Corrosion Behavior of Tubing in High-Salinity Formation Water Environment Containing H2S/CO2 in Yingzhong Block

Abstract

1. Introduction

2. Experimental Procedure

2.1. Material and Solution

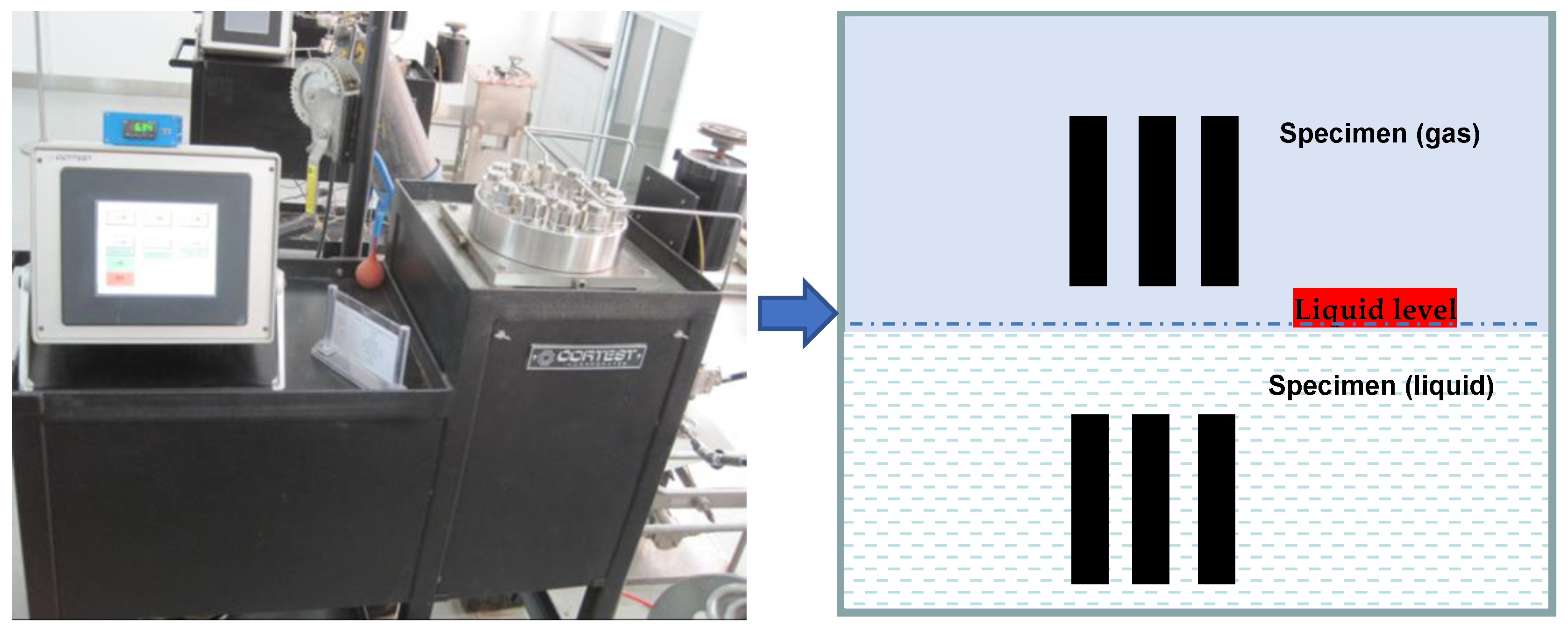

2.2. Weight Loss Tests

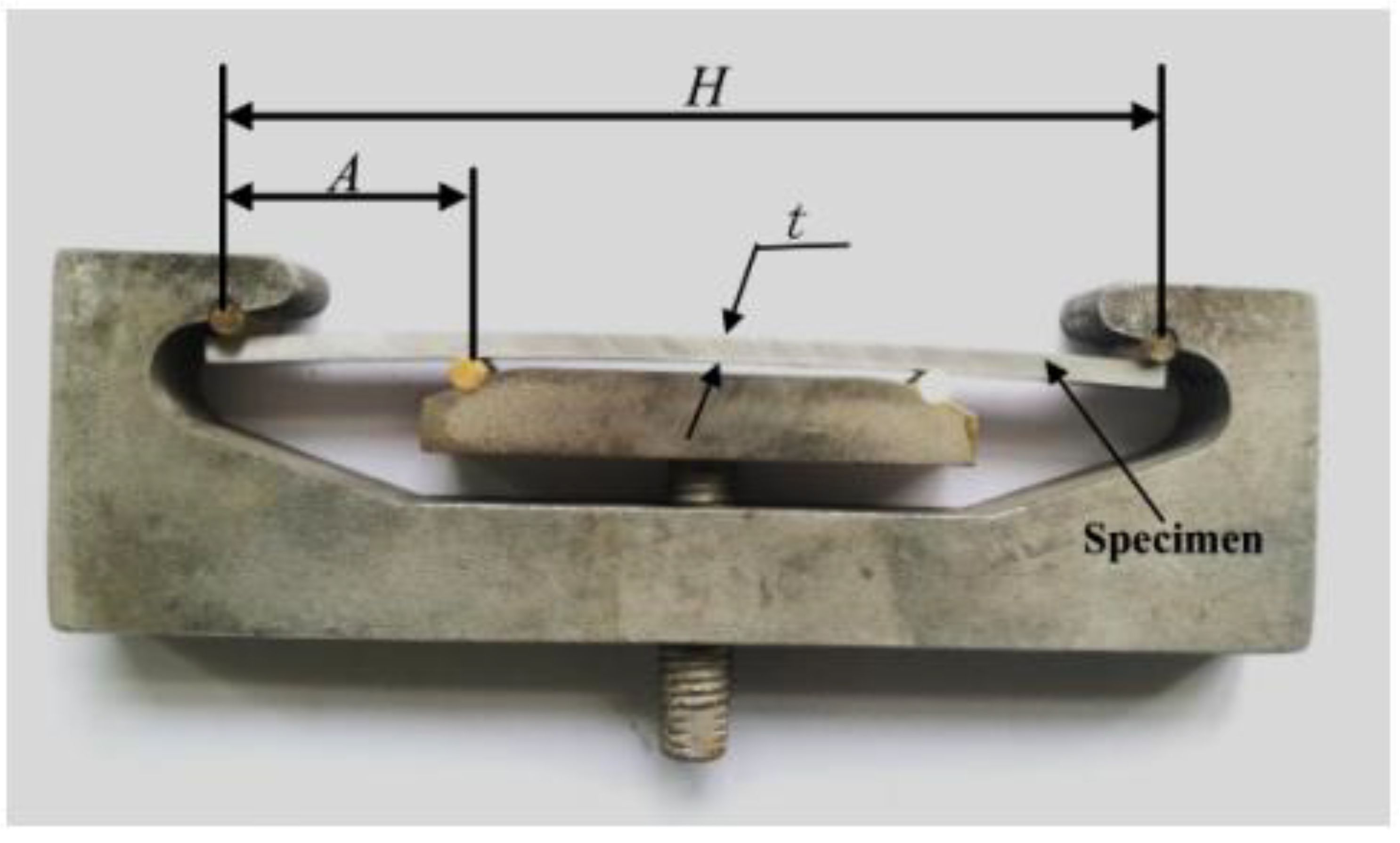

2.3. SCC Testing

2.4. Characterization

3. Results and Analysis

