Abstract

Unlike the term sound insulation, which means reducing the penetration of noise into other areas, sound absorption means reducing the reflection and energy of the sound on the surface. It has become a highly noticed issue in recent years because the noise in our daily life is increasing day by day, and it causes some health and comfort disorders. In many areas, textiles have been used for acoustics control and noise absorption purposes. The purpose of this work is to determine the most effective media for sound absorption performance and its relation to thermal conductivity from needle-punched nonwoven, meltblown nonwoven and hybrid forms in different arrangements of these fabrics. To provide comparable samples, both needle-punched nonwoven and meltblown nonwoven samples were produced from 100% Polypropylene fibres. According to sound absorption tests, the hybrid-structured sample having a composition similar to the needle-punched nonwoven sample placed at the bottom of our study, while the meltblown nonwoven sample placed as a face layer outperformed the rest of the samples in terms of sound absorption and thermal conductivity. ‘Meltblown only’ samples had remarkably higher sound absorption efficiency than most of the samples, while the ‘needle-punched nonwoven only’ sample had the lowest sound absorption efficiency in all frequencies.

1. Introduction

In addition to noise pollution from outside commotion, such as transportation and industry, indoor clamour from ventilation and office machines negatively affect human well-being, and this impact is expanding day by day [1]. Of its negative effects, hearing and sleeping disorders are common; noise pollution also diminishes learning and brain capacity [2]. Novel materials and acoustic science make lowering exposure to noise possible [3].

There are three basic mechanisms to reduce noise: absorbency, damping and isolation. Generally, a thick layer of material absorbs more sound than a thinner layer of the same material [4]. Sound absorption reduces the energy of the sound and its reflection; instead, sound energy is transformed into heat energy by penetrating the porous surface of the absorbent material [5].

It is a well-known fact that nonwoven materials have been used in the automotive, construction and machinery industries for sound/noise insulation purposes. According to the present literature and industrial projects, when cost is a factor in noise insulation, it is useful to consider alternative materials such as meltblown fabrics and/or nanofibrous materials either solely or in different combinations. To this aim, a number of researchers have investigated sound absorption abilities of these materials for various applications.

Production parameters, fibres, methods, etc., are the main factors that determine the acoustic character of a textile. In this context, porous materials are good absorbers for the high-frequency sound ranges due to their interconnected pores. On the other hand, nanofibres behave differently and absorb low-frequency sound waves, possibly due to their high surface area and effective airflow resistance [6]. Thickness is also an important parameter and increases the sound absorption efficiency of the material [7]. Composites provide improved absorption capability compared to single-layer materials due to the exploitation of the superior properties of different materials [8,9]. The diameter of the pore is of importance, and the smaller the pore diameter, the greater the sound absorption at low frequencies [10]. The installation specifications for nonwovens also matter in terms of acoustic performance in that perpendicular laid nonwoven fabric exhibits better sound absorption than a longitudinal laid nonwoven fabric [11]. The above information shows that acoustics and its control is a complex task and should be investigated from many perspectives. Therefore, a number of researchers have investigated this complex phenomenon from different perspectives. Some have concentrated on raw materials, while others have focused on methods and applications for noise control.

Fibre morphology and type play important roles in acoustic control. Researchers have reported that hollow polyester fibre provides higher sound absorption than regular polyester fibre [12]. Researchers have also found that natural fibres, which are gaining importance as a remarkable alternative to synthetic fibres with quite different morphologies, exhibit good sound insulation performance especially at medium and high frequencies [13,14]. Microfibres with low diameter and close structure provide superior sound absorption in a large frequency range [15,16]. Likewise, studies showed that nanofibres with their high surface area and lower diameter have boosted the sound absorption capacity, especially in the low and medium frequency range [17,18,19,20].

A study conducted by Palak and Kayaoglu found that web bonding had the most significant effect on sound absorption capacity compared to the cross section of fibre, the blend ratio of fibres and the areal density parameters [21]. Composite structures also improve sound absorption and are being increasingly used in automotive, civil and aerospace engineering [22,23].

As stressed before, for a porous structure, the ability to transform sound energy into heat energy determines acoustic absorption efficiency. Therefore, it is important to investigate the thermal conductivity of porous acoustic absorbers. The ability of textile materials to transport heat from their surface to another surface is known as thermal conductivity [24].

Not only micro-size or nanomaterials, but also artificial composite periodic materials such as acoustic metamaterials and phononic crystals are being studied as possible and effective sound absorbers. Reetz et al. reported the fabrication of a set of phononic crystals with a variety of defect geometries pertaining to the size of acoustic band gaps that provide good noise reduction [25]. Jin et al. used a square lattice phononic crystal (PnC) to demonstrate metamaterial effects and observed positive and negative refraction and reflection simultaneously, enabling sophisticated development and analysis of acoustic materials [26].

