Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions

Abstract

1. Introduction

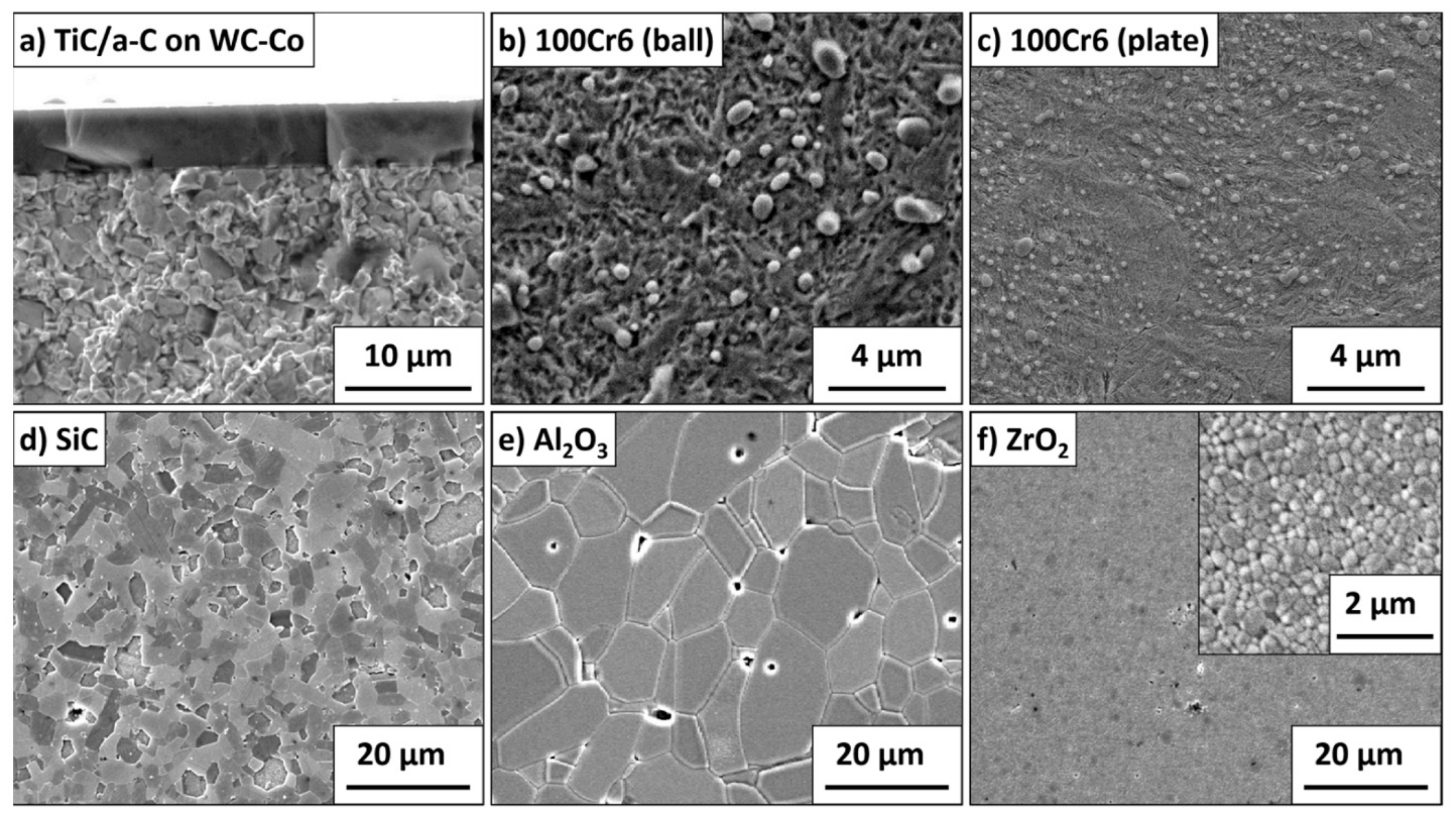

2. Materials and Methods

2.1. Thin Films

2.2. Tribology

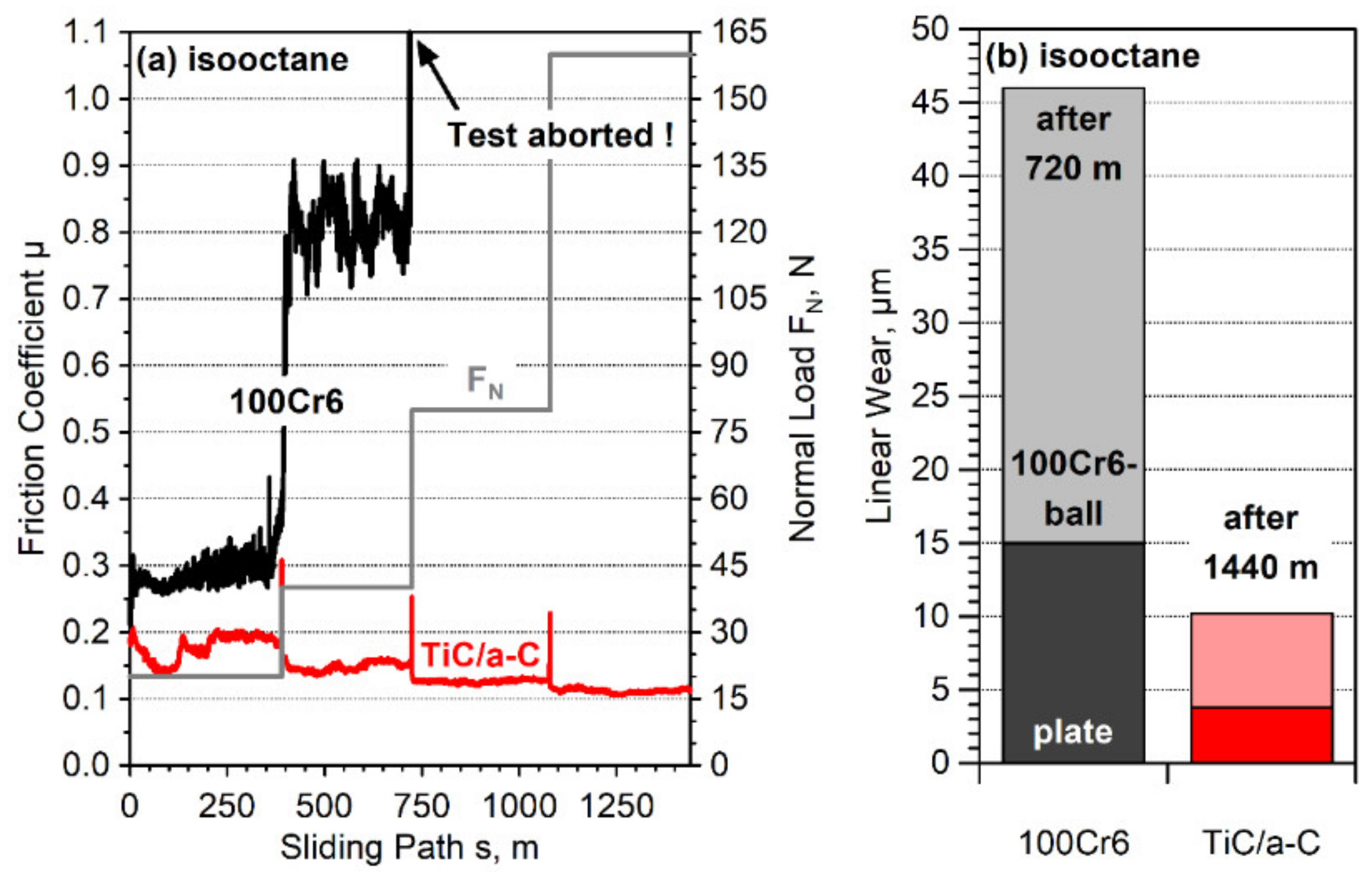

3. Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Voevodin, A.A.; Prasad, S.V.; Zabinski, J.S. Nanocrystalline carbide/amorphous carbon composites. J. Appl. Phys. 1997, 82, 855–858. [Google Scholar] [CrossRef]

- Zehnder, T.; Patscheider, J. Nanocomposite TiC/a-C:H hard coatings deposited by reactive PVD. Surf. Coat. Technol. 2000, 133–134, 138–144. [Google Scholar] [CrossRef]

- Pei, Y.T.; Galvan, D.; De Hosson, J.T.M.; Cavaleiro, A. Nanostructured TiC/a-C coatings for low friction and wear resistant applications. Surf. Coat. Technol. 2005, 198, 44–50. [Google Scholar] [CrossRef]

- Martinez-Martinez, D.; López-Cartes, C.; Fernández, A.; Sánchez-López, J.C. Comparative performance of nanocomposite coatings of TiC or TiN dispersed in a-C matrixes. Surf. Coat. Technol. 2008, 203, 756–760. [Google Scholar] [CrossRef]

- Musil, J.; Novák, P.; Cerstvý, R.; Soukup, Z. Tribological and mechanical properties of nanocrystalline TiC/a-C nanocomposite thin films. J. Vac. Sci. Technol. A 2010, 28, 244–249. [Google Scholar] [CrossRef]