3.1. Average Corrosion Rate

3.2. Corrosion Morphology Characteristics

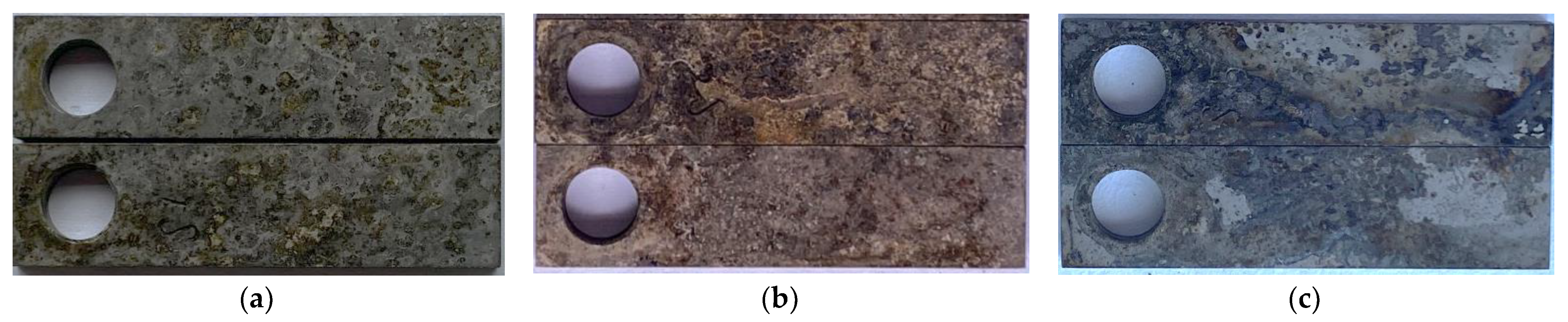

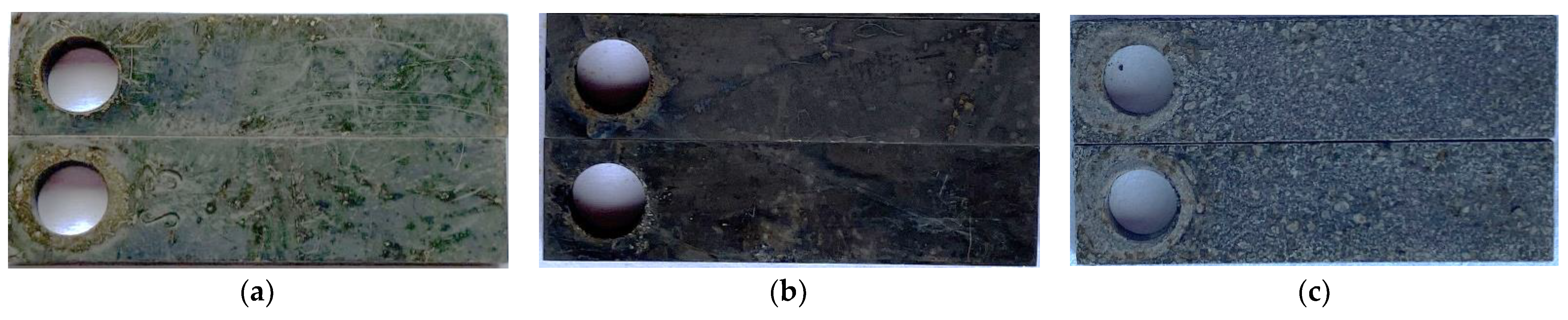

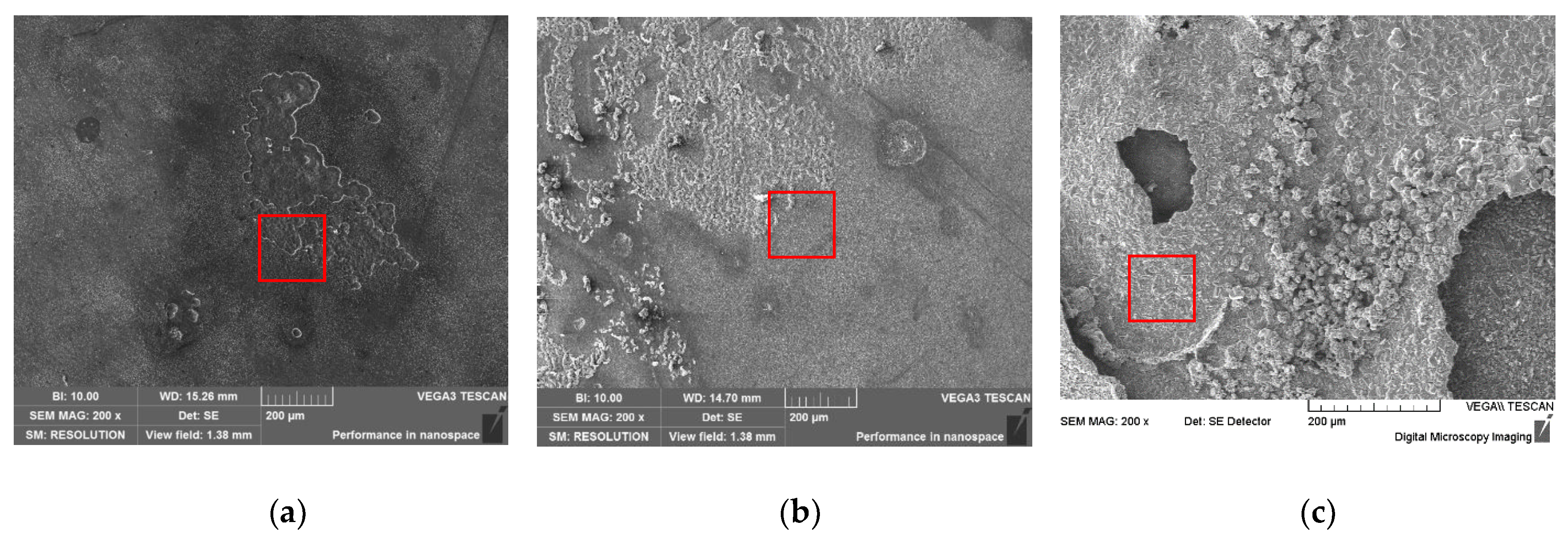

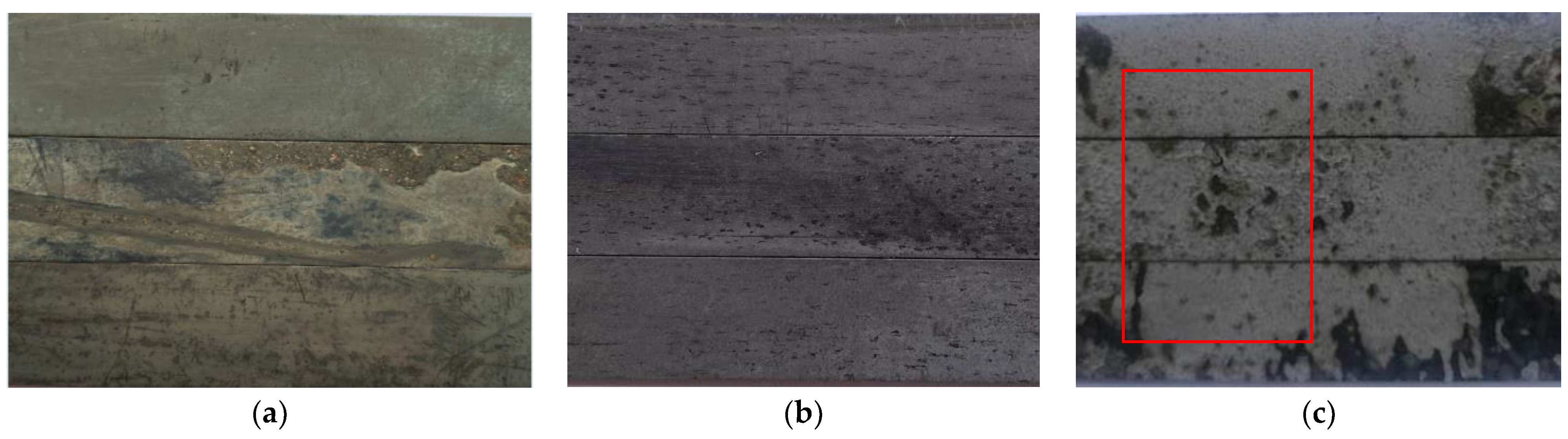

3.2.1. Macroscopic Corrosion Morphology under PH2S = 0.53 MPa

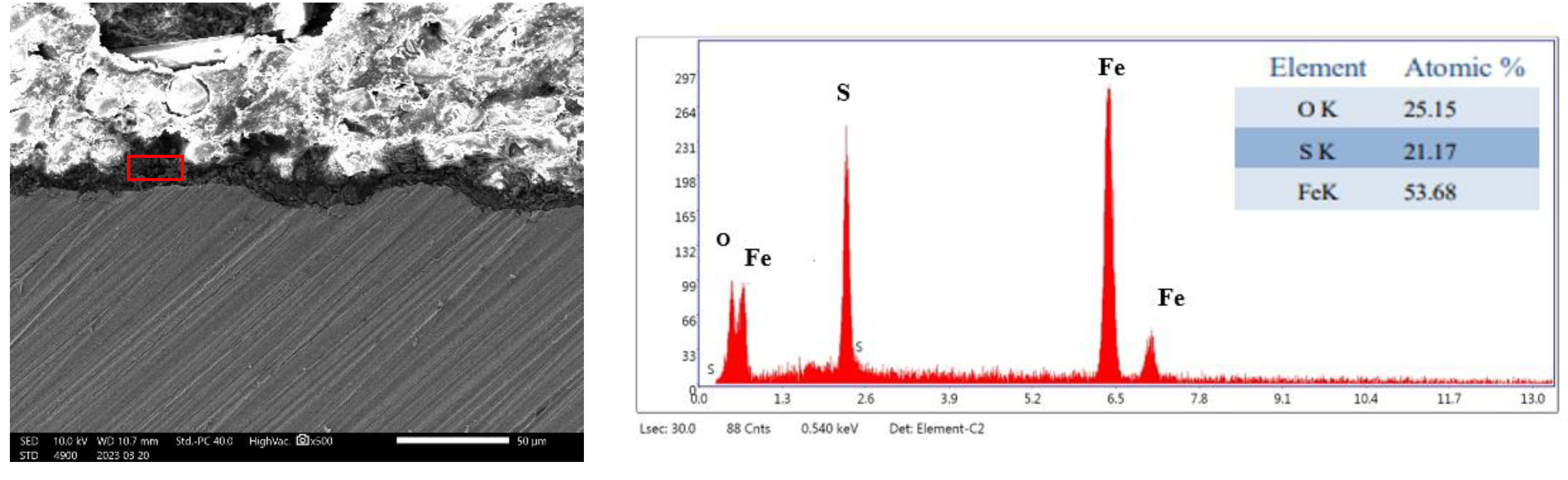

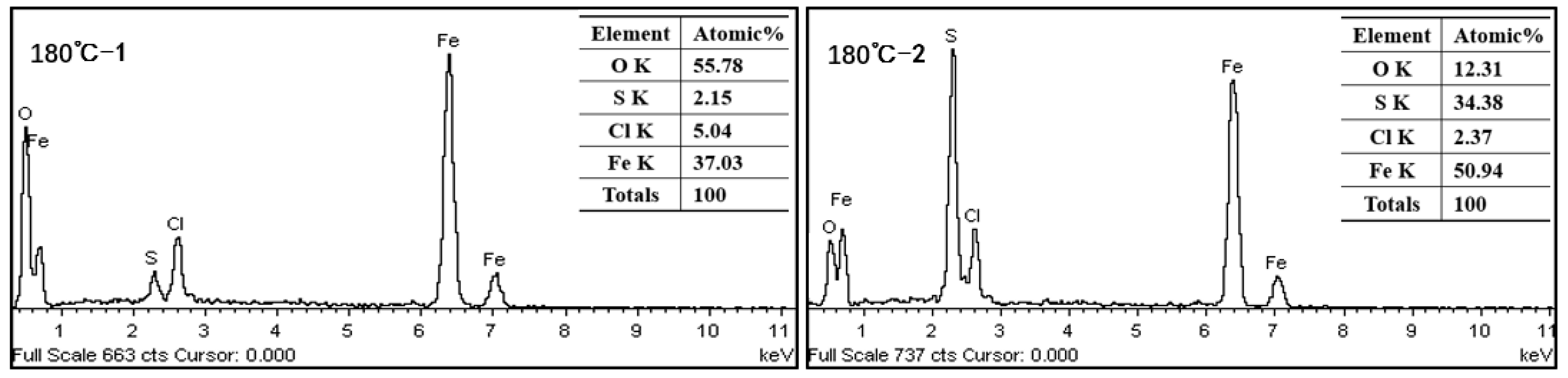