Last but not least, there are also possibilities for developing new materials and applications from recycled materials, for example recycled medical face masks. In particular, the COVID-19 pandemic raised an awareness of the environmental impact of used mask materials and the recycling issue [27]. Varghese et al. demonstrated a novel method for recycling nonwoven layers from medical face masks into a meltblown layer and mention its potentially remarkable applications [28]. Maderuelo-Sanz et al. carried out an experimental investigation of the acoustic performance of surgical face mask waste and found that face mask waste shows an ideal sound absorber efficiency that could be used in acoustic ceiling panels, perforated panel absorbers, sandwich structures or in the core of noise barriers [29].

Based on previous research and their potential in acoustic engineering applications, needle-punched nonwovens and meltblown nonwovens are promising materials for sound absorption applications. For this reason, this work aimed to contribute to the study of sound insulating materials, particularly the sound absorption qualities of needle-punched nonwoven, meltblown nonwovens and their two-layered hybrid combinations having different arrangements. Thermal conductivity as another parameter was investigated to understand its relevance and effect on sound absorption factors of these samples.

Specifically, acoustic nonwovens were prepared in cooperation with two leading companies in this area, and their sound absorption performance was studied along with the basic fabric parameters.

2. Materials and Methods

2.1. Material

In this study, a needle-punched (NP) nonwoven sample was produced in cooperation with an automotive component company in Turkey. Meltblown fabrics in different masses were produced in cooperation with another company that has years of experience in meltblown media production and the development area. Hybrid samples were prepared by spraying melted polymer directly onto the needle-punched nonwoven materials. In this way, a meltblown nonwoven layer was formed either at the top or at the bottom of the needle-punched nonwoven material. To provide a strong bonding of these two layers and prevent delamination further, calendaring was used where hybrid samples passed through two heated rollers at 140 °C. Therefore, no additional layer was needed to provide bonding.

Needle-punching is the most common method for the production of acoustic components [30,31]. Meltblown (MB) fabrics are promising for many engineering applications and also of interest for noise reduction in recent years [32,33]. The detailed information for the needle-punched (NP) sample that was specifically prepared for this study is given in Table 1.

Table 1.

Needle punched nonwoven sample specification.

The detailed information for the meltblown (MB) samples that are specifically prepared for this study are given in Table 2.

Table 2.

Meltblown Samples Specification.

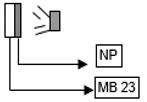

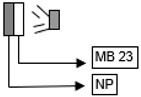

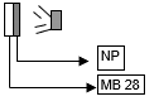

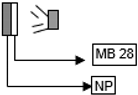

As Table 2 shows, two different meltblown fabric samples having different fibre diameters, thicknesses and weight values were produced with two different screw rotation speeds. The screw speed could be defined as the rotation speed inside the extruder of the meltblown machine. Samples were taken from the rolls in a circular shape, and the sample size was determined as 29 mm. Two-layered NP/MB hybrid fabric samples (Figure 1) were also prepared, and their properties are presented in the methods section of this article.

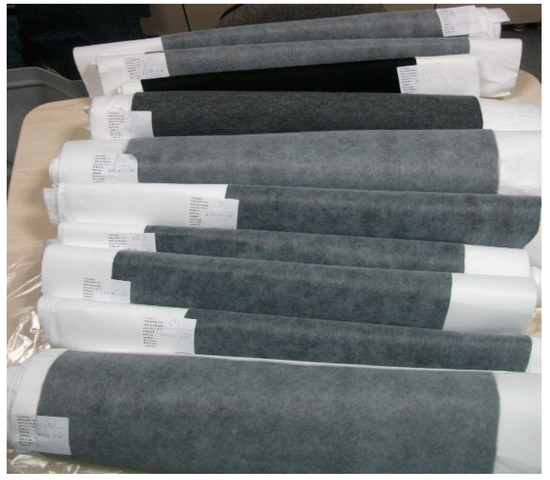

Figure 1.

Photograph of 2 NP/MB hybrid fabric samples.

