Performance and Thermal Properties of 3D Printed CF-Reinforced PLA Monofilaments

Abstract

:1. Introduction

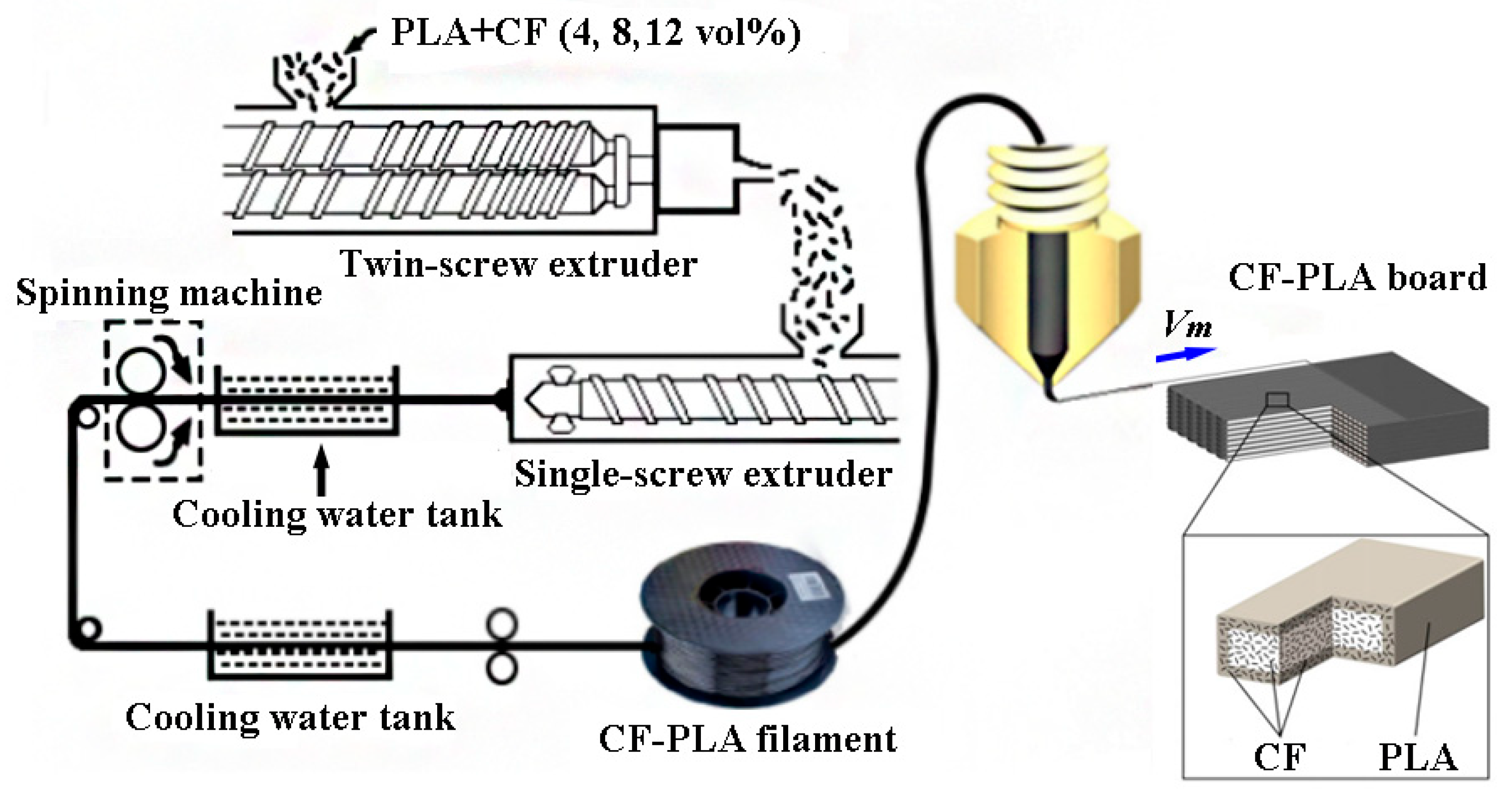

2. Experimental Section

2.1. Materials and Preparation

2.2. Characterization

3. Results and Discussion

