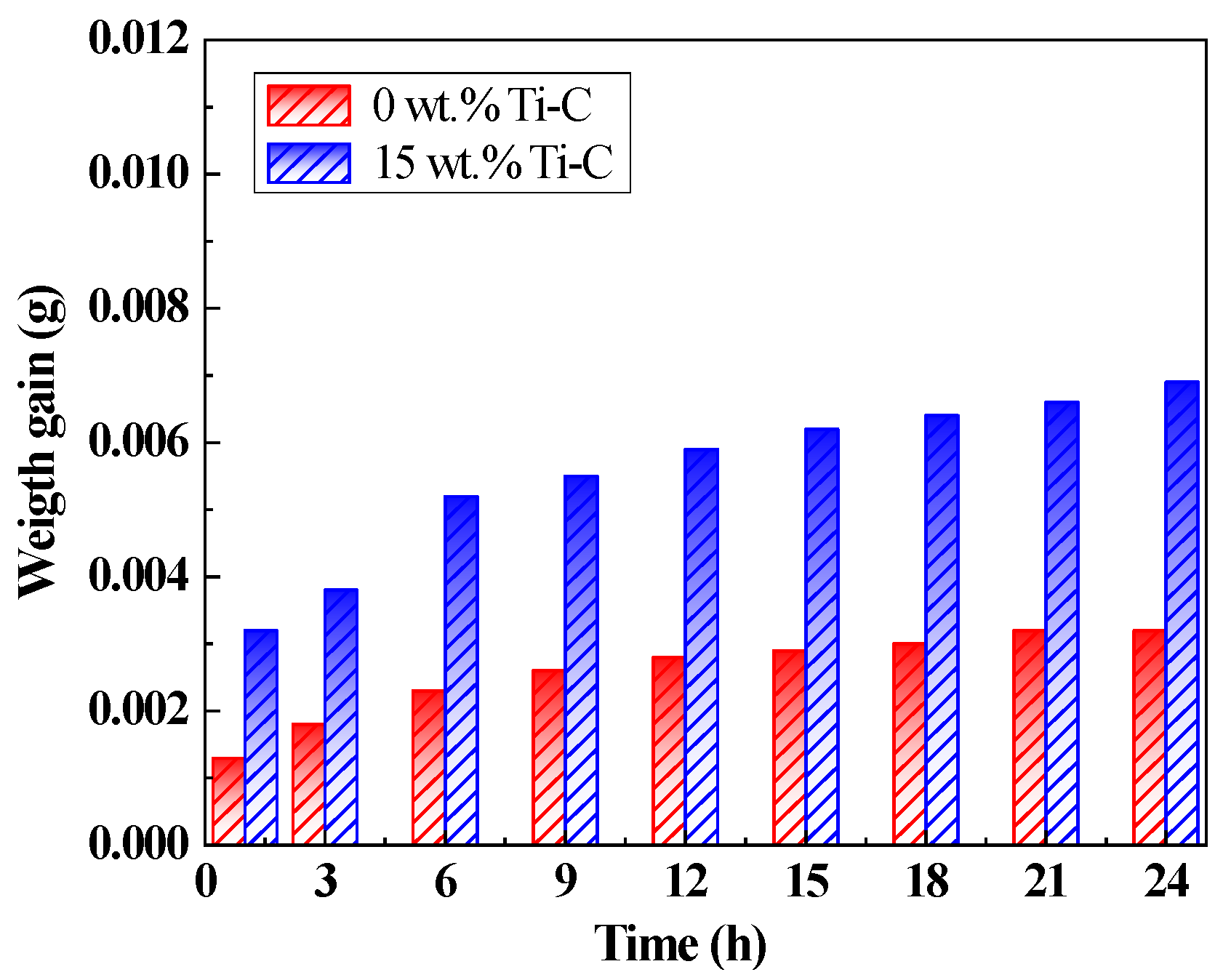

Oxidation and Heat Shock Resistance of Plasma-Sprayed TiC-CoNi Composite Coatings at 900 °C

