Structure and Properties of Ti3AlC2-SiC and Ti3AlC2-TiC Materials Obtained by Powder Injection Molding Technology

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Melt Flow Index of the Feedstocks

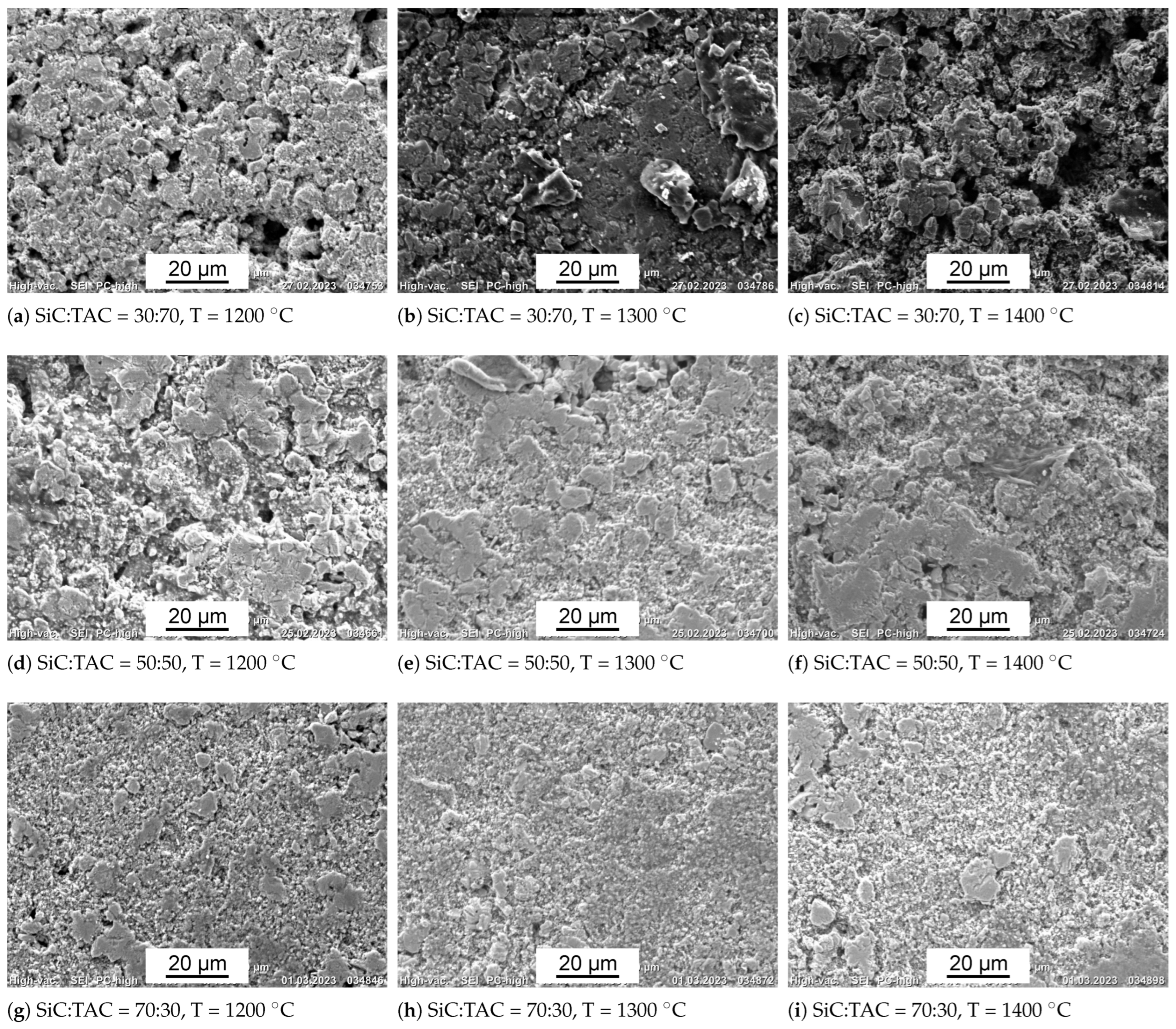

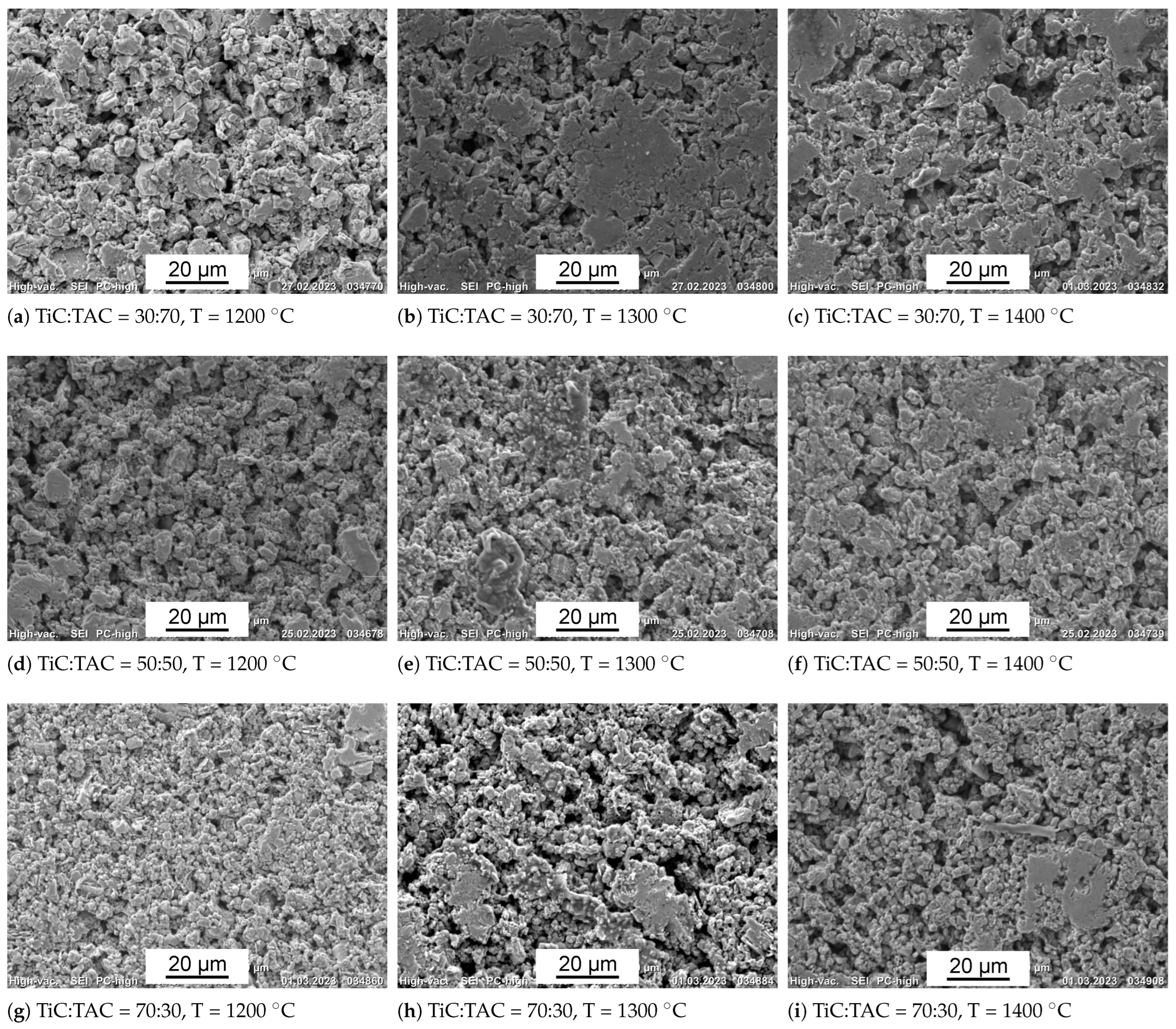

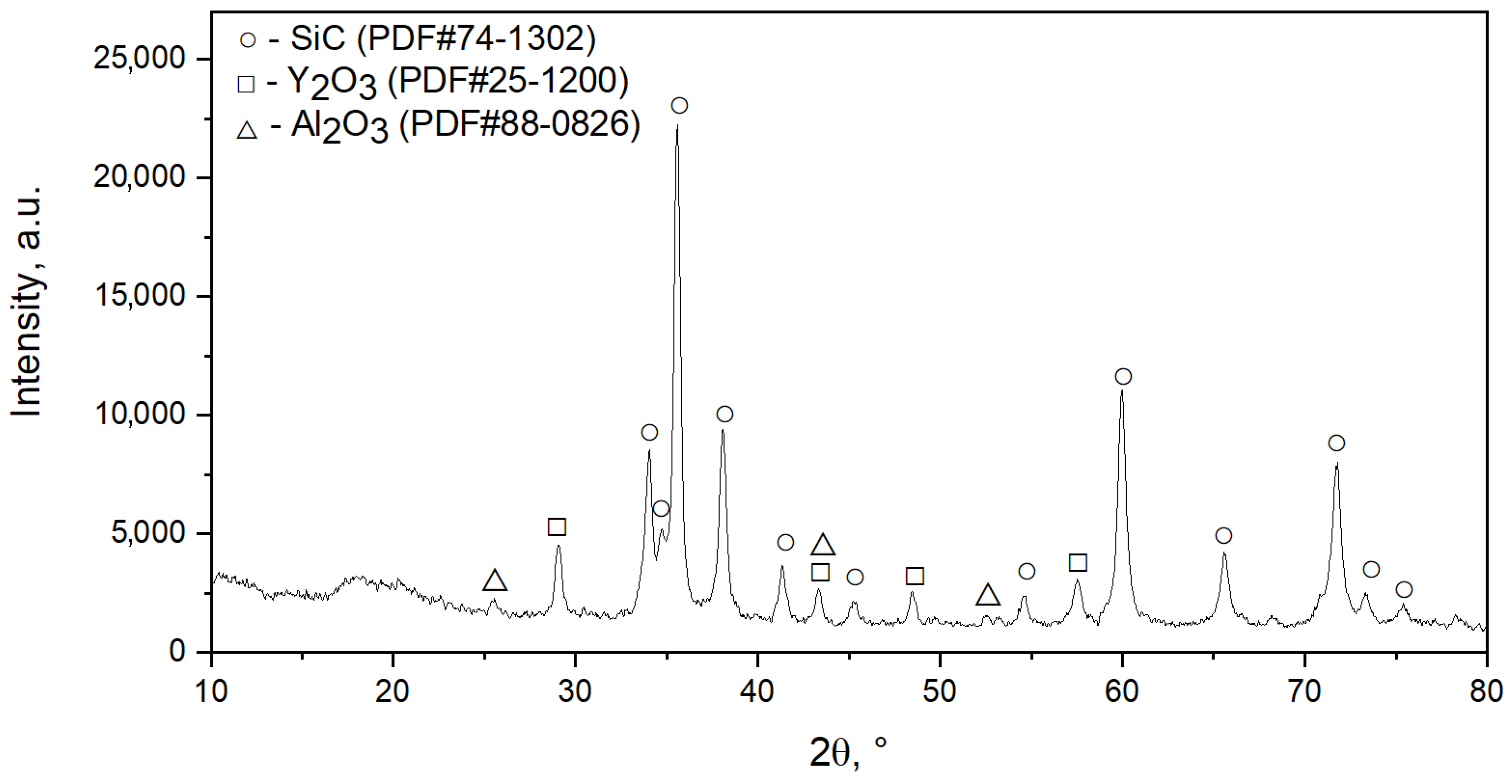

3.2. Microstructure

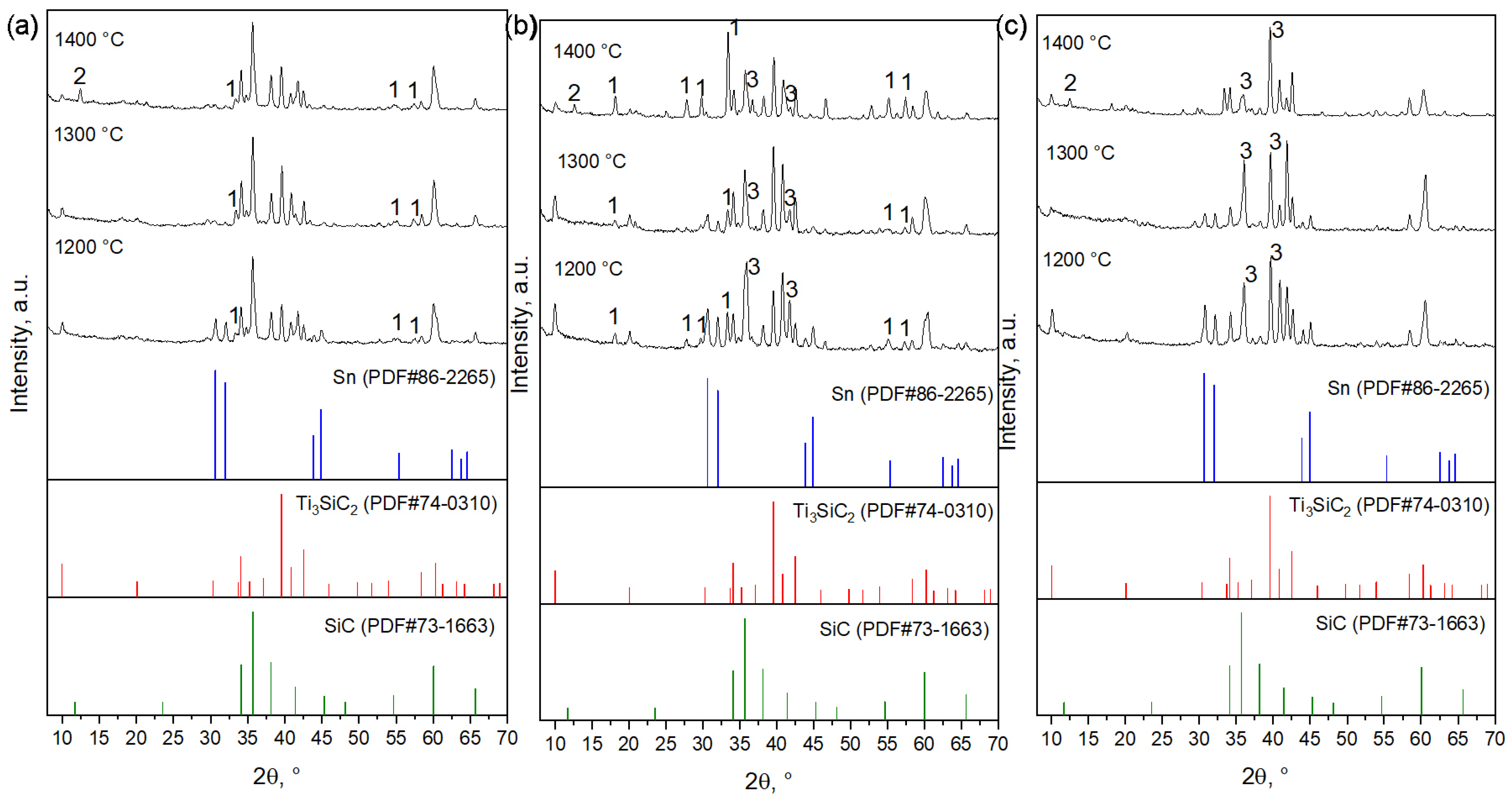

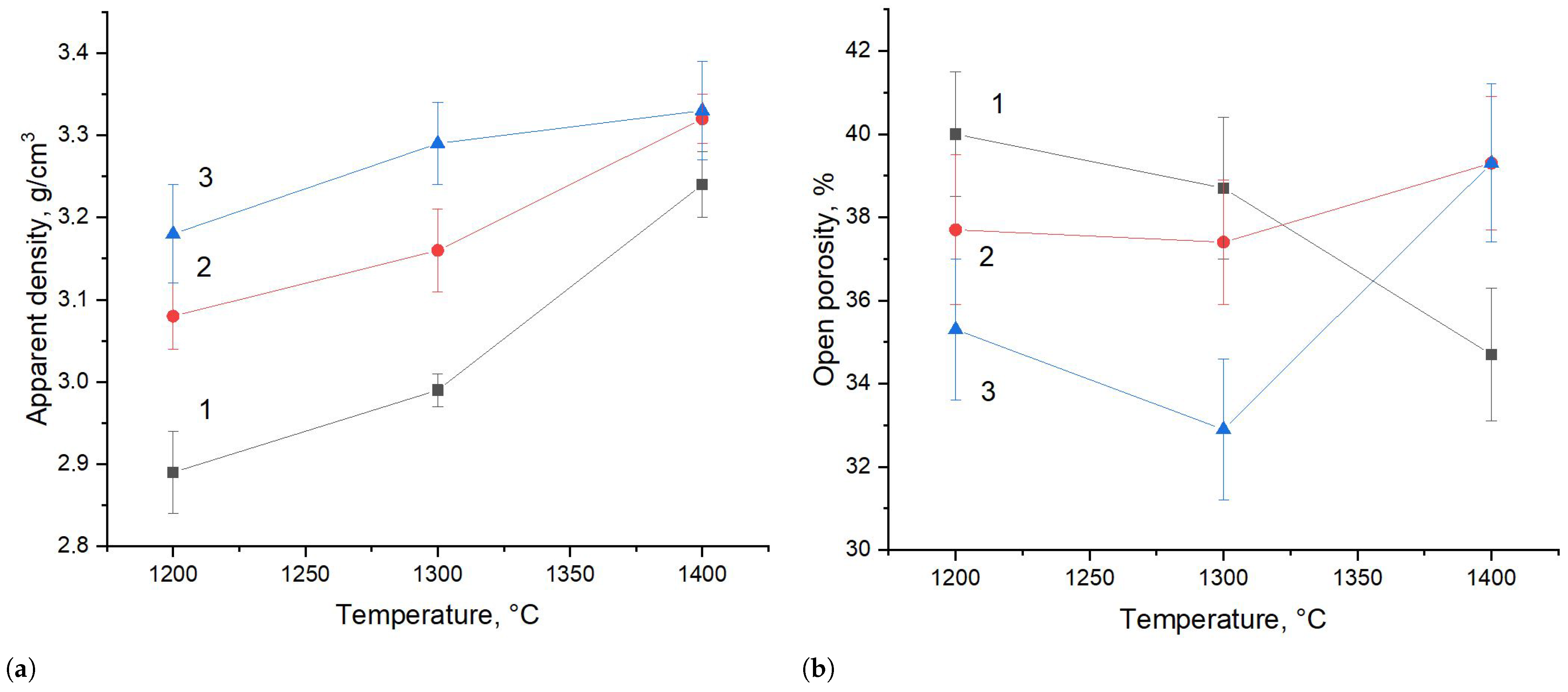

