Electrochemical and DFT Study of NaNO2/NaNO3 Corrosion Inhibitor Blends for Rebar in Simulated Concrete Pore Solution

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

- A mixture of NaNO2 and NaNO3 corrosion inhibitors can successfully protect carbon steel rebar in simulated concrete pore solution with 0.6 M NaCl. All mixtures tested, including 1:0.5, 1:1, and 0.5:1 NO2–:NO3– ratios, showed improvement in the corrosion properties compared to the control test with no inhibitors. The best performing inhibitor mixture was the 1:0.5 ratio, showing an icorr of 1.16 × 10−7 A/cm2 at 25 °C.

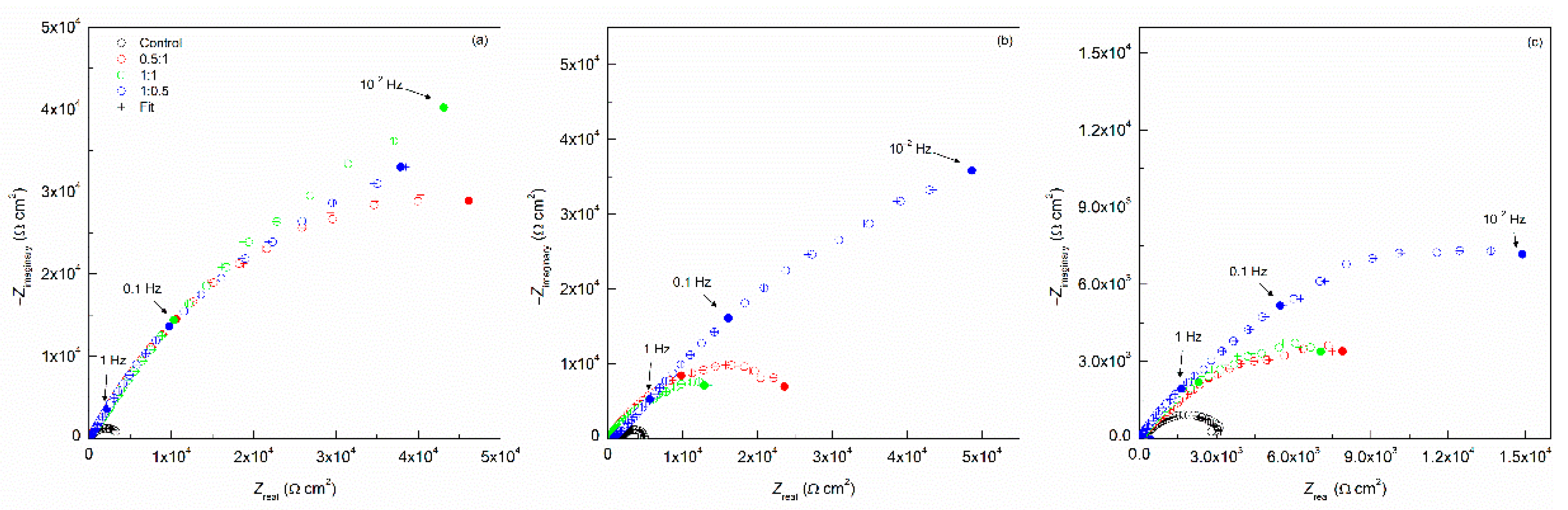

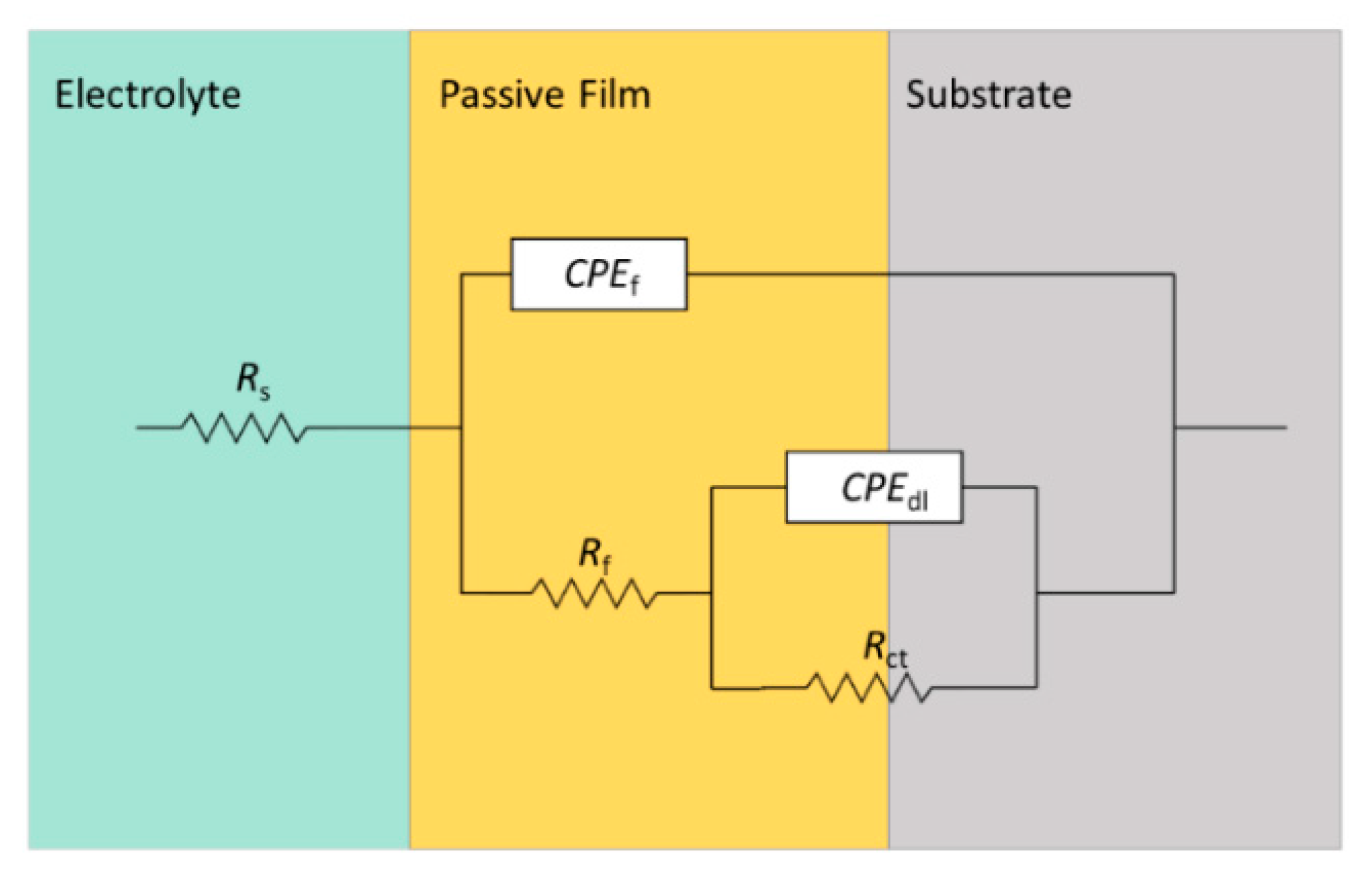

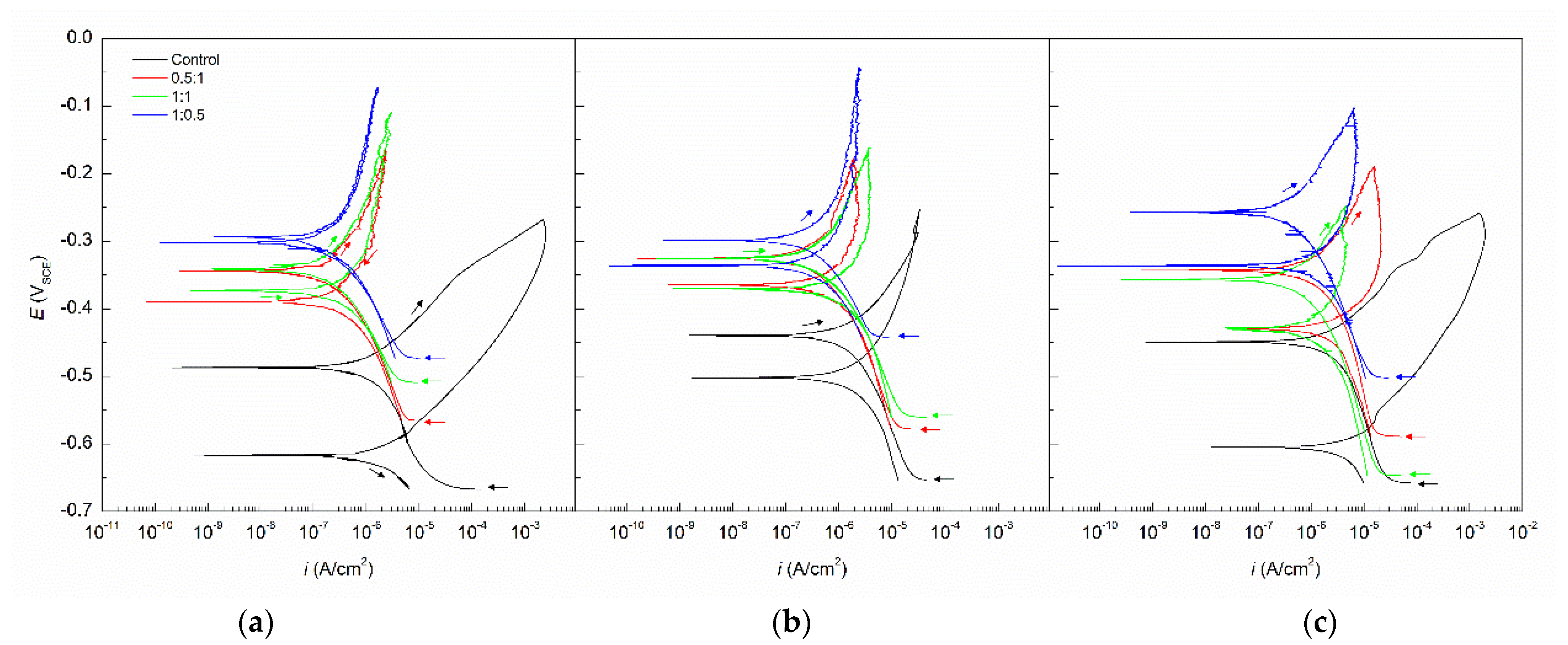

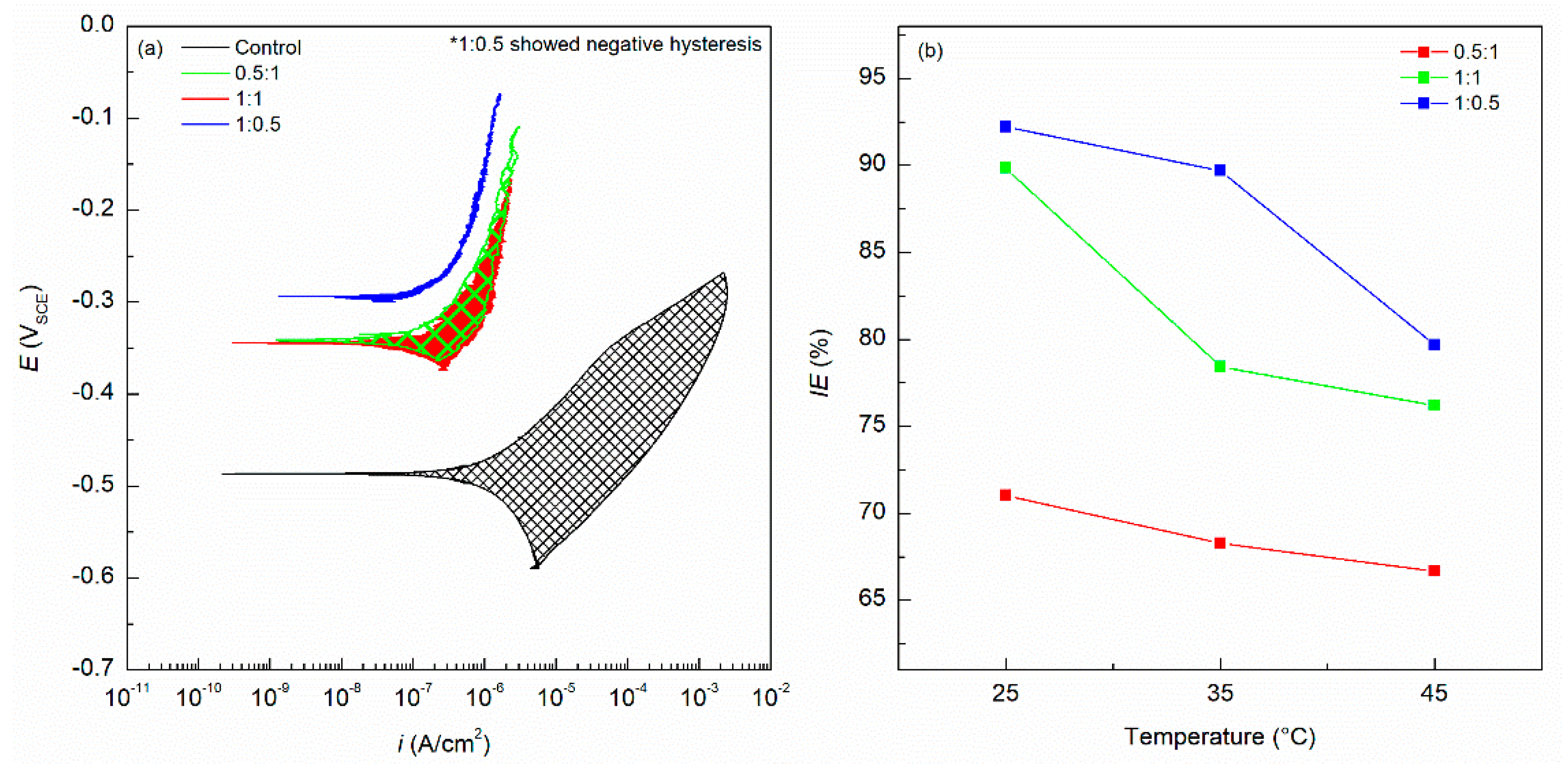

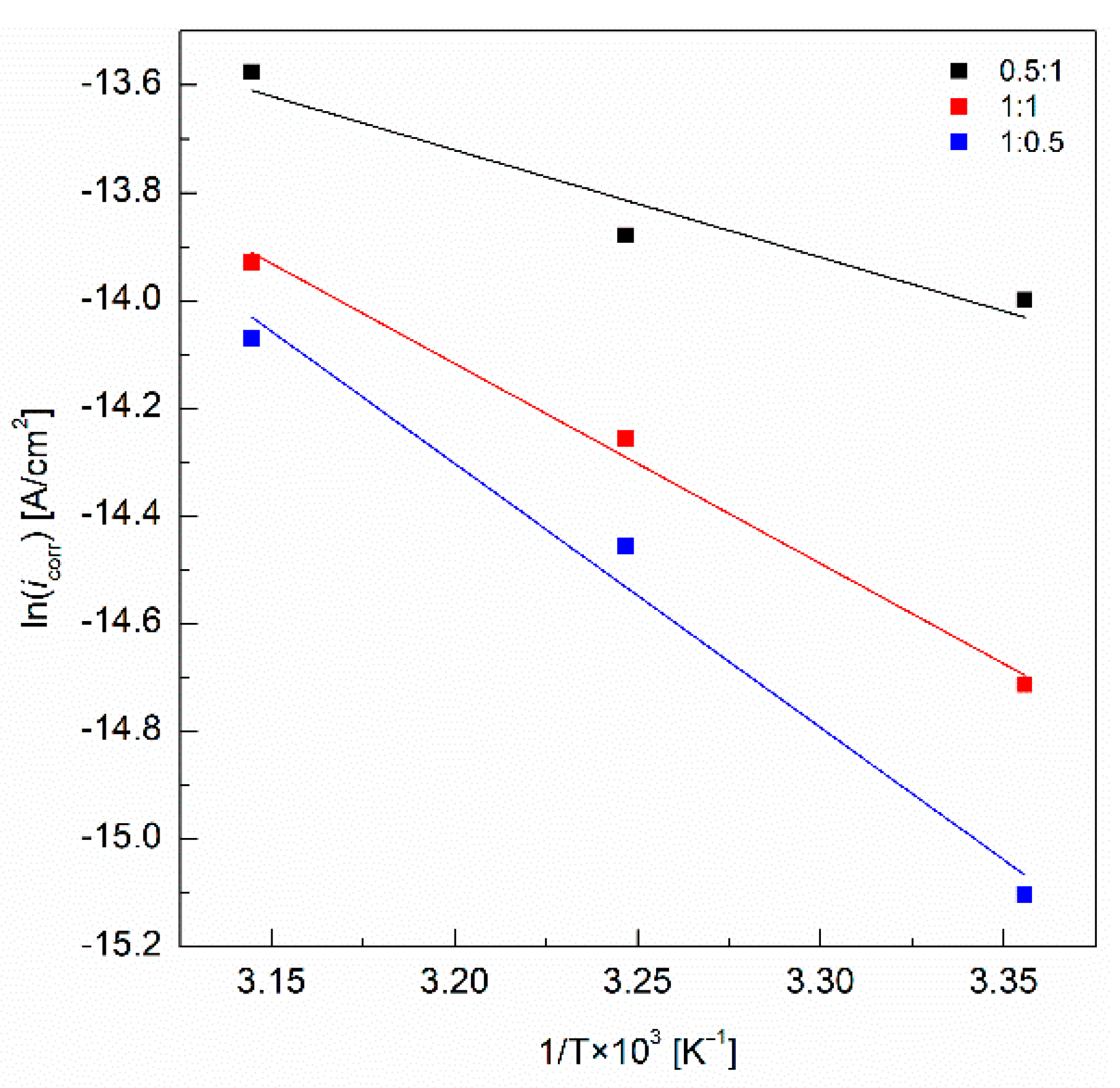

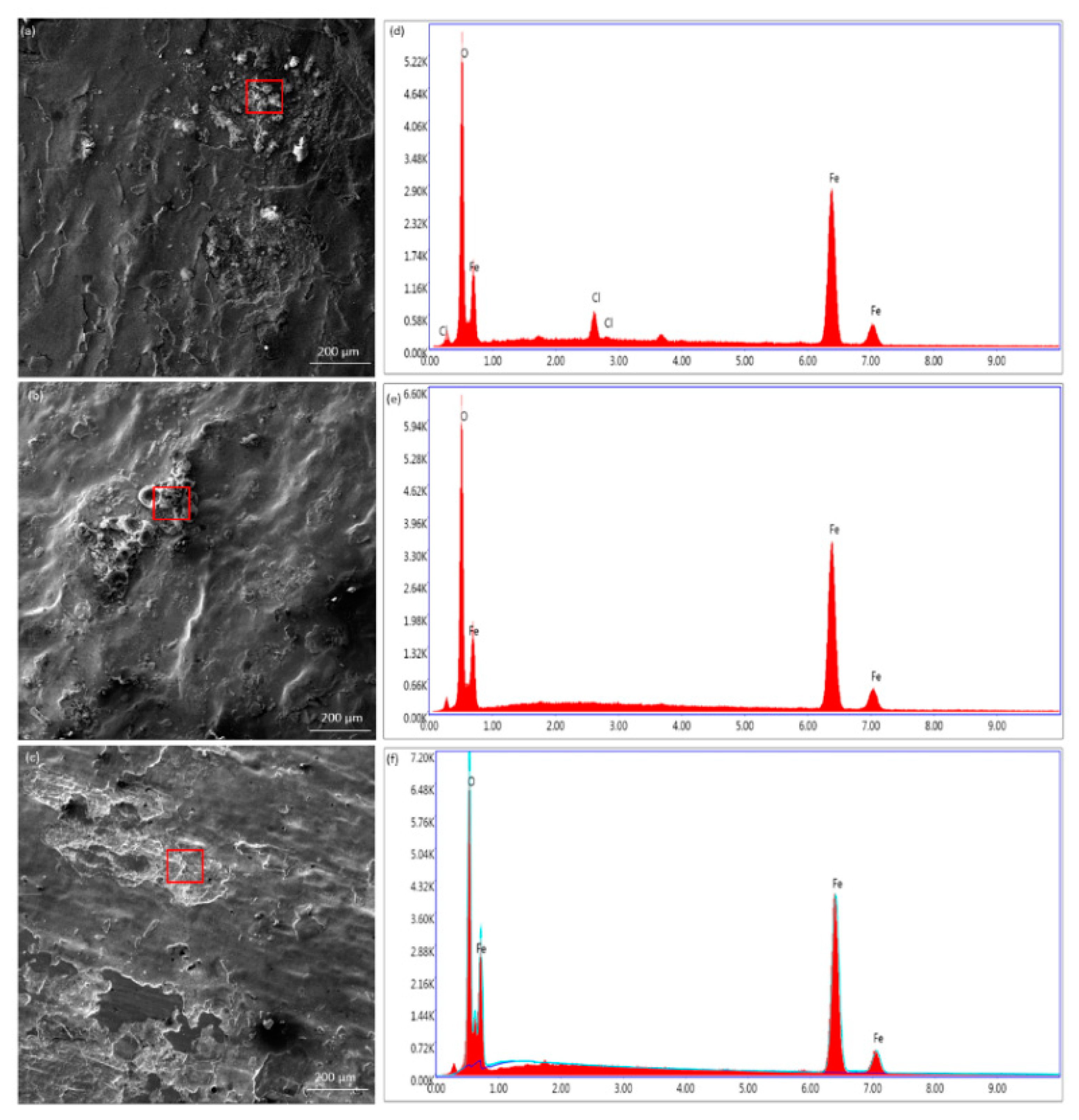

- Greater concentrations of NO2– were associated with higher corrosion inhibition; specifically, the 1:0.5 and 1:1 NO2–:NO3– solutions showed the lowest icorr and highest resistance values associated with passive film (Rf) values of 1.67 × 103 and 1.60 × 103 Ω cm2, respectively, and corrosion process (Rct) values of 1.31 × 105 and 2.39 × 105 Ω cm2, respectively. The activation energy (Ea) also followed this trend, the 1:0.5 inhibitor mixture showing the highest activation energy of 12.1 kJ/mol, indicating that a greater energy barrier needed to be overcome for the corrosion process to be initiated with higher amounts of nitrite compared to nitrate inhibitors. Therefore, the dominating inhibitor in the mixture was found to be NO2−. The inhibitor blends of 1:0.5 and 1:1 NaNO2:NaNO3 showed the best corrosion inhibition; thus, the optimal ratio is 1:1 to maximize inhibition efficiency while minimizing NO2−, as it is toxic and can be harmful to the environment.

