Enhanced Stability of Solution-Processed Indium–Zinc–Tin–Oxide Transistors by Tantalum Cation Doping

Abstract

1. Introduction

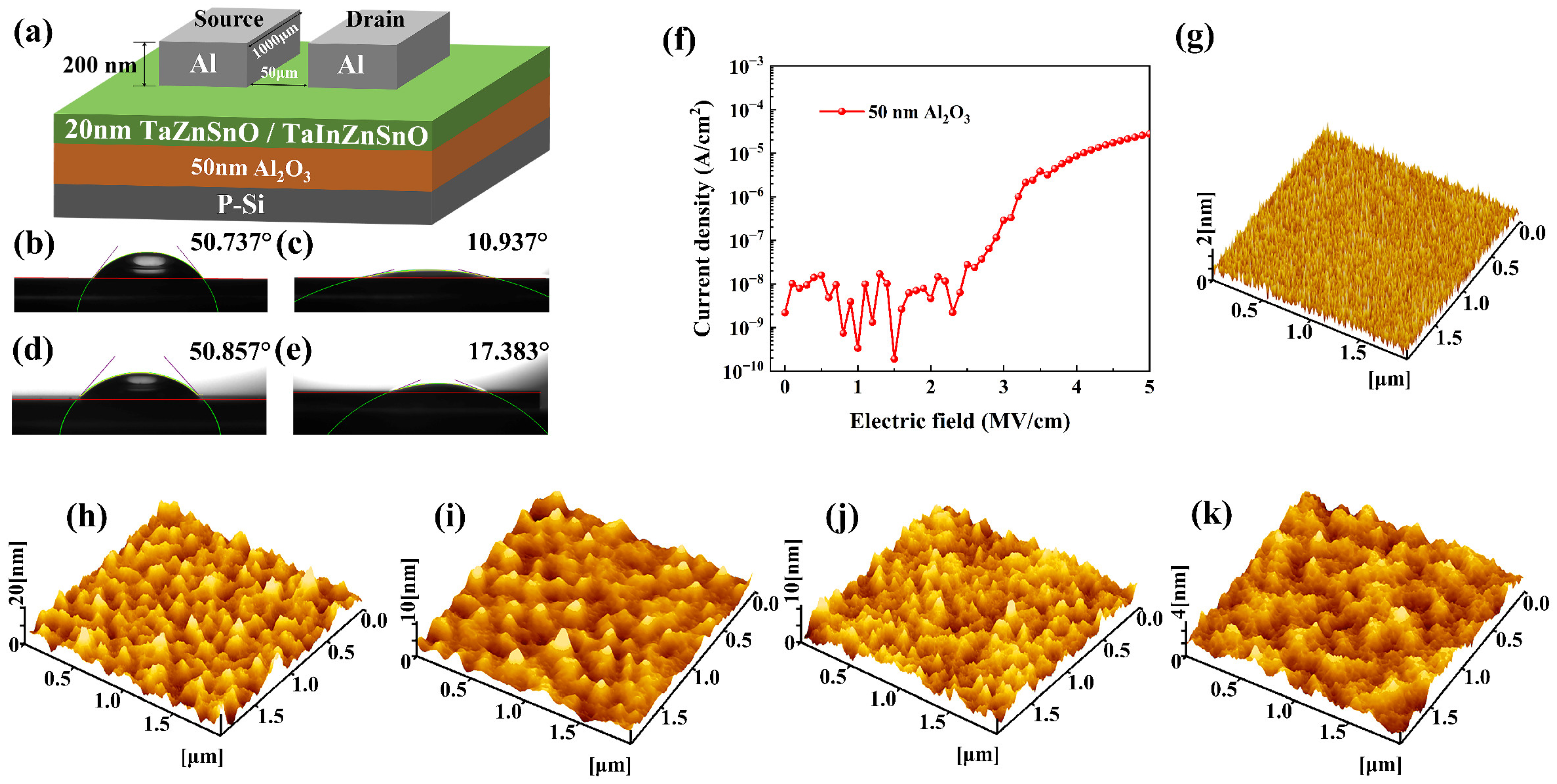

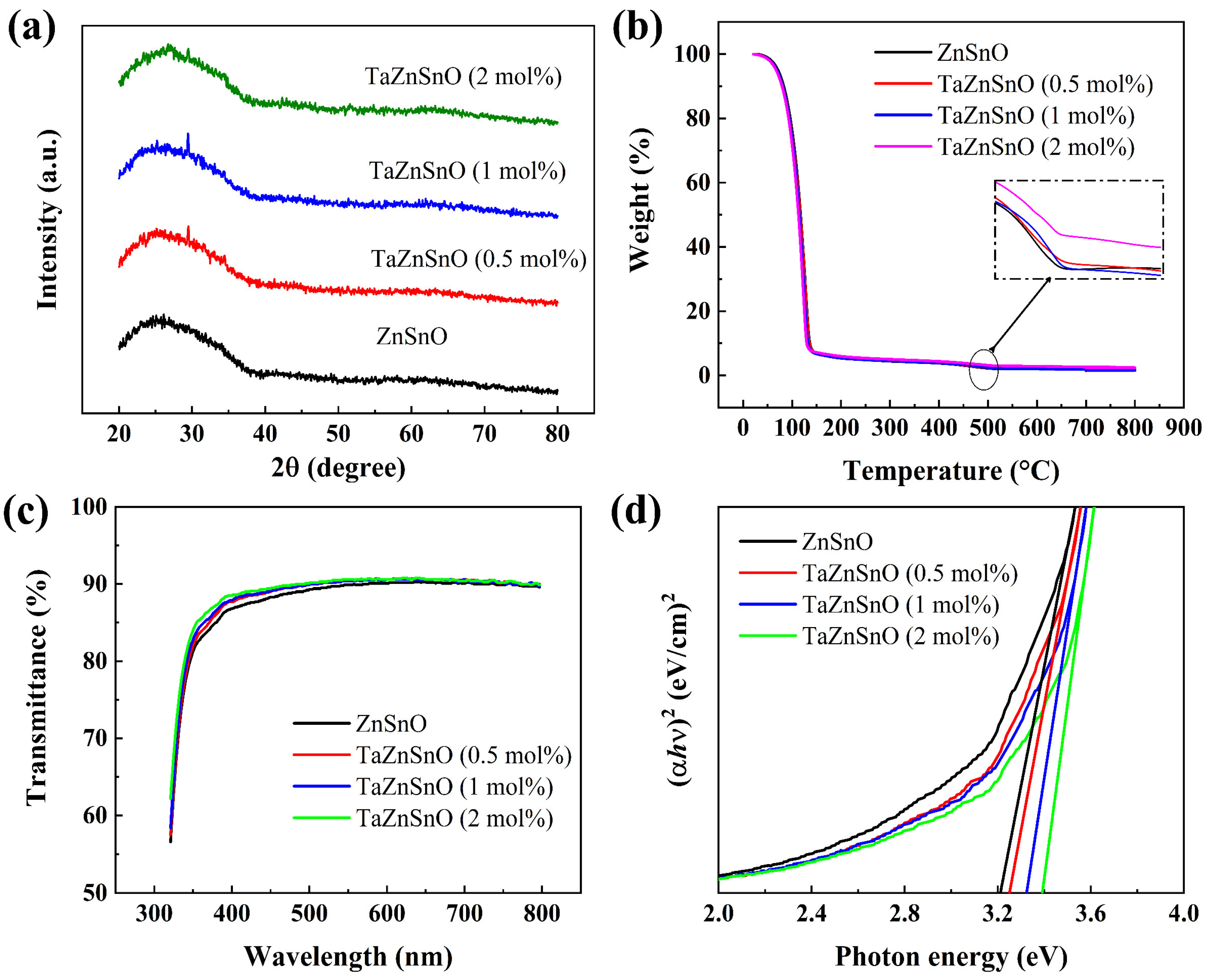

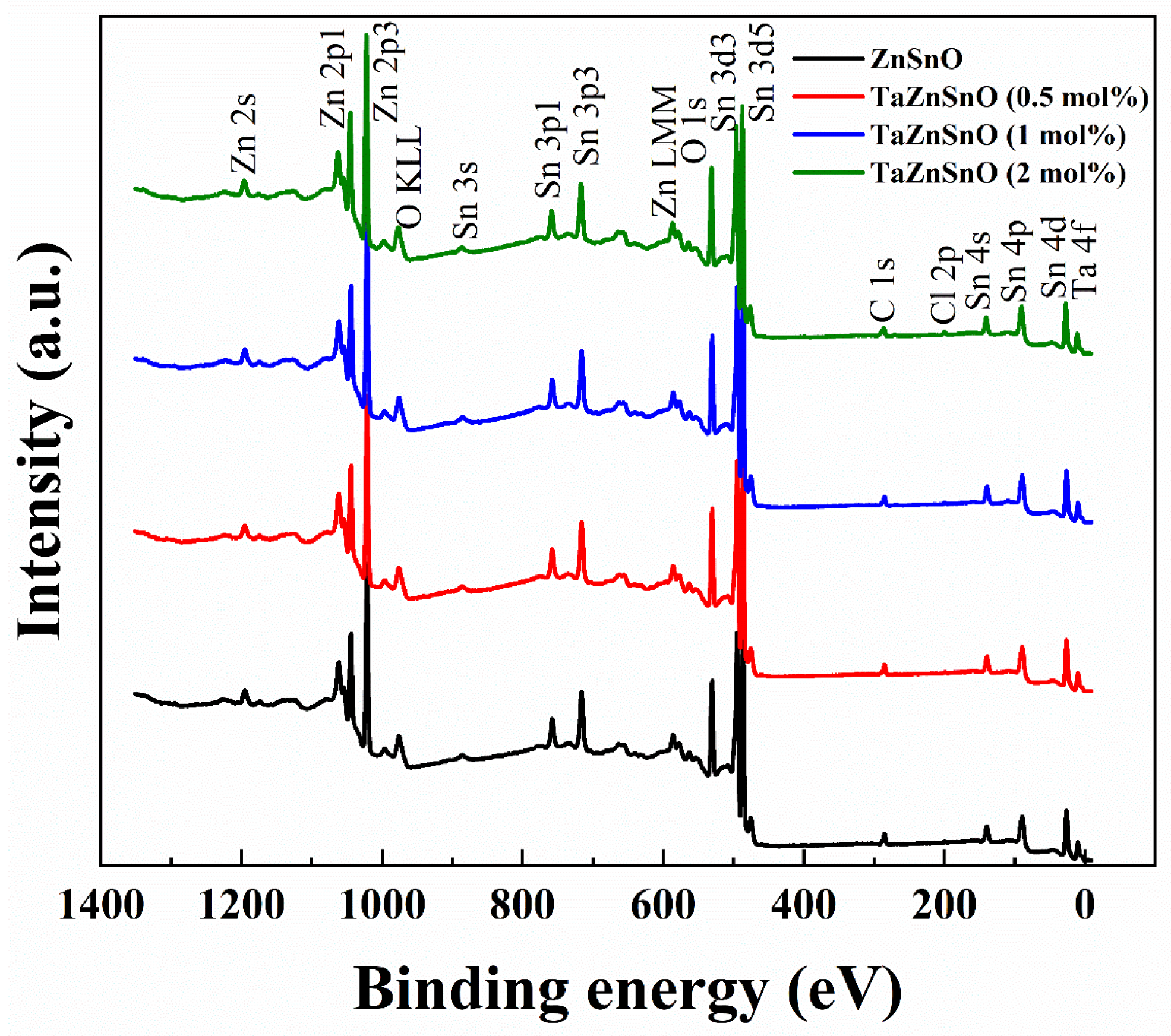