3.2.2. Micro-Corrosion Morphology When PH2S = 0.53 MPa

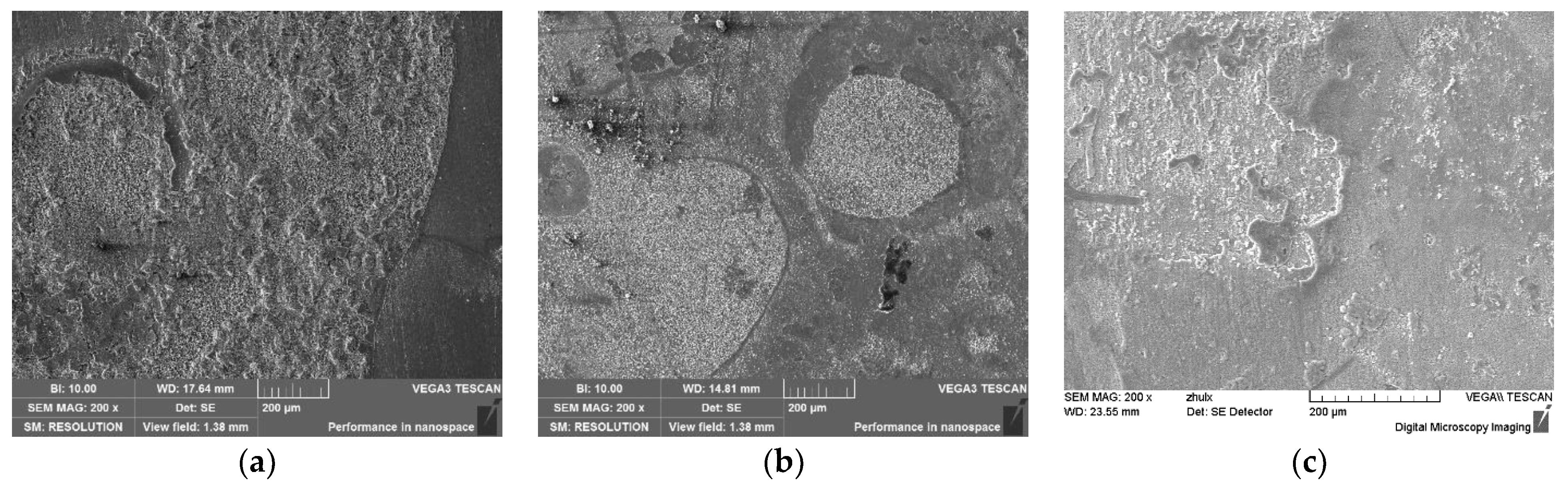

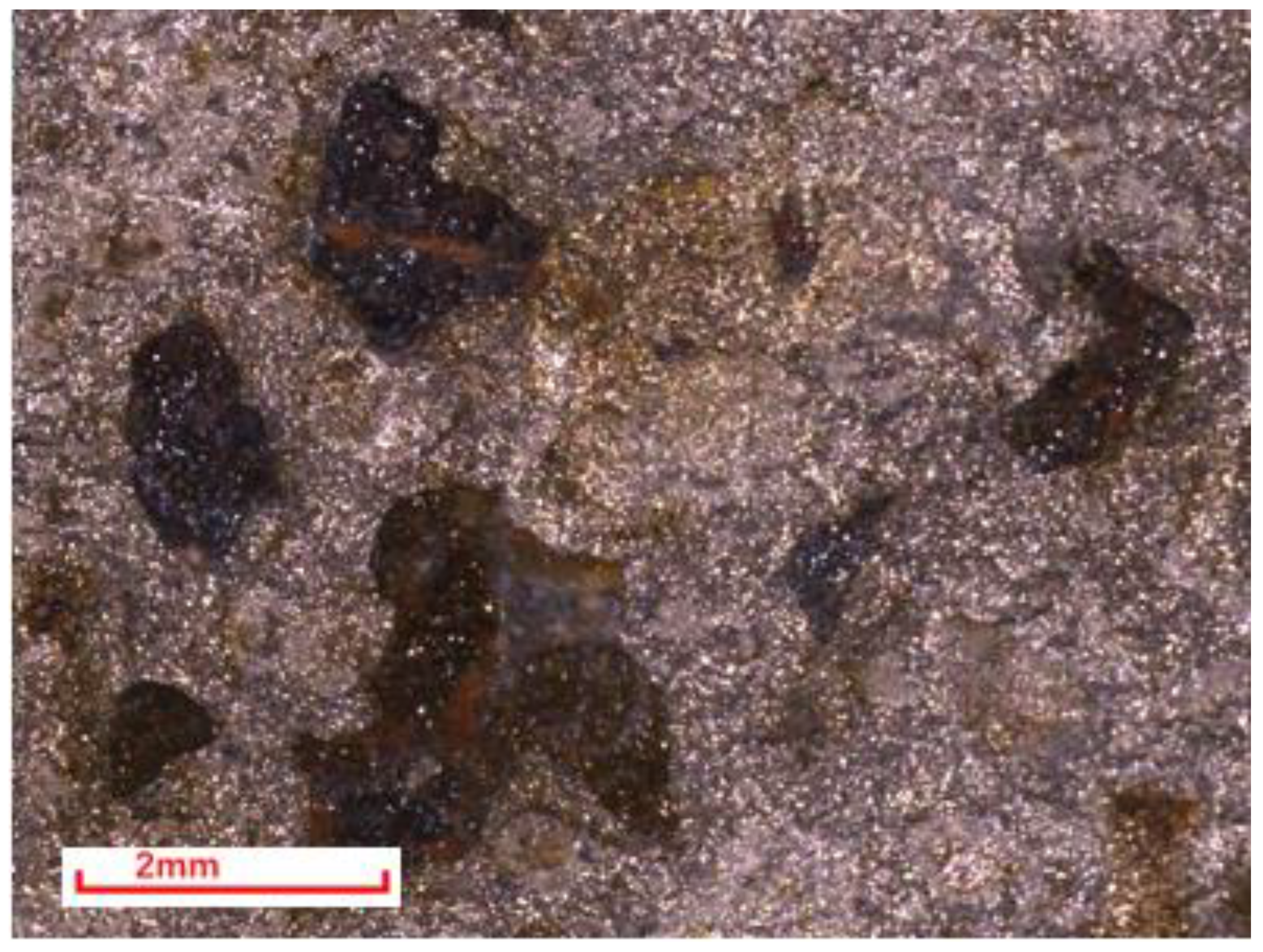

3.2.3. Microscopic Corrosion Morphology under PH2S = 0.28 MPa

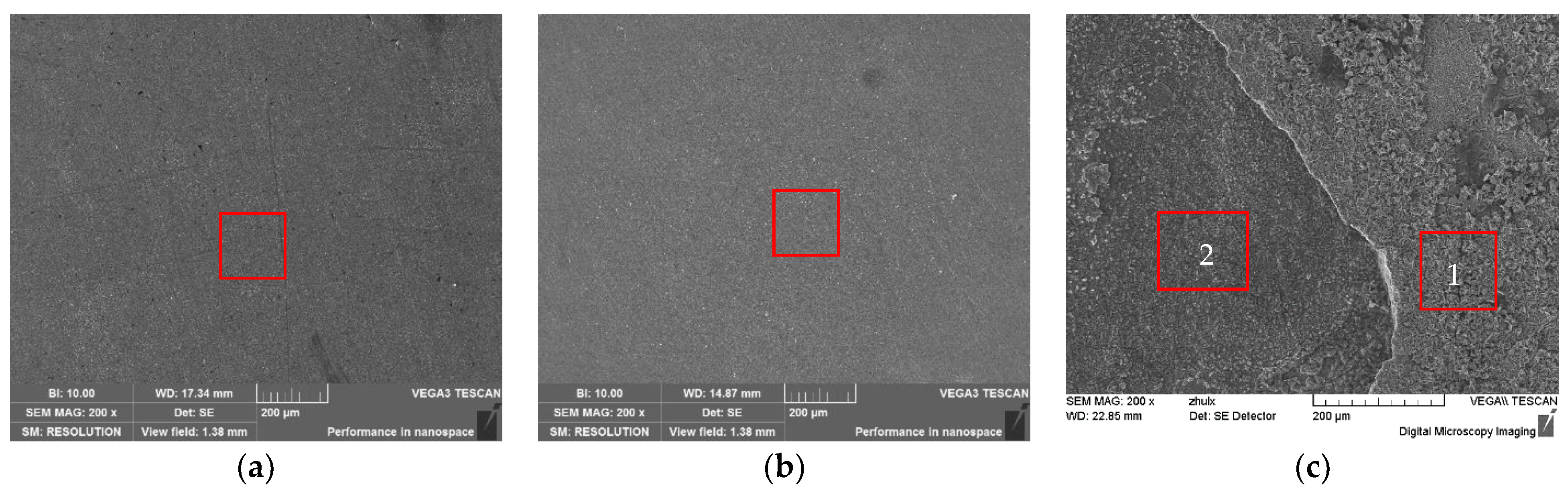

3.3. SCC in H2S-Containing Environment

3.4. Discussion

3.4.1. Corrosion Mechanism

3.4.2. Stress Sensitivity Analysis

4. Conclusions

- (1)

- In the simulated formation water environment with a high salinity of 292 g/L and H2S/CO2 corrosion gas, the average corrosion rate of the P110SS material gradually increases as the temperature rises from 80 °C to 180 °C, and when PH2S = 0.53 MPa and PCO2 = 0.17 MPa, the corrosion rate of P110SS can reach up to 0.99 mm/a.

- (2)

- In both liquid and gas phase environments, the morphology of the corrosion product film on P110SS varies due to the different states of the material that are in contact with the corrosive medium. In a gas phase environment, a locally rough and spotty-shaped corrosion product film is formed as a result of varying degrees of aggregation in the liquid film.

- (3)

- When the simulated test temperature gradually increases from 80 °C to 180 °C with a PH2S: PCO2 ratio of 0.53:0.17, the P110SS material shows no sensitivity to SCC when loaded with stress at 85% YSmin. However, as the temperature increases, the material becomes more susceptible to pitting corrosion. At high temperatures (180 °C), pitting occurs, but does not lead to cracking or fracturing of the material.

