1. Introduction

Wood is one of the earliest and most versatile natural materials employed by humans; a material witnessing the development of human civilization [

1,

2,

3]. Due to its excellent mechanical strength and unique visual beauty, wood has been widely used since ancient times for building houses or bridges and for manufacturing furniture, interior decorative and functional elements, or art objects [

4,

5,

6,

7,

8]. Depending on the application and use conditions, the aesthetic appearance and selected properties of wood may be, however, affected in time by ageing and degradation [

9,

10,

11,

12,

13]. Surface coating is the usual method employed to highlight and protect the beauty of wood surfaces, while also improving their resistance to wear, everyday use, and ageing [

14,

15,

16,

17,

18].

Waxes represent a very important class of ancient natural finishing materials for traditional furniture and wood conservation practice [

18], as well as for current applications and developments in wood treating technologies [

19,

20,

21,

22]. Beeswax and Chinese wax, both produced by insects, are two important representatives of this class. They are hydrophobic organic compounds, with a complex composition, containing different components with long alkyl chains. The main components are the esters of fatty acids with long-chain saturated alcohols, followed by long-chain hydrocarbons, free primary and secondary alcohols and fatty acids, alongside other functional derivatives such as hydroxy-acids, aldehydes, and ketones [

23,

24,

25,

26,

27,

28,

29].

Employment of waxes for aesthetic and protective wood coating/treatment has a long history across the world. In China, traditional hot waxing, employing a mixture of beeswax and Chinese wax, represents a simple and environmentally friendly method for the surface waterproofing of hardwood furniture [

30]. Waxing can enhance wood beauty and influence its ageing resistance [

31,

32,

33,

34], while also improving its dimensional stability due to the hydrophobic properties of the treated material [

35,

36,

37,

38]. In Europe, beeswax has been also used for furniture polishing, being often employed in combination with a drying oil or a natural resin, as a paste or cream material to obtain waterproof and satin/glossy surfaces [

39].

The ageing of materials is an irreversible, in-time occurring complex phenomenon, affecting both wood surfaces and the coating materials. The main ageing factors include temperature, light/UV radiation, humidity, and oxygen exposure, which can lead to different chemical degradation processes, such as photolysis (photodegradation), thermolysis (thermodegradation), and oxidation [

40,

41,

42,

43,

44,

45].

The photodegradation of wood continues to be a subject of wide interest. Many different investigations have demonstrated that wood photodegradation is primarily related to the decomposition of lignin by UV radiation [

11,

43,

44,

45,

46,

47]. Lignin absorbs much more UV radiation than cellulose and hemicellulose, resulting in colour and surface chemical changes. Ultraviolet photons have enough energy to split the chemical bonds of lignin so that phenoxy radicals are generated, and these free radicals react further with oxygen to produce carbonyl chromogenic groups, finally resulting in the wood colour changing [

47].

Light wavelength is an important factor affecting wood photodegradation. Živković and co-workers found that UV light in the spectral region below 335 nm only has a little effect on wood colour change, while the most active wavelength range that induces wood colour change was relatively narrow (360 to 435 nm), although visible light with wavelengths up to 515 nm also had a significant effect on wood surface colour change [

48]. Wood extractives are an important factor affecting wood colour, while also playing an important role in the wood photodegradation process [

49,

50,

51,

52,

53]. The presence of wood extractives increased the O/C ratio during wood UV radiation, indicating that the extractives participated in the photo-oxidation reaction [

52,

53]. However, compared with lignin, the extractives are photodegraded much slower, so light-induced colour changes of wood can be retarded by the oxidation of extractives.

The ageing behavior of wood-coated surfaces is complex and influenced by the properties and ageing resistance of both the substrate and the coating film, its thickness and ability to absorb, dissipate or scatter light, as well as the light source (spectral distribution, intensity), the exposure time, and environmental temperature [

15,

17,

43,

54,

55]. Natural light passing through the normal window glass is an important ageing factor in indoor environments, mainly due to its content in UVA radiation transmitted by glass in proportions varying from 75% to 57% for clear glass and further influenced/decreased by several factors, such as glass thickness, number of glass layers, colouring, protective films/coatings, and other treatments [

56,

57]. Low UVA transmission (0.57) was reported only for special structures of clear double-glazed window panes [

56]. However, the effect of short waves visible light (violet-blue) and the thermic effect of infrared components of natural light passing through window glass [

56,

57] have to be considered as indoor ageing factors as well [

48,

54].

