Enhancing Concrete and Mortar Properties and Durability Using Pristine Graphene Particles

Abstract

1. Introduction

2. Materials and Methods

2.1. Graphene Particles and Dispersion Method

2.2. Preparation of Concrete and Mortar Coupons

2.3. Mechanical Property and Durability Tests

2.3.1. Slump or Workability Test

2.3.2. 28-Day Compressive Strength and Density

2.3.3. Apparent Volume of Permeable Voids (AVPV)

2.4. Sulfate Resistance Testing

3. Results and Discussion

3.1. PureGRAPH® 50 Dispersion in Water

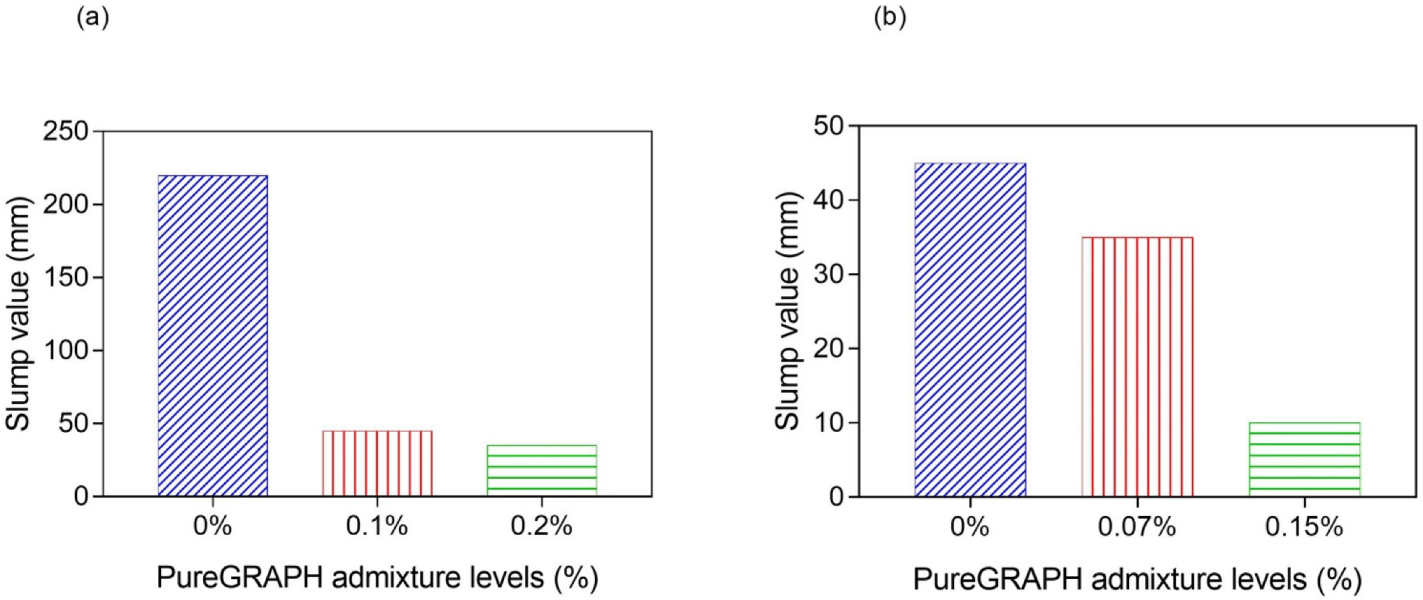