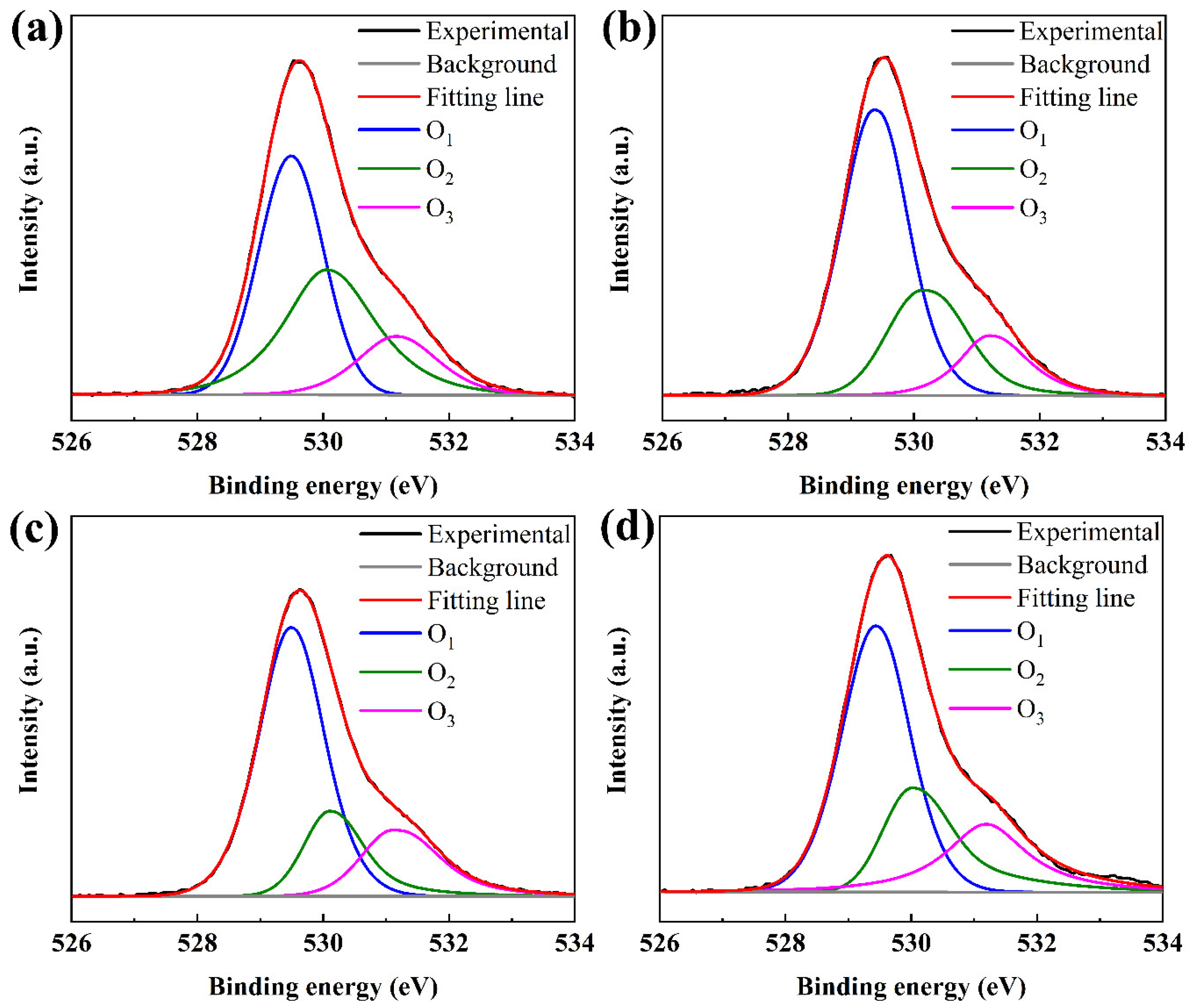

2. Experiments

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, J.; Park, J.; Yoon, G.; Khushabu, A.; Kim, J.-S.; Pae, S.; Cho, E.-C.; Yi, J. Effect of IGZO thin films fabricated by Pulsed-DC and RF sputtering on TFT characteristics. Mater. Sci. Semicond. Process. 2020, 120, 105264. [Google Scholar] [CrossRef]

- Kim, C.-H.; Park, Y.J.; Seo, J.H.; Kim, H.-K. Highly stable Ba-addition InZnSnO channels of light emitting transistors and thin film transistors. J. Alloys Compd. 2022, 900, 163472. [Google Scholar] [CrossRef]

- Liu, A.; Liu, G.; Zhu, H.; Shin, B.; Fortunato, E.; Martins, R.; Shan, F. Eco-friendly, solution-processed In-W-O thin films and their applications in low-voltage, high-performance transistors. J. Mater. Chem. C 2016, 4, 4478–4484. [Google Scholar] [CrossRef]

