Microstructural Evolution of Cold-Rolled Type 347H Austenitic Heat-Resistant Steel

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

- (1)

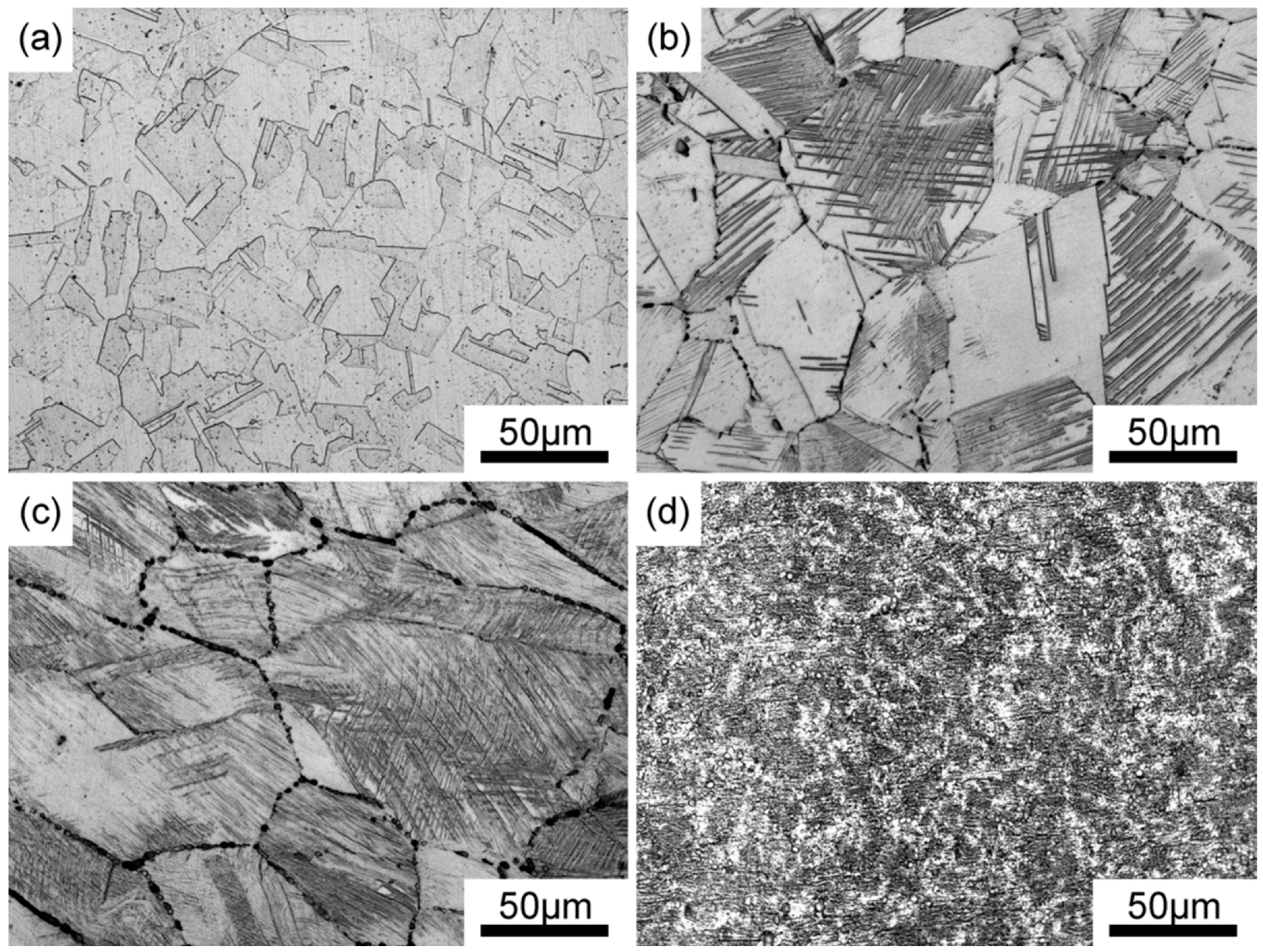

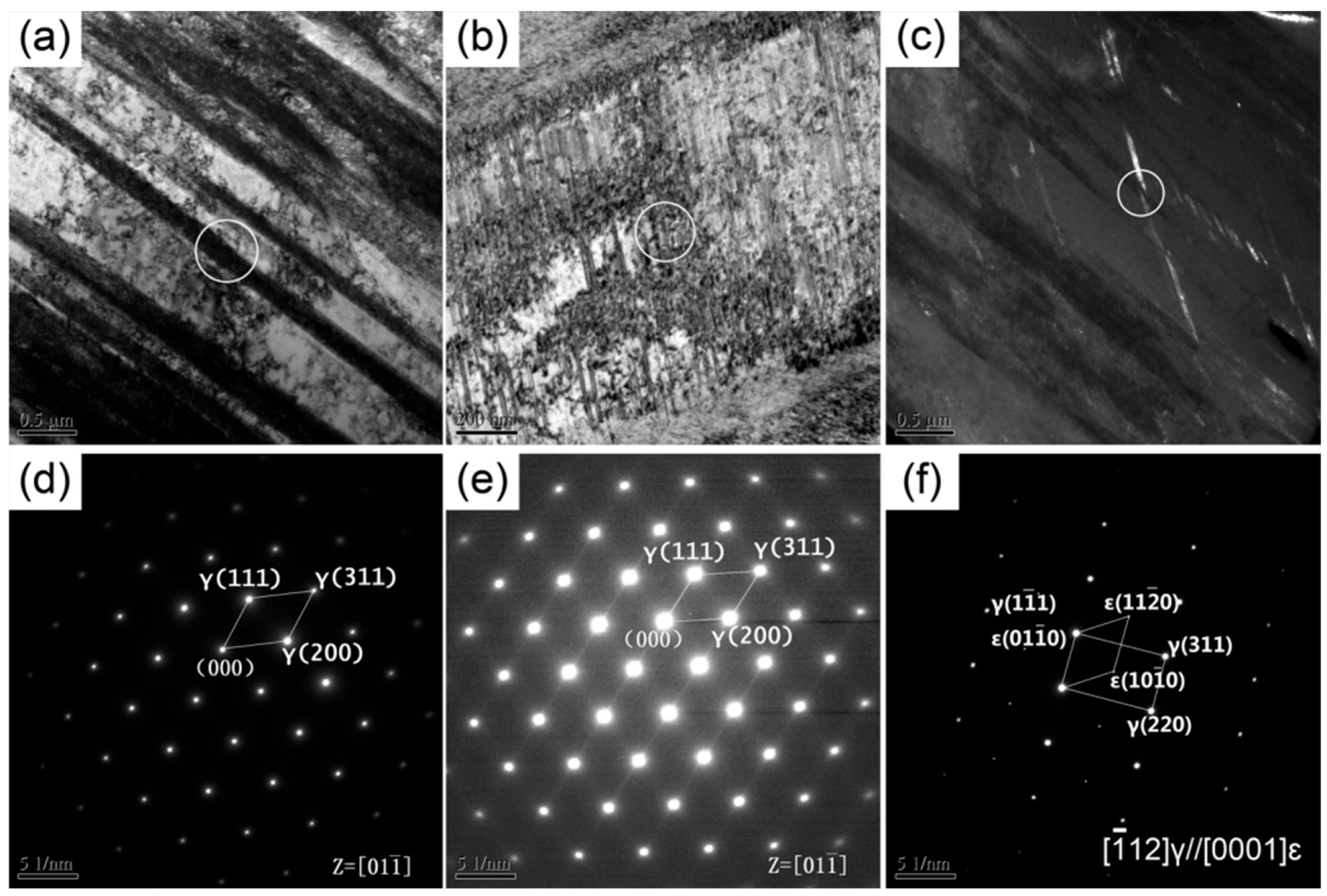

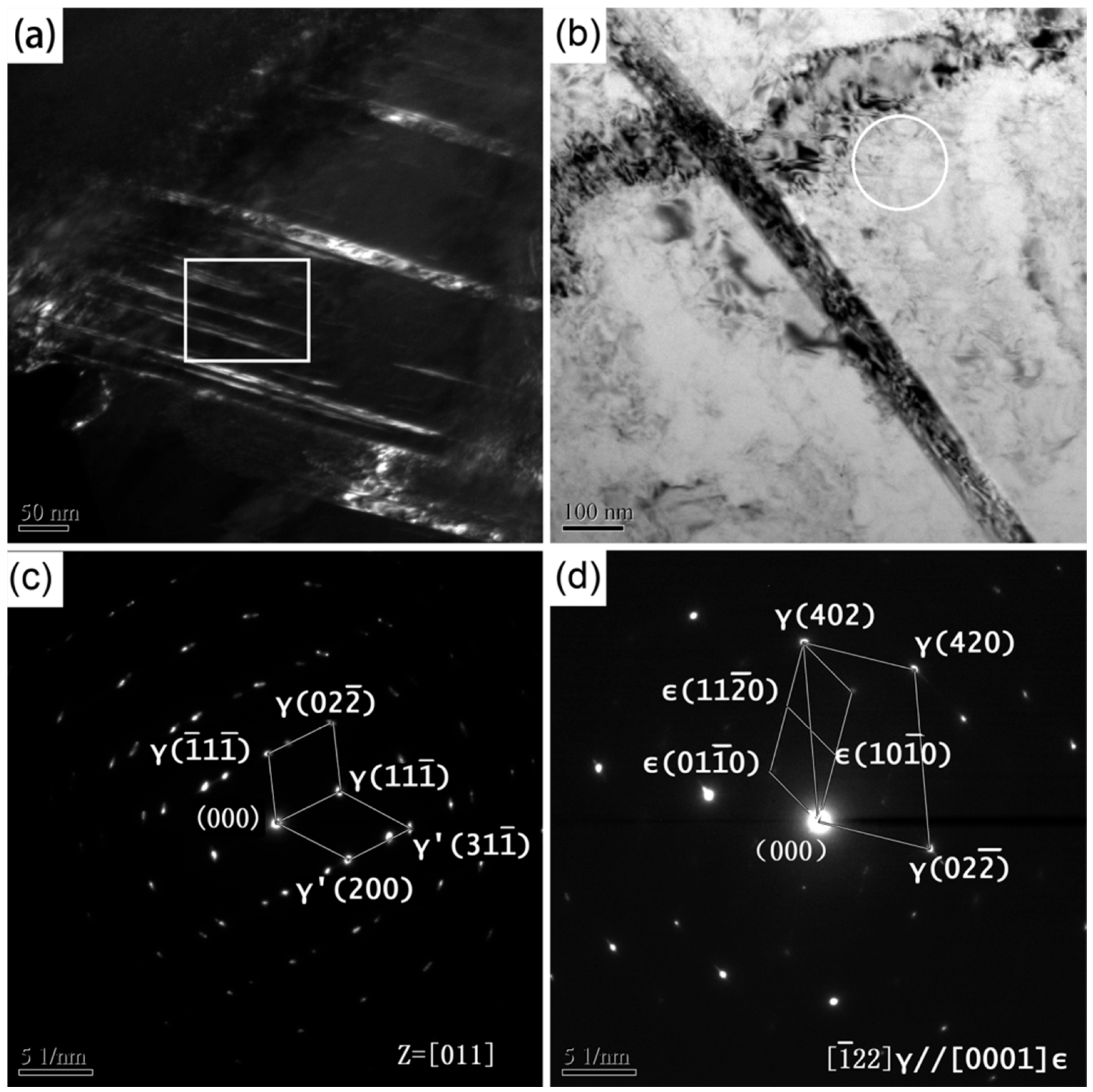

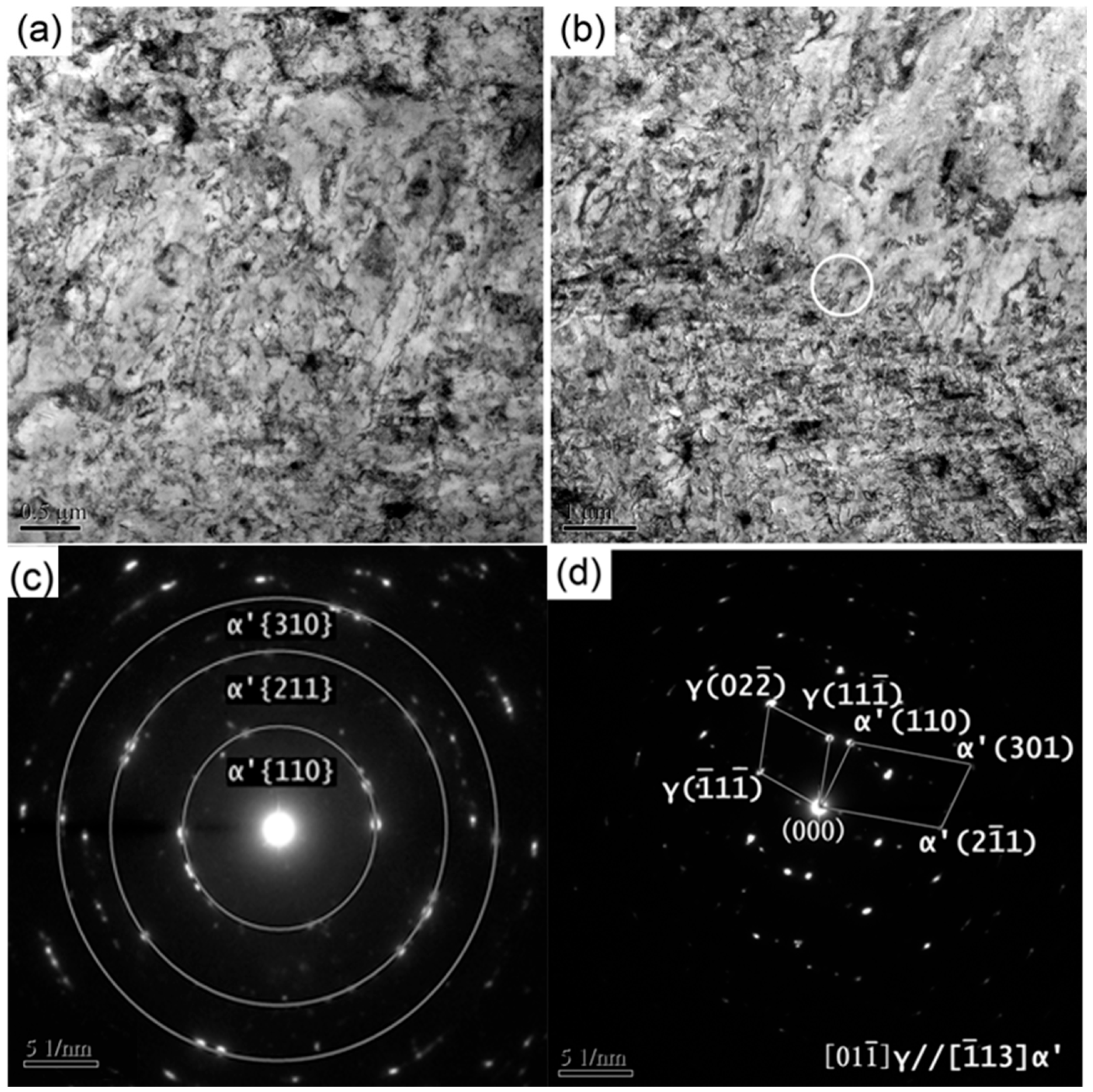

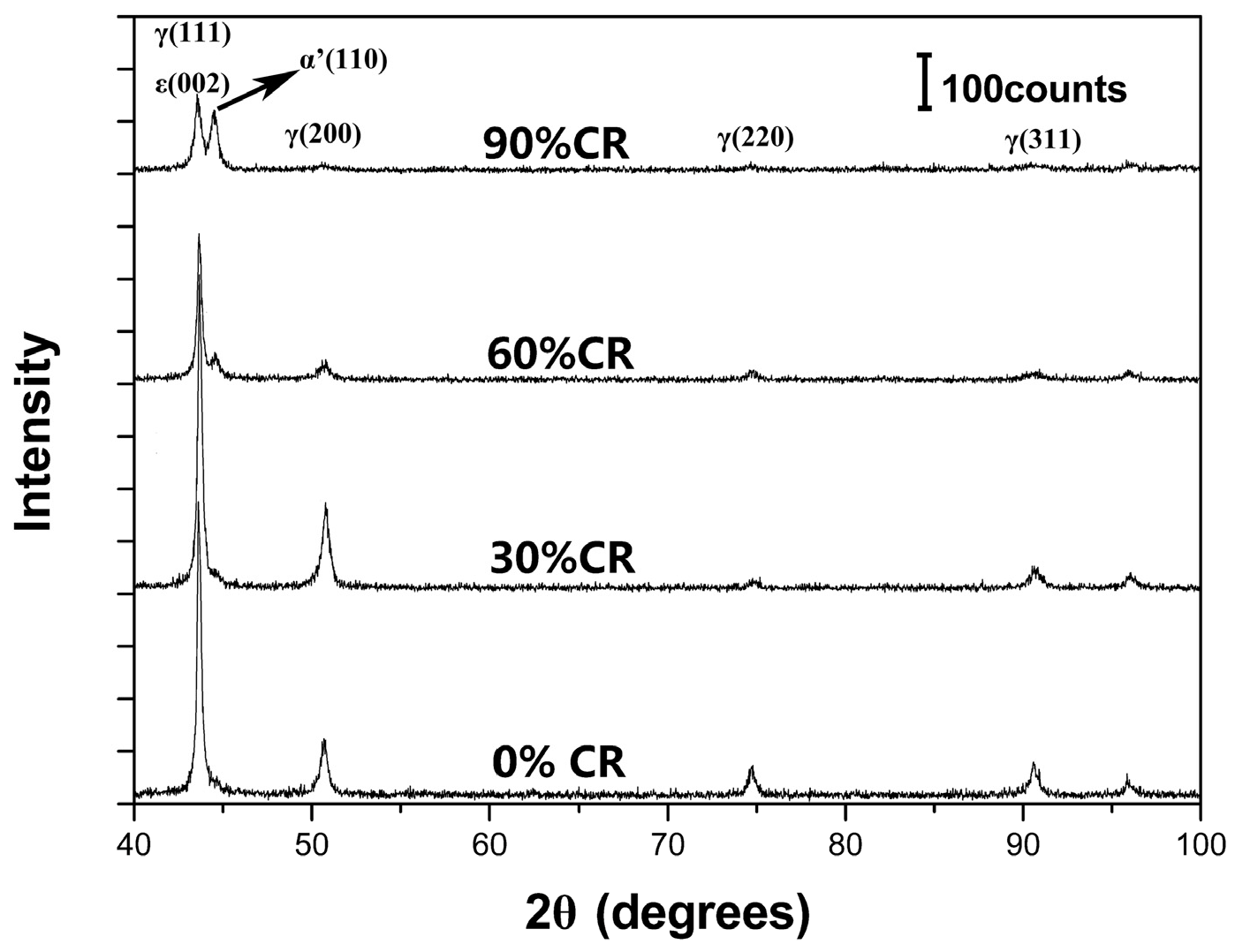