3.2. Workability—Slump Test

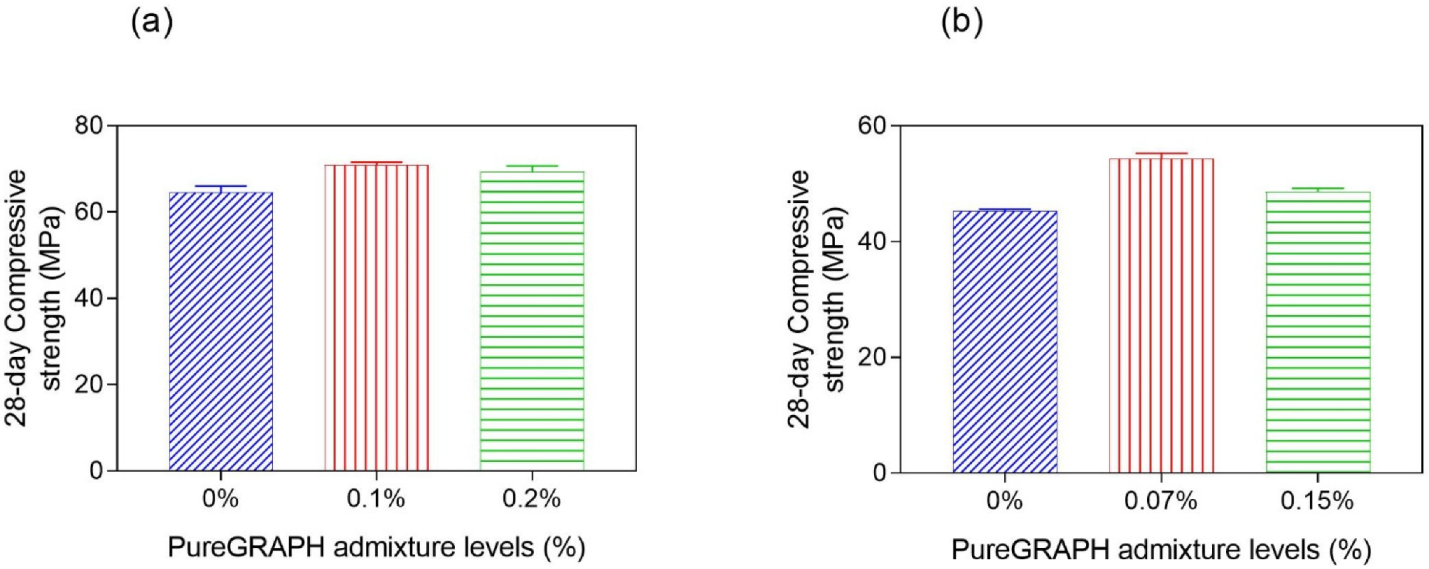

3.3. 28-Day Compressive Strength and Density

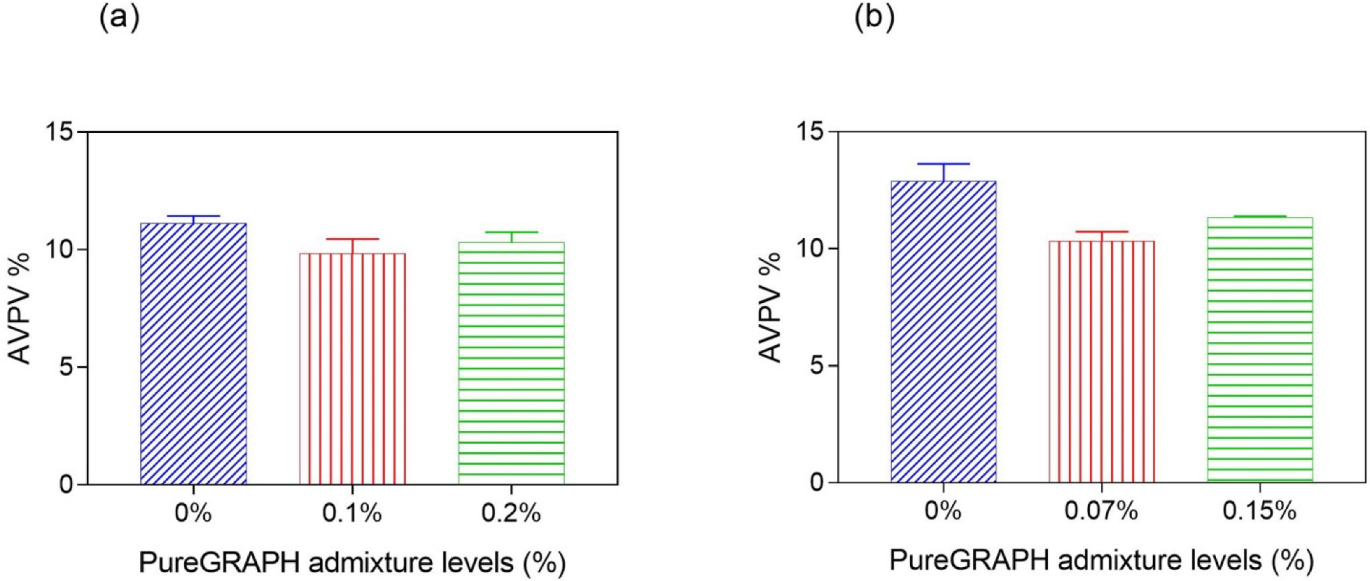

3.4. Apparent Volume of Permeable Voids

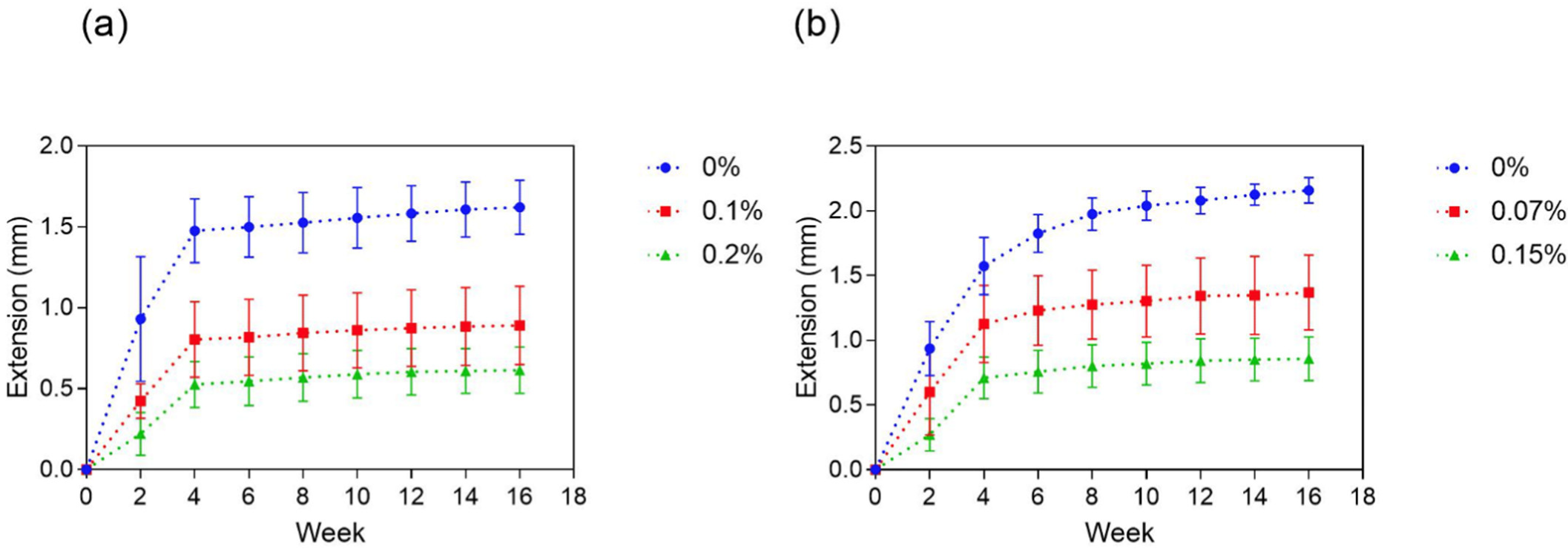

3.5. Sulfate Resistance Testing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehta, P.; Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Mindess, S.; Young, F.J.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 2003. [Google Scholar]

- Han, B.; Zhang, L.; Ou, J. Smart and Multifunctional Concrete toward Sustainable Infrastructures; Springer: New York, NY, USA, 2017. [Google Scholar]

- Li, X.; O’Moore, L.; Song, Y.; Bond, P.L.; Yuan, Z.; Wilkie, S.; Hanzic, L.; Jiang, G. The Rapid Chemically Induced Corrosion of Concrete Sewers at High H2S Concentration. Water Res. 2019, 162, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Wightman, E.; Tian, Y.; Jack, K.; Li, X.; Zhong, H.; Bond, P.L.; Yuan, Z.; Jiang, G. Corrosion of Reinforcing Steel in Concrete Sewers. Sci. Total Environ. 2019, 649, 739–748. [Google Scholar] [CrossRef] [PubMed]