- Kim, Y.J.; Oh, S.; Yang, B.S.; Han, S.J.; Lee, H.W.; Kim, H.J.; Jeong, J.K.; Hwang, C.S.; Kim, H.J. Impact of the Cation Composition on the Electrical Performance of Solution-Processed Zinc Tin Oxide Thin-Film Transistors. ACS Appl. Mater. Interfaces 2014, 6, 14026–14036. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Yoon, J.; Yun, S.O.; Hwang, Y.; Jang, H.S.; Ko, H.C. Ultrathin Sticker-Type ZnO Thin Film Transistors Formed by Transfer Printing via Topological Confinement of Water-Soluble Sacrificial Polymer in Dimple Structure. Adv. Funct. Mater. 2013, 23, 1375–1382. [Google Scholar] [CrossRef]

- Choi, W.S.; Jo, H.; Kwon, M.S.; Jung, B.J. Control of electrical properties and gate bias stress stability in solution-processed a-IZO TFTs by Zr doping. Curr. Appl. Phys. 2014, 14, 1831–1836. [Google Scholar] [CrossRef]

- Hashemi, A.; Bahari, A. Synthesis and characterization of silanized-SiO2/povidone nanocomposite as a gate insulator: The influence of Si semiconductor film type on the interface traps by deconvolution of Si2s. Curr. Appl. Phys. 2018, 18, 1546–1552. [Google Scholar] [CrossRef]

- Hashemi, A.; Bahari, A.; Ghasemi, S. Synthesis and Characterization of Cross-Linked Nanocomposite as a Gate Dielectric for p-Type Silicon Field-Effect Transistor. J. Electron. Mater. 2018, 47, 3717–3726. [Google Scholar] [CrossRef]

- Sanctis, S.; Koslowski, N.; Hoffmann, R.; Guhl, C.; Erdem, E.; Weber, S.; Schneider, J.J. Toward an Understanding of Thin-Film Transistor Performance in Solution-Processed Amorphous Zinc Tin Oxide (ZTO) Thin Films. ACS Appl. Mater. Interfaces 2017, 9, 21328–21337. [Google Scholar] [CrossRef]

- Wang, Z.; Jeon, S.-H.; Hwang, Y.-J.; Lee, S.-H.; Jang, J.; Kang, I.M.; Kim, D.-K.; Bae, J.-H. Physico-Chemical Origins of Electrical Characteristics and Instabilities in Solution-Processed ZnSnO Thin-Film Transistors. Coatings 2022, 12, 1534. [Google Scholar] [CrossRef]

- Hu, S.; Xu, M.; Peng, C.; Chen, L.; Liu, H.; Li, X. Solution-processed high stability top-gate W and F co-doped ZnSnO thin film transistors. Appl. Phys. Lett. 2023, 122, 123502. [Google Scholar] [CrossRef]

- Popov, A.I.; Kotomin, E.A.; Maier, J. Basic properties of the F-type centers in halides, oxides and perovskites. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 3084–3089. [Google Scholar] [CrossRef]

- Dai, S.; Wang, T.; Li, R.; Wang, Q.; Ma, Y.; Tian, L.; Su, J.; Wang, Y.; Zhou, D.; Zhang, X.; et al. Preparation and electrical properties of N-doped ZnSnO thin film transistors. J. Alloys Compd. 2018, 745, 256–261. [Google Scholar] [CrossRef]

- Lee, B.H.; Park, J.; Kumar, A.; Choi, S.; Kim, D.H.; Lee, S.Y. Structural and electronic properties with respect to Si doping in oxygen rich ZnSnO amorphous oxide semiconductor. Mater. Today Commun. 2022, 33, 104809. [Google Scholar] [CrossRef]

- Yang, H.; Yang, W.; Su, J.; Zhang, X. Enhancement-mode thin film transistor using amorphous phosphorus-doped Indium–Zinc–Tin-Oxide channel layer. Mater. Sci. Semicond. Process. 2022, 137, 106228. [Google Scholar] [CrossRef]

- Baek, J.H.; Seol, H.; Cho, K.; Yang, H.; Jeong, J.K. Comparative Study of Antimony Doping Effects on the Performance of Solution-Processed ZIO and ZTO Field-Effect Transistors. ACS Appl. Mater. Interfaces 2017, 9, 10904–10913. [Google Scholar] [CrossRef]

- Huang, C.-X.; Li, J.; Fu, Y.-Z.; Zhang, J.-H.; Jiang, X.-Y.; Zhang, Z.-L.; Yang, Q.-H. Characterization of dual-target co-sputtered novel Hf-doped ZnSnO semiconductors and the enhanced stability of its associated thin film transistors. J. Alloys Compd. 2016, 681, 81–87. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, M.; Song, K.; Wei, L.; Yin, Y.; Zhang, X. Simultaneous enhancement of electrical performance and stability of zinc-tin-oxide thin-film transistors by tantalum doping. Thin Solid Film. 2020, 709, 138135. [Google Scholar] [CrossRef]