Despite the historic and present importance of waxes as wood protective coatings, to the best of our knowledge, research data on the ageing/colour stability of wood surfaces coated with different waxes is rather limited, e.g., [

15,

23,

27,

30,

31,

34], while mostly referring to accelerated weathering tests for outdoor conditions [

30,

34], or simulated accelerated thermal ageing [

27], and only rarely for indoor photo-degradation [

15]. In the respective study, the protective behavior of beeswax (and other two materials) against colour and surface chemistry changes of poplar wood substrate was assessed following an artificial ageing test performed in a Solar Box equipped with a 2.5 kW xenon arc lamp and a filter cutting off UV light bellow 280 nm, for a total period of 1008 h, at a temperature of 55 °C and irradiance of 550 W/m

2 [

15]. In a previous study, we investigated and compared the ageing behavior of beeswax, Chinese wax, and Chinese ash wood surfaces finished with these waxes in two different tests: a short-term natural ageing (6 months) and an artificial accelerated ageing test (UVA source with H2 cut off filter). Ageing effects were evaluated by colour measurements and FTIR investigation. Acceleration indexes for UV exposure compared with exposure to natural sunlight (filtered by window glass) of about 60× for unfinished surfaces, 45× for surfaces finished with beeswax, and 40× for surfaces finished with Chinese wax were calculated [

23].

The purpose of this study was to evaluate the influence of wood coating with BW and Chinese wax on the colour and surface chemical changes after long-term (7 years) exposure to natural light in indoor conditions in a simulated natural ageing test, with the view of adding new useful data in this field. Two wood species important for both historic furniture and actual wood processing sector were employed in a comparative evaluation. Colour changes were measured in the CIELab system and statistically analysed, while FTIR was employed to highlight chemical changes. The in-time evolution of the ageing phenomena for the total period of 7 years was also discussed.

2. Materials and Methods

2.1. Materials and Samples Preparation

Beeswax (BW) was purchased from Conrep SRL, Brașov, Romania and Chinese wax was bought from Heng Hong Feng La Jiao Ye Company, Cangzhou, China. Both waxes were solid materials, which were prepared for application as solutions in white spirit (50 g/250 mL white spirit).

European maple (Acer pseudoplatanus) and European walnut (Juglans regia) were selected for this study. A number of 15 defectless wood samples, with a size of 120 mm × 80 mm × 10 mm, were prepared from the same batch of material (MC = 10%–12%) for each wood species. Prior to finishing with waxes, all samples were sanded successively with grit sizes 120, 180, and 240, respectively, thoroughly cleaned of dust, and conditioned in a Feutron climatic chamber at 20 °C and 55% RH until constant weight was reached (approximately 7 days).

Among the 15 wood samples, 5 samples were kept unfinished as controls, 5 samples were finished with beeswax, and the remaining 5 were finished with Chinese wax. Both waxes were manually applied with a soft pad covered with cotton. Five layers, each of about 25 g/m2, were applied by circular motions on the wood samples. The drying time between layers was 24 h and finally all finished wood samples were polished with a polishing machine equipped with a felt disk. Accordingly, a top film wax layer of about 20 μm was obtained.

