Buried Interface Modification Using Diammonium Ligand Enhances Mechanical Durability of Flexible Perovskite Solar Cells

Abstract

1. Introduction

2. Method and Characterization

2.1. Material Preparation

2.2. Device Fabrication

2.3. Device Characterization

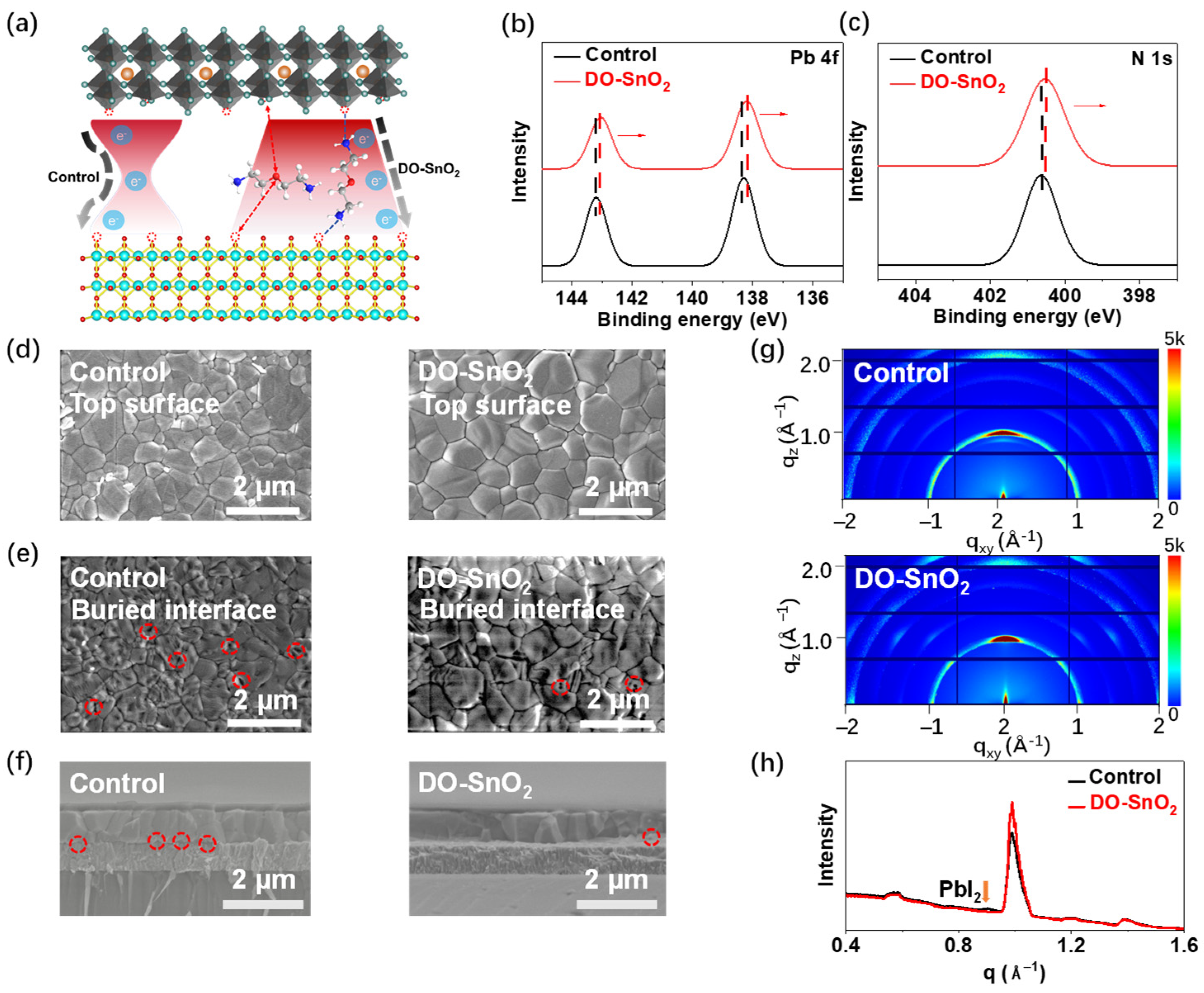

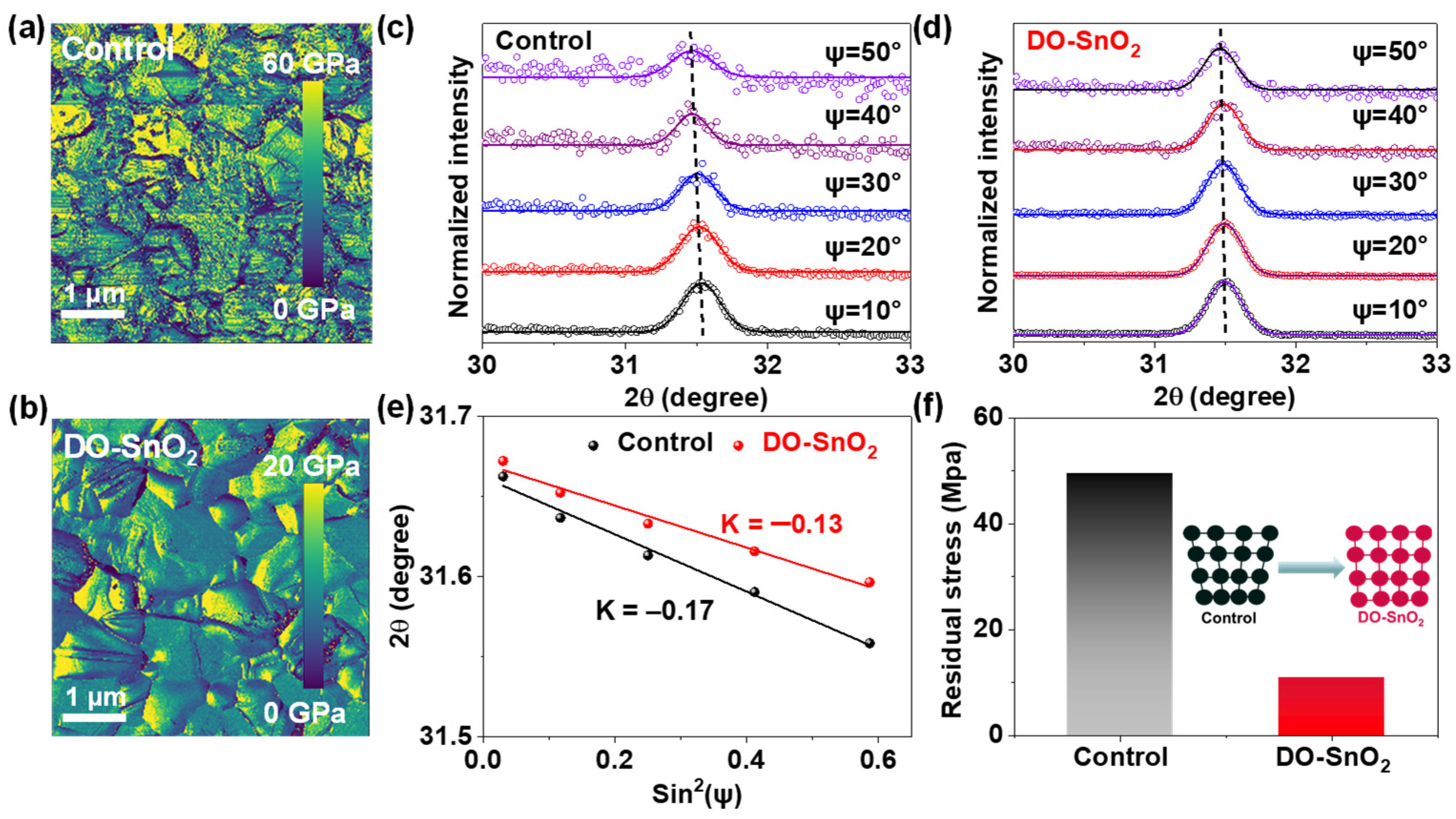

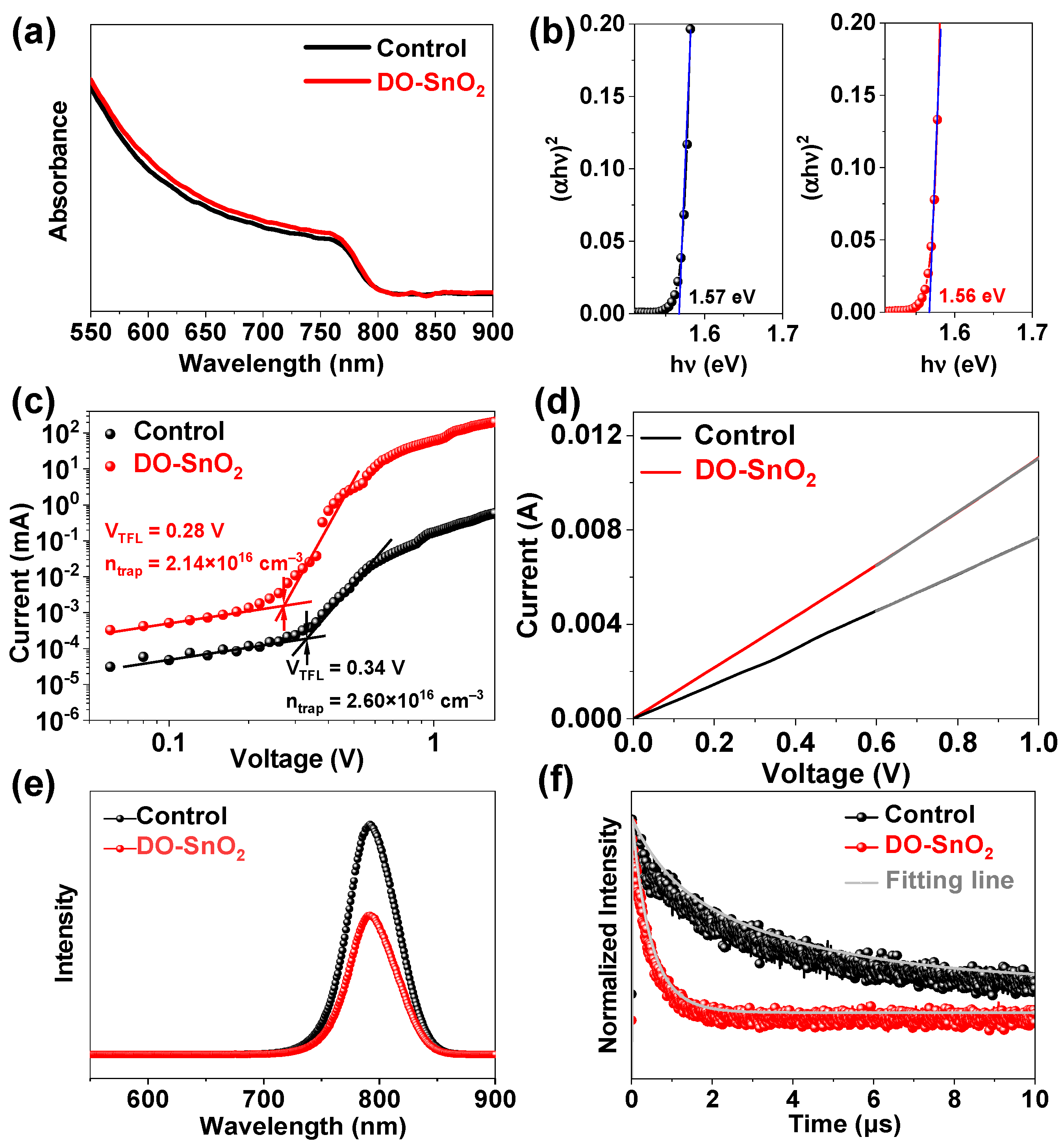

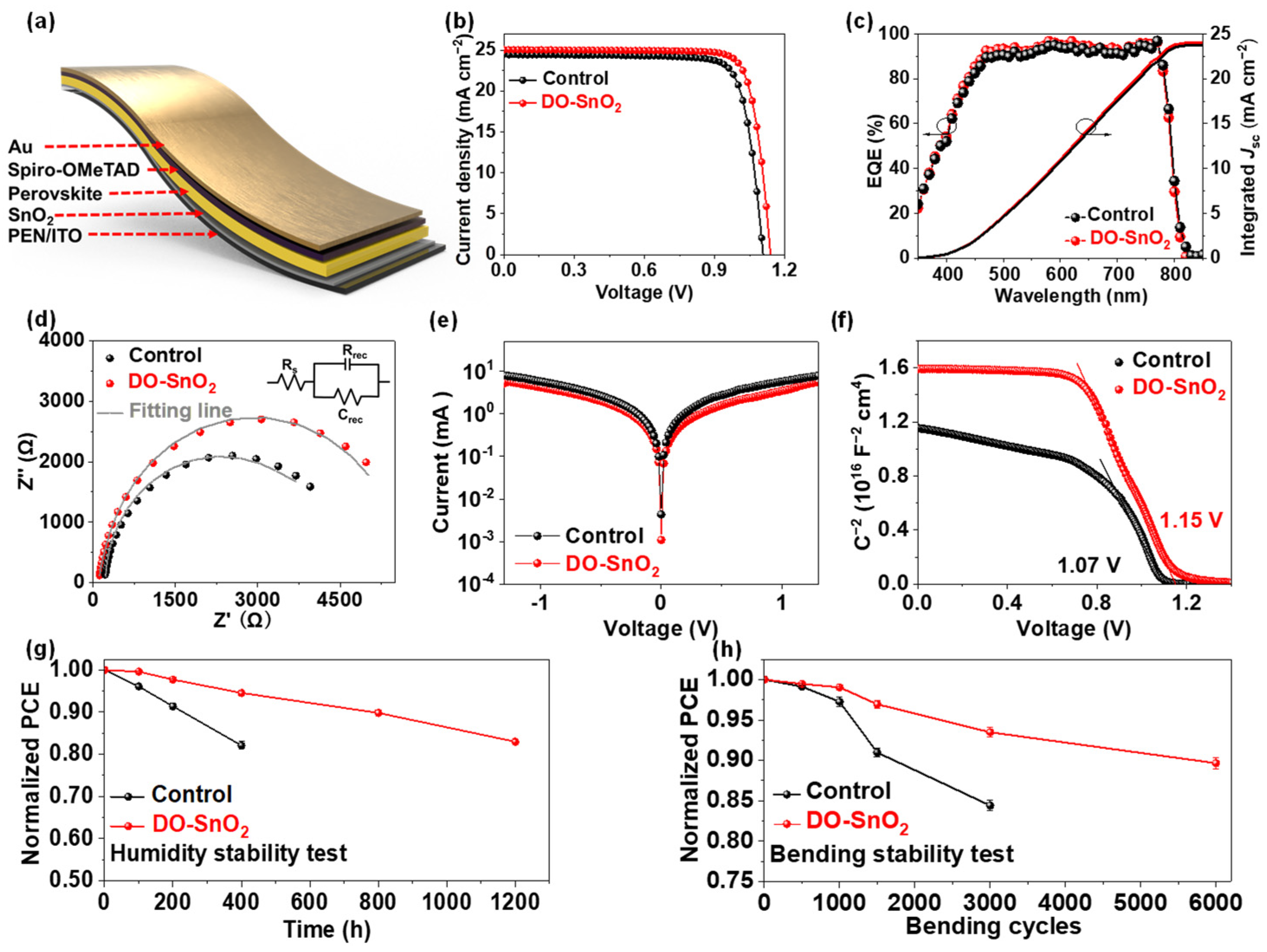

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Y.; Guo, X.; Lin, H.; Wang, Q.; Su, J.; Zhang, J.; Hao, Y.; Yang, K.; Chang, J. Perovskite Films Regulation via Hydrogen-Bonded Polymer Network for Efficient and Stable Perovskite Solar Cells. Angew. Chem. Int. Ed. 2023, 135, e202306229. [Google Scholar] [CrossRef]