Abstract

1. Introduction

2. Experimental Sections

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Wang, L.; Liang, Z.; He, J.; Qiu, J.; Pyczak, F.; Song, M. Effects of Ni and Cr on the high-temperature oxidation behavior and mechanisms of Co- and CoNi-base superalloys. Mater. Des. 2022, 224, 111291. [Google Scholar] [CrossRef]

- Sattawitchayapit, S.; Yordsri, V.; Wutikhun, T.; Chookajorn, T. Stress-induced, debris-modulated friction and wear resistance performance of nanostructured Ni-Co coatings. Wear 2024, 538–539, 205184. [Google Scholar] [CrossRef]

- Bai, S.; Liu, X.; Xu, L.; Xuan, J.; Liu, Y.; Shao, Y.; Xin, Y.; Li, X.; Fan, L. Enhancement of corrosion resistance and lubricating performance of electrodeposited Ni-Co coating composited with mesoporous silica nanoparticles and silicone oil impregnation. Mater. Chem. Phys. 2022, 282, 125929. [Google Scholar] [CrossRef]

- Xu, H.; Huang, H. Microstructure evolution and mechanical properties of thermally sprayed coating modified by laser remelting and injection with tungsten carbide. Ceram. Int. 2022, 48, 22854–22868. [Google Scholar] [CrossRef]

- Lee, H.B.; Hong, Y.H.; Sheu, H.H.; Hsiao, R.C.; Li, W.K.; Lin, H.E. Effects of Cr contents on tribological and corrosion behavior of HVOF sprayed Ni-based alloy coating. Tribol. Int. 2023, 183, 108384. [Google Scholar] [CrossRef]

- Cai, Z.; Cui, X.; Liu, Z.; Li, Y.; Dong, M.; Jin, G. Microstructure and wear resistance of laser cladded Ni-Cr-Co-Ti-V high-entropy alloy coating after laser remelting processing. Opt. Laser Technol. 2018, 99, 276–281. [Google Scholar] [CrossRef]

- Li, R.; Li, J.; Liang, Y.; Ji, C.; Yuan, T. Viscoplastic friction and microstructural evolution behavior of laser-clad Co–Cr–Ni–Mo coating. Trans. Nonferrous Met. Soc. China 2013, 23, 681–691. [Google Scholar] [CrossRef]

- Li, B.; Zhang, W.; Li, D. Synthesis and properties of a novel Ni–Co and Ni–Co/ZrO2 composite coating by DC electrodeposition. J. Alloys Compd. 2020, 821, 153258. [Google Scholar] [CrossRef]

- Yang, G.; Fu, B.; Dong, T.; Li, G. Preparation of AlSi30Cu5 coating with fine microstructure using plasma spraying technology. Mater. Lett. 2024, 357, 135800. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, F.; Zhu, L.; He, J.; Yin, F. The effect of Cu addition on the crystallization behavior and tribological properties of reactive plasma sprayed TiCN–Cu coatings. Ceram. Int. 2019, 46, 8344–8351. [Google Scholar] [CrossRef]

- Reddy, M.S.; Patil, P.P.; Muniraju, M.; Shetty, K.G.; Rao, T.N. Investigation & characterization of plasma sprayed cermet coatings on special steel alloy for gas turbine applications. Mater. Today Proc. 2021, 47, 3720–3725. [Google Scholar] [CrossRef]

- Shi, L.; Sun, C.; Gao, P.; Zhou, F.; Liu, W. Mechanical properties and wear and corrosion resistance of electrodeposited Ni-Co/SiC nanocomposite coating. Appl. Surf. Sci. 2006, 252, 3591–3599. [Google Scholar] [CrossRef]

- Fu, W.; Chen, Q.; Yang, C.; Yi, D.; Yao, H.; Wang, H.; Ji, G.; Wang, F. Microstructure and properties of high velocity oxygen fuel sprayed (WC-Co)-Ni coatings. Ceram. Int. 2020, 46, 14940–14948. [Google Scholar] [CrossRef]