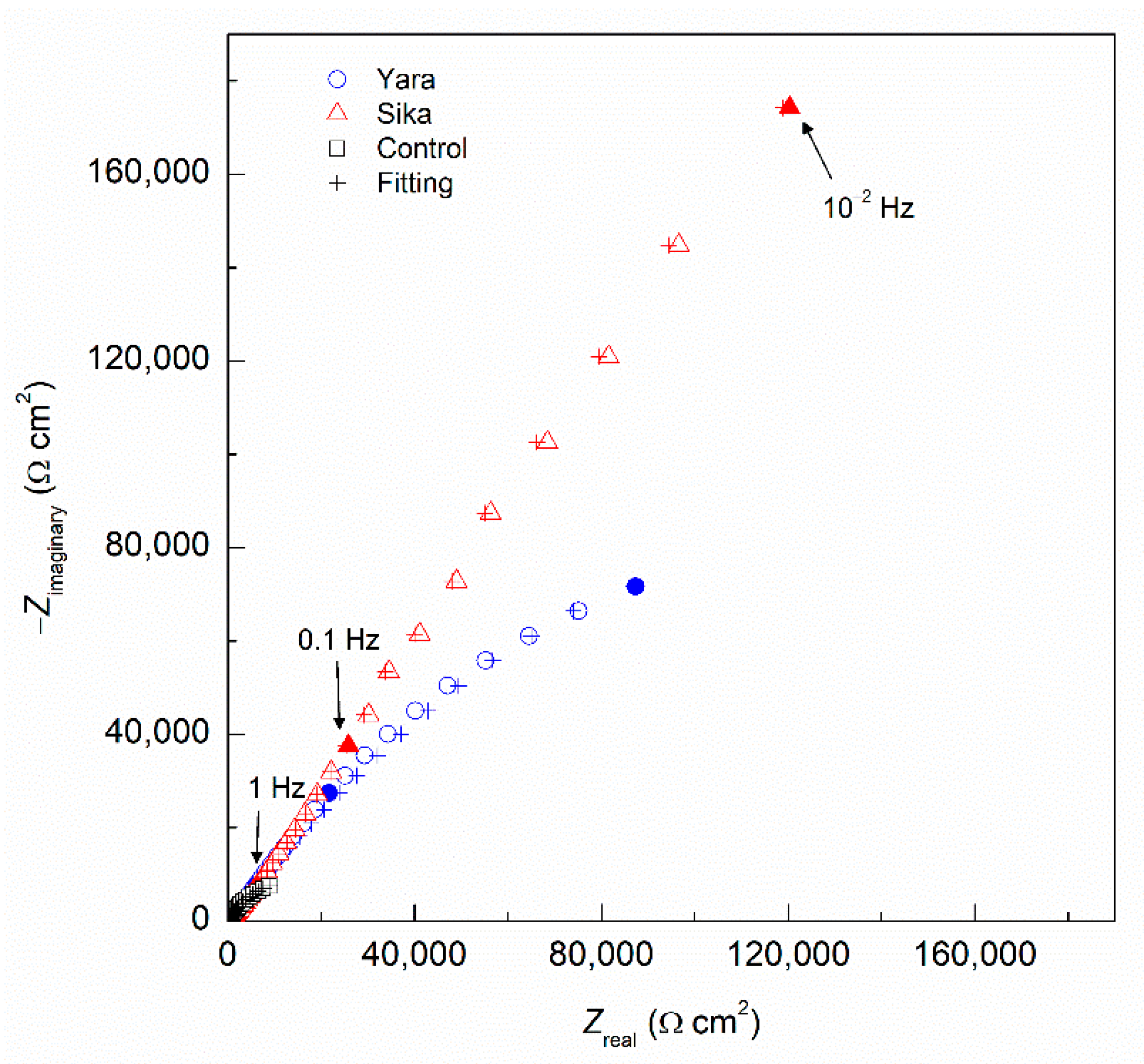

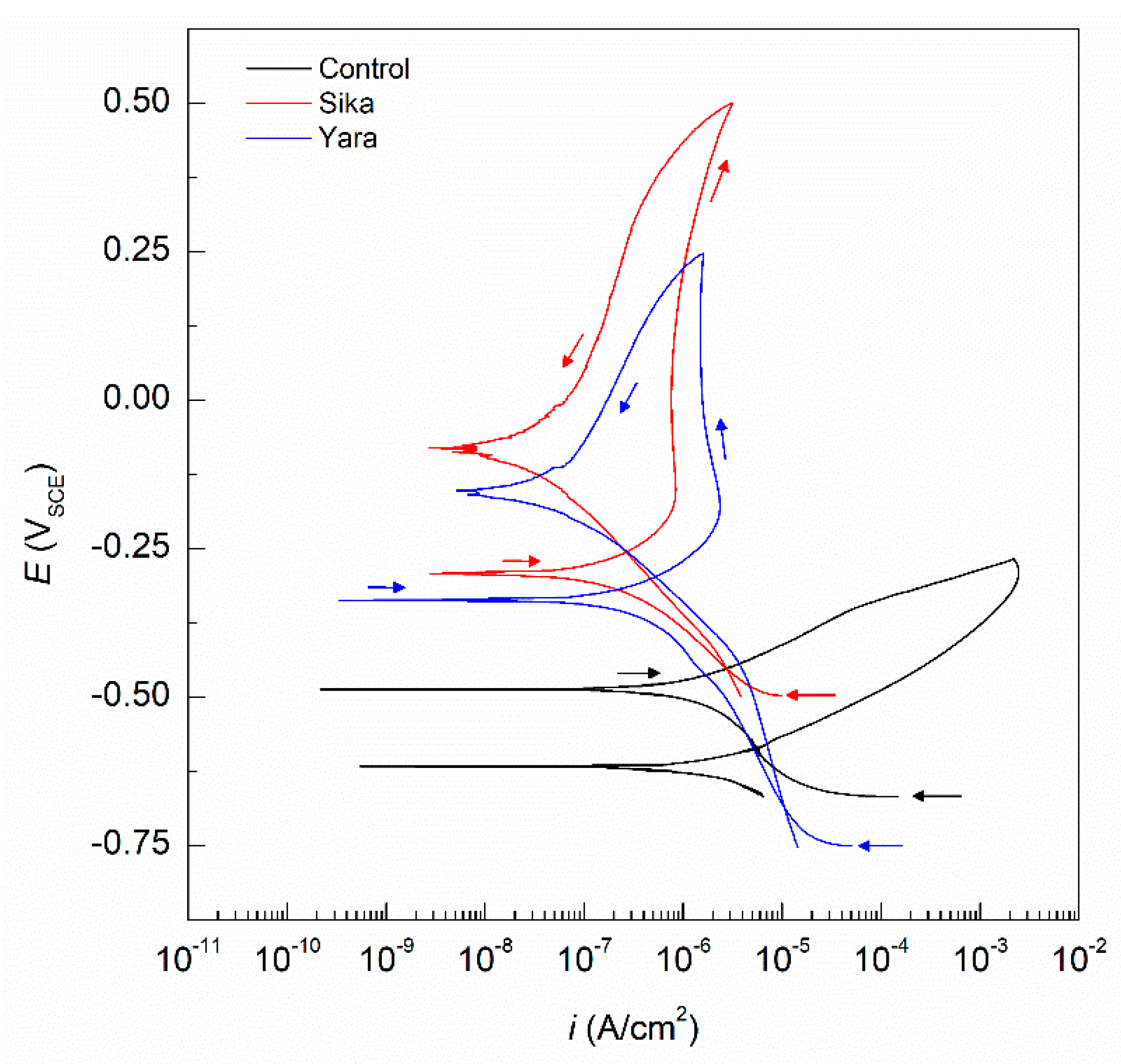

- Finally, by comparison of two commercially available mixtures, the inhibitor mixture with the higher nitrite concentration (Sika) showed the most passive Ecorr of −292 mVSCE and a lower icorr of 4.27 × 10−7 A/cm2, corroborating the hypothesis that nitrite dominated the inhibition process of the NO2–:NO3– mixture.

