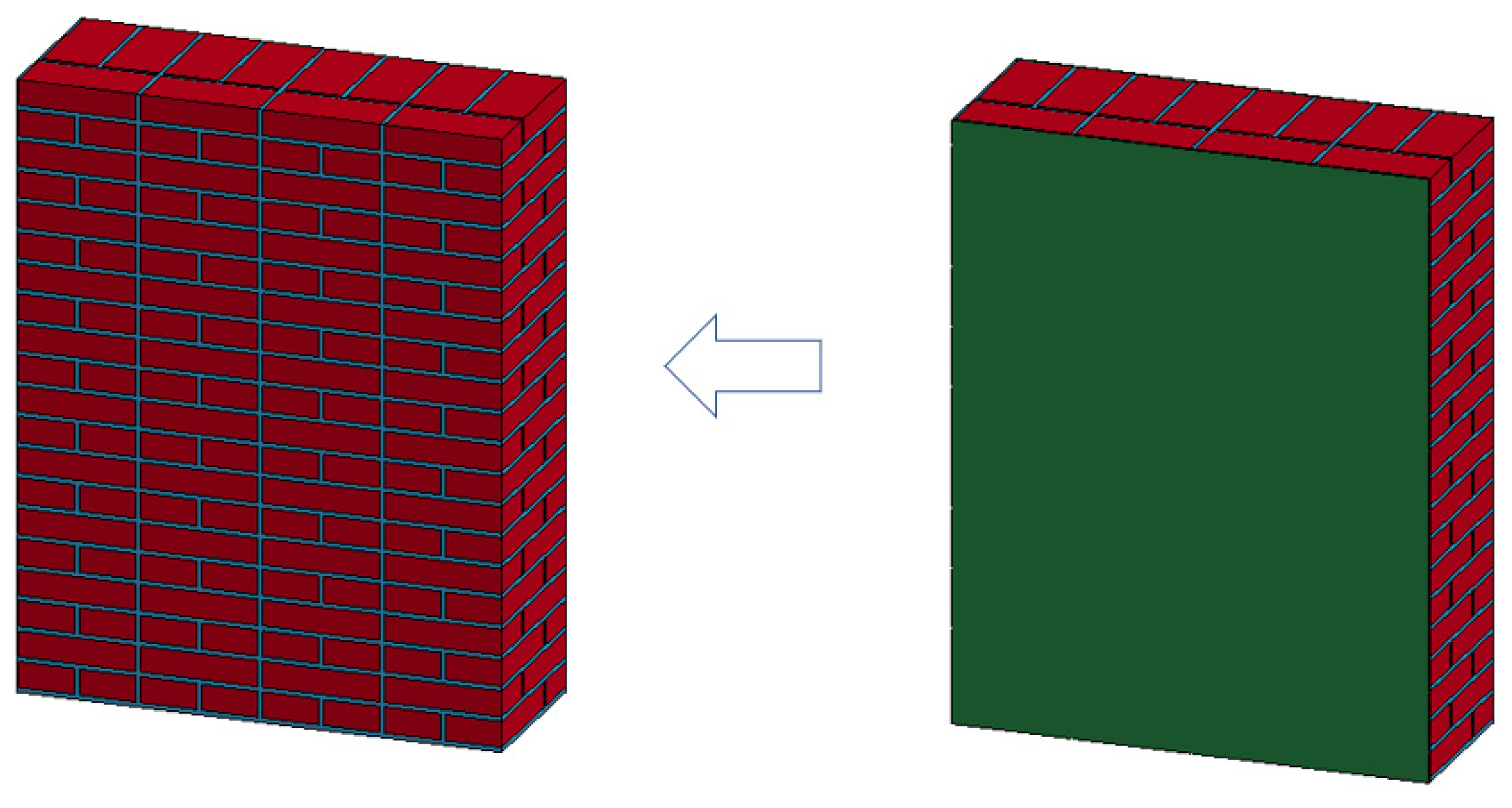

In this section, we detail the numerical simulations of the blast-resistant characteristics of masonry walls sprayed with different thicknesses of a polyurea elastomer.

2.2.2. Numerical Simulation of the Polyurea-Reinforced 370 mm Wall

When the amount of TNT was 1 kg under working condition 2 (the thickness of the reinforcement layer on the front surface was 6 mm and the thickness of the reinforcement layer on the back surface was 4 mm),