3.3. Sintering of SiC-TiAlC

3.4. Sintering of TiC-TiAlC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Węglowski, M.S.; Błacha, S.; Phillips, A. Electron beam welding–techniques and trends–review. Vacuum 2016, 130, 72–92. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y. Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: A review. J. Mater. Sci. Technol. 2010, 26, 385–416. [Google Scholar] [CrossRef]

- Barsoum, M.W.; El-Raghy, T. The MAX phases: Unique new carbide and nitride materials: Ternary ceramics turn out to be surprisingly soft and machinable, yet also heat-tolerant, strong and lightweight. Am. Sci. 2001, 89, 334–343. [Google Scholar] [CrossRef]

- Barsoum, M.W.; Radovic, M. Elastic and mechanical properties of the MAX phases. Annu. Rev. Mater. Res. 2011, 41, 195–227. [Google Scholar] [CrossRef]

- Tang, Q.; Zhou, Z.; Shen, P. Are MXenes promising anode materials for Li ion batteries? Computational studies on electronic properties and Li storage capability of Ti3C2 and Ti3C2X2 (X = F, OH) monolayer. J. Am. Chem. Soc. 2012, 134, 16909–16916. [Google Scholar] [CrossRef]

- Shein, I.; Ivanovskii, A. Graphene-like titanium carbides and nitrides Tin+ 1Cn, Tin+ 1Nn (n = 1, 2, and 3) from de-intercalated MAX phases: First-principles probing of their structural, electronic properties and relative stability. Comput. Mater. Sci. 2012, 65, 104–114. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y. Oxidation behavior of Ti3AlC2 at 1000–1400 °C in air. Corros. Sci. 2003, 45, 891–907. [Google Scholar] [CrossRef]

- Ge, Z.; Chen, K.; Guo, J.; Zhou, H.; Ferreira, J.M. Combustion synthesis of ternary carbide Ti3AlC2 in Ti–Al–C system. J. Eur. Ceram. Soc. 2003, 23, 567–574. [Google Scholar] [CrossRef]