- Soucek, P.; Schmidtová, T.; Bursikova, V.; Vasina, P.; Pei, Y.T.; De Hosson, J.T.M.; Caha, O.; Perina, V.; Miksova, R.; Malinsky, P. Tribological properties of nc-TiC/a-C:H coatings prepared by magnetron sputtering at low and high ion bombardment of the growing film. Surf. Coat. Technol. 2014, 241, 64–73. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, F.-C.; Lee, J.-W.; Chang, C.-L. Effect of an optical emission spectrometer feedback-controlled method on the characterizations of nc-TiC/a-C:H coated by high power impulse magnetron sputtering. Diam. Relat. Mater. 2017, 73, 19–24. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Dominguez-Meister, S.; Rojas, T.C.; Colasuonno, M.; Bazzan, M.; Patelli, A. Tribological properties of TiC/a-C:H nanocomposite coatings prepared by HIPIMS. Appl. Surf. Sci. 2018, 440, 458–466. [Google Scholar] [CrossRef]

- Hauert, R.; Patscheider, J. From alloying to nanocomposites—Improved performance of hard coatings. Adv. Eng. Mater. 2000, 2, 247–259. [Google Scholar] [CrossRef]

- Patscheider, J.; Zehnder, T.; Diserens, M. Structure-property relations in nanocomposite coatings. Surf. Coat. Technol. 2001, 146–147, 201–208. [Google Scholar] [CrossRef]

