Research on Intermittent Tensile Deformation to Improve the Properties of Austenitic Stainless Steel

Abstract

1. Introduction

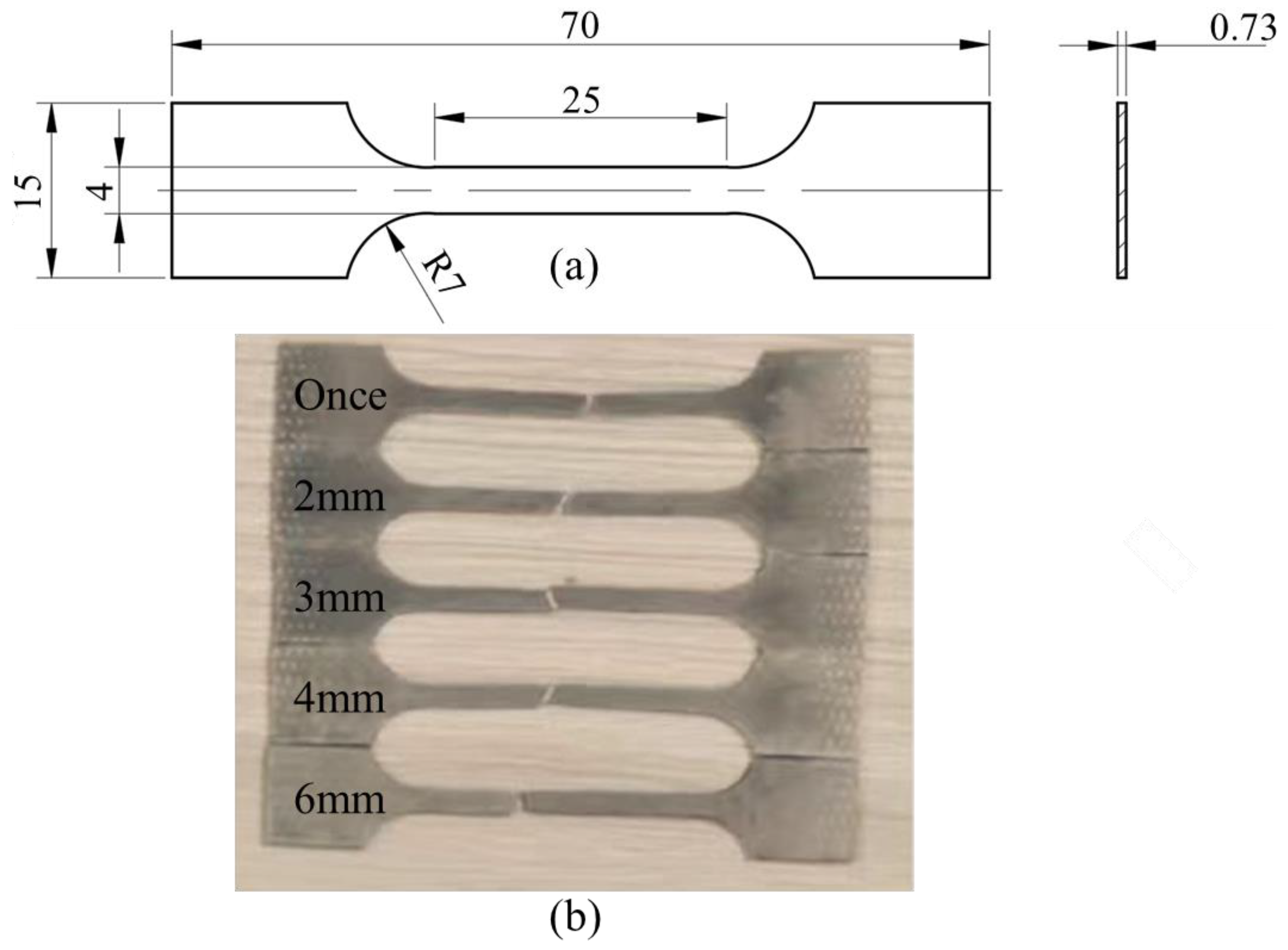

2. Materials and Methods

3. Results

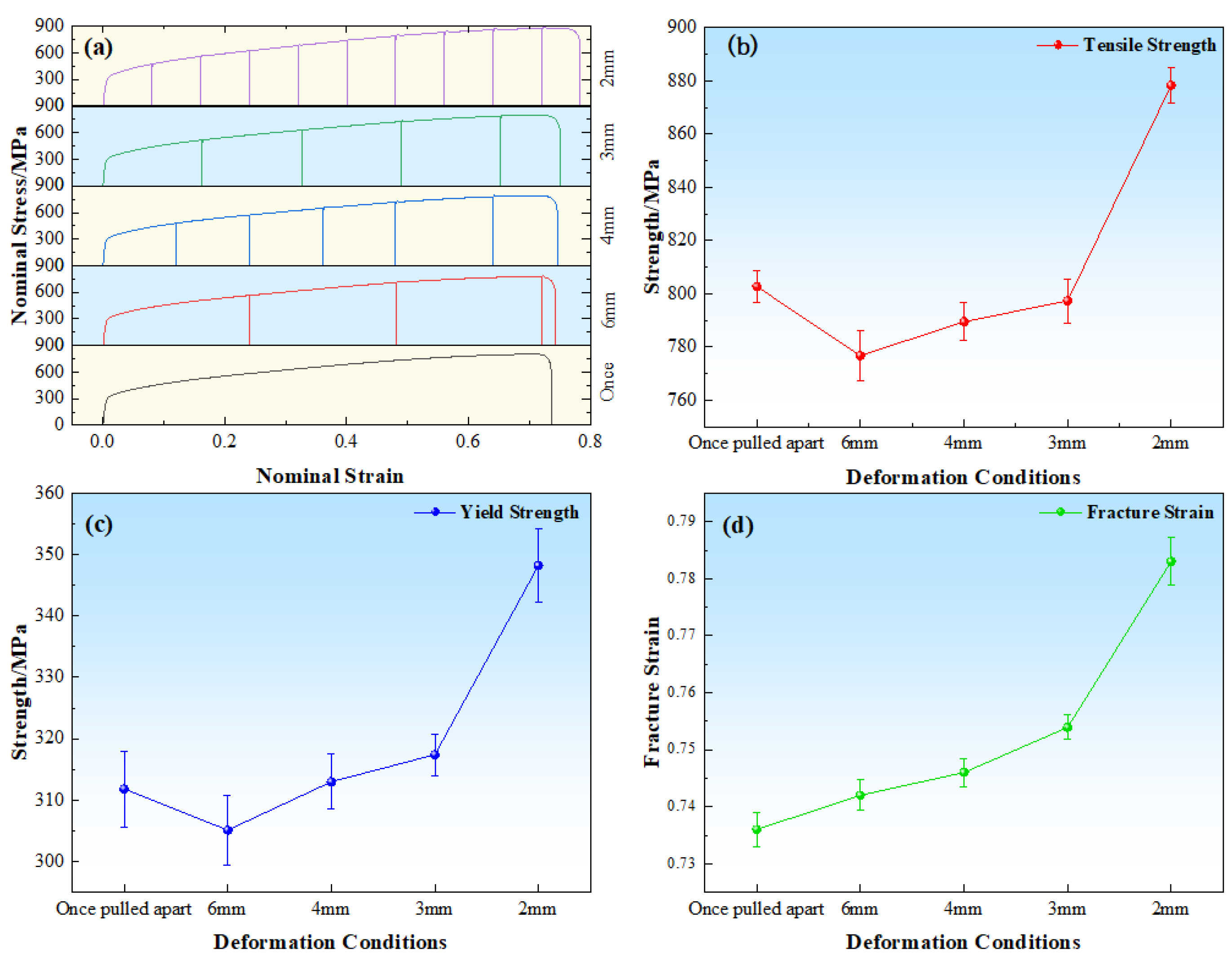

3.1. Mechanical Properties

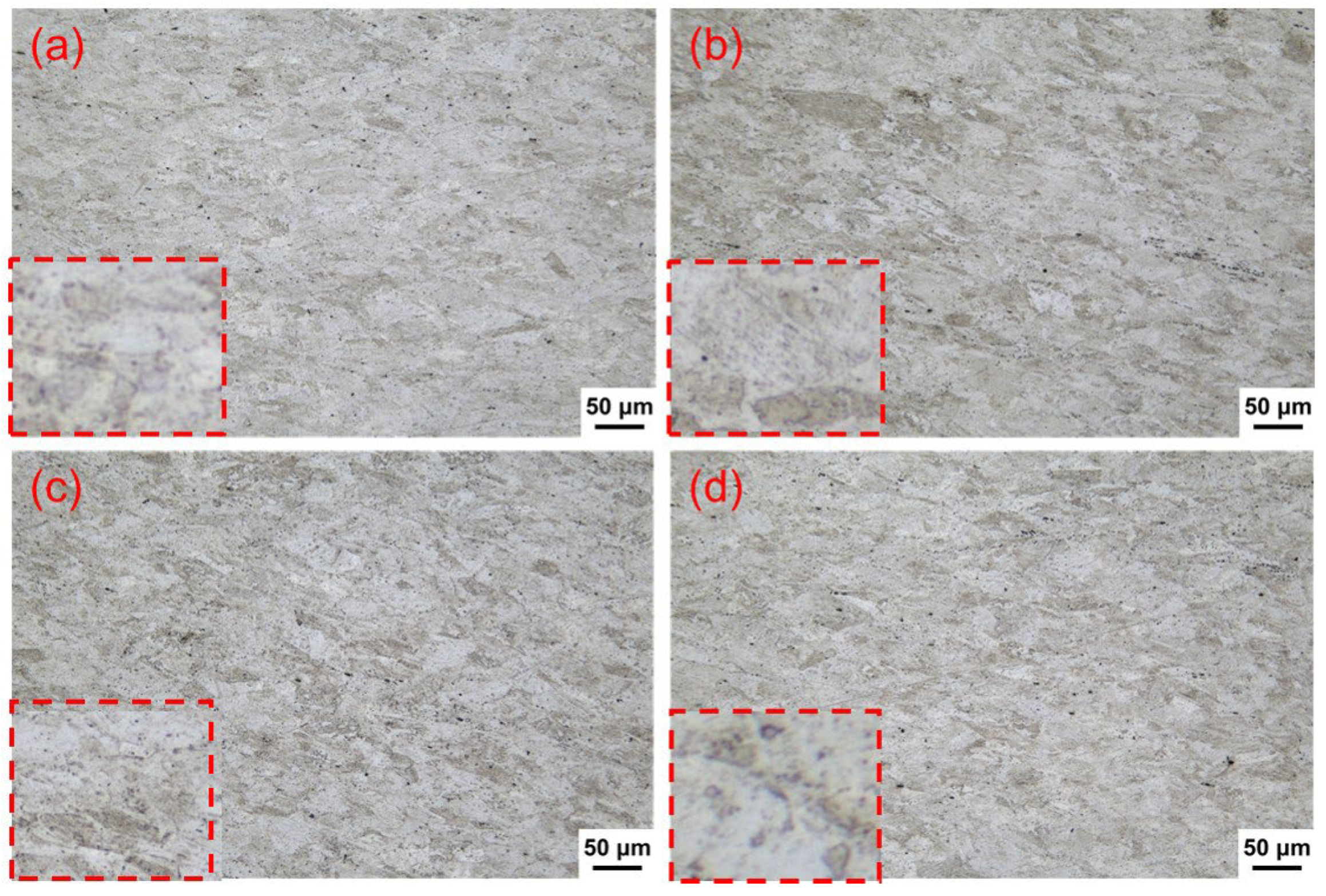

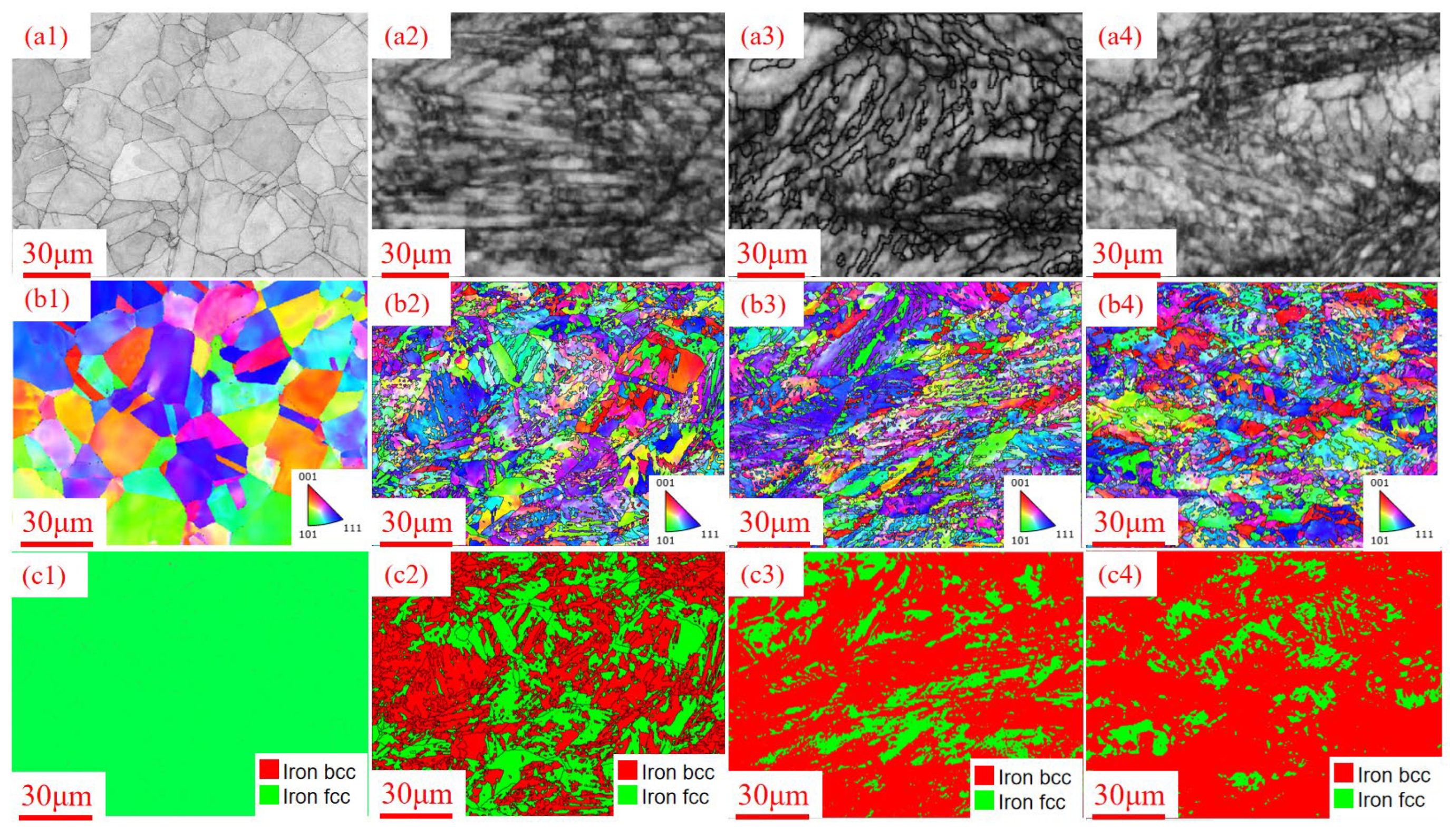

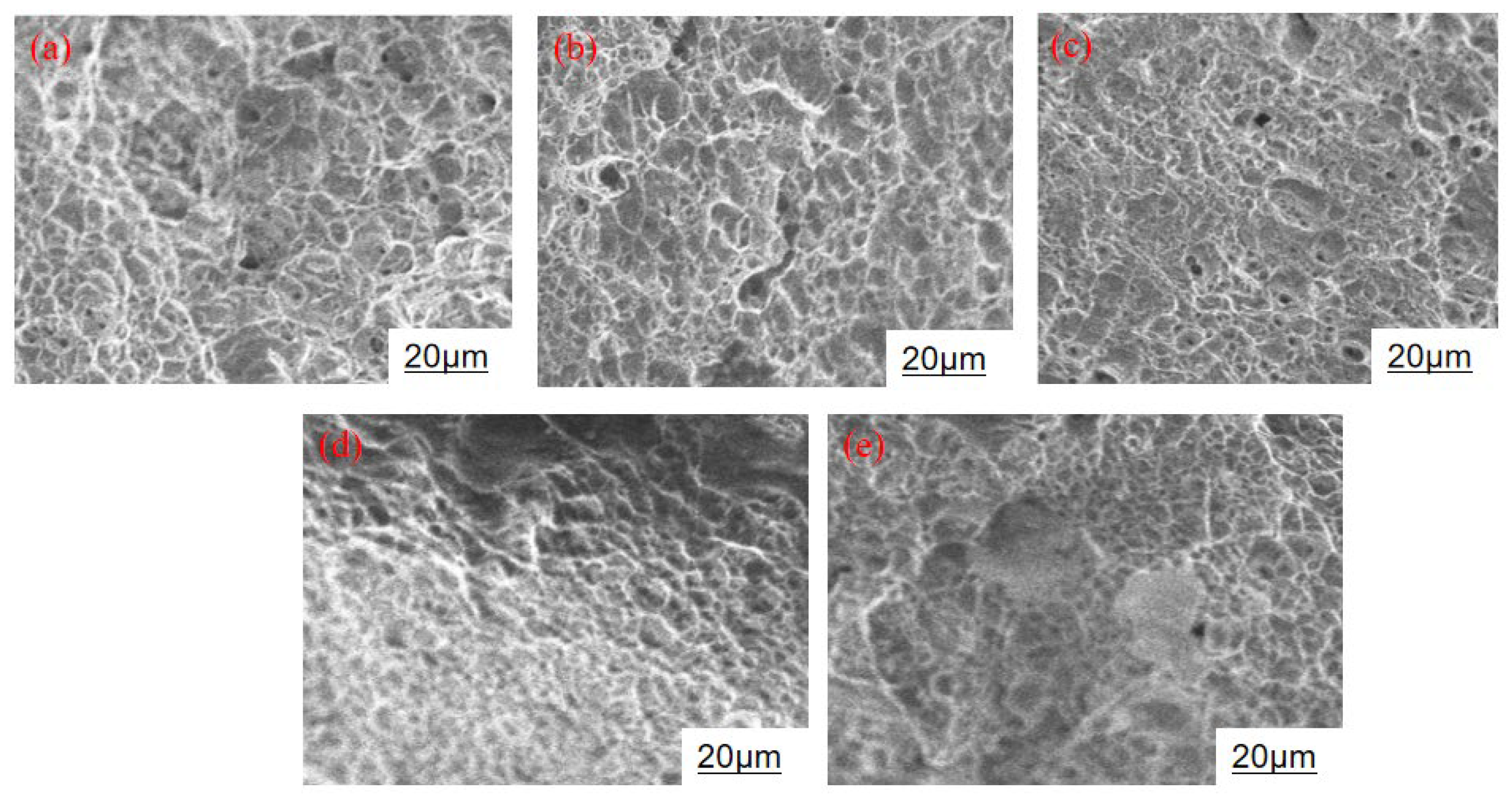

3.2. Microstructure