- Gong, C.; Wang, C.; Meng, X.; Fan, B.; Xing, Z.; Shi, S.; Hu, T.; Huang, Z.; Hu, X.; Chen, Y. An Equalized Flow Velocity Strategy for Perovskite Colloidal Particles in Flexible Perovskite Solar Cells. Adv. Mater. 2024, 36, 2405572. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Xu, G.; Xi, J.; Shen, Y.; Wu, X.; Tang, X.; Ding, J.; Yang, H.; Cheng, Q.; Chen, Z.; et al. In situ crosslinking-assisted perovskite grain growth for mechanically robust flexible perovskite solar cells with 23.4% efficiency. Joule 2023, 7, 398–415. [Google Scholar] [CrossRef]

- Aftab, S.; Hussain, S.; Kabir, F.; Aslam, M.; Rajpar, A.; Al-Sehemi, A. Advances in flexible perovskite solar cells: A comprehensive review. Nano Energy 2024, 120, 109112. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, J.; Chen, X.; Wang, Y.; Li, C.; Huang, Y.; Liu, X.; Li, H.; Ge, Z. Molecular dipole engineering assisted strain release for mechanically robust flexible perovskite solar cells. Energy Environ. Sci. 2023, 16, 2408–2417. [Google Scholar]

- Xu, W.; Chen, B.; Zhang, Z.; Liu, Y.; Xian, Y.; Wang, X.; Shi, Z.; Gu, H.; Fei, C.; Li, N.; et al. Multifunctional entinostat enhances the mechanical robustness and efficiency of flexible perovskite solar cells and minimodules. Nat. Photonics 2024, 18, 379–387. [Google Scholar] [CrossRef]