- Pei, Y.T.; Galvan, D.; De Hosson, J.T.M. Nanostructure and properties of TiC/a-C:H composite coatings. Acta Mater. 2005, 53, 4505–4521. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Martinez-Martinez, D.; López-Cartes, C.; Fernández, A. Tribological behavior of titanium carbide/amorphous carbon nanocomposite coatings: From macro to the micro-scale. Surf. Coat. Technol. 2008, 202, 4011–4018. [Google Scholar] [CrossRef]

- Jansson, U.; Lewin, E.; Rasander, M.; Eriksson, O.; André, B.; Wiklund, U. Design of carbide-based nanocomposite thin films by selective alloying. Surf. Coat. Technol. 2011, 206, 583–590. [Google Scholar] [CrossRef]

- Jansson, U.; Lewin, E. Sputter deposition of transition-metal carbide films—A critical review from a chemical perspective. Thin Solid Film. 2013, 536, 1–24. [Google Scholar] [CrossRef]

- Larhlimi, H.; Ghailane, A.; Makha, M.; Alami, J. Magnetron sputtered titanium carbide-based coatings: A review of science and technology. Vacuum 2022, 197, 110853. [Google Scholar] [CrossRef]

- Feng, B.; Cao, D.M.; Meng, W.J.; Xu, J.; Tittsworth, R.C.; Rehn, L.E.; Baldo, P.M.; Doll, G.L. Characterization of microstructure and mechanical behavior of sputter deposited Ti-containing amorphous carbon coatings. Surf. Coat. Technol. 2001, 148, 153–162. [Google Scholar] [CrossRef]

- Zhang, S.; Bui, X.L.; Jiang, J.; Li, X. Microstructure and tribological properties of magnetron-sputtered nc-TiC/a-C nanocomposite. Surf. Coat. Technol. 2005, 198, 206–211. [Google Scholar] [CrossRef]

- Lewin, E.; Wilhelmsson, O.; Jansson, U. Nanocomposite nc-TiC/a-C thin films for electrical contact applications. J. Appl. Phys. 2006, 100, 054303. [Google Scholar] [CrossRef]

- Moskalewicz, T.; Wendler, B.; Czyrska-Filemonowicz, A. Microstructural characterization of nanocomposite nc-MeC/a-C coatings on oxygen hardened Ti-6Al-4V alloy. Mater. Charact. 2010, 61, 959–968. [Google Scholar] [CrossRef]

- Balászi, K.; Vandrovcová, M.; Bacaková, L.; Balászi, C. Structural and biocompatible characterization of TiC/a:C nanocomposite thin films. Mater. Sci. Eng. C 2013, 33, 1671–1675. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Martinez-Martinez, D.; Abad, M.D.; Fernández, A. Metal carbide/amorphous C-based nanocomposite coatings for tribological applications. Surf. Coat. Technol. 2009, 204, 947–954. [Google Scholar] [CrossRef]

- Glechner, T.; Hahn, R.; Zauner, L.; Rißlegger, S.; Kirnbauer, A.; Polcik, P.; Riedl, H. Structure and mechanical properties of reactive and non-reactive sputter deposited WC based coatings. J. Alloy. Compd. 2021, 885, 161129. [Google Scholar] [CrossRef]

- Stüber, M.; Leiste, H.; Ulrich, S.; Holleck, H.; Schild, D. Microstructure and properties of low friction TiC-C nanocomposite coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2002, 150, 218–226. [Google Scholar] [CrossRef]

- Hu, Y.; Li, L.; Cai, X.; Chen, Q.; Chu, P.K. Mechanical and tribological properties of TiC/amorphous hydrogenated carbon composite coatings fabricated by DC magnetron sputtering with and without sample bias. Diam. Relat. Mater. 2007, 16, 181–186. [Google Scholar] [CrossRef]

- Polcar, T.; Vitu, T.; Cvrcek, L.; Novak, R.; Vyskocil, J.; Cavaleiro, A. Tribological behaviour of nanostructured Ti-C:H coatings for biomedical applications. Solid State Sci. 2009, 11, 1757–1761. [Google Scholar] [CrossRef]

- Soucek, P.; Schmidtová, T.; Zábransky, L.; Bursikova, V.; Vasina, P.; Caha, O.; Jilek, M.; El Mel, A.; Tessier, P.-Y.; Schäfer, J.; et al. Evaluation of composition, mechanical properties and structure of nc-TiC/a-C:H coatings prepared by balanced magnetron sputtering. Surf. Coat. Technol. 2012, 211, 111–116. [Google Scholar] [CrossRef]

- Makowka, M.; Pawlak, W.; Konarski, P.; Wendler, B. Hydrogen content influence on tribological properties of nc-WC/a-C:H coatings. Diam. Relat. Mater. 2016, 67, 16–25. [Google Scholar] [CrossRef]

- Singh, V.; Jiang, J.C.; Meletis, E.I. Cr-diamondlike carbon nanocomposite thin films: Synthesis, characterization and properties. Thin Solid Film. 2005, 489, 150–158. [Google Scholar] [CrossRef]

- Gassner, G.; Patscheider, J.; Mayrhofer, P.H.; Hegedus, E.; Tóth, L.; Kovacs, I.; Pécz, B.; Srot, V.; Scheu, C.; Mitterer, C. Structure of sputtered nanocomposite CrCx/a-C:H thin films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Processing Meas. Phenom. 2006, 24, 1837–1843. [Google Scholar] [CrossRef]