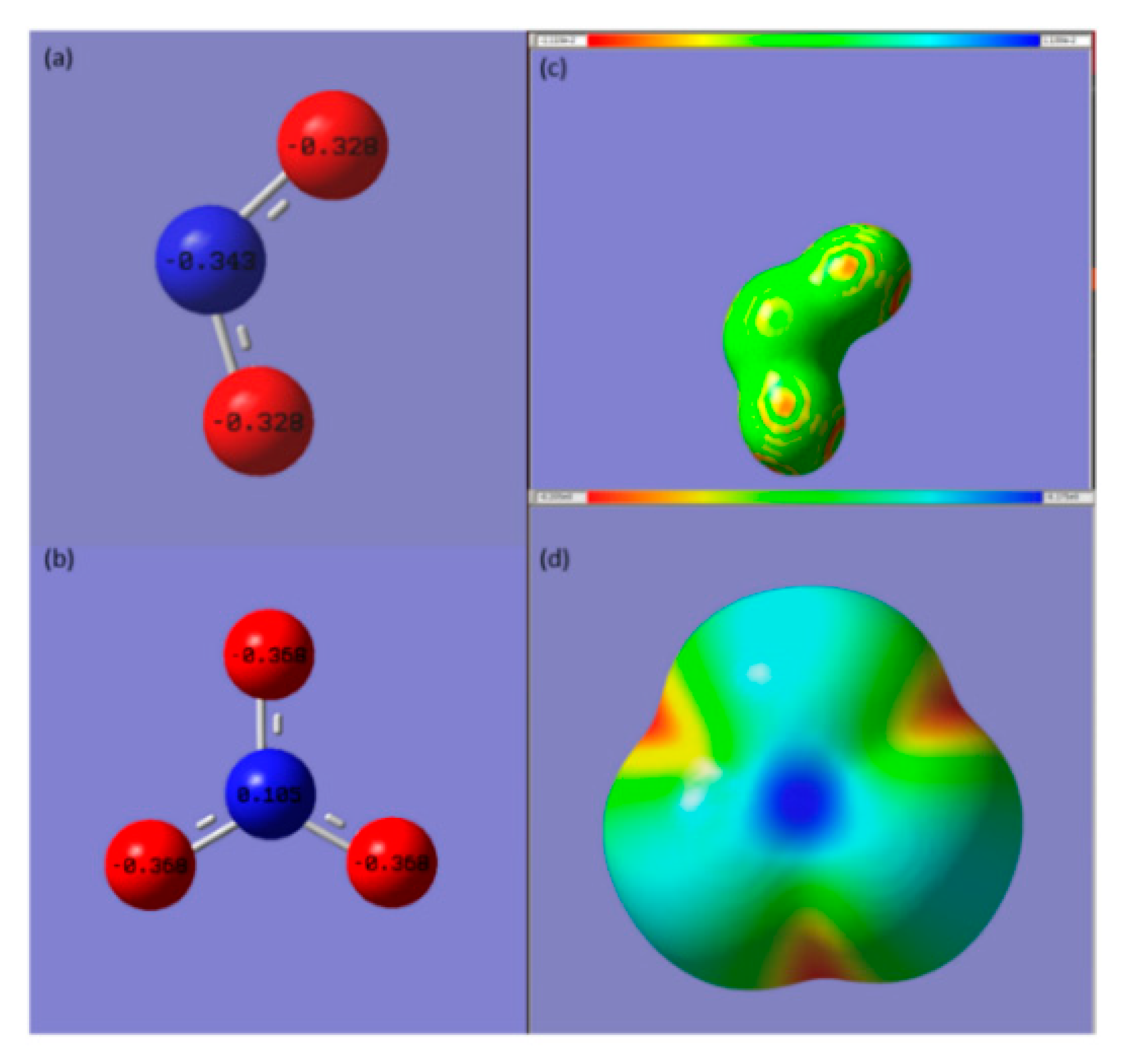

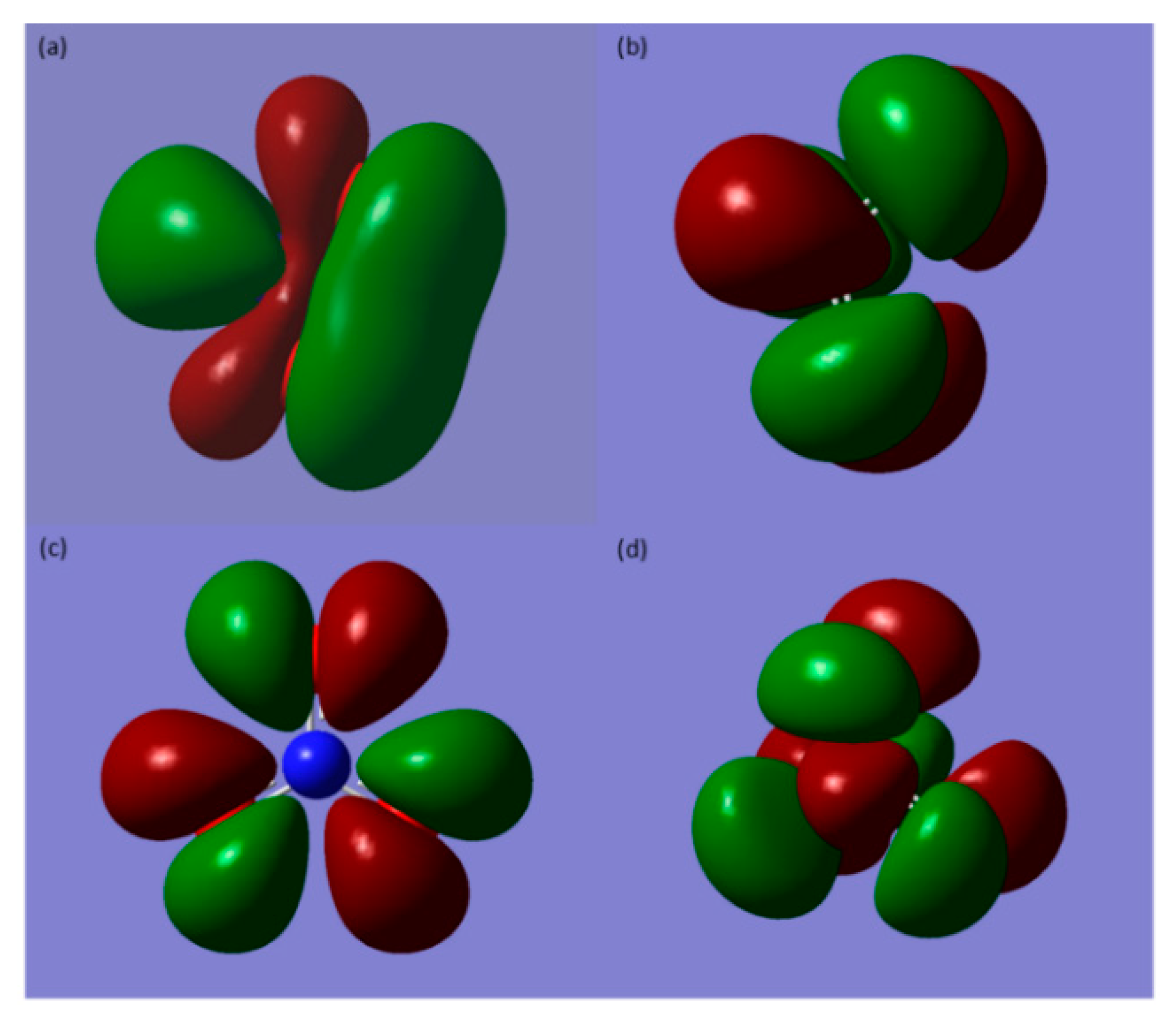

- By DFT analysis of the inhibitors, the EHOMO, ELUMO, ΔE, and dipole moment values obtained were found to be consistent with the experimental results. The EHOMO values indicated that nitrite more readily donated its electrons to the metal atoms and that the ΔE was lower, −5.74 eV, for the higher nitrite mixture (1:0.5), which has been correlated with better corrosion inhibition in the literature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bastidas, D.M.; Cobo, A.; Otero, E.; González, J.A. Electrochemical rehabilitation methods for reinforced concrete structures: Advantages and pitfalls. Corros. Eng. Sci. Technol. 2008, 43, 248–255. [Google Scholar] [CrossRef]

- Martin, U.; Ress, J.; Bosch, J.; Bastidas, D.M. Stress corrosion cracking mechanism of AISI 316LN stainless steel rebars in chloride contaminated concrete pore solution using the slow strain rate technique. Electrochimica Acta 2019, 335, 135565. [Google Scholar] [CrossRef]

- Bastidas, D.M.; González, J.A.; Feliu, S.; Cobo, A.; Miranda, J.M. A quantitative study of concrete-embedded steel corrosion using potentiostatic pulses. Corrosion 2007, 63, 1094–1100. [Google Scholar] [CrossRef]

- Prasad, N.K.; Pathak, A.; Kundu, S.; Panchal, P.; Mondal, K. On the novel approach of sacrificial cathodic protection of mild steel in simulated concrete pore solution and concrete mortar by high phosphorus pig iron anodes. J. Mater. Res. Technol. 2021, 14, 582–608. [Google Scholar] [CrossRef]

- Ress, J.; Martin, U.; Bosch, J.; Bastidas, D.M. Protection of carbon steel rebars by epoxy coating with smart environmentally friendly microcapsules. Coatings 2021, 11, 113. [Google Scholar] [CrossRef]

- Ress, J.; Martin, U.; Bastidas, D.M. Improved corrosion protection of acrylic waterborne coating by doping with microencapsulated corrosion inhibitors. Coatings 2021, 11, 1134. [Google Scholar] [CrossRef]

- Bolzoni, F.; Brenna, A.; Ormellese, M. Recent advances in the use of inhibitors to prevent chloride-induced corrosion in reinforced concrete. Cem. Concr. Res. 2022, 154, 106719. [Google Scholar] [CrossRef]

- Ress, J.; Martin, U.; Bosch, J.; Bastidas, D.M. pH-triggered release of NaNO2 corrosion inhibitors from novel colophony microcapsules in simulated concrete pore solution. ACS Appl. Mater. Interfaces 2020, 12, 46686–46700. [Google Scholar] [CrossRef]

