Optimization of LPCVD Deposition Conditions of Silicon-Rich Silicon Nitride to Obtain Suitable Optical Properties for Photoluminescent Coating

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. First Experiment

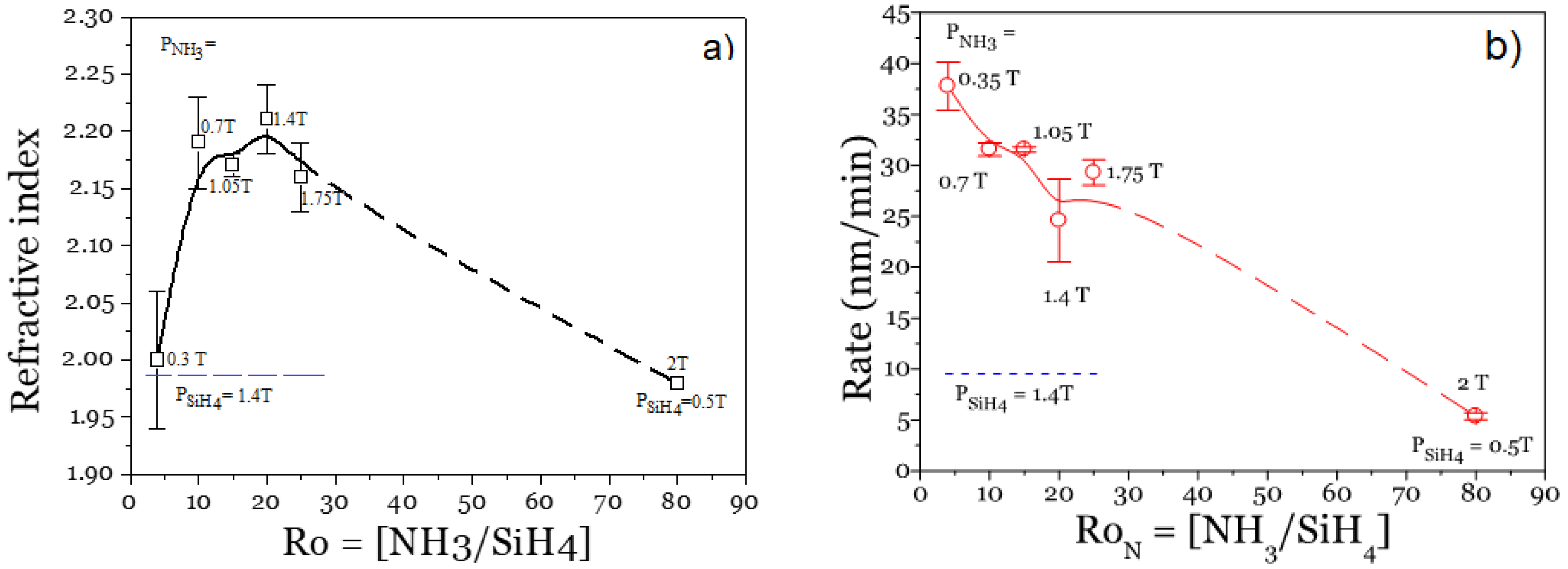

3.1.1. Refractive Index, Deposition Rate, and Pressure Ratio

3.1.2. Refractive Index Selection

3.2. Second Experiment

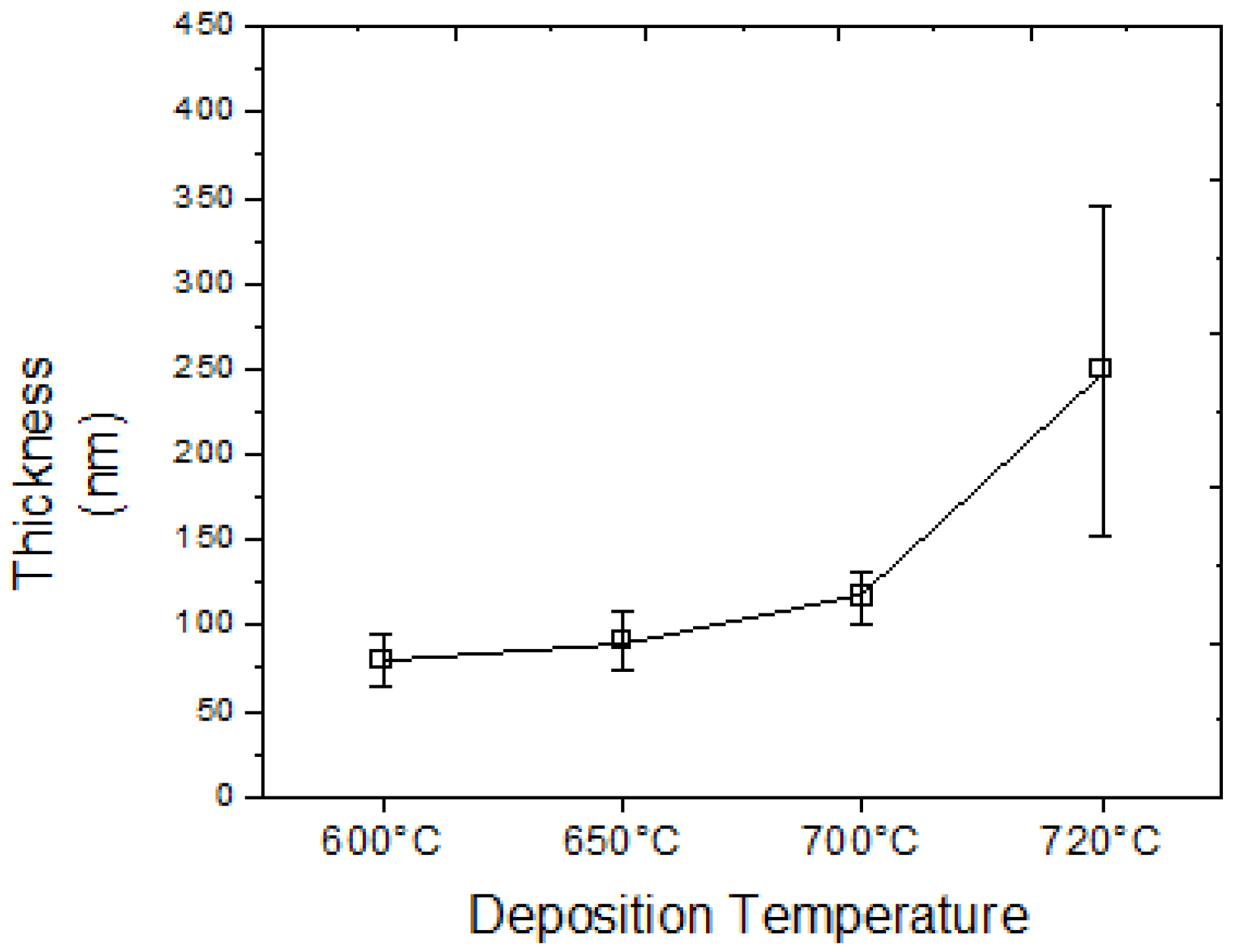

3.2.1. Thickness and Refractive Index Dependence on Temperature

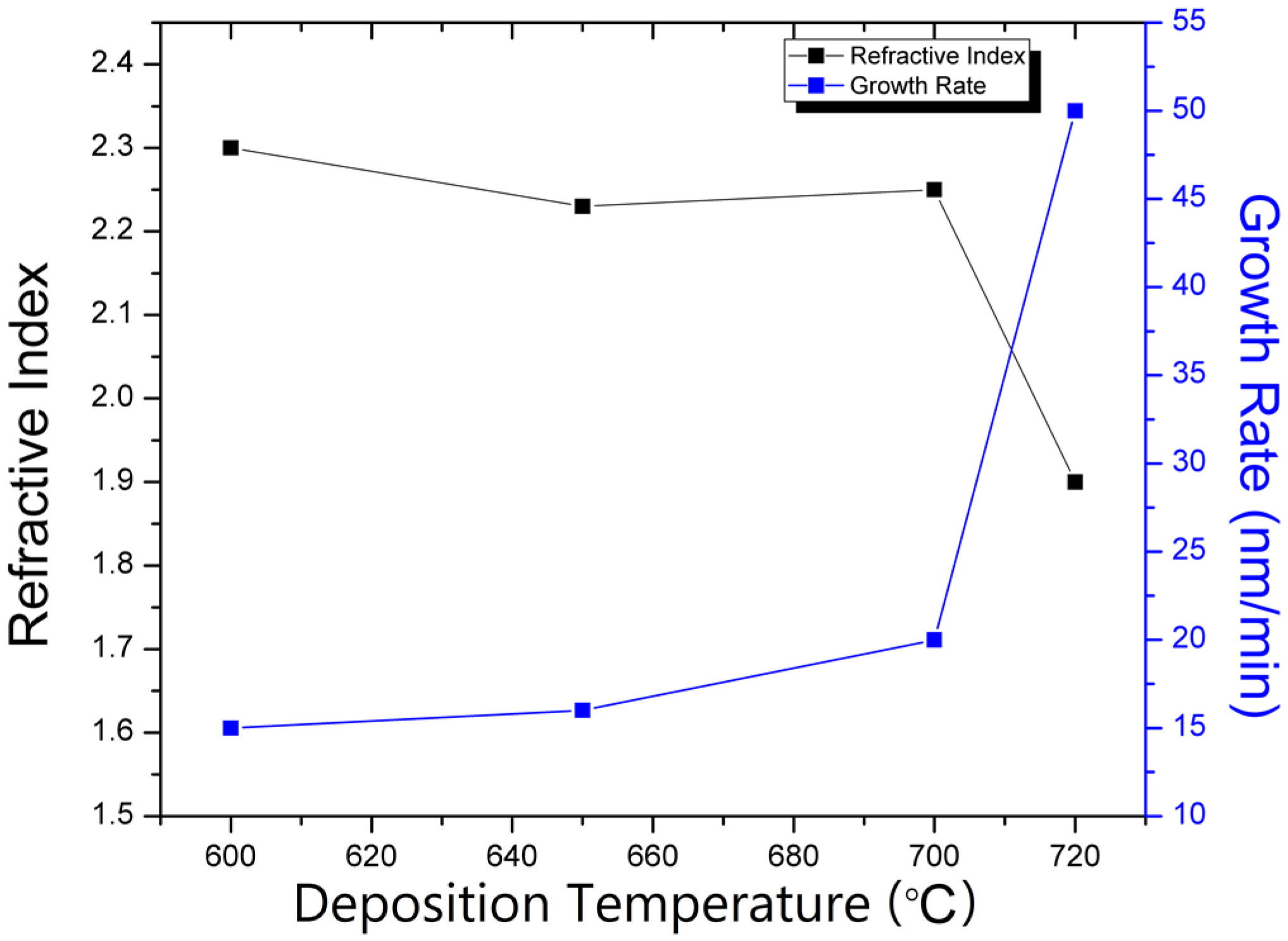

3.2.2. Refractive Index and Deposition Rate Dependence on Deposition Temperature

3.3. EDS Results

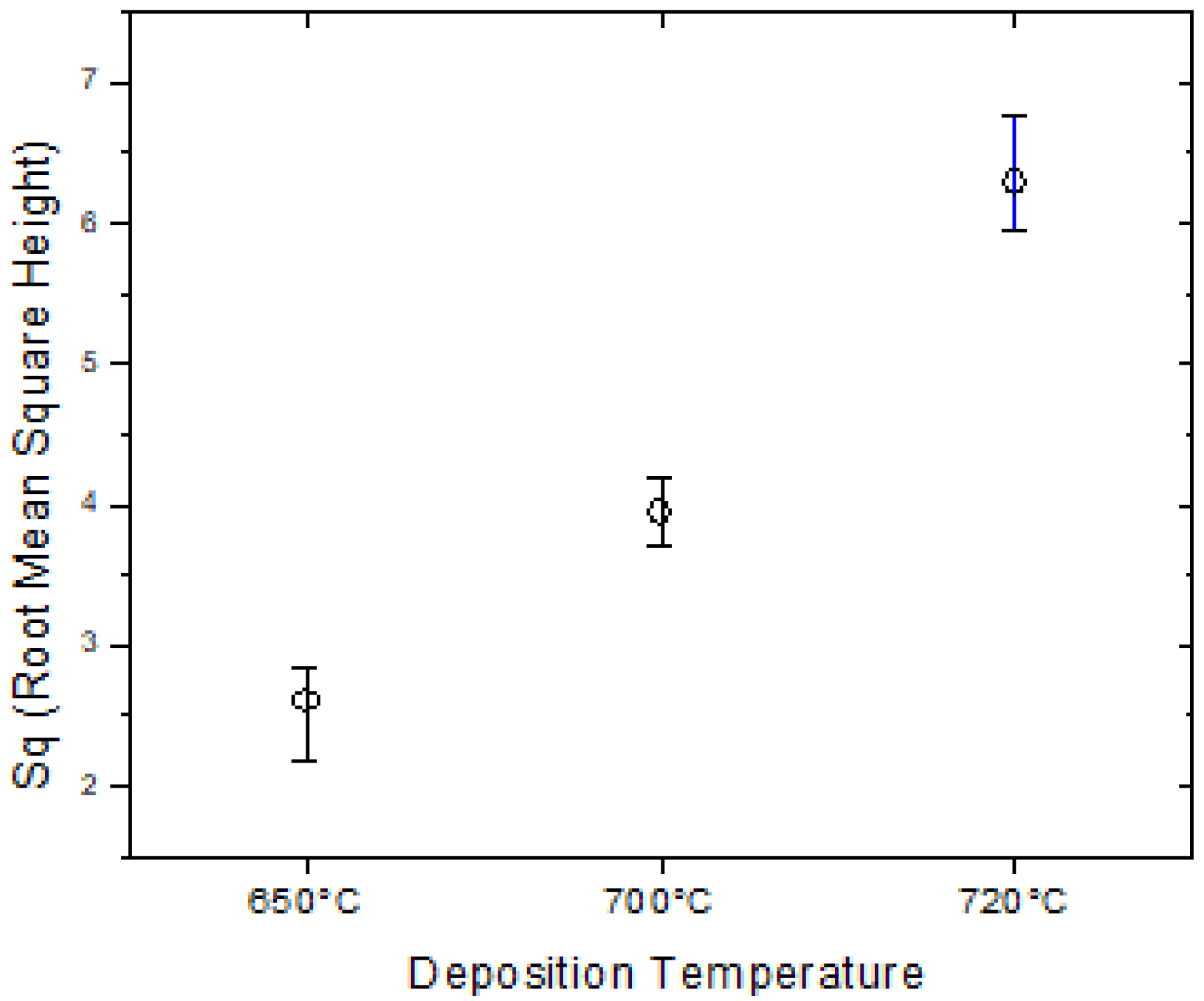

3.4. Surface Morphology Dependence on Temperature

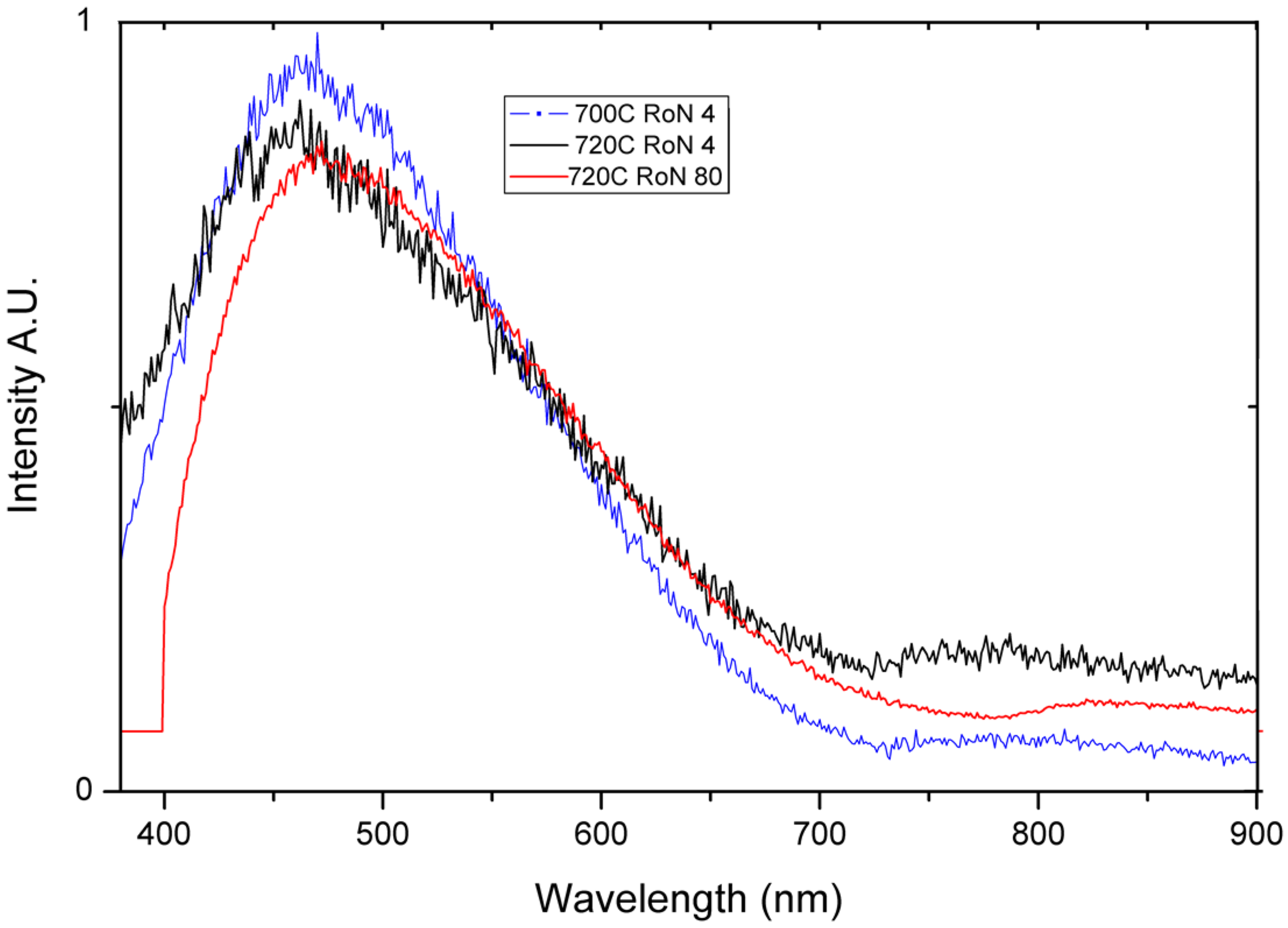

3.5. Photoluminescence

Optimal Thickness Calculation

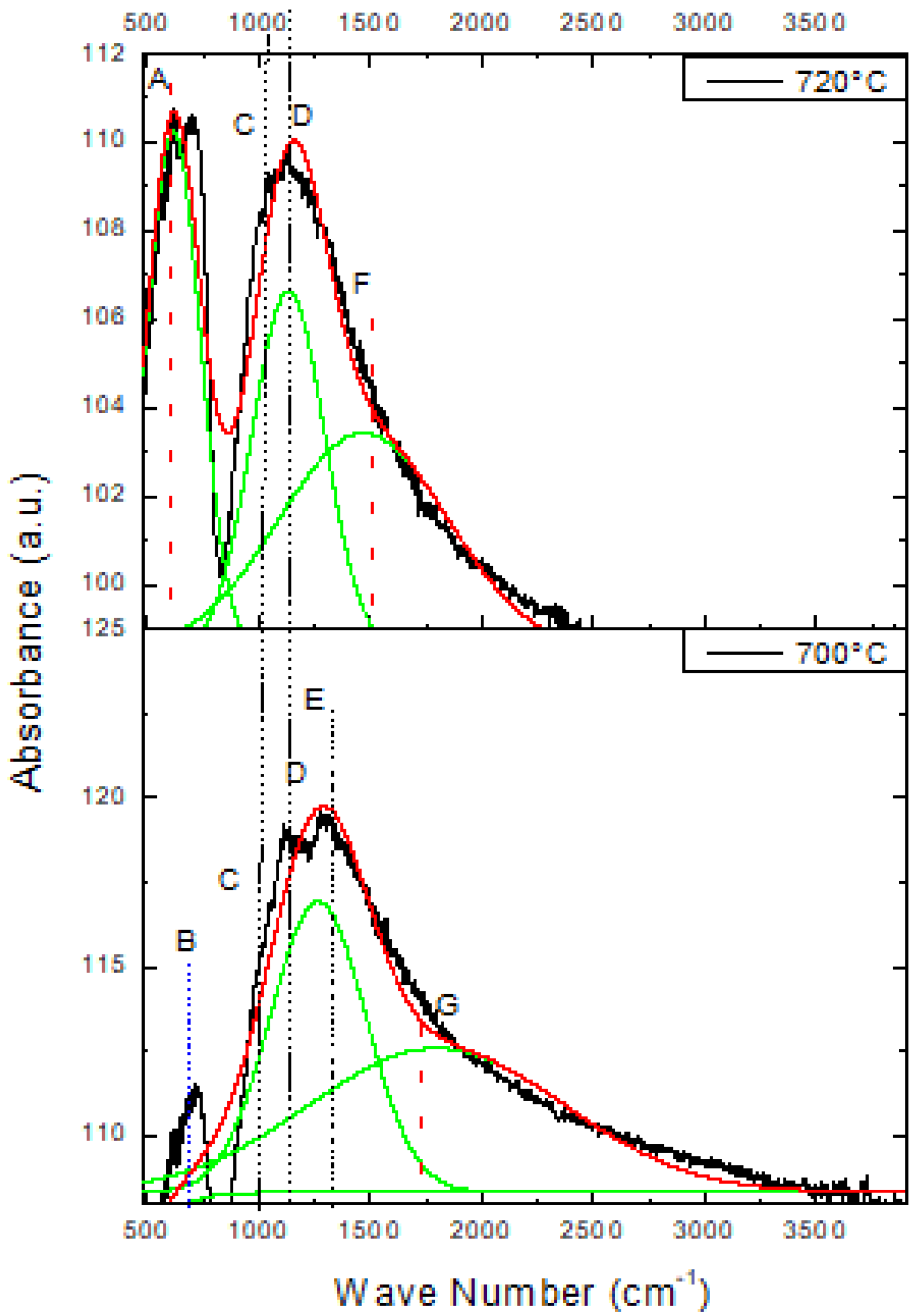