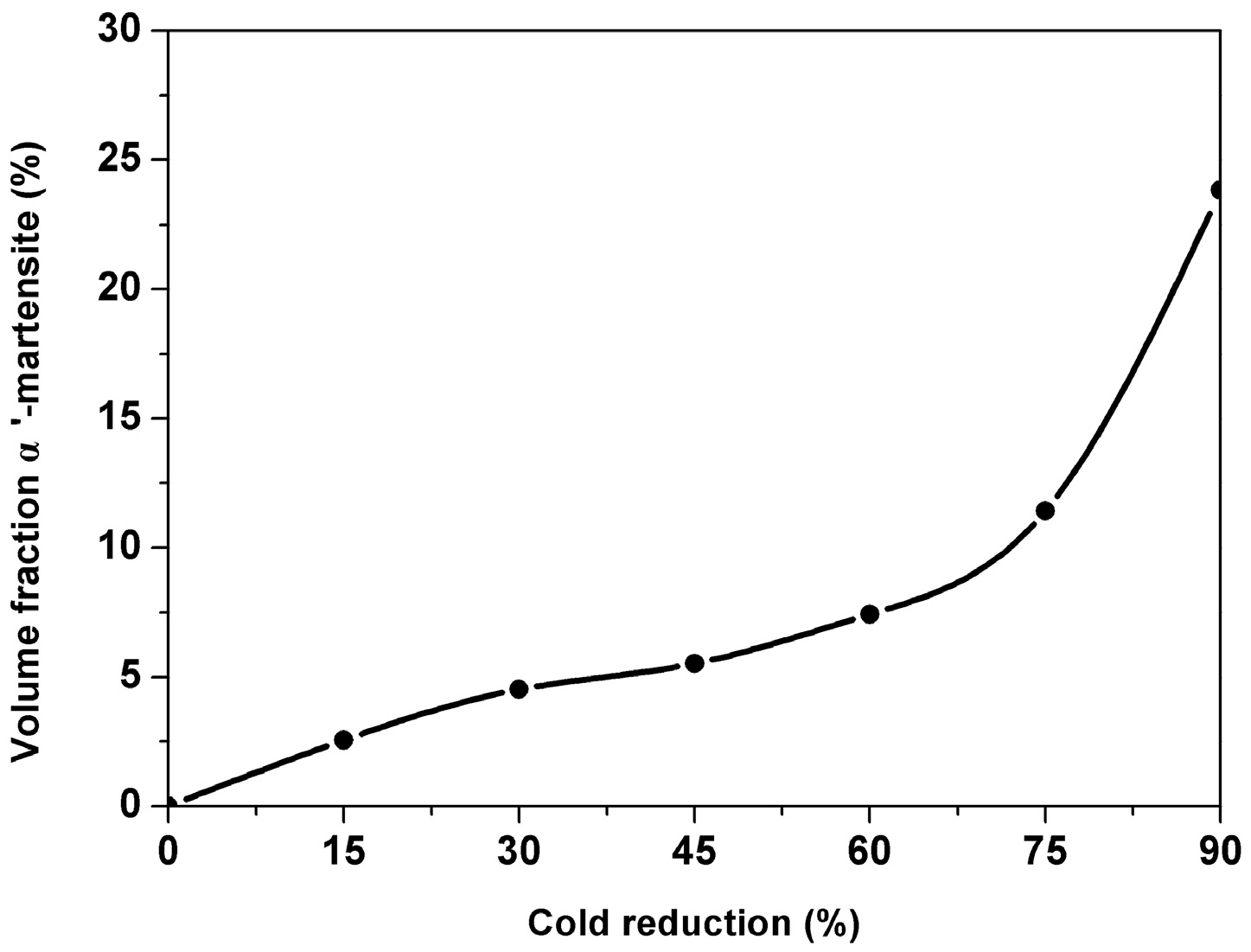

- Cold rolling processing can induce a transition from metastable austenite to deformation-induced martensite. The formation mechanisms include γ (fcc) → ε (hcp), γ (fcc) → mechanical twins, γ (fcc) → ε (hcp) → α ‘(bcc), and γ (fcc) → α′ (bcc).

- (2)

- In the sample with a cold rolling deformation rate of 30%, the austenite { 111 } crystal plane promotes the formation of stacking dislocations through the slip of Shockley’s dislocations. These overlapping stacking dislocation regions undergo partial austenite to ∂ martensite transformation. When the cold rolling deformation reaches 60%, the critical deformation of α′-martensite formation is triggered, and the mechanical twin structure begins to appear in the matrix austenite and a small amount of α′-martensite is formed. When the cold rolling deformation reaches 90%, a significant amount of α′-martensite is produced due to the consumption of ɛ-martensite and the interaction of retained austenite.

- (3)

- It was confirmed by TEM observation that high-density dislocations significantly promoted the formation of α′-martensite. When the cold rolling deformation reached 90%, the content of α′-martensite was the highest and the hardness of the cold-rolled steel sample was increased to 473 HV.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Element | C | Cr | Ni | Nb | N | Mn | P | Mo | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.059 | 17.60 | 10.71 | 0.54 | 0.013 | 1.59 | 0.024 | 0.116 | 0.0008 | Balanced |

| CR (%) | 0 | 15 | 30 | 45 | 60 | 75 | 90 |

| Vα′ (%) | 0 | 2.56 | 4.52 | 5.52 | 7.43 | 11.42 | 23.84 |

References

- Wang, H.; Du, H.; Wei, Y. Precipitation and properties at elevated temperature in austenitic heat-resistant steels—A review. Steel Res. Int. 2021, 92, 2000378. [Google Scholar] [CrossRef]

