Research on Fatigue Performance of Fast Melting Styrene-Butadiene-Styrene-Modified Asphalt with High Viscosity and Elasticity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt Binder

| Technical Indicators | Unit | Measured Value | Test Methods |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 66.9 | T0604-2011 |

| Ductility (15 °C, 5 cm/min) | cm | >100 | T0605-2011 |

| Softening point | °C | 52.8 | T0606-2011 |

| Brinell rotational viscosity (135 °C) | Pa·s | 0.60 | T0625-2011 |

| Modifier | Technical Indicator | Unit | Measured Value |

|---|---|---|---|

| SBS | Structure type | - | Linearity |

| Block ratio S/B | - | 40/60 | |

| Fracture elongation | % | ≥700 | |

| Melt flow rate | g/10 min | 0.1–5.0 | |

| SBS-T | Appearance | - | Granular, uniform |

| SBS content | % | ≥50 | |

| Ash content | % | ≤5.0 | |

| Melt index | g/10 min | ≥2.0 | |

| Dry mix dispersibility | - | No particle residue |

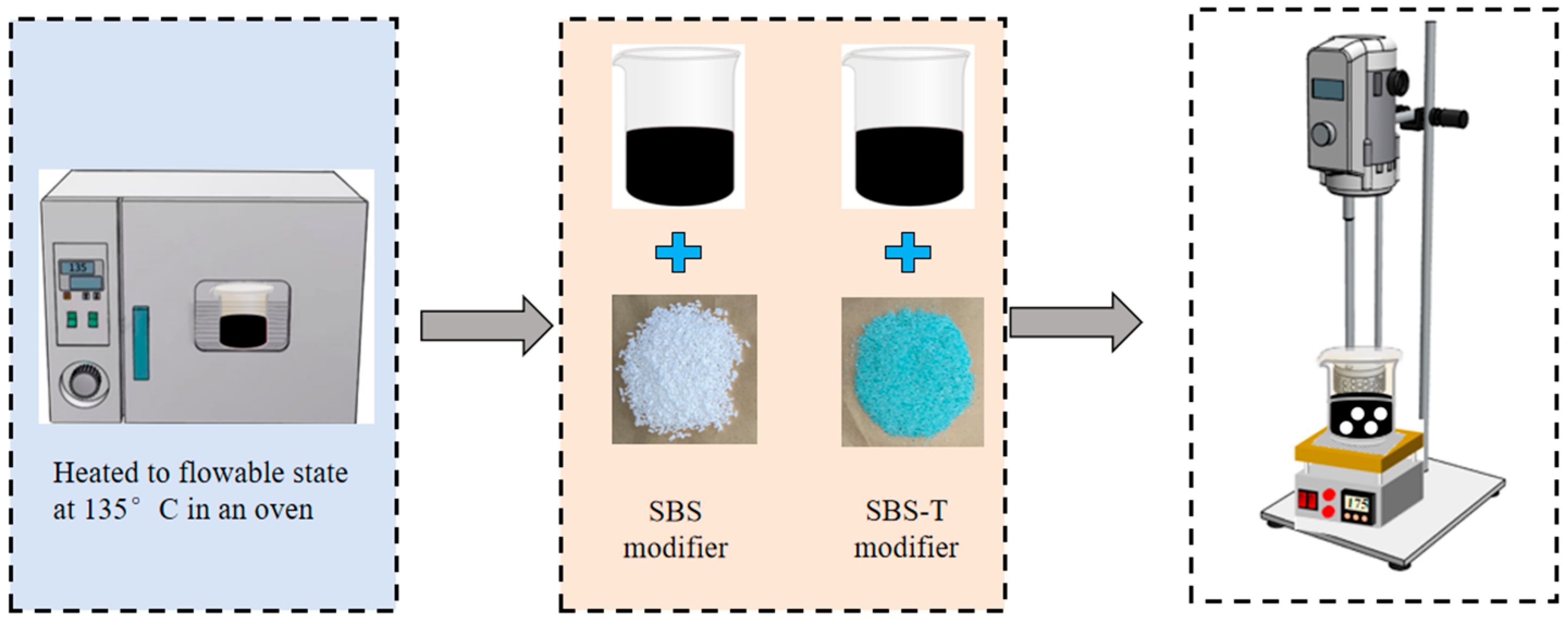

2.1.2. Sample Preparation

- (1)

- The 70# penetration grade base asphalt was heated at 135 °C for approximately 2 h until fully liquefied, then transferred to a temperature-controlled hot plate maintained at 175 ± 2 °C.

- (2)

- The predetermined quantity of SBS or SBS-T modifier was gradually introduced into the molten asphalt. Continuous manual stirring with a glass rod ensured uniform dispersion and prevented particle agglomeration.

- (3)

- The mixture was subjected to high-shear mixing using an FM300 shear mixer (5000 rpm, corresponding to a shear rate of ~18.3 m/s, 30 min) under strict temperature control (175 ± 2 °C) to guarantee consistent polymer dissolution and blend homogeneity.