2.2. Indoors Natural Ageing Procedure

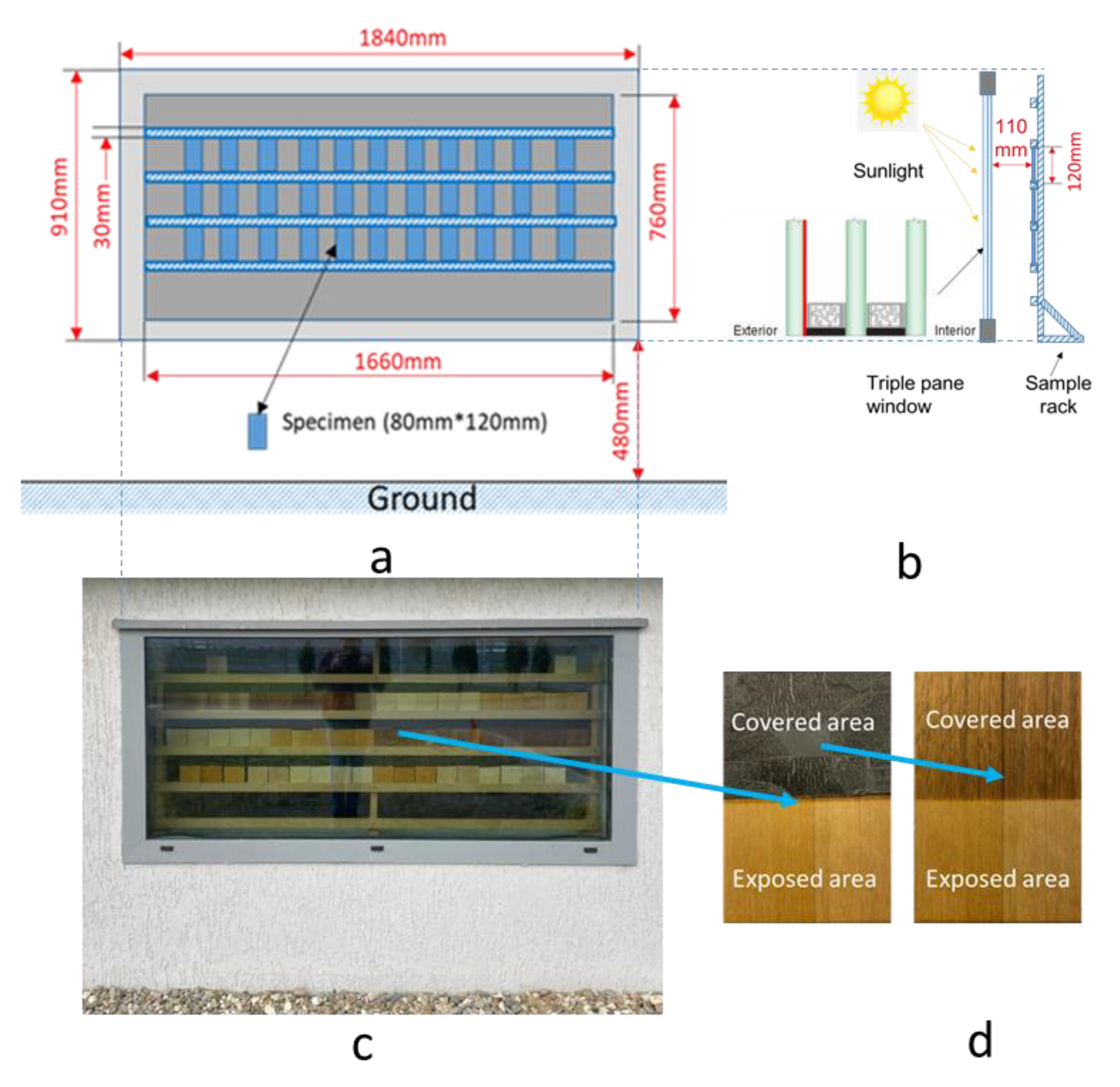

Indoor natural ageing tests were carried out at the CDI Institute of Transilvania University of Brasov (geographical coordinates 45°39′54″ N, 25°33′27″ E and elevation 550 m). The specimens were placed on a special test rack in vertical position, facing south (9 degrees deviation from south to east) and exposed to natural light filtered through a triple-glazed window pane (see

Figure 1). The triple-glazed window pane, with a total thickness of 48 mm, includes three layers of glass: 6 mm secured glass, 4 mm secured glass, and 4 mm float glass, separated by two sealed inter-spaces of 20 mm and 14 mm, filled with argon gas for a better thermal insulation.