- Ren, N.; Tan, L.; Li, M.; Zhou, J.; Ye, Y.; Jiao, B.; Ding, L.; Yi, C. 25%-Efficiency flexible perovskite solar cells via controllable growth of SnO2. iEnergy 2024, 3, 39–45. [Google Scholar] [CrossRef]

- Chen, P.; Xiao, Y.; Li, S.; Jia, X.; Luo, D.; Zhang, W.; Snaith, H.; Gong, Q.; Zhu, R. The Promise and Challenges of Inverted Perovskite Solar Cells. Chem. Rev. 2024, 124, 10623–10700. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, G.; Shen, Y.; Wu, X.; Tang, X.; Han, C.; Chen, Y.; Yang, F.; Chen, H.; Li, Y.; et al. Stereoscopic Polymer Network for Developing Mechanically Robust Flexible Perovskite Solar Cells with an Efficiency Approaching 25%. Adv. Mater. 2024, 36, 2403531. [Google Scholar] [CrossRef]

- Cai, W.; Zou, P.; Rong, S.; Wang, H.; Chen, X.; Zhang, Z.; Wang, Y.; Liu, C.; Yang, T.; Niu, T.; et al. Interlayer reinforcement for improved mechanical reliability for wearable perovskite solar cells. Energy Environ. Sci. 2024, 17, 8162–8173. [Google Scholar] [CrossRef]

- Zhu, X.; Dong, H.; Chen, J.; Xu, J.; Li, Z.; Yuan, F.; Dai, J.; Jiao, B.; Hou, X.; Xi, J.; et al. Photoinduced Cross Linkable Polymerization of Flexible Perovskite Solar Cells and Modules by Incorporating Benzyl Acrylate. Adv. Funct. Mater. 2022, 32, 2202408. [Google Scholar] [CrossRef]

