Abstract

Nonstoichiometric (Ti,Co)Ox coatings were prepared using gas-impulse magnetron sputtering (GIMS). The properties of coatings with 3 at.%, 19 at.%, 44 at.%, and 60 at.% Co content were compared to those of TiOx and CoOx films. Structural studies with the aid of GIXRD indicated the amorphous nature of (Ti,Co)Ox. The fine-columnar, homogeneous microstructure was observed on SEM images, where cracks were identified only for films with a high Co content. On the basis of XPS measurements, TiO2, CoO, and Co3O4 forms were found on their surface. Optical studies showed that these films were semi-transparent (T > 46%), and that the amount of cobalt in the film had a significant impact on the decrease in the transparency level. A shift in the absorption edge position (from 337 to 387 nm) and a decrease in their optical bandgap energy (from 3.02 eV to more than 2.60 eV) were observed. The hardness of the prepared films changed slightly (ca. 6.5 GPa), but only the CoOx film showed a slightly lower hardness value than the rest of the coatings (4.8 GPa). The described studies allowed partial classification of non-stoichiometric (Ti,Co)Ox thin-film materials according to their functionality.

1. Introduction

Materials based on mixtures of Ti and Co oxides have recently gained attention because of their wide range of applications in electronics. Today, there are only a few reports on Co-doped TiO2 [1,2,3,4,5], but mainly in the form of nanopowders, nanoparticles, or nanowires, while thin-film work itself is in a minority. One of the possible reasons for this fact is that the properties of such oxide mixtures are strongly related to the preparation method and additional postprocessing, such as high-temperature annealing. Therefore, a direct comparison of their properties is impossible. There exist only a few reports related to complex modification of the structural, surface, optical, or electrical properties of titanium dioxide as a matrix by doping with Co [6,7,8,9].

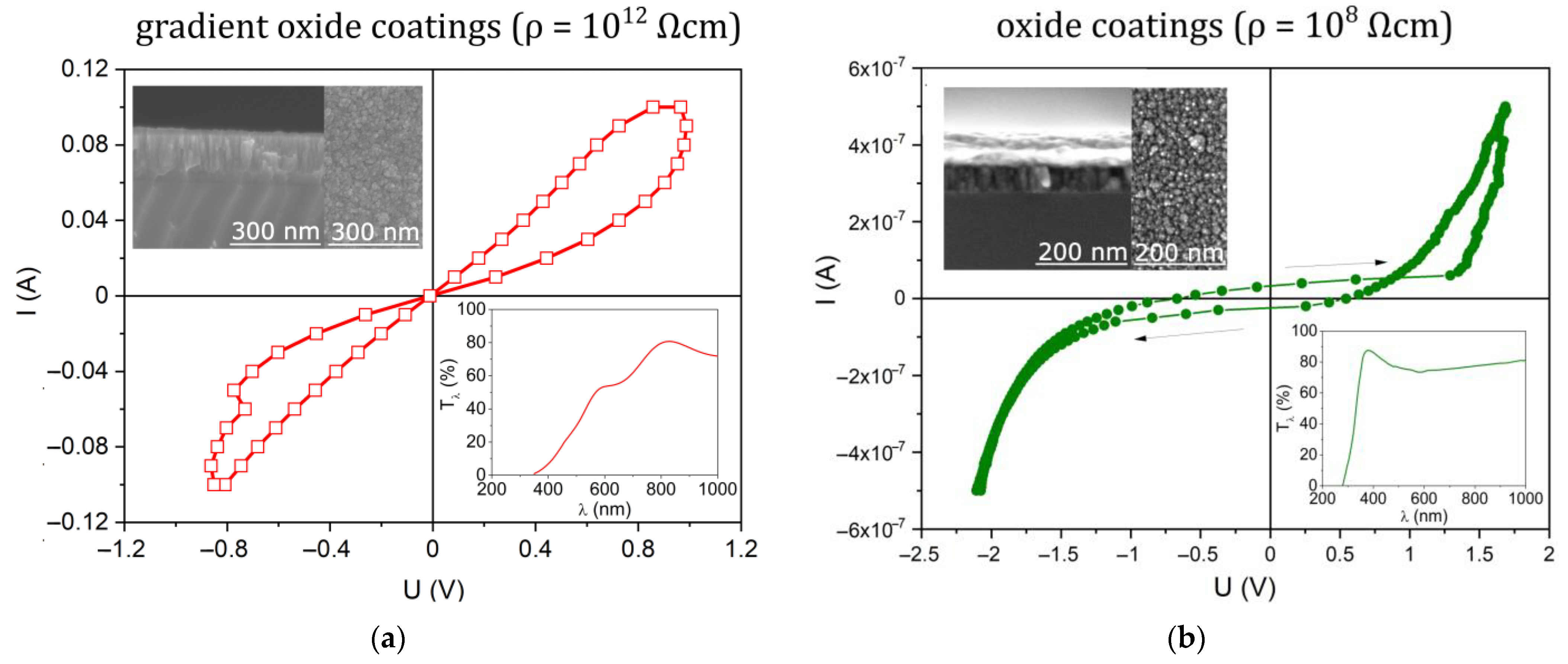

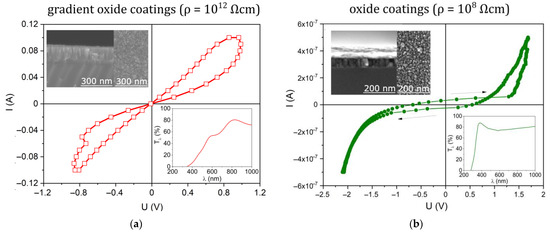

Our previous work is one of the few examples of such studies [10,11]. We have shown how interesting properties and applications can be obtained by combining the advantages of Ti and Co oxides. For example, the gradient coatings that we obtained were transparent and had a high refractive index despite the high content of cobalt [11]. More interesting is the fact that these coatings exhibited a fully recoverable resistive switching effect, which has not been previously reported in the case of such materials (Figure 1a). Their great potential can be used in innovative transparent electronic devices with a memory effect. Furthermore, we also prepared transparent (~80%) oxide films based on titanium with a homogeneous distribution of cobalt [10]. In their case, a unipolar memristive effect was also observed, but only for coatings with a low cobalt content (Figure 1b). To date, no similar results have been reported. The aim of the present work was to manufacture nonstoichiometric (Ti,Co)Ox materials (with reduced oxygen content) in order to obtain a lower resistivity as compared to the mentioned coatings. A compromise between optical and electrical properties was planned to be achieved. In addition, we decided to prepare films with a higher amount of cobalt because of the small number of publications in this field.

Figure 1.

Current to voltage (I–V) of transparent (a) gradient [11] and (b) oxide [10] coatings (Ti,Co)Ox that exhibit a memristive effect. In the insets, SEM images of surface and cross-section, as well as transmission characteristics, are shown.

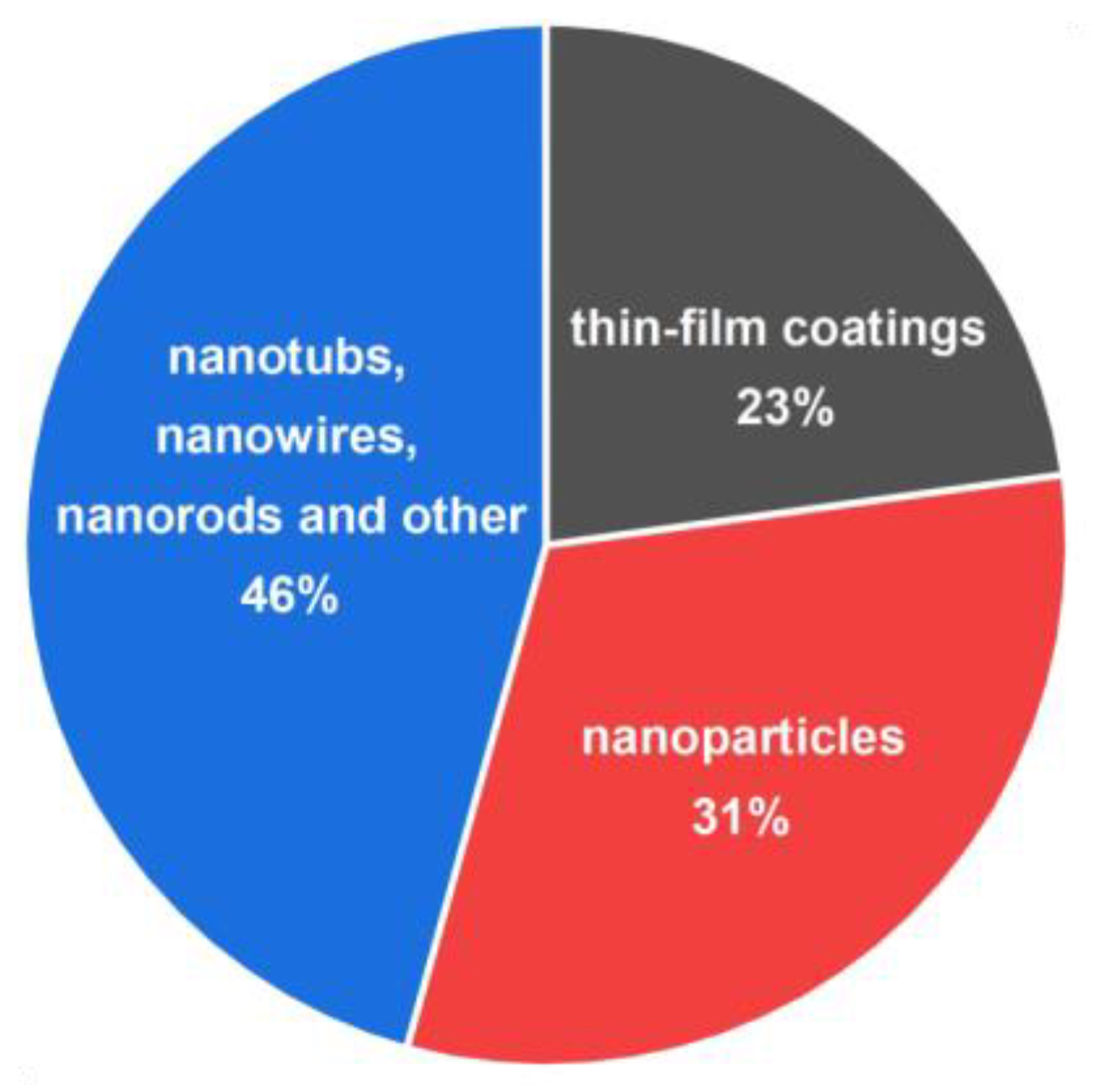

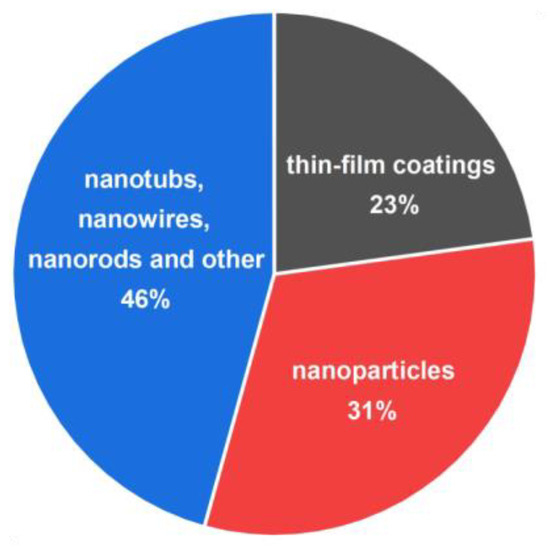

The influence of Co on the properties of Ti-based oxides is not yet well understood, which limits the possibility of fully exploiting the potential that the combination of these two materials can offer. Cobalt and its oxides exhibit high stability (especially in the form of CoO and Co3O4) [12], as well as high photocatalytic activity [13] and ferromagnetic properties [14]. Co-based oxides and metallic materials can be applied in spintronics [15], magneto-optical devices [16], in the construction of semiconducting sensors [17], electrochromic coatings [18], and heterogeneous catalysts [19]. The properties of oxides based on titanium and cobalt are significantly dependent on their preparation technology. These materials are mostly manufactured in the form of nanotubes [1], nanowires [2], nanorods [3], nanoparticles [4], or various types of thin-film coating (single films or multilayers) [5] (Figure 2). Nanotubes, nanowires, and nanorods make up the largest part of the (Ti,Co)Ox forms reported in publications (Figure 2). The hydrothermal [2] or anodisation [1,3] methods are used mainly for their manufacture. The form of nanotubes is interesting for electrochemical applications (e.g., fuel cells) due to their ability to transport electrons unidirectionally and their large surface area [20,21]. These types of nanomaterials exhibit improved catalytic properties [22,23]. In the case of nanowires, an application in efficient photoelectrochemical (PEC) hydrolysis can be presented [2]. Nanorods, on the other hand, are useful in the oxygen evolution reaction (OER), which is a key process in many technologies, including the conversion of electrochemical energy or the production of zinc–air batteries [3]. Unlike the mentioned forms, these oxides are often manufactured as nanoparticles [4,6,9], which are useful in energy storage or solar energy conversion [4].

Figure 2.

Percentage number of publications on various Ti- and Co-based oxide materials (TiO2:Co, TiO2+CoOX, TixCoX-1Oy) [based on the ScienceDirect database from 1980 to 2022].

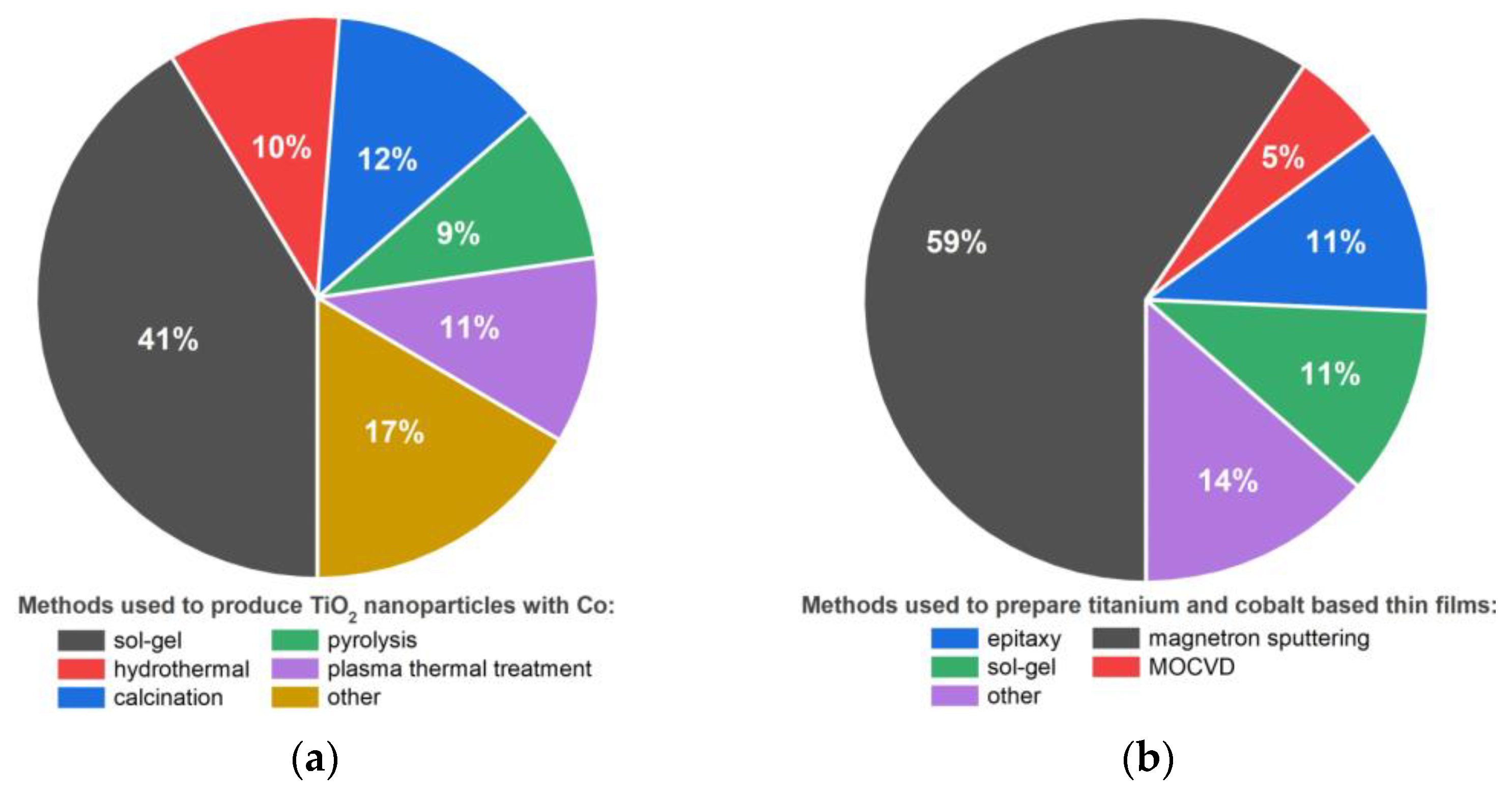

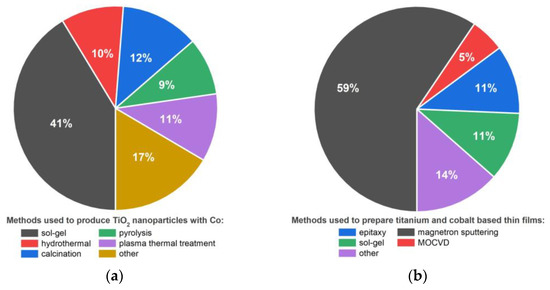

Nanoparticles are usually manufactured by sol-gel [9], hydrothermal [8], calcination [24], pyrolysis [25], or plasma thermal treatment [26] methods (Figure 3a). It should be noted that in the case of nanoparticles, typically only crystalline titanium dioxide is identified, and the influence of Co content on their properties has not been well explored [4,26]. Crystallite sizes depend not only on the amount of cobalt but are also determined by the preparation method of given nanoparticles. Therefore, it is difficult to define the relationship between Co content and crystallite size [4,6,8,9,26,27]. Oxide material-based Ti and Co are also prepared as thin-film coatings. They can have the form of single films [5,10,28,29] and multilayers [30,31,32] (Figure 3b). According to the literature, magnetron sputtering [10,33,34,35], Metal Organic Chemical Vapor Deposition (MOCVD) [28], epitaxy [5], or sol-gel [7,36] are primarily used for their manufacture. Their (material composition (Co-content) can also vary significantly [29,34,37]. Modification of the sputtering conditions results in the receipt of diversified thin-film materials, which is important in their application area [2,33]. As mentioned above, in the case of oxide nanomaterials based on titanium and cobalt, their material composition is a key factor.

