The Charge Transport Properties of Polycrystalline CVD Diamond Films Deposited on Monocrystalline Si Substrate

Abstract

1. Introduction

2. Materials and Methods

- •

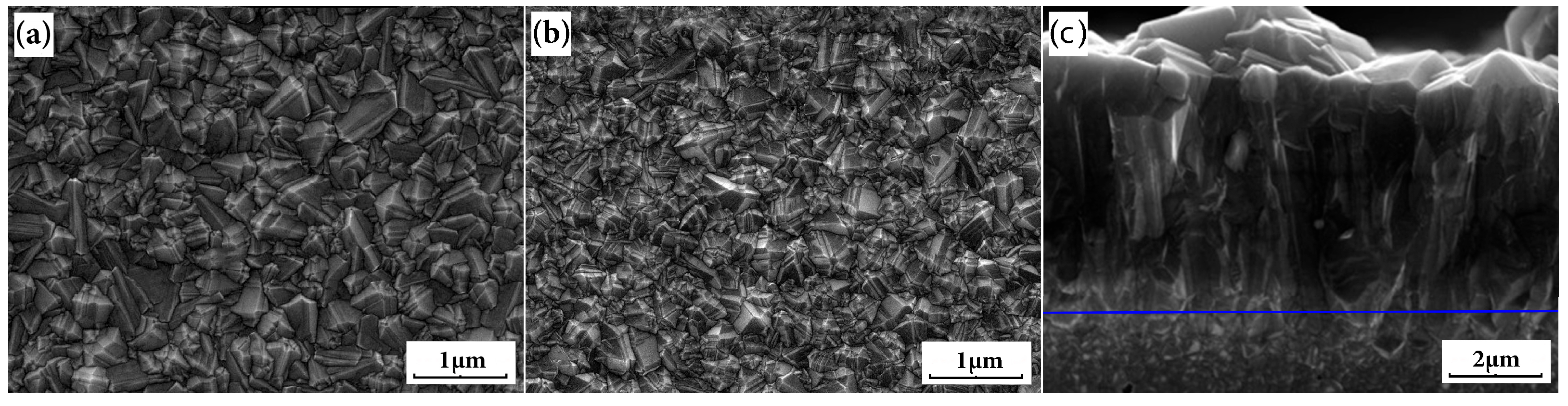

- Morphology: Scanning Electron Microscopy (SEM, JEOL JSM-820, 25 kV).

