The vacuum magnetron sputtering technology used for Al film deposition is intricate and encompasses numerous variables. After pinpointing influential factors via Plackett–Burman screening, we examined more closely the primary determinants of the deposition rate. Factors such as target–substrate distance, working pressure, current intensity, and coating time were subjected to detailed scrutiny in individual experimental studies. The resulting experimental data were then graphically represented in relevant curve diagrams, facilitating comprehensive analysis. The goal of this approach was to produce a paper-based Al film in line with the set design criteria.

4.1. Target Substrate Distance

The separation between the target surface and the paper substrate surface, termed as the target–substrate distance, is a critical parameter in the DC magnetron sputtering coating process. While varying the target–substrate distance does not affect the sputtering coefficient, it notably alters the deposition rate of the Al coating and its application uniformity [

9,

10,

11]. Lengthening the target–substrate distance prolongs the journey of the material source particles to the paper substrate, thereby decreasing the deposition rate. This outcome results from fewer particles reaching the paper-based surface due to the increased distance. Thus, carefully increasing the target-to-substrate distance can reduce potential collisions with other gas molecules, improving the coating’s uniformity [

12].

4.1.1. Experimental Methods

The selected base material, a high-strength specialty fabric paper derived from pure wood pulp, was procured from Shandong Huatai Paper Co., Ltd. Sourced from Zhongnuo New Material (Beijing) Technology Co., Ltd. (Beijing, China). The rectangular target was crafted from 99.999% pure Al and measured 600 mm × 120 mm. The target exhibited a thickness of 8 mm and was positioned with precision at the center of the target material plane. This enabled the acquisition of parameters influencing the deposition rate of the aluminized film during the sputtering process, with the objective of determining the optimal base target spacing.

The experimental process utilized a JRJ-400 winding magnetron sputtering coating machine provided by Beijing Dongfang Gaide Vacuum Technology Co., Ltd. (Beijing, China). Following this, a Hitachi S4800 scanning electron microscope (Tokyo, Japan) was employed to analyze the surface morphology of the Al film.

4.1.2. Influence of Target Base Distance on Deposition Rate of Paper-Based Aluminized Film

For the experiment, a rectangular target was selected due to its crucial features that ensure sputtering stability and superior coating quality.

Figure 1 illustrates the deposition layout of the target material, with the base target spacing oriented along the z-direction. This graph captures the variations in deposition rate in relation to the x and z coordinates.

The substrate–target distance plays a pivotal role in determining the deposition rate on the target surface. Notably, as this distance increases, the deposition rate experiences a decrease. This results in inconsistent uniformity of the Al film deposited on the paper substrate. Adjusting and determining an appropriate substrate–target distance is imperative to ensure uniform performance across different sections of the paper-based Al plating.

In the sputtering process, the typical target–substrate distance lies between 60 and 80 mm, given that sputtering particles usually have an average free path under 100 mm. Considering the sputtering process’s glow plasma discharge characteristics, we chose an experimental target base distance of 70 mm.

Furthermore, the paper base’s transmission speed within the coating area was set between 2.20 and 12.16 m/min. The thickness of the Al film was measured using the HP-CHY-L aluminized film thickness gauge from Jinan Hengpin Electrical and Mechanical Technology Co., Ltd. (Jinan, China), yielding a thickness of 490 nm. The barrier properties of the Al film were evaluated using two methods simultaneously. The first involved using the OX-TRAN Model 2/21 oxygen permeameter, utilizing a high-precision Coulomb electric quantity sensor to analyze oxygen permeability and the electrical properties of polymer barrier materials. The second approach utilized the PERMATRAN-W Model 1/50 water vapor transmittance tester. This tester sets controlled humidity (RH) levels, enabling direct insights into the Al film’s barrier quality during standalone machine operations and presenting the test process curve.