- Moteshakker, A.; Danaee, I. Microstructure and Corrosion Resistance of Dissimilar Weld-Joints between Duplex Stainless Steel 2205 and Austenitic Stainless Steel 316L. J. Mater. Sci. Technol. 2016, 32, 282–290. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Liu, Y.C.; Zhou, X.S.; Liu, C.X.; Yu, L.M.; Li, C.; Ning, B.Q. Processing maps and microstructural evolution of the type 347H austenitic heat-resistant stainless steel. J. Mater. Res. 2015, 30, 2090–2100. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, C.; Liu, Y.; Guo, Q.; Li, H. Coarsening Behavior of MX Carbonitrides in Type 347H Heat-Resistant Austenitic Steel during Thermal Aging. Int. J. Min. Met. Mater. 2016, 23, 283–293. [Google Scholar] [CrossRef]

- Li, S.N.; Withers, P.J.; Chen, W.Q.; Yan, K. Atomic-scale investigation of the mechanisms of deformation-induced martensitic transformation at ultra-cryogenic temperatures. J. Mater. Sci. Technol. 2025, 210, 138–150. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Shimokawa, T.; Fujii, K.; Niiyama, T. Atomic simulation study of the factors affecting nucleation in deformation-induced martensitic transformation in grains and at grain boundaries in pure iron. Acta Mater. 2024, 265, 119629. [Google Scholar] [CrossRef]

- Lee, S.-J.; Park, Y.-M.; Lee, Y.-K. Reverse Transformation Mechanism of Martensite to Austenite in a Metastable Austenitic Alloy. Mater. Sci. Eng. A 2009, 515, 32–37. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Kaibyshev, R.; Haase, C.; Molodov, D.A. Effect of Cold Rolling on Recrystallization and Tensile Behavior of a High-Mn Steel. Mater. Charact. 2016, 112, 180–187. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Neto, J.M.; da Silva, M.R.; Vasconcelos, I.F.; de Abreu, H.F.G. Magnetic Properties and A′ Martensite Quantification in an AISI 301LN Stainless Steel Deformed by Cold Rolling. Mater. Charact. 2008, 59, 901–904. [Google Scholar] [CrossRef]

- Xie, A.; Chen, S.H.; Rong, L.J. Elucidating the contribution of deformation-induced martensitic transformation and deformation twinning to dynamic strain aging in Fe-Cr-Ni metastable austenitic stainless steel. Mater. Charact. 2025, 225, 115204. [Google Scholar] [CrossRef]

- Shakhova, I.; Dudko, V.; Belyakov, A.; Tsuzaki, K.; Kaibyshev, R. Effect of Large Strain Cold Rolling and Subsequent Annealing on Microstructure and Mechanical Properties of an Austenitic Stainless Steel. Mater. Sci. Eng. A 2012, 545, 176–186. [Google Scholar] [CrossRef]

- Mehranpour, M.S.; Rasooli, N.; Kim, H.S.; Langdon, T.G.; Shahmir, H. Deformation-induced martensitic transformations: A strategy forovercoming the strength-ductility trade-off in high-entropy alloys. Curr. Opin. Solid State Mater. Sci. 2024, 31, 101177. [Google Scholar] [CrossRef]

- Das, A.; Sivaprasad, S.; Ghosh, M.; Chakraborti, P.C.; Tarafder, S. Morphologies and Characteristics of Deformation Induced Martensite during Tensile Deformation of 304 LN Stainless Steel. Mater. Sci. Eng. A 2008, 486, 283–286. [Google Scholar] [CrossRef]

- Sun, G.S.; Lv, S.L.; Zhang, T.F.; Xiao, L.R.; Peng, Y.; Zhu, Y.T.; Wang, K.H.; Liu, J.Z. Decoupling the orientation dependence of deformation-induced martensitic transformation via single-crystal micropillar compression. J. Mater. Sci. Technol. 2026, 244, 80–87. [Google Scholar] [CrossRef]

- Kisko, A.; Misra, R.D.K.; Talonen, J.; Karjalainen, L.P. The Influence of Grain Size on the Strain-Induced Martensite Formation in Tensile Straining of an Austenitic 15Cr–9Mn–Ni–Cu Stainless Steel. Mater. Sci. Eng. A 2013, 578, 408–416. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhou, X.; Liu, C.; Yu, J.; Huang, Y.; Li, H.; Li, W. Precipitation and Hot Deformation Behavior of Austenitic Heat-Resistant Steels: A Review. J. Mater. Sci. Technol. 2017, 33, 1448–1456. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mehranpour, M.S.; Heydarinia, A.; Kalhor, A.; Lee, J.H. Deformation-induced martensitic transformation kinetics in TRIP-assisted steels and high-entropy alloys. Acta Mater. 2024, 280, 120354. [Google Scholar] [CrossRef]