- Bastidas, D.M.; Martin, U.; Bastidas, J.M.; Ress, J. Corrosion inhibition mechanism of steel reinforcements in mortar using soluble phosphates: A critical review. Materials 2021, 14, 6168. [Google Scholar] [CrossRef]

- Bastidas, D.M.; La Iglesia, V.; Criado, M.; Fajardo, S.; La Iglesia, A.; Bastidas, J.M. A prediction study of hydroxyapatite entrapment ability in concrete. Constr. Build. Mater. 2010, 24, 2646–2649. [Google Scholar] [CrossRef]

- Leek, D.S. The passivity of steel in concrete. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 55–66. [Google Scholar] [CrossRef]

- Feng, W.; Tarakbay, A.; Memon, S.A.; Tang, W.; Cui, H. Methods of accelerating chloride-induced corrosion in steel-reinforced concrete: A comparative review. Constr. Build. Mater. 2021, 289, 123165. [Google Scholar] [CrossRef]

- Andrade, C. Evaluation of the degree of carbonation of concretes in three environments. Constr. Build. Mater. 2019, 230, 116804. [Google Scholar] [CrossRef]

- Das, J.K.; Pradhan, B. Study on influence of nitrite and phosphate based inhibiting admixtures on chloride interaction, rebar corrosion, and microstructure of concrete subjected to different chloride exposures. J. Build. Eng. 2022, 50. [Google Scholar] [CrossRef]

- Das, J.K.; Pradhan, B. Effect of sodium nitrite on chloride-induced corrosion of steel in concrete. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Zuo, J.; Wu, B.; Luo, C.; Dong, B.; Xing, F. Preparation of MgAl layered double hydroxides intercalated with nitrite ions and corrosion protection of steel bars in simulated carbonated concrete pore solution. Corros. Sci. 2019, 152, 120–129. [Google Scholar] [CrossRef]

- Zhou, Y.; Oehmen, A.; Lim, M.; Vadivelu, V.; Ng, W.J. The role of nitrite and free nitrous acid (FNA) in wastewater treatment plants. Water Res. 2011, 45, 4672–4682. [Google Scholar] [CrossRef]

- Khani, H.; Arefinia, R. Inhibition mechanism of nitrite on the corrosion of carbon steel in simulated cooling water systems. Mater. Corros. 2017, 69, 337–347. [Google Scholar] [CrossRef]

- Karim, S.; Mustafa, C.M.; Assaduzzaman, M.; Islam, M. Effect of nitrate ion on corrosion inhibition of mild steel in simulated cooling water. Chem. Eng. Res. Bull. 2010, 14, 87–91. [Google Scholar] [CrossRef]

- Maliekkal, B.P.; Kakkassery, J.T.; Palayoor, V.R. Efficacies of sodium nitrite and sodium citrate–zinc acetate mixture to inhibit steel rebar corrosion in simulated concrete interstitial solution contaminated with NaCl. Int. J. Ind. Chem. 2018, 9, 105–114. [Google Scholar] [CrossRef]