2.2. Method

In this study, the sound absorption coefficients of the NP, the MB and the two-layered hybrid NP/MB samples were determined using an impedance tube (Brüel&Kjær, 4206 Model, Nærum, Denmark) according to ISO10534-2 ‘Acoustic Absorption Factor’ test standard. This test method covers the use of an impedance tube, two microphone locations and a digital frequency analysis system for the determination of the sound absorption coefficient of sound absorbers for normal sound incidence [34]. The sound absorption coefficient measurements were carried out in three different designs. In the first step, the sound absorption coefficient of the NP was determined. In the second step, the sound absorption coefficient of the MB fabric samples was determined and compared within themselves. In the third step, the sound absorption coefficient of the two-layered hybrid NP/MB samples was determined and compared within themselves. Hybrid samples were prepared in two different arrangements. In other words, while the needle-punched fabric was positioned on the surface in some samples, it was positioned on the bottom in other samples (Table 3). In this way, a comprehensive analysis of the effect of fabric parameters and arrangement on the acoustic character of the samples was carried out and a thorough understanding was achieved.

Table 3.

Arrangement and technical information of samples.

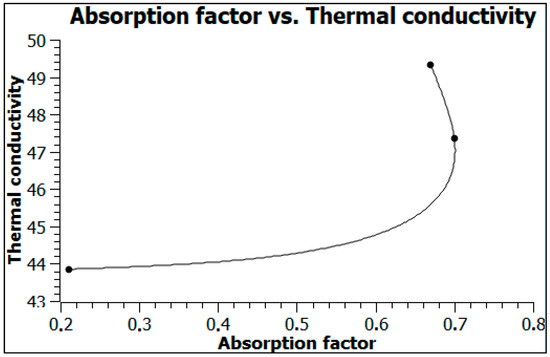

In the second part of the study, thermal conductivity analysis was carried out for three samples (S1, S5 and S7) using an Alambeta instrument according to ISO standard 8301 to understand whether a direct or indirect relationship between this parameter and the acoustic absorption factor exists. These samples were selected based on their acoustic performance. sample S1 showed the lowest acoustic absorption performance, while the S5- and S7-encoded samples outperformed the rest of the samples in acoustic absorption. Specifically, in the test, the measuring head with the sensing block descends as soon as the measurement is initiated. A sudden shift in the sample’s surface temperature causes the sensor to record the heat on the transient temperature region of the thin plate. Thermal conductivity measurements were taken for 10 different areas of each sample; results were averaged and then presented in a graph format comparing sound absorption factors.

3. Results

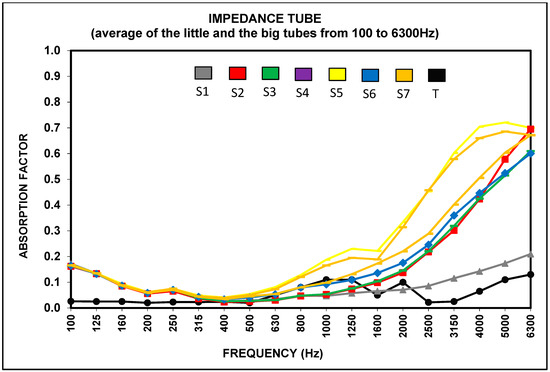

In this part, the sound absorption coefficient and thermal conductivity results of the needle-punched nonwoven fabric, the meltblown fabrics and their hybrid forms were analysed and are presented in Figure 2 and Figure 3. In addition to the sound absorption measurements of the nonwoven samples, the original sound absorption of the impedance tube as the baseline is also presented in the Figure 2 (encoded as ‘T’) to clearly understand the performance of the nonwovens and the meltblown additional layers. The Figures reveal that all samples have shown a higher acoustic absorption performance compared with the original sound absorption of the impedance tube.

Figure 2.

Sound absorption results.

Figure 3.

Thermal conductivity versus sound absorption factors of samples.

In the relevant literature, researchers have found that higher sound transmission loss occurred at higher frequencies for PP needle-punched nonwovens [35]. In the present study, a similar result was obtained: the NP fabric had a slightly higher absorption factor after 5000 Hz frequency (Figure 2).

On the other hand, meltblown nonwovens have become a product of interest for the acoustics area recently; therefore they were included in the present study. As mentioned in a previous citation, Messiry et al. investigated acoustical absorptive properties of meltblown nonwovens and reported that they have excellent sound absorption property, especially for frequencies between 4500 and 5500 Hz [33]. Again, in the present study, two different meltblown nonwoven samples yielded similar results and had ideal sound absorption at frequencies between 4500 and 6300 Hz (Figure 2). Meltblown samples in the present study also outperformed the needle-punched sample for all frequencies.

Hybrid nonwovens have also been studied in the literature for their acoustic efficiency [36,37]. A limited number of research works investigated the effect of the arrangement of the fabric layers in the multi-layered material on acoustic performance under the term ‘layer sequencing’. Yilmaz et al. investigated the effect of layer sequencing of three-layered composite fabrics comprised of needle-punched nonwovens (monofibre or multifibre needle-punched nonwovens included poly(lactic acid) (PLA), polypropylene (PP), glass fibre and hemp fibres) and found that the sound absorption coefficient was higher when the layer including reinforcement fibres was placed on the face side, closest to the sound source [38].