Figure 3.

Methods used to prepare TiO2 nanoparticles doped with Co (a); preparation methods of thin films based on Ti and Co mixed oxides (b) based on the ScienceDirect database from 1980 to 2022.

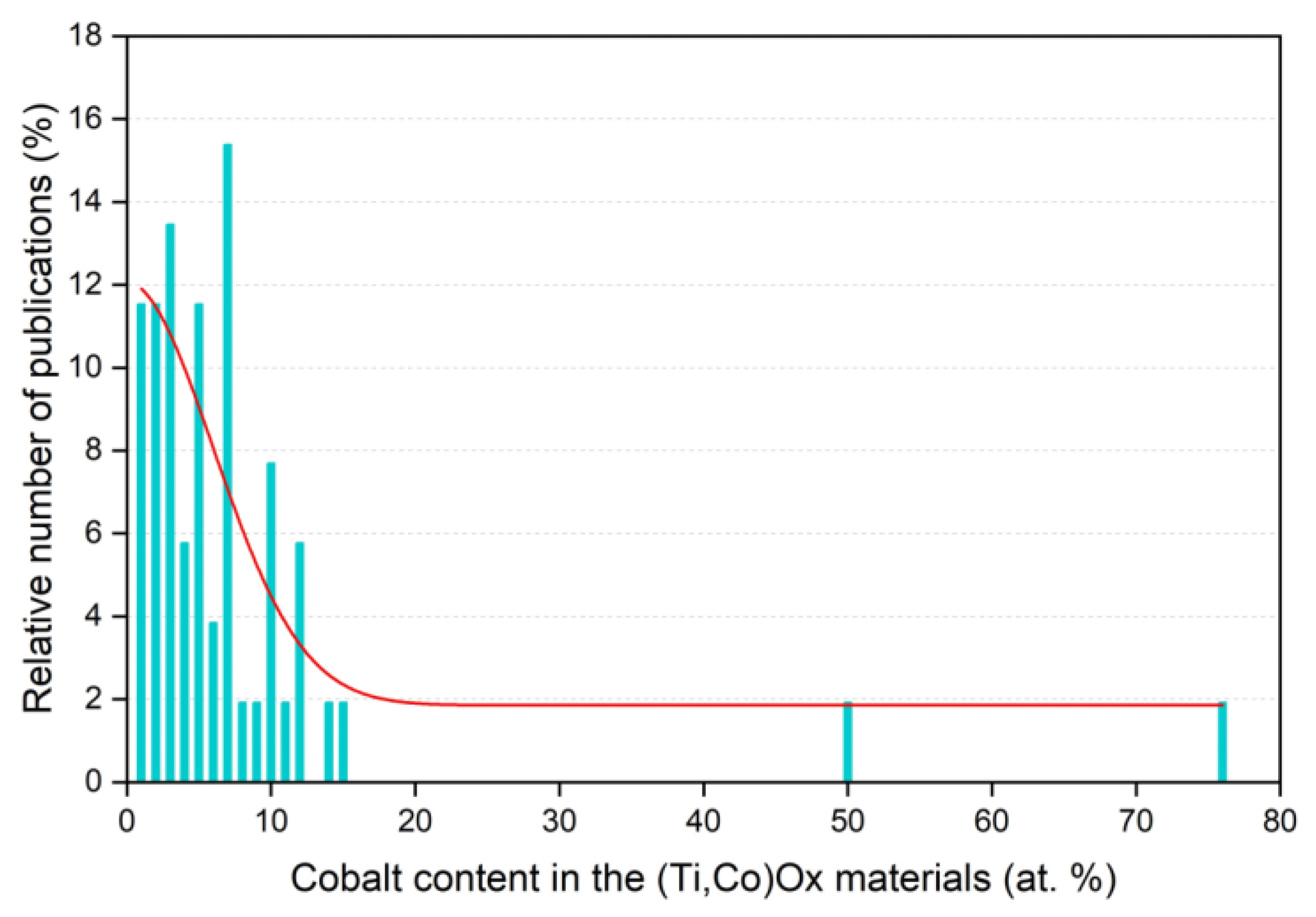

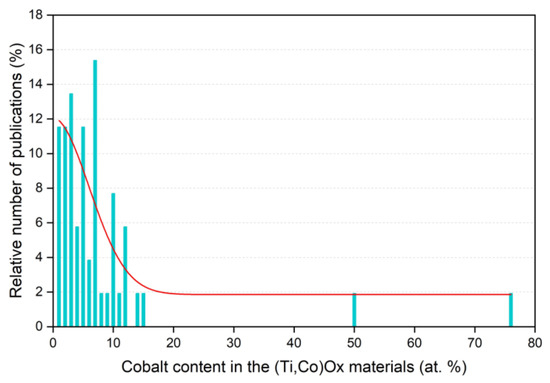

The current state of the art indicates that in nanoparticles, as well as in thin-film coatings, the amount of cobalt is usually below 15 at.% [5,27,38] (Figure 4), although there are some reports that present results for materials with even 50 at.% or 76 at.% cobalt [26,29]. As can be seen, there is a research gap regarding materials with cobalt content comparable to or greater than titanium. As an analysis of the literature shows, most of these materials are crystalline [5,25,38], while approximately 14% of the total work has been devoted to amorphous materials [31,39]. Therefore, it can be seen that the main focus has been on investigating the influence of cobalt on TiO2 properties only within a narrow range of this element, completely discounting what modifications in (Ti,Co)Ox films would be introduced by a higher amount of cobalt. This fact itself makes conducting research for (Ti,Co)Ox coatings with a higher content of cobalt a novelty in the field of the materials in discussion.

Figure 4.

Relative number of publications describing cobalt content in (Ti,Co)Ox films based on the ScienceDirect database from 1980 to 2022.

Among crystalline materials, (Ti,Co)Ox can generally be distinguished by nanoparticles [6,9,37] or also by thin films (but mainly annealed) [28,37,40]. In the case of nanoparticles (often prepared with the sol–gel method), TiO2 with anatase or rutile structure is dominant, while the presence of cobalt as separate phases (oxide or metallic) or as a compound with titanium or its oxides [8] occurs rarely with nanoparticles. However, there exist some works in which crystal forms of their compounds (e.g., CoTiO2 or Co2TiO2) have been identified [26]. Accurate studies on titanium- and cobalt-based thin films are rare, especially in non-stoichiometric (i.e., low oxygen amount) forms. In addition, there is a general strong need to develop multifunctional coatings [10]. This paper investigates the influence of the amount of cobalt on the optical and structural properties of non-stoichiometric thin films based on titanium and cobalt.

2. Materials and Methods

2.1. Preparation of Thin Films

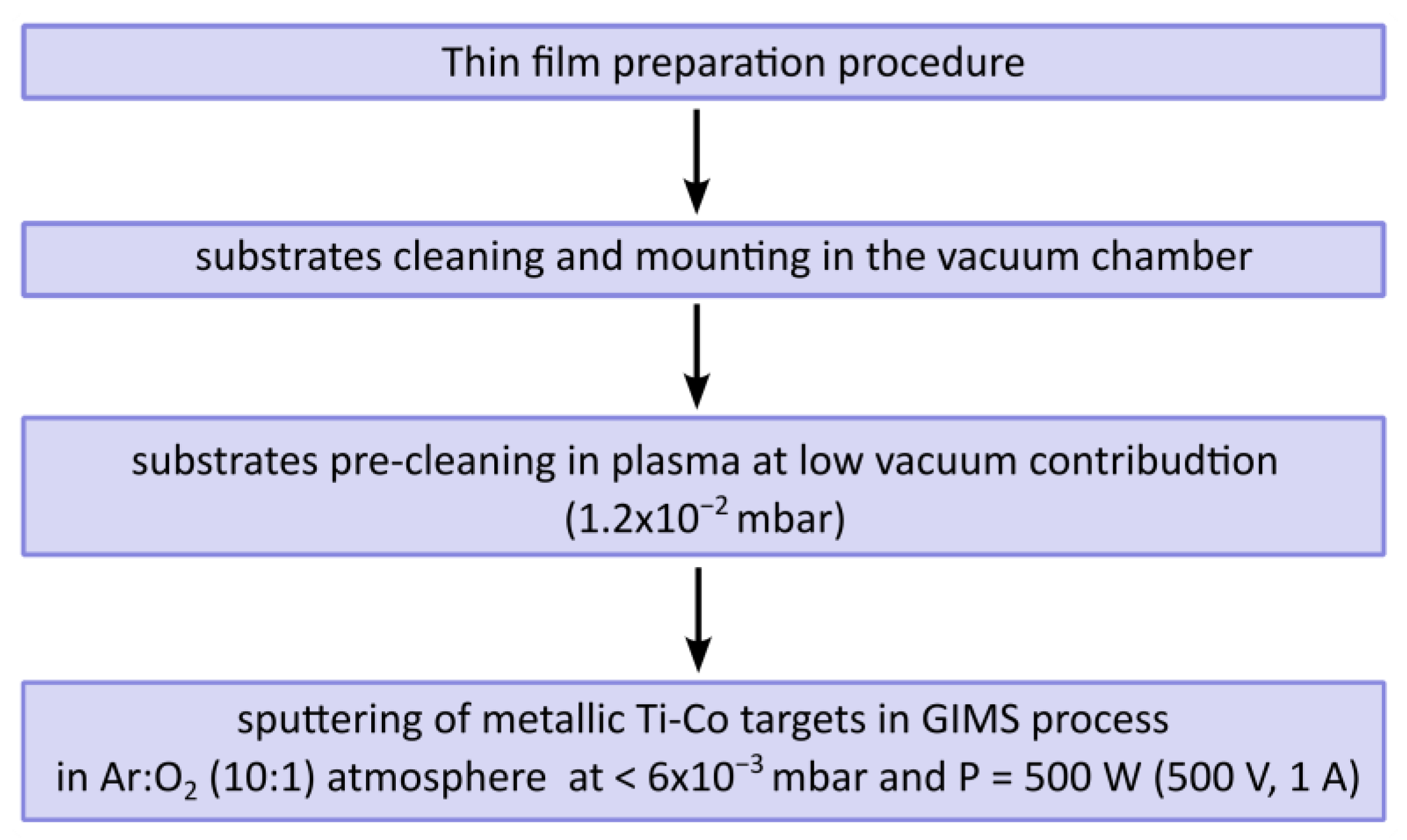

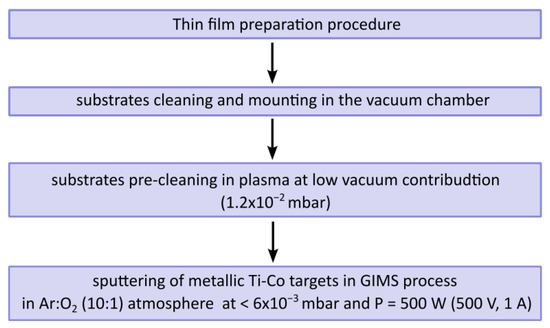

Nonstoichiometric (Ti,Co)Ox thin films with the desired material composition were prepared using the gas impulse magnetron sputtering method (denoted as GIMS). Magnetrons were supplied by an MSS2 2 kW pulsed AC power supply unit (DORA Power System, Wilczyce, Poland) [41,42,43,44,45,46]. The sputtering system was also equipped with vacuum gauges (Pfeiffer Vacuum, Aßlar, Germany) and a gas flow control system that involves mass flow controllers (MKS Instruments, Andover, MA, USA). In the applied GIMS processes, a gas mixture (Ar:O2) with a low O2 content (10:1) was injected into the working chamber directly on the surface of the metallic Ti, Co, and Ti-Co targets (diameter-30 mm, thickness 3 mm, purity 99.95%) mounted on the magnetron. Ti-Co targets with 2 at.%, 12 at.%, and 50 at.% Co content were used for preparation. Targets were prepared with spark plasma sintering (SPS) using a system provided by FCT GmbH (Rauenstein, Germany) [47,48,49]. For sintering, Co and Ti nanopowders (99.95%, Kurt Lesker, Dresden, Germany) in the Lukasiewicz Research Network–Institute of Non-Ferrous Metals [49] were used. The targets were sintered at 1200 °C in a graphite matrix. The material composition of the targets was determined using a JXA-8230 X-ray microanalyzer (JEOL) with wave and energy-dispersive spectrometers (WDS and EDS). A detailed description of the Ti-Co target preparation method was described elsewhere [10]. Due to the possibility of sputtering in multimagnetron configuration (Ti,Co)Ox thin films with various Co content (3, 19, 44, and 60 at.%) were obtained. In addition, TiOx and CoOx reference films were prepared. The Ar:O2 gas mixture was obtained due to the use of a gas mixer that includes two individual MKS mass flow controllers. Ar and O2 flow rates were set at 30 and 3 sccm, respectively. Gas impulses, injected directly into the target, were synchronised with the magnetron supply unit (MSS2 type, Dora Power System), and in each cycle lasted 100 ms. The locally ignited plasma was obtained at <6 × 10−3 mbar, with a supply power of 500 W (500 V, 1 A). The plasma ignition time was 30 ms and the interval between pulses was 70 ms. The sputtering system was equipped with diffusion and rotary pumps. Before the GIMS processes, the vacuum chamber was evacuated to a base pressure of ca. 5 × 10−6 mbar. Thin films were deposited on Si and SiO2 substrates. The distance between the target and the substrate was 16 cm. Figure 5 shows a schematic layout of thin film preparation.

Figure 5.

Schematic layout of (Ti,Co)Ox thin-film preparation.

2.2. Methods of Thin Film Characterisation

The surface morphology of the coatings and their chemical composition were investigated using a high-quality SEM/Xe-FIBFEI Helios NanoLab 600i field-emission scanning electron microscope (FEI, Hillsboro, OR, USA) equipped with an energy dispersive X-ray spectrometer (EDS). In addition, high-resolution SEM images of the surface and cross-sections were examined. Analysis of Ti and Co concentrations on the basis of EDS maps of the elemental distribution was also carried out. The structural properties of the thin films were determined based on the results of GIXRD in the incidence mode of grazing (at 3°) mode. For the measurements, an Empyrean X-ray diffractometer (PANalytical, Malvern, UK) with a PIXel3D detector and Cu Kα radiation with a wavelength of 1.5406 Å (40 kV, 30 mA) using Bragg-Brentano reflecting geometry parafocusing optics was used. By comparing the obtained pattern with PDFcards, a phase structure was determined. For data analysis, MDI JADE 5.0 software (ICDD, Newtown Square, PA, USA) was used. For the analysis of the surface state, X-ray photoelectron spectroscopy (XPS) was used. The Specs Phoibos 100 MCD-5 (5 single-channel electron multiplier) hemispherical analyser (SPECS Surface Nanoanalysis GmbH, Berlin, Germany) using a Specs XR-50 X-ray source with Mg Kα (1253.6 eV) beam was used. The XPS spectra were analysed using Casa XPS software. The thicknesses of the manufactured films were verified with the aid of a contactless Taylor Hobson Tally Surf CCI Lite optical profiler (Talysurf CCI Lite, Leicester, UK). The nanoindentation technique was used to determine the hardness of the prepared thin films. The hardness was obtained from experimental load–displacement curves for an indentation experiment using the Oliver and Pharr method [50,51]. Measurements were made with a CSM Instruments (CSM Instruments, Peseux, Switzerland) NHTT 01-03620 nanoindenter model equipped with a Vickers diamond indenter. For optical characterisation, the light transmission method was used. The measurement setup was equipped with an integrated light source DH-2000-BAL (containing a halogen and deuterium lamp) and Ocean Optics QE 65000 and NIR 256-2.1 spectrophotometers (Ocean Optics, Largo, FL, USA). The transmission coefficient was determined from transmittance spectra measured in the wavelength range of 250–2000 nm. The average transmission was evaluated by calculating the integral in visible wavelength range of 300 to 900 nm. On the basis of the measurements, parameters such as the light transmission coefficient (Tλ), position of the optical absorption edge (λcut-off), and the width of the optical band gap (Egopt) were determined.