- Parthiban, S.; Kwon, J.-Y. Role of dopants as a carrier suppressor and strong oxygen binder in amorphous indium-oxide-based field effect transistor. J. Mater. Res. 2014, 29, 1585–1596. [Google Scholar] [CrossRef]

- Dai, S.; Wang, T.; Li, R.; Zhou, D.; Peng, Y.; Wang, H.; Zhang, X.; Wang, Y. Preparation and effects of post-annealing temperature on the electrical characteristics of Li–N co-doped ZnSnO thin film transistors. Ceram. Int. 2017, 43, 4926–4929. [Google Scholar] [CrossRef]

- Park, S.-H.K.; Hwang, C.-S.; Jeong, H.Y.; Chu, H.Y.; Cho, K.I. Transparent ZnO-TFT Arrays Fabricated by Atomic Layer Deposition. Electrochem. Solid-State Lett. 2008, 11, H10. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Xiong, Q.; Wu, X.; Zhou, J.; Wu, J.; Wu, X.; Qin, W. Multipurpose surface functionalization on AZ31 magnesium alloys by atomic layer deposition: Tailoring the corrosion resistance and electrical performance. Nanoscale 2017, 9, 8591–8599. [Google Scholar] [CrossRef] [PubMed]

- Groner, M.D.; Fabreguette, F.H.; Elam, J.W.; George, S.M. Low-Temperature Al2O3 Atomic Layer Deposition. Chem. Mater. 2004, 16, 639–645. [Google Scholar] [CrossRef]

- Wang, L.-C.; Han, Y.-Y.; Yang, K.-C.; Chen, M.-J.; Lin, H.-C.; Lin, C.-K.; Hsu, Y.-T. Hydrophilic/hydrophobic surface of Al2O3 thin films grown by thermal and plasma-enhanced atomic layer deposition on plasticized polyvinyl chloride (PVC). Surf. Coat. Technol. 2016, 305, 158–164. [Google Scholar] [CrossRef]

- Hasebe, T.; Murakami, K.; Nagashima, S.; Yoshimoto, Y.; Ihara, A.; Otake, M.; Kasai, R.; Kasuya, S.; Kitamura, N.; Kamijo, A.; et al. Design for improved adhesion of fluorine-incorporated hydrogenated amorphous carbon on metallic stent: Three-layered structure with controlled surface free energy. Diam. Relat. Mater. 2011, 20, 902–906. [Google Scholar] [CrossRef]

- Abdullah, H.; Norazia, M.N.; Shaari, S.; Nuawi, M.Z.; Mohamed Dan, N.S. Low-doping Effects of Nanostructure ZnO: Sn tin films annealed at different temperature in Nitrogen ambient to be applied as an Anti-reflecting coating (ARC). Am. J. Eng. Appl. Sci. 2010, 3, 171–179. [Google Scholar] [CrossRef]

- Xu, W.; Wang, H.; Xie, F.; Chen, J.; Cao, H.; Xu, J.-B. Facile and Environmentally Friendly Solution-Processed Aluminum Oxide Dielectric for Low-Temperature, High-Performance Oxide Thin-Film Transistors. ACS Appl. Mater. Interfaces 2015, 7, 5803–5810. [Google Scholar] [CrossRef]

- Xu, H.; Ding, X.; Qi, J.; Yang, X.; Zhang, J. A Study on Solution-Processed Y2O3 Films Modified by Atomic Layer Deposition Al2O3 as Dielectrics in ZnO Thin Film Transistor. Coatings 2021, 11, 969. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Yang, J.; Ding, X.; Zhang, J. Solution-Processed Yttrium-Doped IZTO Semiconductors for High-Stability Thin Film Transistor Applications. IEEE Trans. Electron Devices 2019, 66, 5170–5176. [Google Scholar] [CrossRef]

- Brik, M.G.; Srivastava, A.M.; Popov, A.I. A few common misconceptions in the interpretation of experimental spectroscopic data. Opt. Mater. 2022, 127, 112276. [Google Scholar] [CrossRef]