Thermal conductivity analysis results are presented in Table 4. According to the analysis, the S1-encoded sample had the lowest thermal conductivity, while the S7-encoded sample had the highest thermal conductivity, and the S5-encoded sample performed better than the S1 sample.

Table 4.

Thermal conductivity values of samples.

Thermal conductivity results were compared to the sound absorption results and presented in Figure 3. It is clear from the figure that the sample with the highest sound absorption factor also has the highest thermal conductivity value. In other words, as thermal conductivity values increase, sound absorption factors increase, too. This phenomenon was supported with the high regression value of 0.84.

4. Discussion

The present study investigated the effect of layer sequencing on sound absorption performance of needle-punched/meltblown hybrid structures by arranging layers either on the face or on the bottom. Indeed, the arrangement of the layers in the hybrid structure affects sound absorption; the insulation material can be customized by changing the position of the layers. As shown in Figure 2, samples encoded with ‘S5′ and ‘S7′ obtained the highest sound absorption factors, respectively, thanks to their hybrid structure and specific arrangement. The S5-encoded sample outperformed the rest of the samples in the study in acoustic performance when the meltblown nonwoven was placed as the face layer, and the needle-punched nonwoven was placed as the bottom layer in the hybrid structure. Following this, the S7-encoded sample had a high sound absorption factor in a similar manner when the meltblown nonwoven was placed as the face layer, and the needle-punched nonwoven was placed as the bottom layer in the hybrid structure. The common element in these two samples was the placement of the meltblown nonwoven as the face layer, and it increased the sound absorption capacities for both samples due to its finer diameter and higher surface area. It is thought that the S5-encoded sample had the highest sound absorption because the needle-punched nonwoven was supported by a meltblown nonwoven of finer diameter that was produced at 23 rpm. Except for the S6-encoded sample, all hybrid samples had a higher sound absorption factor than the rest of the samples in the study. The reason behind this result for the S6-encoded sample is its arrangement where the needle-punched nonwoven was placed on the face and the relatively thicker meltblown fabric was used as a supporting layer.

In comparison to the other samples in the study, the needle-punched nonwoven performed as the worst sample in terms of sound absorption for all frequencies. Even though traditional nonwovens provide better sound absorption due to their thickness and mass in theory, it does not really work when compared with meltblown nonwovens.

In this study, all meltblown only samples and meltblown-supported needle-punched nonwoven samples performed better than the needle-punched only samples despite their lower thickness and lower mass. This fact can also be explained by the higher surface area of the meltblown nonwovens. Last but not the least, the fibre diameter has been observed to play an important role in the acoustic performance of the fibrous structures of the study. According to the relevant literature, it was reported that sound absorption of the fibrous materials increases as the fibre diameter decreases [39]. Findings supporting this information were obtained within this study. In fact, the S5-encoded sample, which has the lowest diameter meltblown component, had the highest sound absorption factor among all samples. Researchers developing fibrous acoustic materials explained the reason of this phenomenon; with sound waves, thin fibres can travel more easily than thick ones [40]. This will limit the propagation of air through the fibrous structure, resulting in an increase in sound absorption. The S7-encoded sample also displayed high acoustic performance in a similar manner because the air movement was being limited there as well. Researchers working on improving sound-absorbing materials using natural fibres reported that higher surface area and lower diameter create a more tortuous path and higher airflow resistance [41]. This is because a higher number of fibres are required for lower-sized materials to reach the same number of fibres available in higher-sized materials. This limits air movement because of the higher density in the same space. Thus, the S7-encoded sample, despite its relatively higher thickness, provided one of the best acoustic dampening materials within the study due to the finer fibres on the surface that increased airflow resistance. Although used as a single layer, the S2-encoded sample performed better than most of the samples of the study, especially in higher frequencies because of its relatively low fibre diameter which enabled a higher surface area. This result supports findings from the previously mentioned studies from the literature mentioned throughout the paper. To the best of our knowledge, there is no study available in the relevant literature investigating the effect of layer sequencing on the sound absorption factor of hybrid structures comprised of needle-punched nonwoven and meltblown nonwoven materials. This part of the study promises a novelty. Traditional needle-punched nonwovens were already assessed for different layer sequencing arrangements in previous studies; however, these studies did not cover their hybrid combinations with meltblown nonwovens. The reason for this might be that even though meltblown nonwovens are considered as a promising material for future acoustic applications, the use of meltblown nonwovens has not yet become as widespread as needle-punched nonwovens. In this way, this part of the study not only provides a general performance analysis for hybrid structures but also investigates the performance of different hybrid samples with different sequencing arrangements, i.e., meltblown layer placed either at the top or bottom of the hybrid structure. This novel information can be used by scientists when deciding a material for each layer that will perform better, and it can also be used by developers in industry when designing acoustic materials for different applications.