- Keunecke, M.; Bewilogua, K.; Becker, J.; Gies, A.; Grischke, M. CrC/a-C:H coatings for highly loaded, low friction applications under formulated oil lubrication. Surf. Coat. Technol. 2012, 207, 270–278. [Google Scholar] [CrossRef]

- Meng, W.J.; Tittsworth, R.C.; Rehn, L.E. Mechanical properties and microstructure of TiC/amorphous hydrocarbon nanocomposite coatings. Thin Solid Film. 2000, 377–378, 222–232. [Google Scholar] [CrossRef]

- Voevodin, A.A.; O`Neill, J.P.; Prasad, S.V.; Zabinski, J.S. Nanocrystalline WC and WC/a-C composite coatings produced from intersected plasma fluxes at low deposition temperature. J. Vac. Sci. Technol. A 1999, 17, 986–992. [Google Scholar] [CrossRef]

- Zhou, Z.; Rainforth, W.M.; Gass, M.H.; Bleloch, A.; Ehiassarian, A.P.; Hovsepian, P.E. C/CrC nanocomposite coating deposited by magnetron sputtering at high ion irradiation conditions. J. Appl. Phys. 2011, 110, 073301. [Google Scholar] [CrossRef]

- Makówka, M.; Pawlak, W.; Konarski, P.; Wendler, B.; Szymanowski, H. Modification of magnetron sputter deposition of nc-WC/a-C(:H) coatings with an additional RF discharge. Diam. Relat. Mater. 2019, 98, 107509. [Google Scholar] [CrossRef]

- Coronel, E.; Wiklund, U.; Olsson, E. The effect of carbon content on the microstructure of hydrogen-free physical vapour deposited titanium carbide films. Thin Solid Film. 2009, 518, 71–76. [Google Scholar] [CrossRef]

- Pei, Y.T.; Chen, C.Q.; Shaha, K.P.; De Hosson, J.Th.M.; Bradley, J.W.; Voronin, S.A.; Cada, M. Microstructural control of TiC/a-C nanocomposite coatings with pulsed magnetron sputtering. Acta Mater. 2008, 56, 696–709. [Google Scholar] [CrossRef]

- Precht, W.; Czyzniewski, A. Deposition and some properties of carbide/amorphous carbon nanocomposites for tribological application. Surf. Coat. Technol. 2003, 174–175, 979–983. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Mishra, B.; Pinkas, M.; Sproul, W.D. Syntheses and characterization of TiC/a:C composite coatings using pulsed closed field unbalanced magnetron sputtering (P-CFUBMS). Thin Solid Film. 2008, 517, 1131–1135. [Google Scholar] [CrossRef]

- Gulbinski, W.; Mathur, S.; Shen, H.; Suszko, T.; Gilewicz, A.; Warcholinski, B. Evaluation of phase, composition, microstructure and properties in TiC/a-C:H thin films deposited by magnetron sputtering. Appl. Surf. Sci. 2005, 239, 302–310. [Google Scholar] [CrossRef]

- Shaha, K.P.; Pei, Y.T.; Martinez-Martinez, D.; Sanchez-Lopez, J.C.; De Hosson, J.T.M. Effect of process parameters on mechanical an tribological performance of pulsed-DC sputtered TiC/a-C:H nanocomposite films. Surf. Coat. Technol. 2010, 205, 2633–2642. [Google Scholar] [CrossRef]

- Samuelsson, M.; Sarakinos, K.; Högberg, H.; Lewin, E.; Jansson, U.; Wälivaara, B.; Ljungcrantz, H.; Helmersson, U. Growth of Ti-C nanocomposite films by reactive high power impulse magnetron sputtering under industrial conditions. Surf. Coat. Technol. 2012, 206, 2396–2402. [Google Scholar] [CrossRef]

- Soucek, P.; Daniel, J.; Hnilica, J.; Bernátova, K.; Zábransky, L.; Bursikova, V.; Stupavski, M.; Vasina, P. Superhard nanocomposite nc-TiC/a-C:H coatings: The effect of HIPIMS on coating microstructure and mechanical properties. Surf. Coat. Technol. 2017, 311, 257–267. [Google Scholar] [CrossRef]

- Lou, B.-S.; Hsiao, Y.-T.; Chang, L.-C.; Diyatmika, W.; Lee, J.-W. The influence of different power supply modes on the microstructure, mechanical, and corrosion properties of nc-TiC/a-C:H nanocomposite coatings. Surf. Coat. Technol. 2021, 422, 127512. [Google Scholar] [CrossRef]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Room and high temperature tribological behaviour of W-DLC coatings produced by DCMS and hybrid DCMS-HIPIMS configuration. Coatings 2020, 10, 319. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Wu, X.; Zhang, H.; Zhang, X. Superhard nanocomposite nc-TiC/a-C:H film fabricated by filtered cathodic vacuum arc technique. Appl. Surf. Sci. 2008, 254, 5085–5088. [Google Scholar] [CrossRef]

- Zhai, Y.-H.; Zhang, Y.-J.; Peng, Y.; Zhang, S.-M.; Zhang, P.-Y.; Zhang, X.-M. Structure and mechanical properties of nc-TiC/a-C:H nanocomposite films deposited by filtered cathodic arc technique. Rare Met. 2016, 35, 177–183. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Z.Q.; Pang, P.; Chen, L.; Liao, B.; Shang, H.Z.; Zhang, X.; Wu, X.Y. Low friction coefficient of superhard nc-TiC/a-C:H nanocomposite coatings deposited by filtered cathodic vacuum arc. Mater. Res. Express 2019, 6, 096418. [Google Scholar] [CrossRef]