- Hime, W.G.; Mather, B. “Sulfate Attack,” or Is It? Cem. Concr. Res. 1999, 29, 789–791. [Google Scholar] [CrossRef]

- Song, H.-W.; Kwon, S.-J. Permeability Characteristics of Carbonated Concrete Considering Capillary Pore Structure. Cem. Concr. Res. 2007, 37, 909–915. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. Experimental Investigation and Mathematical Modeling of the Concrete Carbonation Problem. Chem. Eng. Sci. 1991, 46, 1333–1338. [Google Scholar] [CrossRef]

- Jiang, C.; Gu, X. Discussion of “Assessing Concrete Carbonation Resistance through Air Permeability Measurements” by R. Neves et al. [Construction and Building Materials 82(2015): 304–309]. Constr. Build. Mater. 2016, 102, 913–915. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, D.; De Schutter, G. Does Concrete Suffer Sulfate Salt Weathering? Constr. Build. Mater. 2014, 66, 692–701. [Google Scholar] [CrossRef]

- Munns, R.L.; Kao, G.; Chang, T.Z. Durability Performance of Australian Commercial Concrete Modified with Permeability Reducing Admixture; ACCI, School of Civil & Environmental Engineering: Kensington, Australia, 2010. [Google Scholar]

- Jonkers, H.M. Self Healing Concrete: A Biological Approach. In Self Healing Concrete: A Biological Approach; Springer: Dordrecht, The Netherlands, 2007; Volume 100, pp. 195–204. [Google Scholar] [CrossRef]

- Václavík, V.; Dvorský, T.; Šimíček, V.; Ondová, M.; Valíček, J.; Kušnerová, M.; Gola, L. Steel Slag as a Substitute for Natural Aggregate in the Production of Concrete. In Solid State Phenomena; Trans Tech Publications: Bäch, Switzerland, 2016; Volume 244, pp. 77–87. [Google Scholar]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of Bacteria on the Compressive Strength, Water Absorption and Rapid Chloride Permeability of Fly Ash Concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Khestl, F.; Boháčová, J.; Staněk, S. Thermal Insulating Alkali-Activated Systems. In Advanced Materials Research; Trans Tech Publications: Bäch, Switzerland, 2014; Volume 1000, pp. 182–185. [Google Scholar]

- Boháčová, J.; Staněk, S.; Mec, P. Preparation and Properties of Pressed Metakaolin and Fly Ash Based Alkali-Activated Binders. In Advanced Materials Research; Trans Tech Publications: Bäch, Switzerland, 2014; Volume 897, pp. 65–68. [Google Scholar]

- Du, H.; Gao, H.J.; Pang, S.D. Improvement in Concrete Resistance against Water and Chloride Ingress by Adding Graphene Nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. [Google Scholar] [CrossRef]

- Shamsaei, E.; de Souza, F.B.; Yao, X.; Benhelal, E.; Akbari, A.; Duan, W. Graphene-Based Nanosheets for Stronger and More Durable Concrete: A Review. Constr. Build. Mater. 2018, 183, 642–660. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-Scale Mechanical and Fracture Characteristics and Early-Age Strain Capacity of High Performance Carbon Nanotube/Cement Nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in Concrete—A Review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical Properties and Microstructure of a Graphene Oxide–Cement Composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self Sensing Carbon Nanotube (CNT) and Nanofiber (CNF) Cementitious Composites for Real Time Damage Assessment in Smart Structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Tyson, B.M.; Abu Al-Rub, R.K.; Yazdanbakhsh, A.; Grasley, Z. Carbon Nanotubes and Carbon Nanofibers for Enhancing the Mechanical Properties of Nanocomposite Cementitious Materials. J. Mater. Civ. Eng. 2011, 23, 1028–1035. [Google Scholar] [CrossRef]