- Altaf, C.T.; Yolacan, D.; Sankir, N.D. Decoration of 3D ZnO nanoelectrodes with CuInS2 for solar water splitting. Mater. Lett. 2019, 236, 710–714. [Google Scholar] [CrossRef]

- Jeong, Y.; Bae, C.; Kim, D.; Song, K.; Woo, K.; Shin, H.; Cao, G.; Moon, J. Bias-Stress-Stable Solution-Processed Oxide Thin Film Transistors. ACS Appl. Mater. Interfaces 2010, 2, 611–615. [Google Scholar] [CrossRef] [PubMed]

- Abliz, A.; Gao, Q.; Wan, D.; Liu, X.; Xu, L.; Liu, C.; Jiang, C.; Li, X.; Chen, H.; Guo, T.; et al. Effects of Nitrogen and Hydrogen Codoping on the Electrical Performance and Reliability of InGaZnO Thin-Film Transistors. ACS Appl. Mater. Interfaces 2017, 9, 10798–10804. [Google Scholar] [CrossRef]

- Matar, S.F.; Campet, G.; Subramanian, M.A. Electronic properties of oxides: Chemical and theoretical approaches. Prog. Solid State Chem. 2011, 39, 70–95. [Google Scholar] [CrossRef]

- Bukke, R.N.; Avis, C.; Jang, J. Solution-Processed Amorphous In–Zn–Sn Oxide Thin-Film Transistor Performance Improvement by Solution-Processed Y2O3 Passivation. IEEE Electron Device Lett. 2016, 37, 433–436. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Qin, C.; Ding, X.; Zhang, J. Enhanced Stability in Zr-Doped ZnO TFTs with Minor Influence on Mobility by Atomic Layer Deposition. IEEE Trans. Electron Devices 2019, 66, 1760–1765. [Google Scholar] [CrossRef]

- Huang, X.D.; Ma, Y.; Song, J.Q.; Lai, P.T. High-Performamce Amorphous InGaZnO Thin-Film Transistor with ZrLaO Gate Dielectric Fabricated at Room Temperature. J. Disp. Technol. 2016, 12, 1522–1527. [Google Scholar] [CrossRef]

| Device | Vth (V) | μ (cm2/Vs) | Ion/Ioff | SS (V/Decade) |

|---|---|---|---|---|

| ZnSnO | 0.29 ± 0.03 | 0.38 ± 0.080 | ~106 | 0.103 |

| TaZnSnO (0.5 mol%) | 1.26 ± 0.06 | 0.14 ± 0.005 | ~105 | 0.093 |

| TaZnSnO (1 mol%) | 2.29 ± 0.05 | 0.12 ± 0.050 | ~105 | 0.067 |

| TaZnSnO (2 mol%) | 3.43 ± 0.20 | 0.06 ± 0.004 | ~104 | 0.149 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Li, P.; Chen, Z.; Yang, B.; Wei, B.; Fu, C.; Ding, X.; Zhang, J. Enhanced Stability of Solution-Processed Indium–Zinc–Tin–Oxide Transistors by Tantalum Cation Doping. Coatings 2023, 13, 767. https://doi.org/10.3390/coatings13040767

Xu H, Li P, Chen Z, Yang B, Wei B, Fu C, Ding X, Zhang J. Enhanced Stability of Solution-Processed Indium–Zinc–Tin–Oxide Transistors by Tantalum Cation Doping. Coatings. 2023; 13(4):767. https://doi.org/10.3390/coatings13040767

Chicago/Turabian StyleXu, Haiyang, Pingping Li, Zihui Chen, Bing Yang, Bin Wei, Chaoying Fu, Xingwei Ding, and Jianhua Zhang. 2023. "Enhanced Stability of Solution-Processed Indium–Zinc–Tin–Oxide Transistors by Tantalum Cation Doping" Coatings 13, no. 4: 767. https://doi.org/10.3390/coatings13040767

APA StyleXu, H., Li, P., Chen, Z., Yang, B., Wei, B., Fu, C., Ding, X., & Zhang, J. (2023). Enhanced Stability of Solution-Processed Indium–Zinc–Tin–Oxide Transistors by Tantalum Cation Doping. Coatings, 13(4), 767. https://doi.org/10.3390/coatings13040767