- Akhlaghi, M.; Tayebifard, S.A.; Salahi, E.; Asl, M.S.; Schmidt, G. Self-propagating high-temperature synthesis of Ti3AlC2 MAX phase from mechanically-activated Ti/Al/graphite powder mixture. Ceram. Int. 2018, 44, 9671–9678. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, C.A.; Ge, Z.; Wu, L. Preparation of Ti3AlC2 and Ti2AlC by self-propagating high-temperature synthesis. J. Mater. Sci. Lett. 2001, 20, 1971–1973. [Google Scholar]

- Zhou, A.; Wang, C.A.; Hunag, Y. Synthesis and mechanical properties of Ti3AlC2 by spark plasma sintering. J. Mater. Sci. 2003, 38, 3111–3115. [Google Scholar] [CrossRef]

- Zhou, W.; Mei, B.; Zhu, J.; Hong, X. Synthesis of high-purity Ti3SiC2 and Ti3AlC2 by spark plasma sintering (SPS) technique. J. Mater. Sci. 2005, 40, 2099–2100. [Google Scholar] [CrossRef]

- Yang, C.; Jin, S.; Liang, B.; Jia, S. Low-temperature synthesis of high-purity Ti3AlC2 by MA-SPS technique. J. Eur. Ceram. Soc. 2009, 29, 181–185. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y. Microstructure and properties of Ti3AlC2 prepared by the solid–liquid reaction synthesis and simultaneous in-situ hot pressing process. Acta Mater. 2002, 50, 3143–3151. [Google Scholar] [CrossRef]

- Ai, T.; Yu, N.; Feng, X.; Xie, N.; Li, W.; Xia, P. Low-temperature synthesis and characterization of Ti2AlC/TiAl in situ composites via a reaction hot-pressing process in the Ti3AlC2-Ti-Al system. Met. Mater. Int. 2015, 21, 179–184. [Google Scholar] [CrossRef]

- Ai, T.; Wang, F.; Feng, X.; Ruan, M. Microstructural and mechanical properties of dual Ti3AlC2–Ti2AlC reinforced TiAl composites fabricated by reaction hot pressing. Ceram. Int. 2014, 40, 9947–9953. [Google Scholar] [CrossRef]

- Ruan, M.M.; Feng, X.M.; Ai, T.T.; Yu, N.; Hua, K. Microstructure and mechanical properties of TiC/Ti3AlC2 in situ composites prepared by hot pressing method. In Materials Science Forum; Trans Tech Publ: Baech, Switzerland, 2015; Volume 816, pp. 200–204. [Google Scholar]

- Akhlaghi, M.; Tayebifard, S.A.; Salahi, E.; Asl, M.S. Spark plasma sintering of TiAl–Ti3AlC2 composite. Ceram. Int. 2018, 44, 21759–21764. [Google Scholar] [CrossRef]

- Huang, X.; Feng, Y.; Qian, G.; Zhao, H.; Zhang, J.; Zhang, X. Physical, mechanical, and ablation properties of Cu–Ti3AlC2 composites with various Ti3AlC2 contents. Mater. Sci. Technol. 2018, 34, 757–762. [Google Scholar] [CrossRef]

- Liu, M.; Chen, J.; Cui, H.; Sun, X.; Liu, S.; Xie, M. Ag/Ti3AlC2 composites with high hardness, high strength and high conductivity. Mater. Lett. 2018, 213, 269–273. [Google Scholar] [CrossRef]

- Hu, W.; Huang, Z.; Cai, L.; Lei, C.; Zhai, H.; Hao, S.; Yu, W.; Zhou, Y. Preparation and mechanical properties of TiCx-Ni3(Al, Ti)/Ni composites synthesized from Ni alloy and Ti3AlC2 powders. Mater. Sci. Eng. A 2017, 697, 48–54. [Google Scholar] [CrossRef]

- Hu, W.; Huang, Z.; Cai, L.; Lei, C.; Zhai, H.; Wo, S.; Li, X. In-situ TiC and γ′-Ni3 (Al, Ti) triggered microstructural modification and strengthening of Ni matrix composite by reactive hot-press sintering pure Ni and Ti2AlC precursor. J. Alloys Compd. 2018, 747, 1043–1052. [Google Scholar] [CrossRef]

- Guo, S.; Hu, C.; Gao, H.; Tanaka, Y.; Kagawa, Y. SiC (SCS-6) fiber-reinforced Ti3AlC2 matrix composites: Interfacial characterization and mechanical behavior. J. Eur. Ceram. Soc. 2015, 35, 1375–1384. [Google Scholar] [CrossRef]