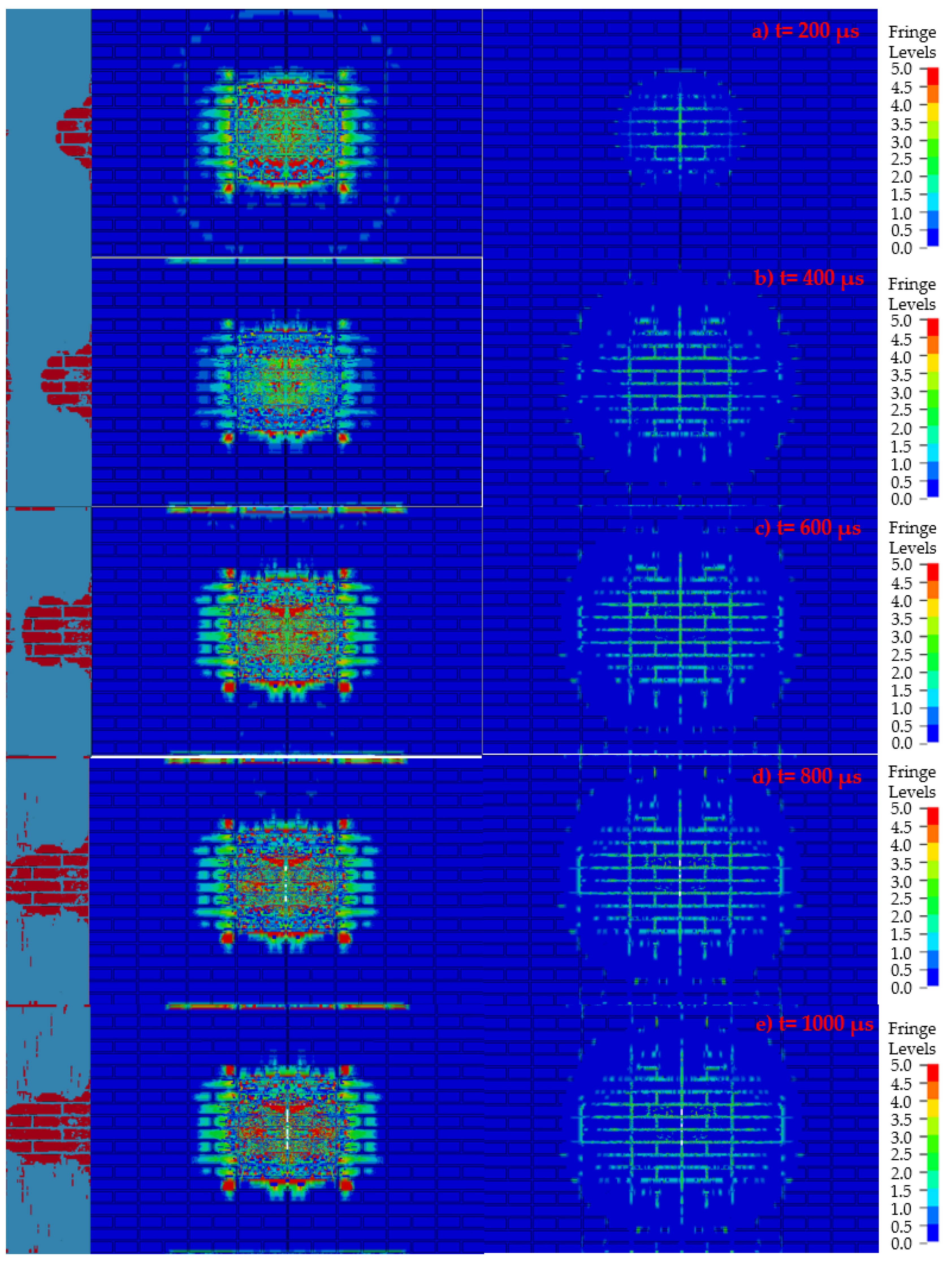

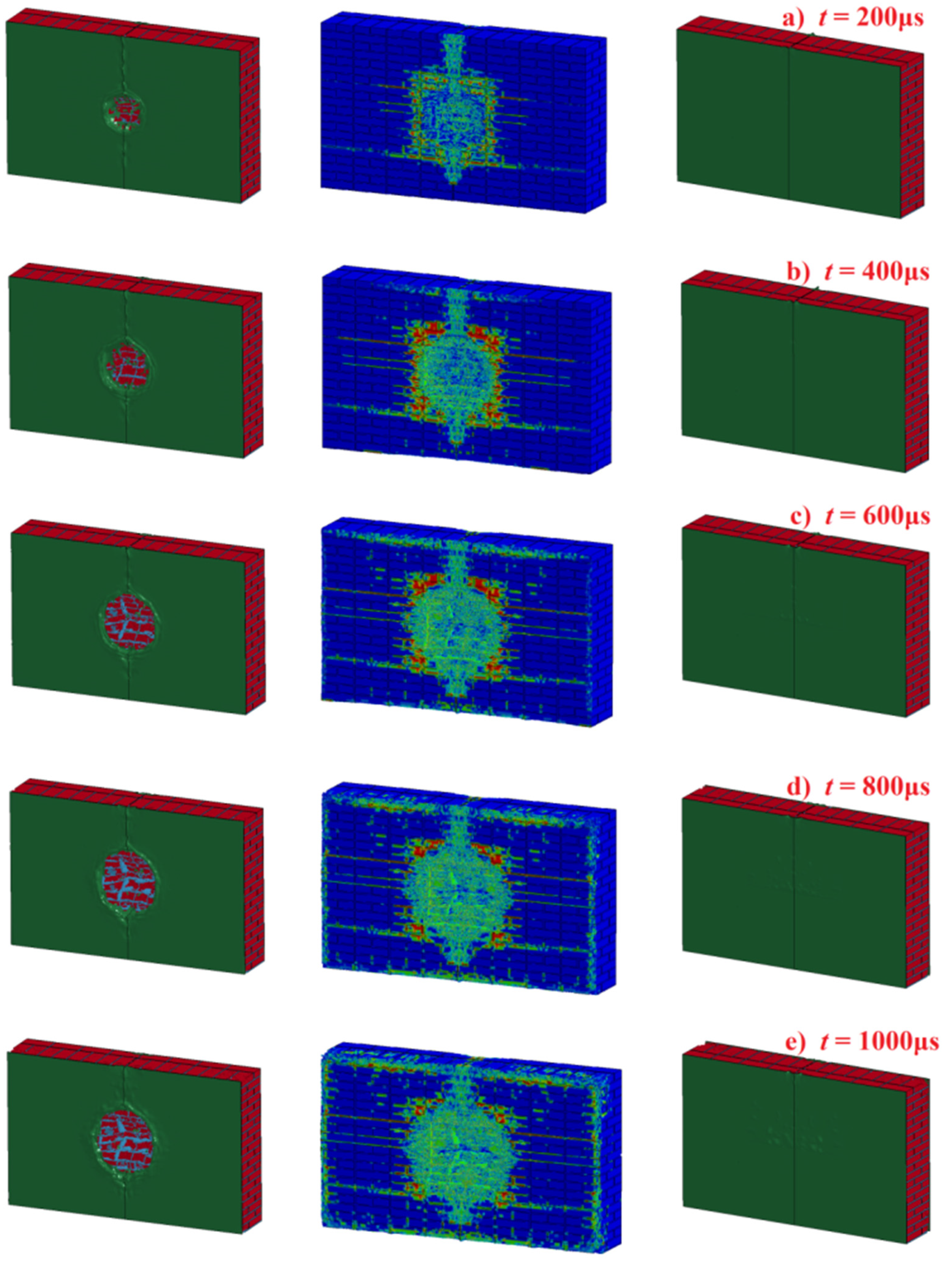

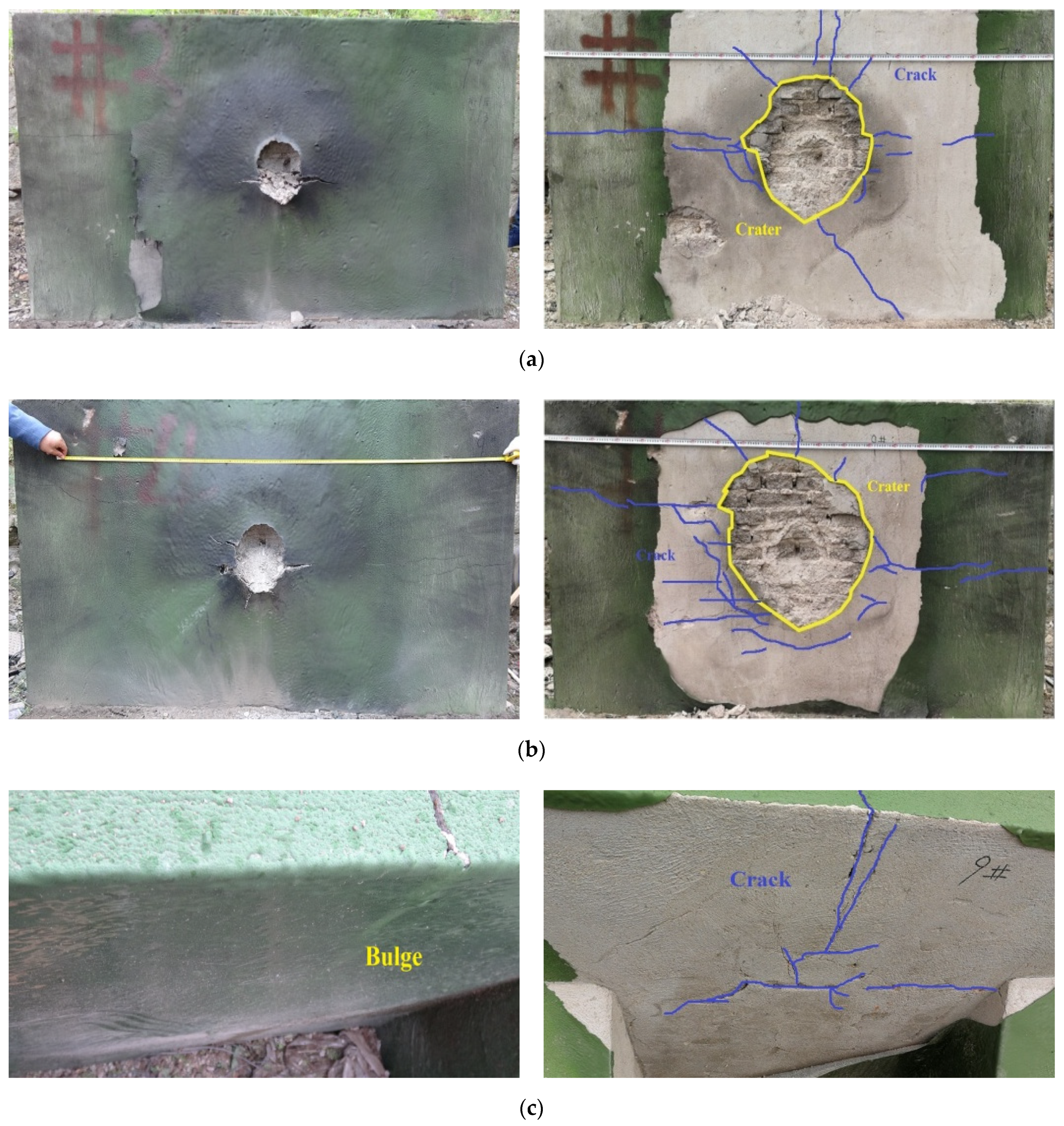

Figure 6 illustrates the 370 mm wall’s damage over time. The figure on the left shows the front side of the reinforced wall before the explosion, which reflects the damage to the surface of the polyurea reinforcement layer before the explosion. The middle figure is only the stress cloud diagram of the wall, reflecting the damage of the inner wall of the masonry. The figure on the right shows the rear side of the reinforced wall after blasting, reflecting the damage to the polyurea reinforcement layer on the blasted surface.

From the front view on the left, after the contact explosion, the polyurea layer on the front surface stretched and dented quickly under the action of the explosion load and was quickly damaged to expose the masonry wall structure of the lower layer. The polyurea layer at the central symmetry plane showed wavy distortion (see