- Fan, B.; Xiong, J.; Zhang, Y.; Gong, C.; Li, F.; Meng, X.; Hu, X.; Yuan, Z.; Wang, F.; Chen, Y. A Bionic Interface to Suppress the Coffee-Ring Effect for Reliable and Flexible Perovskite Modules with a Near-90% Yield Rate. Adv. Mater. 2022, 34, 2201840. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Yang, T.; Cai, W.; Wang, Y.; Chen, X.; Wang, S.; Huang, W.; Du, Y.; Wu, N.; Wang, Z.; et al. Flexible Indoor Perovskite Solar Cells by In Situ Bottom-Up Crystallization Modulation and Interfacial Passivation. Adv. Mater. 2024, 36, 2311562. [Google Scholar] [CrossRef]

- Gao, D.; Li, B.; Li, Z.; Wu, X.; Zhang, S.; Zhao, D.; Jiang, X.; Zhang, C.; Wang, Y.; Li, Z.; et al. Highly Efficient Flexible Perovskite Solar Cells through Pentylammonium Acetate Modification with Certified Efficiency of 23.35%. Adv. Mater. 2023, 35, 2206387. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, F.; Gong, J.; Ma, Y.; Gu, J.; Liu, X.; Chen, S.; Liu, M. Pre-Buried Additive for Cross-Layer Modification in Flexible Perovskite Solar Cells with Efficiency Exceeding 22%. Adv. Mater. 2022, 34, 2109879. [Google Scholar] [CrossRef]

- Xue, T.; Fan, B.; Jiang, K.-J.; Guo, Q.; Hu, X.; Su, M.; Zhou, E.; Song, Y. Self-healing ion-conducting elastomer towards record efficient flexible perovskite solar cells with excellent recoverable mechanical stability. Energy Environ. Sci. 2024, 17, 2621–2630. [Google Scholar] [CrossRef]

- Huang, Z.; Li, L.; Wu, T.; Xue, T.; Sun, W.; Pan, Q.; Wang, H.; Xie, H.; Chi, J.; Han, T.; et al. Wearable perovskite solar cells by aligned liquid crystal elastomers. Nat. Commun. 2023, 14, 1204. [Google Scholar] [CrossRef]

- Chen, Z.; Cheng, Q.; Chen, H.; Wu, Y.; Ding, J.; Wu, X.; Yang, H.; Liu, H.; Chen, W.; Tang, X.; et al. Perovskite Grain-Boundary Manipulation Using Room-Temperature Dynamic Self-Healing “Ligaments” for Developing Highly Stable Flexible Perovskite Solar Cells with 23.8% Efficiency. Adv. Mater. 2023, 35, 2300513. [Google Scholar] [CrossRef]

- Meng, Y.; Liu, C.; Cao, R.; Zhang, J.; Xie, L.; Yang, M.; Xie, L.; Wang, Y.; Yin, X.; Liu, C.; et al. Pre-Buried ETL with Bottom-Up Strategy Toward Flexible Perovskite Solar Cells with Efficiency over 23%. Adv. Funct. Mater. 2023, 33, 2214788. [Google Scholar] [CrossRef]

- Luo, L.; Zeng, H.; Wang, Z.; Li, M.; You, S.; Chen, B.; Maxwell, A.; An, Q.; Cui, L.; Luo, D.; et al. Stabilization of 3D/2D perovskite heterostructures via inhibition of ion diffusion by cross-linked polymers for solar cells with improved performance. Nat. Energy 2023, 8, 294–303. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, Y.; Liu, C.; Cao, R.; Han, B.; Xie, L.; Tian, R.; Lu, X.; Song, Z.; Li, J.; et al. Utilizing electrostatic dynamic bonds in zwitterion elastomer for self-curing of flexible perovskite solar cells. Joule 2024, 8, 1120–1141. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Yao, Y.; Yang, J.; Tang, W.; Qiu, W.; Wu, Y.; Peng, Q. Synergistic transition metal ion co-doping and multiple functional additive passivation for realizing 25.30% efficiency perovskite solar cells. Energy Environ. Sci. 2023, 16, 5243–5254. [Google Scholar] [CrossRef]