3.6. Analysis of Vibrational Modes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luft, W. Effects of electron irradiation on N on P silicon solar cells. Adv. Energy Convers. 1965, 5, 21–41. [Google Scholar] [CrossRef]

- Shah, A. Thin-Film Silicon Solar Cells. In Practical Handbook of Photovoltaics; Elsevier: Amsterdam, The Netherlands, 2012; pp. 209–281. [Google Scholar] [CrossRef]

- Lokteva, A.A.; Kotelnikova, A.A.; Kovylin, R.S.; Konev, A.N.; Piskunov, A.V. Novel Antireflection Coatings Obtained by Low-Temperature Annealing in the Presence of Tetrabutylammonium Bromide and Gold Nanoparticles. Materials 2022, 15, 7658. [Google Scholar] [CrossRef] [PubMed]

- Abu-Shamleh, A.; Alzubi, H.; Alajlouni, A. Optimization of antireflective coatings with nanostructured TiO2 for GaAs solar cells. Photonics Nanostruct. Fundam. Appl. 2021, 43, 100862. [Google Scholar] [CrossRef]

- Ho, W.-J.; Lin, J.-C.; Liu, J.-J.; Bai, W.-B.; Shiao, H.-P. Electrical and Optical Characterization of Sputtered Silicon Dioxide, Indium Tin Oxide, and Silicon Dioxide/Indium Tin Oxide Antireflection Coating on Single-Junction GaAs Solar Cells. Materials 2017, 10, 700. [Google Scholar] [CrossRef]

- Lee, Y.S.; Chuang, L.Y.; Tang, C.J.; Yan, Z.Z.; Le, B.S.; Jaing, C.C. Investigation into the Characteristics of Double-Layer Transparent Conductive Oxide ITO/TNO Anti-Reflection Coating for Silicon Solar Cells. Crystals 2023, 13, 80. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H.; Matovic, B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater. Sci. Eng. A 2010, 1314–1338. [Google Scholar] [CrossRef]

- Nguyen, V.S.; Burton, S.; Pan, P. The Variation of Physical Properties of Plasma-Deposited Silicon Nitride and Oxynitride with Their Compositions. J. Electrochem. Soc. 1984, 131, 2348. [Google Scholar] [CrossRef]

