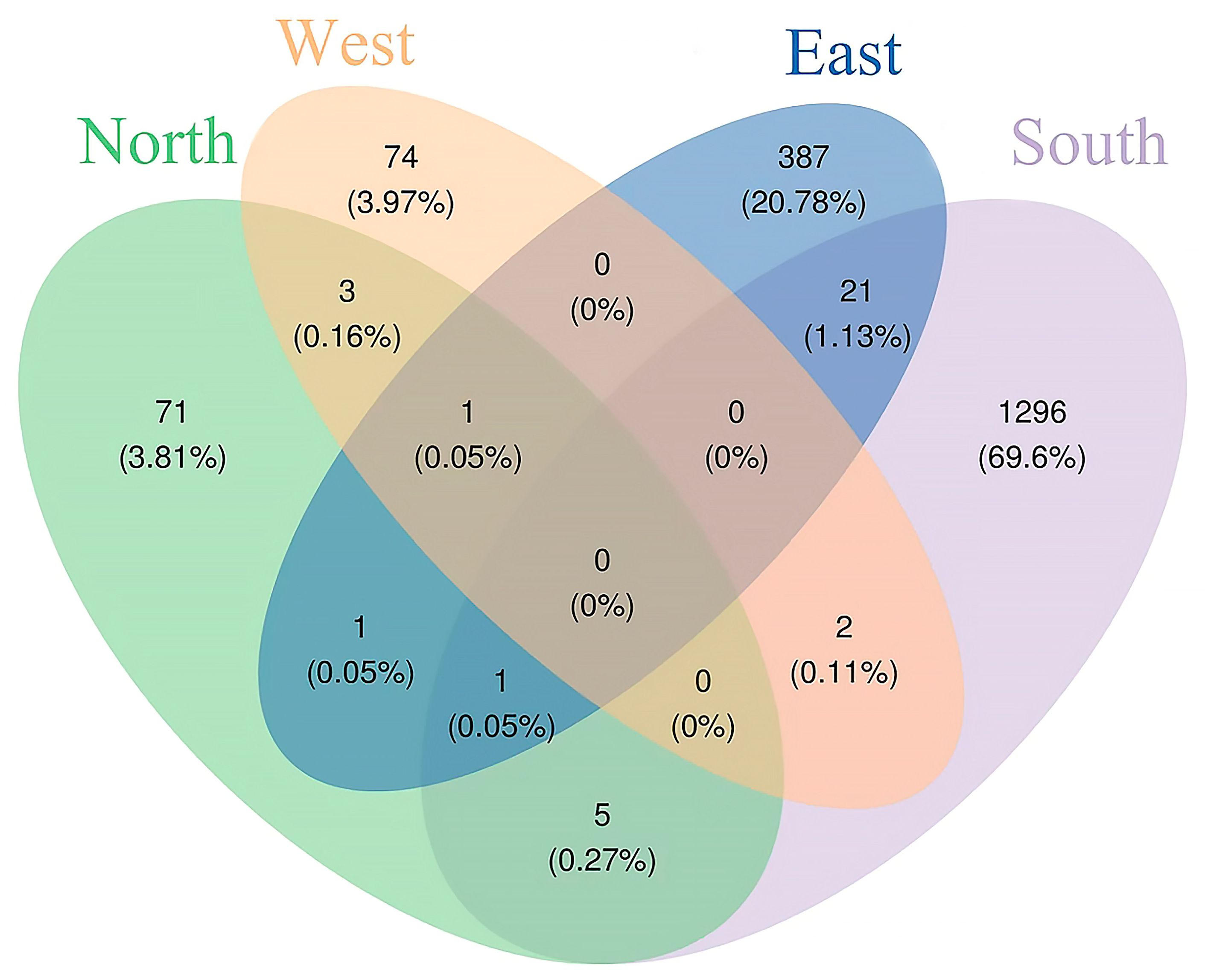

2.3.2. Detection of Diversity Composition of Microbial Communities

2.3.3. Scanning Electron Microscope (SEM) Analysis

3. Results

3.1. XRD Analysis Results

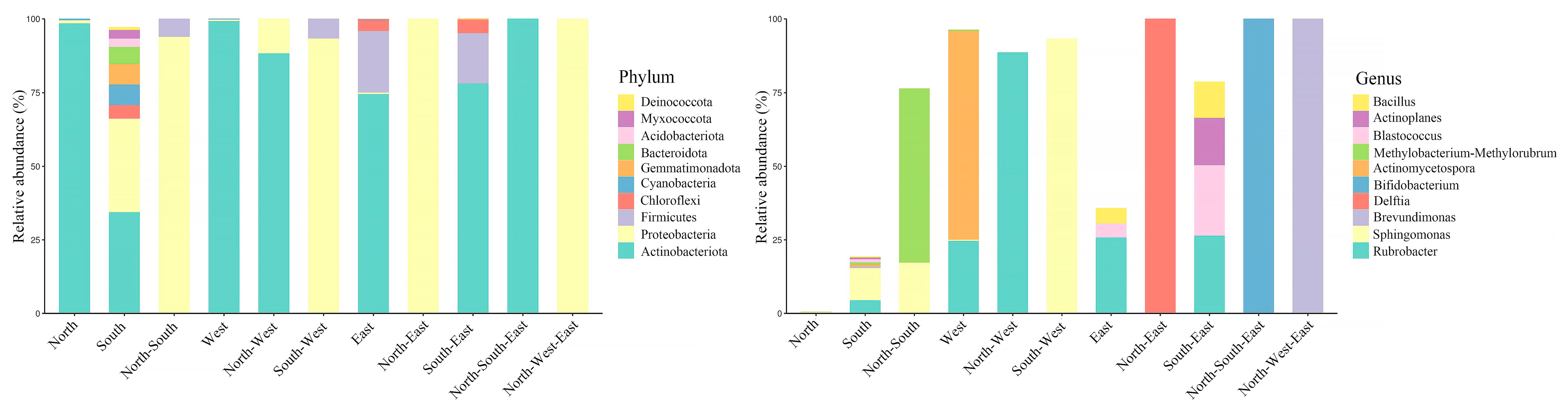

3.2. Analysis of the Microbial Diversity Detection Data

3.3. SEM Analysis Results

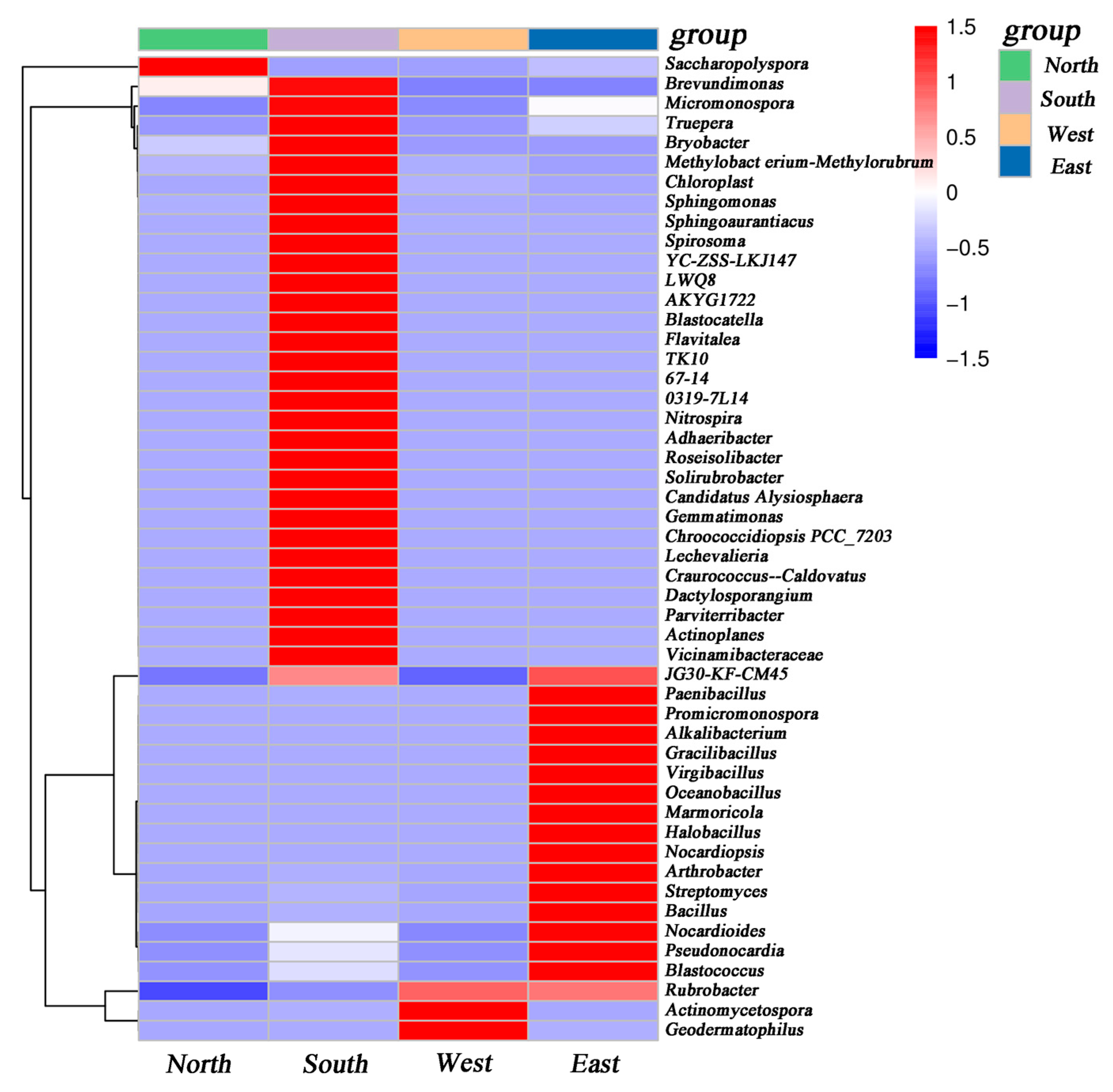

3.3.1. Comparative Analysis of SEM Images

- (1)

- The particles in the eastern samples are regular polygons, large in size, with significant size differences, relatively concentrated distribution, and a relatively smooth overall surface.

- (2)

- In contrast, the particles in the south are more irregular in shape, mostly polygonal in structure, unevenly distributed, and not obviously aggregated. Its surface is rough and accompanied by cracks, indicating that this orientation may have been affected by greater stress during its formation.

- (3)

- The particle morphology of the western samples is between the eastern and southern ones, mainly round and polygonal, with a large number of total particles; the particle size is relatively consistent, the particle size difference is slight, the distribution is relatively concentrated, and the surface is relatively flat, showing good particle uniformity. The particles in the northern samples are characterized by a fragmented or flaky morphology, a broad size distribution, and an uneven spatial arrangement.

- (4)

- The particle morphology of the northern samples is relatively dispersed, and the particles are mainly distributed on the right side. The particle size is relatively large. There are microorganisms in the north of samples. The organisms may aggregate small particles into larger clusters through secretions or produce fine fragments by decomposition. This microbial activity could lead to the observed heterogeneous particle size distribution, which may result from uneven microbial corrosion or deposition.