- Gu, Y.; Xia, K.; Wei, Z.; Jiang, L.; She, W.; Lyu, K. Synthesis of NanoSiO2@graphene-Oxide Core-Shell Nanoparticles and Its Influence on Mechanical Properties of Cementitious Materials. Constr. Build. Mater. 2020, 236, 117619. [Google Scholar] [CrossRef]

- Pakharukov, Y.V.; Shabiev, F.K.; Safargaliev, R.F.; Voronin, V.V. Research the Mechanism of Hardening Cement Stone in the Presence of Graphene Nanoparticles; American Institute of Physics: College Park, MD, USA, 2019; Volume 2174. [Google Scholar] [CrossRef]

- Şimşek, B.; Uygunoğlu, T.; Dilmaç, Ö.F. Comparative Evaluation of the Effectiveness of PTFE Nanoparticles on Cement Pastes Properties with Multi-Wall Carbon Nanotubes, Graphene Oxide and Silver Nanoparticles. Constr. Build. Mater. 2022, 319, 126077. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Lu, W.; Thomas, A.V.; Zandiatashbar, A.; Rafiee, J.; Tour, J.M.; Koratkar, N.A. Graphene Nanoribbon Composites. ACS Nano 2010, 4, 7415–7420. [Google Scholar] [CrossRef]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef]

- Changgu, L.; Xiaoding, W.; Kysar, J.W.; James, H. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Ho, V.D.; Ng, C.-T.; Coghlan, C.J.; Goodwin, A.; Mc Guckin, C.; Ozbakkaloglu, T.; Losic, D. Electrochemically Produced Graphene with Ultra Large Particles Enhances Mechanical Properties of Portland Cement Mortar. Constr. Build. Mater. 2020, 234, 117403. [Google Scholar] [CrossRef]

- Dimov, D.; Amit, I.; Gorrie, O.; Barnes, M.D.; Townsend, N.J.; Neves, A.I.S.; Withers, F.; Russo, S.; Craciun, M.F. Ultrahigh Performance Nanoengineered Graphene–Concrete Composites for Multifunctional Applications. Adv. Funct. Mater. 2018, 28, 1705183. [Google Scholar] [CrossRef]

- Alexander, M.; Bertron, A.; De Belie, N. Performance of Cement-Based Materials in Aggressive Aqueous Environments; Springer: Dordrecht, The Netherlands, 2013; Volume 10. [Google Scholar]

- Peyvandi, A.; Soroushian, P.; Balachandra, A.M.; Sobolev, K. Enhancement of the Durability Characteristics of Concrete Nanocomposite Pipes with Modified Graphite Nanoplatelets. Constr. Build. Mater. 2013, 47, 111–117. [Google Scholar] [CrossRef]

- Le, J.-L.; Du, H.; Pang, S.D. Use of 2D Graphene Nanoplatelets (GNP) in Cement Composites for Structural Health Evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Pang, S.D.; Gao, H.J.; Xu, C.; Quek, S.T.; Du, H. Strain and Damage Self-Sensing Cement Composites with Conductive Graphene Nanoplatelet. Proc. SPIE 2014, 9061, 546–556. [Google Scholar] [CrossRef]

- Du, H.; Quek, S.T.; Pang, S.D. Smart Multifunctional Cement Mortar Containing Graphite Nanoplatelet. Proc. SPIE 2013, 8692, 871–880. [Google Scholar] [CrossRef]

- Papanikolaou, I.; Arena, N.; Al-Tabbaa, A. Graphene Nanoplatelet Reinforced Concrete for Self-Sensing Structures—A Lifecycle Assessment Perspective. J. Clean. Prod. 2019, 240, 118202. [Google Scholar] [CrossRef]

- Alkhateb, H.; Al-Ostaz, A.; Cheng, A.H.D.; Li, X. Materials Genome for Graphene-Cement Nanocomposites. J. Nanomech. Micromech. 2013, 3, 67–77. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the Mechanical Properties and Microstructure of Graphene Nanoplatelet-Cement Composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, R.; Zhang, T. Pore Structure and Durability of Cement-Based Composites Doped with Graphene Nanoplatelets. Mater. Express 2018, 8, 149–156. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of Barrier Properties of Cement Mortar with Graphene Nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lu, C.; Liu, B.; Zhang, K.; Li, C. Influence of Graphene Oxide Additions on the Microstructure and Mechanical Strength of Cement. New Carbon Mater. 2015, 30, 349–356. [Google Scholar] [CrossRef]