- Strondl, C.; Carvalho, N.M.; De Hosson, J.Th.M.; van der Kolk, G.J. Investigation on the formation of tungsten carbide in tungsten-containing diamond like carbon coatings. Surf. Coat. Technol. 2003, 162, 288–293. [Google Scholar] [CrossRef]

- Abad, M.D.; Munoz-Marquez, M.A.; El Mrabet, S.; Justo, A.; Sánchez-López, J.C. Tailored synthesis of nanostructured WC/a-C coatings by dual magnetron sputtering. Surf. Coat. Technol. 2010, 204, 3490–3500. [Google Scholar] [CrossRef]

- Drábik, M.; Truchlý, M.; Ballo, V.; Roch, T.; Kvetková, L.; Kús, P. Influence of substrate material and its plasma pretreatment on adhesion and properties of WC/a-C:H nanocomposite coatings deposited at low temperature. Surf. Coat. Technol. 2018, 333, 138–147. [Google Scholar] [CrossRef]

- Chang, C.-L.; Yang, F.-C.; Chang, T.-M.; Hwang, J.-J. Effect of insert mid-frequency pulses on I-V characterisation, deposition rates and properties of nc-WC/a-C:H films prepared by superimposed HIPIMS process. Surf. Coat. Technol. 2018, 350, 977–984. [Google Scholar] [CrossRef]

- Gassner, G.; Patscheider, J.; Mayrhofer, P.H.; Sturm, S.; Scheu, C.; Mitterer, C. Tribological properties of nanocomposite CrCx/a-C:H thin films. Tribol. Lett. 2007, 27, 97–104. [Google Scholar] [CrossRef]

- Yate, L.; Martinez-de-Olcoz, L.; Esteve, J.; Lousa, A. Effect of the bias voltage on the structure of nc-CrC/a-C:H coatings with high carbon content. Surf. Coat. Technol. 2012, 206, 2877–2883. [Google Scholar] [CrossRef]

- Nygren, K.; Andersson, M.; Högström, J.; Frederiksson, W.; Edström, K.; Nyholm, L.; Jansson, U. Influence of deposition temperature and amorphous carbon on microstructure and oxidation resistance of magnetron sputtered nanocomposite Cr-C films. Appl. Surf. Sci. 2014, 305, 143–153. [Google Scholar] [CrossRef]

- Nilsson, D.; Svahn, F.; Wiklund, U.; Hogmark, S. Low-friction carbon-rich carbide coatings deposited by co-sputtering. Wear 2003, 254, 1084–1091. [Google Scholar] [CrossRef]

- Bobzin, K.; Lugscheider, E.; Maes, M. PVD-Niedertemperaturbeschichtung für Bauteile zur Integration tribologischer Funktionen in die Oberfläche. Mat. Wiss. U. Werkstofftech. 2004, 35, 843–850. [Google Scholar] [CrossRef]

- Meng, Q.N.; Wen, M.; Mao, F.; Nedfors, N.; Jansson, U.; Zheng, W.T. Deposition and characterization of magnetron sputtered zirconium carbide films. Surf. Coat. Technol. 2013, 232, 876–883. [Google Scholar] [CrossRef]

- Escudeiro, A.; Figueiredo, N.M.; Polcar, T.; Cavaleiro, A. Structural and mechanical properties of nanocrystalline Zr co-sputtered a-C(:H) amorphous films. Appl. Surf. Sci. 2015, 325, 64–72. [Google Scholar] [CrossRef]

- Braic, M.; Braic, V.; Balaceanu, M.; Vladescu, A.; Zoita, C.N.; Titorenco, I.; Jinga, V.; Miculescu, F. Preparation and characterization of biocompatible Nb-C coatings. Thin Solid Film. 2011, 519, 4064–4068. [Google Scholar] [CrossRef]

- Nedfors, N.; Tengstrand, O.; Lewin, E.; Furlan, A.; Eklund, P.; Hultman, L.; Jansson, U. Structural, mechanical and electrical-contact properties of nanocrystalline-NbC/amorphous-C coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2011, 206, 354–359. [Google Scholar] [CrossRef]

- Nedfors, N.; Tengstrand, O.; Flink, A.; Andersson, A.M.; Eklund, P.; Hultman, L.; Jansson, U. Reactive sputtering of NbCx-based nanocomposite coatings: An up-scaling study. Surf. Coat. Technol. 2014, 253, 100–108. [Google Scholar] [CrossRef]

- Aouni, A.; Weisbecker, P.; Loi, T.H.; Bauer-Grosse, E. Search for new materials in sputtered V1−xCx films. Thin Solid Film. 2004, 469, 315–321. [Google Scholar] [CrossRef]

- Krause, M.; Mücklich, A.; Wilde, C.; Vinnichenko, M.; Gemming, S.; Abrasonis, G. Structure, optical and mechanical properties of direct current magnetron sputtered carbon: Vanadium nanocomposite thin films. Nanosci. Nanotechnol. Lett. 2013, 5, 94–100. [Google Scholar] [CrossRef]