- Zhou, W.; Li, K.; Zhu, J.; Li, R. In situ synthesis, mechanical and cyclic oxidation properties of Ti3AlC2/Al2O3 composites. Adv. Appl. Ceram. 2018, 117, 340–346. [Google Scholar] [CrossRef]

- Hausnerova, B.; Mukund, B.N.; Sanetrnik, D. Rheological properties of gas and water atomized 17-4PH stainless steel MIM feedstocks: Effect of powder shape and size. Powder Technol. 2017, 312, 152–158. [Google Scholar] [CrossRef]

- Islam, S.T.; Samanta, S.K.; Nagahanumaniah; Roy, H.; Lohar, A.K.; Das, S.; Bandyopadhyay, A. Rheological behavior of 316L stainless steel feedstock for μ-MIM. Mater. Today Proc. 2018, 5, 8152–8158. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.M.; Bouvard, D.; Chaix, J.M. Copper additive manufacturing using MIM feedstock: Adjustment of printing, debinding, and sintering parameters for processing dense and defectless parts. Int. J. Adv. Manuf. Technol. 2021, 115, 449–462. [Google Scholar] [CrossRef]

- Berges, C.; Gallego, A.; Naranjo, J.A.; Herranz, G. Manufacturing porcelain components by CIM: Viability of processing different ceramic powders. Boletín Sociedad Española Cerámica Vidrio 2021, 60, 307–317. [Google Scholar] [CrossRef]

- McNamara, S.L.; McCarthy, E.M.; Schmidt, D.F.; Johnston, S.P.; Kaplan, D.L. Rheological characterization, compression, and injection molding of hydroxyapatite-silk fibroin composites. Biomaterials 2021, 269, 120643. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, J.H.; Hwang, K.T.; Hwang, H.J.; Han, K.S. Digital inkjet printing in three dimensions with multiple ceramic compositions. J. Eur. Ceram. Soc. 2021, 41, 1490–1497. [Google Scholar] [CrossRef]

- Afornu, B.; Lider, A.; Ismail, O.; Agyekum, E. Sintered Silicon Carbide composites deposited on zirconium alloy substrates in air and Ar atmosphere—Part I: Evaluation of scratch adhesion and tribology properties. Mater. Lett. 2022, 306, 130963. [Google Scholar] [CrossRef]

- Krinitcyn, M. Thermal stability of TiC–Ti3AlC2 and TiC–Ti3AlC composites during selective laser treatment. Adv. Appl. Ceram. 2022, 121, 138–142. [Google Scholar] [CrossRef]

- Askari, A.; Momeni, V. Rheological investigation and injection optimization of Fe–2Ni–2Cu feedstock for metal injection molding process. Mater. Chem. Phys. 2021, 271, 124926. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Toropkov, N.; Pervikov, A.; Glazkova, E.; Lerner, M. Characterization of nano/micro bimodal 316L SS powder obtained by electrical explosion of wire for feedstock application in powder injection molding. Powder Technol. 2021, 394, 225–233. [Google Scholar] [CrossRef]

- Tao, X.; Jiazheng, Z.; Kang, X. The ball-bearing effect of diamond nanoparticles as an oil additive. J. Phys. Appl. Phys. 1996, 29, 2932. [Google Scholar] [CrossRef]

- Ng, W.H.; Gnanakumar, E.S.; Batyrev, E.; Sharma, S.K.; Pujari, P.K.; Greer, H.F.; Zhou, W.; Sakidja, R.; Rothenberg, G.; Barsoum, M.W.; et al. The Ti3AlC2 MAX Phase as an Efficient Catalyst for Oxidative Dehydrogenation of n-Butane. Angew. Chem. 2018, 130, 1501–1506. [Google Scholar] [CrossRef]

- Wang, K.; Du, H.; Wang, Z.; Gao, M.; Pan, H.; Liu, Y. Novel MAX-phase Ti3AlC2 catalyst for improving the reversible hydrogen storage properties of MgH2. Int. J. Hydrog. Energy 2017, 42, 4244–4251. [Google Scholar] [CrossRef]