2.2. Aging Method

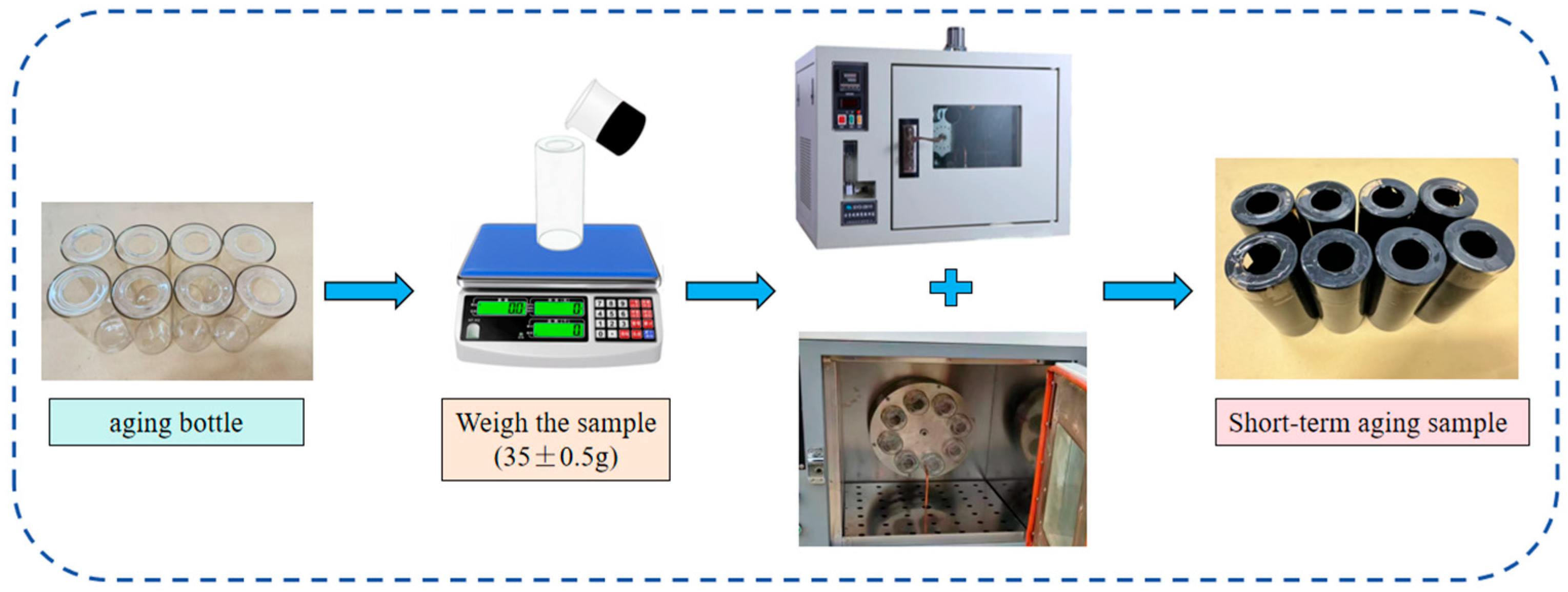

2.2.1. Short-Term Aging

2.2.2. UV Aging

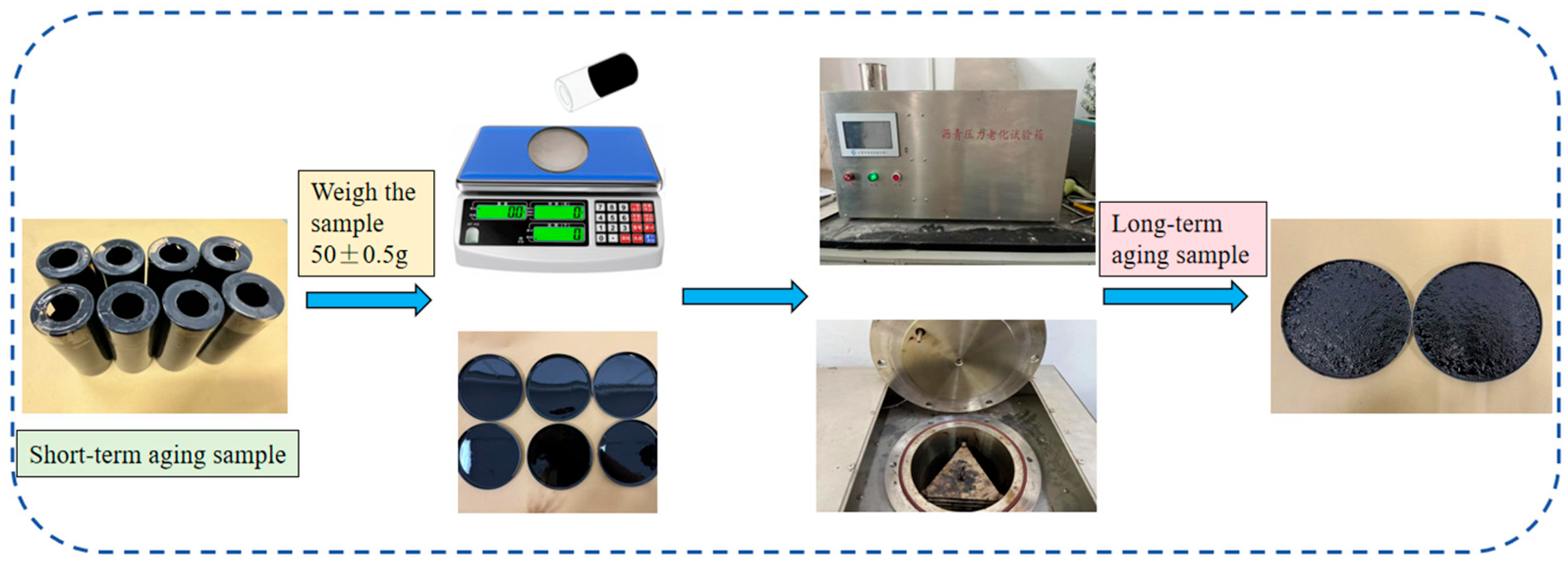

2.2.3. Long-Term Aging

2.3. Laboratory Testing

2.3.1. Frequency Sweep (FS) Test

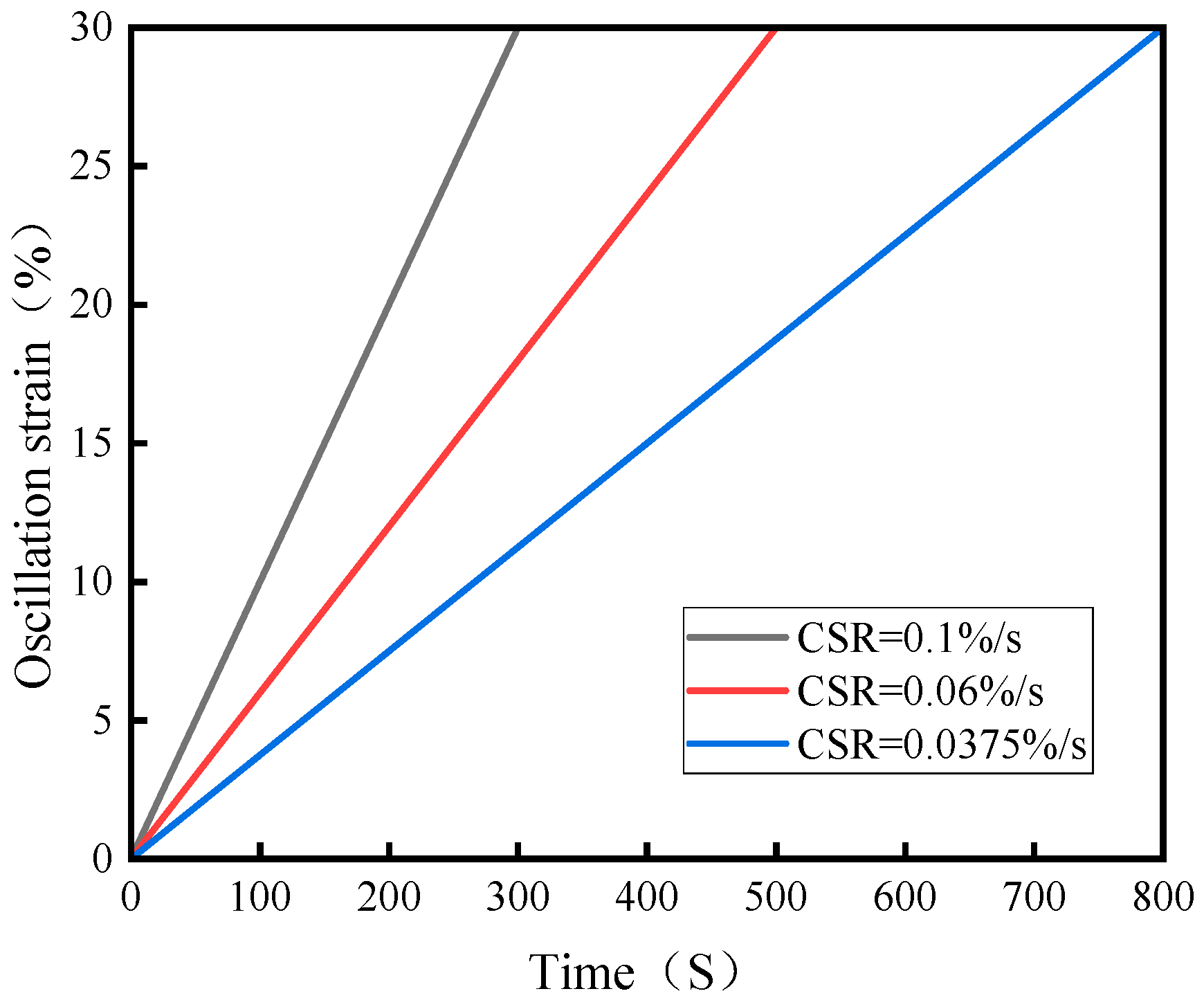

2.3.2. Linear Amplitude Sweep Test (LAS)

3. Results and Discussion

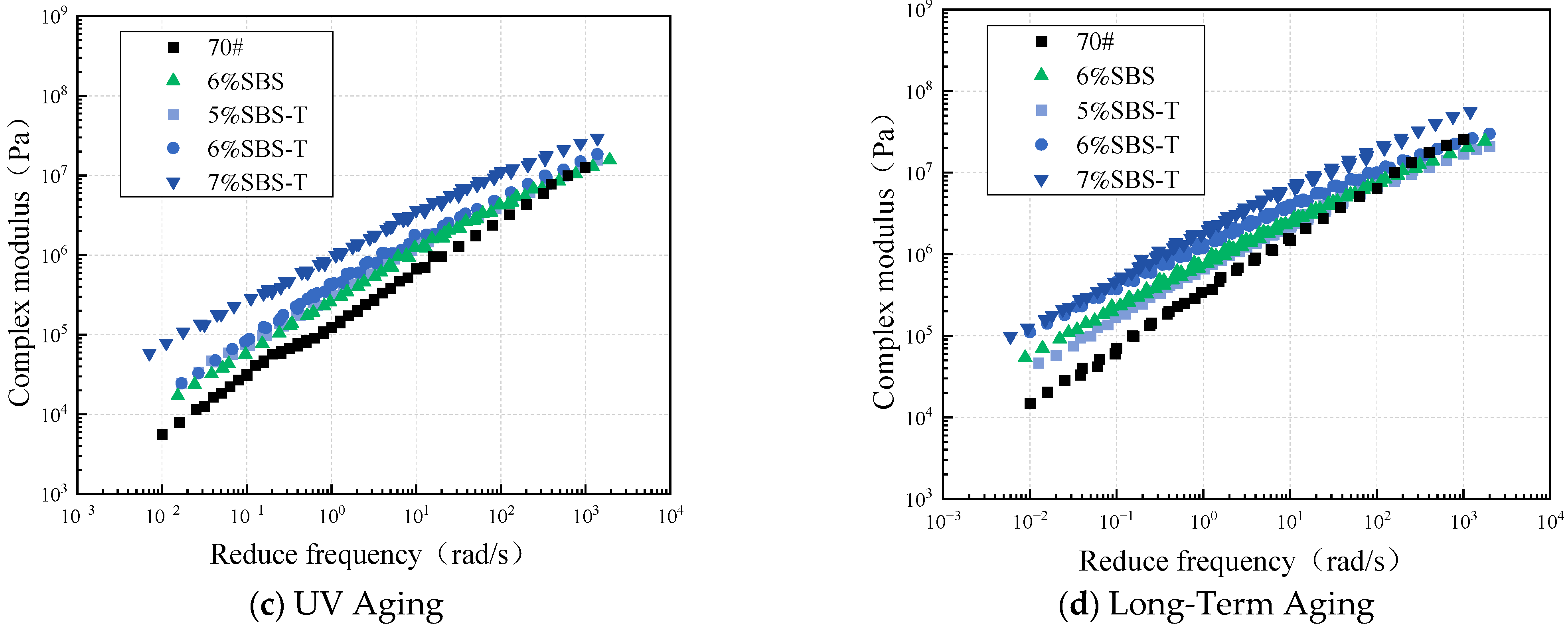

3.1. Dynamic Modulus Master Curve

- (1)

- In the unaged state, with increasing content of the SBS-T modifier, the complex modulus of the high-viscosity high-elasticity SBS-T-modified asphalt shows an upward trend, particularly in the low-frequency range (under low-shear-stress conditions). This indicates that the high-viscosity high-elasticity SBS-T-modified asphalt exhibits stronger elasticity and deformation resistance in its unaged condition. The reason lies in the optimized molecular structure and improved melting efficiency of the SBS-T modifier, which ensures its thorough dissolution and uniform dispersion within the asphalt matrix. Consequently, this enhances the overall rigidity and elastic recovery capability of the modified asphalt material. Compared with the traditional 6% SBS-modified asphalt with the same dosage, the 6% high-viscosity and high-elasticity SBS-T-modified asphalt shows a higher complex modulus in the unaged state, proving that it can provide better crack resistance and fatigue performance under low-temperature or low-stress conditions.