4.2. Working Air Pressure

During the fabrication of paper-based Al-coated magnetron sputtering, the operational pressure environment is governed by two key factors. These factors are the working vacuum level achieved by adjusting the volume of Ar gas and the background vacuum level attained within the vacuum chamber prior to sputtering. Throughout the experiment, adjustments to the working pressure were made by altering the Ar gas flow rate, and the background vacuum was consistently maintained at 10

−3 Pa [

13,

14,

15].

4.2.1. Experimental Methods

Due to its superior ionization rate relative to other gases, Argon (Ar) gas is the preferred ion gas source for target bombardment. Being a monatomic inert gas, Argon plays a pivotal role in the deposition of the Al film in DC magnetron sputtering. In this experiment, the sputtering current was set at 2 A, the Ar gas flow rate was adjusted, the sputtering time was maintained at 35 min, and the background vacuum was set to 1.0 × 10−2 Pa. The impact of the Ar gas flow rate on barrier performance was further investigated.

4.2.2. Effect of Ar Flow Rate on the Thickness of Al Coating on a Paper Substrate

The operational conditions of working pressure are determined by factors like the Ar gas flow rate, making this factor crucial for controlling the thickness of the paper-based Al film. The experiment reveals the relationship between the Ar gas flow rate and Al coating thickness across three stages: A, B, and C. As illustrated in

Figure 2, during the A phase, a decrease in coating thickness from 90 nm to 80 nm is observed as the Ar gas flow rate is set at 85 sccm. Here, Ar ions effectively bombard the pure Al target, ensuring complete ionization and sputtering of Al atoms, thus yielding the highest deposition rate.

In the subsequent B phase, reducing the Ar gas flow rate from 75 sccm to 70 sccm results in a decline in the Al layer thickness from 80 nm to 20 nm. At this juncture, the deposition rate experiences a substantial decrease. As the Ar gas flow rate continues to decrease, the DC sputtering current fails to fully ionize the Ar gas, leading to an excessive volume of Ar gas that impedes sputtering particles from reaching the substrate, thus failing to enhance film barrier.

In the final C phase, as the Ar gas flow rate is further reduced, the deposition rate continues to decrease.

4.2.3. Effect of Ar Flow Rate on the Barrier Properties of Paper-Based Aluminized Film

The experimental results established a connection between moisture permeability, oxygen permeability, and Ar gas flow rate, as depicted in

Figure 3. The findings are as follows:

As the Ar flow rate reduced from 85 sccm to 75 sccm, the Al film’s barrier properties exhibited a gradual decline. Moisture permeability and oxygen permeability increased from 0.46 g/(m2 × atm × 24 h) and 2.08 cm3/(m2 × atm × 24 h) to 0.5 g/(m2 × atm × 24 h) and 2.28 cm3/(m2 × atm × 24 h), respectively.

With a further decrease in the Ar flow rate to 70 sccm, the Al film’s barrier properties experienced a substantial deterioration. Moisture permeability and oxygen permeability escalated to 3.51 g/(m2 × atm × 24 h) and 26.08 cm3/(m2 × atm × 24 h), respectively.

Upon reducing the Ar flow rate to 65 sccm, the barrier properties of the Al film exhibited a minor decline once again. Moisture permeability and oxygen permeability demonstrated gradual increases, measuring 3.6 g/(m2 × atm × 24 h) and 28.01 cm3/(m2 × atm × 24 h), respectively.

The most substantial barrier properties, accompanied by the thickest film, were achieved at an Ar flow rate of 85 sccm. Moisture permeability and oxygen permeability were determined as 0.46 g/(m2 × atm × 24 h) and 2.08 cm3/(m2 × atm × 24 h), respectively.

As shown in

Figure 3, the mutagenic nature of the relation curves between Ar flow rate, moisture permeability, oxygen permeability, and Al film thickness can be attributed to the deposition process occurring at diverse positions. The variations in barrier parameters stem from measurements of the thickness of Al plating coating prepared under distinct Ar partial pressures, as indicated in

Figure 2.