- (4)

- When the simulated test temperature is ≥120 °C, the P110SS material experiences extremely severe corrosion, Therefore, it is recommended to take appropriate anti-corrosion measures when using P110SS in an environment with a temperature of ≥120 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Zheng, Y.S.; Li, J.; Liu, W.Y.; Liu, M.Q.; Gao, W.X.; Shi, T.H. Stress corrosion crack evaluation of super 13Cr tubing in high-temperature and high-pressure gas wells. Eng. Fail. Anal. 2019, 95, 263. [Google Scholar] [CrossRef]

- Zhao, M.F.; Fu, A.Q.; Qin, H.-D.; Xie, J.-F.; Xie, G.; Long, Y.; Li, Y.; Wang, H. Overview and Future Research Prospect of Tubing String Corrosion of High Pressure and High Temperature Gas Well. Surf. Technol. 2018, 47, 44–50. [Google Scholar]

- Fu, A.Q.; Feng, Y.R.; Cai, R.; Yuan, J.T.; Yin, C.X.; Yang, D.M.; Long, Y.; Bai, Z.Q. Downhole corrosion behavior of NiW coated carbon steel in spent acid & formation water and its application in full-scale tubing. Eng. Fail. Anal. 2016, 66, 566–576. [Google Scholar]

- Chudyk, I.; Poberezhny, L.; Hrysanchuk, A.; Poberezhna, L. Corrosion of drill pipes in high mineralized produced waters. Procedia Struct. Integr. 2019, 16, 260–264. [Google Scholar] [CrossRef]

- Gao, S.; Dong, C.; Fu, A.; Xiao, K.; Li, X. Corrosion behavior of the expandable tubular in formation water. Int. J. Miner. Metall. Mater. 2015, 22, 149–156. [Google Scholar] [CrossRef]

- Zhang, P. Study on Formation Water and Wellbore Corrosion and Scaling after CO2 Flooding in Changqing. Ph.D. Thesis, China University of Petroleum (Beijing), Beijing, China, 2022. [Google Scholar]

- Wang, S.; Zheng, X.; Li, M.; Huang, X.; Guan, J.; Zheng, S.; Chen, C.; Chen, Y. Stress corrosion cracking sensitivity of sulfide-resistant casing steel P110SS in hyperbaric H2S/CO2 enviroments. Corros. Prot. 2013, 34, 189–192. [Google Scholar]

- Deng, H.; Li, Y.; Zhang, Z.; Lu, Q.; Hou, D. Environment cracking and surface protection of C110 casing in sour and deep well. J. Southwest Pet. Univ. 2021, 43, 118–128. [Google Scholar]

- Huang, S.; Ke, Y.; Liu, J.; Fan, Z. Analysis of Corrosion Influencing Factors of P110SS Steel in Simulated Annular Fluid Environment of Gas Well Containing Sulfur. Mater. Prot. 2022, 55, 46–51. [Google Scholar]

- Liu, J.; Wang, Y.; Li, G.; Wang, Q.; Wang, F.; Luo, J.; Zhao, X. Study on the Corrosion Behavior of Oil Casing String in Annular Protection Fluid Environment of Kunteyi Block. Mater. Prot. 2022, 55, 46–53. [Google Scholar]

- Li, M.; Zhang, Z.; Li, Y.; Dong, X.; Li, Q. Study on the Influence Factors of Corrosion Behavior of Gas Well Tubing in Environments Containing CO2-H2S-Cl−. Mater. Prot. 2022, 55, 41–45. [Google Scholar]

- Wang, Y. Corrosion rule of P110SS under high H2S and CO2 conditions. Fault-Block Oil Gas Field 2017, 24, 863–865. [Google Scholar]

- Zhang, N.Y.; Zhang, Z.; Zhao, W.T.; Liu, L.; Shi, T.H. Corrosion Evaluation of Tubing Steels and Material Selection in the CO2/H2S Coexistent Environment. In CORROSION 2018; NACE International: Phoenix, AZ, USA, 2018. [Google Scholar]

- Bueno, A.H.S.; Moreira, E.D.; Gomes, J.A.C.P. Evaluation of stress corrosion cracking and hydrogen embrittlement in an API grade steel. Eng. Fail. Anal. 2014, 36, 423. [Google Scholar] [CrossRef]

- Xue, H.; Feng, Y.; Tang, S.; Zhang, J. Electrochemical Corrosion Behavior of 15Cr-6Ni-2Mo Stainless Steel with/without Stress under the coexistence of CO2 and H2S. Int. J. Electrochem. Sci. 2018, 13, 6296–6309. [Google Scholar]

- JB/T (1999). GB/T Standard 7901; Metal Materials-Uniform Corrosion-Methods of Laboratory Immersion Testing. Institute of Integrated Technology and Economics of Mechanical Industrial Instruments and Meters: Beijing, China, 2001.

- Zhao, X.; Huang, W.; Li, G.; Feng, Y.; Zhang, J. Effect of CO2/H2S and Applied Stress on Corrosion Behavior of 15Cr Tubing in Oil Field Environment. Metals 2020, 10, 409. [Google Scholar] [CrossRef]

- Liu, Q.Y.; Mao, L.J.; Zhou, S.W. Effects of chloride content on CO2 corrosion of carbon steel in simulated oil and gas well environments. Corros. Sci. 2014, 84, 165–171. [Google Scholar] [CrossRef]

- Zhang, G.A.; Zeng, Y.; Guo, X.P.; Jiang, F.; Shi, D.Y.; Chen, Z.Y. Electrochemical corrosion behavior of carbon steel under dynamic high pressure H2S/CO2 environment. Corros. Sci. 2012, 65, 37. [Google Scholar] [CrossRef]