- (2)

- Under short-term aging conditions, the complex modulus of high-viscosity and high-elasticity SBS-T-modified asphalt is generally increased compared with that of unmodified asphalt. The high-viscosity and high-elasticity modified asphalts of 5% SBS-T, 6% SBS-T, and 7% SBS-T all show good high-temperature stability. Short-term aging usually causes crosslinking and hardening of asphalt molecular chains, thereby enhancing its rigidity. During this process, high-viscosity and high-elasticity SBS-T-modified asphalt exhibits superior anti-aging ability compared to base asphalt, indicating that it can still maintain good elasticity and viscosity under high-temperature conditions. High-viscosity and high-elasticity SBS-T-modified asphalt can maintain better fluidity and elasticity during the short-term aging process, reducing cracks and fatigue damage caused by aging. In contrast, the modulus increase of SBS-modified asphalt with the same dosage was relatively small, and the extent of rigidity enhancement during the short-term aging process was limited, further verifying the superiority of high-viscosity and high-elasticity SBS-T-modified asphalt.

- (3)

- During the ultraviolet aging process, the complex modulus of all high-viscosity and high-elasticity SBS-T-modified asphalts showed a significant increase, especially in the high-frequency band (under greater shear stress). Ultraviolet radiation can cause oxidation and crosslinking of the molecular chains in asphalt, resulting in an increase in the rigidity of the material. However, compared with SBS-modified asphalt and base asphalt of the same dosage, high-viscosity and high-elasticity SBS-T-modified asphalt shows a better recovery ability and lower hardening trend after ultraviolet aging. This indicates that high-viscosity and high-elasticity SBS-T-modified asphalt has obvious advantages in resisting ultraviolet aging.

- (4)

- Under long-term aging conditions, the complex modulus of modified asphalt increased, particularly for 6% SBS-T and 7% SBS-T high-viscosity high-elasticity modified asphalt. Long-term aging enhances oxidation and crosslinking reactions in asphalt, thereby improving its stiffness and fatigue resistance. The high-viscosity high-elasticity SBS-T-modified asphalt demonstrates superior durability compared to both base asphalt and SBS-modified asphalt with the same dosage during this process. Notably, the 7% SBS-T-modified asphalt exhibits the highest complex modulus values, indicating that it maintains excellent mechanical performance and durability even under prolonged loading and environmental variations.