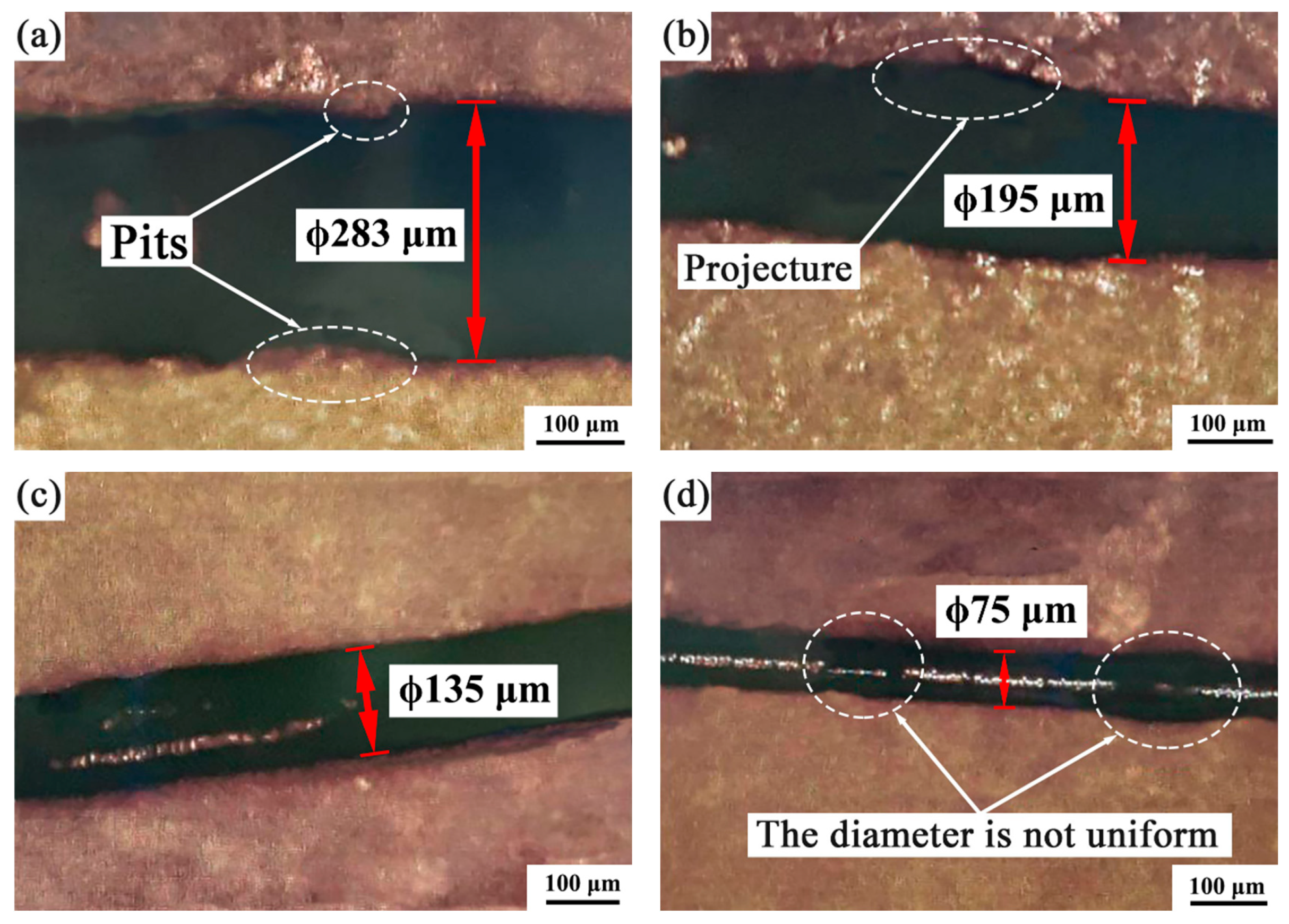

3.1. Influence of Retraction Rate on Uniformity of CF-PLA Monofilaments

3.2. Influence of Movement Rate on Diameters of CF-PLA Monofilaments

3.3. Analysis of Cross-Sectional Morphologies