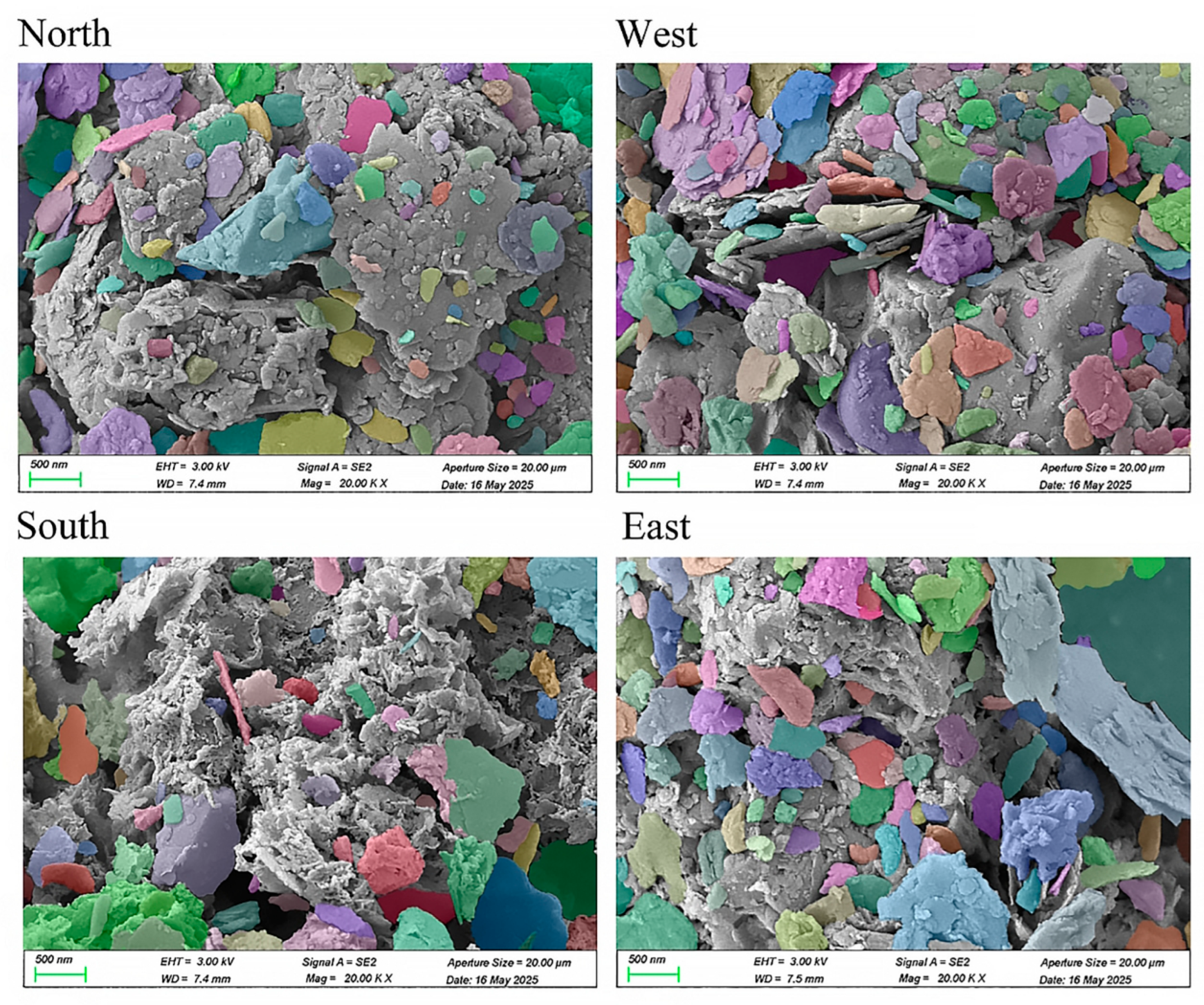

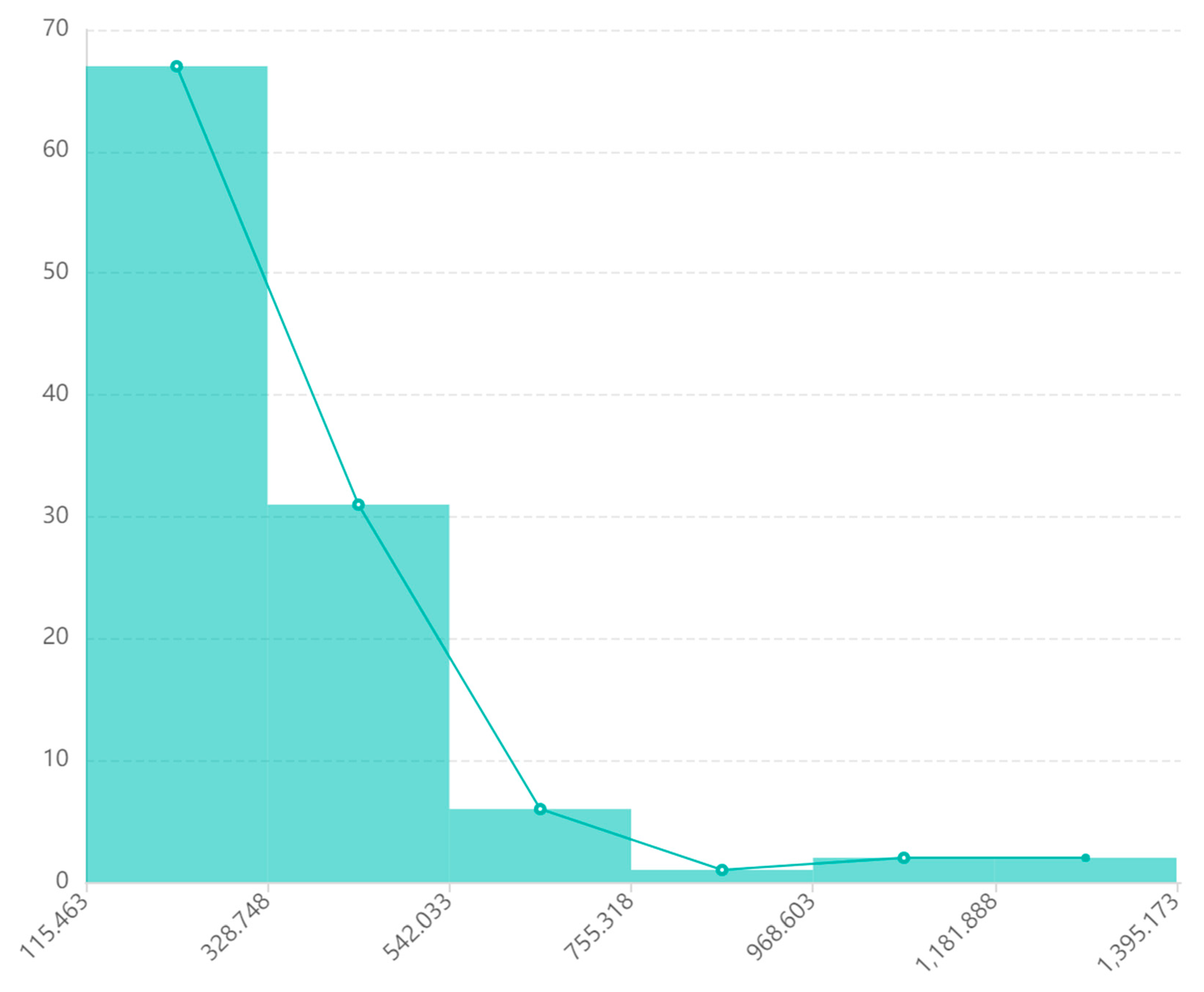

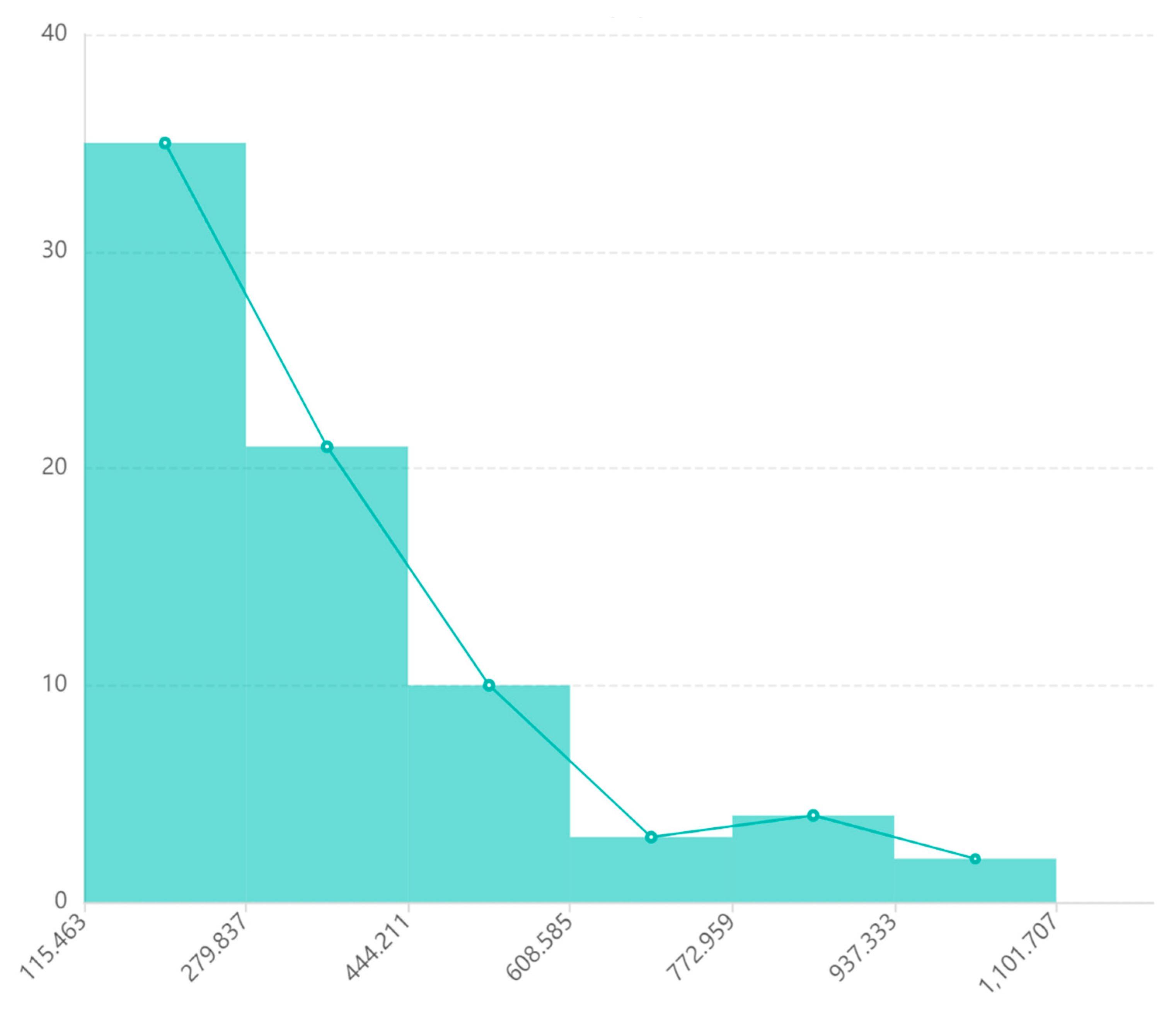

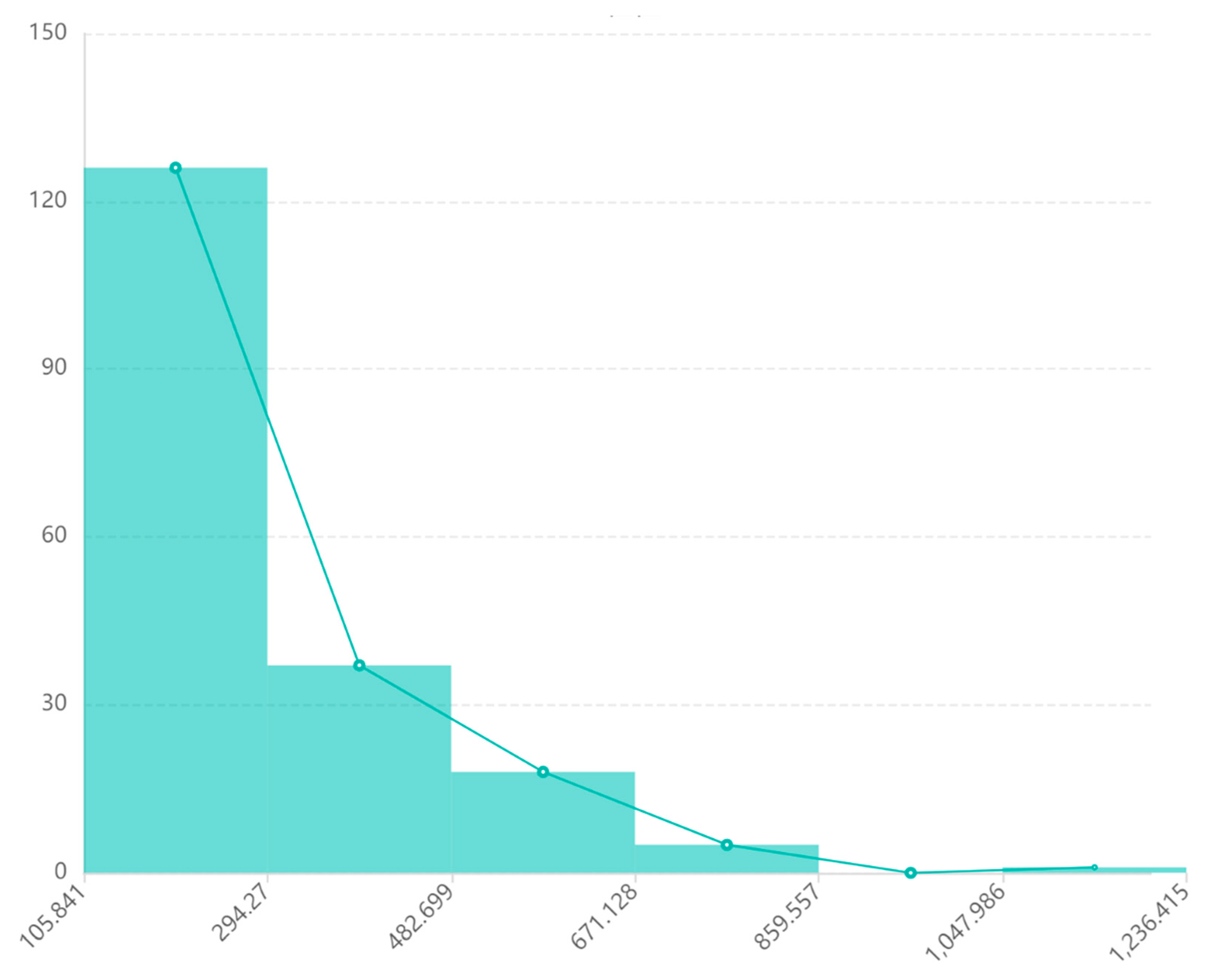

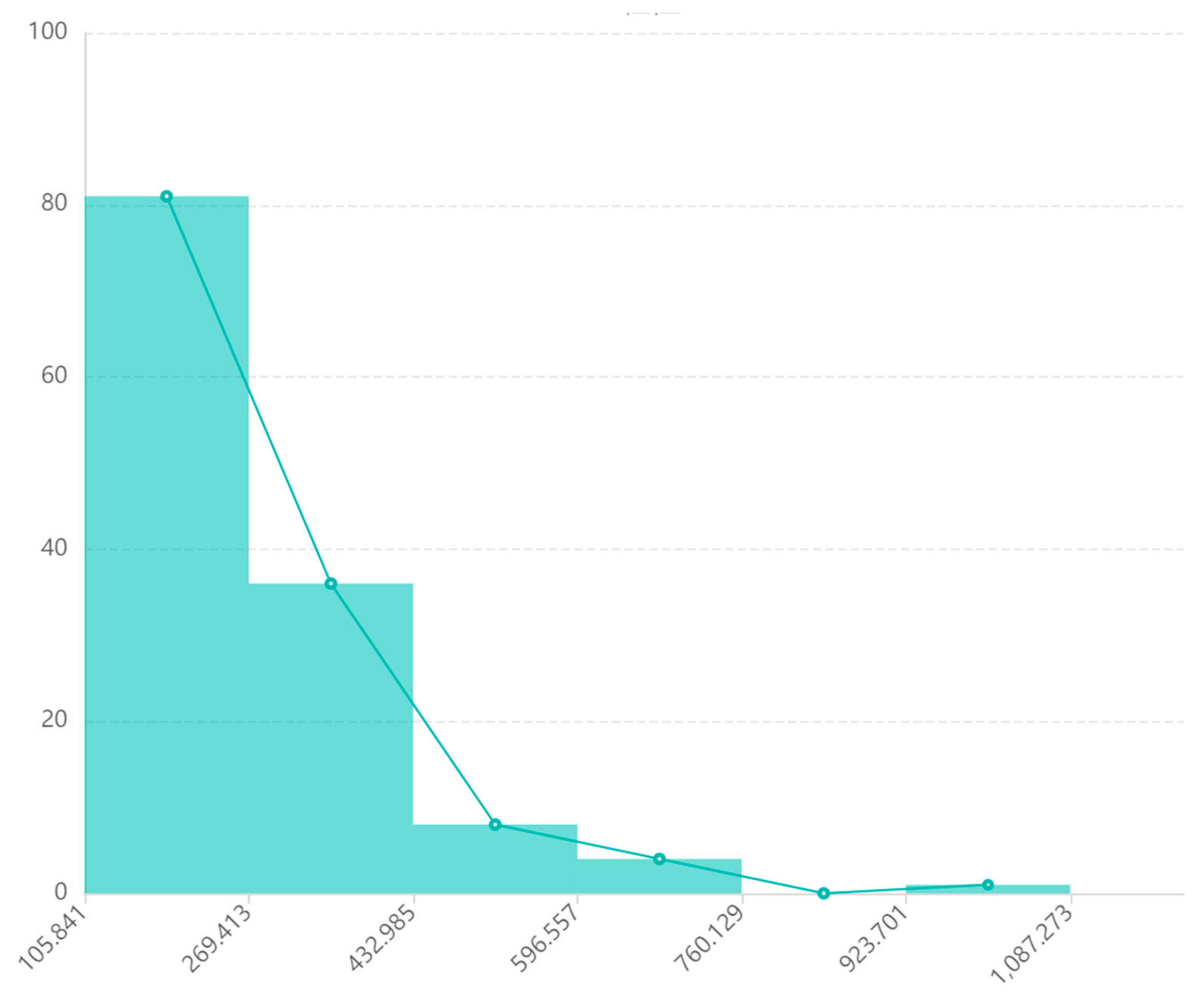

3.3.2. Particle Size Distribution Analysis

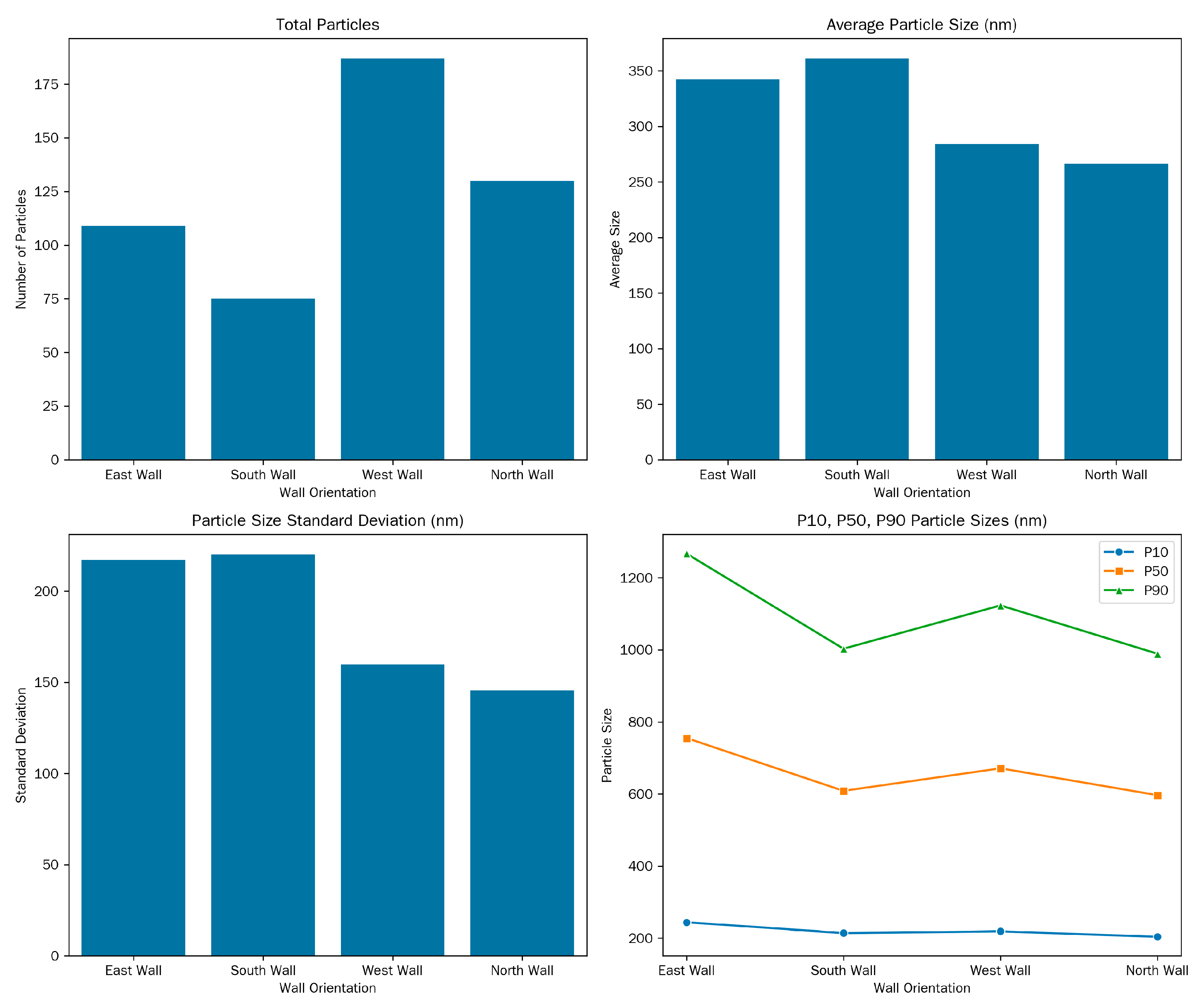

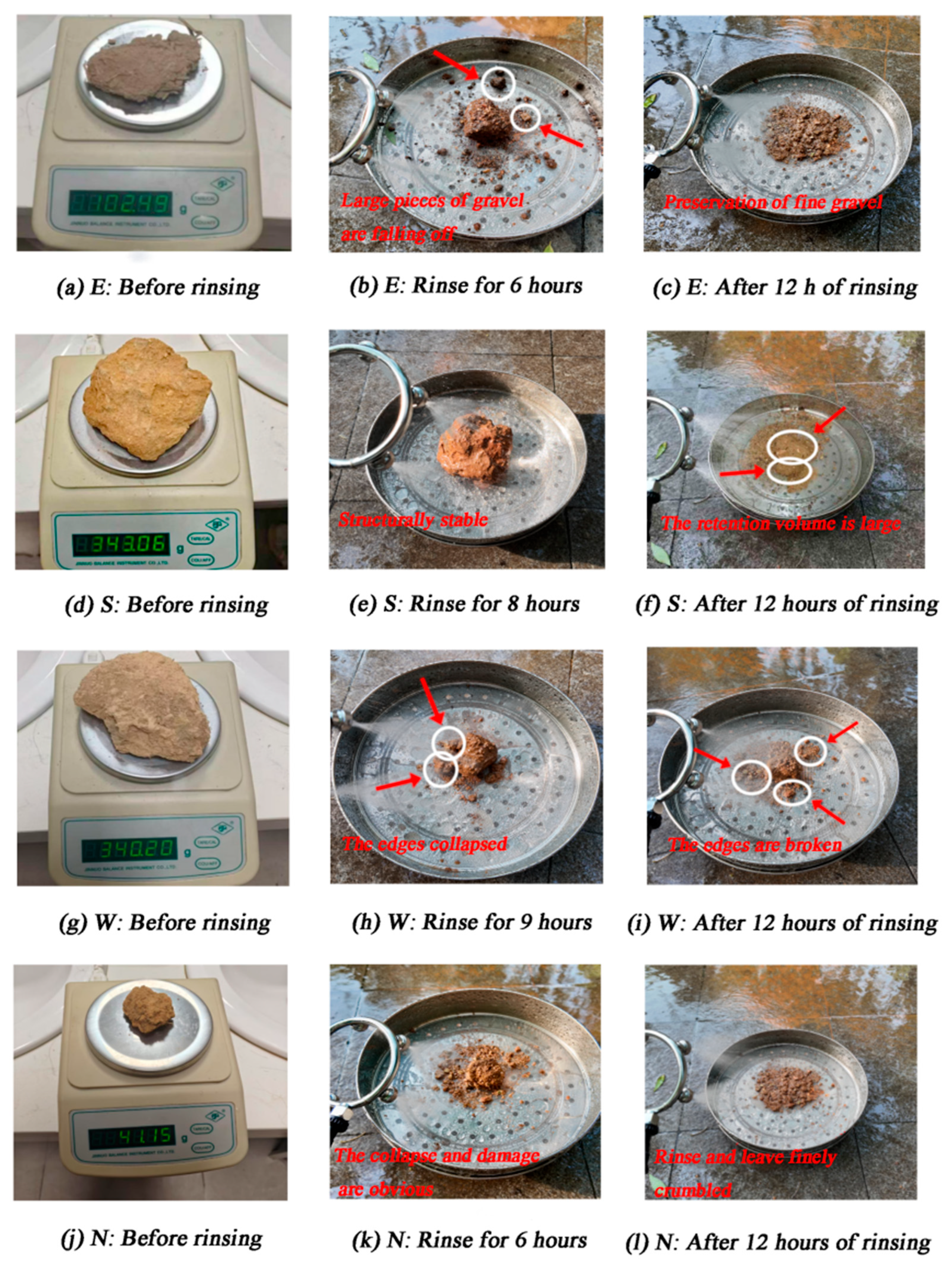

3.4. Spray Water Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, L.; Wang, D.; Zhao, H.; Gao, J.; Gallo, T. Architectural energetics for rammed-earth