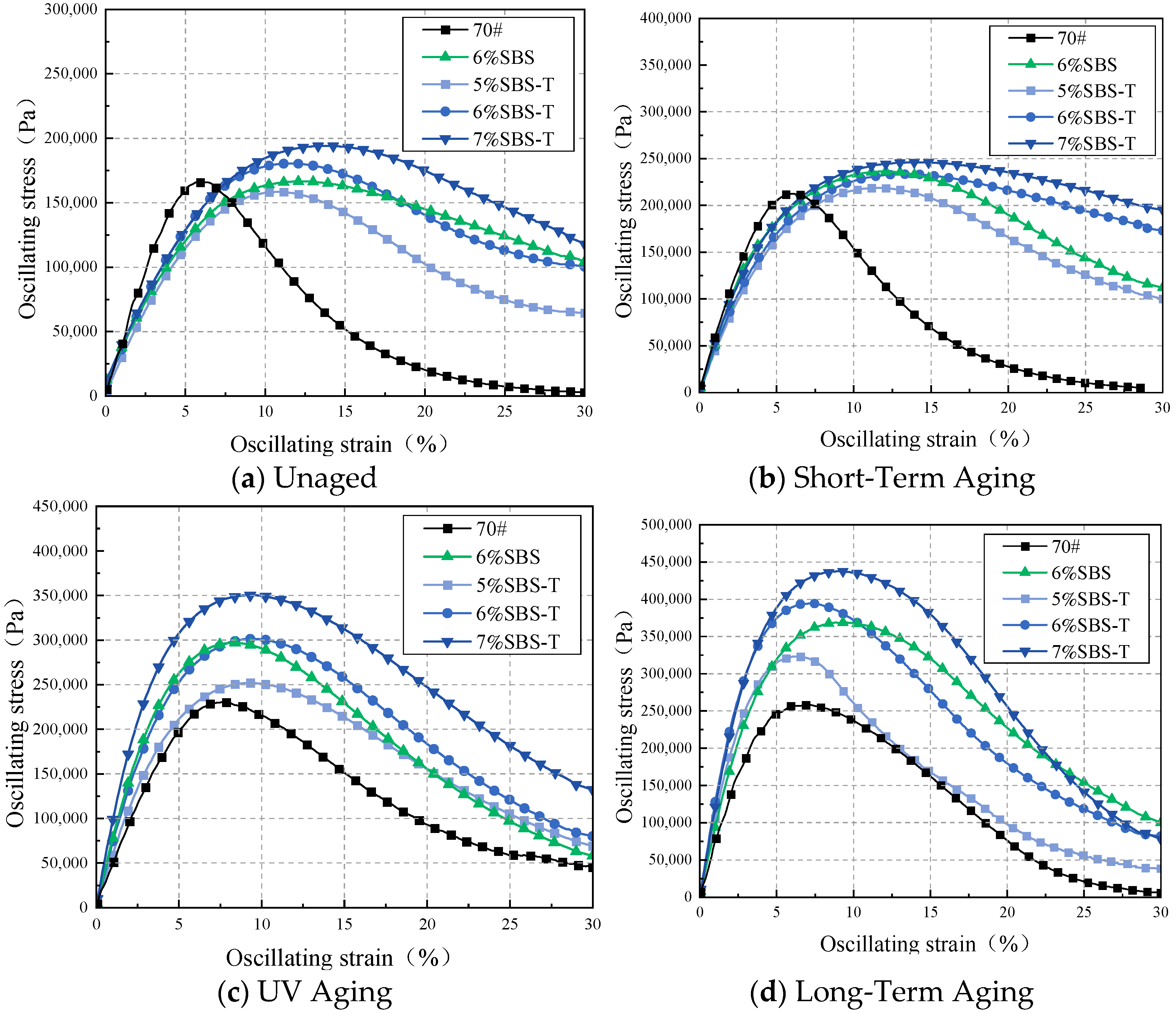

3.2. Analysis of Stress–Strain Relationship

- (1)

- The increasing stress amplitude with the higher SBS-T dosage indicates a significant enhancement in stiffness. This is attributed to the formation of a more robust and continuous crosslinked polymer network within the asphalt matrix, which effectively restricts the mobility of asphalt molecules and bears a greater portion of the applied load. This microstructural reinforcement is consistent with the observed increase in complex modulus.

- (2)

- Compared with 70# base asphalt and SBS-modified asphalt at the same dosage, high-viscosity and high-elasticity SBS-T-modified asphalt shows a larger stress peak width under the same aging conditions. Studies show that the larger the peak stress width, the greater the degree of shear deformation that asphalt can withstand. Therefore, the SBS-T modifier can enhance the stiffness and anti-deformation ability of asphalt.

- (3)

- In the non-aging and short-term aging states, the stress–strain curves of high-viscosity and high-elasticity SBS-T-modified asphalt show a relatively clear elastic stage. All asphalt samples exhibit a higher stress response in the area with less strain, indicating that it can effectively store elastic energy during the initial strain. With the increase in strain, the curve tends to be stable, indicating that the material has entered the plastic deformation stage.

- (4)

- Under ultraviolet aging conditions, the stress–strain curve of high-viscosity and high-elasticity SBS-T-modified asphalt shows more obvious changes. The molecular chain breakage or degradation caused by ultraviolet aging leads to a reduction in the elastic properties of the material. In contrast, the stress response change of 7% SBS-T high-viscosity and high-elasticity modified asphalt after ultraviolet aging is relatively small, and it still maintains a relatively high stress value, showing its stronger ability to resist ultraviolet aging.

- (5)

- The peak shear stress of 70# base asphalt, SBS-modified asphalt, and high-viscosity and high-elasticity SBS-T-modified asphalt after long-term aging is greater than that after ultraviolet aging, indicating that the long-term aging effect has a greater influence on the hardening and stiffness of asphalt materials than ultraviolet aging.

- (6)

- Compared with 5% SBS-T and 6% SBS-T, 7% SBS-T asphalt shows stronger crack resistance and rutting resistance at each aging stage. Especially under high strain, its stress response is significantly stronger, reflecting that a higher content of SBS-T can effectively improve the durability of asphalt.