All samples within the study are porous nonwoven material. They have 90% porosity, allowing sound waves to easily travel through and be dampened. In a wide range of applications, such materials can be used as noise control components [42]. The present findings support this assertion. Our study showed that hybrid samples perform better in terms of sound absorption as they have a higher total number of pores in comparison with the single-layer samples. On the other hand, even though the total number of the pores in the single-layered meltblown nonwoven samples is less than some of the hybrid samples, these samples performed closer to the hybrid samples. This might be because the lower fibre diameter and higher surface area enable a more functional surface that improves sound absorption. This finding can be useful for the design and development of novel acoustic materials comprised of meltblown nonwovens. Researchers have reported that porous nonwoven materials sound insulation characteristics in the audible frequency range of 125–4000 Hz can be effectively used applications such as acoustic ceilings, noise reducing quilts and noise proof barriers [43]. To relate to the results of the paper, especially the S2-, S4-, S5- and S7-encoded samples provide relatively higher absorption factors for the 3150–6300 frequency ranges and offer possibilities to obtain customized absorption for different applications.

As far as we know, this is the first study comparing thermal conductivity and sound absorption factors of nonwoven materials in terms of acoustic performance on a layer-sequencing basis. Normally, thermal conductivity parameters in textile materials are measured to determine thermal insulation properties to understand whether the fabric provides warm or cool feeling, primarily in clothing. Thermal conductivity is also analyzed to determine the thermal load of a material. Normally, thicker samples have a lower thermal conductivity due to an increase in their thermal resistance, a phenomenon that was already reported in previous studies [44,45]. However, in our study, even though the S5- and S7-encoded samples are thicker than the S1-encoded sample, they have higher thermal conductivity values. The reason of this phenomenon could be attributed to the finer fibres making the surface of the hybrid structure more functional as previously explained. It was also thought that this increase in thermal conductivity would have contributed to the increase in sound absorption performance by increasing the amount of sound energy converted into thermal energy and transferring it directly outside, lowering noise inside the hybrid structure. In other words, the acoustic absorption capabilities of the nonwoven materials could possibly be improved by raising the thermal conductivity. This novel finding can lead to planning and developing new procedures in the experimental design of acoustic testing. This would mark the first time that thermal conductivity was used for an area outside clothing comfort or thermal insulation analysis for any material. Therefore, it might open-up new possibilities for further development of fibrous acoustic materials. Traditional needle-punched nonwoven fabrics such as the S1-encoded sample do not follow this phenomenon since higher diameter fibres within a structure diminish the surface functionality of the material. It is also important to discuss whether there is any acoustic power dependence on the sound absorption for the samples of the study. This can be explained by considering principles of either Hooke’s Law or Newton’s Law of Cooling. It is thought that the acoustic power dependence on the sound absorption for our samples follows Newton’s Law of Cooling, as thermal conduction proportionally increases heat loss from the surface of the material [46]. Newton’s Law of Cooling is based on Newton’s Second Law of Motion which relates to the simple harmonic oscillator acceleration of the mass to the net external force acting on the mass [47]. As perpendicular displacement on the membrane approaching the thickness of the membrane in our samples’ have a thickness of less than 3 mm, the vibration response has power and frequency dependence. In considering all aspects mentioned: mass, thickness, vibration response, fibre type and diameter and surface area play a critical role in determining the acoustic performance. Kalinova reported that an increase in the number of merged fibres might affect the resonance frequency of the membrane, and these local places can resonate at a slightly different frequency, enabling an increase in the absorbed frequency range [48]. In fact, the hybrid samples of the present study provide a wider range of absorption frequency due to the explained merged fibres phenomenon compared with single-layered samples.

5. Conclusions

The present work investigated the effect of different forms of fabrics, such as single-layer needle-punched nonwoven, single layer meltblown and their hybrid combinations, on sound absorption performance and its relation to their thermal conductivity values. It also shows potential results of using these fabrics either at the bottom or at the face in terms of design for acoustic performance. The laboratory testing revealed the following highlights:

- The needle-punched nonwoven fabric provides the lowest sound absorption performance for all frequencies when it is used alone.

- Meltblown fabrics produced at two different rpms performed remarkably better than needle-punched nonwoven when they are used alone. Of these fabrics, the meltblown fabric produced at 23 rpm outperformed the other meltblown fabric (28 rpm) in low, medium and higher frequencies. The finer diameter contributed to the acoustic performance of the material.