- •

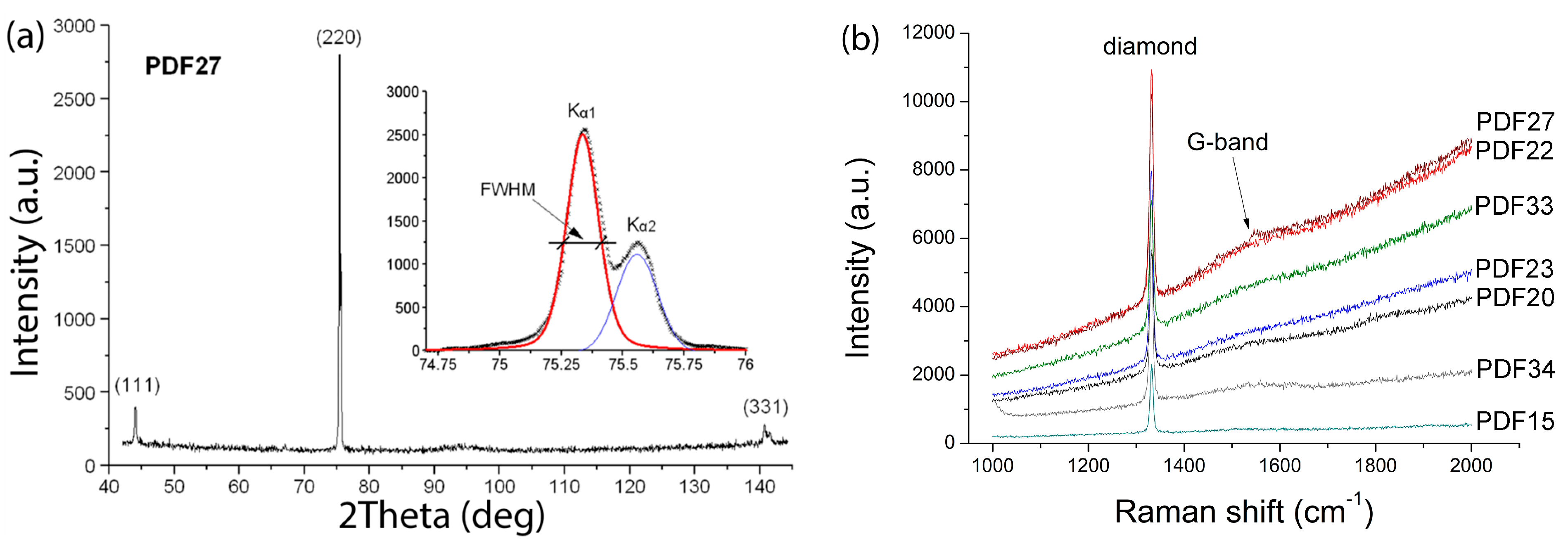

- Structural Analysis: Raman spectroscopy (Renishaw inVia, 488 nm laser, ±2 cm−1 resolution) and X-ray diffraction (XRD, DRON-4a Θ–2Θ diffractometer, Cu Kα radiation, 32 kV, 12 mA).

- •

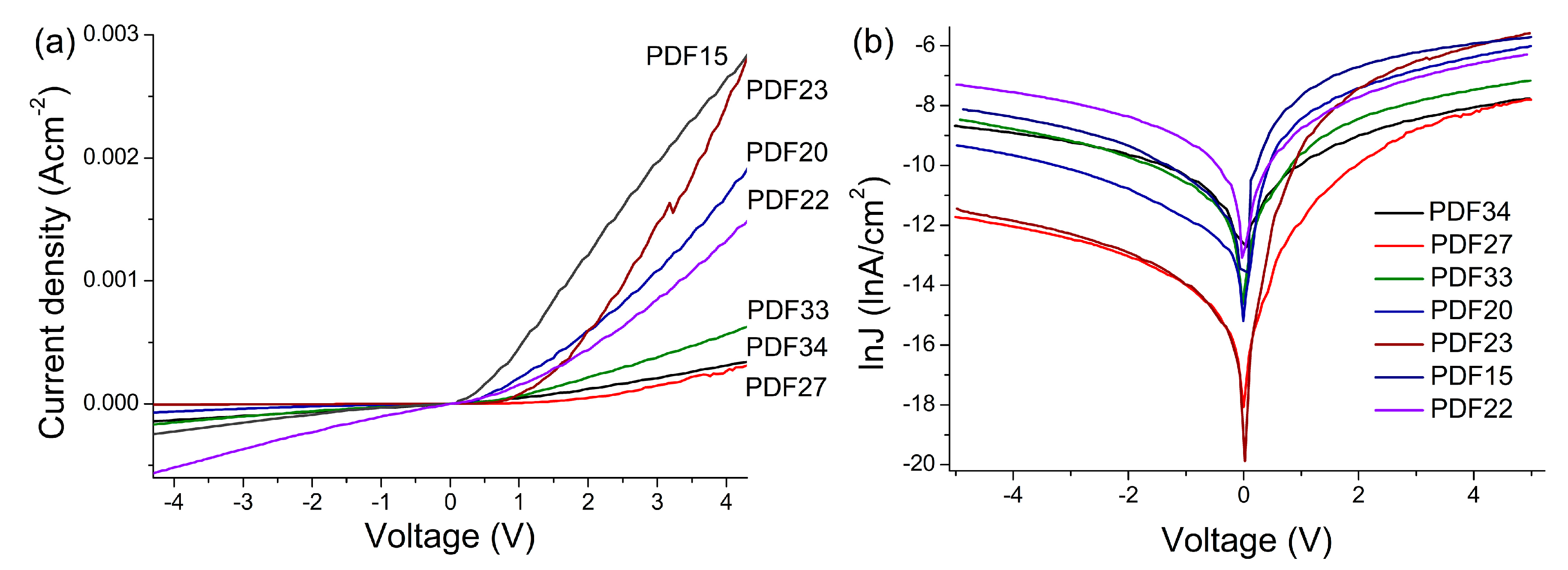

- Electrical Measurements: I–V characteristics were recorded at room temperature using an Oxford Optistat cryostat. A 4–20 V rectangular waveform was applied (Rigol DG1022A), and current/voltage data were collected using a Keithley 6485 picoammeter and Fluke 8505A multimeter.