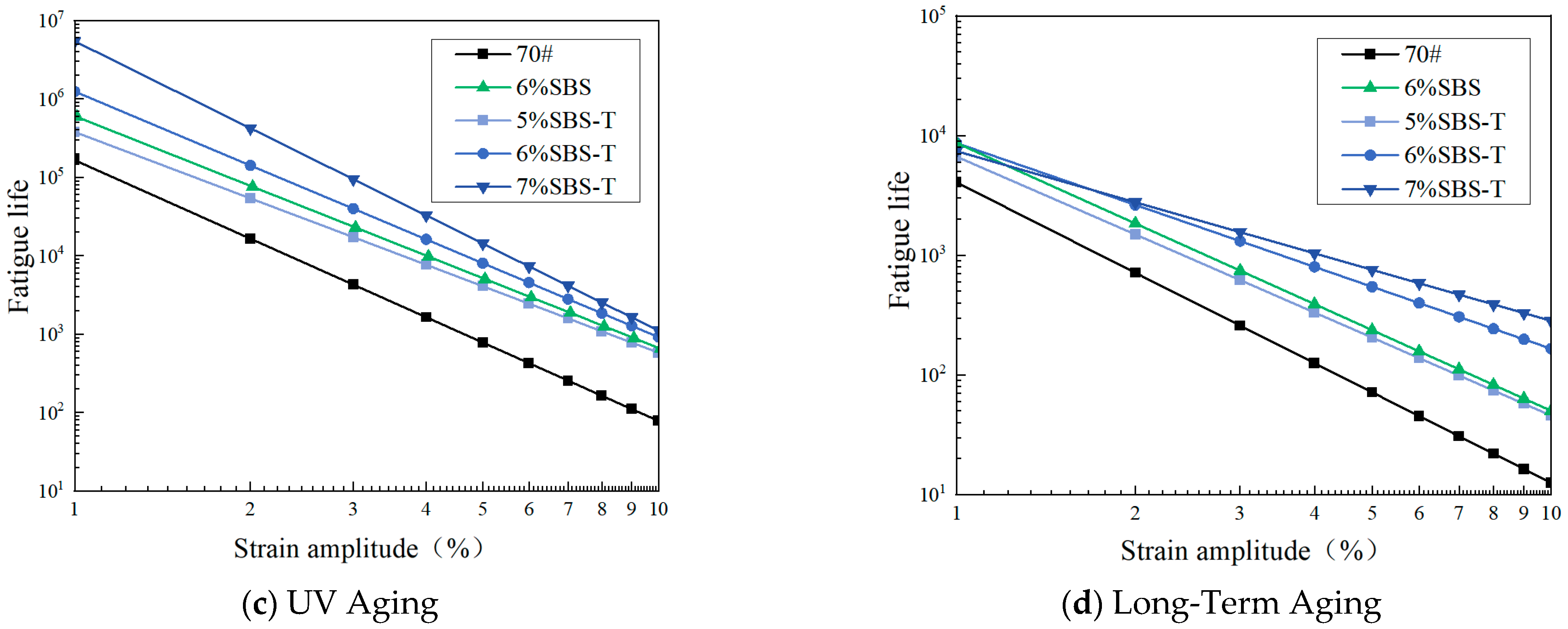

3.3. Fatigue Damage Curve Analysis

- (1)

- After short-term aging, ultraviolet aging, and long-term aging, the damage curve of 7% SBS-T high-viscosity and high-elasticity modified asphalt is always at the top, indicating that 7% SBS-T high-viscosity and high-elasticity modified asphalt can still maintain high stiffness after experiencing complex environmental effects, and therefore has better anti-aging performance.

- (2)

- With the deepening of the aging degree, the downward trend of the DCC gradually slows down. After long-term aging, the DCCs of asphalt with different SBS-T dosages vary greatly and are significantly different from the samples after ultraviolet aging. This indicates that the influence of the photo-oxidation aging mechanism on the damage characteristics of asphalt binders is different from that of the thermal oxidation aging mechanism. Different aging mechanisms have different influences on the internal state characteristics of asphalt materials.

- (3)

- For 6% SBS-T high-viscosity and high-elasticity modified asphalt and 6% SBS-modified asphalt at the same dosage, under long-term aging conditions, the high-viscosity and high-elasticity SBS-T-modified asphalt shows a lower damage accumulation than the traditional SBS asphalt. The fatigue failure point of 6% SB-T high-viscosity and high-elasticity modified asphalt is located after the curve of 6% SBS-modified asphalt, which indicates that SBS-T-modified asphalt is superior to ordinary SBS-modified asphalt in terms of fatigue durability.

3.4. Fatigue Life Analysis

- (1)

- Across all aging conditions, SBS-T-modified asphalt exhibits superior fatigue life compared to both 70# base asphalt and conventional SBS-modified asphalt at equivalent dosages, with a pronounced increasing trend observed with higher SBS-T content.

- (2)

- Short-term aging causes a systematic reduction in fatigue life for all specimens compared to the unaged state, while UV aging significantly deteriorates the fatigue performance of asphalt materials; nevertheless, the 7% SBS-T-modified asphalt maintains exceptional fatigue resistance.

- (3)

- As the most severe service condition, long-term aging leads to dramatic fatigue life reduction for all asphalt types, yet the high-viscosity high-elasticity SBS-T-modified asphalt still demonstrates the most outstanding durability advantages.

4. Conclusions

- (1)

- The high-viscosity high-elasticity SBS-T-modified asphalt demonstrates excellent viscoelastic properties across various temperatures and loading frequencies. Its dynamic modulus and phase angle exhibit greater stability with frequency variations, particularly showing enhanced viscoelastic performance under high-frequency and high-temperature conditions. Compared to 70# base asphalt and conventional SBS-modified asphalt, this material maintains superior viscoelasticity during long-term service, demonstrating better aging resistance and more stable performance.