3. Results and Discussion

3.1. Material Composition of (Ti,Co)Ox Thin Films

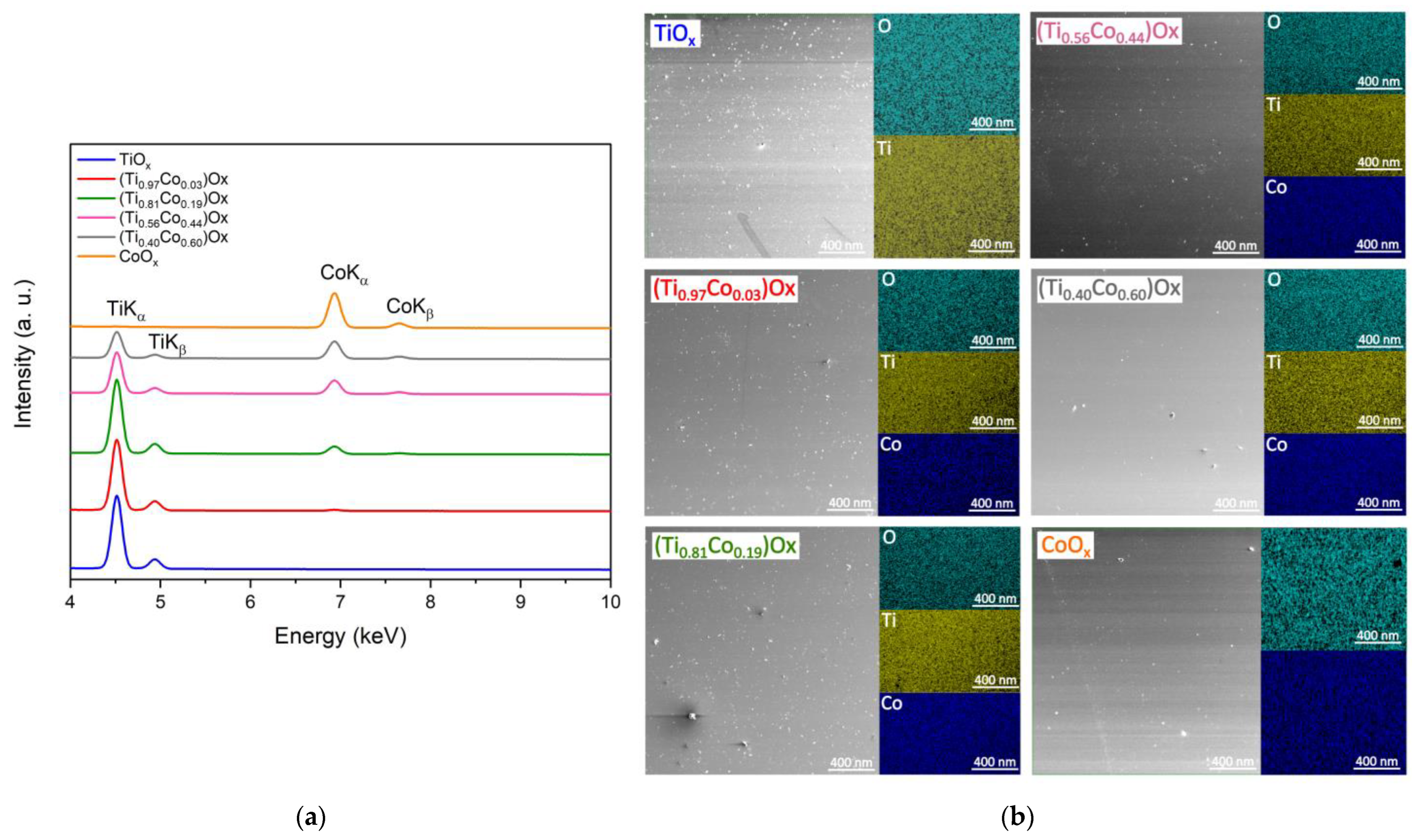

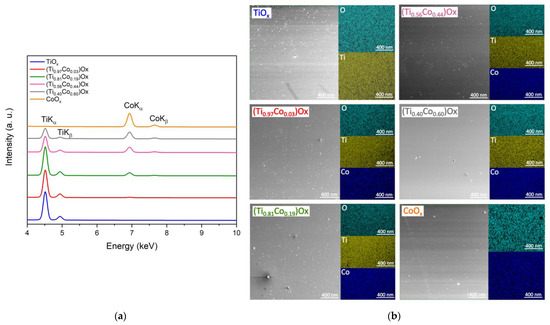

In Figure 6b, SEM images of surface topography with EDS maps of elemental distribution of (Ti,Co)Ox thin films are shown. It was found that films with 3 at.%, 19 at.%, 44 at.%, 60 at.%, and 100 at.% of cobalt content in the TiOx matrix were prepared. EDS maps indicate a homogeneous distribution of Ti, O, and Co, as well as a lack of agglomeration effects. The absence of areas with a clearly higher concentration of cobalt should be emphasised because it proves the high quality of sintered targets and the possibility of manufacturing Ti-based oxide coatings with a homogeneous distribution of Co. Detailed results of the EDS analysis are collected in Table 1.

Figure 6.

Results of X-ray microanalysis investigations for as-deposited Ti, Co, and O for (Ti,Co)Ox thin films: (a) EDS spectra and (b) maps of elemental distribution of mixed oxides.

Table 1.

Material composition of thin-film coatings based on Ti and Co and targets used for their deposition by magnetron sputtering.

3.2. Optical Characterisation of (Ti,Co)Ox Thin Films

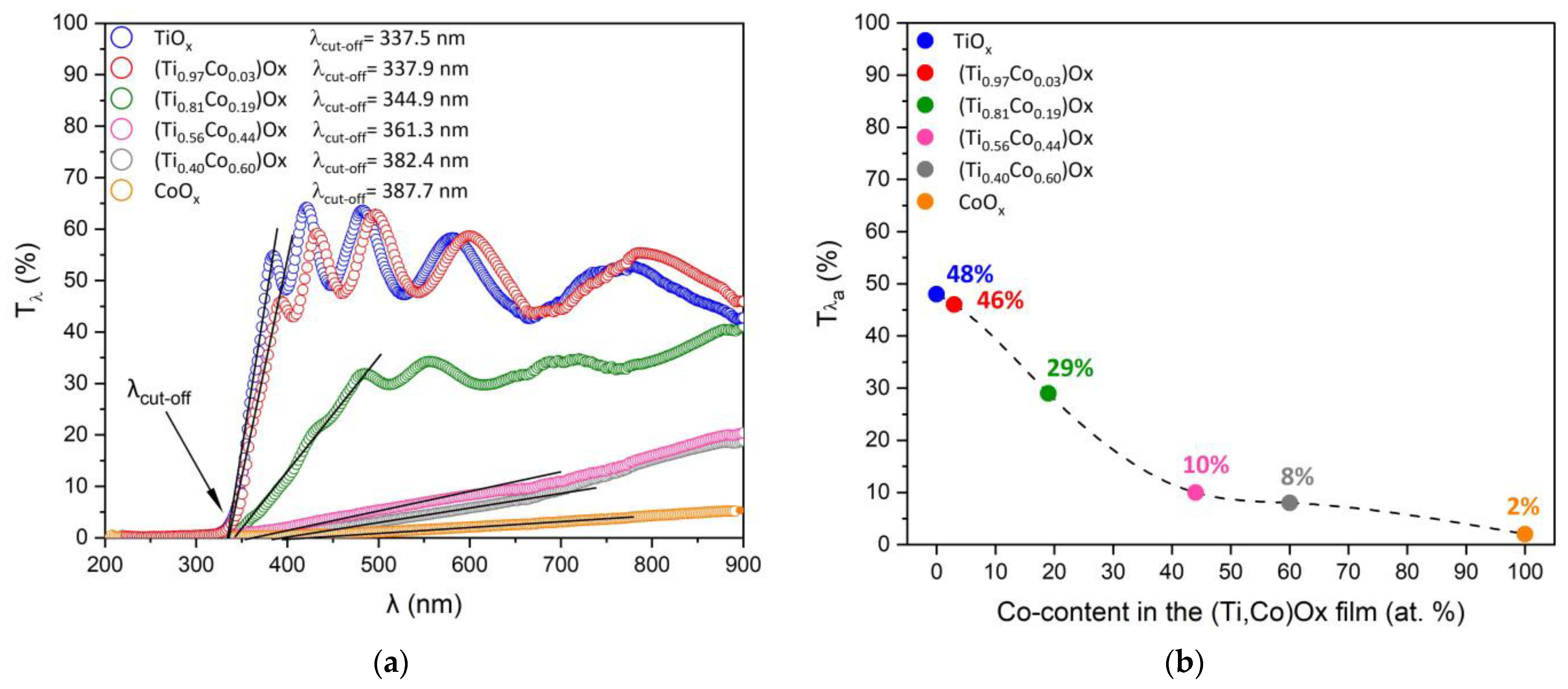

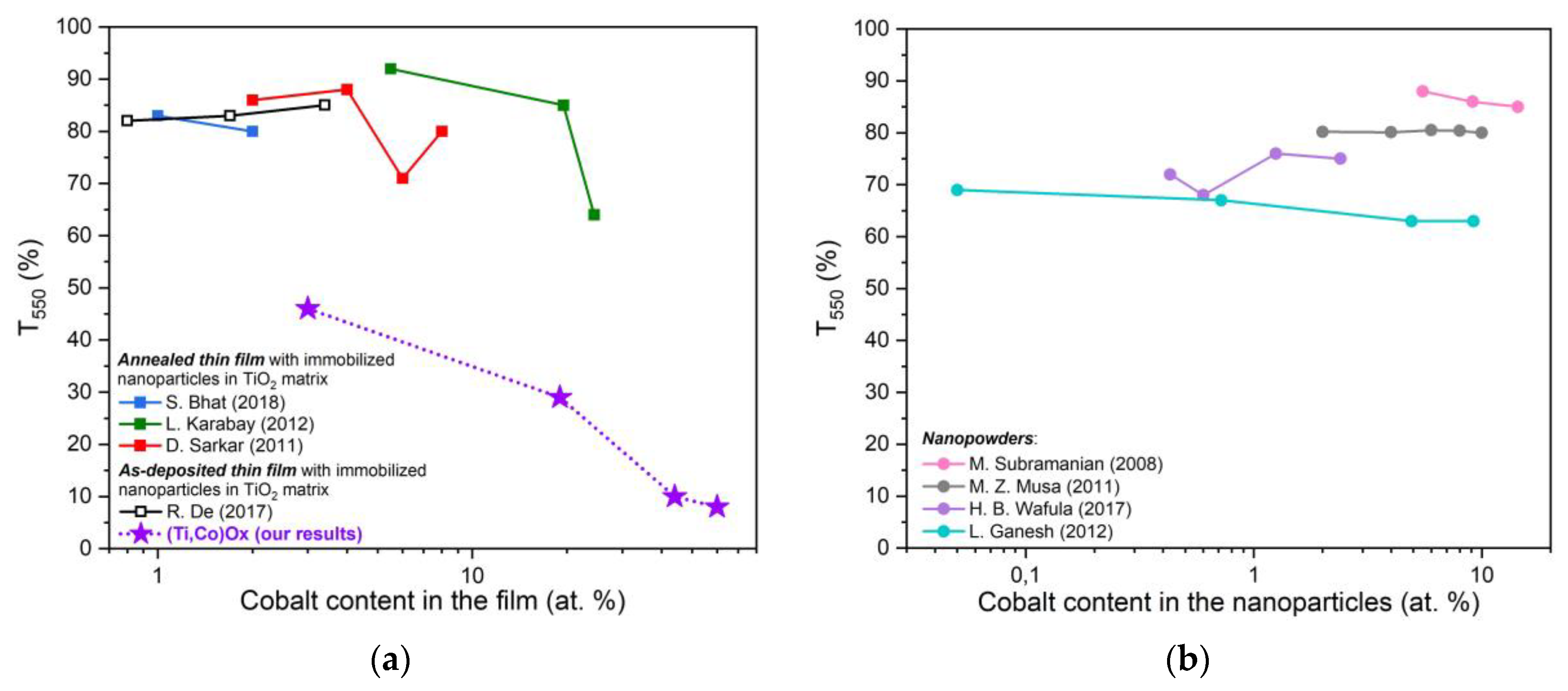

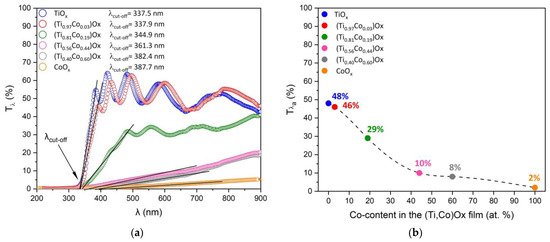

The optical properties of the coatings were determined on the basis of transmission characteristics (Figure 7a). In the case of undoped TiOx, the average transmission level of value Tλa = 48% (average transmission related to the area under the characteristic) was the highest compared to other films (Figure 7b). The addition of Co resulted in a decrease in the transparency. The (Ti,Co)Ox films with 3 at.% and 19 at.% of cobalt were semitransparent due to the 46% and 29% values of Tλa, respectively (Figure 7b). The increase in Co content resulted in a significant decrease in the transparency level to <10% for (Ti00.56Co0.44)Ox and (Ti0.40Co0.60)Ox, respectively. In the case of CoOx, an opaque film was received (Tλa < 2%) (Figure 7b). Except for analysis of transmission level, the position of the optical absorption edge (λcut-off) was determined (Figure 7a). It was found that with the increase of cobalt content, the λcut-off position shifts to longer wavelengths (‘red shift’). This effect has also been reported in other works [9,27], but it should be noted that the position of the optical absorption edge is also related to the preparation method. Therefore, the ‘blue shift’ of the λcut-off can also be observed in oxide materials based on Ti and Co [7]. These results are in agreement with other works, e.g., [5,7,36,52,53,54,55]. In general, the transmission level of Ti oxides decreases with increasing Co content, but the preparation method and the form of (Ti,Co)Ox material (thin film or nanoparticles) determine these changes [52,53,54], as can be seen for the thin films, where the light transmission level decreases with increasing Co content [7,36,52].

Figure 7.

Transmission characteristics of TiOx (t = 410 nm), (Ti0.97Co0.03)Ox (t = 335 nm), (Ti0.81Co0.19)Ox (t = 480 nm), (Ti0.56Co0.44)Ox (t = 270 nm), (Ti0.40Co0.60)Ox (t = 226 nm), and CoOx (t = 150 nm) thin films (a) with average transmission level (Tλa) as a function of the cobalt content in the film (b). Designations: Tλ—transmission, Tλa—average transmission in the range of 300 to 900 nm, t—thickness of the films.

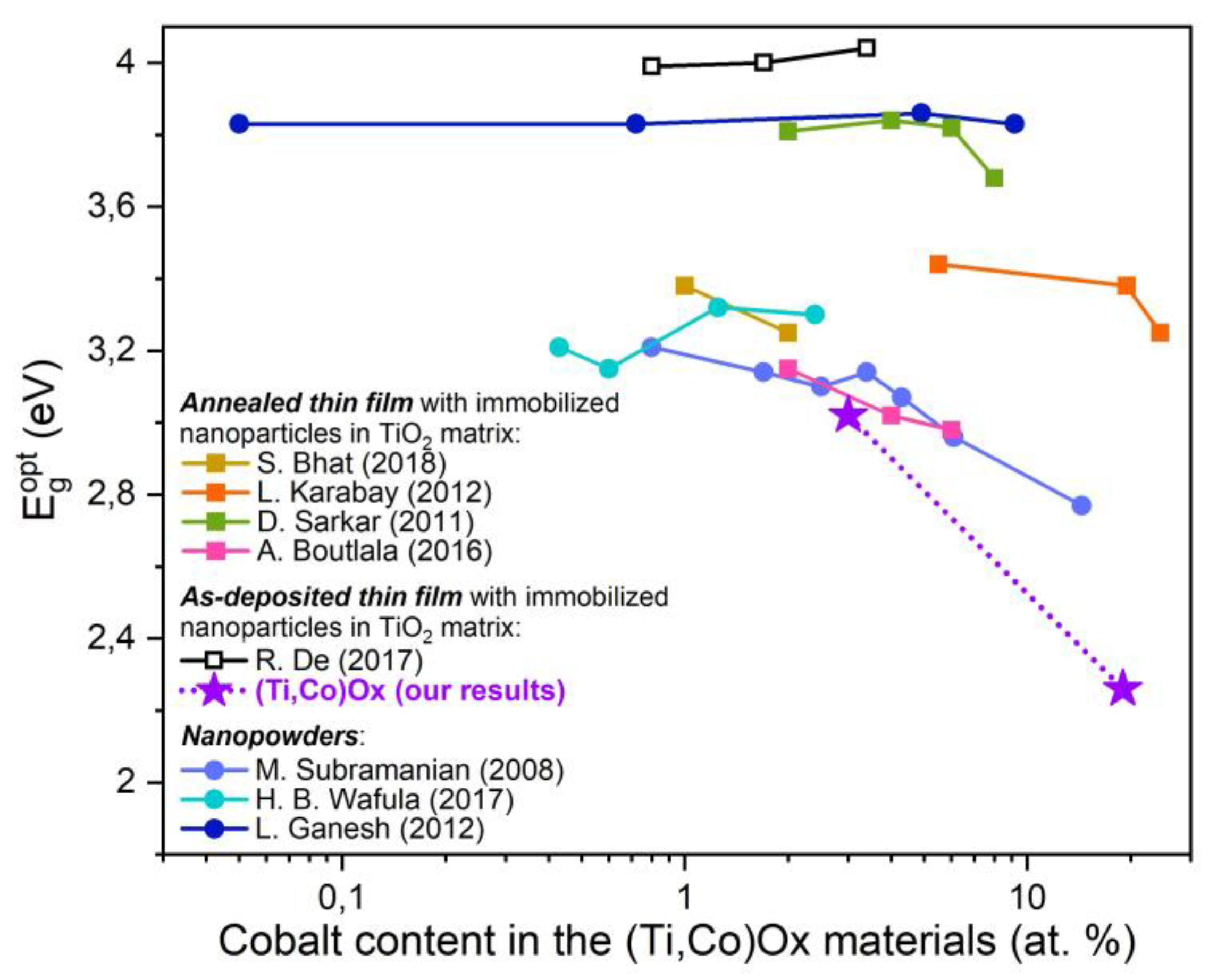

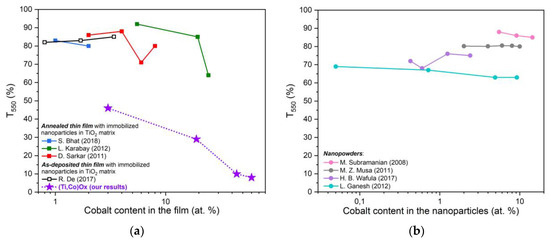

Films containing a low amount of cobalt are characterised by a level of transparency similar to that of undoped TiO2 or the mentioned nanoparticles (ca. 80%). Above 10 at.% cobalt results in a significant reduction of transmission (Figure 8a). However, the literature lacks comprehensive analyses of titanium oxide coatings with neither low nor high Co content. A significantly different character can be seen for nanoparticles (Figure 8b) [9,21,25,27]. These nanomaterials have a similar value of the light transmission coefficient (from 60% to 90%). It is difficult to determine the reason for the lack of changes with the increase in Co content. This can be determined by the manufacturing method or may be related to the fact that the core of the nanoparticles is TiO2 and cobalt is located in its shell [9,25,27]. The solution to this shortcoming may be additional annealing, which will almost certainly cause oxygenation of the film structure.