- Lv, S.; Ting, S.; Liu, J.; Zhou, Q. Use of Graphene Oxide Nanosheets to Regulate the Microstructure of Hardened Cement Paste to Increase Its Strength and Toughness. CrystEngComm 2014, 16, 8508–8516. [Google Scholar] [CrossRef]

- Intarabut, D.; Sukontasukkul, P.; Phoo-Ngernkham, T.; Zhang, H.; Yoo, D.-Y.; Limkatanyu, S.; Chindaprasirt, P. Influence of Graphene Oxide Nanoparticles on Bond-Slip Reponses between Fiber and Geopolymer Mortar. Nanomaterials 2022, 12, 943. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Influence of Graphene Oxide as Dispersed Phase in Cement Mortar Matrix in Defining the Crystal Patterns of Cement Hydrates and Its Effect on Mechanical, Microstructural and Crystallization Properties. Rsc Adv. 2015, 5, 52642–52657. [Google Scholar] [CrossRef]

- Chu, K.; Li, W.; Dong, H. Role of Graphene Waviness on the Thermal Conductivity of Graphene Composites. Appl. Phys. A 2013, 111, 221–225. [Google Scholar] [CrossRef]

- Metaxa, Z.S. Polycarboxylate Based Superplasticizers as Dispersant Agents for Exfoliated Graphene Nanoplatelets Reinforcing Cement Based Materials. J. Eng. Sci. Technol. Rev. 2015, 8, 1–5. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.; Yu, Q. Investigation of the Effects of Graphene and Graphene Oxide Nanoplatelets on the Micro- and Macro-Properties of Cementitious Materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of Graphene Oxide Nanosheets of Microstructure and Mechanical Properties of Cement Composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Tao, J.; Wang, X.; Wang, Z.; Zeng, Q. Graphene Nanoplatelets as an Effective Additive to Tune the Microstructures and Piezoresistive Properties of Cement-Based Composites. Constr. Build. Mater. 2019, 209, 665–678. [Google Scholar] [CrossRef]

- AS 3972-2010; General Purpose and Blended Cements. Standards Austria: Wien, Austria, 2010.

- AS 1478.1-2000; Chemical Admixtures for Concrete, Mortar and Grout-admixtures for Concrete. Standards Austria: Wien, Austria, 2000.

- Li, X.; Bond, P.L.; O’Moore, L.; Wilkie, S.; Hanzic, L.; Johnson, I.; Mueller, K.; Yuan, Z.; Jiang, G. Increased Resistance of Nitrite-Admixed Concrete to Microbially Induced Corrosion in Real Sewers. Environ. Sci. Technol. 2020, 54, 2323–2333. [Google Scholar] [CrossRef] [PubMed]

- AS 1012.3.1; Determination of Properties Related to the Consistency of Concrete- Slump Test. Standards Austria: Wien, Austria, 2014.

- AS 1012.9; Methods of Testing Concrete Method 9: Compressive Strength Tests-Concrete, Mortar and Grout Specimens. Standards Austria: Wien, Austria, 2014.

- AS 2350.11; Methods of Testing Portland, Blended and Masonry Cements—Compressive Strength. Standards Austria: Wien, Austria, 2006.

- AS 1012.12.1; Methods of Testing Concrete, Method 12.2: Determination of Mass per Unit Volume of Hardened Concrete- Rapid Measuring Method. Standards Austria: Wien, Austria, 1998.

- AS 1012.21; Methods of Testing Concrete, Determination of Water Absorption and Apparent Volume of Permeable Voids in Hardened Concrete. Standards Austria: Wien, Austria, 1999.

- AS 2350.14; Methods of Testing Portland, Blended and Masonry Cements, Method 14: Length Change of Cement Mortars Exposed to Sulfate Solution. Standards Austria: Wien, Austria, 2006.