- Aghajani, H.; Hadavand, E.; Peighambardoust, N.S.; Khameneh-asl, S. Electro spark deposition of WC-TiC-Co-Ni cermet coatings on St52 steel. Surf. Interfaces 2020, 18, 100392. [Google Scholar] [CrossRef]

- Kamel, M.M.; Hamid, Z.A.; Rashwan, S.M.; Ibrahim, I.S.; Sheikh SM, E.; Mohamed, M.M. Electrodeposition of Ni-Co/nano Al2O3 composite coating on low carbon steel and its characterization. Int. J. Electrochem. Sci. 2020, 15, 6343–6358. [Google Scholar] [CrossRef]

- Rasooli, A.; Safavi, M.S.; Hokmabad, M.K. Cr2O3 nanoparticles: A promising candidate to improve the mechanical properties and corrosion resistance of Ni-Co alloy coatings. Ceram. Int. 2018, 44, 6466–6473. [Google Scholar] [CrossRef]

- Ranjith, B.; Kalaignan, G.P. Ni–Co–TiO2 nanocomposite coating prepared by pulse and pulse reversal methods using acetate bath. Appl. Surf. Sci. 2010, 257, 42–47. [Google Scholar] [CrossRef]

- Hefnawy, A.; Elkhoshkhany, N.; Essam, A. Ni-TiN and Ni-Co-TiN composite coatings for corrosion protection: Fabrication and electrochemical characterization. J. Alloys Compd. 2018, 735, 600–606. [Google Scholar] [CrossRef]

- Zhang, W.; Du, S.; Li, B.; Mei, T.; Miao, Y.; Chu, H.; Wang, J. Synthesis and characterization of TiN nanoparticle reinforced binary Ni-Co alloy coatings. J. Alloys Compd. 2021, 865, 158722. [Google Scholar] [CrossRef]

- He, B.; Liu, X.; Zhang, F.; Zhang, S.; Liu, Z.; Zhang, S. Tribological and oxidation behaviors of TiN reinforced Co matrix composite coatings on Inconel718 alloy by laser cladding. Tribol. Int. 2023, 188, 108781. [Google Scholar] [CrossRef]

- He, J.; Zheng, G.; Guo, F.; Fu, G.; Li, C.; Zhao, H.; Qin, Y.; Jiang, Y.; Yin, F. Microstructure and tribological properties of in-situ synthesized TiC reinforced reactive plasma sprayed Co-based coatings. Mater. Chem. Phys. 2020, 248, 122913. [Google Scholar] [CrossRef]

- Hu, L.; Li, S.; Li, C.; Fu, G.; He, J.; Dong, Y.; Yang, Y.; Zhao, H.; Qin, Y.; Yin, F. Deposition and properties of plasma sprayed NiCrCoMo–TiC composite coatings. Mater. Chem. Phys. 2020, 254, 123502. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | S | P | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| % | 0.14–0.22 | 0.3–0.65 | ≤0.3 | ≤0.05 | ≤0.045 | ≤0.3 | ≤0.3 | ≤0.3 | Bal. |