A photo-radiometer (HD2102.2, Delta OHM, Padova, Italy) equipped with 2 different sensors for the wavelength ranges 240–400 nm (sensor LP 471A-UV eff) and 800–1050 nm (sensor LP 471 RAD) was employed to measure solar light irradiance (W/m2) reaching the surface of the window glass (outdoors measurements) and passing through the triple glazed window pane (indoors measurements). According to experimental comparative measurements, the calculated percentage irradiance transmissions through the glass were 2.43% for UV-B radiation, 5.20% for UV-A radiation, and 31.99% for the visible and NIR radiation (up to 1050 nm). The actual irradiance average values measured (in a clear-sky sunny day and hours of maximum solar light irradiation) at the surface of the exposed test samples were around 204 W/m2 for visible light (plus NIR up to 1050 nm), while considerably lower for UV radiation: 0.49 W/m2 UVA radiation and 0.001 W/m2 UVB radiation.

In order to allow a clear differentiation of sunlight-induced ageing effects from any temperature-induced effects (the indoor ambient temperature varied in the range of about 15–40 °C, depending on the season), half of the test surface was covered with black cardboard.

2.3. Visual Assessment and Colour Measurements

In order to highlight and document the aspect changes of wood surfaces before and after natural ageing, all samples were scanned at a resolution of 600 dpi, employing a Mustek Scan Express A3 USB, 1200 PRO Scanner (Neuss, Germania) connected to a computer for picture acquisition and processing.

Colour measurements of the CIEL*a*b* system were performed using an AvaSpec-USB2 (Avantes B.V., Apeldoorn, The Netherlands) spectrometer (10° standard observer, standard D65 light source) equipped with an integrated AVA sphere of 80 mm diameter connected by fiber optics. This was connected to a computer for data acquisition and processing, using the dedicated colour application software AVASOFT (version 7.7, Company, Tamil Nadu, India). The colour coordinates: lightness L*, redness a*, and yellowness b* of all wood samples were measured both initially and after different periods of ageing. For each test sample, colour measurements were taken at four spots (two exposed to sunlight, two covered with black cardboard), which were actually circular areas of approximately 8 mm diameter, and averages were calculated for each group of samples in terms of coating, ageing condition, and exposure situation. For reliable results and data dispersion minimization, all colour measurements, before and after different ageing periods, were performed in the same areas for each test piece. For this purpose, a samples fixation plate was employed.

Colour differences between aged and not-aged control samples were calculated based on the Equation (1):

where ΔL*, Δa*, and Δb* are the differences of initial and final values (before and after ageing for different periods of time) of L*, a*, and b* parameters, respectively. A low ΔE value corresponds to a low colour difference.

2.4. FTIR Investigation of Surface Chemistry Changes

Fourier-transform infrared (FTIR) spectra were recorded for both unfinished and wax-finished wood samples, before and after different ageing periods, employing a FTIR spectrometer (ALPHA, Bruker, Ettlingen, Germany) equipped with an ATR (attenuated total reflection) module. Spectra were recorded within the range 4000 to 400 cm−1, at a resolution of 4.0 cm−1 and 24 scans for each measurement. Two replicates from each batch of samples (uncoated/coated, not aged/aged) were investigated by FTIR. Spectra from three randomly chosen measuring areas were registered for each sample, resulting in six spectra for each tested variant. Spectra were further processed for baseline correction and smoothing and were computed employing OPUS software (version 7.2, Bruker, Ettlingen, Germany). Average spectra were further normalized (Min-Max normalization) and compared to highlight chemical changes due to ageing. Assignment of characteristic absorption bands was based on literature references.