- Kaur, R.; Kothiyal, N.C.; Arora, H. Studies on Combined Effect of Superplasticizer Modified Graphene Oxide and Carbon Nanotubes on the Physico-Mechanical Strength and Electrical Resistivity of Fly Ash Blended Cement Mortar. J. Build. Eng. 2020, 30, 101304. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Z.; Lu, F.; Li, H. Effect of Side Chain Density of Comb-Shaped Structure on Performance of Polycarboxylate Superplasticizer. J. Chin. Ceram. Soc. 2012, 40, 1570–1575. [Google Scholar]

- Wang, Q.; Zhan, D.; Qi, G.; Wang, Y.; Zheng, H. Impact of the Microstructure of Polycarboxylate Superplasticizers on the Dispersion of Graphene. New Carbon Mater. 2020, 35, 547–558. [Google Scholar] [CrossRef]

- Lu, L.; Ouyang, D. Properties of Cement Mortar and Ultra-High Strength Concrete Incorporating Graphene Oxide Nanosheets. Nanomaterials 2017, 7, 187. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Pang, S.D. Dispersion and Stability of Graphene Nanoplatelet in Water and Its Influence on Cement Composites. Constr. Build. Mater. 2018, 167, 403–413. [Google Scholar] [CrossRef]

- Chen, G.; Yang, M.; Xu, L.; Zhang, Y.; Wang, Y. Graphene Nanoplatelets Impact on Concrete in Improving Freeze-Thaw Resistance. Appl. Sci. 2019, 9, 3582. [Google Scholar] [CrossRef]

- Jing, G.; Ye, Z.; Lu, X.; Hou, P. Effect of Graphene Nanoplatelets on Hydration Behaviour of Portland Cement by Thermal Analysis. Adv. Cem. Res. 2017, 29, 63–70. [Google Scholar] [CrossRef]

- Lin, Y.; Du, H. Graphene Reinforced Cement Composites: A Review. Constr. Build. Mater. 2020, 265, 120312. [Google Scholar] [CrossRef]

- Suo, Y.; Guo, R.; Xia, H.; Yang, Y.; Yan, F.; Ma, Q. Study on Modification Mechanism of Workability and Mechanical Properties for Graphene Oxide-Reinforced Cement Composite. Nanomater. Nanotechnol. 2020, 10, 1847980420912601. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Panesar, D.K. Nano Reinforced Cement Paste Composite with Functionalized Graphene and Pristine Graphene Nanoplatelets. Compos. Part B Eng. 2020, 197, 108063. [Google Scholar] [CrossRef]

- Baomin, W.; Shuang, D. Effect and Mechanism of Graphene Nanoplatelets on Hydration Reaction, Mechanical Properties and Microstructure of Cement Composites. Constr. Build. Mater. 2019, 228, 116720. [Google Scholar] [CrossRef]

- Madbouly, A.I.; Mokhtar, M.M.; Morsy, M.S. Evaluating the Performance of RGO/Cement Composites for SHM Applications. Constr. Build. Mater. 2020, 250, 118841. [Google Scholar] [CrossRef]

- Long, W.-J.; Wei, J.-J.; Ma, H.; Xing, F. Dynamic Mechanical Properties and Microstructure of Graphene Oxide Nanosheets Reinforced Cement Composites. Nanomaterials 2017, 7, 407. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating Graphene Oxide in Cement Composites: A Study of Transport Properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Jiang, G.; Sun, J.; Sharma, K.R.; Yuan, Z. Corrosion and Odor Management in Sewer Systems. Curr. Opin. Biotechnol. 2015, 33, 192–197. [Google Scholar] [CrossRef]

- Jiang, G.; Sharma, K.R.; Guisasola, A.; Keller, J.; Yuan, Z. Sulfur Transformation in Rising Main Sewers Receiving Nitrate Dosage. Water Res. 2009, 43, 4430–4440. [Google Scholar] [CrossRef]