Figure 8.

Influence of cobalt content on the optical energy gap coefficient of oxide materials based on Ti: (a) thin films with immobilised nanoparticles in the TiOx matrix [7,52,53,54]; (b) nanopowders [9,21,25,27]. On the basis of data from the publication, the cobalt content was converted from wt.% to at.%.

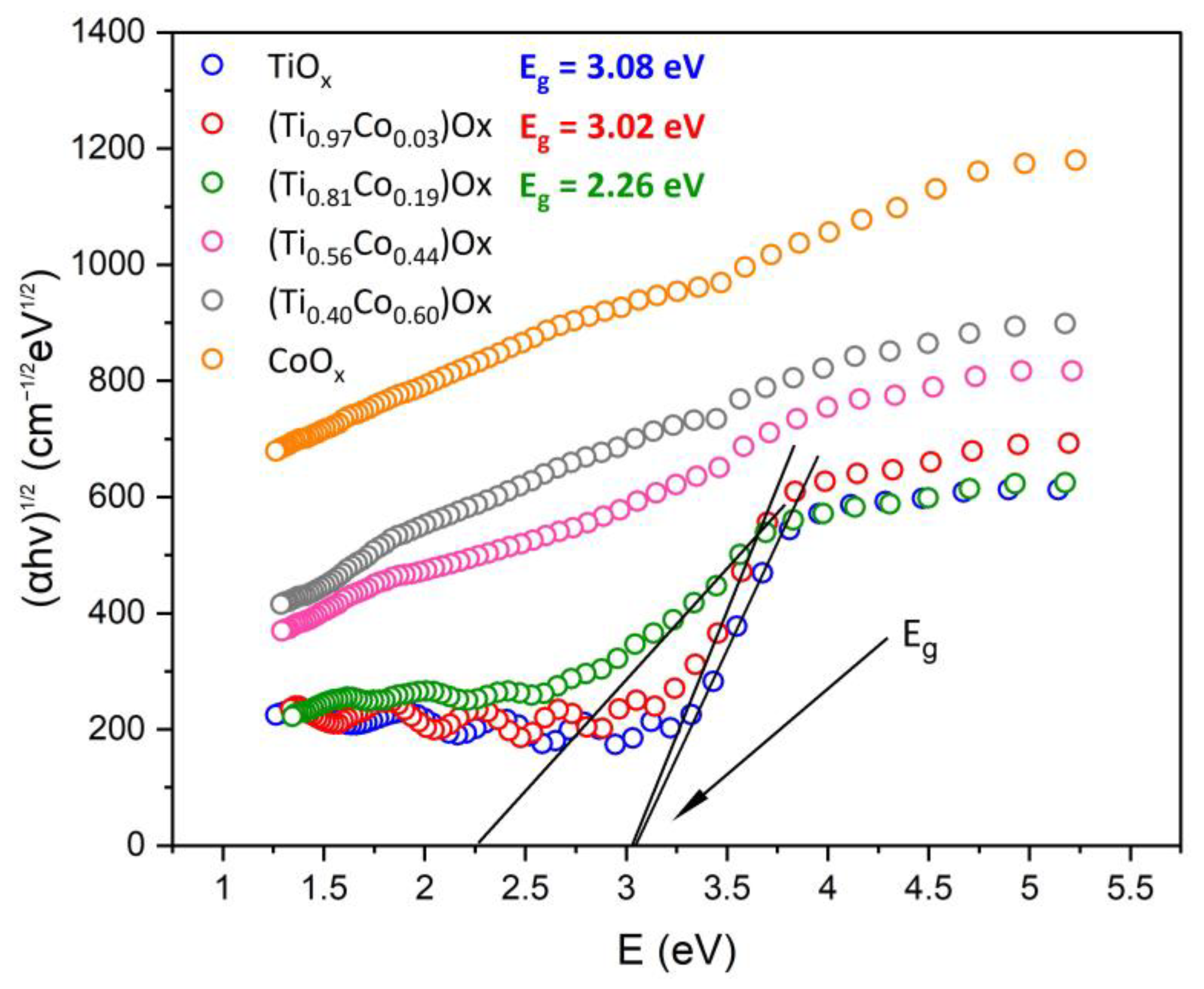

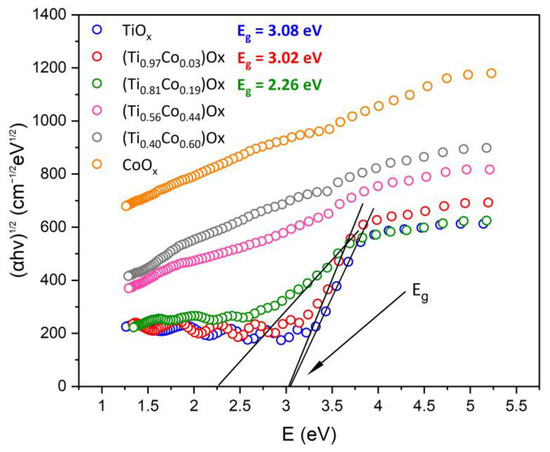

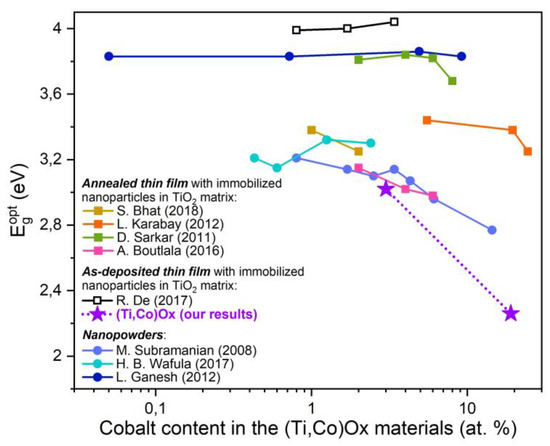

Based on transmission characteristics, the Tauc plots (for indirect transitions) were obtained and the optical band gap was estimated (Figure 9). The Egopt values for the TiOx and (Ti0.97Co0.03)Ox films were very similar and equal to 3.08 and 3.02 eV, respectively. The increase in the Co content resulted in a decrease in the Egopt value. In the case of the film with 19 at.% of Co, 2.26 eV was noticed. For films with greater amounts of cobalt, a transmission level that was too low did not allow us to determine the value of the optical band gap. However, it should be noted that the results obtained are consistent with reports in the literature [6,56]. The results available for thin films show the crucial role of their form and method of preparation. There is a general tendency for the value of Eg to decrease with the increase of Co content [7,21,25,27,52,53,54,57] (Figure 10).

Figure 9.

Tauc plots for the thin films of TiOx, (Ti,Co)Ox, and CoOx with marked areas of determination of the optical band gap (Egopt).

Figure 10.

Influence of cobalt content on the light transmission coefficient of oxide materials based on Ti [7,21,25,27,52,53,54,57]. On the basis of data from the publication, the cobalt content was converted from wt.% to at.%.

3.3. Structural Characterisation of Thin Films of (Ti,Co)Ox

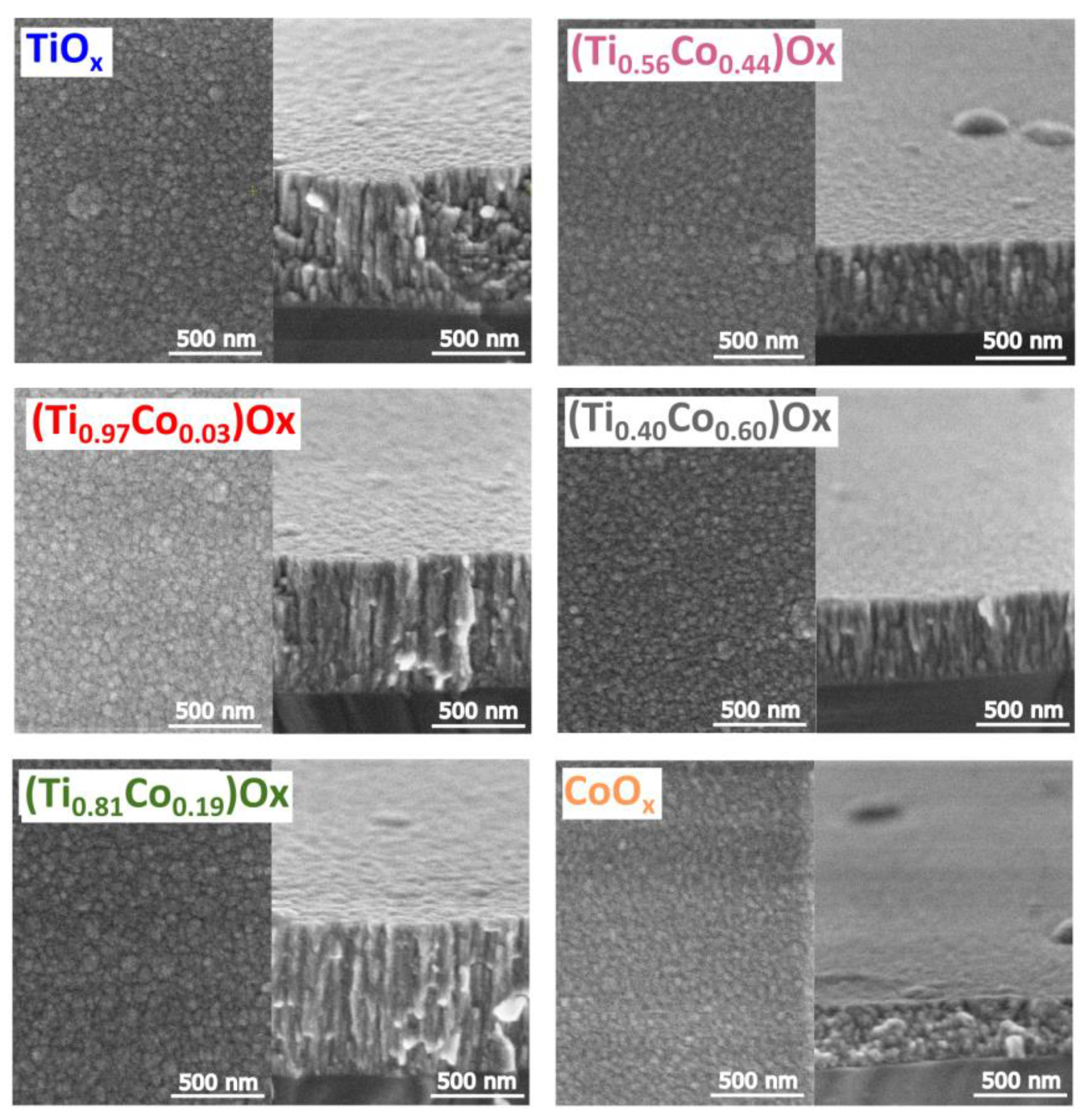

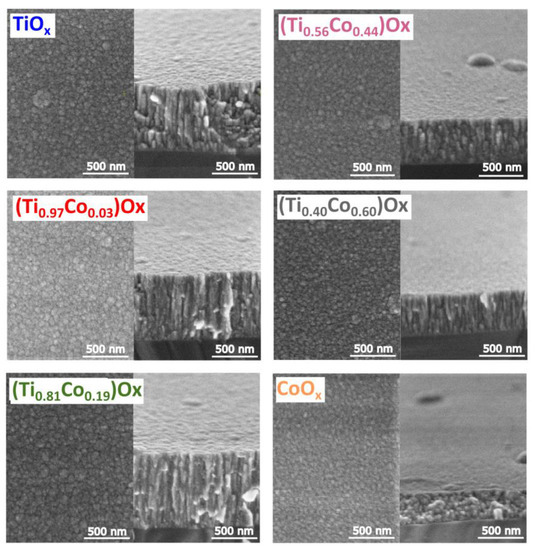

In Figure 11, SEM images of the surface and cross-sectional topography of the prepared oxide films are shown. It can be stated that the microstructure of all coatings from the GIMS processes was very homogeneous.

Figure 11.

SEM images of the surface and cross-sectional topography of TiOx, (Ti,Co)Ox, and CoOx thin films.

Cross-sectional images indicate that the TiOx and (Ti,Co)Ox films had a columnar character. Their microstructure was densely packed and free of cracks or gaps between columns. The increase in Co content resulted in a decrease in the width of the columns from 30 to 15 nm. The lack of titanium in the film resulted in a microstructure of a different nature, i.e., grainy. This means that the presence of titanium has a key influence on the process of nucleation of (Ti,Co)Ox coatings in the GIMS process.

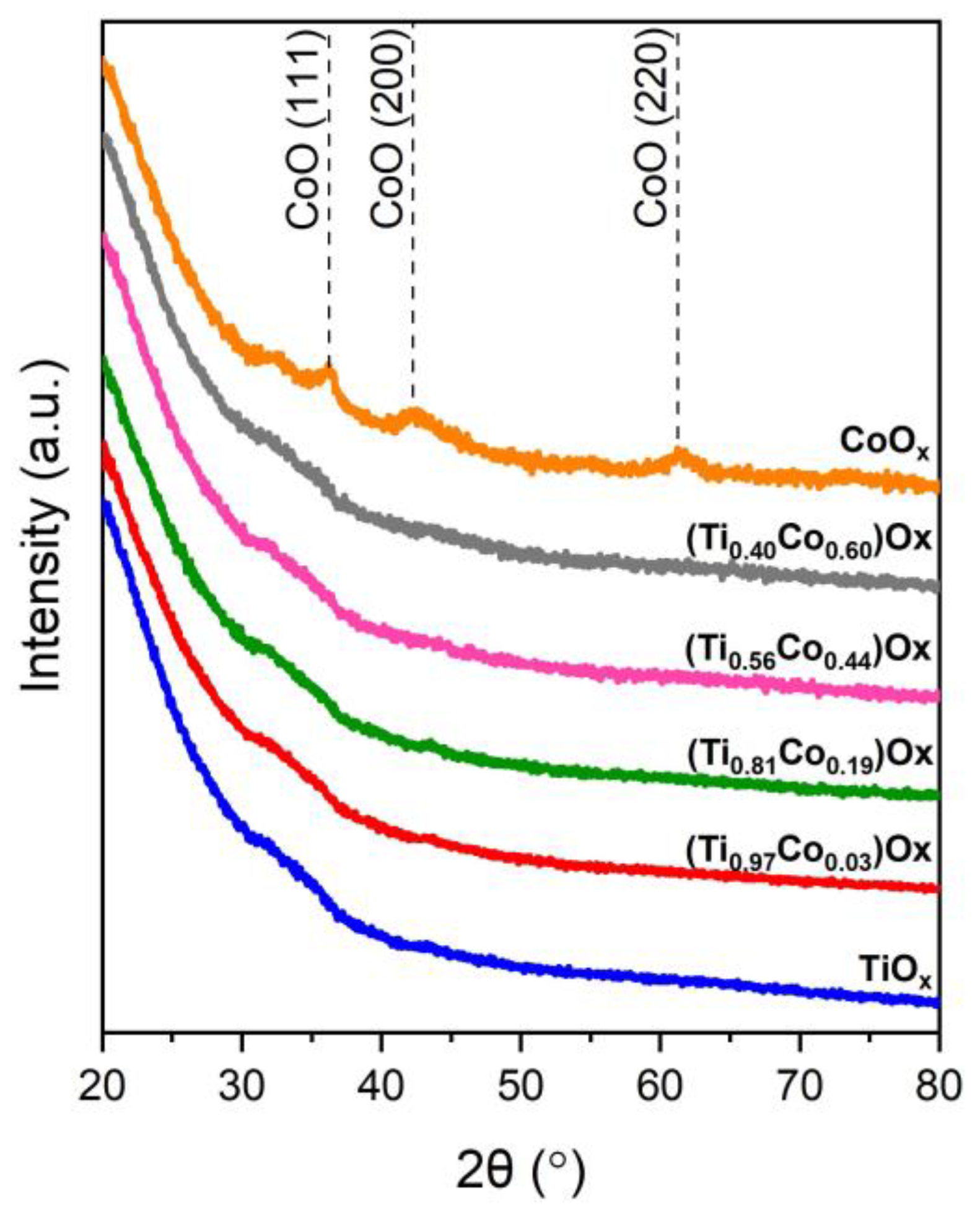

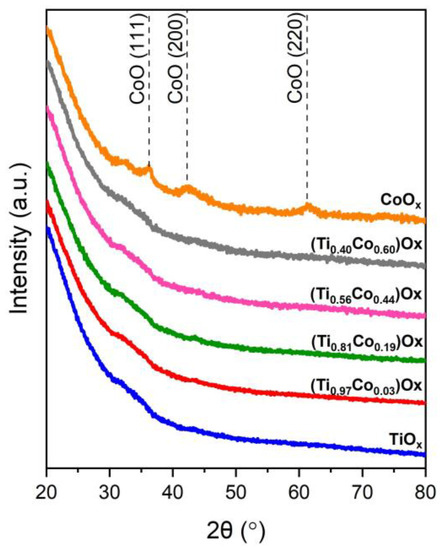

The structure of the as-deposited (Ti,Co)Ox coatings was examined using X-ray diffraction (XRD) in the grazing incidence mode (GIXRD). In Figure 12, the GIXRD patterns of the films are shown.