3. Results

3.1. Structural Characterization (SEM, XRD)

3.2. Structural Characterization (Raman)

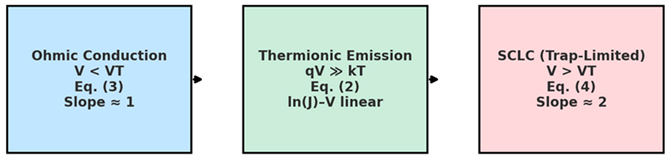

3.3. Electrical Transport Properties of the p-Diamond/n-Si Heterojunctions

3.4. Thermionic Emission Regime (Junction-Limited Transport)

3.5. Ohmic Region (Bulk-Limited Transport, Very Low Bias: V < VT)

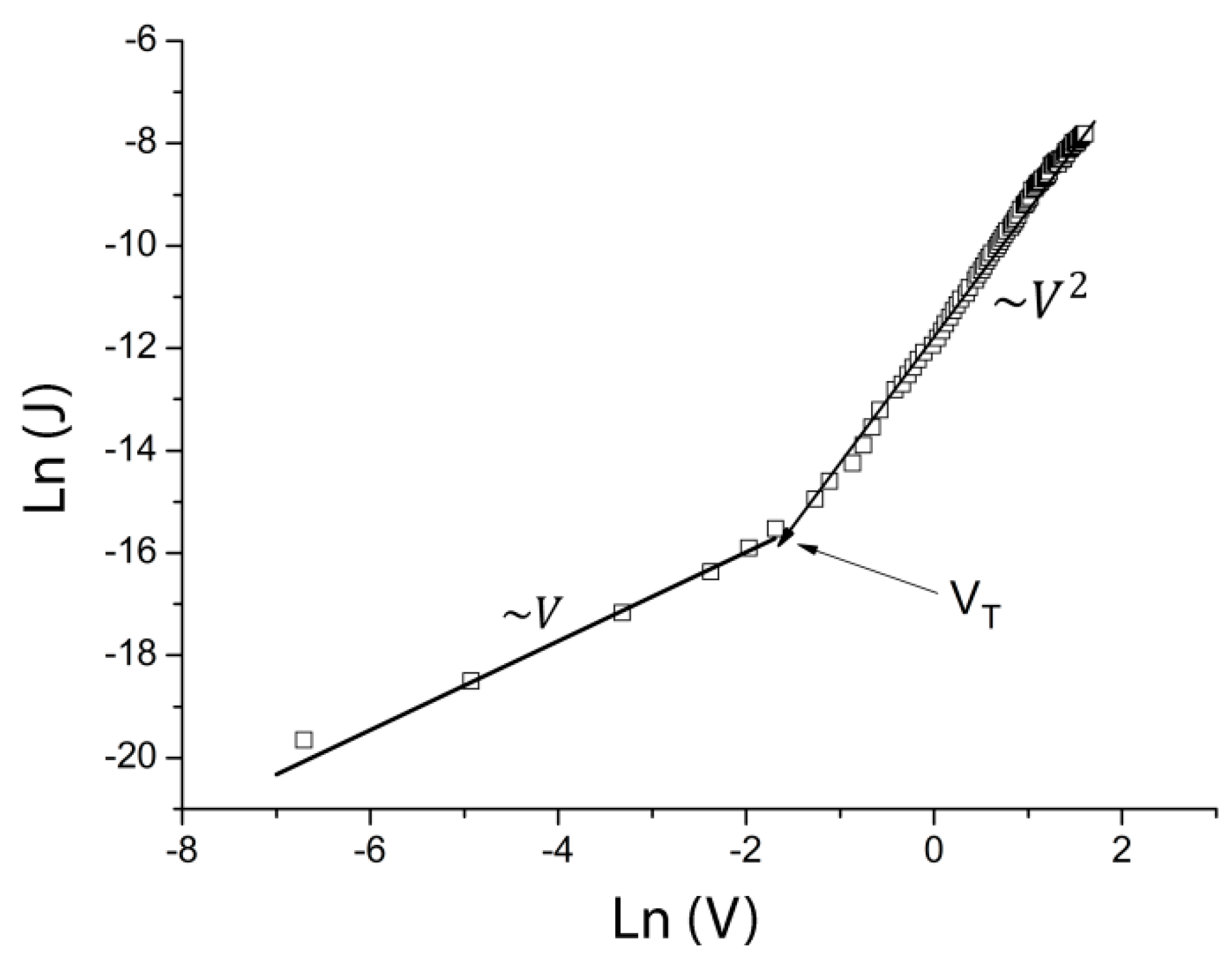

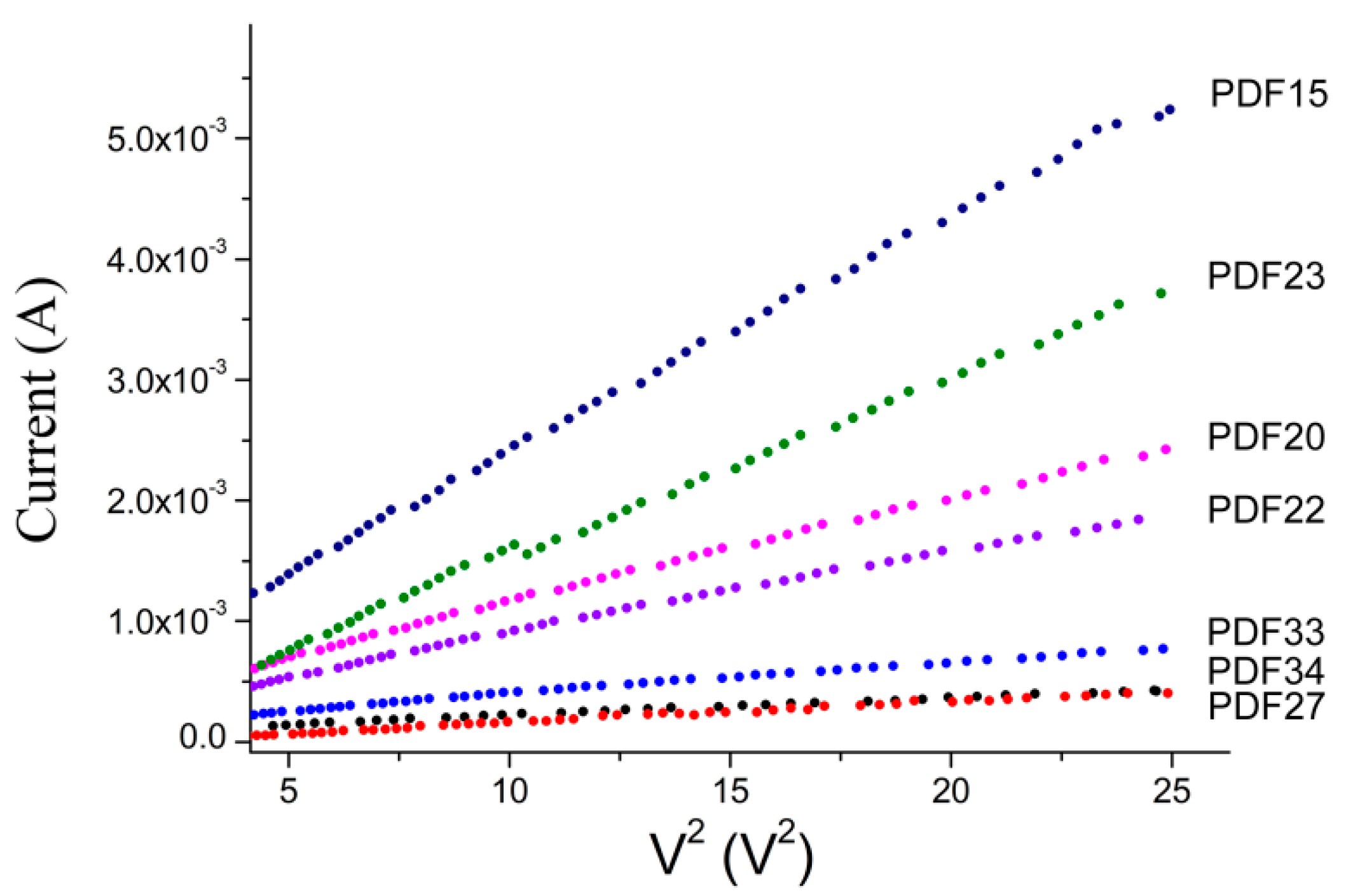

3.6. Space-Charge-Limited Conduction (Trap-Controlled Transport, V > VT )

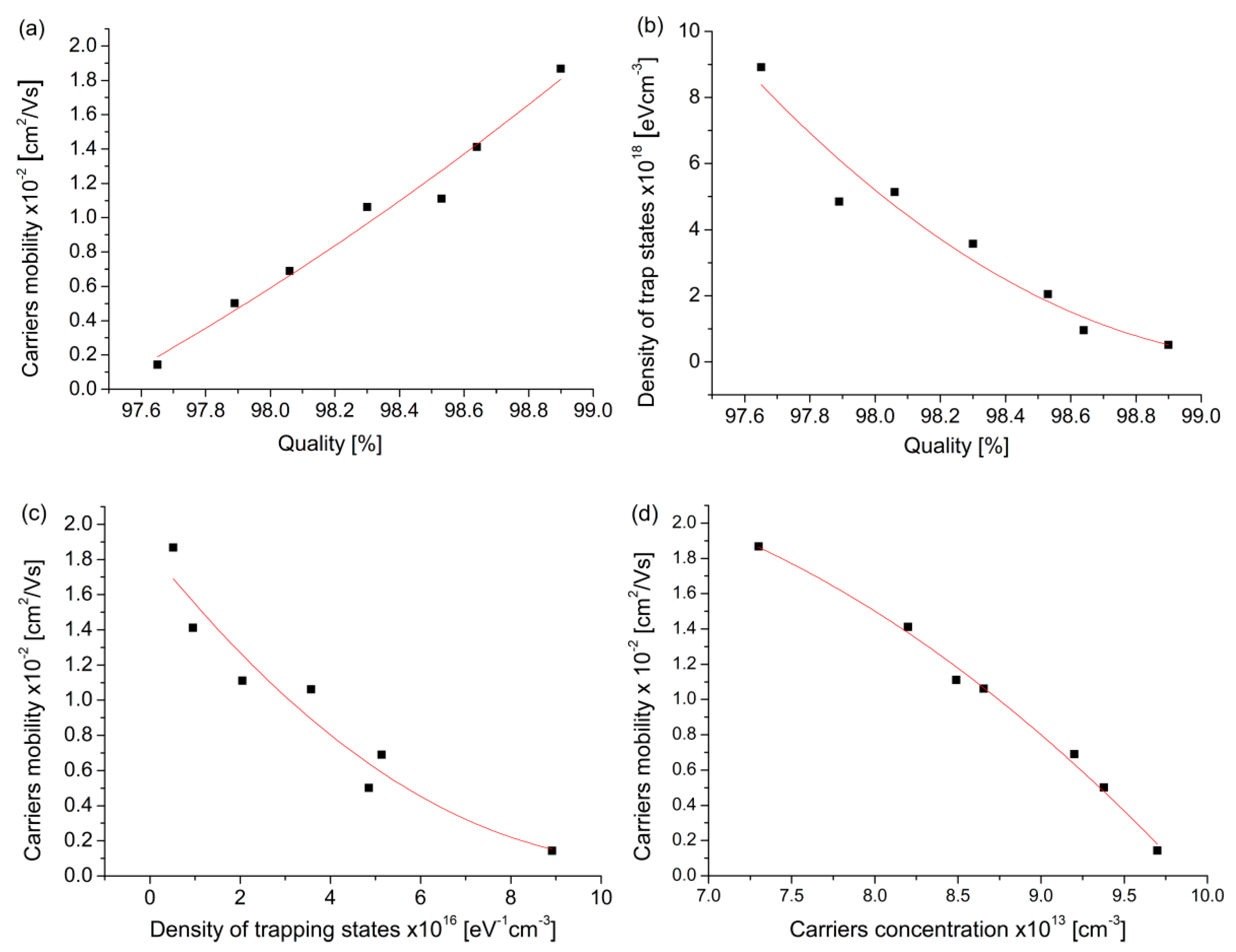

3.7. Trap Density and Carrier Mobility

3.8. Discussion of Transport Mechanisms

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wild, C.; Wörner, E. The CVD Diamond Booklet; Diamond Materials GmbH: Freiburg, Germany, 2023. [Google Scholar]