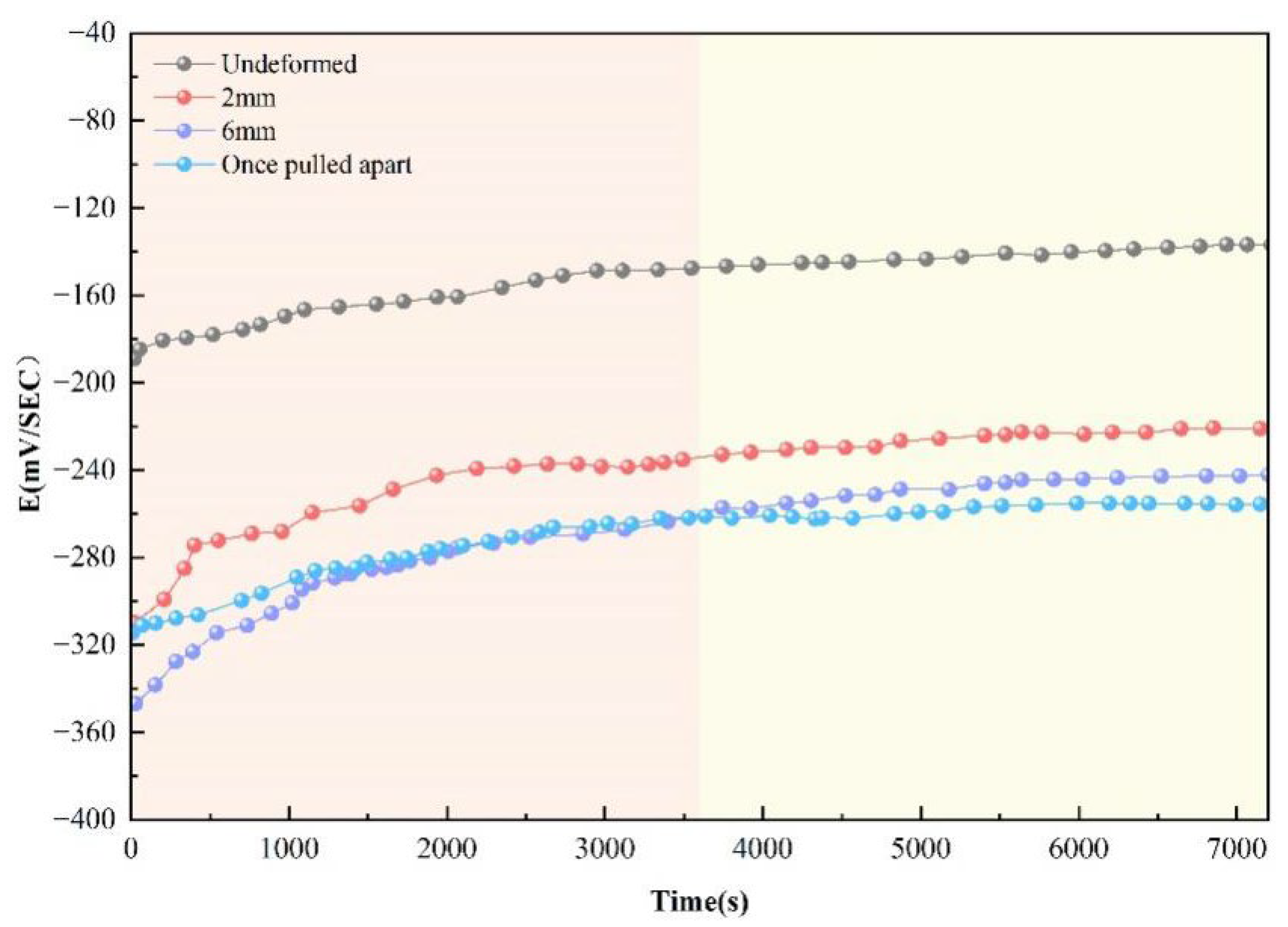

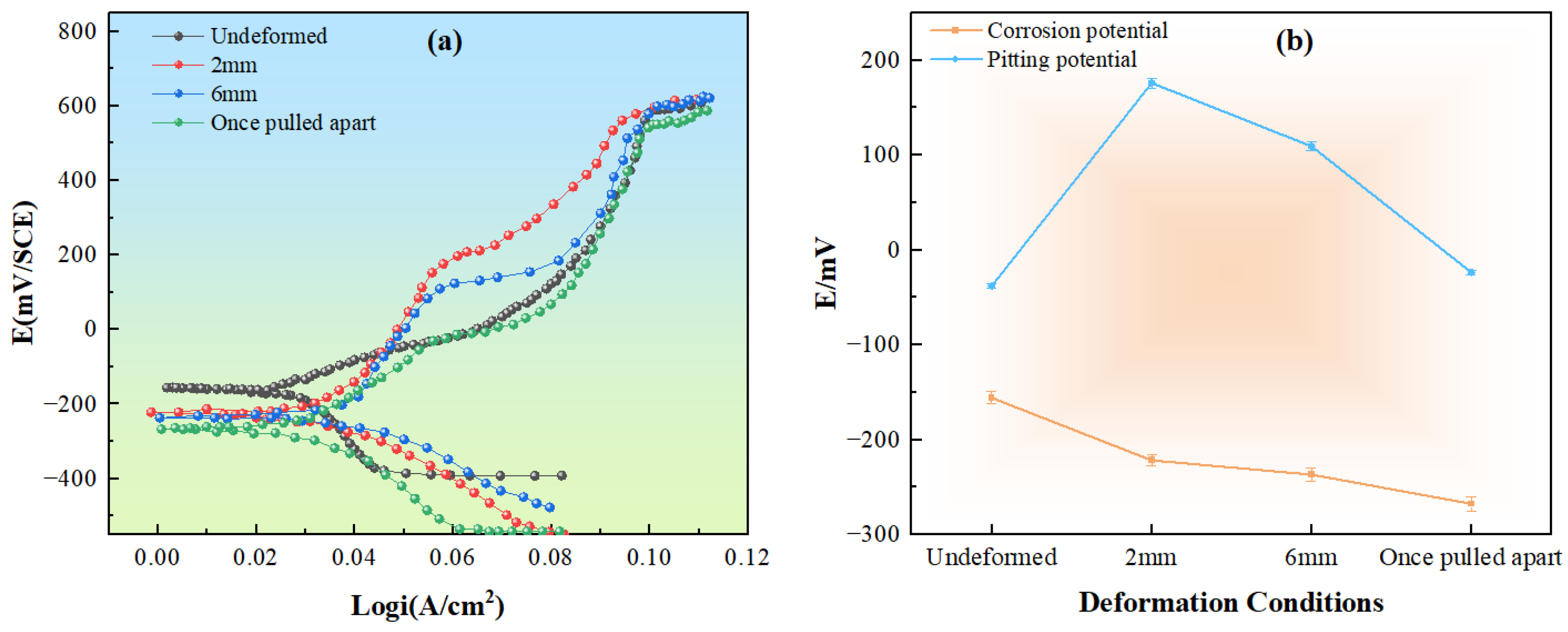

3.3. Corrosion Performance

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, D.D. Effect of Cold Rolling Deformation on microstructure and mechanical properties of 0Cr18Ni9 austenitic stainless steel. Hot Work. Technol. 2024, 53, 84–90. [Google Scholar] [CrossRef]

- Zhou, L.J.; Wen, S.L.; Qi, X.; Zhang, Y. Research on process parameters of friction stir welding for 304 stainless steel. Chem. Equip. Technol. 