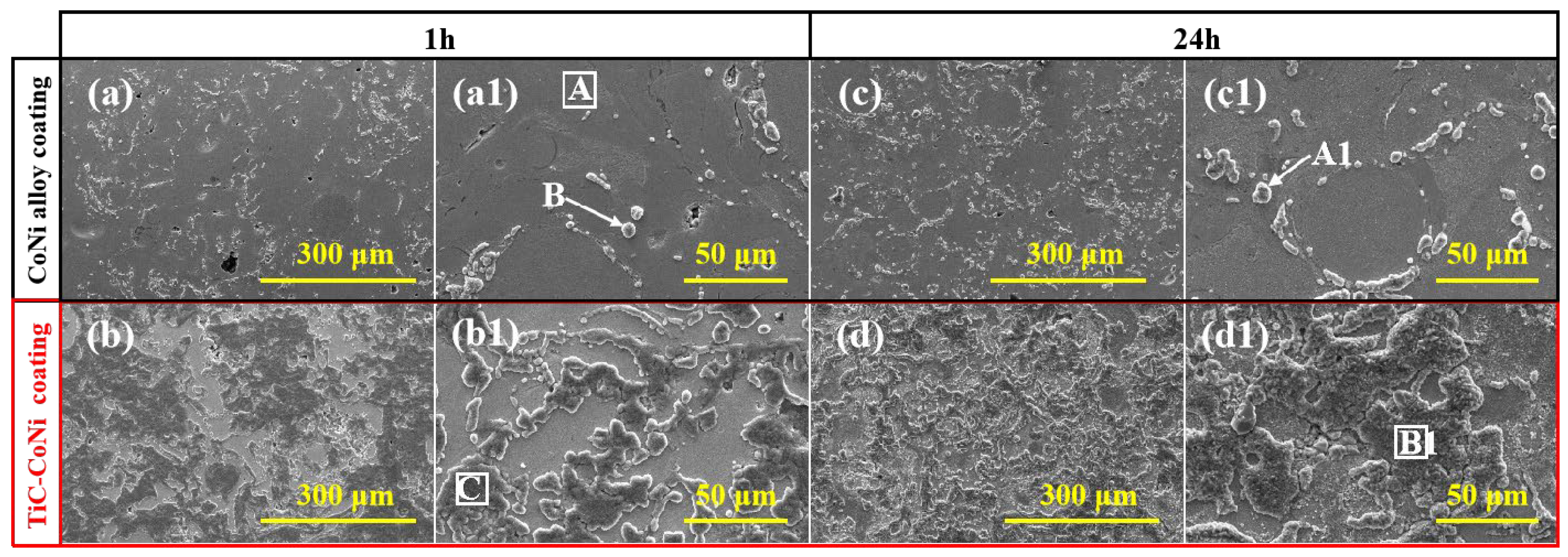

| Element | O | Ti | C | Co | Ni | Cr | Mo | |

|---|---|---|---|---|---|---|---|---|

| A | wt% | 7.73 | - | - | 32.74 | 23.63 | 27.58 | 8.32 |

| at% | 23.95 | - | - | 27.55 | 19.96 | 26.30 | 2.24 | |

| B | wt% | 27.03 | - | - | 28.54 | 6.70 | 37.74 | - |

| at% | 56.06 | - | - | 16.07 | 3.79 | 24.08 | - | |

| C | wt% | 36.17 | 56.60 | 3.45 | - | - | 3.79 | - |

| at% | 59.46 | 31.08 | 7.55 | - | - | 1.92 | - | |

| A1 | wt% | 21.73 | - | - | 49.71 | - | 28.56 | - |

| at% | 60.08 | - | - | 26.46 | - | 13.46 | - | |

| B1 | wt% | 36.76 | 59.76 | 1.35 | 2.13 | - | - | - |

| at% | 62.13 | 33.74 | 3.03 | 1.11 | - | - | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Li, B.; Zhao, H.; Fu, G.; Fan, J.; Qin, Y. Oxidation and Heat Shock Resistance of Plasma-Sprayed TiC-CoNi Composite Coatings at 900 °C. Coatings 2024, 14, 296. https://doi.org/10.3390/coatings14030296

He J, Li B, Zhao H, Fu G, Fan J, Qin Y. Oxidation and Heat Shock Resistance of Plasma-Sprayed TiC-CoNi Composite Coatings at 900 °C. Coatings. 2024; 14(3):296. https://doi.org/10.3390/coatings14030296

Chicago/Turabian StyleHe, Jining, Baoqiang Li, Hongjian Zhao, Guanya Fu, Jiawei Fan, and Yanfang Qin. 2024. "Oxidation and Heat Shock Resistance of Plasma-Sprayed TiC-CoNi Composite Coatings at 900 °C" Coatings 14, no. 3: 296. https://doi.org/10.3390/coatings14030296

APA StyleHe, J., Li, B., Zhao, H., Fu, G., Fan, J., & Qin, Y. (2024). Oxidation and Heat Shock Resistance of Plasma-Sprayed TiC-CoNi Composite Coatings at 900 °C. Coatings, 14(3), 296. https://doi.org/10.3390/coatings14030296