- Isberg, J.; Hammersberg, J.; Bernhoff, H.; Twitchen, D.; Whitehead, A. Charge collection distance measurements in single and polycrystalline CVD diamond. Diam. Relat. Mater. 2004, 13, 872–875. [Google Scholar] [CrossRef]

- Pan, L.S.; Pianetta, P.; Kania, D.; Han, S.; Landen, O.; Ager, J., III; Landstrass, M. Electrical transport properties of undoped CVD diamond films. Science 1992, 255, 830–833. [Google Scholar] [CrossRef]

- Pleskov, Y.; Tameev, A.; Varnin, V.; Teremetskaya, I. Comparison of the hole mobility in undoped and boron-doped polycrystalline CVD diamond films. J. Solid State Electrochem. 1998, 3, 25–30. [Google Scholar] [CrossRef]

- Łoś, S.; Fabisiak, K.; Paprocki, K.; Szybowicz, M.; Dychalska, A.; Spychaj-Fabisiak, E.; Franków, W. The Hydrogenation Impact on Electronic Properties of p-Diamond/n-Si Heterojunctions. Materials 2021, 14, 6615. [Google Scholar] [CrossRef] [PubMed]

- Gajewski, W.; Achatz, P.; Williams, O.A.; Haenen, K.; Bustarret, E.; Stutzmann, M.; Garrido, J.A. Electronic and optical properties of boron-doped nanocrystalline diamond films. Phys. Rev. B 2009, 79, 045206. [Google Scholar] [CrossRef]

- Chaudhuri, S.K.; Malakoutian, M.; Kleppinger, J.W.; Dutta, M.; Koeck, F.A.; Nemanich, R.J.; Chowdhury, S.; Mandal, K.C. Current transient spectroscopic study of vacancy complexes in diamond Schottky pin diode. IEEE Trans. Electron Devices 2022, 69, 4469–4473. [Google Scholar] [CrossRef]

- Seshan, V.; Murthy, D.H.; Castellanos-Gomez, A.; Sachdeva, S.; Ahmad, H.A.; Janssens, S.D.; Janssen, W.; Haenen, K.; van der Zant, H.S.; Sudholter, E.J. Contactless photoconductance study on undoped and doped nanocrystalline diamond films. ACS Appl. Mater. Interfaces 2014, 6, 11368–11375. [Google Scholar] [CrossRef]

- Kalish, R. Doping of diamond. Carbon 1999, 37, 781–785. [Google Scholar] [CrossRef]

- Kohn, E.; Denisenko, A. CVD Diamond-The Next Generation Electronic Material. In Proceedings of the 2006 IEEE Compound Semiconductor Integrated Circuit Symposium, San Antonio, TX, USA, 12–15 November 2006; IEEE: New York, NY, USA, 2006; pp. 247–252. [Google Scholar]

- Rezek, B.; Watanabe, H.; Nebel, C. High carrier mobility on hydrogen terminated ⟨100⟩ diamond surfaces. Appl. Phys. Lett. 2006, 88, 042110. [Google Scholar] [CrossRef]

- Heydari Gharahcheshmeh, M. Fabrication of Conjugated Conducting Polymers by Chemical Vapor Deposition (CVD) Method. Nanomaterials 2025, 15, 452. [Google Scholar] [CrossRef]

- Faggio, G.; Politano, G.; Lisi, N.; Capasso, A.; Messina, G. The structure of chemical vapor deposited graphene substrates for graphene-enhanced Raman spectroscopy. J. Phys. Condens. Matter 2024, 36, 195303. [Google Scholar] [CrossRef]

- Higashi, G.; Chabal, Y.; Trucks, G.; Raghavachari, K. Ideal hydrogen termination of the Si (111) surface. Appl. Phys. Lett. 1990, 56, 656–658. [Google Scholar] [CrossRef]

- Tokumoto, H.; Morita, Y.; Miki, K. Scanning Tunneling Microscopy of HF-Controlled Si (111) Surfaces. MRS Online Proc. Libr. OPL 1992, 259, 409. [Google Scholar] [CrossRef]

- Crawford, K.G.; Maini, I.; Macdonald, D.A.; Moran, D.A. Surface transfer doping of diamond: A review. Prog. Surf. Sci. 2021, 96, 100613. [Google Scholar] [CrossRef]