2.5. Statistical Analysis

The statistical significance of colour changes as a result of coating of wood samples with the two types of waxes and of those resulting during the ageing of the test specimens was assessed by subjecting the measured colour coordinates data for lightness (L*), redness (a*), and yellowness (b*) to variance analysis using SPSS (IBM Corp., IBM SPSS Statistics for Windows, v. 25, Armonk, NY, USA), with the probability level being set at 0.05. The ANOVA analysis by two factors, including “surface type” and “ageing conditions” as independent factors, and their interaction “surface type × ageing conditions” was applied. Levene’s test was conducted to analyze homogeneity of variance, whereas the Shapiro–Wilk test was applied to check the normality distribution of data. Both these tests were the preconditions of the two-way ANOVA test. Fisher’s protected least significant difference (LSD) test was employed to separate treatment averages at α = 0.05.

3. Results and Discussions

3.1. Colour Changes of European Maple Samples

Data and pictures in

Table 1 comparatively illustrate the visual aspect, the average values of the corresponding colour parameters (L*, a*, b*), and the calculated colour differences (ΔE) as result of ageing for the European maple wood samples, both unfinished and finished with the two types of waxes (BW, CW), before and after ageing. These pictures show that the wood samples, both unfinished and finished, suffered colour changes perceived as darkening and/or minor shade modification. These changes were more obvious for the unfinished samples (ΔE = 12.54) compared with the finished ones (ΔE = 4.79 for CW and ΔE = 6.44 for BW). This indicates a long-term protective effect of the wax finishing layers against colour changes induced by the natural light filtered by the window glass. Compared with the initial aspect, some small colour changes also occurred in the areas covered by black cardboard, protected from the direct action of light; these changes were due to thermal-induced ageing. The corresponding ΔE values were only slightly different among the three types of tested European maple samples (3.06 BW; 3.34 CW; 3.87 unfinished). It seems reasonable to consider a similar contribution of thermal ageing on the uncovered areas of the samples, which would highlight the fact that daylight passing through window glass was a more active factor than temperature during natural ageing. Furthermore, the protective effect of the waxes seems to be active against this main ageing factor in indoor conditions.

The results of Levene’s test and the Shapiro–Wilk test indicated the homogeneous variance and normal distribution of the measured colour data such that the two-way ANOVA test was appropriate for their statistical analysis. A summary of the results of the two-way ANOVA statistical analysis of the measured colour data for the European maple wood samples is presented in

Table 2. When comparing the specimens’ color under all three ageing conditions, the surface type (uncoated or coated with BW or CW) is not a significant factor affecting the lightness and redness of the specimens (

p values of 0.176 and 0.131), but it has a significant effect on the yellowness (

p value < 0.0001). However, when one-way ANOVA tests were explored on the control group, the

p value was <0.0001, indicating that there was a significant difference of redness between the uncoated and coated groups.

On the other hand, ageing condition has a significant effect on all three colour coordinates L*, a*, and b* (p values < 0.0001). The effects of ageing on the colour of the samples could be visually observed for all series of samples, uncoated and coated with the two types of waxes, with clearly detectable differences between the areas directly exposed to light and those covered with black cardboard.

The influence of the interaction between surface type and ageing condition is also a significant factor affecting specimens’ colour changes. This is an important finding highlighting the significant influence of ageing on the colour of wood surfaces and the specific different behavior of uncoated and coated surfaces for the same wood species, as well as the influence of the actual coating material (BW or CW in this case).

The plots in

Figure 2 illustrate the dynamics of colour changes (ΔE, ΔL*, Δa*, Δb*) during indoor natural ageing for the whole period of 7 years (84 months). They show that the colour changes were mainly yellowing and darkening, with positive Δb* values and negative ΔL* values, which were considerably higher than redness changes (Δa*). Additionally, the evolution of colour changes (ΔE, ΔL*, Δa*, Δb*) was not linear, but followed patterns with rapid and important changes in the first 6 months, followed by a trend of reverse evolution up to 12–18 months, and then continued by a slower process of modification. The values of total colour changes (ΔE) during the ageing of the European maple specimens coated with waxes were considerably smaller than those for the uncoated specimens, highlighting a protective effect of waxes on European maple wood. Decrease of lightness was sharp at the beginning of the process, reaching a turning point after 4 or 5 months of ageing, corresponding to ΔL* values of −13.03 for the unfinished samples and −5.33 and −7.83 for the samples finished with BW and CW, respectively. After this period, a reverse trend of lightening was registered up to 12 months. From 12 to 84 months, the value of ΔL* decreased with less than 3.08 units, which means that from the 2nd to the 7th year of ageing, the wood samples suffered only a slight darkening. The curves of Δb* (yellowness changes) followed a mirrored pattern, with a sharp increase, reaching maximum positive Δb* values of +9.05 for the uncoated samples and +9.75 and +10.32 for those coated with BW and CW, respectively, after 6–12 months. This phase was followed by a sharp or slow decrease. Yellowing was mostly associated with lignin degradation [