- Xing, G.; Li, C.; Gao, W.; Yang, J.; Zhao, X.; Wang, J.; Ran, X.; Chao, L.; Huang, H.; Zhou, Y.; et al. Molecule Anchoring Strategy Promotes Vertically Homogeneous Crystallization and Aligned Interfaces for Efficient Pb–Sn Perovskite Solar Cells and Tandem Device. Adv. Mater. 2024, 36, 2404185. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liu, H.; Hou, C.-H.; Yan, H.; Li, S.; Chen, P.; Xu, H.; Yu, W.-Y.; Zhao, Y.; Sui, Y.; et al. Harmonizing the bilateral bond strength of the interfacial molecule in perovskite solar cells. Nat. Energy 2024, 9, 1506–1516. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Wu, H.; Wang, F.; Yan, K.; Zhou, Y.; Xu, X.; Fu, W.; Hu, H.; Wu, G.; et al. A Novel Thiazole-Core Spacer Based Dion–Jacobson Perovskite with Type II Quantum Well Structure for Efficient Photovoltaics. Adv. Energy Mater. 2024, 14, 2401907. [Google Scholar] [CrossRef]

- Chen, X.; Cai, W.; Niu, T.; Wang, H.; Liu, C.; Zhang, Z.; Du, Y.; Wang, S.; Cao, Y.; Liu, P.; et al. Crystallization control via ligand–perovskite coordination for high-performance flexible perovskite solar cells. Energy Environ. Sci. 2024, 17, 6256–6267. [Google Scholar] [CrossRef]

- Yang, G.; Wang, C.; Lei, H.; Zheng, X.; Qin, P.; Xiong, L.; Zhao, X.; Yan, Y.; Fang, G. Interface engineering in planar perovskite solar cells: Energy level alignment, perovskite morphology control and high performance achievement. J. Mater. Chem. A 2017, 5, 1658–1666. [Google Scholar] [CrossRef]

- Liu, C.; Yang, Y.; Chen, H.; Xu, J.; Liu, A.; Bati, A.; Zhu, H.; Grater, L.; Hadke, S.; Huang, C.; et al. Bimolecularly passivated interface enables efficient and stable inverted perovskite solar cells. Science 2023, 382, 810–815. [Google Scholar] [CrossRef]

- Tong, X.; Xie, L.; Li, J.; Pu, Z.; Du, S.; Yang, M.; Gao, Y.; He, M.; Wu, S.; Mai, Y.; et al. Large Orientation Angle Buried Substrate Enables Efficient Flexible Perovskite Solar Cells and Modules. Adv. Mater. 2024, 36, 2407032. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Xiao, W.; Chen, R.; Sun, Z.; Zhang, Y.; Lei, X.; Hu, S.; Kober-Czerny, M.; Wang, J.; et al. Buried interface molecular hybrid for inverted perovskite solar cells. Nature 2024, 632, 536–542. [Google Scholar] [CrossRef]

- Yu, X.; Sun, X.; Zhu, Z.; Li, Z. Stabilization Strategies of Buried Interface for Efficient SAM-Based Inverted Perovskite Solar Cells. Angew. Chem. Int. Ed. 2024, e202419608. [Google Scholar]

- Chen, X.; Wang, Q.; Wei, H.; Yang, J.; Yao, Y.; Tang, W.; Qiu, W.; Xu, X.; Song, L.; Wu, Y.; et al. Minimizing the buried interfacial energy loss using a fluorine-substituted small molecule for 25.92%-efficiency and stable inverted perovskite solar cells. Energy Environ. Sci. 2024, 17, 7342–7354. [Google Scholar] [CrossRef]