- Ramasubramanian, M.; Haran, B.S.; Popova, S.; Popov, B.N.; Petrou, M.; White, R.E. Inhibiting action of calcium nitrite on carbon steel rebars. J. Mater. Civ. Eng. 2001, 13, 10–17. [Google Scholar] [CrossRef]

- Saricimen, H.; Mohammad, M.; Quddus, A.; Shameem, M.; Barry, M. Effectiveness of concrete inhibitors in retarding rebar corrosion. Cem. Concr. Compos. 2002, 24, 89–100. [Google Scholar] [CrossRef]

- Tommaselli, M.; Mariano, N.; Kuri, S. Effectiveness of corrosion inhibitors in saturated calcium hydroxide solutions acidified by acid rain components. Constr. Build. Mater. 2009, 23, 328–333. [Google Scholar] [CrossRef]

- Dhouibi, L.; Triki, E.; Raharinaivo, A. The application of electrochemical impedance spectroscopy to determine the long-term effectiveness of corrosion inhibitors for steel in concrete. Cem. Concr. Compos. 2002, 24, 35–43. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, B.; Deng, Y.; Yang, L.; Zhang, J. Nitrate on localized corrosion of carbon steel and stainless steel in aqueous solutions. Electrochim. Acta 2020, 369, 137660. [Google Scholar] [CrossRef]

- Lee, H.-S.; Shin, S.-W. Evaluation on the effect of lithium nitrite corrosion inhibitor by the corrosion sensors embedded in mortar. Constr. Build. Mater. 2007, 21, 1–6. [Google Scholar] [CrossRef]

- Pradhan, B. A study on effectiveness of inorganic and organic corrosion inhibitors on rebar corrosion in concrete: A review. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, J.; Li, G.; Wang, P.; Wang, P.; Li, F.; Zhang, B.; Chi, H. Corrosion inhibition efficiency of compound nitrite with D-sodium gluconate on carbon steel in simulated concrete pore solution. Constr. Build. Mater. 2021, 288, 123101. [Google Scholar] [CrossRef]

- Tsikas, D. Analysis of nitrite and nitrate in biological fluids by assays based on the Griess reaction: Appraisal of the Griess reaction in the l-arginine/nitric oxide area of research. J. Chromatogr. B 2007, 851, 51–70. [Google Scholar] [CrossRef]

- Griess, P. On a new series of bodies in which nitrogen substituted for hydrogen. Philos. Trans. R. Soc. Lond. 1864, 154, 667–731. [Google Scholar] [CrossRef][Green Version]

- Çopuroğlu, O.; Fraaij, A.; Bijen, J. Effect of sodium monofluorophosphate treatment on microstructure and frost salt scaling durability of slag cement paste. Cem. Concr. Res. 2006, 36, 1475–1482. [Google Scholar] [CrossRef]

- Becke, A.D. Density-functional exchange-energy approximation with correct asymptotic behavior. Phys. Rev. A 1988, 38, 3098–3100. [Google Scholar] [CrossRef] [PubMed]

- Ditchfield, R.; Hehre, W.J.; Pople, J.A. Self-consistent molecular-orbital methods. IX. An extended Gaussian-type basis for molecular-orbital studies of organic molecules. J. Chem. Phys. 1971, 54, 724–728. [Google Scholar] [CrossRef]

- Brug, G.J.; Van Den Eeden, A.L.G.; Sluyters-Rehbach, M.; Sluyters, J.H. The analysis of electrode impedances complicated by the presence of a constant phase element. J. Electroanal. Chem. Interfacial Electrochem. 1984, 176, 275–295. [Google Scholar] [CrossRef]

- Mansfeld, F.; Shih, H.; Greene, H.; Tsai, C.H. Analysis of EIS Data for Common Corrosion Processes; Scully, J.R., Silverman, C., Kendig, M.W., Eds.; ASTM International: West Conshohocken, PA, USA, 1993; pp. 37–53. [Google Scholar]

- Liu, J.; Macdonald, D.D. The passivity of iron in the presence of ethylenediaminetetraacetic acid. II. The defect and electronic structures of the barrier layer. J. Electrochem. Soc. 2001, 148, B425–B430. [Google Scholar] [CrossRef]

- Garcés, P.; Saura, P.; Zornoza, E.; Andrade, C. Influence of pH on the nitrite corrosion inhibition of reinforcing steel in simulated concrete pore solution. Corros. Sci. 2011, 53, 3991–4000. [Google Scholar] [CrossRef]

- Montemor, M.F.; Simoes, A.; Ferreira, M. Analytical characterization of the passive film formed on steel in solutions simulating the concrete interstitial electrolyte. Corrosion 1998, 54, 347–353. [Google Scholar] [CrossRef]

- Paredes, C.; Bautista, M.A.; Alvarez, S.; Velasco, F.J. Influence of the forming process of corrugated stainless steels on their corrosion behaviour in simulated pore solutions. Corros. Sci. 2012, 58, 52–61. [Google Scholar] [CrossRef]

- Ellobody, E. Chapter 2—Nonlinear Material Behavior of the Bridge Components. In Finite Element Analysis and Design of Steel and Steel-Concrete Composite Bridges; Butterworth-Heinemann: Oxford, UK, 2014; pp. 47–111. [Google Scholar]

- Sayed, A.; El-Lateef, H. Thiocarbohydrazones based on adamantane and ferrocene as efficient corrosion inhibitors for hydrochloric acid pickling of C-steel. Coatings 2020, 10, 1068. [Google Scholar] [CrossRef]

- Mohamed, A.; Visco, D.P.; Bastidas, D.M. Significance of π–electrons in the design of corrosion inhibitors for carbon steel in simulated concrete pore solution. Corrosion 2021, 77, 976–990. [Google Scholar] [CrossRef]

- Hadisaputra, S.; Purwoko, A.; Savalas, L.; Prasetyo, N.; Yuanita, E.; Hamdiani, S. Quantum chemical and Monte Carlo simulation studies on inhibition performance of caffeine and its derivatives against corrosion of copper. Coatings 2020, 10, 1086. [Google Scholar] [CrossRef]

- Hamani, H.; Daoud, D.; Benabid, S.; Douadi, T. Electrochemical, density functional theory (DFT) and molecular dynamic (MD) simulations studies of synthesized three news Schiff bases as corrosion inhibitors on mild steel in the acidic environment. J. Indian Chem. Soc. 2022, 99, 100492. [Google Scholar] [CrossRef]

- Obi-Egbedi, N.; Obot, I.; El-Khaiary, M.I. Quantum chemical investigation and statistical analysis of the relationship between corrosion inhibition efficiency and molecular structure of xanthene and its derivatives on mild steel in sulphuric acid. J. Mol. Struct. 2011, 1002, 86–96. [Google Scholar] [CrossRef]

- Niamien, P.; Essy, K.F.; Trokourey, A.; Yapi, A.; Aka, H.; Diabate, D. Correlation between the molecular structure and the inhibiting effect of some benzimidazole derivatives. Mater. Chem. Phys. 2012, 136, 59–65. [Google Scholar] [CrossRef]