3.4. Mechanical Properties of CF-PLA Monofilaments

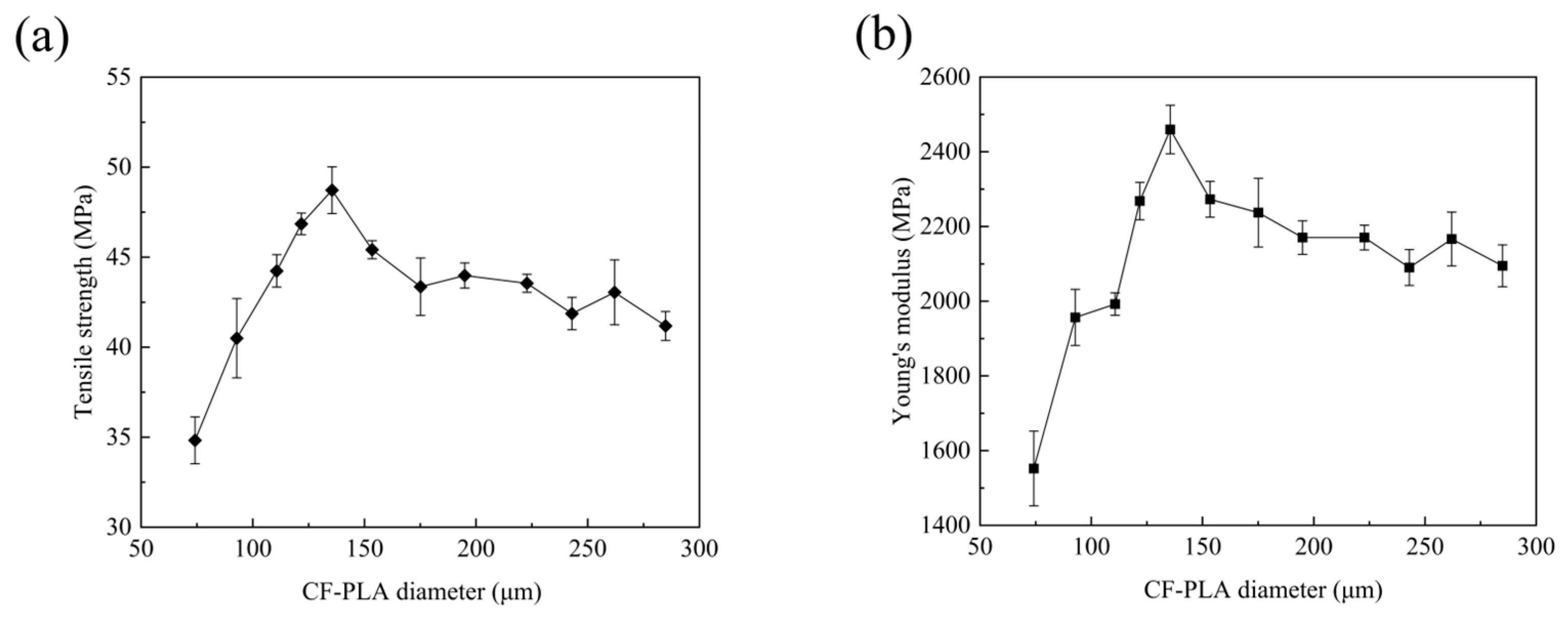

3.4.1. Tensile Strength and Young’s Modulus of CF-PLA Monofilaments

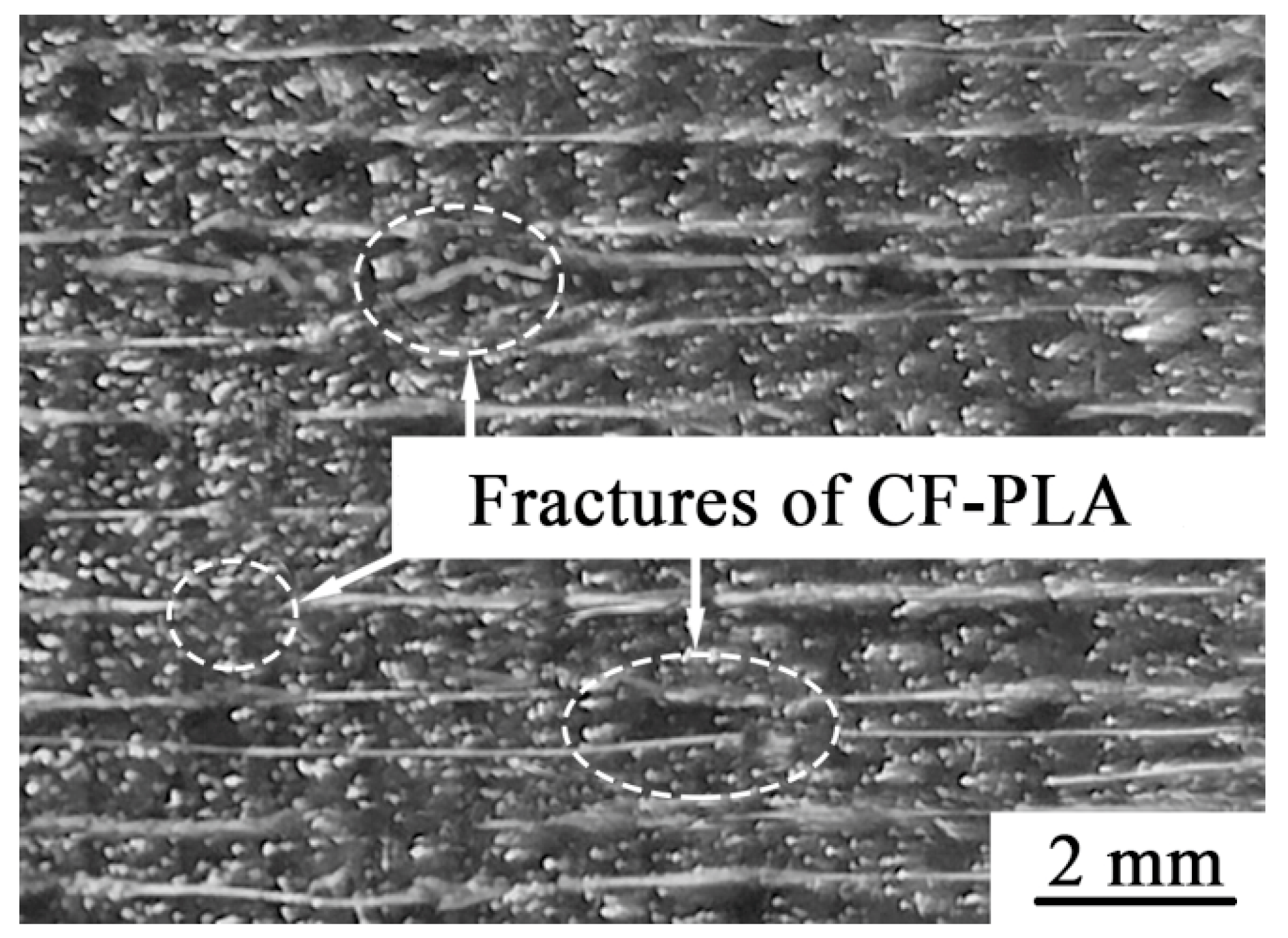

3.4.2. Properties of Boards Fabricated from Monofilaments