- De Brito Mota, F.; Justo, J.F.; Fazzio, A. Structural and electronic properties of silicon nitride materials. Int. J. Quant. Chem. 1998, 70, 973–980. [Google Scholar] [CrossRef]

- Beliaev, L.Y.; Shkondin, E.; Lavrinenko, A.V.; Takayama, O. Optical, structural and composition properties of silicon nitride films deposited by reactive radio-frequency sputtering, low pressure and plasma-enhanced chemical vapor deposition. Thin Solid Films 2022, 763, 139568. [Google Scholar] [CrossRef]

- Tahir, S.; Saeed, R.; Ashfaq, A.; Ali, A.; Mehmood, K.; Almousa, N.; Shokralla, E.A.; Macadangdang, R.R., Jr.; Soeriyadi, A.H.; Bonilla, R.S. Optical modeling and characterization of bifacial SiNx/AlOx dielectric layers for surface passivation and antireflection in PERC. Prog. Photovolt. Res. Appl. 2024, 32, 63–72. [Google Scholar] [CrossRef]

- Lelièvre, J.-F.; Kafle, B.; Saint-Cast, P.; Brunet, P.; Magnan, R.; Hernandez, E.; Pouliquen, S.; Massines, F. Efficient silicon nitride SiNx:H antireflective and passivation layers deposited by atmospheric pressure PECVD for silicon solar cells. Progress. Photovolt. 2019, 27, 1007–1019. [Google Scholar] [CrossRef]

- Yu, J.; Daoming, Y.; Yingchun, C.; Wentao, G.; Manqing, T. High-performance SiO2-SiNX distributed Bragg reflectors fabricated by ion-assisted reactive magnetron sputtering. Vacuum 2024, 220, 112775. [Google Scholar] [CrossRef]

- Lee, Y.; Gong, D.; Balaji, N.; Lee, Y.J.; Yi, J. Stability of SiNX/SiNX double stack antireflection coating for single crystalline silicon solar cells. Nanoscale Res. Lett. 2012, 7, 50. Available online: http://www.nanoscalereslett.com/content/7/1/50 (accessed on 2 September 2024). [CrossRef]