In this experiment, the background vacuum is maintained at 1.0 × 10−2 Pa, and the Ar gas flow rate is set at 85 sccm. As a result, the Al film exhibits satisfactory barrier properties, and its surface appears uniformly smooth.

4.3. Current Intensity

As a critical parameter in the process, the sputtering current plays a significant role in determining the state of increased incident ion energy. An escalation in ion energy is directly linked a rise in sputtering particle energy, ultimately leading to an augmented deposition rate. This increase is driven by the elevation in both the sputtering coefficient and substrate temperature. However, it is important to note that an excessively high sputtering current can trigger a secondary sputtering effect, which in turn causes a decrease in the growth rate of the Al film.

This phenomenon can lead to weakened adhesion of the target Al ions to the substrate surface, resulting in a situation where the stripping of Al ions from the target is not firmly secured. The use of an excessively high sputtering current introduces multiple concerns. On one hand, the target—serving as the sputtering source—is bombarded by high-speed, high-energy ions and electrons, potentially leading to excessive ion injection and causing the target to overheat and melt. On the other hand, the impact of high-speed ions and electrons on the substrate can elevate the temperature to undesirable levels. This not only hampers the adhesion of the Al coating but can even result in the burning of the substrate material.

4.3.1. Experimental Methods

The relationship between different DC sputtering currents and moisture permeability, oxygen permeability, and Al film thickness was analyzed based on the PB experimental results. At a sputtering current of 3A, the moisture permeability is 0.50 g/(m2 × atm × 24 h), the oxygen permeability is 4.08 cm3/(m2 × atm × 24 h), and the coating thickness is 76 nm. Conversely, at a sputtering current of 0.5A, the moisture permeability is 2.52 g/(m2 × atm × 24 h), the oxygen permeability is 23.48 cm3/(m2 × atm × 24 h), and the coating thickness is 21 nm.

Consequently, an increase in sputtering current results in a uniform silver-gray appearance of the paper-based Al film. The Al target powder within the sputtering chamber emits a purple glow. This increase in sputtering current leads to alterations in moisture permeability, oxygen transmission rate, and plating thickness.

4.3.2. Effect of Current Intensity on Thickness and Barrier Properties of Aluminized Film on Paper Substrate

The experiment reveals the correlation between sputtering current and Al coating thickness. It is observed that Al coating thickness experiences changes as the sputtering current varies. Sputtering initiates when the sputtering current reaches 0.25 A, establishing this value as the threshold current for target sputtering. With the continuous increase in current, the target’s surface current density also rises. Notably, as the sputtering current increases from 0.5 A to 2 A, a corresponding augmentation in plasma density within the sputtering chamber is evident. Consequently, the thickness of the plated Al film increases from 21 nm to 82 nm. This improvement positively impacts both the sputtering rate of the target and the deposition rate of the Al film.

Upon surpassing 2 A in sputtering current, the thickness of the Al film gradually decreases. This diminishing trend persists until the Al coating thickness reaches 76 nm, coinciding with a sputtering current of 3 A.

As the sputtering current increases from 0.5 A to 2.5 A there is a notable reduction in moisture permeability of the Al film, diminishing from 2.52 g/(m2 × atm × 24 h) to 0.43 g/(m2 × atm × 24 h), along with a decrease in oxygen permeability from 23.45 cm3/(m2 × atm × 24 h) to 2.06 cm3/(m2 × atm × 24 h). This change translates to a substantial enhancement in barrier properties. Upon further increasing the sputtering current from 2.5 A to 3 A, the moisture permeability of the Al film regresses from 0.43 g/(m2 × atm × 24 h) to 0.50 g/(m2 × atm × 24 h), while the oxygen transmission rate rises from 2.06 cm³/(m2 × atm × 24 h) to 4.08 cm3/(m2 × atm × 24 h).