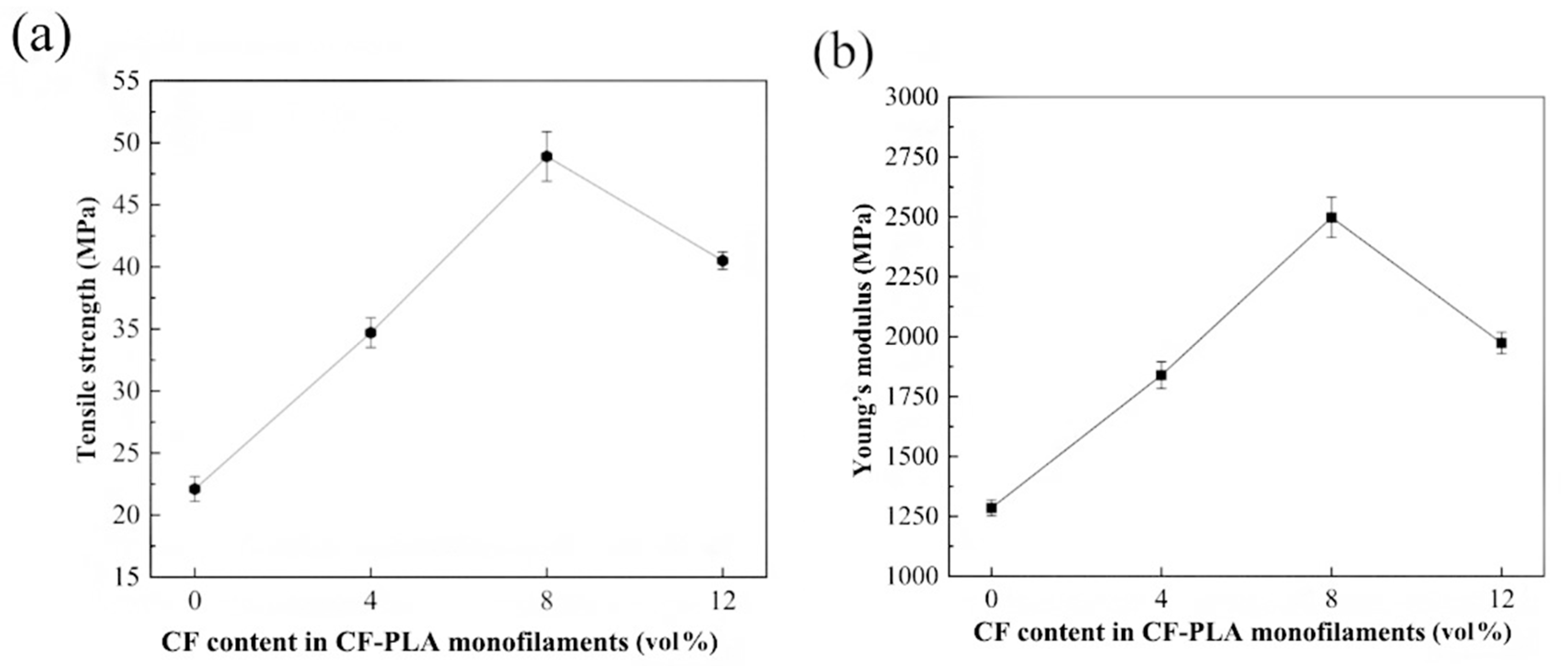

3.4.3. Effect of CF Content on Properties of CF-PLA Monofilaments

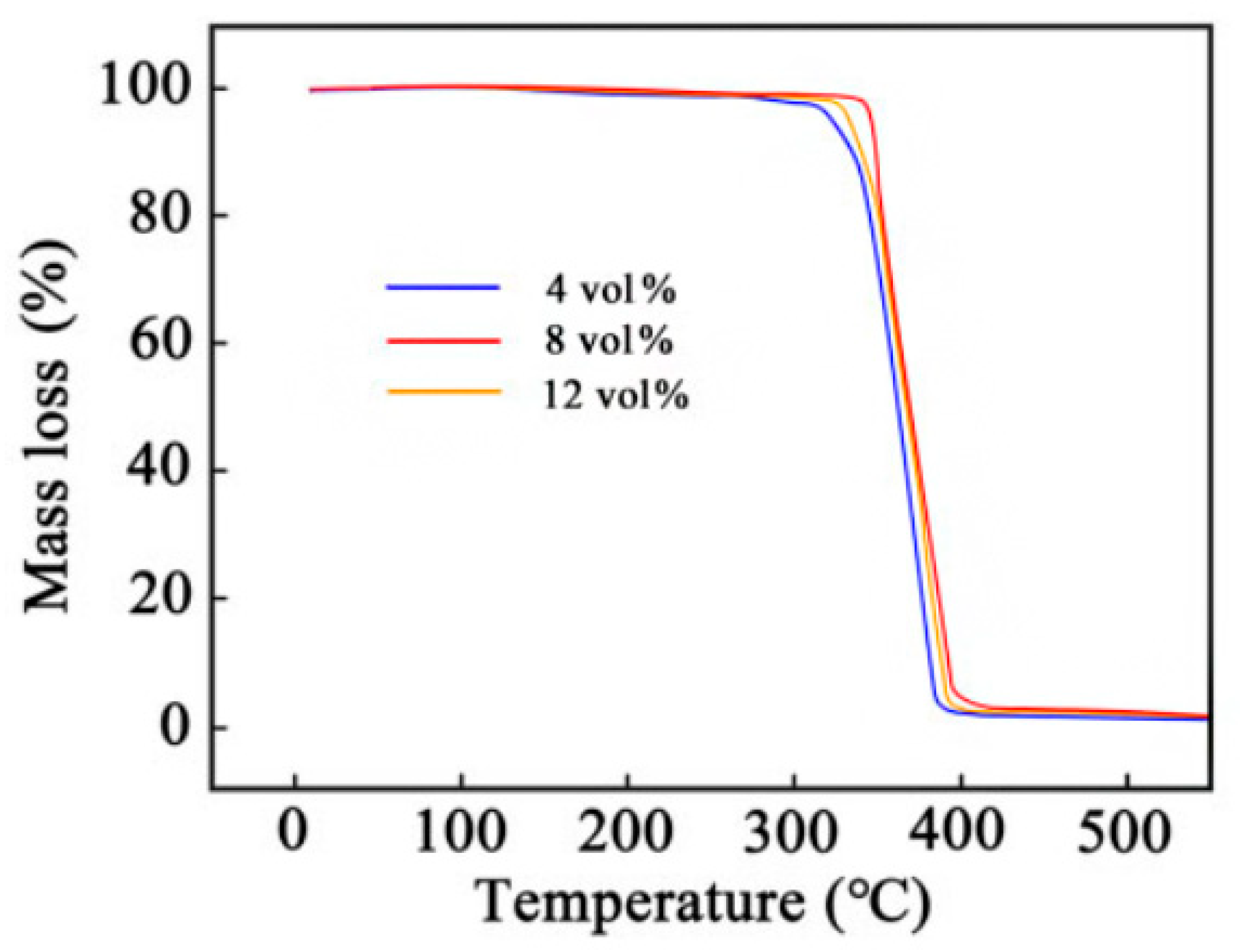

3.5. Thermal Properties of CF-PLA Monofilaments

4. Conclusions

- During 3D printed CF-PLA monofilaments, the optimal printing parameters were a nozzle diameter of ϕ0.4 mm, fiber feed rate (Vf) of 3 mm/s, print head movement speed (Vm) of 40 mm/s, and a retraction speed (Vr) of 5 mm/s.

- At a CF-PLA monofilament diameter of ϕ135 µm, the tensile strength and Young’s modulus reached maximum values of 48.3 MPa and 2481.8 MPa, respectively. At a CF content equivalent to 8 vol%, the monofilaments exhibited the highest tensile strength and Young’s modulus—approximately 2.5 times greater than those of PLA monofilaments.