- Xing, Z.; Lin, S.; Meng, X.; Hu, T.; Li, D.; Fan, B.; Cui, Y.; Li, F.; Hu, X.; Chen, Y. A Highly Tolerant Printing for Scalable and Flexible Perovskite Solar Cells. Adv. Funct. Mater. 2021, 31, 2107726. [Google Scholar] [CrossRef]

- Zhu, C.; Niu, X.; Fu, Y.; Li, N.; Hu, C.; Chen, Y.; He, X.; Na, G.; Liu, P.; Zai, H.; et al. Strain engineering in perovskite solar cells and its impacts on carrier dynamics. Nat. Commun. 2019, 10, 815. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Wang, Y.; Liu, C.; Yan, P.; Sun, K.; Wang, Y.; Tian, R.; Cao, R.; Zhu, J.; Do, H.; et al. Epitaxial Growth of α-FAPbI3 at a Well-Matched Heterointerface for Efficient Perovskite Solar Cells and Solar Modules. Adv. Mater. 2024, 36, 2309208. [Google Scholar] [CrossRef]

- Yuan, G.; Xie, W.; Song, Q.; Ma, S.; Ma, Y.; Shi, C.; Xiao, M.; Pei, F.; Niu, X.; Zhang, Y.; et al. Inhibited Crack Development by Compressive Strain in Perovskite Solar Cells with Improved Mechanical Stability. Adv. Mater. 2023, 35, 2211257. [Google Scholar] [CrossRef]

- Cao, Y.; Feng, J.; Wang, M.; Yan, N.; Lou, J.; Feng, X.; Xiao, F.; Liu, Y.; Qi, D.; Yuan, Y.; et al. Interface Modification by Ammonium Sulfamate for High-Efficiency and Stable Perovskite Solar Cells. Adv. Energy Mater. 2023, 13, 2302103. [Google Scholar] [CrossRef]

- Sun, Q.; Duan, S.; Liu, G.; Meng, X.; Hu, D.; Deng, J.; Shen, B.; Kang, B.; Silva, S. Porous Lead Iodide Layer Promotes Organic Amine Salt Diffusion to Achieve High Performance p-i-n Flexible Perovskite Solar Cells. Adv. Energy Mater. 2023, 13, 2301259. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Chen, X.; Dai, W.; Gong, Y.; Zhang, Z.; Zhang, L.; Ma, C.; Yang, T.; Dong, Y.; Yan, B.; et al. Buried Interface Modification Using Diammonium Ligand Enhances Mechanical Durability of Flexible Perovskite Solar Cells. Coatings 2025, 15, 15. https://doi.org/10.3390/coatings15010015

Ji X, Chen X, Dai W, Gong Y, Zhang Z, Zhang L, Ma C, Yang T, Dong Y, Yan B, et al. Buried Interface Modification Using Diammonium Ligand Enhances Mechanical Durability of Flexible Perovskite Solar Cells. Coatings. 2025; 15(1):15. https://doi.org/10.3390/coatings15010015

Chicago/Turabian StyleJi, Xuan, Xin Chen, Wanlei Dai, Yongshuai Gong, Zheng Zhang, Lei Zhang, Cheng Ma, Tinghuan Yang, Yixin Dong, Buyi Yan, and et al. 2025. "Buried Interface Modification Using Diammonium Ligand Enhances Mechanical Durability of Flexible Perovskite Solar Cells" Coatings 15, no. 1: 15. https://doi.org/10.3390/coatings15010015

APA StyleJi, X., Chen, X., Dai, W., Gong, Y., Zhang, Z., Zhang, L., Ma, C., Yang, T., Dong, Y., Yan, B., Liu, D., & Niu, T. (2025). Buried Interface Modification Using Diammonium Ligand Enhances Mechanical Durability of Flexible Perovskite Solar Cells. Coatings, 15(1), 15. https://doi.org/10.3390/coatings15010015