Figure 12.

GIXRD patterns of TiOx, (Ti,Co)Ox, and CoOx thin films prepared by gas impulse magnetron sputtering.

As can be seen, all coatings prepared by the GIMS technique were amorphous except for CoOx, which was nanocrystalline. In this case, the crystalline form of CoO was identified, but it should be emphasised that the intensity of the peaks in the pattern is very weak.

Furthermore, broad peaks were also exposed in patterns related to the SiO2 substrate. However, there is a lack of peaks that could testify about the crystal form of titanium, cobalt, or their oxides. Similar results were also obtained for other oxide materials prepared using the GIMS technique [44,45,46], which is a consequence of this innovative sputtering method [42]. Detailed results of the XRD analysis are collected in Table 2.

Table 2.

Structural properties of TiOx, (Ti,Co)Ox, and CoOx thin films, based on GIXRD measurements.

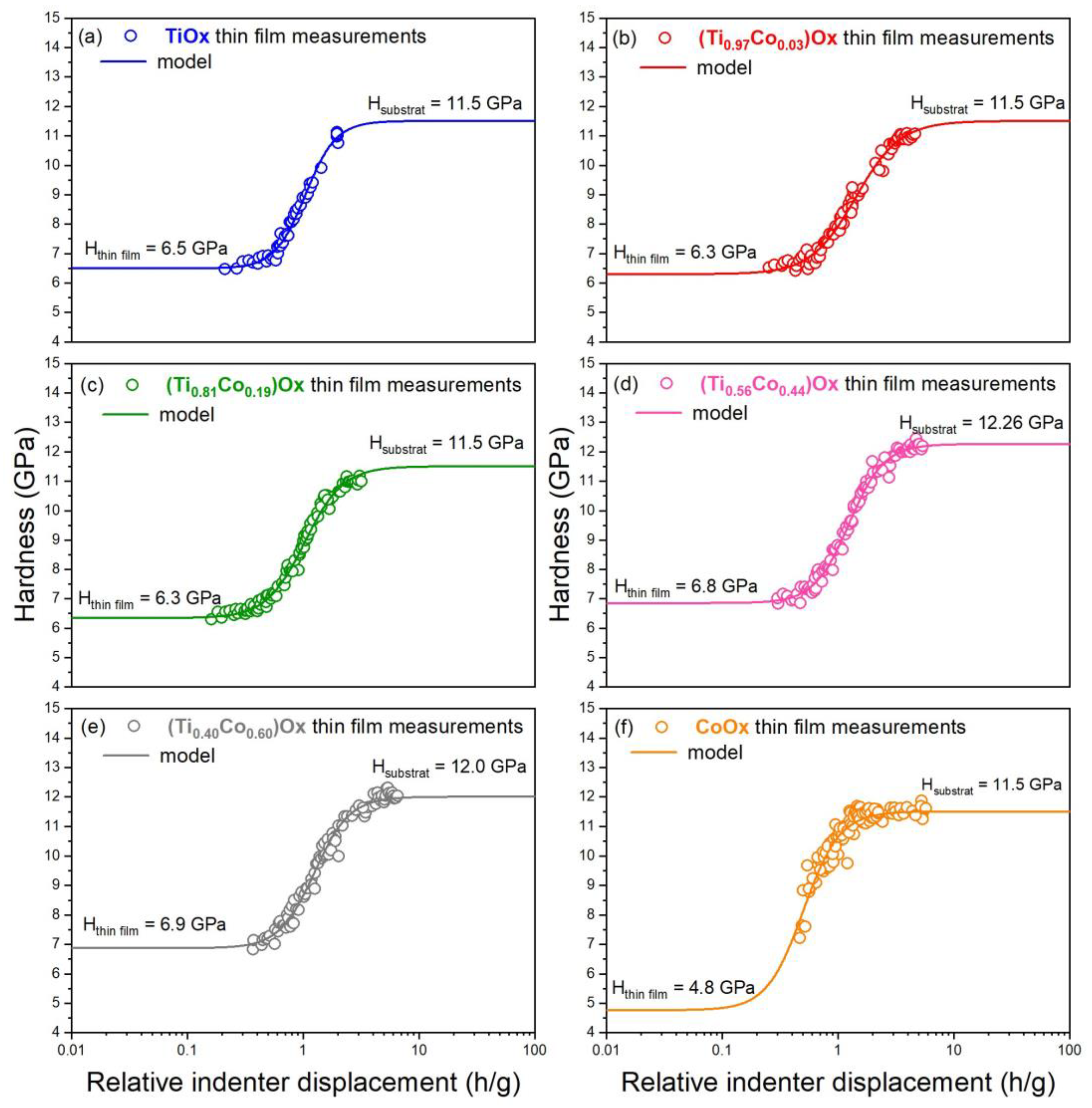

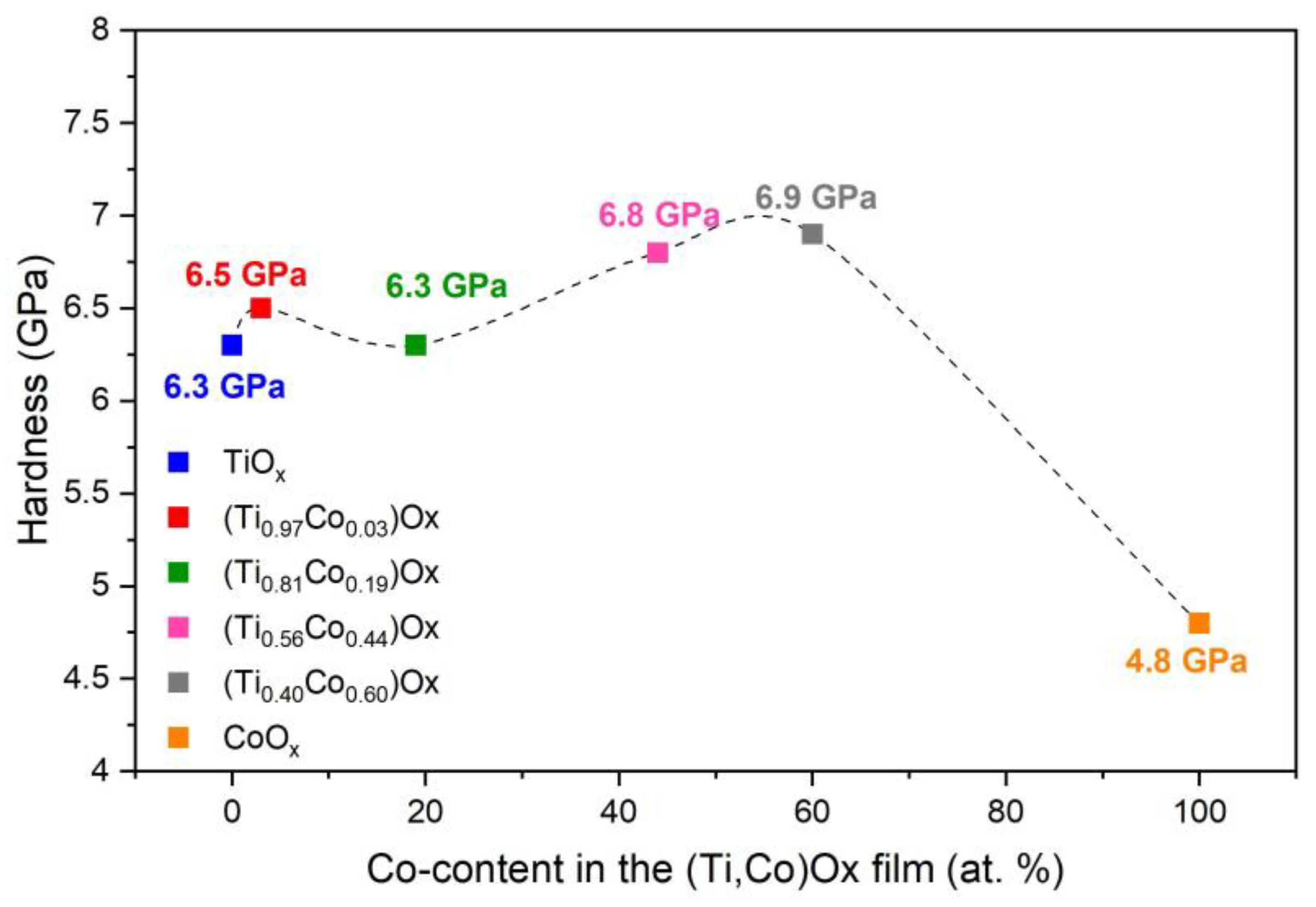

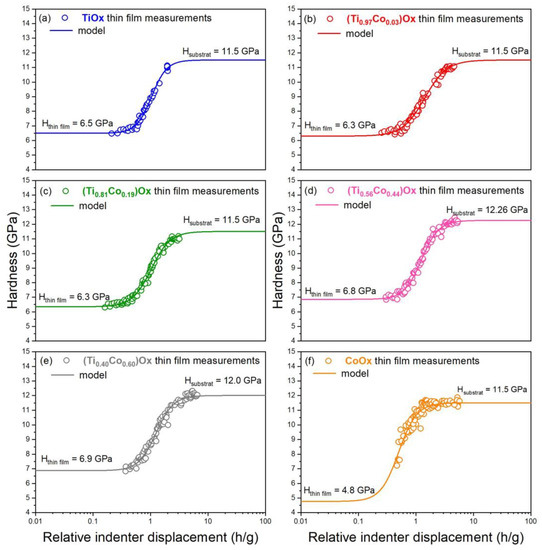

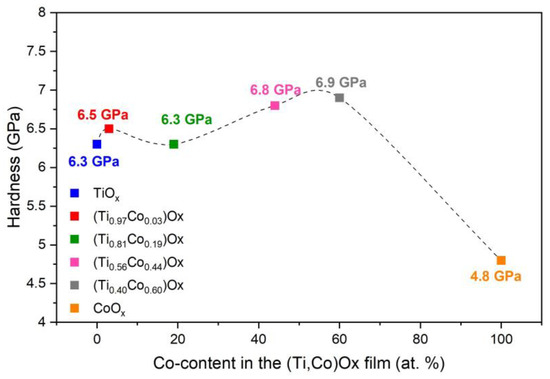

The influence of the Co content on the hardness of nonstoichiometric Ti-based films with the aid of nanoindentation was also investigated. Figure 13 shows the results of hardness as a function of the relative intender displacement for all prepared TiOx, (Ti,Co)Ox, and CoOx coatings. There was no significant change in the hardness value (H) with increasing cobalt. The value of H was in the range of 6.3 GPa to 6.9 GPa. Only for the CoOx film was a lower value (4.8 GPa) observed (Figure 14). These results may testify to the influence of the type of microstructure on the hardness. Thus, the TiOx and (Ti,Co)Ox films with columnar microstructure had a similar hardness, whereas the grainy microstructure of the CoOx film resulted in ca. 25% lower hardness. However, there is a lack of data related to the hardness of such mixed Ti-Co oxide materials, especially non-stoichiometric.

Figure 13.

Hardness of (a) TiOx, (b) (Ti0.93Co0.03)Ox, (c) (Ti0.81Co0.19)Ox, (d) (Ti0.56Co0.44)Ox, (e) (Ti0.40Co0.60)Ox and (f) CoOx oxide thin films.

Figure 14.

The effect of cobalt on the hardness of TiOx films.

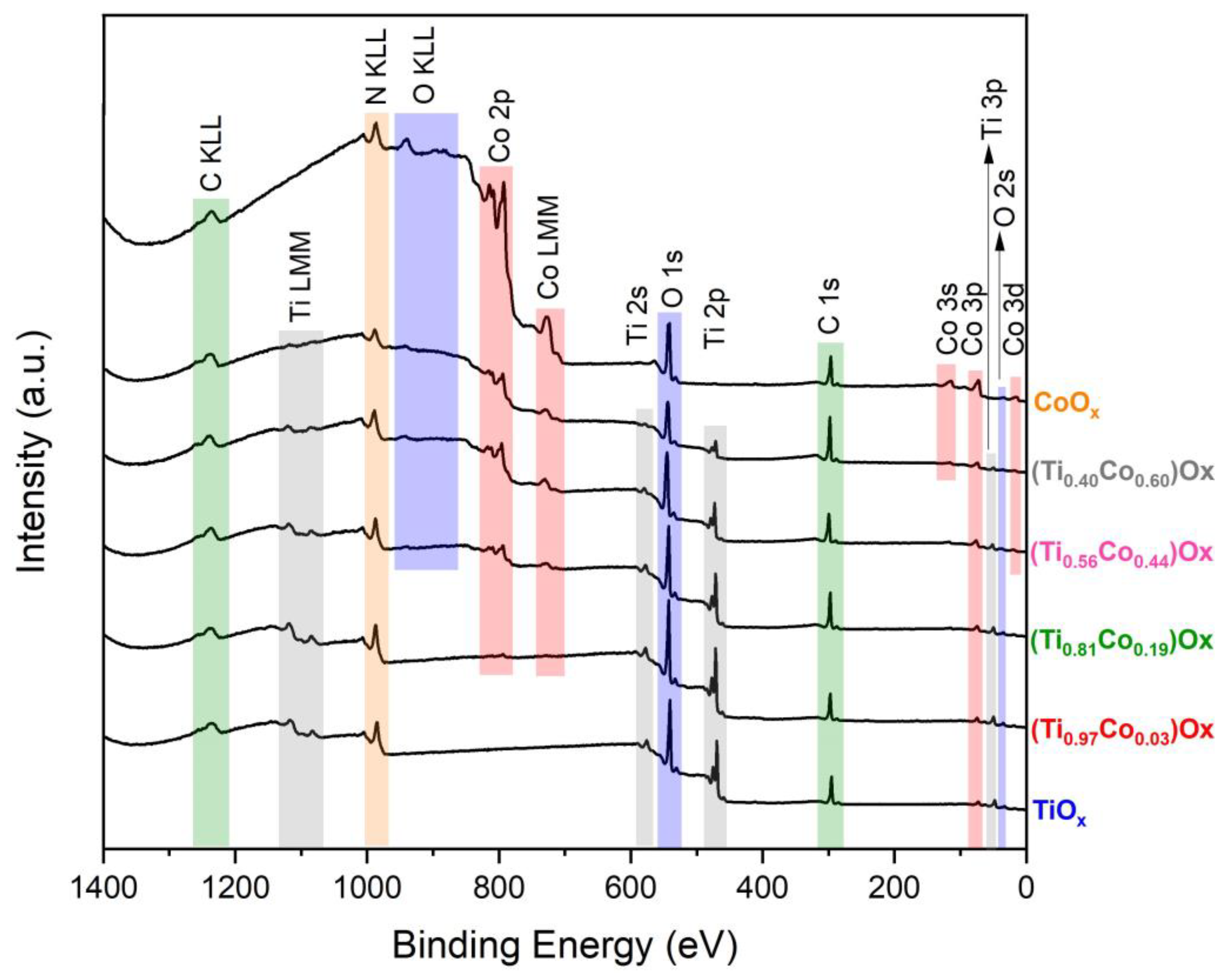

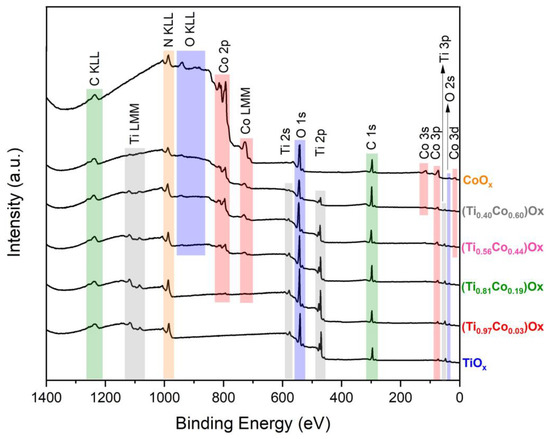

Because the GIXRD results did not reveal the forms in which cobalt of titanium occurred in the (Ti,Co)Ox coatings, we decided to perform photoelectron spectroscopy (XPS). In Figure 15, the XPS survey spectra recorded for composite bonding are shown [61,62,63,64].

Figure 15.

XPS survey spectra of the as-deposited TiOx, (Ti,Co)Ox, and CoOx thin films.