2025, 46, 25–28. [Google Scholar] [CrossRef]

- Qi, Y.T.; Qin, J.J.; Liu, J.; Zhang, Y. Numerical simulation study on hot stamping of 304 stainless steel. China Met. Equip. Manuf. Technol. 2025, 60, 123–127. [Google Scholar] [CrossRef]

- Xu, Q.H.; Zhu, J.X.; Zong, Y.; Liu, L.; Zhu, X.; Zhang, F.; Luan, B. Effect of drawing and annealing on the microstructure and mechanical properties of 304 austenitic stainless steel wire. Mater. Res. Express 2021, 8, 126530. [Google Scholar] [CrossRef]

- Tao, H.M.; Cai, Y.F.; Li, Z.; Xiu, H.; Tong, Z.; Ding, M. Research on the synergistic evolution law of microstructure and properties of deformed austenitic stainless steel. Coatings 2025, 15, 845. [Google Scholar] [CrossRef]

- Xie, Q.F.; Zhang, H.X.; Wang, S.B.; Yan, Z. Research on the internal and external synergistic strengthening mechanism of fatigue performance of austenitic stainless steel. Int. J. Fatigue 2025, 197, 108948. [Google Scholar] [CrossRef]

- Duan, H.Y.; Di, R.Z.; Yue, S.Q.; Gao, Y. Grain size base low cycle fatigue life prediction model for 304 austenitic stainless steel. Mater. Today Commun. 2025, 42, 111537. [Google Scholar] [CrossRef]

- Yuan, Z.; Huo, S.H. The effect of the pre-strain process on the mechanical properties, microstructure, fatigue life, and fracture mode of 304 austenitic stainless steel. Journal of Materials Eng. Perform. 2023, 32, 4446–4455. [Google Scholar] [CrossRef]

- Yang, W.; Shen, Y.; Chen, S.; Wang, X.; Shu, D.; Wang, H. Study of the constitutive equations of austenitic stainless steels under high strain rate loading considering phase transformation effects. JOM 2025, 77, 2875–2887. [Google Scholar] [CrossRef]