- Kittel, J.; Ropital, F.; Grosjean, F.; Sutter, E.M.M.; Tribollet, B. Corrosion mechanisms in aqueous solutions containing dissolved H2S. Part 1: Characterisation of H2S reduction on a 316L rotating disc electrode. Corros. Sci. 2013, 66, 324–329. [Google Scholar] [CrossRef]

- Zhao, X.H.; Han, Y.; Bai, Z.Q.; Wei, B. The experiment research of corrosion behavior about Ni-based alloys in simulant solution containing H2S/CO2. Electrochim. Acta 2011, 56, 7725. [Google Scholar] [CrossRef]

- Jiang, W.J. Piping Material Selection for Wet H2S Environment of Hydrotreating Unit. Shandong Chem. Ind. 2019, 48, 118. [Google Scholar]

- Lin, P. Study on Mechanism and Inhibition Strategy of Under-Deposit Corrosion of Carbon Steel Pipeline in Oil and Gas Fields. Ph.D. Thesis, University of Science and Technology of China, Jiangsu, China, 2021. [Google Scholar]

- Zhu, Y.; Qiu, Y.; Guo, X. Underscale corrosion behavior of carbon steel in a NaCl solution using a new occluded cavity cell for simulation. J. Appl. Electrochem. 2009, 39, 1017–1023. [Google Scholar] [CrossRef]

- He, S.; Luo, S.; Zhao, H.; Xue, P. Review of Carbon Steel Under Deposit Corrosion in CO2 Environment. Surf. Technol. 2023, 52, 148–157. [Google Scholar]

- Liu, Y.; Chang, Z.; Zhao, G.; Xue, Y.; Niu, K. Corrosion Behavior of Super 13% Cr Martensitic Stainless Steel Under Ultra-deep, Ultra-high Pressure and High Temperature Oil and Gas Well Environment. Mater. Heat Treat. 2012, 41, 71–75. [Google Scholar]

- Zhao, G.; Chen, C.; Lu, M.; Li, H. The formation of product scale and mass transfer channels during CO2 corrosion. J. Chin. Soc. Corros. Prot. 2002, 22, 363–366. [Google Scholar]

- Li, M.; Hu, Z.; Yang, G.; Wu, C. CO2 Corrosion Behaviour of Three kinds of Pipeline Steels with Different Cr Contents. Corros. Prot. 2013, 34, 586–589. [Google Scholar]

- Zakroczymski, T.; Glowacka, A.; Swiatnicki, W. Effect of hydrogen concentration on the embrittlement of a duplex stainless steel. Corros. Sci. 2005, 47, 1403–1414. [Google Scholar] [CrossRef]

| Cl− | Mg2+ | Ca2+ | K+ | Na+ | SO42+ | HCO3− | PH | Salinity |

|---|---|---|---|---|---|---|---|---|

| 186 | 0.035 | 0.11 | 7.05 | 104 | 24.3 | 1.07 | 6.28 | 292 |

| Items | Test Temperature (°C) | H2S Content (MPa) | CO2 Content (MPa) | Total Pressure (MPa) | Test Period (h) |

|---|---|---|---|---|---|

| Parameters | 80 | 0.53 0.28 | 0.17 | 10 | 168 |

| 120 | |||||

| 180 |

| Ambient Temperature Elements | 80 °C | 120 °C | 180 °C | |||

|---|---|---|---|---|---|---|

| Gas | Liquid | Gas | Liquid | Gas | Liquid | |

| O Wt% | 7.12 | 8.82 | 8.69 | 9.86 | 9.29 | 8.48 |

| S Wt% | 29.09 | 10.21 | 32.49 | 18.64 | 29.41 | 32.47 |

| Fe Wt% | 63.79 | 80.09 | 58.82 | 73.49 | 59.77 | 59.06 |

| Items | Temperature/°C | H2S Content (MPa) | CO2 Content (MPa) | Test Cycle/h | State | Applied Stress |

|---|---|---|---|---|---|---|

| Parameters | 80, 120, 180 | 0.53 | 0.17 | 720 | Liquid | 85%YSmin |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Liu, J.; Yao, B.; Li, C.; Xia, X.; Fu, A. Corrosion Behavior of Tubing in High-Salinity Formation Water Environment Containing H2S/CO2 in Yingzhong Block. Coatings 2023, 13, 1342. https://doi.org/10.3390/coatings13081342

Zhao X, Liu J, Yao B, Li C, Xia X, Fu A. Corrosion Behavior of Tubing in High-Salinity Formation Water Environment Containing H2S/CO2 in Yingzhong Block. Coatings. 2023; 13(8):1342. https://doi.org/10.3390/coatings13081342

Chicago/Turabian StyleZhao, Xuehui, Junlin Liu, Baisheng Yao, Cheng Li, Xue Xia, and Anqing Fu. 2023. "Corrosion Behavior of Tubing in High-Salinity Formation Water Environment Containing H2S/CO2 in Yingzhong Block" Coatings 13, no. 8: 1342. https://doi.org/10.3390/coatings13081342

APA StyleZhao, X., Liu, J., Yao, B., Li, C., Xia, X., & Fu, A. (2023). Corrosion Behavior of Tubing in High-Salinity Formation Water Environment Containing H2S/CO2 in Yingzhong Block. Coatings, 13(8), 1342. https://doi.org/10.3390/coatings13081342