- (2)

- Under identical strain conditions, the peak shear stress of SBS-T-modified asphalt is significantly higher than that of 70# base asphalt and SBS-modified asphalt at equivalent dosages, with a broader peak shear stress range. This indicates that SBS-T-modified asphalt possesses greater strength and enhanced resistance to shear deformation. After long-term aging, the peak stress of SBS-T-modified asphalt exceeds that of UV-aged samples, suggesting that long-term aging has a more pronounced effect on its strength and hardness than UV aging.

- (3)

- The superior pseudo-strain energy characteristics and maintained rigidity under various aging conditions confirm SBS-T’s exceptional durability. This suggests that infrastructure incorporating SBS-T-modified asphalt may require less frequent maintenance and have an extended service life, potentially offering better life cycle cost efficiency despite potentially higher initial costs.

- (4)

- The fatigue resistance of SBS-T-modified asphalt improves significantly with increasing SBS-T content, indicating that the SBS-T modifier effectively enhances the asphalt’s fatigue performance for extended service life under cyclic loading. However, fatigue life decreases noticeably with progressive aging, primarily due to increased hardness and brittleness during the aging process, which leads to material degradation and reduced fatigue strength.

- (5)

- Laboratory simulation was used to mimic the UV aging of asphalt during pavement service, with only one irradiation duration selected. In subsequent research, the UV aging protocol can be optimized to investigate the performance changes of warm-mix polymer-modified asphalt under different UV aging degrees.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, L.; Li, M.; Li, Q.; Li, H. Modified asphalt based on polyethylene with broad molecular weight distribution. Constr. Build. Mater. 2020, 260, 119707. [Google Scholar] [CrossRef]

- Li, H.; Han, Y.; Guangxun, E.; Sun, Y.; Wang, L.; Liu, X.; Ren, J.; Lin, Z. Recycling of waste polyethylene in asphalt and its performance enhancement methods: A critical literature review. J. Clean. Prod. 2024, 451, 142072. [Google Scholar] [CrossRef]

- Zheng, C.; Li, R.; Hu, M.; Zou, L. Determination of low-temperature crack control parameter of binding asphalt materials based on gray correlation analysis. Constr. Build. Mater. 2019, 217, 226–233. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhao, C.; Ling, J.; Wu, T.; Li, D.; Liu, J.; Sun, B. Anti-rutting performance evaluation of modified asphalt binders: A review. J. Traffic Transp. Eng. 2021, 8, 339–355. [Google Scholar] [CrossRef]

- Bai, Z.; Pei, Z.; Qiao, Y.; Cheng, P.; Guo, J.; Liu, Z.; Abdukadir, A.; Xiong, Y.; Yi, J. Study on the development and performance optimization of gussasphalt containing high percent of fine reclaimed asphalt pavement. Constr. Build. Mater. 2024, 420, 135557. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Zhang, H.; Zhang, M.; Zhang, K.; Zhao, Y. Performance optimization of high viscosity modified asphalt with SBS composite modifier and comparison of different high viscosity modified asphalts. Int. J. Pavement Res. Technol. 2021, 15, 1386–1398. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Wang, Z.; Liu, H.; Zhang, D.; Sun, J. Using SBS Terpene-styrene Resin Blends as a Novel High-viscosity Asphalt Modifier. J. Appl. Polym. Sci. 2023, 140, e53355. [Google Scholar] [CrossRef]

- Hu, M.; Sun, G.; Sun, D.; Zhang, Y.; Ma, J.; Lu, T. Effect of thermal aging on high viscosity modified asphalt binder: Rheological property, chemical composition and phase morphology. Constr. Build. Mater. 2020, 241, 118023. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion characteristics of graphene oxide modified asphalt unveiled by surface free energy and AFM-scanned micro-morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

- Luo, H.; Zheng, C.; Yang, X.; Bao, C.; Liu, W.; Lin, Z. Development of technology to accelerate SBS-modified asphalts swelling in dry modification mode. Constr. Build. Mater. 2022, 314, 125703. [Google Scholar] [CrossRef]

- Luo, H.; Zheng, C.; Liu, B.; Bao, C.; Tian, B.; Liu, W. Study on SBS modifier of bio-oil/sulfur compound under dry modification mode. Constr. Build. Mater. 2022, 326, 127059. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yer, J.; Men, B.; Tang, G.; Wang, R. Experimental Study on Mechanism, Aging and Fatigue Performance of Warm Mixing Speed Melting SBS Modified Asphalt Binders. Coatings 2023, 13, 311. [Google Scholar] [CrossRef]

- Yue, J.; Fu, J.; Wang, Y.; Ming, Y.; Tang, G.; Li, R. Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt. Materials 2025, 18, 2157. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Zhang, X.; Sha, T.; Wang, D.; Niu, B.; Wang, R.; Hou, X. A Rheological Study of the High-Temperature Properties of Fast-Melting SBS/Epoxy-Modified Asphalt Binders. Polymers 2025, 17, 581. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Wang, Y.; Zhu, W.; Chen, Y.; Yue, J. Research on the Rheological Performance of Fast-Melting SBS-Modified Asphalt under Complex Environmental Factors. Coatings 2024, 14, 1241. [Google Scholar] [CrossRef]

- Men, B.; Li, X.; Sha, T.; Guo, F.; Tang, G.; Yue, J. Research on Fatigue Performance of Fast-Melting SBS/Epoxy Resin Composite-Modified Asphalt. Coatings 2024, 14, 789. [Google Scholar] [CrossRef]