Figure 6a). The breach of the polyurea layer on the blast front face expanded rapidly with time, and the polyurea layer around the breach was stacked and folded after extrusion and stretching (see

Figure 6a–d). After 800 μs, when the central breach of the polyurea layer expanded to a certain extent, the size growth slowed down and some near-circular bulges appeared on the periphery of the stacked fold layer of the breach, leading to the uneven periphery of the folds (see

Figure 6d,e).

Based on the stress diagram of the brick masonry in the middle, the explosive load first caused a rapidly expanding central blasting pit and large longitudinal cracks on the front surface of the masonry wall, with some divergent cracks formed along the mortar joint around the blasting pit (see

Figure 6a). After 400 μs, the area and volume of the central blasting pit increased, radial cracks around it developed and were densely distributed, and the upper and lower sides of the wall were damaged (see

Figure 6b,c). After 800 μs, the increase in size of the central blasting pit was no longer obvious, and a little peeling damage also appeared on the left and right sides of the wall (see

Figure 6d,e). Based on a comparison of the figures on the left and in the middle, the area of the polyurea elastomer coating breach was always smaller than the area of the central blasting pit sandwiched by the masonry wall at any time.

The back surface on the right showed that the explosion load caused large longitudinal cracks in the center of the wall on the back surface, resulting in slight distortion in the top and middle of the back polyurea reinforcement layer (see

Figure 6a,b). From 600 μs, the middle gray seam of the polyurea reinforcement layer on the back surface gradually showed lumpy protrusions under the action of impact waves, and the raised lumps merged with each other and expanded (see

Figure 6c–e).