- Heras, I.; Krause, M.; Abrasonis, G.; Pardo, A.; Endrino, J.L.; Guillén, E.; Escobar-Galindo, R. Advanced characterization and optical simulation for the design of solar selective coatings based on carbon:transition metal carbide nanocomposites. Sol. Energy Mater. Sol. Cells 2016, 157, 580–590. [Google Scholar] [CrossRef]

- Stoyanov, P.; Schneider, J.; Rinke, M.; Ulrich, S.; Nold, E.; Dienwiebel, M.; Stüber, M. Microstructure, mechanical properties and friction behavior of magnetron-sputtered V-C coatings. Surf. Coat. Technol. 2017, 321, 366–377. [Google Scholar] [CrossRef]

- Olofsson, J.; Gerth, J.; Nyberg, H.; Wiklund, U.; Jacobson, S. On the influence from micro topography of PVD coatings on friction behaviour, material transfer and tribofilm formation. Wear 2011, 271, 2046–2057. [Google Scholar] [CrossRef]

- Hu, J.; Li, H.; Li, J.; Huang, J.; Kong, J.; Zhu, H.; Xiong, D. Structure, mechanical and tribological properties of TaCx composite films with different graphite powers. J. Alloy. Compd. 2020, 832, 153769. [Google Scholar] [CrossRef]

- Luo, H.; Yazdi, M.A.P.; Chen, S.-C.; Sun, H.; Gao, F.; Heintz, O.; de Monteynard, A.; Sanchette, F.; Billard, A. Structure, mechanical and tribological properties, and oxidation resistance of TaC/a-C:H films deposited by high power impulse magnetron sputtering. Ceram. Int. 2020, 46, 24986–25000. [Google Scholar] [CrossRef]

- Nilsson, D.; Stavlid, N.; Lindquist, M.; Hogmark, S.; Wiklund, U. The role of aluminum additions in the oxidation and wear of a TaC:C low-friction coating. Surf. Coat. Technol. 2009, 203, 2989–2994. [Google Scholar] [CrossRef]

- Abad, M.D.; Sánchez-López, J.C.; Brizuela, M.; García-Luis, A.; Shtansky, D.V. Influence of carbon chemical bonding on the tribological behavior of sputtered nanocomposite TiBC/a-C coatings. Thin Solid Film. 2010, 518, 5546–5552. [Google Scholar] [CrossRef]

- Lauridsen, J.; Nedfors, N.; Jansson, U.; Jensen, J.; Eklund, P.; Hultman, L. Ti-B-C nanocomposite coatings deposited by magnetron sputtering. Appl. Surf. Sci. 2012, 258, 9907–9912. [Google Scholar] [CrossRef]

- Stueber, M.; Barna, P.B.; Simmonds, M.C.; Albers, U.; Leiste, H.; Ziebert, C.; Holleck, H.; Kovács, A.; Hovsepian, P.; Gee, I. Constitution and microstructure of magnetron sputtered nanocomposite coatings in the system Ti-Al-N-C. Thin Solid Film. 2005, 493, 104–112. [Google Scholar] [CrossRef]

- Poltorak, C.; Stüber, M.; Leiste, H.; Bergmaier, A.; Ulrich, S. Study of (Ti,Zr)C:H/a-C:H nanocomposite thin film formation by low temperature reactive high power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 398, 125958. [Google Scholar] [CrossRef]

- Lewin, E.; Persson, P.O.A.; Lattemann, M.; Stüber, M.; Gorgoi, M.; Sandell, A.; Ziebert, C.; Schäfers, F.; Braun, W.; Halbritter, J.; et al. On the origin of a third spectral component of the C1s XPS-spectra for nc-TiC/a-C nanocomposite thin films. Surf. Coat. Technol. 2008, 202, 3563–3570. [Google Scholar] [CrossRef]

- Magnuson, M.; Lewin, E.; Hultman, L.; Jansson, U. Electronic structure and chemical bonding of nanocrystalline-TiC/amorphous-C nanocomposites. Phys. Rev. B 2009, 80, 235108. [Google Scholar] [CrossRef]

- El Mel, A.A.; Angleraud, B.; Gautron, E.; Granier, A.; Tessier, P.Y. XPS study of the surface composition modification of nc-TiC/C nanocomposite films under in situ argon ion bombardment. Thin Solid Film. 2011, 519, 3982–3985. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311–R327. [Google Scholar] [CrossRef]

- Djoufack, M.H.; May, U.; Repphun, G.; Brögelmann, T.; Bobzin, K. Wear behaviour of hydrogenated DLC in a pin-on-disc model test under lubrication with different diesel fuel types. Tribol. Int. 2015, 92, 12–20. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Tribology of Diamond-Like Carbon Films. Spinger Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- Mandal, P.; Ehiasarian, A.P.; Hovsepian, P.E. Lubricated sliding wear mechanism of chromium-doped graphite-like carbon coating. Tribol. Int. 2014, 77, 186–195. [Google Scholar] [CrossRef]

- Mohrbacher, H.; Blanpain, B.; Celis, J.P.; Roos, J.R. Frictional behaviour of diamond-like carbon and diamond coatings in oscillating sliding. Surf. Coat. Technol. 1993, 62, 583–588. [Google Scholar] [CrossRef]

- Ronkainen, H.; Varjus, S.; Holmberg, K. Tribological performance of different DLC coatings in water-lubricated conditions. Wear 2001, 249, 267–271. [Google Scholar] [CrossRef]

- Tung, S.C.; Gao, H. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear 2003, 255, 1276–1285. [Google Scholar] [CrossRef]