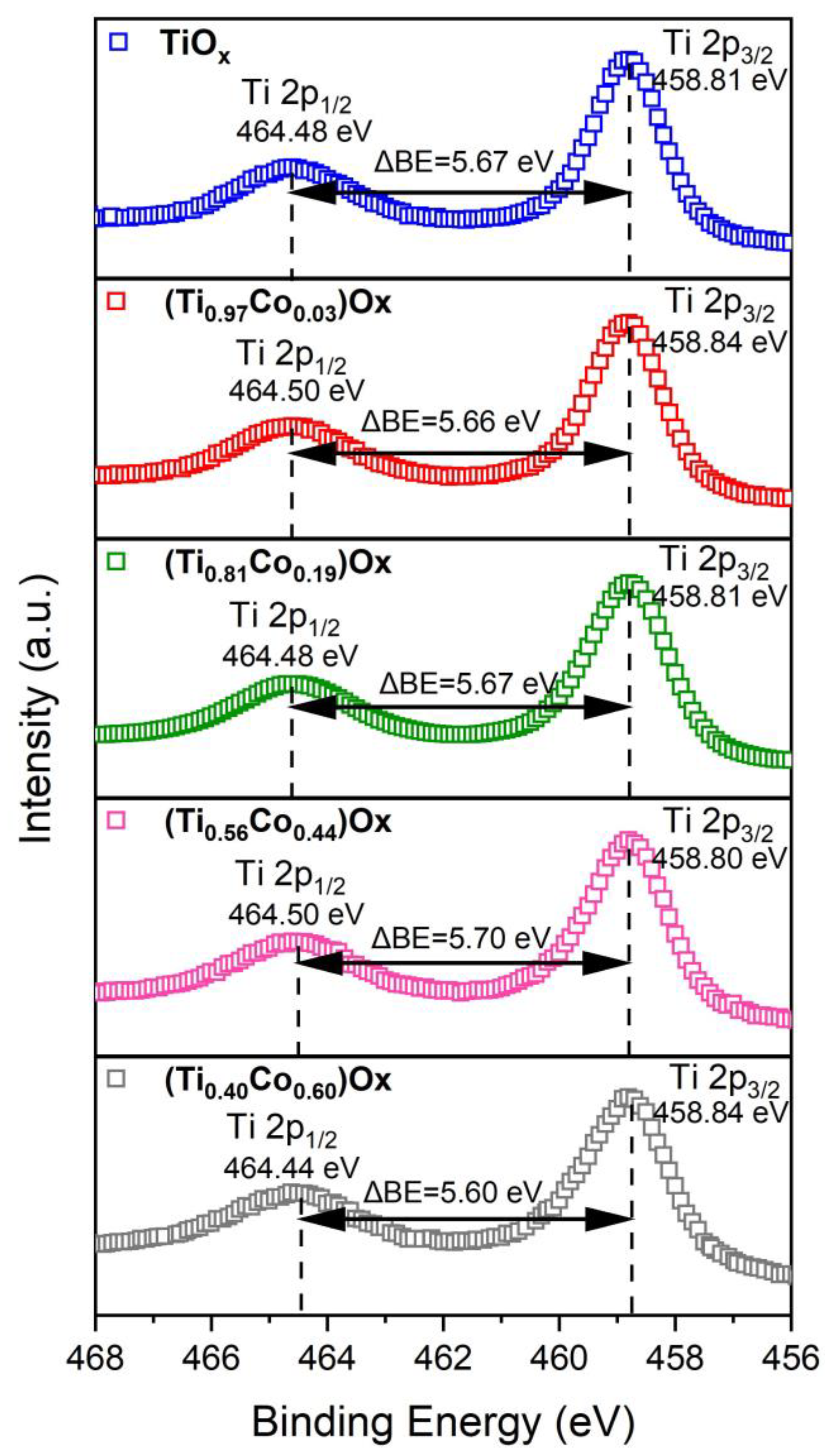

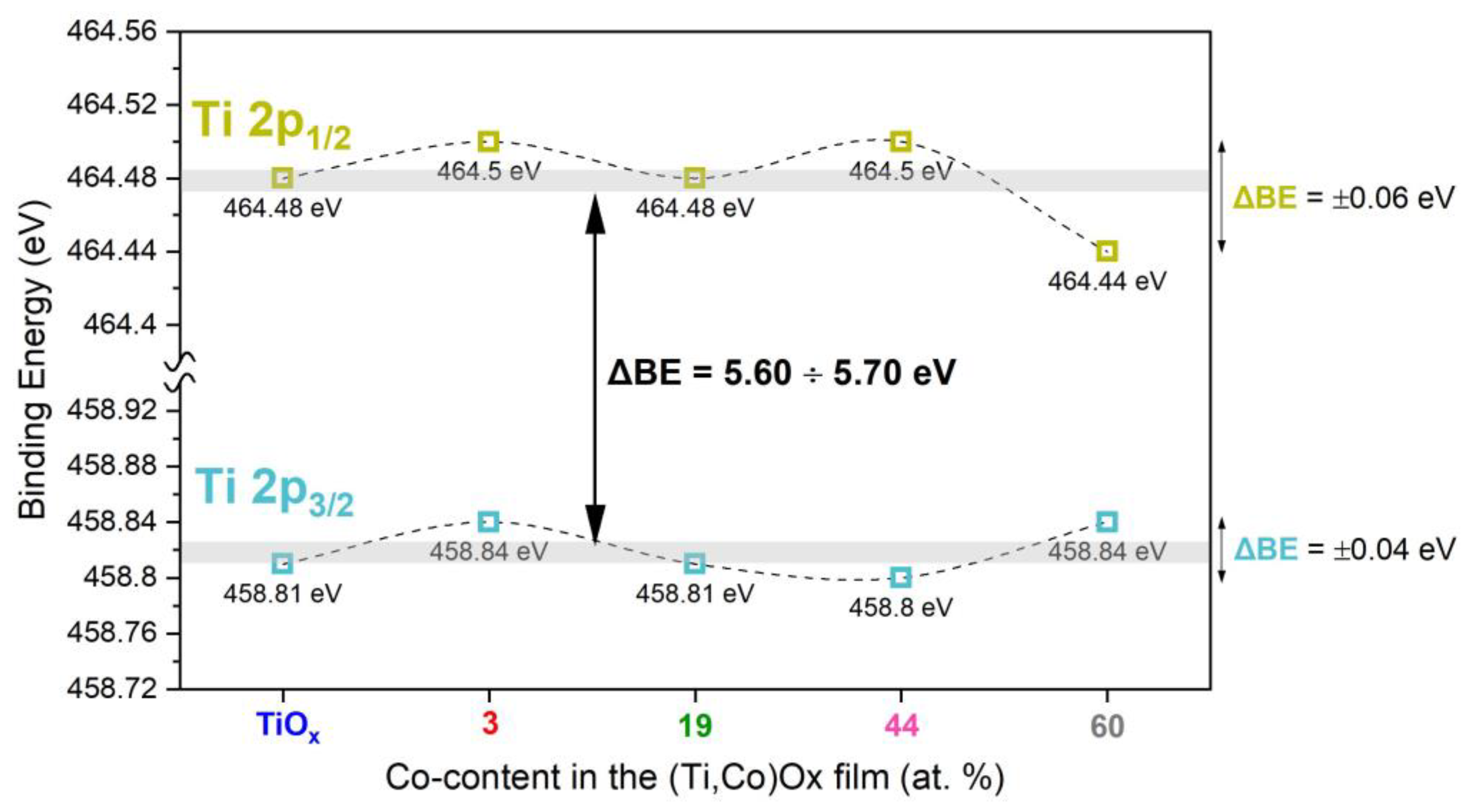

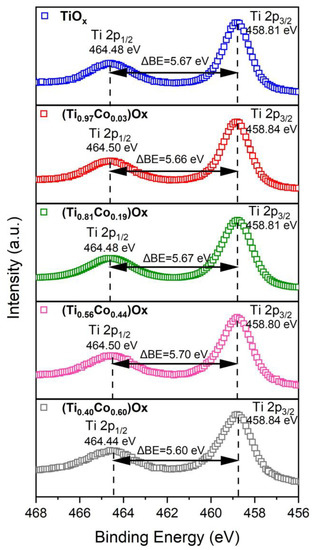

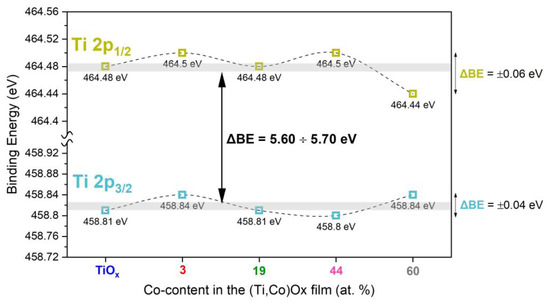

In Figure 16 the XPS spectra recorded for Ti2p peaks recorded for (Ti,Co)Ox and TiOx thin films are shown. For all films, the presence of a characteristic doublet of Ti2p peaks can be observed. The positions of both Ti2p3/2 and Ti2p1/2 photoelectron peaks correspond to the +4 oxidation state of titanium [61,62,65,66]. The differences in the positions of the Ti2p doublet peaks are very small, i.e., below 0.1 eV (Figure 17). Therefore, the amount of Co addition does not affect the position of the Ti2p doublet. This suggests that titanium only forms its distinct oxide forms and not compounds with cobalt. It should also be noted that the difference in the position of the peaks in the doublet (ΔBE) itself, which is in the range of 5.6 to 5.7 eV, indicates the presence of the TiO2 form (Figure 17).

Figure 16.

The XPS spectra of the Ti2p state for TiOx and (Ti,Co)Ox thin films.

Figure 17.

The influence of Co content on the position of Ti2p doublet peak.

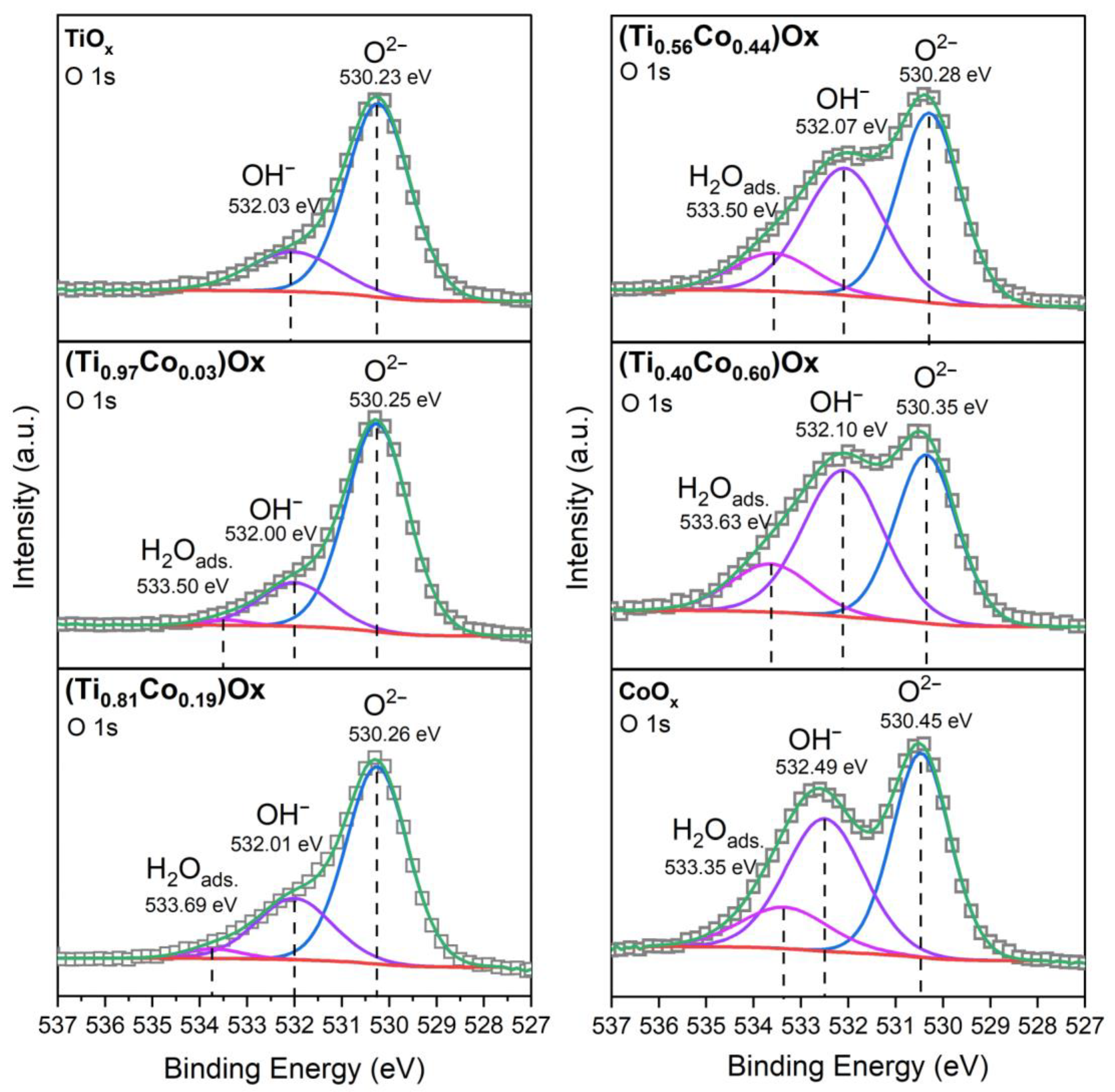

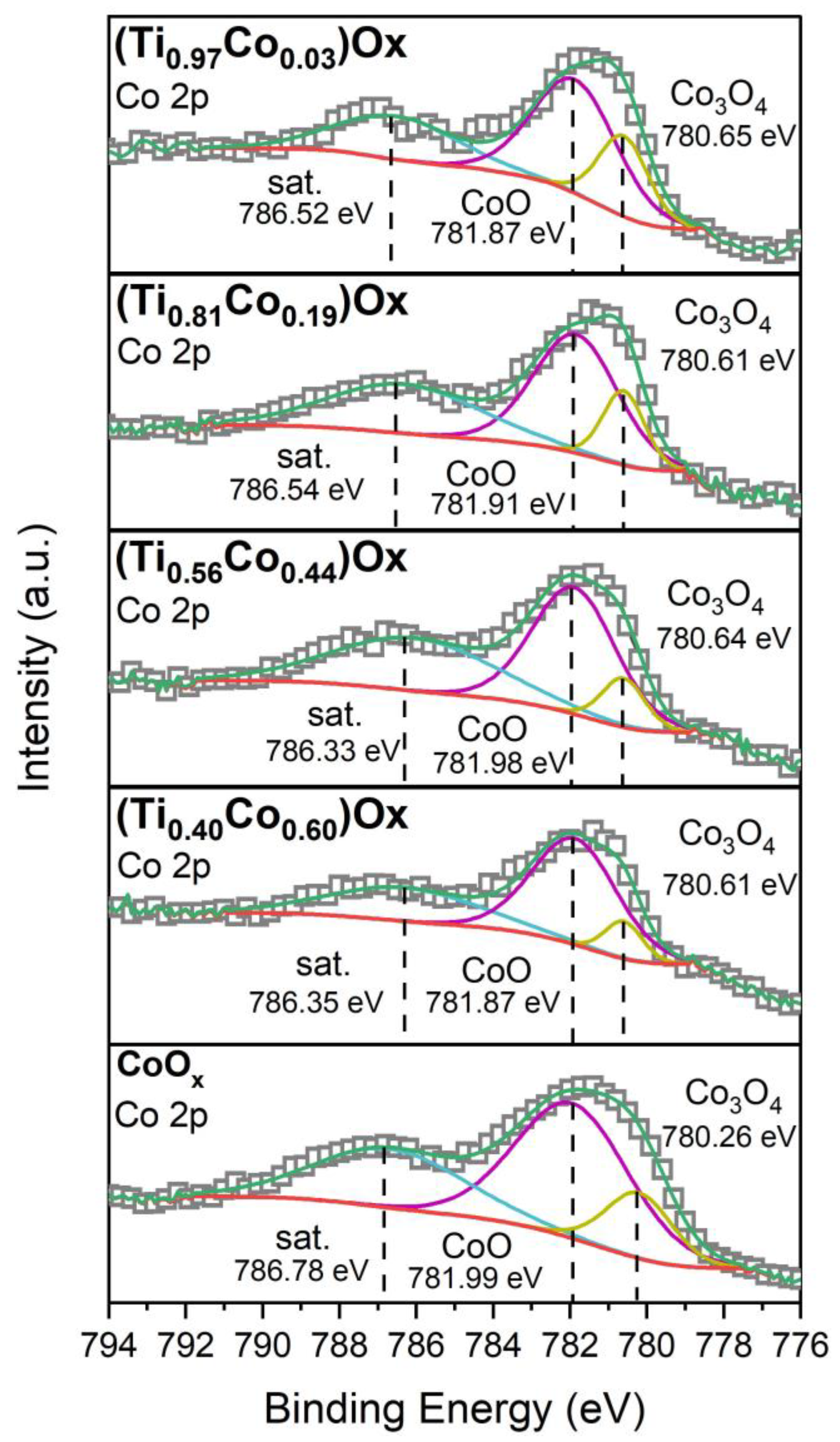

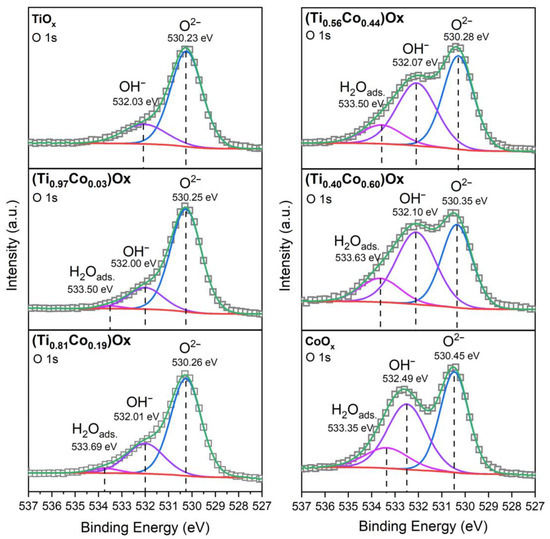

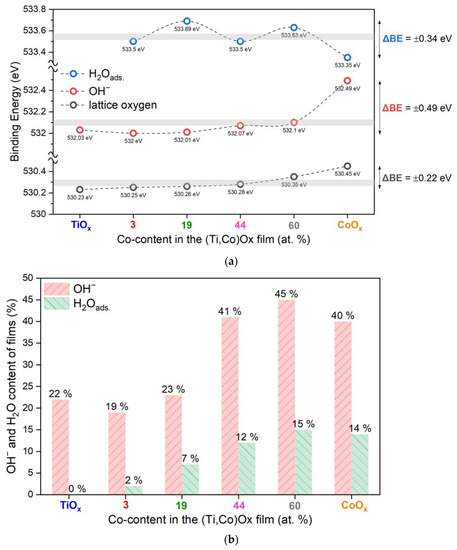

Figure 18 presents the XPS spectra for the O1s peaks recorded for the prepared TiOx, (Ti,Co)Ox, and CoOx thin films. Deconvolution of the multipeak (Figure 19a) showed that it consisted of three peaks, centred on: (i) 530.3 eV, attributed to lattice oxygen [61,62,66,67]; (ii) 532.1 eV, related to the presence of hydroxyl groups (OH-) on the surface [61,62,66,67]; and (iii) 533.6 eV, related to the water molecules adsorbed on the surface (H2Oads) [61,62,66]. The differences in the positions of the O1s doublet peaks are very small, i.e., below 0.5 eV. Taking into account the intensity of the multipeak O1s (Figure 19b), it could be concluded that the surfaces of (Ti,Co)Ox with 44 at.% and 60 at.% cobalt, as well as CoOx thin films, are more likely to absorb OH- from the surrounding environment than TiOx and (Ti,Co)Ox with 19 at.% or 3 at.% Co. Furthermore, with increasing Co content, the level of H2Oads also increased from 2% to 15%.