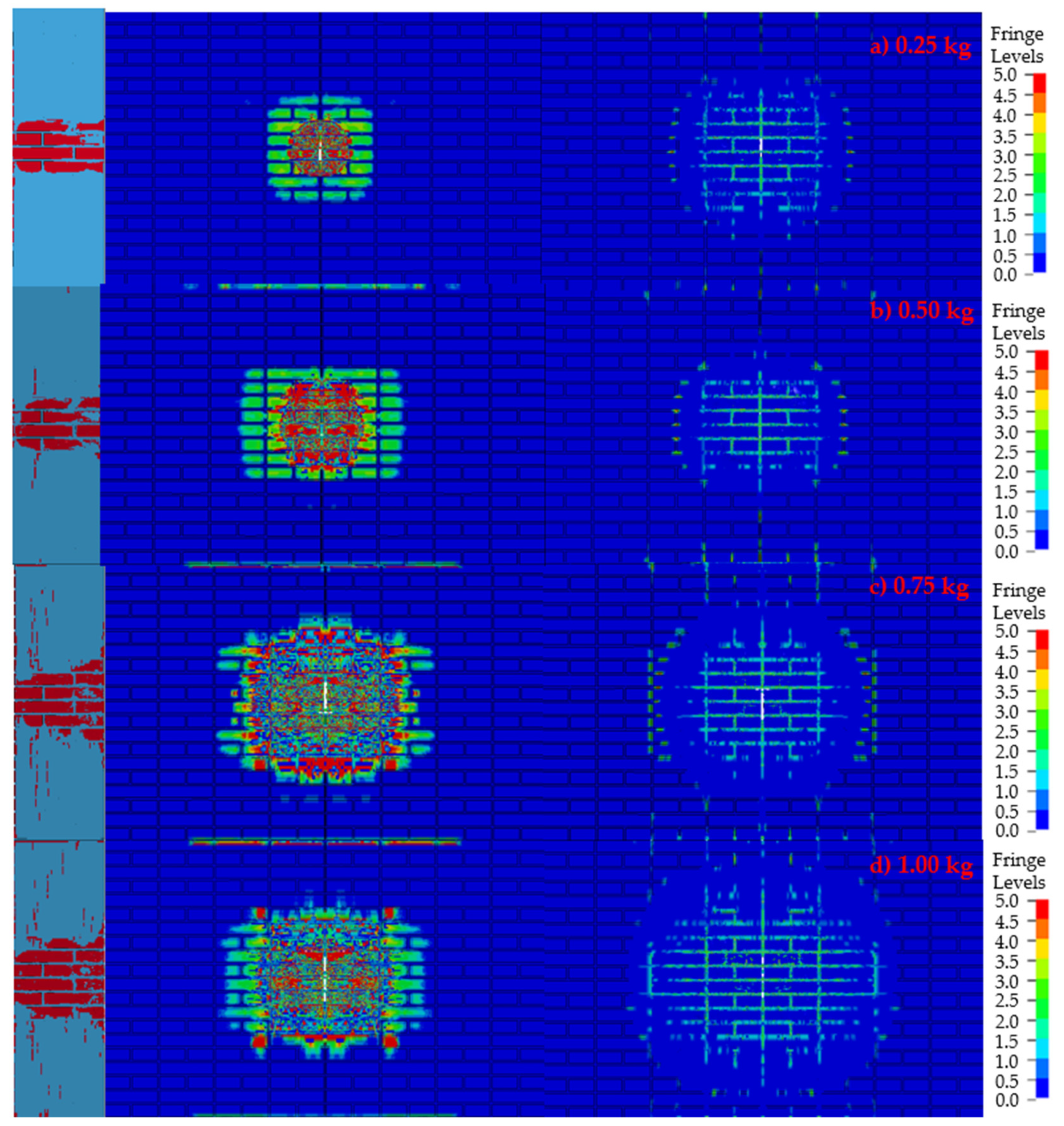

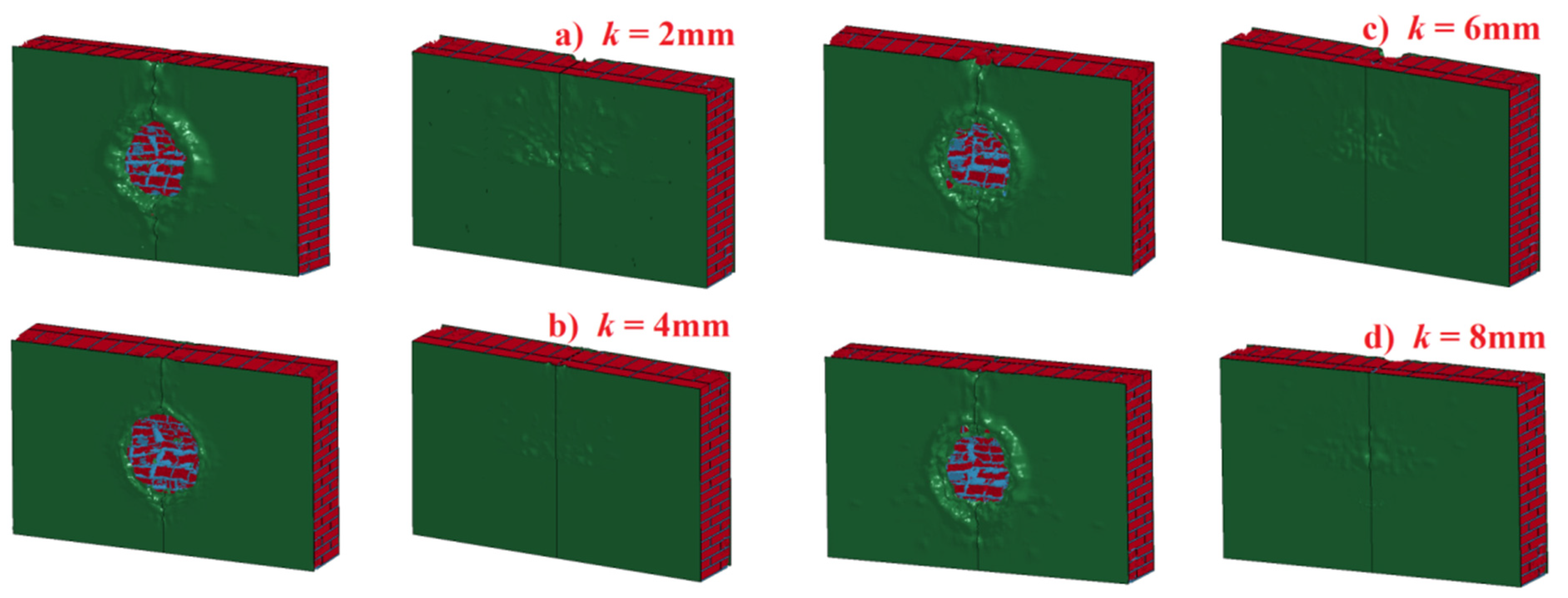

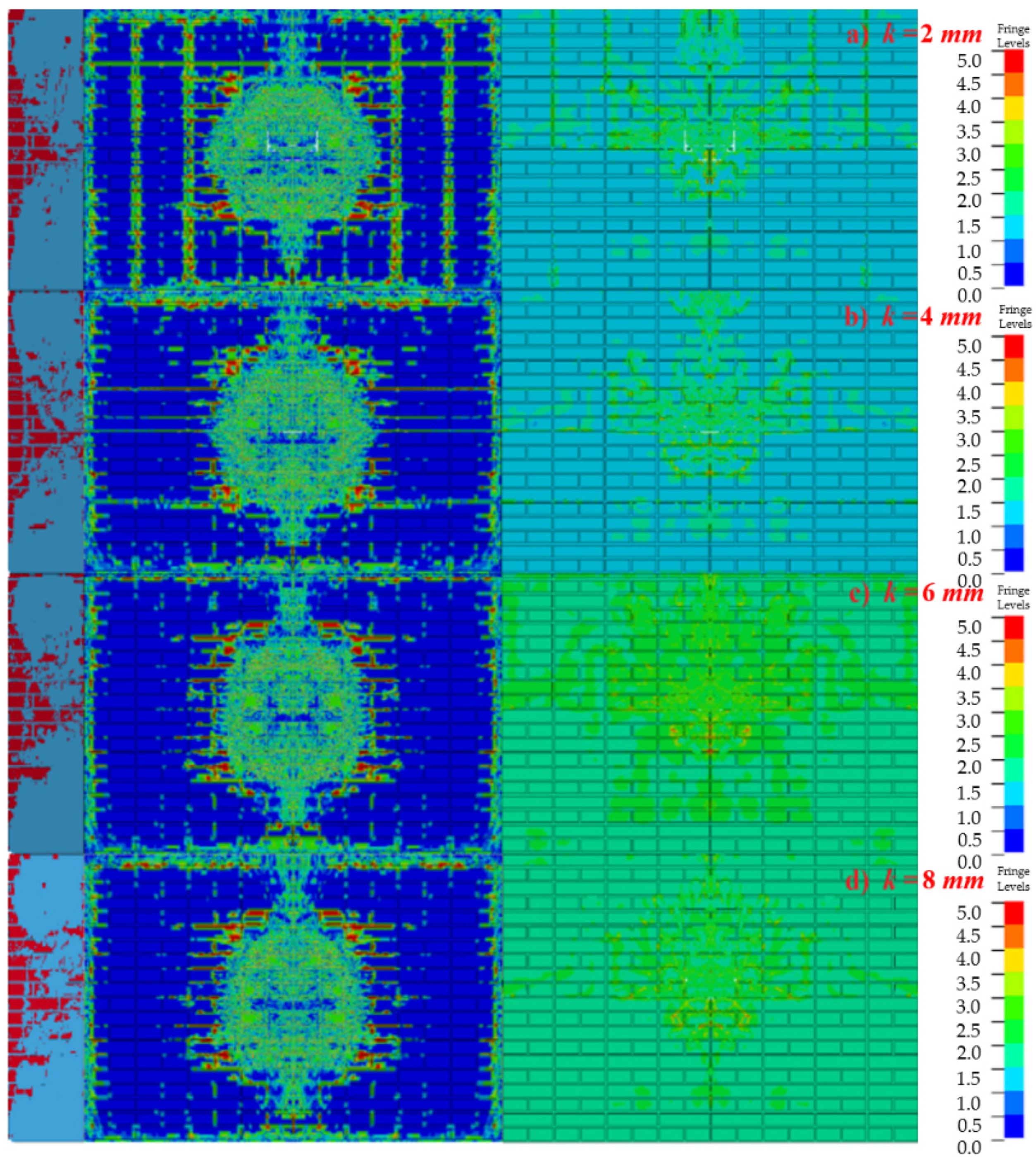

Figure 7 shows the damage to the polyurea reinforcement layer on both sides under contact explosion at t = 1000 μs. The back surface reinforcement layer has thickness

k values of 2, 4, 6, and 8 mm, which correspond to the damage of working conditions 1–4, respectively, as shown by labels a through d. The figure on the left is the front surface of the reinforced wall, reflecting the damage of the polyurea reinforcement layer on the front surface; the figure on the right is the back side of the wall, reflecting the damage of the polyurea reinforcement layer on the back surface. Based on the front surface on the left under the same contact explosion load, the levels of deformation of the reinforcement layers from the explosions on the surfaces of the same thickness were very similar. The wavy distortions of the central symmetry plane were similar, and the sizes of the openings were almost the same. The polyurea layers around the break showed similar stacking, folding, and bulging after extrusion and stretching.

Based on the back surface on the right, when the polyurea reinforcement layer on the back surface was thin (i.e., in working conditions 1 and 2, as shown in

Figure 7a,b), the distortion of the top and middle parts of the reinforcement layer was obvious, and the uplift of the reinforcement layer was small and dense, often distributed along the mortar joint. When the polyurea reinforcement layer was thick (i.e., in working conditions 3 and 4, as shown in

Figure 7c,d), the distortion of the top and middle parts of the reinforcement layer was not obvious, and the uplifts of the reinforcement layer were larger but smaller in number, distributed in the corresponding central part of the blasting pit.