- For the hybrid, when the meltblown fabric was placed at the face and the needle-punched was placed at the bottom, it provided a higher sound absorption performance compared to the hybrid samples having the opposite arrangement. It can be explained by higher surface area and finer fibre diameter greatly contributing to the acoustic performance. Therefore, it is better to place the finer diameter fibrous material on the face when higher sound absorption performance is desired in fibrous hybrid structures. This phenomenon also contributed to an increase in thermal conductivity values of the hybrid structures that would possibly advance sound absorption capability by transferring a higher amount of the heat energy that was converted from sound energy.

- The needle-punched nonwoven/meltblown hybrid samples performed slightly better than meltblown alone fabrics in sound absorption in general.

- Contrary to theory, higher mass and thickness did not make needle-punched nonwoven the best material for acoustic performance. On the other hand, meltblown nonwovens and their hybrid combinations performed better due to their finer diameter and surface area even though they have lower mass and thickness.

Of these hybrid structures, the needle-punched only sample had the lowest sound absorption performance; therefore it should not be used as a single material in technical applications and should be supported with another material, i.e., meltblown nonwovens to increase acoustic efficiency. However, although they are lighter and thinner, meltblown nonwovens are more promising in terms of acoustic performance due to their lower fibre diameters making them a potential candidate for various engineering applications. In fact, meltblown nonwovens can be an ideal component as potential sound absorbers even for automotive applications in future depending on new designs and developments in morphology, fibre size and materials.

Outlook and Suggested Future Work

Future studies may investigate different meltblown fabrics produced at a higher rpm range and needle-punched nonwoven produced in different mass and fibre types. Future studies can also investigate the effect of thermal conductivity on sound absorption performance for the fabrics made of different polymers. The hybrid combinations of these fabrics, including nanofibre layer(s), may pioneer designing the next generation of sound absorption materials. Therefore, more studies need to be carried out to investigate the efficacy of incorporating nanofibrous layers into acoustic materials, considering surface area, thickness, surface functionality, fibre diameter, etc. Future studies can also consider using recycled materials obtained from abundantly consumed materials such as nonwoven-based face masks.

Author Contributions

Conceptualization, Ç.S. and A.H.; methodology, Ç.S. and A.H.; software, Ç.S.; validation, A.H.; formal analysis, Ç.S.; investigation, Ç.S. and A.H.; resources, Ç.S. and A.H.; data curation, Ç.S.; writing—original draft preparation, Ç.S. and A.H.; writing—review and editing, A.H.; visualization, Ç.S.; supervision, A.H.; project administration, Ç.S. and A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- De Paiva Vianna, K.; Rodrigues, R.M.; Alves, C.M. Noise pollution and annoyance: An urban soundscapes study. Noise Health 2015, 17, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Test, T.; Canfi, A.; Eyal, A.; Shoam-Vardi, I.; Sheiner, E.K. The Influence of Hearing Impairment on Sleep Quality Among Workers Exposed to Harmful Noise. Sleep 2011, 34, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Yan, X. Multi-layer fibrous structures for noise reduction. J. Text. Inst. 2017, 108, 2096–2106. [Google Scholar] [CrossRef]

- Fung, W.; Hardcastle, M. Textiles in Automotive Engineering, 1st ed.; Technomic Publishing Co.: Lancaster, UK, 2001; pp. 1–23. [Google Scholar]

- Kang, Y.; Lee, E.; Lee, K.; Choi, S.; Shin, E. Acoustic properties of sound-absorbing polyester fabrics woven with thick staple and thin draw textured yarn for use in interior decoration. J. Text. Inst. 2019, 110, 202–210. [Google Scholar] [CrossRef]

- Tang, X.; Yan, X. Acoustic energy absorption properties of fibrous materials: A review. Compos. Part Appl. Sci. Manuf. 2017, 101, 360–380. [Google Scholar] [CrossRef]

- Moretti, E.; Belloni, E.; Agosti, F. Innovative mineral fiber insulation panels for buildings: Thermal and acoustic characterization. Appl. Energy 2016, 169, 421–432. [Google Scholar] [CrossRef]

- Küçük, M.; Korkmaz, Y. The effect of physical parameters on sound absorption properties of natural fiber mixed nonwoven composites. Text. Res. J. 2012, 82, 2043–2053. [Google Scholar] [CrossRef]

- Soyaslan, D. High structural insulation composite material development with electromagnetic protection effect reinforced with carbon fibers and particles. J. Ind. Text. 2021, 51, 424–434. [Google Scholar] [CrossRef]