- Podgornik, B.; Jacobson, S.; Hogmark, S. Influence of EP additive concentration on the tribological behaviour of DLC-coated steel surfaces. Surf. Coat. Technol. 2005, 191, 357–366. [Google Scholar] [CrossRef]

- Kalin, M.; Vizintin, J. A comparison of the tribological behaviour of steel/steel, steel/DLC and DLC/DLC contacts when lubricated with mineral and biodegradable oils. Wear 2006, 261, 22–31. [Google Scholar] [CrossRef]

- Haque, T.; Morina, A.; Neville, A.; Kapadia, R.; Arrowsmith, S. Non-ferrous coating/lubricant interactions in tribological contacts: Assessment of tribofilms. Tribol. Int. 2007, 40, 1603–1612. [Google Scholar] [CrossRef]

- Grimm, W.; Weihnacht, V. Properties of super-hard carbon films deposited by pulsed arc process. Vacuum 2010, 85, 506–509. [Google Scholar] [CrossRef]

- Kosarieh, S.; Morina, A.; Lainé, E.; Flemming, J.; Neville, A. Tribological performance and tribochemical processes in a DLC/steel system when lubricated in a fully formulated oil and base oil. Surf. Coat. Technol. 2013, 217, 1–12. [Google Scholar] [CrossRef]

- Strmcnik, E.; Majdic, F.; Kalin, M. Water-lubricated behaviour of AISI 440C stainless steel and a DLC coating for an orbital hydraulic motor application. Tribol. Int. 2019, 131, 128–136. [Google Scholar] [CrossRef]

- Barriga, J.; Kalin, M.; Van Acker, K.; Vercammen, K.; Ortega, A.; Leiaristi, L. Tribological performance of titanium doped and pure DLC coatings combined with a synthetic bio-lubricant. Wear 2006, 261, 9–14. [Google Scholar] [CrossRef]

- Krzan, B.; Novotny-Farkas, F.; Vizintin, J. Tribological behavior of tungsten-doped DLC coating under oil lubrication. Tribol. Int. 2009, 42, 229–235. [Google Scholar] [CrossRef]

- Yang, L.; Neville, A.; Brown, A.; Ransom, P.; Morina, A. Friction reduction mechanisms in boundary lubricated W-doped DLC coatings. Tribol. Int. 2014, 70, 26–33. [Google Scholar] [CrossRef]

- Zhang, S.; Yue, W.; Kang, J.; Wang, Y.; Fu, Z.; Zhu, L.; She, D.; Wang, C. Ti content on the tribological properties of W/Ti-doped diamond-like carbon film lubricated with additives. Wear 2019, 430–431, 137–144. [Google Scholar] [CrossRef]

- Bai, M.; Yang, L.; Li, J.; Luo, L.; Sun, S.; Inkson, B. Mechanical and tribological properties of Si and W doped diamond like carbon (DLC) under dry reciprocating sliding friction. Wear 2021, 484, 204046. [Google Scholar] [CrossRef]

- Beake, B.D.; McMaster, S.J.; Liskiewicz, T.W.; Neville, A. Influence of Si- and W-doping on micro-scale reciprocating wear and impact performance of DLC coatings on hardened steels. Tribol. Int. 2021, 160, 107063. [Google Scholar] [CrossRef]

- Scharf, T.W.; Singer, I.L. Role of the transfer film on the friction and wear of metal carbide reinforced amorphous carbon coatings during run-in. Tribol. Lett. 2009, 36, 43–53. [Google Scholar] [CrossRef]

- Ciarsolo, I.; Fernández, X.; Ruiz de Gopegui, U.; Zubizarreta, C.; Abad, M.D.; Mariscal, A.; Caretti, I.; Jiménez, I.; Sánchez-López, J.C. Tribological comparison of different C-based coatings in lubricated and unlubricated conditions. Surf. Coat. Technol. 2014, 257, 278–285. [Google Scholar] [CrossRef][Green Version]

- Abad, M.D.; Sánchez-López, J.C.; Cusnir, N.; Sanjines, R. WC/a-C nanocomposite thin films: Optical and electrical properties. J. Appl. Phys. 2009, 105, 033510. [Google Scholar] [CrossRef]

- Oláh, N.; Fogarassy, Z.; Furkó, M.; Balászi, C.; Balászi, K. Sputtered nanocrystalline ceramic TiC/amorphous C thin films as potential materials for medical applications. Ceram. Int. 2015, 41, 5863–5871. [Google Scholar] [CrossRef]

- Park, Y.S.; Kim, N.-H. TiC/a-C nano composite films fabricated by using closed-field unbalanced magnetron sputtering for biomedical applications. J. Korean Phys. Soc. 2019, 75, 380–384. [Google Scholar] [CrossRef]

- Xiao, Y.; Hwang, J.-Y.; Sun, Y.-K. Transition metal carbide-based materials: Synthesis and applications in electrochemical energy storage. J. Mater. Chem. A 2016, 4, 10379–10393. [Google Scholar] [CrossRef]

- Qiu, F.; He, P.; Jiang, J.; Zhang, X.; Tong, S.; Zhou, H. Ordered mesoporous TiC-C composites as cathode materials for Li-O2 batteries. Chem. Commun. 2016, 52, 2713. [Google Scholar] [CrossRef]