compaction in the context of Neolithic to early Bronze Age urban sites in the Middle Yellow River Valley, China. J. Archaeol. Sci. 2021, 126, 105303. [Google Scholar] [CrossRef]

- Lu, P.; Tian, Y.; Storozum, M.; Chen, P.; Wang, H.; Wang, X.; Xu, J.; Jing, L.; Yan, L.; Zhang, L.; et al. Shifting Patterns of House Structures during the Neolithic-Bronze Age in the Yellow River Basin: An Environmental Perspective. Land 2021, 10, 574. [Google Scholar] [CrossRef]

- Tang, X.; Shen, S.; Su, X. From rammed earth to stone wall: Chronological insight into the settlement change of the Lower Xiajiadian culture. PLoS ONE 2022, 17, e0273161. [Google Scholar] [CrossRef] [PubMed]

- Akbulut, D.E.; Alibeyoglu, R.N. Rammed Earth Construction: From Tradition to a Sustainable Future; IntechOpen: London, UK, 2025. [Google Scholar] [CrossRef]

- Ciancio, D.; Beckett, C. Rammed earth: An overview of a sustainable construction material. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies, SCMT 2013, Kyoto, Japan, 18–21 August 2013; University of Edinburgh Research Explorer: Kyoto, Japan, 2013; pp. 1–9. Available online: http://www.claisse.info/2013%20papers/data/e053.pdf (accessed on 11 May 2024).

- Avila, F.; Puertas, E.; Gallego, R. Characterization of the mechanical and physical properties of stabilized rammed earth: A review. Constr. Build. Mater. 2022, 325, 126693. [Google Scholar] [CrossRef]

- Dobson, S. Rammed earth in the modern world. In Rammed Earth Construction: Cutting-Edge Research on Traditional and Modern Rammed Earth; Ciancio, D., Beckett, C., Eds.; CRC Press: London, UK, 2015; pp. 3–10. [Google Scholar]

- Jaquin, P.A.; Augarde, C.E.; Gerrard, C.M. Chronological description of the spatial development of rammed earth techniques. Int. J. Archit. Herit. 2008, 2, 377–400. [Google Scholar] [CrossRef]

- National Geographic Recommendation: The Last Secret Place in Jiangnan. Available online: https://www.sohu.com/a/776405018_100133113 (accessed on 10 May 2025).