9,

10,

11,

13,

15,

58,

59,

60] and these results suggest that UV light penetrated through the wax layer affecting lignin at the interface wood/coating, which is in accordance with previously reported research [

15]. Redness slightly increased (Δa* values of +1.13 to +2.25 units) during the first 5 months of natural ageing, then slightly decreased up to 18 months, remaining then almost unchanged until the end of the test. As a result of all these changes, the ΔE curves showed a sharp rapid increase at the beginning of the process, with a maximum reached after 5 months, followed by a trend of decrease and a further evolution after 18 months influenced by the type of surface: slight increase for uncoated wood, slight decrease for the samples coated with BW, and more advanced decrease for those coated with CW. The described dynamics of colour changes is in good accordance with the literature, highlighting the role of light as main actor in indoor natural ageing, while also pointing towards degradation of lignin as a main photo-chemically induced process occurring rapidly in the first stages of wood ageing [

11,

46]. The different slope yellowness changes (Δb* in

Figure 2b) after 18 months for the coated samples as compared with the control wood suggest only a time-limited protective effect against yellowing, respectively lignin degradation, which is in line with previous work concluding that BW as protective material had a positive effect on colour changes in the first stages of ageing (first 96 h from a 1008 h artificial ageing test employing a xenon lamp and 280 nm cut off filter in a solar box), while no relevant effect on the chemical modification of the substrate could be detected after longer exposure times [

15].

3.2. Colour Changes of European Walnut Samples

Table 3 presents images for visual assessment of the colour of uncoated and wax-coated European walnut samples, before and after 7 years of indoor natural ageing, alongside the average values of their colour measurements in the CIELab system. At first sight, it is obvious that the light-induced colour changes are opposite to those occurring in the case of European maple, while also visibly more pronounced. These changes mainly consisted of lightening and chromatic changes perceived as increase of yellowness and some variation of redness. These changes were more obvious for the European walnut samples coated with waxes (ΔE = 13.80 for BW and 20.83 for CW) than those determined for the uncoated controls (ΔE = 11.66). Similar to European maple, small colour changes due to thermal-induced ageing also occurred in the areas covered by black cardboard, protected from the direct action of light. The corresponding ΔE values in these areas were slightly lower than those for European maple, varying from 2.15 units for the uncoated samples to 1.38 units and 1.83 units, respectively, for those finished with BW and CW. Light passing through the window glass was again the most active factor during natural ageing, but coating with the two waxes could not impart a better colour fastness to the European walnut samples, as was the case for the European maple samples.

The results of Levene’s test and the Shapiro–Wilk test indicated the homogeneous variance and normal distribution of the measured colour data such that the two-way ANOVA test was appropriate for their statistical analysis.

Table 4 presents a summary of the results of two-way ANOVA statistical analysis of the measured colour data for the European walnut wood samples, uncoated and coated with waxes (BW, CW), before and after 7 years of natural ageing.

Accordingly, the colour of European walnut samples was significantly influenced by coating with waxes and the type of wax (BW, CW); this influence was clearly significant for the lightness (L*) and redness (a*) coordinates (p < 0.0001), while somehow uncertain for yellowness (b*) (p = 0.050). This is exactly the opposite of what occurred in the case of European maple wood samples and could be due to the different initial colours of the two wood species, with European walnut darker than European maple.