- Solano-Alvarez, W.; Abreu, H.F.G.; da Silva, M.R.; Peet, M.J. Phase Quantification in Nanobainite via Magnetic Measurements and X-Ray Diffraction. J. Magn. Magn. Mater. 2015, 378, 200–205. [Google Scholar] [CrossRef]

- Gilapa, L.C.M.; de Oliveira, C.A.S.; da Silva, M.R. Effect of Copper on the Formation of Strain-Induced Martensite in Two Austenitic Stainless Steels AISI 304. Mater. Sci. Eng. A 2015, 622, 212–218. [Google Scholar] [CrossRef]

- Ahn, T.-H.; Lee, S.B.; Park, K.-T.; Oh, K.H.; Han, H.N. Strain-Induced ε-Martensite Transformation during Nanoindentation of High-Nitrogen Steel. Mater. Sci. Eng. A 2014, 598, 56–61. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Li, Y.M.; Liu, Y.C.; Guo, Q.Y.; Liu, C.X.; Yu, L.M.; Li, C.; Li, H.J. Precipitation behavior of type 347H heat-resistant austenitic steel during long-term high-temperature aging. J. Mater. Res. 2015, 30, 3642–3652. [Google Scholar] [CrossRef]

- Yanushkevich, Z.; Belyakov, A.; Haase, C.; Molodov, D.A.; Kaibyshev, R. Structural/Textural Changes and Strengthening of an Advanced High-Mn Steel Subjected to Cold Rolling. Mater. Sci. Eng. A 2016, 651, 763–773. [Google Scholar] [CrossRef]

- Jee, K.K.; Han, J.H.; Jang, W.Y. Measurement of Volume Fraction of ε Martensite in Fe–Mn Based Alloys. Mater. Sci. Eng. A 2004, 378, 319–322. [Google Scholar] [CrossRef]

- Schramm, R.E.; Reed, R.P. Stacking Fault Energies of Seven Commercial Austenitic Stainless Steels. Met. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Hedayati, A.; Najafizadeh, A.; Kermanpur, A.; Forouzan, F. The Effect of Cold Rolling Regime on Microstructure and Mechanical Properties of AISI 304L Stainless Steel. J. Mater. Process. Technol. 2010, 210, 1017–1022. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Sicupira, F.L.; Malheiros, L.R.C.; Kawasaki, M.; Santos, D.B.; Langdon, T.G. Formation of Epsilon Martensite by High-Pressure Torsion in a TRIP Steel. Mater. Sci. Eng. A 2015, 625, 114–118. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, X.; Zhang, M.; Li, Q.; Niu, L.; Wang, Z.; Xu, Z.; Wang, W.; Li, P.; Chen, B.; et al. Microstructural Evolution of Cold-Rolled Type 347H Austenitic Heat-Resistant Steel. Coatings 2025, 15, 1157. https://doi.org/10.3390/coatings15101157

Li Y, Liu X, Zhang M, Li Q, Niu L, Wang Z, Xu Z, Wang W, Li P, Chen B, et al. Microstructural Evolution of Cold-Rolled Type 347H Austenitic Heat-Resistant Steel. Coatings. 2025; 15(10):1157. https://doi.org/10.3390/coatings15101157

Chicago/Turabian StyleLi, Yanmo, Xiangqian Liu, Minghui Zhang, Qiulong Li, Long Niu, Zhihua Wang, Zhe Xu, Wei Wang, Peiyue Li, Bin Chen, and et al. 2025. "Microstructural Evolution of Cold-Rolled Type 347H Austenitic Heat-Resistant Steel" Coatings 15, no. 10: 1157. https://doi.org/10.3390/coatings15101157

APA StyleLi, Y., Liu, X., Zhang, M., Li, Q., Niu, L., Wang, Z., Xu, Z., Wang, W., Li, P., Chen, B., Liu, C., & Sun, Z. (2025). Microstructural Evolution of Cold-Rolled Type 347H Austenitic Heat-Resistant Steel. Coatings, 15(10), 1157. https://doi.org/10.3390/coatings15101157