- Old Houses Are Fully Revived, and the Village Is Reborn. This Is How Yangjiatang Village in Songyang Protects and Utilizes the Ancient Town. Available online: http://www.qstheory.cn/2020-07/22/c_1126270926.htm (accessed on 17 May 2025).

- Juan, P.V.; Bernardo, C.; Eduardo, J.R.; Laura, I.; Johana, A. Homogenization of rammed earth walls under changing environmental conditions. Constr. Build. Mater. 2024, 425, 136082. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, R.; Zhao, Q. The weathering effect of moisture on ancient rammed-earth city walls. J. Cap. Norm. Univ. (Nat. Sci. Ed.) 2025, 46, 12–17. [Google Scholar] [CrossRef]

- Joo, L.P.; António, S.S.; Cotrim, M. Mineralogical and microstructural characterisation of rammed earth and earthen mortars from 12th century Paderne Castle. J. Cult. Heritage 2020, 42, 226–239. [Google Scholar] [CrossRef]

- Zhou, Z. The application of contemporary rammed earth materials in architectural design is divided. Urban. Archit. 2023, 20, 143–146. [Google Scholar] [CrossRef]

- Martin-Antunes, M.A.; Espuelas, S. Recent developments in stabilized rammed earth: Testing protocols and the recommendations for standardization. J. Build. Eng. 2025, 106, 112436. [Google Scholar] [CrossRef]

- Luo, L.; Chen, X.; Zhou, J. The Application of modern rammed earth construction technology in landscape architecture. J. Build. Technol. 2024, 55, 1655–1658. [Google Scholar] [CrossRef]

- Jiang, M.; Jiang, B.; Lu, R. Thermal and Humidity Performance Test of Rammed-Earth Dwellings in Northwest Sichuan during Summer and Winter. Materials 2023, 16, 6283. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Wu, E.; Chi, X. A New Rammed Earth Construction Strategy Based on the Endogenous Development Model in Rural Areas: Taking the “One Specialization, One Village” Project in Rural Southwest China as an Example. Archit. J. 2024, 105–111. [Google Scholar] [CrossRef]

- Looking at the Path of Urban-Rural Integrated Development | Songyang: Ancient Villages and Ancient Charm, the Story of Shared Prosperity in Traditional Villages. Available online: http://www.news.cn/20241012/fbc64ff310a241c58a94ca37d2341714/c.html (accessed on 18 May 2025).

- Yang, Q.; Davenport, B.; Zhang, L. How do older people conserve cultural heritage in rural areas: Evidence from Zhejiang, China. J. Inst. Conserv. 2025, 48, 31–50. [Google Scholar] [CrossRef]

| Sample lD | Input | Filtered | Denoised | Merged | Non-Chimeric | Non-Singleton |

|---|---|---|---|---|---|---|

| North | 60,951 | 51,354 | 51,220 | 50,881 | 50,630 | 50,629 |

| South | 76,418 | 63,719 | 60,721 | 47,966 | 44,304 | 44,099 |

| West | 82,270 | 68,601 | 68,543 | 68,104 | 67,048 | 67,048 |

| East | 67,285 | 56,416 | 55,846 | 52,831 | 49,873 | 49,823 |

| Wall Orientation | East Wall | South Wall | West Wall | North Wall | |

|---|---|---|---|---|---|

| Total particles | 109 | 75 | 187 | 130 | |

| Particle size information | Average particle size | 342.636 nm | 361.141 nm | 284.309 nm | 266.304 nm |

| Particle size standard deviation | 217.108 nm | 220.090 nm | 159.866 nm | 145.531 nm | |

| P10 | 243.434 nm | 214.087 nm | 218.898 nm | 203.984 nm | |

| P50 | 755.318 nm | 608.584 nm | 671.127 nm | 596.557 nm | |

| P90 | 1267.203 nm | 1003.082 nm | 1123.356 nm | 989.13 nm | |

| Sample Name | Sample Initial Weight/g | Weight After 6 h of Showering/g | Weight After 12 h of Showering/g |

|---|---|---|---|

| East | 102.49 | 68.7 | 35.6 |

| South | 343.06 | 96.3 | 58.4 |

| West | 340.2 | 86.8 | 43.2 |

| North | 41.15 | 24.5 | 10.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Song, J.; Zhang, X.; Hu, Y.; Chen, R.; Yang, S. Experimental Study on the Anti-Erosion of the Exterior Walls of Ancient Rammed-Earth Houses in Yangjiatang Village, Lishui. Coatings 2025, 15, 1173. https://doi.org/10.3390/coatings15101173

Zheng Y, Song J, Zhang X, Hu Y, Chen R, Yang S. Experimental Study on the Anti-Erosion of the Exterior Walls of Ancient Rammed-Earth Houses in Yangjiatang Village, Lishui. Coatings. 2025; 15(10):1173. https://doi.org/10.3390/coatings15101173

Chicago/Turabian StyleZheng, Yujun, Junxin Song, Xiaohan Zhang, Yake Hu, Ruihang Chen, and Shuai Yang. 2025. "Experimental Study on the Anti-Erosion of the Exterior Walls of Ancient Rammed-Earth Houses in Yangjiatang Village, Lishui" Coatings 15, no. 10: 1173. https://doi.org/10.3390/coatings15101173

APA StyleZheng, Y., Song, J., Zhang, X., Hu, Y., Chen, R., & Yang, S. (2025). Experimental Study on the Anti-Erosion of the Exterior Walls of Ancient Rammed-Earth Houses in Yangjiatang Village, Lishui. Coatings, 15(10), 1173. https://doi.org/10.3390/coatings15101173