Nevertheless, similar to European maple, the ageing condition of surface was found to be a significant factor influencing all three colour coordinates L*, a*, and b* (p values < 0.0001); however, the lightness (L*) values of control and aged covered samples did not have significant differences. The effects of ageing on the colour of European walnut samples could be visually observed for all series of samples: uncoated and coated with the two types of waxes, with clearly detectable differences between the areas directly exposed to light and those covered with black cardboard.

However, the interaction between the two factors: (1) surface type (uncoated, coated with BW or CW) and its (2) ageing condition (not aged, aged exposed to light, aged covered) resulted to be a significant factor influencing the colour of European walnut specimens only in the case of the lightness (L*) coordinate (p = 0.029). The influence of this combined factor on the chromaticity of the European walnut samples (a*, b* coordinates) was not significant (p = 0.177, p = 0.689).

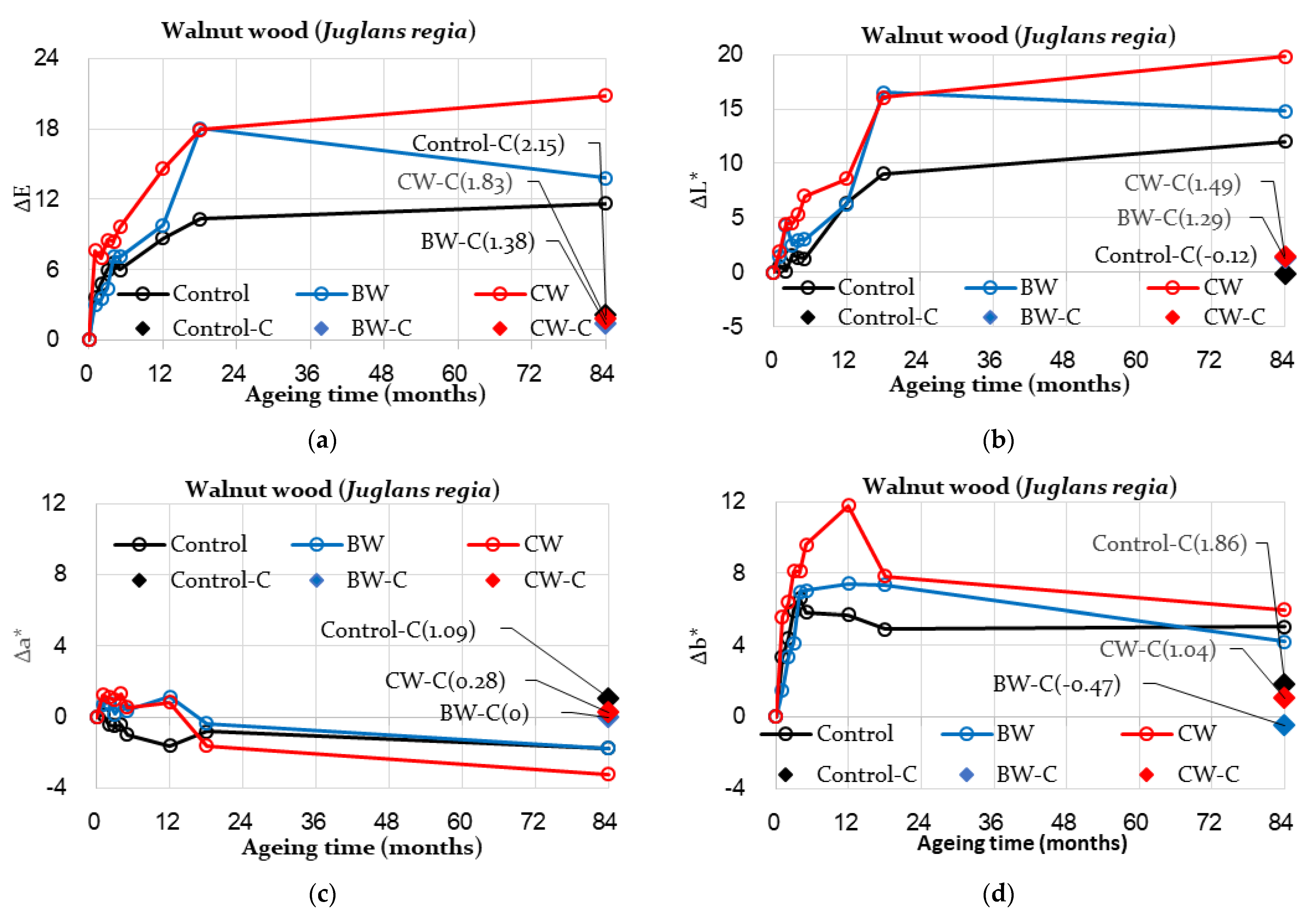

The plots in

Figure 3 show that the in-time evolution of colour changes during the natural ageing of European walnut samples mainly consisted of advanced lightening with positive ΔL* values (up to 10–20 units) occurring in parallel with an increase of yellowness (positive Δb* values up to a maximum of about 12 units for CW) and considerably lower variation of redness (positive and negative Δa* values, generally lower than 2 units). The values of colour changes for the specimens coated with waxes were considerably bigger as compared with uncoated specimens, suggesting that waxes could not provide protection against light-induced advanced bleaching of European walnut wood. All European walnut samples became lighter during the whole process, though dynamic changes and particularities as a function of finishing were visible (

Figure 2b). The maximum ΔL* values registered after 84 months of indoor ageing under the action of light were +20.83 units in the case of European walnut samples coated with CW and +13.80 units for those coated with BW, compared with +11.66 for the uncoated controls. An increase of lightness of about 3 units occurred in the last five years for the uncoated walnut samples and those coated with CW, while a slight decrease of lightness of about 2 units occurred in the same period for those coated with BW. Redness (Δa*) of uncoated European walnut samples slightly decreased during the whole natural ageing process, but a wavy variation was registered for the samples coated with waxes: slight increase up to 12 months followed by slight decrease until the end of the test (84 months). The variation