- Chetty, K.; Xie, S.; Song, Y.; McCarthy, T.; Garbe, U.; Li, X.; Jiang, G. Self-Healing Bioconcrete Based on Non-Axenic Granules: A Potential Solution for Concrete Wastewater Infrastructure. J. Water Process Eng. 2021, 42, 102139. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, G.; Bond, P.L.; Wells, T.; Keller, J. A Rapid, Non-Destructive Methodology to Monitor Activity of Sulfide-Induced Corrosion of Concrete Based on H2S Uptake Rate. Water Res. 2014, 59, 229–238. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, G.; Chiu, T.H.; Zhou, M.; Keller, J.; Bond, P.L. Effects of Surface Washing on the Mitigation of Concrete Corrosion under Sewer Conditions. Cem. Concr. Compos. 2016, 68, 88–95. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, G.; Bond, P.L.; Keller, J. Impact of Fluctuations in Gaseous H2S Concentrations on Sulfide Uptake by Sewer Concrete: The Effect of High H2S Loads. Water Res. 2015, 81, 84–91. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Wightman, E.; Kulandaivelu, J.; Bu, H.; Wang, Z.; Yuan, Z.; Jiang, G. Rebar Corrosion and Its Interaction with Concrete Degradation in Reinforced Concrete Sewers. Water Res. 2020, 182, 115961. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Arora, S. Economical Graphene Reinforced Fly Ash Cement Composite Made with Recycled Aggregates for Improved Sulphate Resistance and Mechanical Persformance. Constr. Build. Mater. 2018, 162, 608–612. [Google Scholar] [CrossRef]

| Product | Average Particle Size (µm) | Thickness (nm) | Purity (%) | Tapped Density (g/cm3) |

|---|---|---|---|---|

| PureGRAPH® 50 | 50 | 16.7 | 92.6 ± 0.5 (XPS) 89.7 ± 0.4 (Dumas method) | 0.3 |

| Constituents a, (kg/m3) | Admixture | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| w/c b | Cement | Water | Aggregates c | PureGRAPH® 50 | S.P. d | ||||

| 10 mm | MS | CS | FS | ||||||

| Control | 0.4 | 420 | 168 | 750 | 375 | 469 | 281 | 0 | 4.2 |

| PureGRAPH® 50-Low | 0.4 | 420 | 168 | 750 | 375 | 469 | 281 | 0.10% | 4.2 |

| PureGRAPH® 50-High | 0.4 | 420 | 168 | 750 | 375 | 469 | 281 | 0.20% | 4.2 |

| Constituents a, (kg/m3) | Admixture | |||||

|---|---|---|---|---|---|---|

| Samples | w/c b | Cement | Water | CS c | FS d | PureGRAPH® 50 |

| Control (no treatment) | 0.5 | 600 | 300 | 863 | 464 | 0 |

| PureGRAPH® 50-Low | 0.5 | 600 | 300 | 863 | 464 | 0.07% |

| PureGRAPH® 50-High | 0.5 | 600 | 300 | 863 | 464 | 0.15% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chetty, K.; Watson, M.; Raine, T.; McGurgan, T.; Ladislaus, P.; Chen, J.; Zhang, S.; Lin, L.; Jiang, G. Enhancing Concrete and Mortar Properties and Durability Using Pristine Graphene Particles. Coatings 2022, 12, 1703. https://doi.org/10.3390/coatings12111703

Chetty K, Watson M, Raine T, McGurgan T, Ladislaus P, Chen J, Zhang S, Lin L, Jiang G. Enhancing Concrete and Mortar Properties and Durability Using Pristine Graphene Particles. Coatings. 2022; 12(11):1703. https://doi.org/10.3390/coatings12111703

Chicago/Turabian StyleChetty, Kirthi, Michael Watson, Thomas Raine, Todd McGurgan, Paul Ladislaus, Jun Chen, Shuai Zhang, Liangxu Lin, and Guangming Jiang. 2022. "Enhancing Concrete and Mortar Properties and Durability Using Pristine Graphene Particles" Coatings 12, no. 11: 1703. https://doi.org/10.3390/coatings12111703

APA StyleChetty, K., Watson, M., Raine, T., McGurgan, T., Ladislaus, P., Chen, J., Zhang, S., Lin, L., & Jiang, G. (2022). Enhancing Concrete and Mortar Properties and Durability Using Pristine Graphene Particles. Coatings, 12(11), 1703. https://doi.org/10.3390/coatings12111703