- Ebenso, E.E.; Isabirye, D.A.; Eddy, N.O. Adsorption and quantum chemical studies on the inhibition potentials of some thiosemicarbazides for the corrosion of mild steel in acidic medium. Int. J. Mol. Sci. 2010, 11, 2473–2498. [Google Scholar] [CrossRef]

| C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.28 | 1.08 | 0.019 | 0.043 | 0.20 | 0.37 | 0.16 | 0.16 | 0.050 | 0.0379 | Bal. |

| Temp. °C | Molar Ratio NO2−:NO3− | Rs Ω cm2 | Rf Ω cm2 | Rct Ω cm2 | Yf S cm−2 snf | nf | Ydl S cm−2 sndl | ndl | χ2 | Ceff,f F cm−2 | Ceff,dl F cm−2 | deff nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 1:0.5 | 19 | 1.67 × 103 | 1.31 × 105 | 7.50 × 10−5 | 0.75 | 1.66 × 10−6 | 0.77 | 9.18 × 10−4 | 3.03 × 10−4 | 9.40 × 10−8 | 9 |

| 0.5:1 | 18 | 1.31 × 103 | 1.09 × 105 | 6.07 × 10−5 | 0.75 | 9.61 × 10−6 | 0.79 | 2.26 × 10−3 | 4.29 × 10−4 | 4.18 × 10−7 | 6 | |

| 1:1 | 18 | 1.60 × 103 | 2.39 × 105 | 7.69 × 10−5 | 0.72 | 8.87 × 10−6 | 0.72 | 9.40 × 10−4 | 3.74 × 10−4 | 1.40 × 10−7 | 7 | |

| 35 | 1:0.5 | 21 | 1.92 × 103 | 1.76 × 105 | 5.54 × 10−5 | 0.76 | 3.76 × 10−6 | 0.80 | 3.90 × 10−4 | 3.78 × 10−4 | 3.54 × 10−7 | 7 |

| 0.5:1 | 22 | 1.61 × 103 | 1.66 × 104 | 8.35 × 10−6 | 0.76 | 4.01 × 10−5 | 0.78 | 9.61 × 10−4 | 4.98 × 10−4 | 3.95 × 10−5 | 5 | |

| 1:1 | 21 | 1.80 × 103 | 1.04 × 105 | 2.28 × 10−5 | 0.71 | 4.44 × 10−6 | 0.70 | 1.70 × 10−3 | 4.60 × 10−4 | 4.58 × 10−7 | 6 | |

| 45 | 1:0.5 | 23 | 5.15 × 103 | 1.98 × 104 | 2.44 × 10−4 | 0.81 | 1.40 × 10−4 | 0.72 | 2.04 × 10−3 | 4.47 × 10−4 | 7.90 × 10−6 | 6 |

| 0.5:1 | 22 | 2.27 × 103 | 9.28 × 103 | 1.89 × 10−4 | 0.75 | 5.83 × 10−4 | 0.71 | 4.69 × 10−4 | 6.05 × 10−4 | 1.81 × 10−5 | 4 | |

| 1:1 | 24 | 3.59 × 103 | 1.34 × 104 | 2.08 × 10−4 | 0.75 | 1.44 × 10−4 | 0.88 | 6.94 × 10−4 | 5.07 × 10−4 | 6.16 × 10−5 | 5 |

| Temperature °C | Molar Ratio NO2–:NO3– | Ecorr mVSCE | icorr A/cm2 | βa V/dec | –βc V/dec | IE % | Rp Ω cm2 |

|---|---|---|---|---|---|---|---|

| 25 | Control | −487 | 1.49 × 10−6 | 0.082 | 0.126 | - | - |

| 0.5:1 | −345 | 4.32 × 10−7 | 0.229 | 0.185 | 71 | 1.33 × 105 | |

| 1:1 | −341 | 1.51 × 10−7 | 0.257 | 0.159 | 90 | 1.11 × 105 | |

| 1:0.5 | −303 | 1.16 × 10−7 | 0.503 | 0.187 | 93 | 2.41 × 105 | |

| 35 | Control | −440 | 2.01 × 10−6 | 0.110 | 0.191 | - | - |

| 0.5:1 | −325 | 6.38 × 10−7 | 0.115 | 0.096 | 68 | 1.78 × 105 | |

| 1:1 | −326 | 4.34 × 10−7 | 0.211 | 0.142 | 78 | 1.82 × 104 | |

| 1:0.5 | −299 | 2.07 × 10−7 | 0.412 | 0.354 | 90 | 1.05 × 105 | |

| 45 | Control | −449 | 3.81 × 10−6 | 0.098 | 0.208 | - | - |

| 0.5:1 | −343 | 1.27 × 10−6 | 0.183 | 0.229 | 67 | 2.50 × 104 | |

| 1:1 | −305 | 9.07 × 10−7 | 0.191 | 0.191 | 76 | 1.16 × 104 | |

| 1:0.5 | −257 | 7.75 × 10−7 | 0.204 | 0.201 | 80 | 1.72 × 104 |

| Corrosion Inhibitor Blend | Rs Ω cm2 | Rf Ω cm2 | Rct Ω cm2 | Yf S cm–2 snf | nf | Ydl S cm–2 sndl | ndl | χ2 |

|---|---|---|---|---|---|---|---|---|

| Yara | 16 | 969 | 2.44 × 105 | 3.02 × 10−5 | 0.71 | 6.12 × 10−6 | 0.75 | 2.99 × 10−3 |

| Sika | 16 | 1230 | 1.25 × 107 | 2.82 × 10−5 | 0.70 | 2.14 × 10−6 | 0.78 | 4.68 × 10−3 |

| Control | 21 | 20 | 4.72 × 103 | 5.46 × 10−4 | 0.84 | 9.15 × 10−6 | 0.71 | 2.74 × 10−3 |

| Corrosion Inhibitor Blend | Ecorr mVSCE | icorr A/cm2 | IE % |

|---|---|---|---|

| Sika | −292 | 4.27 × 10−7 | 71 |

| Yara | −336 | 5.62 × 10−7 | 62 |

| Control | −487 | 1.49 × 10−6 | - |

| Inhibitor | EHOMO eV | ELUMO eV | ΔE eV | µD eV |

|---|---|---|---|---|

| NO2− | −5.55 | −0.55 | −5.74 | 121.91 |

| NO3− | −6.49 | −0.78 | −5.45 | 199.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ress, J.; Martin, U.; Breimaier, K.; Bastidas, D.M. Electrochemical and DFT Study of NaNO2/NaNO3 Corrosion Inhibitor Blends for Rebar in Simulated Concrete Pore Solution. Coatings 2022, 12, 861. https://doi.org/10.3390/coatings12060861

Ress J, Martin U, Breimaier K, Bastidas DM. Electrochemical and DFT Study of NaNO2/NaNO3 Corrosion Inhibitor Blends for Rebar in Simulated Concrete Pore Solution. Coatings. 2022; 12(6):861. https://doi.org/10.3390/coatings12060861

Chicago/Turabian StyleRess, Jacob, Ulises Martin, Karl Breimaier, and David M. Bastidas. 2022. "Electrochemical and DFT Study of NaNO2/NaNO3 Corrosion Inhibitor Blends for Rebar in Simulated Concrete Pore Solution" Coatings 12, no. 6: 861. https://doi.org/10.3390/coatings12060861

APA StyleRess, J., Martin, U., Breimaier, K., & Bastidas, D. M. (2022). Electrochemical and DFT Study of NaNO2/NaNO3 Corrosion Inhibitor Blends for Rebar in Simulated Concrete Pore Solution. Coatings, 12(6), 861. https://doi.org/10.3390/coatings12060861