It is evident that the moisture permeability and oxygen permeability of the Aluminized film initially undergo significant reductions before gradually increasing. This trend is a consequence of the sputtering current’s incremental rise. Referencing

Figure 4 and

Figure 5, a sputtering current of 2 A corresponds to a coating thickness of 82 nm. Meanwhile, a sputtering current of 2.5 A results in a coating thickness of 78 nm, accompanied by an optimal Al film barrier performance.

4.3.3. Effect of Current Intensity on the Structure of Al Coating on Paper Substrate

Al films were produced under various current intensities within the range of 2 A to 2.5 A. Within this range, the barrier properties, moisture permeability, oxygen permeability, and thickness of the Al coating were evaluated. The results did not exhibit a consistent trend of simultaneous increase and decrease. Notably, the thickest aluminized film did not yield the best barrier properties. At a sputtering current of 2.5 A, the deposited aluminized film demonstrated a thinner profile compared with its 2 A sputtering current counterpart. However, this thinner film exhibited enhanced barrier performance, smoother surface quality, and improved evenness.

In the case of the 2 A sputtering current, the Al film surface displayed inadequate flatness and cracks. Additionally, a comparison between sputtering currents I = 2 A and I = 2.5 A revealed a decrease in aluminized film thickness from 82 nm to 78 nm. This reduction coincided with decreased moisture and oxygen permeability, decreasing from 0.47 g/(m

2 × atm × 24 h) and 2.10 cm

3/(m

2 × atm × 24 h) to 0.43 g/(m

2 × atm × 24 h) and 2.06 cm

3/(m

2 × atm × 24 h), respectively. This led to an improvement in barrier performance, which was corroborated by the surface morphology of the aluminized film displayed in

Figure 6. Notably, the paper-based Al coating exhibited satisfactory results, as evident in

Figure 7.

The experiment underscores the significance of sputtering current as a critical technical parameter influencing the Al film formation process. The judicious selection of an appropriate current value is the essential precondition and pivotal factor in achieving high-quality Al film.

4.4. Effect of Coating Time on Paper-Based Al Film

Our research indicates that under consistent conditions, while other parameters remain unchanged throughout the coating process, a specific critical range of coating deposition thickness exists. Within this range, a correlation between barrier properties and film thickness is discernible. Notably, the barrier performance demonstrates a proportional relationship with increasing film thickness. However, upon surpassing this critical thickness, augmenting the film layer thickness has limited impact on barrier performance. Consequently, a blind increase in coating time may not necessarily enhance the film’s barrier properties.

The experimental findings reveal that optimal results are achieved when the coating time falls within the range of 45 to 80 min and a stable sputtering current is maintained at 2 A to 2.5 A. These conditions foster uniform sputtering across the target surface and lead to an expanded glow region. This, in turn, yields an ideal combination of deposited film thickness and Al film barrier effectiveness.

To ensure that the film barrier aligns with requirements, it is imperative to select the most suitable coating time based on specific needs and considerations.

4.4.1. Experimental Method

In the experiment, with a sputtering current of 2 A, an Ar gas flow rate of 80 sccm, and a background vacuum of 7.5 × 10

−3 Pa, the connection between coating time and the resulting Al film’s oxygen permeability, moisture permeability, and coating thickness was established. This relationship is illustrated in

Table 4.

Table 4 presents variations in coating time, oxygen permeability, moisture permeability, and coating thickness of the Al film. The scientific validity and accuracy of the experimental data significantly impact the quality of the Al film. The experimental data were derived from a range of testing equipment. Specifically, measurements for coating thickness SD, CV, and n were acquired using the FTS-S3 C step meter and S4800 cold field emission scanning electron microscope. Optimal conditions for Al coating on the paper substrate were achieved when the coating time was 40 min and the Al coating thickness was below 82 nm.