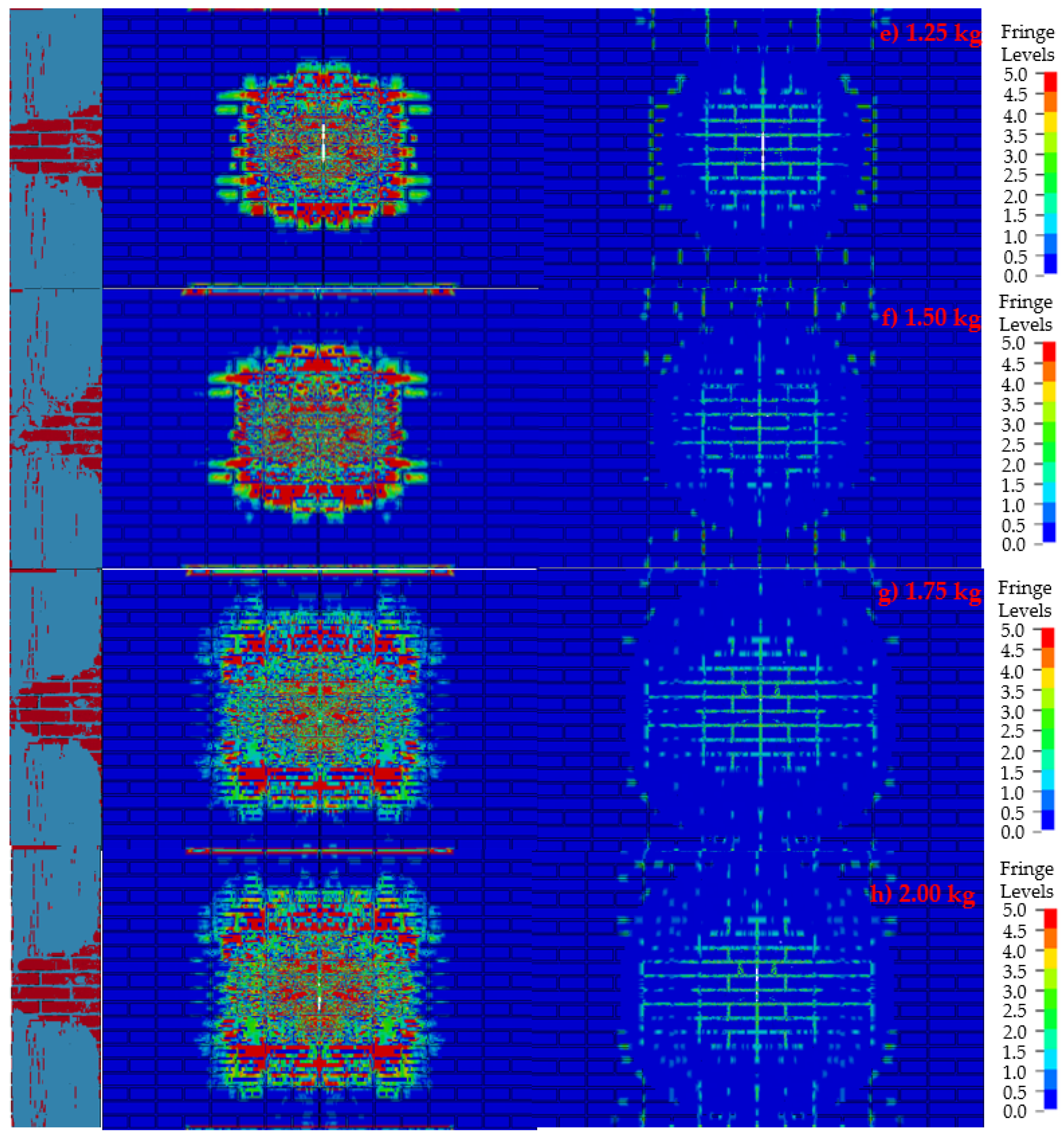

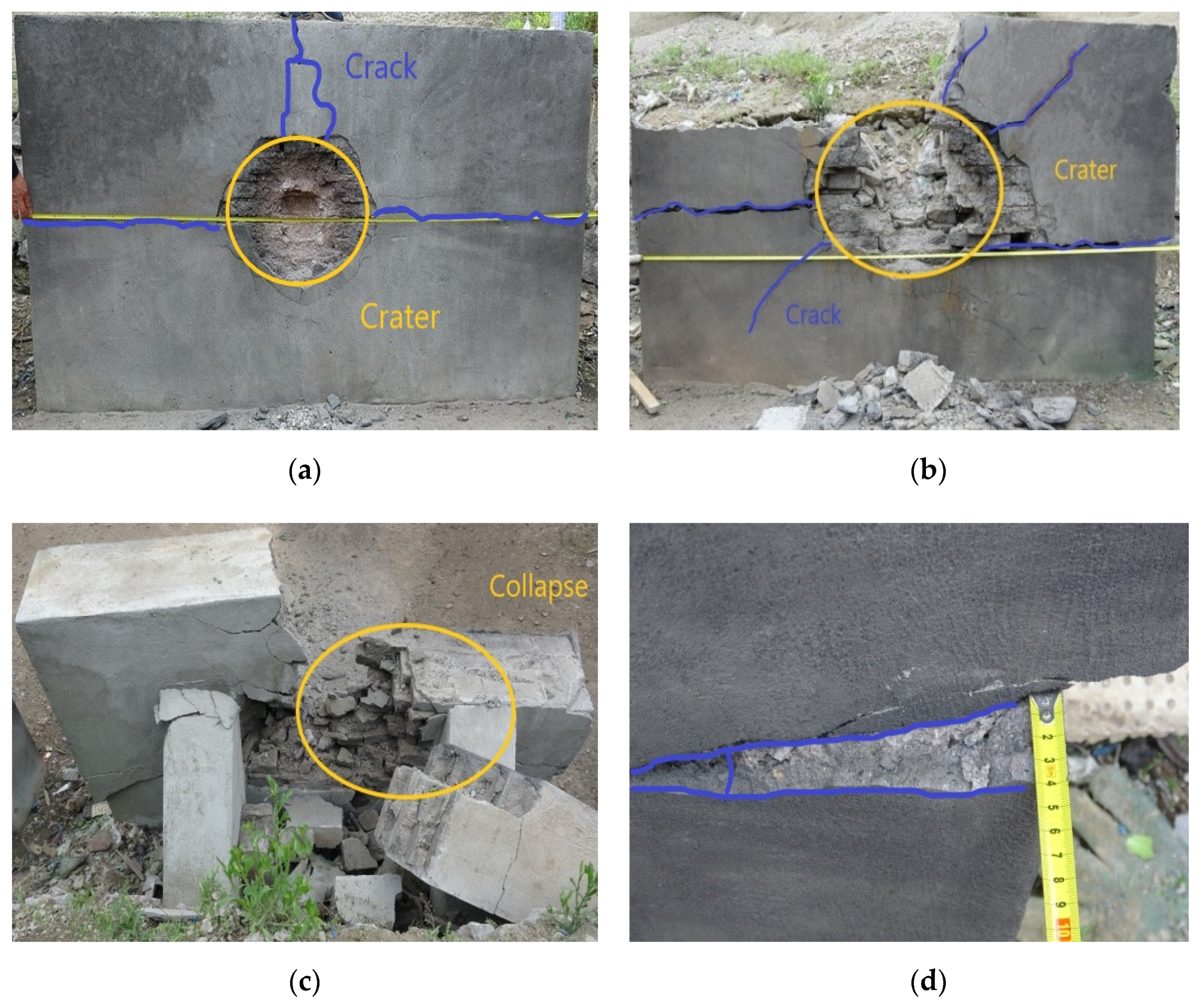

To more clearly see the damage to the reinforced masonry wall under contact explosions,

Figure 8 was created without the polyurea reinforcement layers on each side. Only the damage to the bricks and mortar under the four working conditions in

Table 4 is depicted in the image. The reinforced masonry wall’s longitudinal section or symmetrical plane, blast front surface, and blast back surface are all destroyed on the figure’s left, middle, and right sides, respectively.

As shown in the longitudinal section on the left, when the thickness of the polyurea reinforcement layer on the front surface remained unchanged, the depth of the central blasting pit of the masonry wall did not change much with the increasing thickness of the back surface reinforcement layer, and the cracks were densely distributed inside the masonry wall. The damage to the front surface in the middle shows that the areas of the central blasting pit (circled in the figure) under the four working conditions were different. When the back surface was thin (i.e., in conditions 1 and 2, as shown in

Figure 8a,b), the area of the blasting pit was larger. When the polyurea reinforcement layer was thicker (i.e., in conditions 3 and 4, as shown in

Figure 8c,d), the area of the blasting pit was smaller; the spalling and cracking of the explosion-proof surface of the wall under the four working conditions were also different. Compared with conditions 3 and 4, the damage phenomena, such as the spalling and cracks on the blast front surface of the masonry wall concentrated in the mortar joint in conditions 1 and 2, were more obvious. The damage to the back surface on the right shows that under the four working conditions, the mortar joints were all weak links, and the collapse and spalling developed along the joints, with an overall radial trend (except for the rib plate). Compared with working conditions 3 and 4, where the polyurea reinforcement layer on the back surface was thicker, the strain on the back surface of the masonry wall in working conditions 1 and 2 was smaller.

By selecting the damaged areas along the bounding box, the size statistics of the same wall with different reinforcement methods under the same contact explosion load are shown in

Table 6. As the thickness of the polyurea elastomer reinforcement layer on the blast back surface increased, the area of the central blasting pit decreased slightly; the values of working conditions 1 and 2 were close to those of working conditions 3 and 4. With the increasing thickness of the polyurea reinforcement layer on the blast back surface, the overall depth of the blasting pit did not change much, whereby the depths for working conditions 1, 2, and 4 were quite close, at about half of the thickness of the masonry wall.