- Kawarada, H. Diamond held effect transistors using h-terminated surfaces. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 2004; Volume 77, pp. 311–338. [Google Scholar]

- Łoś, S.; Fabisiak, K.; Paprocki, K.; Szybowicz, M.; Dychalska, A. The undoped polycrystalline diamond film—Electrical transport properties. Sensors 2021, 21, 6113. [Google Scholar] [CrossRef]

- Kowalska, M.; Paprocki, K.; Szybowicz, M.; Wrzyszczyński, A.; Łoś, S.; Fabisiak, K. Electrochemical sensitivity of undoped CVD diamond films as function of their crystalline quality. J. Electroanal. Chem. 2020, 859, 113811. [Google Scholar] [CrossRef]

- Łoś, S.; Fabisiak, K.; Paprocki, K.; Kozera, W.; Knapowski, T.; Szybowicz, M.; Dychalska, A. The Barrier’s Heights and Its Inhomogeneities on Diamond Silicon Interfaces. Materials 2022, 15, 5895. [Google Scholar] [CrossRef]

- Salerno, R.; Pede, B.; Mastellone, M.; Serpente, V.; Valentini, V.; Bellucci, A.; Trucchi, D.M.; Domenici, F.; Tomellini, M.; Polini, R. Etching kinetics of nanodiamond seeds in the early stages of CVD diamond growth. ACS Omega 2023, 8, 25496–25505. [Google Scholar] [CrossRef] [PubMed]

- Paprocki, K.; Dittmar-Wituski, A.; Trzciński, M.; Szybowicz, M.; Fabisiak, K.; Dychalska, A. The comparative studies of HF CVD diamond films by Raman and XPS spectroscopies. Opt. Mater. 2019, 95, 109251. [Google Scholar] [CrossRef]

- Ballutaud, D.; Jomard, F.; Kociniewski, T.; Rzepka, E.; Girard, H.; Saada, S. Sp3/sp2 character of the carbon and hydrogen configuration in micro-and nanocrystalline diamond. Diam. Relat. Mater. 2008, 17, 451–456. [Google Scholar] [CrossRef]

- Sanders, N.; Kioupakis, E. Phonon-and defect-limited electron and hole mobility of diamond and cubic boron nitride: A critical comparison. Appl. Phys. Lett. 2021, 119, 062101. [Google Scholar] [CrossRef]

- Sharma, G.; Saxena, D.; Roy, M. Electrical and impedance spectral characterisation of ITO/DAG/In device. Synth. Met. 2001, 123, 189–196. [Google Scholar] [CrossRef]

- Sharma, G.; Sangodkar, S.; Roy, M. Study on electrical and photoelectrical behaviour of undoped and doped furazano [3, 4-b] piperazine (FP) thin-film devices. Synth. Met. 1995, 75, 201–207. [Google Scholar] [CrossRef]

- Abdel-Malik, T. Direct current conductivity and thermally stimulated current of β-nickel phthalocyanine films using gold and aluminium electrodes. Int. J. Electron. 1992, 72, 409–418. [Google Scholar] [CrossRef]

- Srivastava, S.; Ratna, V.; Bhattacharyya, R. Temperature dependence of current decay and trap evaluation in thin films of Cds. Inernatl. J. Electron. Theor. Exp. 1970, 29, 269–274. [Google Scholar]

- Nespurek, S.; Sworakowski, J. Use of space-charge-limited current measurements to determine the properties of energetic distributions of bulk traps. J. Appl. Phys. 1980, 51, 2098–2102. [Google Scholar] [CrossRef]

- Mackenzie, K.; Comber, P.L.; Spear, W. The density of states in amorphous silicon determined by space-charge-limited current measurements. Philos. Mag. B 1982, 46, 377–389. [Google Scholar] [CrossRef]

- Padovani, F.; Stratton, R. Field and thermionic-field emission in Schottky barriers. Solid. State Electron. 1966, 9, 695–707. [Google Scholar] [CrossRef]

- Rhoderick, E.H.; Williams, R.H. Metal-Semiconductor Contacts; Clarendon Press: Oxford, UK, 1988. [Google Scholar]

- Liu, J.-l.; Chen, L.-x.; Zheng, Y.-t.; Wang, J.-j.; Feng, Z.-h.; Li, C.-m. Carrier transport characteristics of H-terminated diamond films prepared using molecular hydrogen and atomic hydrogen. Int. J. Miner. Metall. Mater. 2017, 24, 850–856. [Google Scholar] [CrossRef]