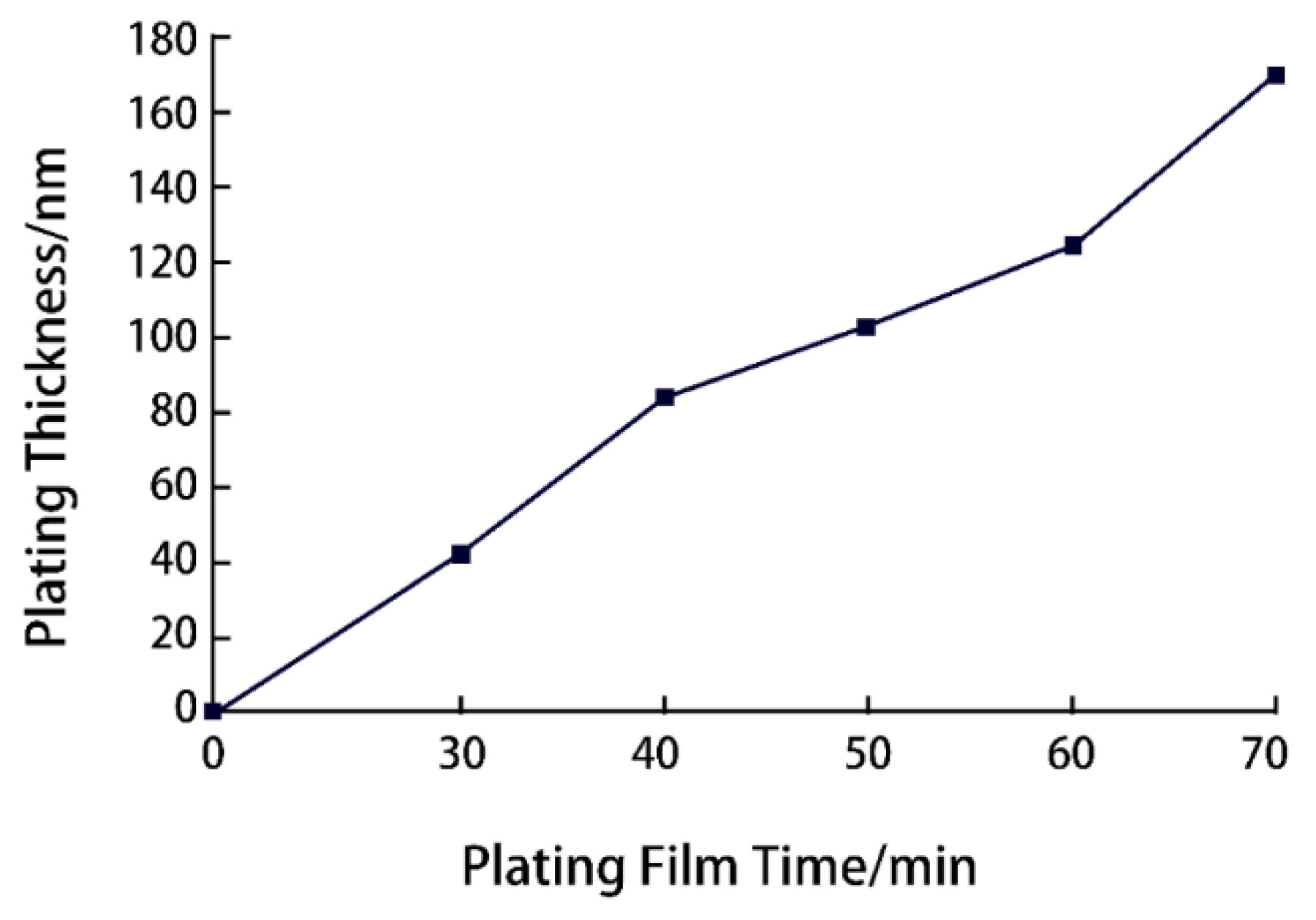

4.4.2. Effect of Coating Time on the Thickness of Al Film on Paper Substrate

Figure 8 presents the curve delineating the relationship between coating time and coating thickness. The figure displays a distinct linear correlation between film thickness and coating time, indicating that film thickness can be readily controlled as a manageable variable in the experiment. The coating thickness evidently increases proportionally with the extension of the coating time. The film’s growth progresses steadily and maintains a near-uniform pattern throughout the continuous discharge period. Furthermore, to ensure a robust linear relationship between film thickness and coating time, estimating the experimental and measurement errors is essential.