Figure 18.

XPS spectra for the O1 state of TiOx, (Ti,Co)Ox, and CoOx thin films.

Figure 19.

The influence of cobalt content on the position of O1 multipeak (a); the relative content of OH groups and H2Oads molecules adsorbed on the surface of prepared coatings to the O1 signal (b).

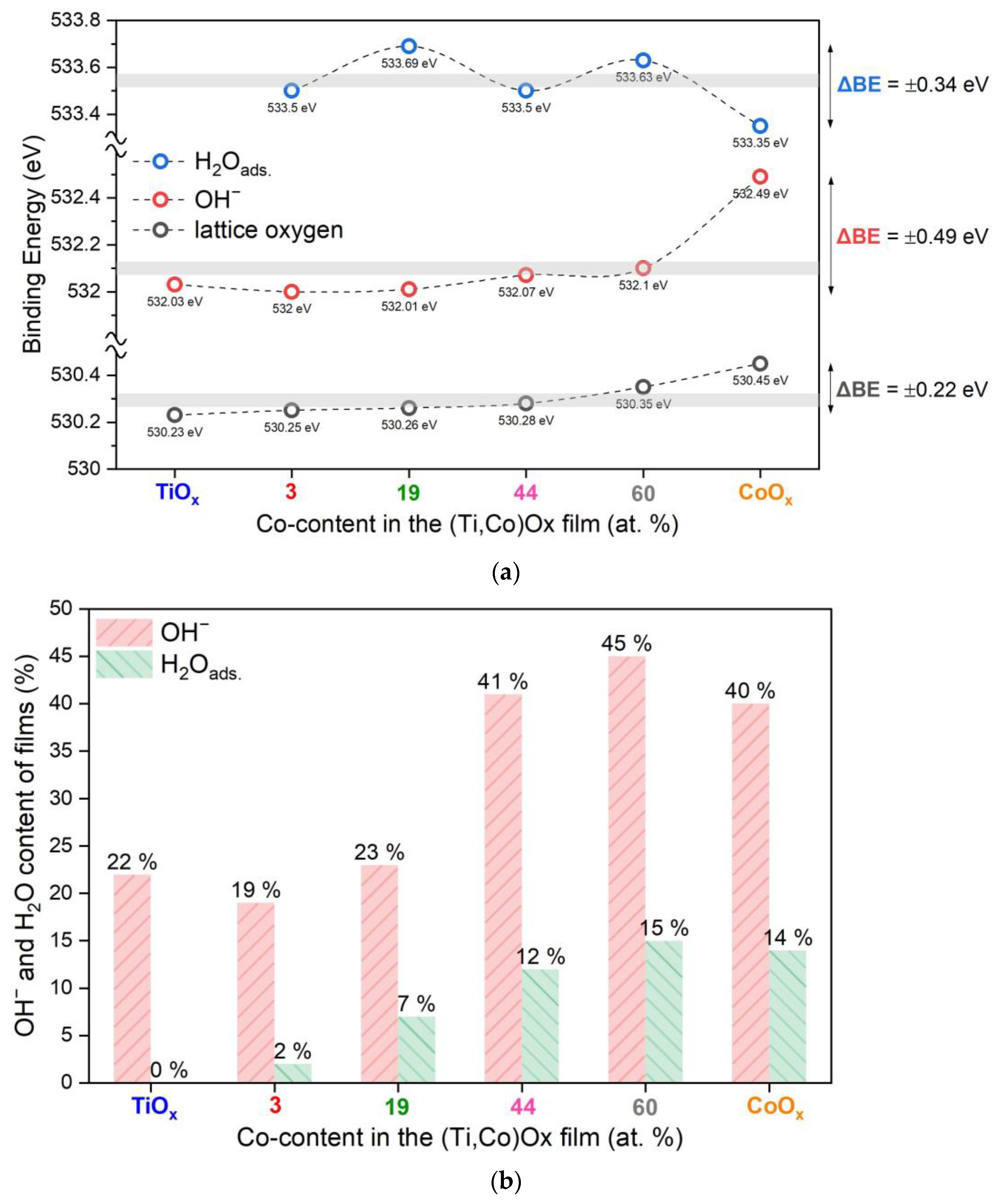

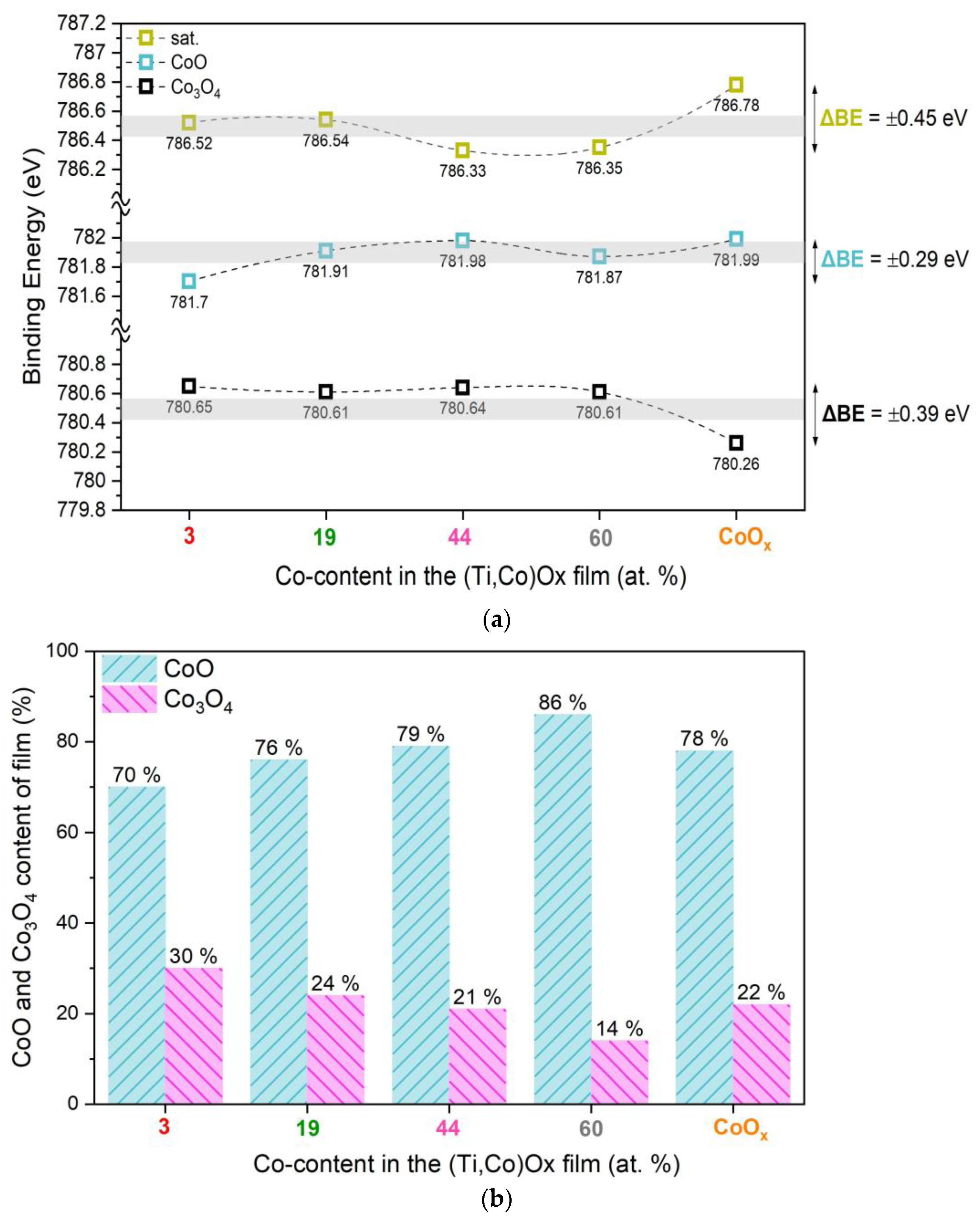

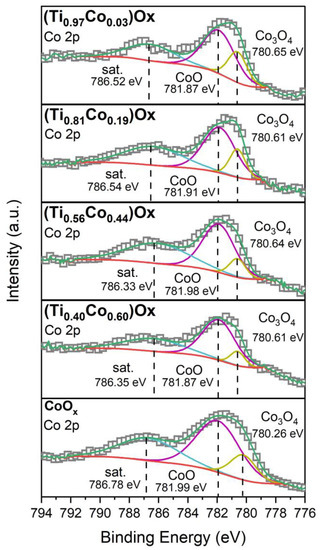

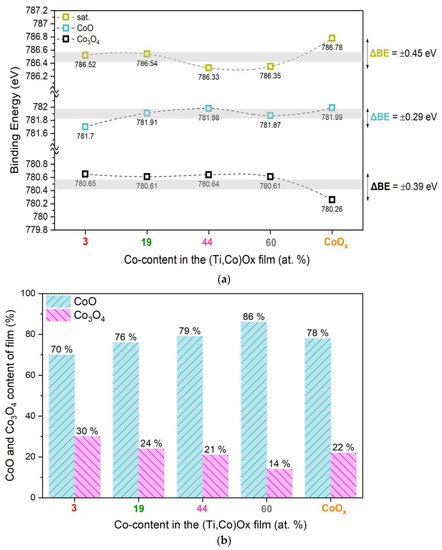

The most important part of the XPS research was the analysis of the spectra recorded for the Co2p state. We aimed to reveal the degree of oxidation of cobalt ions and thus the forms in which its oxides may occur in the coatings. In Figure 8a, the Co2p3/2 spectra of prepared (Ti,Co)Ox and CoOx thin films are shown. In each spectrum, a multipeak can be observed (Figure 20). It was deconvoluted into a satellite (786.5 eV) and two main peaks.

Figure 20.

XPS spectra for Co2p3/2 state of (Ti,Co)Ox and CoOx thin films.

The first Co2p3/2 peak centred at approximately 781.8 eV is related to Co2+ ions; thus, the presence of the CoO form can be confirmed [61,62,68,69,70]. The second Co2p3/2 peak of Co2p3/2 located at approximately 780.6 eV corresponds to Co2+ and Co3+ ions and can be related to the appearance of Co3O4 [61,62,68,69,70,71]. However, some authors argue that, based on XPS measurements of Co2O3 and Co3O4, which contain both Co2+ and Co3+, cannot be distinguished by chemical shift or satellite [21]. This suggests that the surface films of Co2O3 and Co3O4 are similar. The binding energy values estimated for Co2p3/2 core levels are in agreement with those reported for Co oxides in the literature [61,62,68,69,70]. There are no references to mixed oxides in the literature, while quite a few examples involve single oxides. Due to the very low number of literature reports on such materials, it was relatively difficult to compare the peaks to Co2p3/2 spectra. Comparison of the areas under the peaks revealed that the percentage of Co ions in the +2 oxidation state is about 3–4 times that of +3. Differences in the positions of the Co2p3/2 doublet peaks are very small, i.e., below 0.5 eV (Figure 21a). Furthermore, with an increase in the Co content in the (Ti,Co)Ox films, the percentage content of the CoO form increases at the expense of Co3O4 (Figure 21b).

Figure 21.

The influence of cobalt on the multipeak position of Co2p3/2 (a); the content of adsorbed hydroxy groups and water molecules on the surface of the examined coatings (b).

4. Conclusions

In this work, the influence of the Co content on the properties of non-stoichiometric (Ti,Co)Ox thin films prepared by a GIMS process has been described. The aim of our research was to obtain a broad change in the material composition for coatings prepared under the same conditions. The application of gas impulse sputtering resulted in the manufacture of amorphous (Ti,Co)Ox films with a homogeneous distribution of cobalt. The change in Co content resulted in modification of the morphology and optical properties. The most significant changes were observed for the optical parameters. A large drop in the transparency level and the optical band gap was observed along with the increase in the cutoff wavelength (‘red shift’). Structural studies revealed that, except for the nanocrystalline CoOx film (with crystallites of <5 nm in size) with fine-grained microstructure, the morphology of all amorphous TiOx and (Ti,Co)Ox coatings had a columnar nature. The hardness of TiOx and (Ti,Co)Ox films (6.5 GPa) was higher compared to CoOx (4.8 GPa). The XPS analysis has revealed that the prepared films consisted of mixed oxides. For all (Ti,Co)Ox films, the occurrence of TiO2 form was observed, while in the cobalt, the additive was present in its own forms. The occurrence of CoO and Co3O4 forms was identified. The quantity of cobalt ions in the +2 state was 3–4 times higher compared to the +3 ions. However, modification of the composition of the material resulted in a decrease in CoO at the expense of Co3O4 with an increase in the cobalt content of the film.

Author Contributions

Conceptualization, P.P. and D.W.; methodology, P.P. and D.W.; validation, D.W.; investigation, P.P., M.S., M.K., P.M. and D.W.; resources, D.W.; writing—original draft preparation, P.P. and D.W.; writing—review and editing, P.P. and D.W.; supervision, D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was co-financed from the sources given by the Polish National Science Centre (NCN) as a research project number 2018/29/B/ST8/00548.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following table shows all abbreviations used in this work.

| a | lattice parameters |

| d | interplane distance |

| dPDF | standard interplane distance (according to PDF card) |

| D | average crystallite size |

| E | energy |

| Eg | width of the energy gap |

| Egopt. | width of the optical energy gap |

| Hsubstart | hardness of the substrate |

| Hthin film | hardness of the thin film |

| h | Planck’s constant |

| Tλ | light transmission coefficient |

| T550 | average value of the light transmission coefficient for the wavelength λ = 550 nm |

| Tλa | average transmission in the range of 300 to 900 nm |

| t | thickness of the films |

| α | absorption coefficient |

| λ | wavelength of electromagnetic radiation |

| λcut-off | position of the edge of optical absorption |

| EDS | energy-dispersive spectroscopy |

| (Ti0.97Co0.03)Ox | abbreviated notation of the thin film as a mixture of oxides in which the atomic content is: 97% at. Ti to 3% at. Co |

| powder diffraction files | |

| SEM | transmission electron microscopy |

| XPS | X-ray photoelectron spectroscopy |

| XRD | grazing incidence X-ray diffraction |

References

- Venturini, J.; Bonatto, F.; Guaglianoni, W.C.; Lemes, T.; Arcaro, S.; Alves, A.K.; Bergmann, C.P. Cobalt-doped titanium oxide nanotubes grown via one-step anodization for water splitting applications. Appl. Surf. Sci. 2019, 464, 351–359. [Google Scholar] [CrossRef]

- Liu, C.; Wang, F.; Zhu, S.; Xu, Y.; Liang, Q.; Chen, Z. Controlled charge-dynamics in cobalt-doped TiO2 nanowire photoanodes for enhanced photoelectrochemical water splitting. J. Colloid Interface Sci. 2018, 530, 403–411. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Makabu, C.M.; Du, X.; Li, J.; Sun, D.; Liu, G. Cobalt nanorods decorated titanium oxide arrays as efficient and stable electrocatalyst for oxygen evolution reaction. Electrochim. Acta 2021, 396, 139213. [Google Scholar] [CrossRef]

- Khan, W.; Ahmad, S.; Hassan, M.M.; Naqvi, A.H. Structural phase analysis, band gap tuning and fluorescence properties of Co doped TiO2 nanoparticles. Opt. Mater. 2014, 38, 278–285. [Google Scholar] [CrossRef]

- Yamada, Y.; Toyosaki, H.; Tsukazaki, A.; Fukumura, T. Epitaxial growth and physical properties of a room temper ferromagnetic semiconductor: Anatase phase Ti1-xCoxO2. J. Appl. Phys. 2004, 96, 5097. [Google Scholar] [CrossRef]

- Husain, S.; Alkhtaby, L.A.; Giorgetti, E.; Zoppi, A.; Miranda, M.M. Influence of cobalt doping on the structural, optical and luminescence properties of sol-gel derived TiO2 nanoparticles. Philos. Mag. 2017, 97, 17–27. [Google Scholar] [CrossRef]

- Bhat, S.; Sandeep, K.M.; Kumar, P.; Dharmaprakash, S.M.; Byrappa, K. Characterization of transparent semiconducting cobalt doped titanium dioxide thin films prepared by sol–gel process. J. Mater. Sci. Mater. Electron. 2018, 29, 1098–1110. [Google Scholar] [CrossRef]

- Jiang, P.; Xiang, W.; Kuang, J.; Liu, W.; Cao, W. Effect of cobalt doping on the electronic, optical and photocatalytic properties of TiO2. Solid State Sci. 2015, 46, 27–32. [Google Scholar] [CrossRef]