- She, J.; Ueno, K. Densification behavior and mechanical properties of pressureless-sintered silicon carbide ceramics with alumina and yttria additions. Mater. Chem. Phys. 1999, 59, 139–142. [Google Scholar] [CrossRef]

- Ihle, J.; Herrmann, M.; Adler, J. Phase formation in porous liquid phase sintered silicon carbide: Part III: Interaction between Al2O3–Y2O3 and SiC. J. Eur. Ceram. Soc. 2005, 25, 1005–1013. [Google Scholar] [CrossRef]

- Bentzel, G.; Ghidiu, M.; Anasori, B.; Barsoum, M. On the interactions of Ti2AlC, Ti3AlC2, Ti3SiC2 and Cr2AlC with silicon carbide and pyrolytic carbon at 1300 °C. J. Eur. Ceram. Soc. 2015, 35, 4107–4114. [Google Scholar] [CrossRef]

- Pang, W.K.; Low, I.M.; Sun, Z.M. In situ high-temperature diffraction study of the thermal dissociation of Ti3AlC2 in vacuum. J. Am. Ceram. Soc. 2010, 93, 2871–2876. [Google Scholar] [CrossRef]

- Perevislov, S.; Sokolova, T.; Stolyarova, V. The Ti3SiC2 max phases as promising materials for high temperature applications: Formation under various synthesis conditions. Mater. Chem. Phys. 2021, 267, 124625. [Google Scholar] [CrossRef]

- Mingxing, A.; Hongxiang, Z.; Yang, Z.; Zhaoyun, T.; Zhenying, H.; Zhili, Z.; Shibo, L. Synthesis of Ti3AlC2 powders using Sn as an additive. J. Am. Ceram. Soc. 2006, 89, 1114–1117. [Google Scholar] [CrossRef]

- Galashov, E.; Atuchin, V.; Gavrilova, T.; Korolkov, I.; Mandrik, Y.; Yelisseyev, A.; Xia, Z. Synthesis of Y3Al5O12: Ce3+ phosphor in the Y2O3–Al metal–CeO2 ternary system. J. Mater. Sci. 2017, 52, 13033–13039. [Google Scholar] [CrossRef]

- Barzilai, S.; Aizenshtein, M.; Froumin, N.; Frage, N. Interface phenomena in the Y2O3/(Al–Cu) system. Mater. Sci. Eng. A 2006, 420, 291–295. [Google Scholar] [CrossRef]

- Yoon, S.; Manthiram, A. Nanoengineered Sn–TiC–C composite anode for lithium ion batteries. J. Mater. Chem. 2010, 20, 236–239. [Google Scholar] [CrossRef]

- Tabares, E.; Kitzmantel, M.; Neubauer, E.; Jimenez-Morales, A.; Tsipas, S.A. Sinterability, Mechanical Properties and Wear Behavior of Ti3SiC2 and Cr2AlC MAX Phases. Ceramics 2022, 5, 55–74. [Google Scholar] [CrossRef]

- Cai, K.; McLachlan, D.; Axen, N.; Manyatsa, R. Preparation, microstructures and properties of Al2O3–TiC composites. Ceram. Int. 2002, 28, 217–222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krinitcyn, M.; Sharafeev, S.; Afanasyev, A. Structure and Properties of Ti3AlC2-SiC and Ti3AlC2-TiC Materials Obtained by Powder Injection Molding Technology. Coatings 2023, 13, 1013. https://doi.org/10.3390/coatings13061013

Krinitcyn M, Sharafeev S, Afanasyev A. Structure and Properties of Ti3AlC2-SiC and Ti3AlC2-TiC Materials Obtained by Powder Injection Molding Technology. Coatings. 2023; 13(6):1013. https://doi.org/10.3390/coatings13061013

Chicago/Turabian StyleKrinitcyn, Maksim, Sharif Sharafeev, and Alexandr Afanasyev. 2023. "Structure and Properties of Ti3AlC2-SiC and Ti3AlC2-TiC Materials Obtained by Powder Injection Molding Technology" Coatings 13, no. 6: 1013. https://doi.org/10.3390/coatings13061013

APA StyleKrinitcyn, M., Sharafeev, S., & Afanasyev, A. (2023). Structure and Properties of Ti3AlC2-SiC and Ti3AlC2-TiC Materials Obtained by Powder Injection Molding Technology. Coatings, 13(6), 1013. https://doi.org/10.3390/coatings13061013