For instance, taking into account the limitation on the temperature of the paper substrate, the duration of the substrate passing through the discharge area is kept brief. In response, a higher winding speed is employed to avert abrupt temperature elevation of the substrate. As a result, while the deposition time remains constant, the winding speed is elevated. Despite the accelerated pace and reduced deposition time, the substantial frequency of depositions per unit time aligns with the observation that the deposition rate remains unaffected by the winding speed.

4.4.3. Effect of Coating Time on the Isolation of Paper-Based Al Film

The relationship underscores that, as coating time extends, the aluminized film becomes thicker, and there exists a linear proportionality between coating time and Al coating thickness. At the critical point of 40 min, the film thickness reaches 82 nm. Nonetheless, plating film time exerts a limited influence on the oxygen permeability and moisture permeability of the aluminized film. Hence, a thicker Al coating does not unequivocally yield superior barrier properties.

As depicted in

Figure 9, at the 30 min mark, the oxygen and moisture permeability of the aluminized film display a gradual trend. With increased coating time, both oxygen and moisture permeability decrease initially. At 40 min coating time, the barrier performance is optimal. The oxygen permeability is nearly 15 times lower than that of the original film, measuring at 2.04 cm

3/(m

2 × atm × 24 h), while the water vapor permeability is eight times lower, registering at 0.47 g/(m

2 × atm × 24 h). Subsequently, within the 50 min to 60 min interval, the rates of oxygen and water vapor transmission increase.

The formation process of Al film on the paper substrate follows an island growth mechanism. During the initial stages, when the film is extremely thin, its continuity is disrupted due to the paper’s rough surface. A continuous film can only emerge after the concave sections of the substrate’s surface are filled. The experiment highlights that as coating time extends, the film continuity improves progressively alongside increased thickness. This bolsters the barrier properties of the Al film.

However, beyond a thickness of 82 nm, the oxygen and water vapor permeability of the film cease to decrease with further thickness increases. Oxygen and water vapor penetration primarily occurs through cracks, minuscule pinholes, and other film defects. At this critical thickness, the barrier performance reaches its zenith. Any further increase in Al coating thickness results in heightened film brittleness and exacerbated defect deterioration. Consequently, oxygen and water vapor transmittance through the Al film increases. It is imperative to recognize that blindly extending coating time to augment film thickness can lead to adverse outcomes. Instead, one must heed the critical thickness threshold and explore alternative methods to further enhance the barrier properties of the aluminized film.