- Liu, X.; Yan, X.; Zhang, H. Effects of pore structure on sound absorption of kapok-based fiber nonwoven fabrics at low frequency. Text. Res. J. 2016, 86, 755–764. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Mishra, R.; Novak, J.; Militky, J. Sound absorption and compression properties of perpendicular-laid nonwovens. Text. Res. J. 2019, 89, 612–624. [Google Scholar] [CrossRef]

- Zakriya, G.M.; Ramakrishnan, G. Insulation and mechanical properties of jute and hollow conjugated polyester reinforced nonwoven composite. Energy Build. 2018, 158, 1544–1552. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Ganesan, P.; Karthik, T. Development of acoustic nonwoven materials from kapok and milkweed fibres. J. Text. Inst. 2016, 107, 477–482. [Google Scholar] [CrossRef]

- Bhat, G.; Messiry, M.E. Effect of microfiber layers on acoustical absorptive properties of nonwoven fabrics. J. Ind. Text. 2020, 50, 312–332. [Google Scholar] [CrossRef]

- Na, Y.; Lancaster, J.; Casali, J.; Cho, G. Sound Absorption Coefficients of Micro-fiber Fabrics by Reverberation Room Method. Text. Res. J. 2007, 77, 330–335. [Google Scholar] [CrossRef]

- Rabbi, A.; Bahrambeygi, H.; Nasouri, K.; Shoushtari, A.M.; Babaei, M.R. Manufacturing of PAN or PU Nanofiber Layers/PET Nonwoven Composite as Highly Effective Sound Absorbers. Adv. Polym. Technol. 2014, 33, 21425. [Google Scholar] [CrossRef]

- Kucukali-Ozturk, M.; Ozden-Yenigun, E.; Nergisi, B.; Candan, C. Nanofiber-enhanced lightweight composite textiles for acoustic applications. J. Ind. Text. 2017, 46, 1498–1510. [Google Scholar] [CrossRef]

- Rabbi, A.; Bahrambeygi, H.; Shoushtari, A.M.; Nasouri, K. Incorporation of Nanofiber Layers in Nonwoven Materials for Improving Their Acoustic Properties. J. Eng. Fibers Fabr. 2013, 8, 155892501300800412. [Google Scholar] [CrossRef]

- Xiang, H.; Tan, S.; Yu, X.; Long, Y.; Zhang, X.; Zhao, N.; Xu, J. Sound absorption behavior of electrospun polyacrylonitrile nanofibrous membranes. Chin. J. Polym. Sci. 2011, 29, 650–657. [Google Scholar] [CrossRef]

- Palak, H.; Kayaoğlu, B.K. Analysis of the effect of fiber cross section and different bonding methods on sound absorption performance of PET fiber based nonwovens using Taguchi method. J. Text. Inst. 2020, 111, 575–585. [Google Scholar] [CrossRef]

- Gliścińska, E.; Michalak, M.; Krucińska, I. Sound absorption property of nonwoven based composites. Autex Res. J. 2013, 13, 150–155. [Google Scholar] [CrossRef][Green Version]

- Ramamoorthy, M.; Pisal, A.A.; Rengasamy, R.S.; Rao, A.V. In-situ synthesis of silica aerogel in polyethylene terephthalate fibre nonwovens and their composite properties on acoustical absorption behavior. J. Porous Mater. 2018, 25, 179–187. [Google Scholar] [CrossRef]

- Islam, S.; Alam, S.M.M.; Akter, S. Mathematical investigation of the thermal conductivity of fabrics using thermal equation. Mater. Today Proc. 2020, 46, 413–424. [Google Scholar] [CrossRef]

- Reetz, C.; Fischer, R.; Assumpcao, G.G.; McNally, D.P.; Burns, P.S.; Sankey, J.C.; Regal, C.A. Analysis of Membrane Phononic Crystals with Wide Band Gaps and Low-Mass Defects. Phys. Rev. Appl. 2019, 12, 44027. [Google Scholar] [CrossRef]

- Jin, Y.; Walker, E.; Choi, T.; Neogi, A.; Krokhin, A. Simultaneous negative reflection and refraction and reverse-incident right-angle collimation of sound in a solid-fluid phononic crystal. J. Acoust. Soc. Am. 2022, 151, 2723–2731. [Google Scholar] [CrossRef]

- Gül, S.; Sivri, Ç.; Aksu, O.R. The selection of face mask as a personal protective equipment under the spherical fuzzy environment considering technical and material properties. Int. J. Cloth. Sci. Technol. 2022. ahead of print. [Google Scholar] [CrossRef]