- Musa, M.Z.; Ameran, Z.F.; Mamat, M.H.; Malek, M.F.; Rasheid, B.A.; Noor, U.M.; Rusop, M. Effects of cobalt doping concentration on the structural, electrical, and optical properties of titanium dioxide thin films. In Proceedings of the 2011 International Conference on Electronic Devices, Systems and Applications (ICEDSA), Kuala Lumpur, Malaysia, 25–27 April 2011; pp. 339–342. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Mazur, M.; Pokora, P.; Wrona, A.; Bilewska, K.; Kijaszek, W.; Kotwica, T.; Posadowski, W.; Domaradzki, J. Properties of metallic and oxide thin films based on Ti and Co prepared by magnetron sputtering from sintered targets with different Co-content. Materials 2021, 14, 3797. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Domaradzki, J.; Pokora, P.; Sikora, M.; Mazur, M.; Chodasewicz, P.; Morgiel, J.; Gibson, D. Optical and structural properties of gradient (Ti,Co)Ox thin-film coatings with a resistive switching effect. Appl. Opt. 2022, 34, 10283–10289. [Google Scholar] [CrossRef]

- Mei, J.; Liao, T.; Ayoko, G.A.; Bell, J.; Sun, Z. Cobalt oxide-based nanoarchitectures for electrochemical energy applications. Prog. Mater. Sci. 2019, 103, 596–677. [Google Scholar] [CrossRef]

- Verma, M.; Mitan, M.; Kim, H.; Vaya, D. Efficient photocatalytic degradation of malachite green dye using facilely synthesized cobalt oxide nanomaterials using citric acid and oleic acid. J. Phys. Chem. Solids 2021, 155, 110125. [Google Scholar] [CrossRef]

- Gajbhiye, N.S.; Sharma, S.; Nigam, A.K.; Ningthoujam, R.S. Tuning of single to multi-domain behavior for monodispersed ferromagnetic cobalt nanoparticles. Chem. Phys. Lett. 2008, 466, 181–185. [Google Scholar] [CrossRef]

- Kaloyeros, A.E.; Pan, Y.; Goff, J.; Arles, B. Cobalt thin films: Trends in processing technologies and emerging applications. ECS J. Solid State Sci. Technol. 2019, 8, 119–152. [Google Scholar] [CrossRef]

- Hirohata, A.; Yamada, K.; Nakatani, Y.; Prejbeanu, I.L.; Dieny, B.; Pirro, P.; Hillebrands, B. Review on spintronics: Principles and device applications. J. Magn. Magn. Mater. 2020, 509, 166711. [Google Scholar] [CrossRef]

- Bewan, S.; Ndolomingo, M.J.; Meijboom, R.; Bingwa, N. Cobalt oxide promoted tin oxide catalysts for highly selective glycerol acetalization reaction. Inorg. Chem. Commun. 2021, 128, 108578. [Google Scholar] [CrossRef]

- Svegl, F.; Orel, B.; Hutchins, M.G.; Kalcher, K. Structural and Spectroelectrochemical Investigations of sol-gel derived electrochromic spinel Co3O4 films. J. Electrochem. Soc. 1996, 143, 1532. [Google Scholar] [CrossRef]

- Bahlawane, N.; Rivera, E.F.; Hoinghaus, K.K.; Brechling, A.; Kleineberg, U. Characterization and tests of planar Co3O4 model catalysts prepared by chemical vapor deposition. Appl. Catal. B Environ. 2004, 53, 245–255. [Google Scholar] [CrossRef]

- Yao, W.; Fang, H.; Ou, E.; Wang, J.; Yan, Z. Highly efficient catalytic oxidation of cyclohexane over cobalt-doped mesoporous titania with anatase crystalline structure. Catal. Commun. 2006, 7, 387–390. [Google Scholar] [CrossRef]

- Ganesh, I.; Gupta, A.K.; Kumar, P.P.; Sekhar, P.S.C.; Radha, K.; Padmanabham, G.; Sundararajan, G. Preparation and characterization of Co-doped TiO2 materials for solar light induced current and photocatalytic applications. Mater. Chem. Phys. 2012, 135, 220–234. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Wu, Z.; Liu, Y. NO catalytic oxidation behaviors over CoOx/TiO2 catalysts synthesized by sol–gel method. Catal. Lett. 2010, 134, 295–302. [Google Scholar] [CrossRef]

- Yang, W.H.; Kim, M.H.; Ham, S.W. Effect of calcination temperature on the low-temperature oxidation of CO over CoOx/TiO2 catalysts. Catal. Today 2007, 123, 94–103. [Google Scholar] [CrossRef]

- Sadanandam, G.; Lalitha, K.; Kumari, V.D.; Shankar, M.V.; Subrahmanyam, M. Cobalt doped TiO2: A stable and efficient photocatalyst for continuous hydrogen production from glycerol: Water mixtures under solar light irradiation. Int. J. Hydrogen Energy 2013, 38, 9655–9664. [Google Scholar] [CrossRef]

- Wafula, H.B.; Musembi, R.J.; Juma, A.; Tonui, P.; Simiyu, J.; Sakwa, T.; Prakash, D.; Verma, K.D. Compositional analysis and optical properties of Co doped TiO2 thin films fabricated by spray pyrolysis method for dielectric and photocatalytic applications. Optik 2017, 128, 212–217. [Google Scholar] [CrossRef]

- Li, J.G.; Buchel, R.; Isobe, M.; Mori, T.; Ishigaki, T. Cobalt-doped TiO2 nanocrystallites: Radio-frequency thermal plasma processing, phase structure, and magnetic properties. J. Phys. Chem. C 2009, 113, 8009–8015. [Google Scholar] [CrossRef]

- Subramanian, M.; Vijayalakshmi, S.; Venkataraj, S.; Jayavel, R. Effect of cobalt doping on the structural and optical properties of TiO2 films prepared by sol-gel process. Thin Solid Films 2008, 516, 3776–3782. [Google Scholar] [CrossRef]

- Seong, N.J.; Yoon, S.G. Effects of Co-doping level on the microstructural and ferromagnetic properties of liquid-delivery metalorganic-chemical-vapor-deposited Ti1-xCoxO2 thin films. Appl. Phys. Lett. 2002, 81, 4209. [Google Scholar] [CrossRef]

- Song, H.Q.; Mei, L.M.; Zhang, Y.P.; Yan, S.S.; Ma, X.; Wang, Y.; Zhang, Z.; Chen, L.Y. Magneto-optical Kerr rotation in amorphous TiO2/Co magnetic semiconductor thin films. Phys. B Condens. Matter 2007, 388, 130–133. [Google Scholar] [CrossRef]

- Logacheva, V.A.; Lukin, A.N.; Afonin, N.N.; Serbin, O.V. Synthesis and optical properties of cobalt-modified titanium oxide films. Opt. Spectrosc. 2019, 126, 674–680. [Google Scholar] [CrossRef]

- Ko, Y.; Park, D.S.; Seo, B.S.; Yang, H.J.; Shin, H.J.; Kim, J.Y.; Lee, J.H.; Lee, W.H.; Reucroft, P.J.; Lee, J.G. Studies of cobalt thin films deposited by sputtering and MOCVD. Mater. Chem. Phys. 2003, 80, 560–564. [Google Scholar] [CrossRef]

- Quiroz, H.P.; Calderon, J.A.; Dussan, A. Magnetic switching control in Co/TiO2 bilayer and TiO2:Co thin films for magnetic-resistive random access memories (M-RRAM). J. Alloys Compd. 2020, 840, 155674. [Google Scholar] [CrossRef]

- Quiroz, H.; Galindez, E.F.; Dussan, A. Ferromagnetic-like behavior of Co doped TiO2 flexible thin films fabricated via co-sputtering for spintronic applications. Heliyon 2020, 6, e03338. [Google Scholar] [CrossRef]

- Afonin, N.N.; Logacheva, V.A. Cobalt modification of thin rutile films magnetron-sputtered in vacuum. Tech. Phys. 2018, 63, 605–611. [Google Scholar] [CrossRef]

- Griffin, K.A.; Pakhomov, A.B. Cobalt-doped anatase TiO2: A room temperature dilute magnetic dielectric material. J. Appl. Phys. 2005, 97, 10D320. [Google Scholar] [CrossRef]

- Ahmad, M.K.; Rasheid, N.A.; Ahmed, A.Z.; Abdullah, S.; Rusop, M. Study of cobalt doping on the electrical and optical properties of titanium dioxide thin film prepared by sol-gel method. In Proceedings of the 2008 IEEE International Conference on Semiconductor Electronics, Johor Bahru, Malaysia, 25–27 November 2008; pp. 561–565. [Google Scholar] [CrossRef]

- Park, W.; Ortega-Hertogs, R.J.; Moodera, J.S. Semiconducting and ferromagnetic behavior of sputtered Co-doped TiO2 thin films above room temperature. J. Appl. Phys. 2002, 91, 8093. [Google Scholar] [CrossRef]

- Tian, J.; Deng, H.; Sun, L.; Kong, H.; Yang, P.; Chu, J. Effects of Co doping on structure and optical properties of TiO2 thin films prepared by sol–gel method. Thin Solid Films 2012, 520, 5179–5183. [Google Scholar] [CrossRef]

- Quiroz, H.P.; Dussan, A. Synthesis temperature dependence on magnetic properties of cobalt doped TiO2 thin films for spintronic applications. Appl. Surf. Sci. 2019, 484, 688–691. [Google Scholar] [CrossRef]

- Park, Y.R.; Kim, K.J. Structural and optical properties of rutile and anatase TiO2 thin films: Effects of Co doping. Thin Solid Films 2005, 484, 34–38. [Google Scholar] [CrossRef]

- Chodun, R.; Dypa, M.; Wicher, B.; Langier, K.N.; Okrasa, S.; Minikayev, R.; Zdunek, K. The sputtering of titanium magnetron target with increased temperature in reactive atmosphere by gas injection magnetron sputtering technique. Appl. Surf. Sci. 2022, 574, 151597. [Google Scholar] [CrossRef]

- Zdunek, K.; Nowakowska-Langier, K.; Dora, J.; Chodun, R. Gas injection as a tool for plasma process control during coating deposition. Surf. Coat. Technol. 2013, 228, S367–S373. [Google Scholar] [CrossRef]

- Skowronski, L.; Zdunek, K.; Nowakowska-Langier, K.; Chodun, R.; Trzcinski, M.; Kobierski, M.; Kustra, M.; Wachowiak, A.; Wachowiak, W.; Hiller, T.; et al. Characterization of microstructural, mechanical and optical properties of TiO2 layers deposited by GIMS and PMS methods. Surf. Coat. Technol. 2015, 282, 16–23. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Mazur, M.; Obstarczyk, A.; Wojcieszak, D.; Kaczmarek, D.; Morgiel, J.; Gibson, D. Comparison of the physicochemical properties of TiO2 thin films obtained by magnetron sputtering with continuous and pulsed gas flow. Coatings 2018, 8, 412. [Google Scholar] [CrossRef]

- Mazur, M. Analysis of the properties of functional titanium dioxide thin films deposited by pulsed DC magnetron sputtering with various O2: Ar ratios. Opt. Mater. 2017, 69, 96–104. [Google Scholar] [CrossRef]

- Mazur, M.; Wojcieszak, D.; Wiatrowski, A.; Kaczmarek, D.; Lubanska, A.; Domaradzki, J.; Mazur, P.; Kalisz, M. Analysis of amorphous tungsten oxide thin films deposited by magnetron sputtering for application in transparent electronics. Appl. Surf. Sci. 2021, 570, 151151. [Google Scholar] [CrossRef]

- Lei, C.; Du, Y.; Zhu, M.; Huo, W.; Wu, H.; Zhang, Y. Microstructure and mechanical properties of in situ TiC/Ti composites with a laminated structure synthesized by spark plasma sintering. Mater. Sci. Eng. A 2021, 812, 141136. [Google Scholar] [CrossRef]

- Wimler, D.; Lindemann, J.; Gammer, C.; Spoerk-Erdely, P.; Stark, A.; Clemens, H.; Mayer, S. Novel intermetallic-reinforced near-α Ti alloys manufactured by spark plasma sintering. Mater. Sci. Eng. A 2020, 792, 139798. [Google Scholar] [CrossRef]

- Lis, M.; Wrona, A.; Mazur, J.; Dupont, C.; Kamińska, M.; Kopyto, D.; Kwarciński, M. Fabrication And Properties Of Silver Based Multiwall Carbon Nanotube Composite Prepared By Spark Plasma Sintering Method. Arch. Metall. Mater. 2015, 60, 1351–1355. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Jung, Y.-G.; Lawn, B.; Martyniuk, M.; Huang, H.; Hu, X. Evaluation of elastic modulus and hardness of thin films by nanoindentation. J. Mater. Res. 2004, 19, 3076–3080. [Google Scholar] [CrossRef]

- Karabay, I.; Yuksel, S.A.; Ongul, F.; Ozturk, S.; Asli, M. Structural and optical characterization of TiO2 thin films prepared by sol-gel process. Acta Phys. Pol. A 2012, 121, 265–267. [Google Scholar] [CrossRef]

- Sarkar, D.; Ghosh, C.K.; Maiti, U.N.; Chattopadhyay, K.K. Effect of spin polarization on the optical properties of Co-doped TiO2 thin films. Phys. B 2011, 406, 1429–1435. [Google Scholar] [CrossRef]

- De, R.; Tripathi, S.; Naidu, S.C.; Prathap, C.; Tripathu, J.; Singh, J.; Haque, S.M.; Rao, K.D.; Sahoo, N.K. Investigation on optical properties of spin coated TiO2/Co composite thin films. AIP Conf. Proc. 2017, 1832, 080038. [Google Scholar] [CrossRef]

- Adewinbi, S.A.; Buremoh, W.; Owoeye, V.A.; Ajayeoba, Y.A.; Salau, A.O.; Busari, H.K.; Tijani, M.A.; Taleatu, B.A. Preparation and characterization of TiO2 thin film electrode for optoelectronic and energy storage potentials: Effects of Co incorporation. Chem. Phys. Lett. 2021, 779, 138854. [Google Scholar] [CrossRef]

- Islam, M.N.; Podder, J. The role of Al and Co co-doping on the band gap tuning of TiO2 thin films for applications in photovoltaic and optoelectronic devices. Mater. Sci. Semicond. Process. 2021, 121, 105419. [Google Scholar] [CrossRef]

- Boutlala, A.; Bourfaa, F.; Mahtili, M.; Bouaballou, A. Deposition of Co-doped TiO2 thin films by sol-gel method. IOP Conf. Ser. Mater. Sci. Eng. 2016, 108, 012048. [Google Scholar] [CrossRef]

- Waseda, Y.; Matsubara, E.; Shinoda, K. X-ray Diffraction Crystallography: Introduction, Examples and Solved Problems; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-16634-1. [Google Scholar] [CrossRef]

- Jauch, W.; Reehuls, M.; Bleif, H.J.; Kubanek, F.; Pattison, P. Crystallographic symmetry and magnetic structure of CoO. Phys. Rev. B 2001, 64, 052102. [Google Scholar] [CrossRef]

- Wdowik, U.D.; Parlinski, K. Lattice dynamics of CoO from first principles. Phys. Rev. B 2007, 75, 104306. [Google Scholar] [CrossRef]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-ray Photoelectron Spectroscopy; Physical Electronics, Inc.: Eden Prairie, MN, USA, 1995. [Google Scholar]

- Crist, B.V. Handbooks of Monochromatic XPS Spectra: Volume 1—The Elements and Native Oxides; XPS International, Inc.: Ames, IA, USA, 1999. [Google Scholar]

- Cole, K.M.; Kirk, D.; Thorpe, S. Co3O4 nanoparticles characterized by XPS and UPS. Surf. Sci. Spectrs. 2021, 28, 014001. [Google Scholar] [CrossRef]

- Velhal, N.B.; Yun, T.H.; Ahn, J.; Kim, T.; Kim, J.; Yim, C. Tailoring cobalt oxide nanostructures for stable and high-performance energy storage applications. Ceram. Int. 2023, 49, 4889–4897. [Google Scholar] [CrossRef]

- Gong, B.; Luo, X.; Bao, N.; Ding, J.; Li, S.; Yi, J. XPS study of cobalt TiO2 films prepared by pulsed laser deposition. Surf. Interface Anal. 2014, 46, 1043–1046. [Google Scholar] [CrossRef]

- Naseem, S.; Pinchuk, I.V.; Luo, Y.K.; Kawakami, R.K.; Khan, S.; Husain, S.; Khan, W. Epitaxial growth of cobalt doped TiO2 thin films on LaAlO3(100) substrate by molecular beam epitaxy and their opto-magnetic based applications. Appl. Surf. Sci. 2019, 493, 691–702. [Google Scholar] [CrossRef]

- Kim, J.; Livonen, T.; Hamalainen, J.; Kemell, M.; Meinander, K.; Mizohata, K.; Wang, L.; Raisanen, J.; Beranek, R.; Leskela, M.; et al. Low-temperature atomic layer deposition of cobalt oxide as effective catalyst for photoelectrochemical water-splitting devices. Chem. Mater. 2017, 29, 5796–5805. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Payne, B.P.; Grosvenor, A.P.; Lau, L.W.M.; Gerson, A.R.; Smart, R.S.C. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 2011, 257, 2717–2730. [Google Scholar] [CrossRef]

- Liu, T.; Guo, Y.F.; Yan, Y.M.; Wang, F.; Deng, C.; Rooney, D.; Sun, K.N. CoO nanoparticles embedded in the tree-dimensional nitrogen/sulfur co-doped carbon nanofiber networks as a bifunctional catalyst for oxygen reduction/evolution reactions. Carbon 2016, 106, 84–92. [Google Scholar] [CrossRef]

- Li, X.C.; She, F.S.; Shen, D.; Liu, C.P.; Chen, L.H.; Li, Y.; Deng, Z.; Chen, Z.H.; Wang, H.E. Coherent nanoscale cobalt/cobalt oxide heterostructures embedded in porous carbon for the oxygen reduction reaction. R. Soc. Chem. 2018, 8, 28625. [Google Scholar] [CrossRef] [PubMed]

- Chuang, T.J.; Brundle, C.R.; Rice, D.W. Interpretation of the X-ray photoemission spectra of cobalt oxides and cobalt oxide surfaces. Surf. Sci. 1976, 59, 413–429. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).