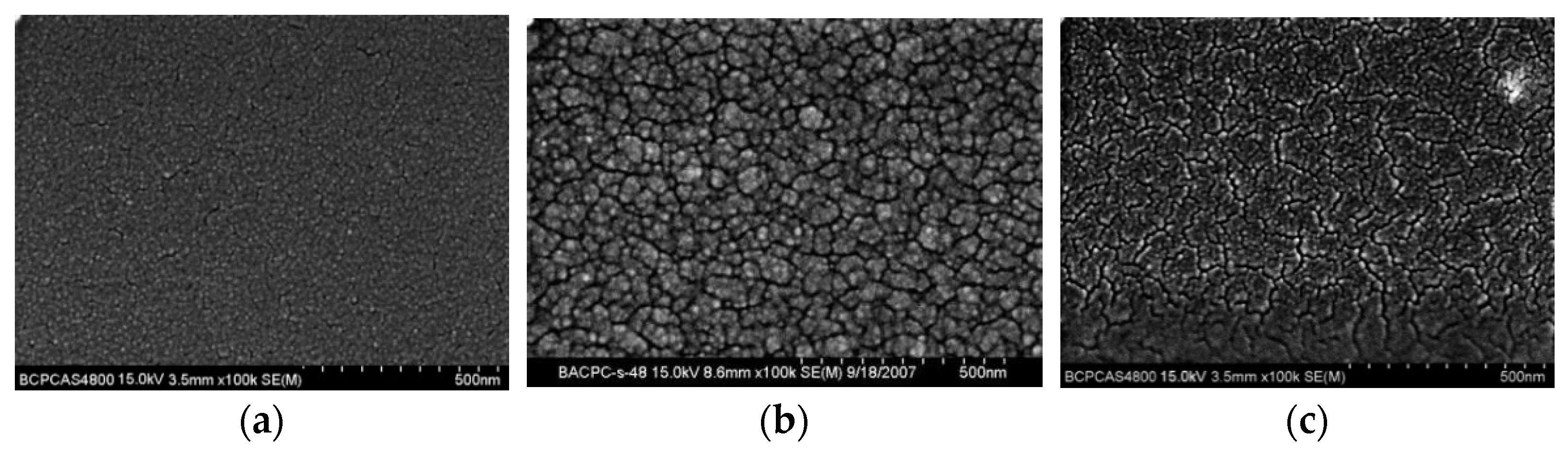

4.4.4. Effect of Coating Time on the Structure of Al Film on Paper Substrate

In

Figure 10, the surface morphology of the Al films for varying deposition times is exhibited. Initially, as deposition time increases, the Al film demonstrates a tendency towards densification. However, as the coating time continues to extend, a notable increase in Al particles is observed, accompanied by the emergence of stress-induced cracks with heightened film thickness. This development adversely affects the properties of the films, resulting in a decrease in overall quality. Consequently, it can be inferred that the gas barrier properties of the film are enhanced when the surface of the paper-based Al film exhibits greater uniformity.

Surface cracks on the paper-based Al film reduce its ability to resist fluid infiltration, which leads to the infiltration of water vapor into the natural plant cellulose in the paper to form a water bridge, resulting in decreased paper strength. Therefore, the crack phenomenon should be avoided when producing films.