- Sharma, R. Silicon nitride as antireflection coating to enhance the conversion efficiency of silicon solar cells. Turk. J. Phys. 2018, 42, 350–355. [Google Scholar] [CrossRef]

- Guler, I. Optical and structural characterization of silicon nitride thin films deposited by PECVD. Mater. Sci. Eng. B 2019, 246, 21–26. [Google Scholar] [CrossRef]

- TuHuynh, T.C.; Keisuke, O. Long-term stability of low-temperature deposited Cat-CVD SiNx thin film against damp-heat stress. Jpn. J. Appl. Phys. 2024, 63, 01SP25. [Google Scholar] [CrossRef]

- Verlaan, V.; Van Der Werf, C.H.M.; Houweling, Z.S.; Romijn, I.G.; Weeber, A.W.; Dekkers, H.F.W.; Goldbach, H.D.; Schropp, R.E.I. Multi-crystalline Si solar cells with very fast deposited (180 nm/min) passivating hot-wire CVD silicon nitride as antireflection coating. Prog. Photovolt. Res. Appl. 2007, 15, 563–573. [Google Scholar] [CrossRef]

- Alain, E.K.; Jové, F.A.; Goff, J.; Arkles, B. Silicon Nitride and Silicon Nitride-Rich Thin Film Technologies: Trends in Deposition Techniques and Related Applications. ECS J. Solid State Sci. Technol. 2017, 6, P691. [Google Scholar] [CrossRef]

- Jones, S.W. Difussion in Silicon. 2008 IC Knowledge LLCC. Available online: https://api.semanticscholar.org/CorpusID:14437811 (accessed on 5 September 2024).

- Braña, A.F.; Gupta, H.; Bommali, R.K.; Srivastava, P.; Ghosh, S.; Casero, R.P. Enhancing efficiency of c-Si solar cell by coating nano structured silicon rich silicon nitride films. Thin Solid Films 2018, 662, 21–26. [Google Scholar] [CrossRef]

- Ali, R.M.; Zahran, M.B.; Youssif, A.M.; Eliwa, A. Characterization of Monocrystalline Silicon Solar Cells based on the Phosphorus Diffusion Temperature. Int. J. Eng. Sci. Invent. 2021, 10, 01–07. [Google Scholar] [CrossRef]

- de la Mora, M.B.; Amelines-Sarria, O.; Monroy, B.M.; Hernández-Pérez, C.D.; Lugo, J.E. Materials for down conversion in solar cells: Perspectives and challenges. Sol. Energy Mater. Sol. Cells 2017, 165, 59–71. [Google Scholar] [CrossRef]

- El amrani, A.; Menous, I.; Mahiou, L.; Tadjine, R.; Touati, A.; Lefgoum, A. Silicon nitride film for solar cells. Renew. Energy 2008, 33, 2289–2293. [Google Scholar] [CrossRef]

- Jana, T.; Mukhopadhyay, S.; Ray, S. Low temperature silicon oxide and nitride for surface passivation of silicon solar cells. Sol. Energy Mater. Sol. Cells 2002, 71, 197–211. [Google Scholar] [CrossRef]

- Hendawi, R.; Ciftja, A.; Stokkan, G.; Arnberg, L.; Di Sabatino, M. The effect of preliminary heat treatment on the durability of reaction bonded silicon nitride crucibles for solar cells applications. J. Cryst. Growth 2020, 542, 125670. [Google Scholar] [CrossRef]

- Sahouane, N.; Zerga, A. Optimization of antireflection multilayer for industrial crystalline silicon solar cells. Energy Procedia 2014, 44, 118–125. [Google Scholar] [CrossRef]

- Torchynska, T.V.; Espinola, J.L.C.; Khomenkova, L.; Hernandez, E.V.; Adame, J.A.A.; Slaoui, A. Structural and light emitting properties of silicon-rich silicon nitride films grown by plasma enhanced-chemical vapor deposition. Mater. Sci. Semicond. Process. 2015, 37, 46–50. [Google Scholar] [CrossRef]

- Cabañas-Tay, S.A.; Palacios-Huerta, L.; Aceves-Mijares, M.; Coyopol, A.; Morales-Morales, F.; Pérez-García, S.A.; Licea-Jiménez, L.; Domínguez-Horna, C.; Monfil-Leyva, K.; Morales-Sánchez, A. Study of narrow and intense UV electroluminescence from ITO/SRO/Si-p and ITO/SRN/SRO/Si-p based lightemitting capacitors. J. Lumin. 2017, 183, 334–340. [Google Scholar] [CrossRef]

- Yoshinaga, S.; Ishikawa, Y.; Kawamura, Y.; Nakai, Y.; Uraoka, Y. The optical properties of silicon-rich silicon nitride prepared by plasma-enhanced chemical vapor deposition. Mater. Sci. Semicond. Process. 2019, 90, 54–58. [Google Scholar] [CrossRef]

- Kaloyeros, A.; Pan, Y.; Goff, J.; Arkles, B. Review—Silicon Nitride and Silicon Nitride-Rich Thin Film Technologies: State-of-the-Art Processing Technologies, Properties, and Applications. ECS J. Solid State Sci. Technol. 2020, 9, 063006. [Google Scholar] [CrossRef]

- Bommali, R.; Preet, S.; Rai, S.; Mishra, P.; Sekhar, B.; Prakash, V.G.; Srivastava, P. Excitation dependent photoluminescence study of Si-rich a-SiNx:H thin films. J. Appl. Phys. 2012, 112, 123518. [Google Scholar] [CrossRef]