- Qin, X. Hydrogen Embrittlement and Corrosion Behavior of Low-Temperature Carburized Austenitic Stainless Steel; Hydrogen Embrittlement and Corrosion Behavior of Low-Temperature Carburized Austenitic Stainless Steel-All Databases; Chalmers Tekniska Hogskola: Gothenburg, Sweden, 2023. [Google Scholar]

- De Oliveira, D.A.; Brito, P.P.; de Castro Magalhães, F.; Cangussu, V.M.; Azzi, P.C.; Ardisson, J.D.; da Silva Rocha, A.; Abrao, A.M. Influence of deep rolling on the a’-martensite formation in the subsurface, geometrically necessary dislocations and corrosion resistance of austenitic stainless steel AISI 304. Surf. Coat. Technol. 2024, 487, 131011. [Google Scholar] [CrossRef]

- Lu, Z.M.; Lin, S.K.; Liang, H.; Xu, C.; Wei, S. Effects of thermal laser shock peening on stress corrosion susceptibility of 304 stainless steel. J. Mater. Eng. Perform. 2024, 33, 12259–12266. [Google Scholar] [CrossRef]

- Gao, Y.; Shao, F.; Fan, P.; Xu, Q.; Xie, X. Effect of internal support on the tensile properties and fracture mode of 304 stainless steel thin-walled tubes. Materials 2021, 14, 172. [Google Scholar] [CrossRef] [PubMed]

- Sabzi, M.; Far, S.M.; Dezfuli, S.M. Characterisation of microstructure, mechanical properties and fracture mode of the dissimilar joining of AISI 304 stainless steel and DP780 dual phase steel by resistance spot welding. Int. J. Mater. Prod. Technol. 2019, 59, 3–15. [Google Scholar] [CrossRef]

- Lv, N.X.; Fu, A.Q.; Liu, H.W.; Lv, W.; Gao, Y.; Bai, H.; Song, S.; Yin, C.; Liang, X.; Xu, Z. Influence of oxygen partial pressure on the passivation and depassivation of super 13Cr stainless steel in high temperature and CO2 rich environment. Sci. Rep. 2024, 14, 28147. [Google Scholar] [CrossRef]

- Li, Q.-D.; Ran, D.; Zhai, F.-Q.; Guo, W.-H.; Gong, X.-F.; Ni, R.; Jiang, Y.; Gong, X.-L.; Dai, J.; Meng, H.-M.; et al. Effect of CO32− on the electrochemical behaviour of 14Cr12Ni3Mo2VN stainless steel in a sodium chloride solution. Int. Sci. 2020, 15, 2973–2986. [Google Scholar] [CrossRef]

- Li, Q.D.; Meng, H.M.; Randou; Gong, X.; Long, B.; Ni, R.; Gong, X.; Dai, J. Research on the corrosion behavior of 14Cr12Ni3Mo2VN stainless steel in different concentrations of nacl solution. Int. J. Electrochem. Sci. 2020, 15, 109–120. [Google Scholar] [CrossRef]

- Zhang, S.H.; Huang, Y.N.; Wang, Y.L. Influence of reversed austenite on the properties of a 13Cr4NiMo ultra-low carbon martensitic stainless steel in different environments. Mater. Corros. Werkst. Und Korros. 2022, 73, 358–366. [Google Scholar] [CrossRef]

- Man, C.; Dong, C.F.; Kong, D.C.; Wang, L.; Li, X. Beneficial effect of reversed austenite on the intergranular corrosion resistance of martensitic stainless steel. Corros. Sci. 2019, 151, 108–121. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, S.J.; Kang, J.H. Effects of short-range ordering and stacking fault energy on tensile behavior of nitrogen-containing austenitic stainless steels. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 836, 142730. [Google Scholar] [CrossRef]

- Meng, L.X.; Li, W.Q.; Zhang, Q.F.; Zheng, L.; Shi, Q.; Ma, J.; Liang, W.; Lu, H. Deformation behavior and fracture mechanisms of 430 ferritic stainless steel after dual-phase zone annealing via quasi in-situ tensile testing. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2025, 920, 147561. [Google Scholar] [CrossRef]

- Wang, W.X.; Wang, J.J.; Wang, Q.; Huang, X.; Lu, G.; Liu, Y.; Liu, C. Ferrite-austenite synergistic deformation behavior in a 2205 duplex stainless steel containing equiaxed austenite domains. Mater. Charact. 2023, 205, 113363. [Google Scholar] [CrossRef]

- Ye, W.H.; Liu, P.R.; Li, D.I.; Xu, L.; Qiao, L. Effect of tensile elastic stress on the electrochemical passivation behaviour of cold-rolled 2205 duplex stainless steel. Corros. Sci. 2025, 248, 112794. [Google Scholar] [CrossRef]

- Zhao, L.D.; Zang, X.M.; Pang, Q.H.; Xu, M.; Li, W.; Mo, J. Effects of pre-deformation on microstructure and corrosion resistance of 304L Cu-containing austenitic stainless steel. J. Mater. Eng. Perform. 2025, 34, 20212–20222. [Google Scholar] [CrossRef]