4.4.5. Preparation Results of Paper-Based Al Film and Preparation of Al-Coated Corrugated Paperboard

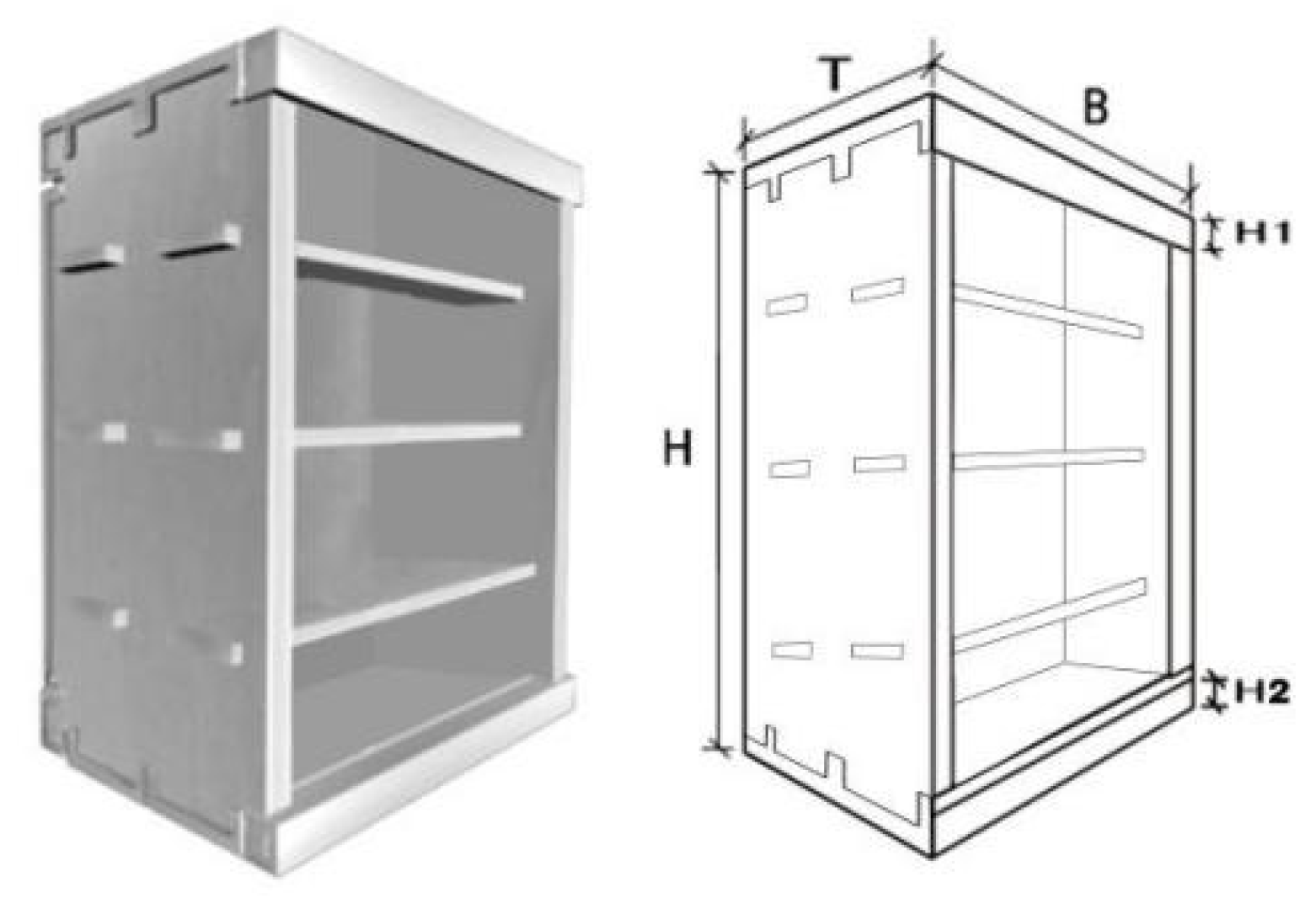

A high-strength specialty paper was selected as the substrate, and various paper-based Al films were prepared using DC magnetron sputtering, as shown in

Figure 11.

By means of the DC magnetron sputtering Al film process, a significant achievement has been realized in producing paper-based Al film. This innovative approach employs high-strength specialty paper as the substrate and utilizes DC magnetron sputtering to create the required Al film, thereby paving the way for the production of aluminum-coated corrugated paperboard. This novel technique contributes to a remarkable enhancement in the surface strength and folding resistance in comparison with the original high-strength specialty paper. Furthermore, the physical properties of the film are substantially improved.

The resultant paper-based Al film exhibits a soft, clear, and delicate surface texture, characterized by a uniform coating. Notably, this transformation also alters the color dynamics. The once vibrant hue of the base paper undergoes a transformation, presenting an array of shades including silver gray, light brown, and light gray. The enhanced color palette ensures improved observability and provides a conducive backdrop for the creation of aluminized corrugated cardboard and the fabrication of innovative furniture designs.

In the context of corrugated paperboard, which consists of surface paper, inner paper, and corrugated core paper bonded together through adhesives to form multi-layer paperboard, the preparation of Al-coated corrugated cardboard hinges on utilizing the developed paper-based Al-coated film as the surface paper. This process adheres to established principles of corrugated cardboard production, leveraging existing equipment and technical workflows. Depending on the specific application requirements, diverse specifications of high-quality Al-plated corrugated cardboard can be manufactured to serve as raw materials for creative furniture, packaging solutions, and cultural and artistic products.