- Mamgain, S. Structural and optical study of amorphous hydrogenated silicon nitride thin film as antireflection coating on solar cell. Adv. Mater. Proc. 2017, 2, 570–574. [Google Scholar] [CrossRef]

- Rezgui, B.; Sibai, A.; Nychyporuk, T.; Lemiti, M.; Brémond, G. Photoluminescence and Optical Absorption Properties of Silicon Quantum Dots Embedded in Si-Rich Silicon Nitride Matrices; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar] [CrossRef]

- Liao, W.; Zeng, X.; Wen, X.; Zheng, W.; Yao, W. Synthesis and Optical Properties of Si-Rich Containing Silicon Quantum Dots. J. Electron. Mater. 2013, 42, 3445–3450. [Google Scholar] [CrossRef]

- Takeoda, S.; Fujii, M.; Hayashi, S. Size-dependent photoluminescence from surface-oxidized Si nanocrystals in a weak confinement regime. Phys. Rev. B 2000, 62, 16820–16825. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Ho, J.J.; Lee, W.J.; Tsai, S.Y.; Lu, Y.A.; Liou, J.J.; Chang, S.H.; Wang, K.L. Investigation of Low-Cost Surface Processing Techniques for Large-Size Multicrystalline Silicon Solar Cells. Int. J. Photoenergy 2010, 268035. [Google Scholar] [CrossRef]

- Liu, X.J.; Zhang, J.J.; Sun, X.W.; Pan, Y.B.; Huang, L.P.; Jin, C.Y. Growth and properties of silicon nitride films prepared by low pressure chemical vapor deposition using trichlorosilane and ammonia. Thin Solid Films 2004, 460, 72–77. [Google Scholar] [CrossRef]

- Komarov, F.F.; Parkhomenko, I.N.; Vlasukova, L.A.; Milchain, O.V.; Togambayeva, A.K.; Kovalchuck, N.S. Annealing Effects on Photoluminescence of SiNx films grown by PECVD. In Proceedings of the 10th International Conference: “Interaction of radiation with solids”, Minsk, Belarus, 24–27 September 2013; pp. 238–241, ISBN 978-985-553-141-9. [Google Scholar]

- Sharma, V.; Tracy, C.; Schroder, D.; Heresimenka, S.; Dauksher, W.; Bowden, S. Manipulation of K Center Charge Staates in silicon nitride films to achieve excellent Surface passivation for silicon solar cells. Appl. Phys. Lett. 2014, 104, 053503. [Google Scholar] [CrossRef]

- Kilian, S.O.; Wiggers, H. Gas-Phase Synthesis of Silicon-Rich Silicon Nitride Nanoparticles for High Performance Lithium–Ion Batteries. Part. Part. Syst. Charact. 2021, 38, 2100007. [Google Scholar] [CrossRef]

- Zhingunov, D.M.; Popov, A.A.; Chesnokov, Y.M.; Vasiliev, A.L.; Lebedev, A.M.; Subbotin, I.A.; Yakunin, S.N.; Shalygina, O.A.; Kamenskikh, I.A. Near-IR Emitting Si Nanocrystals Fabricated by thermal Annealing of SiNx/Si3N4 Multilayers. App. Sci. 2019, 9, 4725. [Google Scholar] [CrossRef]

- Chen, X.; Yang, W.; Yang, P.; Yuan, J.; Zhao, F.; Hao, J.; Tang, Y. Size-controlled Si Quantum dots embedded in B-doped SiNx/Si3N4 superlatice for Si quantum dot solar cells. J. Mater. Sci. Mater. Electron. 2017, 28, 1322–1327. [Google Scholar] [CrossRef]

- So, Y.-H.; Huang, S.; Conibeer, G.; Green, M.A. Formation and Photoluminiscence of Si nanocrystals in solid films. Thin Solid Films 2011, 519, 5408–5412. [Google Scholar] [CrossRef]

- Linnros, J.; Lalic, N.; Galeckas, A.; Grivickas, V. Analysis of the stretched exponential photoluminescence decay from nanometer-sized silicon crystals in SiO2. J. Appl. Phys. 1999, 86, 6128–6134. [Google Scholar] [CrossRef]

- Wang, M.; Li, D.; Yuan, Z.; Yang, D.; Que, D. Photoluminescence of Si-rich silicon nitride: Defect-related states and silicon nanoclusters. Appl. Phys. Lett. 2007, 90, 131903. [Google Scholar] [CrossRef]

- Esposito, E.M.; Mercado, L.V.; Veneri, P.D.; Lancellotti, L.; Privato, C. Annealing Effects on PECVD-Grown Si rich aSiNx Thin Films; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar] [CrossRef]

- Deshpande, S.V. Optical properties of silicon nitride films deposited by hot filament chemical vapor deposition. J. Appl. Phys. 1995, 77, 6534–6541. [Google Scholar] [CrossRef]

- Ko, C. Annealing effects on the photoluminescence of amorphous silicon-nitride films. J. Korean Phys. Soc. 2006, 48, 1277–1280. [Google Scholar]

- Valiei, M.; Shaibani, P.M.; Abdizadeh, H.; Kolahdouz, M.; Soleimani, E.A.; Poursaf, J. Design and optimization of single, double and multilayer anti-reflection coatings on planar and textured surface of silicon solar cells. Mater. Today Commun. 2022, 32, 104144. [Google Scholar] [CrossRef]

- Bugaev, K.O.; Zelenina, A.A.; Volodin, V.A. Vibrational Spectroscopy of Chemical Species in Silicon and Silicon-Rich Nitride Thin Films, Russian Academy of Sciences, Novosibirsk 63090, Russia. Int. J. Spectrosc. 2011, 2012, 2011. [Google Scholar] [CrossRef]

- Scardera, G.; Puzzer, T.; Conibeer, G.; Green, M. Fourier transform infrared spectroscopy of annealed silicon-rich silicon nitride thin films. J. Appl. Phys. 2008, 104, 104310. [Google Scholar] [CrossRef]

- Hoyos-García, J.E. Caracterización óptica y morfológica de partículas de silicio en una matriz SiNx obtenidas por PECVD, Instituto Politécnico Nacional. 2006. Available online: http://tesis.ipn.mx (accessed on 6 September 2024).