- Varghese, G.; David, D.A.; Karuth, A.; Manamkeri Jafferali, J.F.; Begum, S.; George, J.J.; Rasulev, B.; Raghavan, P. Experimental and Simulation Studies on Nonwoven Polypropylene–Nitrile Rubber Blend: Recycling of Medical Face Masks to an Engineering Product. ACS Omega 2022, 7, 4791–4803. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Acedo-Fuentes, P.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M. The recycling of surgical face masks as sound porous absorbers: Preliminary evaluation. Sci. Total Environ. 2021, 786, 147461. [Google Scholar] [CrossRef]

- Sengupta, S. Sound reduction by needle-punched nonwoven fabrics. Indian J. Fibre Text. Res. 2010, 35, 237–242. [Google Scholar]

- Jia, M.G.; Yan, R.S.; Cao, B.; Shi, J. Investigation on the structure and mechanical properties of acoustic-absorbing composite laminates. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 22084. [Google Scholar] [CrossRef]

- Hoda, N.; Mert, F.; Kara, F.; Atasagun, H.G.; Bhat, G.S. Effect of Process Parameters on Fiber Diameter and Fiber Distribution of Melt-Blown Polypropylene Microfibers Produced by Biax Line. Fibers Polym. 2021, 22, 285–293. [Google Scholar] [CrossRef]

- Messiry, M.E.; Bhat, G.; Eloufy, A.; Latif, S.A.; Ayman, Y. Acoustical absorptive properties of meltblown nonwovens for textile machinery. Text. Res. J. 2020, 91, 1341–1353. [Google Scholar] [CrossRef]

- International Standards Organization. Available online: https://www.iso.org/standard/22851.html (accessed on 25 April 2022).

- Ghorbani, K.; Hasani, H.; Zarrebini, M.; Saghafi, R. An investigation into sound transmission loss by polypropylene needle-punched nonwovens. Alex. Eng. J. 2016, 55, 907–914. [Google Scholar] [CrossRef]

- Temesgen, A.G.; Eren, R.; Aykut, Y.; Süvari, F. Evaluation of Enset Fabric Reinforced Green Composite as Sound Absorber Structure. Text. Appar. 2021, 31, 73–81. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Yilmaz, N.; Banks-lee, P.; Powell, N.; Michielsen, S. Effects of porosity, fiber size, and layering sequence on sound absorption performance of needle-punched nonwovens. J. Appl. Polym. Sci. 2011, 121, 3056–3069. [Google Scholar] [CrossRef]

- Seddeq, H.S. Factors Influencing Acoustic Performance of Sound Absorptive Materials. Aust. J. Basic Appl. Sci. 2009, 3, 4610–4617. [Google Scholar]

- Koizumi, T.; Tsujiuchi, N.; Adachi, A. The Development of Sound Absorbing Materials Using Natural Bamboo Fibers. High Performance. Struct. Compos. WIT Trans. Built Environ. 2002, 59, 157–166. [Google Scholar]

- Sun, F.Y.; Banks-Lee, P.; Peng, H. Sound Absorption in An Anisotropic Periodically Layered Fluid-Saturated Porous Medium. Appl. Acoust. 1993, 39, 65–76. [Google Scholar] [CrossRef]

- Midha, V.K.; Chavhan, V. Nonwoven Sound Absorption Materials. Int. J. Text. Fash. Technol. 2012, 2, 45–55. [Google Scholar]

- Shahani, F.; Soltani, P.; Zarrebini, M. The Analysis of Acoustic Characteristics and Sound Absorption Coefficient of Needle Punched Nonwoven. J. Eng. Fibers Fabr. 2014, 9, 84–92. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q.; Zheng, Q.; Li, T.; Chong, N.; Bai, Y. Bonding and Thermal-Mechanical Property of Gradient NiCoCrAlY/YSZ Thermal Barrier Coatings with Millimeter Level Thickness. Coatings 2021, 11, 600. [Google Scholar] [CrossRef]

- Sivri, Ç. Experimental Comfort Evaluation of Baby Diapers in Terms of Liquid Accumulation, Moisture Management and Heat Transfer via Non Destructive Testing. Text. Appar. 2021, 31, 122–128. [Google Scholar] [CrossRef]

- Garrett, S.L. Understanding Acoustics an Experimentalist’s View of Sound and Vibration, 2nd ed.; Springer: Pine Grove Mills, PA, USA, 2020; 781p. [Google Scholar]

- Davidzon, M.I. Newton’s law of cooling and its interpretation. Int. J. Heat Mass Transf. 2012, 55, 5397–5402. [Google Scholar] [CrossRef]

- Kalinova, K. A sound absorptive element comprising an acoustic resonance nanofibrous membrane. Recent Pat. Nanotechnol. 2015, 9, 61–69. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).