- Wang, H.Q.; Zhou, Q.; Ou, Y.X.; Liao, B.; Zhang, X.; Hua, Q.S.; Ouyang, X.P.; Luo, C.W. Tribocorrosion behaviors of nc-TiC/a-C:H nanocomposite coatings: In-Situ electrochemical response. Thin Solid Film. 2021, 730, 138719. [Google Scholar] [CrossRef]

- Oláh, N.; Fogarassy, Z.; Sulyok, A.; Szívos, J.; Csanádi, T.; Balàszi, K. Ceramic TiC/a:C protective nanocomposite coatings: Structure and composition versus mechanical properties and tribology. Ceram. Int. 2016, 42, 12215–12220. [Google Scholar] [CrossRef]

- Oláh, N.; Fogarassy, Z.; Sulyok, A.; Veres, M.; Kaptay, G.; Balászi, K. TiC crystallite formation and the role of interfacial energies on the composition during the deposition process of TiC/a:C thin films. Surf. Coat. Technol. 2016, 302, 410–419. [Google Scholar] [CrossRef]

- Balászi, K.; Balászi, C. Application of sputtered ceramic TiC/a:C thin films with different structures by changing the deposition parameters. Int. J. Appl. Ceram. Technol. 2022, 19, 753–761. [Google Scholar] [CrossRef]

- Bauer, C. Superharte, Unterschiedlich Gradierte PVD-Kohlenstoffschichten Mit Und Ohne Zusatz Von Titan Und Silizium, Wissenschaftliche Berichte FZKA 6740, Forschungszentrum Karlsruhe in der Helmholtz-Gemeinschaft; Forschungszentrum Karlsruhe GmbH: Karlsruhe, Germany, 2003. [Google Scholar]

- Stueber, M.; Ziebert, C.; Leiste, H.; Ulrich, S.; Sanz, C.; Fuentes, E.; Etxarri, I.; Solay, M.; Garcia, A.; Barna, P.B.; et al. Wear Studies and Cutting Tests of Ti-Al-N-C Nanocomposite Coatings in Milling Operations—Technical Communication. Mach. Sci. Technol. 2009, 13, 122–141. [Google Scholar] [CrossRef]

- Erdemir, A.; Martin, J.M. Superior wear resistance of diamond and DLC coatings. Curr. Opin. Solid State Mater. Sci. 2018, 22, 243–254. [Google Scholar] [CrossRef]

- Buckley, D.H.; Miyoshi, K. Friction and wear of ceramics. Wear 1984, 100, 333–353. [Google Scholar] [CrossRef]

- Jahanmir, S. Friction and Wear of Ceramics. CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Wallstabe, R. On the tribological behaviour of SiC and alumina mated against different steels under dry sliding conditions. Tribol. Lett. 2011, 44, 247–257. [Google Scholar] [CrossRef]

- Muratov, V.A.; Fischer, T.E. Tribochemical polishing. Ann. Rev. Mater. Sci. 2000, 30, 27–51. [Google Scholar] [CrossRef]

- Zhu, Z.; Muratov, V.; Fischer, T.E. Tribochemical polishing of silicon carbide in oxidant solution. Wear 1999, 225, 848–856. [Google Scholar] [CrossRef]

- Jahnke, H.; Schoenborn, M. Electrochemical corrosion measurements in motor fuels based on methanol and ethanol. Mater. Corros. 1985, 36, 561–566. [Google Scholar] [CrossRef]

- Alves Radi, P.; Vieira, A.; Manfroi, L.; Carvalho de Farias Nass, K.; Ramirez Ramos, M.A.; Leite, P.; Martins, G.V.; Jofre, J.B.F.; Vieira, L. Tribocorrosion and corrosion behavior of stainless steel coated with DLC films in ethanol with different concentrations of water. Ceram. Int. 2019, 45, 9686–9693. [Google Scholar] [CrossRef]

- Dienwiebel, M.; Poehlmann, K.; Scherge, M. Origins of the wear resistance of AlSi cylinder bore surfaces studies by surface analytical tools. Tribol. Int. 2007, 40, 1597–1602. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, L.; Xue, Q. Testing atmosphere effect on friction and wear behaviors of duplex TiC/a-C(Al) nanocomposite carbon-based coating. Tribol. Lett. 2012, 47, 435–446. [Google Scholar] [CrossRef]

- Li, H.; Xu, T.; Wang, C.; Chen, J.; Zhou, H.; Liu, H. Tribochemical effects on the friction and wear behaviors of a-C:H and a-C films in different environment. Tribol. Int. 2007, 40, 132–138. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schneider, J.; Ulrich, S.; Patscheider, J.; Stueber, M. Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions. Coatings 2022, 12, 446. https://doi.org/10.3390/coatings12040446

Schneider J, Ulrich S, Patscheider J, Stueber M. Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions. Coatings. 2022; 12(4):446. https://doi.org/10.3390/coatings12040446

Chicago/Turabian StyleSchneider, Johannes, Sven Ulrich, Jörg Patscheider, and Michael Stueber. 2022. "Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions" Coatings 12, no. 4: 446. https://doi.org/10.3390/coatings12040446

APA StyleSchneider, J., Ulrich, S., Patscheider, J., & Stueber, M. (2022). Wear Study of a Magnetron-Sputtered TiC/a-C Nanocomposite Coating under Media-Lubricated Oscillating Sliding Conditions. Coatings, 12(4), 446. https://doi.org/10.3390/coatings12040446