- When the CF content was 4 vol%, the thermal decomposition temperature of the CF-PLA monofilament was 312.53 °C. At 8 vol% CF content, the thermal decomposition temperature increased to 342.62 °C—approximately 30 °C higher than that of the monofilament with 4 vol% CF. The CF-PLA monofilaments fabricated at 8 vol% demonstrated high thermal stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, S.; Singh, M.; Prakash, C.; Gupta, M.K.; Mia, M.; Singh, R. Optimization and Reliability Analysis to Improve Surface Quality and Mechanical Characteristics of Heat-Treated Fused Filament Fabricated Parts. Int. J. Adv. Manuf. Technol. 2019, 102, 1521–1536. [Google Scholar] [CrossRef]

- Tüfekci, K.; Çakan, B.G.; Küçükakarsu, V.M. Stress Relaxation of 3D Printed PLA of Various Infill Orientations under Tensile and Bending Loadings. J. Appl. Polym. Sci. 2023, 140, e54463. [Google Scholar] [CrossRef]

- Prajapati, A.R.; Dave, H.K.; Raval, H.K. Effect of Fiber Volume Fraction on the Impact Strength of Fiber Reinforced Polymer Composites Made by FDM Process. Mater. Today Proc. 2021, 44, 2102–2106. [Google Scholar] [CrossRef]

- Tutar, M. A Comparative Evaluation of the Effects of Manufacturing Parameters on Mechanical Properties of Additively Manufactured PA and CF-Reinforced PA Materials. Polymers 2023, 15, 38. [Google Scholar] [CrossRef] [PubMed]

- Tunçel, O. Optimization of Charpy Impact Strength of Tough PLA Samples Produced by 3D Printing Using the Taguchi Method. Polymers 2024, 16, 459. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.F. Evaluation of Cell Compatibility for Porous 3D CF/PLA/CS Composites Scaffold In Vitro. Chin. J. Appl. Chem. 2011, 28, 214–218. (In Chinese) [Google Scholar]

- Ansari, A.A.; Kamil, M. Izod impact and hardness properties of 3D printed lightweight CF-reinforced PLA composites using design of experiment. Int. J. Lightweight Mater. Manuf. 2022, 5, 369–383. [Google Scholar] [CrossRef]

- Lei, M.; Wang, Y.; Wei, J.W.Y. Micromechanical modeling and numerical homogenization calculation of effective stiffness of 3D printing PLA/CF composites. J. Manuf. Process. 2023, 102, 37–49. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, M.; Wang, Y.; Dai, W.; Li, L.; Chen, Y.; Kong, X.; Xu, K.; Yang, R.; Gong, P.; et al. Ultrahigh thermal conductive polymer composites by the 3D printing induced vertical alignment of carbon fiber. J. Mater. Chem. A 2023, 11, 10971–10983. [Google Scholar] [CrossRef]

- GB/T 9997-1988; Man-Made Fibres—Determination of Breaking Strength and Elongation of Individual Fibres. China National Textile Industry Federation: Beijing, China, 1988.

- Gantenbein, S.; Mascolo, C.; Houriet, C.; Zboray, R.; Neels, A.; Masania, K.; Studart, A. Spin-Printing of Liquid Crystal Polymer into Recyclable and Strong All-Fiber Materials. Adv. Funct. Mater. 2021, 31, 2104574. [Google Scholar] [CrossRef]

- Hivet, G.; Vidal-Sallé, E.; Boisse, P. Analysis of the stress components during the forming of a textile composite reinforcement. Key Eng. Mater. 2013, 554–557, 492–500. [Google Scholar] [CrossRef]

- Symes, M.D.; Kitson, P.J.; Yan, J.; Richmond, C.J.; Cooper, G.J.T.; Bowman, R.W.; Vilbrandt, T.; Cronin, L. Integrated 3D-printed reactionware for chemical synthesis and analysis. Nat. Chem. 2012, 4, 349–354. [Google Scholar] [CrossRef]

- Luo, H.; Xiong, G.; Ma, C.; Chang, P.; Yao, F.; Zhu, Y.; Zhang, C.; Wan, Y. Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym. Test. 2014, 39, 45–52. [Google Scholar] [CrossRef]

- Shen, L.; Yang, H.; Ying, J.; Qiao, F.; Mao, P. Preparation and mechanical properties of carbon fiber reinforced hydroxyapatite/polylactide biocomposites. J. Mater. Sci. Mater. Med. 2007, 20, 2259–2265. [Google Scholar] [CrossRef] [PubMed]