- Mort, J.; Machonkin, M.; Okumura, K. Density of states distribution in diamond thin films. Appl. Phys. Lett. 1991, 59, 455–457. [Google Scholar] [CrossRef]

- Al-Douri, A.J.; Al-Shakily, F.; Alnajjar, A.A.; Alias, M.F. The role of dopant concentration on conductivity and mobility of CdTe thin films. Adv. Condens. Matter Phys. 2011, 2011, 910967. [Google Scholar] [CrossRef]

- Zhang, B.; Wan, W.; Liu, Y.; Ge, Y. First-principles study of carrier mobility and strain effect in MX (M = Sn, Pb; X = P, As) monolayers. J. Phys. D Appl. Phys. 2024, 57, 365104. [Google Scholar] [CrossRef]

| Sample | Filament Temp. [K] | Gas Flow Rate [sccm] | Substrate Temp. [K] | CH4/H2 Ratio [%] | Deposition Pressure [mbar] |

|---|---|---|---|---|---|

| PDF34 | 2300 ± 50 | 100 ± 5 | 2.60 | 20 | |

| PDF27 | 2.60 | 80 | |||

| PDF33 | 2.30 | 100 | |||

| PDF20 | 980 ± 30 | 2.35 | 40 | ||

| PDF23 | 2.55 | 60 | |||

| PDF15 | 2.35 | 20 | |||

| PDF22 | 2.75 | 60 |

| Sample | FWHM [cm−1] | Diamond Quality Q [%] | L(220) [nm] |

|---|---|---|---|

| PDF34 | 7.6 | 97.65 | 71 |

| PDF27 | 8.65 | 98.06 | 67 |

| PDF33 | 8.49 | 97.89 | 66 |

| PDF20 | 8.03 | 98.64 | 59 |

| PDF23 | 7.51 | 98.53 | 63 |

| PDF15 | 6.83 | 98.90 | 57 |

| PDF22 | 9.26 | 98.30 | 65 |

| Sample | Ideality Factor n | E00 [meV] | Nt × 1016 [eV−1cm−3] | Mobility μp × 10−2 [cm2/Vs] |

|---|---|---|---|---|

| PDF34 | 6.4 | 159.6 | 8.915 | 0.143 |

| PDF27 | 4.2 | 105.0 | 5.139 | 0.69 |

| PDF33 | 3.6 | 90.1 | 4.850 | 0.501 |

| PDF20 | 2.0 | 52.3 | 0.956 | 1.412 |

| PDF23 | 2.5 | 63.1 | 2.049 | 1.111 |

| PDF15 | 1.6 | 38.5 | 0.519 | 1.867 |

| PDF22 | 4.1 | 101.2 | 3.571 | 1.061 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paprocki, K.; Fabisiak, K.; Łoś, S.; Kozera, W.; Knapowski, T.; Szybowicz, M.; Dychalska, A. The Charge Transport Properties of Polycrystalline CVD Diamond Films Deposited on Monocrystalline Si Substrate. Coatings 2025, 15, 1171. https://doi.org/10.3390/coatings15101171

Paprocki K, Fabisiak K, Łoś S, Kozera W, Knapowski T, Szybowicz M, Dychalska A. The Charge Transport Properties of Polycrystalline CVD Diamond Films Deposited on Monocrystalline Si Substrate. Coatings. 2025; 15(10):1171. https://doi.org/10.3390/coatings15101171

Chicago/Turabian StylePaprocki, Kazimierz, Kazimierz Fabisiak, Szymon Łoś, Wojciech Kozera, Tomasz Knapowski, Mirosław Szybowicz, and Anna Dychalska. 2025. "The Charge Transport Properties of Polycrystalline CVD Diamond Films Deposited on Monocrystalline Si Substrate" Coatings 15, no. 10: 1171. https://doi.org/10.3390/coatings15101171

APA StylePaprocki, K., Fabisiak, K., Łoś, S., Kozera, W., Knapowski, T., Szybowicz, M., & Dychalska, A. (2025). The Charge Transport Properties of Polycrystalline CVD Diamond Films Deposited on Monocrystalline Si Substrate. Coatings, 15(10), 1171. https://doi.org/10.3390/coatings15101171