- Men, B.; Guo, F.; Kang, X.; Yue, J. Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory. Materials 2023, 16, 7601. [Google Scholar] [CrossRef]

- Huo, W.; Zhuang, Y.; Wang, Z.; Kang, X.; Wang, R. The Microscopic Mechanism and Rheological Properties of SBS-Modified Asphalt with Warm Mixing Fast-Melting. Materials 2023, 16, 5690. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Chen, G. Preparation, Performance, and modification mechanism of high viscosity modified asphalt. Constr. Build. Mater. 2021, 310, 125007. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, H.; Cao, D.; Xia, L.; Du, R.; Shi, Z.; Dong, R.; Wang, X. Study on cohesion and adhesion of high-viscosity modified asphalt. Int. J. Transp. Sci. Technol. 2019, 8, 394–402. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. Preparation and properties of high viscosity modified asphalt. Polym. Compos. 2017, 38, 936–946. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Y.; Jin, K.; Zhou, Z. Properties and mechanism of SBS/crumb rubber composite high viscosity modified asphalt. J. Clean. Prod. 2022, 378, 134534. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Liu, J.; Yang, C.; Wang, F. A Methodological Review on Development of Crack Healing Technologies of Asphalt Pavement. Sustainability 2023, 15, 9659. [Google Scholar] [CrossRef]

- Yang, S.; Park, H.; Baek, C. Fatigue Cracking Characteristics of Asphalt Pavement Structure under Aging and Moisture Damage. Sustainability 2023, 15, 4815. [Google Scholar] [CrossRef]

- Shi, C.; Cai, X.; Yi, X.; Wang, T.; Yang, J. Fatigue crack density of asphalt binders under controlled-stress rotational shear load testing. Constr. Build. Mater. 2021, 272, 121899. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Song, L. Investigating the Crack Initiation and Propagation of Asphalt Binder in Linear Amplitude Sweep Test. J. Mater. Civ. Eng. 2020, 32, 04020362. [Google Scholar] [CrossRef]

- Zhang, Z.; Oeser, M. Energy dissipation and rheological property degradation of asphalt binder under repeated shearing with different oscillation amplitudes. Int. J. Fatigue 2021, 152, 106417. [Google Scholar] [CrossRef]

- Yan, Y.; Hernando, D.; Park, B.; Allen, C.; Roque, R. Understanding asphalt binder cracking characterization at intermediate temperatures: Review and evaluation of two approaches. Constr. Build. Mater. 2021, 312, 125163. [Google Scholar] [CrossRef]

- Jiao, L.; Elkashef, M.; Harvey, J.T.; Rahman, M.A.; Jones, D. Investigation of fatigue performance of asphalt mixtures and FAM mixes with high recycled asphalt material contents. Constr. Build. Mater. 2022, 314, 125607. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Guo, F.; Wang, S.; Yue, J. Research on the Adhesion Performance of Fast-Melting SBS-Modified Emulsified Asphalt–Aggregate Based on the Surface Free Energy Theory. Materials 2025, 18, 3523. [Google Scholar] [CrossRef]

- Schwarzl, F.R.; Staverman, A.J. Time-temperature dependence of linear viscoelastic behavior. J. Appl. Phys. 1952, 23, 838–843. [Google Scholar] [CrossRef]

- Findley, W.N.; Lai, J. A modified superposition principle applied to creep of nonlinear viscoelastic material under abrupt changes in state of combined stress. Trans. Soc. Rheol. 1967, 11, 361–380. [Google Scholar] [CrossRef]

- Wang, C.; Castorena, C.; Zhang, J.; Kim, Y.R. Unified failure criterion for asphalt binder under cyclic fatigue loading. Road Mater. Pavement Des. 2015, 16, 125–148. [Google Scholar] [CrossRef]

| Technical Indicators | Unit | 6% SBS | 5% SBS-T | 6% SBS-T | 7%SBS-T | Standard Values |

|---|---|---|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 50.1 | 53.7 | 49.3 | 48.1 | 40–80 |

| Softening point | °C | 76 | 77.5 | 86.7 | 89 | ≥70 |

| Ductility (5 °C) | cm | 28.1 | 31.3 | 33.7 | 36.3 | ≥20 |

| Dynamic viscosity (60 °C) | Pa·s | 25,370 | 23,100 | 26,880 | 29,630 | ≥20,000 |

| Elastic recovery | % | 92 | 94 | 96.5 | 98.1 | ≥85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Guo, F.; Li, X.; Wang, S.; Yue, J. Research on Fatigue Performance of Fast Melting Styrene-Butadiene-Styrene-Modified Asphalt with High Viscosity and Elasticity. Coatings 2025, 15, 1143. https://doi.org/10.3390/coatings15101143

Zhang H, Guo F, Li X, Wang S, Yue J. Research on Fatigue Performance of Fast Melting Styrene-Butadiene-Styrene-Modified Asphalt with High Viscosity and Elasticity. Coatings. 2025; 15(10):1143. https://doi.org/10.3390/coatings15101143

Chicago/Turabian StyleZhang, Hao, Fei Guo, Xiaoyu Li, Shige Wang, and Jinchao Yue. 2025. "Research on Fatigue Performance of Fast Melting Styrene-Butadiene-Styrene-Modified Asphalt with High Viscosity and Elasticity" Coatings 15, no. 10: 1143. https://doi.org/10.3390/coatings15101143

APA StyleZhang, H., Guo, F., Li, X., Wang, S., & Yue, J. (2025). Research on Fatigue Performance of Fast Melting Styrene-Butadiene-Styrene-Modified Asphalt with High Viscosity and Elasticity. Coatings, 15(10), 1143. https://doi.org/10.3390/coatings15101143