- Nekrashevich, S.S.; Shaposhnikov, A.V.; Gritsenko, V.A. Study of the atomic and electronic structures of amorphous silicon nitride and defects in it, institute of semiconductor physics. JETP Lett. 2011, 94, 202–205. [Google Scholar] [CrossRef]

- Torchynska, T.; Khomenkova, L.; Slaqui, A. Modification of light Emission in Si. Rich Silicon Nitride Films Versus Stoichiometry and Excitation light Energy. J. Electron. Mater. 2018, 47, 3927–3933. [Google Scholar] [CrossRef]

- Xie, M.; Li, D.; Wang, F.; Yang, D. Luminescence Properties of Silicon-Rich Silicon Nitride Films and Light Emitting Devices. ECS Trans. 2011, 35, 3–19. [Google Scholar] [CrossRef]

- Ahmed, N.; Singh, C.B.; Bhattacharya, S.; Dhara, S.; Bhargav, P.B. Raman and FTIR Studies on PECVD Grown Ammonia-Free Amorphous Silicon Nitride Thin Films for Solar Cell Applications. Conf. Pap. Sci. 2013, 2013, 837676. [Google Scholar] [CrossRef]

| Sample | NH3 (Torr) | SIH4 (Torr) | RoN | RATE (nm/min) | REFRACTIVE INDEX |

|---|---|---|---|---|---|

| LPC01 | 0.35 | 1.40 | 4 | 37.5 | 2.00 |

| LPC02 | 0.70 | 1.40 | 10 | 32.5 | 2.19 |

| LPC03 | 1.05 | 1.40 | 15 | 31.9 | 2.16 |

| LPC04 | 1.40 | 1.40 | 20 | 24 | 2.21 |

| LPC05 | 1.75 | 1.40 | 25 | 30 | 2.15 |

| LPC06 | 2.00 | 0.50 | 80 | 5 | 1.98 |

| Sample | Substrate | RoN | Thickness (nm) | Deposition Temperature (°C) | Growth Time (min) |

|---|---|---|---|---|---|

| LP21 | 2′′ N + (2.0 Ω·cm) | 4.00 | 75 | 600 | 5 |

| LP22 | 2′′ N + (2.0 Ω·cm) | 4.00 | 95 | 650 | 5 |

| LP23 | 2′′ N + (2.0 Ω·cm) | 4.00 | 112 | 700 | 5 |

| LP24 | 2′′ N + (2.0 Ω·cm) | 4.00 | 250 | 720 | 5 |

| Sample | Deposition Temperature (°C) | Silicon (At.%) | Nitrogen (At.%) | Oxygen (At.%) |

|---|---|---|---|---|

| LP24 | 720 | 60 | 25 | 2.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uribe González, F.; Monfil Leyva, K.; Moreno Moreno, M.; Morales Sánchez, A.; Muñoz Zurita, A.L.; Luna López, J.A.; Carrillo López, J.; Hernández de la Luz, J.A.D.; Salazar Valdez, A.S.L. Optimization of LPCVD Deposition Conditions of Silicon-Rich Silicon Nitride to Obtain Suitable Optical Properties for Photoluminescent Coating. Coatings 2024, 14, 1383. https://doi.org/10.3390/coatings14111383

Uribe González F, Monfil Leyva K, Moreno Moreno M, Morales Sánchez A, Muñoz Zurita AL, Luna López JA, Carrillo López J, Hernández de la Luz JAD, Salazar Valdez ASL. Optimization of LPCVD Deposition Conditions of Silicon-Rich Silicon Nitride to Obtain Suitable Optical Properties for Photoluminescent Coating. Coatings. 2024; 14(11):1383. https://doi.org/10.3390/coatings14111383

Chicago/Turabian StyleUribe González, Francisco, Karim Monfil Leyva, Mario Moreno Moreno, Alfredo Morales Sánchez, Ana L. Muñoz Zurita, José A. Luna López, Jesús Carrillo López, José A. D. Hernández de la Luz, and Alma S. L. Salazar Valdez. 2024. "Optimization of LPCVD Deposition Conditions of Silicon-Rich Silicon Nitride to Obtain Suitable Optical Properties for Photoluminescent Coating" Coatings 14, no. 11: 1383. https://doi.org/10.3390/coatings14111383

APA StyleUribe González, F., Monfil Leyva, K., Moreno Moreno, M., Morales Sánchez, A., Muñoz Zurita, A. L., Luna López, J. A., Carrillo López, J., Hernández de la Luz, J. A. D., & Salazar Valdez, A. S. L. (2024). Optimization of LPCVD Deposition Conditions of Silicon-Rich Silicon Nitride to Obtain Suitable Optical Properties for Photoluminescent Coating. Coatings, 14(11), 1383. https://doi.org/10.3390/coatings14111383