- Xia, F.; Yan, P.; Ma, C.; Wang, B.; Liu, Y. Effect of different heat-treated temperatures upon structural and abrasive performance of Ni-TiN composite nanocoatings. J. Mater. Res. Technol. 2023, 27, 2874–2881. [Google Scholar] [CrossRef]

- Pandey, D.; Pandey, R.; Mishra, A.; Tewari, R.P. Effect of Printing Temperature on Fatigue and Impact Performance of 3-D Printed Carbon Fiber Reinforced PLA Composites for Ankle Foot Orthotic Device. Mech. Compos. Mater. 2024, 60, 549–560. [Google Scholar] [CrossRef]

- Mahesh, S.; Beyerlein, I.J.; Phoenix, S.L. Size and heterogeneity effects on the strength of fibrous composites. Phys. D Nonlinear Phenom. 1999, 133, 371–389. [Google Scholar] [CrossRef]

- Keith, J.M.; King, J.A.; Miller, M.G.; Tomson, A.M. Thermal conductivity of carbon fiber/liquid crystal polymer composites. J. Appl. Polym. Sci. 2006, 102, 5456–5462. [Google Scholar] [CrossRef]

- Hasdiansah, H.; Yaqin, R.I.; Pristiansyah, P.; Umar, M.L.; Priyambodo, B.H. FDM-3D Printing Parameter Optimization Using Taguchi Approach on Surface Roughness of Thermoplastic Polyurethane Parts. Int. J. Interact. Des. Manuf. 2023, 17, 3011–3024. [Google Scholar] [CrossRef]

- Fan, W.; Li, J.; Zheng, Y.; Liu, T.; Tian, X.; Sun, R. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites. Polym. Degrad. Stab. 2016, 123, 162–169. [Google Scholar] [CrossRef]

| References | Products | Preparation Method | Performances |

|---|---|---|---|

| Ref. [6] | CF-PLA-CS (CS: Chitosan) composites | Solution blending and freeze-drying method | Porous biomaterials |

| Ref. [7] | CF-reinforced PLA composites | 3D printing |

|

| Ref. [8] | PLA/CF lamina | 3D printing |

|

| Contents | Parameters |

|---|---|

| Model | DF-G3545 |

| Printing size (mm) | 350 × 350 × 450 |

| Printing accuracy (mm) | ±0.05 |

| Filament diameter (mm) | ϕ1.75 |

| Nozzle diameter (mm) | ϕ0.4 |

| Print temperature (°C) | 200 |

| Table temperature (°C) | 50 |

| Top and bottom line | 3 |

| Wall line | 3 |

| CAD program | Solidwork2023 |

| Slicer program | Ultimaker Cura5.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, P.; Pan, T.; Li, Y.; Zhong, T.; Jiang, J.; Pu, C.; Ma, C. Performance and Thermal Properties of 3D Printed CF-Reinforced PLA Monofilaments. Coatings 2024, 14, 1479. https://doi.org/10.3390/coatings14121479

Jin P, Pan T, Li Y, Zhong T, Jiang J, Pu C, Ma C. Performance and Thermal Properties of 3D Printed CF-Reinforced PLA Monofilaments. Coatings. 2024; 14(12):1479. https://doi.org/10.3390/coatings14121479

Chicago/Turabian StyleJin, Pen, Tuo Pan, Yaxuan Li, Tianran Zhong, Jing Jiang, Chengcui Pu, and Chunyang Ma. 2024. "Performance and Thermal Properties of 3D Printed CF-Reinforced PLA Monofilaments" Coatings 14, no. 12: 1479. https://doi.org/10.3390/coatings14121479

APA StyleJin, P., Pan, T., Li, Y., Zhong, T., Jiang, J., Pu, C., & Ma, C. (2024). Performance and Thermal Properties of 3D Printed CF-Reinforced PLA Monofilaments. Coatings, 14(12), 1479. https://doi.org/10.3390/coatings14121479