- Wang, D.C.; Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, D.X.; Sun, X.Y. Cavitation erosion and corrosion-cavitation synergism behaviour of CoCrFeNiMnTix high entropy alloy coatings prepared by laser cladding. Corros. Eng. Sci. Technol. 2023, 58, 766–774. [Google Scholar] [CrossRef]

- Hu, J.Z.; Hu, X.; Geng, B.Y.; Yang, J.R. Coordination of cerium salts in electrochemical passivation of stainless steel. Equip. Environ. Eng. 2025, 22, 112–119. [Google Scholar]

- Gong, K.; Yang, M.S.; Liu, C.J.; Shen, X.; Xiao, L.; Li, M.; Mao, F. Synergistic effect of chloride ions and surface film on depassivation mechanism of Q355B steel in simulated concrete pore solution. J. Build. Eng. 2023, 78, 107742. [Google Scholar] [CrossRef]

- Yu, K.P.; Chen, X.L.; Ye, K.Q.; Huang, M. Counterintuitive passivation role of manganese in stainless steel under high potential in neutral NaCl solution. Corros. Sci. 2025, 246, 112756. [Google Scholar] [CrossRef]

- Yue, X.Q.; Larsson, A.; Tang, H.J.; Grespi, A.; Scardamaglia, M.; Shavorskiy, A.; Krishnan, A.; Lundgren, E.; Pan, J. Synchrotron-based near ambient-pressure X-ray photoelectron spectroscopy and electrochemical studies of passivation behavior of N- and V-containing martensitic stainless steel. Corros. Sci. 2023, 214, 111018. [Google Scholar] [CrossRef]

- Pei, W.; Yang, S.G.; Cao, K.; Zhao, A. Effect of annealing temperature on mechanical properties and work hardening of nickel-saving stainless steel. Materials 2023, 16, 3988. [Google Scholar] [CrossRef]

- Takeshita, K.; Ogawa, T.; Sun, F.; Adachi, Y. The initial grain size effect on the tensile-deformed microstructure in type 310S austenitic stainless steel. Mater. Lett. 2023, 314, 134285. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 304 | 0.07 | 0.33 | 1.13 | 0.039 | 0.022 | 18.09 | 8.06 |

| Specimen | Fracture Strain | Yield Strength /MPa | Tensile Strength /MPa |

|---|---|---|---|

| Once pulled apart | 0.736 ± 0.0030 | 783.2 ± 7.1 | 311.8 ± 6.2 |

| 6 mm | 0.742 ± 0.0027 | 776.7 ± 9.3 | 305.1 ± 5.7 |

| 4 mm | 0.746 ± 0.0025 | 789.5 ± 7.1 | 313.0 ± 4.5 |

| 3 mm | 0.751 ± 0.0022 | 797.3 ± 8.2 | 317.4 ± 3.4 |

| 2 mm | 0.783 ± 0.0042 | 797.3 ± 8.2 | 348.2 ± 5.9 |

| Specimen | Epit (mV) | ipas (μA/cm2) | Ecor (mV) | icor (nA/cm2) |

|---|---|---|---|---|

| Undeformed | −37.94 ± 2.7 | 0.199 ± 0.0008 | −155.94 ± 6.5 | 0.794 ± 0.0016 |

| 2mm | 175.98 ± 5.3 | 0.316 ± 0.0016 | −221.88 ± 5.1 | 1.002 ± 0.0020 |

| 6mm | 109.34 ± 4.5 | 0.399 ± 0.002 | −236.99 ± 6.9 | 1.122 ± 0.0020 |

| Once pulled apart | −23.73 ± 2.6 | 0.501 ± 0.004 | −267.80 ± 7.4 | 1.259 ± 0.0024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, H.; Cai, Y.; Huang, Y.; Wu, X.; Tong, Z.; Ding, M. Research on Intermittent Tensile Deformation to Improve the Properties of Austenitic Stainless Steel. Coatings 2025, 15, 1158. https://doi.org/10.3390/coatings15101158

Tao H, Cai Y, Huang Y, Wu X, Tong Z, Ding M. Research on Intermittent Tensile Deformation to Improve the Properties of Austenitic Stainless Steel. Coatings. 2025; 15(10):1158. https://doi.org/10.3390/coatings15101158

Chicago/Turabian StyleTao, Huimin, Yafang Cai, Yong Huang, Xiaoliang Wu, Zeqi Tong, and Mingming Ding. 2025. "Research on Intermittent Tensile Deformation to Improve the Properties of Austenitic Stainless Steel" Coatings 15, no. 10: 1158. https://doi.org/10.3390/coatings15101158

APA StyleTao, H., Cai, Y., Huang, Y., Wu, X., Tong, Z., & Ding, M. (2025). Research on Intermittent Tensile Deformation to Improve the Properties of Austenitic Stainless Steel. Coatings, 15(10), 1158. https://doi.org/10.3390/coatings15101158