of yellowness followed a pattern resembling the one registered for the European maple samples. It registered an initial sharp increase reaching a distinct maximum (CW) or a plateau value in the first 5–12 months, followed by a sharp (CW) or slow decrease up to 18 months, after which a slight and slow variation was registered until 84 months. As yellowing was mostly related to chromophores resulting from lignin photo-degradation [

9,

10,

11,

46,

47], it would suggest that in the first 5 up to 12 months (for coated samples), the most important chemical change in the wood support must have been lignin degradation. As a result of all these changes, the ΔE curves showed a continuous increase, more rapid at the beginning of the process (5–6 months), followed by a slower evolution, with a change of slope at 18 months and a further evolution influenced by the type of coating.

Comparing the results of colour changes for the two considered wood species, a common feature is that colour changes were relatively fast in the first 6 months, and then became slower. In addition, the light-coloured European maple became darker, and the darker-coloured European walnut became lighter, which might be correlated to the different content and types of extractives of the two types of wood [

58], considering the demonstrated effect of the extractives in the photo-degradation of wood and the correlated particular behavior of various wood species [

49,

50,

51,

52,

53]. In line with literature data, it could be assumed that during the 7 years of light-induced natural ageing process, the colour change of wood was mainly related to lignin degradation in the early stages (first 5–12 months) when maximum variation of yellowness was observed, being related more to the extractives’ photo-degradation in the later stages [

11,

52,

53]. The extractives in walnut might have delayed, to some extent, lignin degradation by the absorption of UV and visible light and scavenging free radicals, processes leading to their oxidative degradation [

58]. Additionally, it was previously demonstrated that visible blue light can bleach dark wood species, although IR spectra did not reveal chemical changes after photo-bleaching [

59]. However, more research is needed to clarify this aspect, as well as to understand the opposite effect of coating with waxes on the colour stability of the two wood species

3.3. FTIR Investigation of Ageing of Uncoated and Coated Wood Surfaces

Colour changes as a visible indicator of ageing are the result of specific chemical processes. Surface chemistry changes as effects of daylight-induced ageing in indoor conditions were investigated by FTIR spectroscopy for the uncoated and coated wood samples.

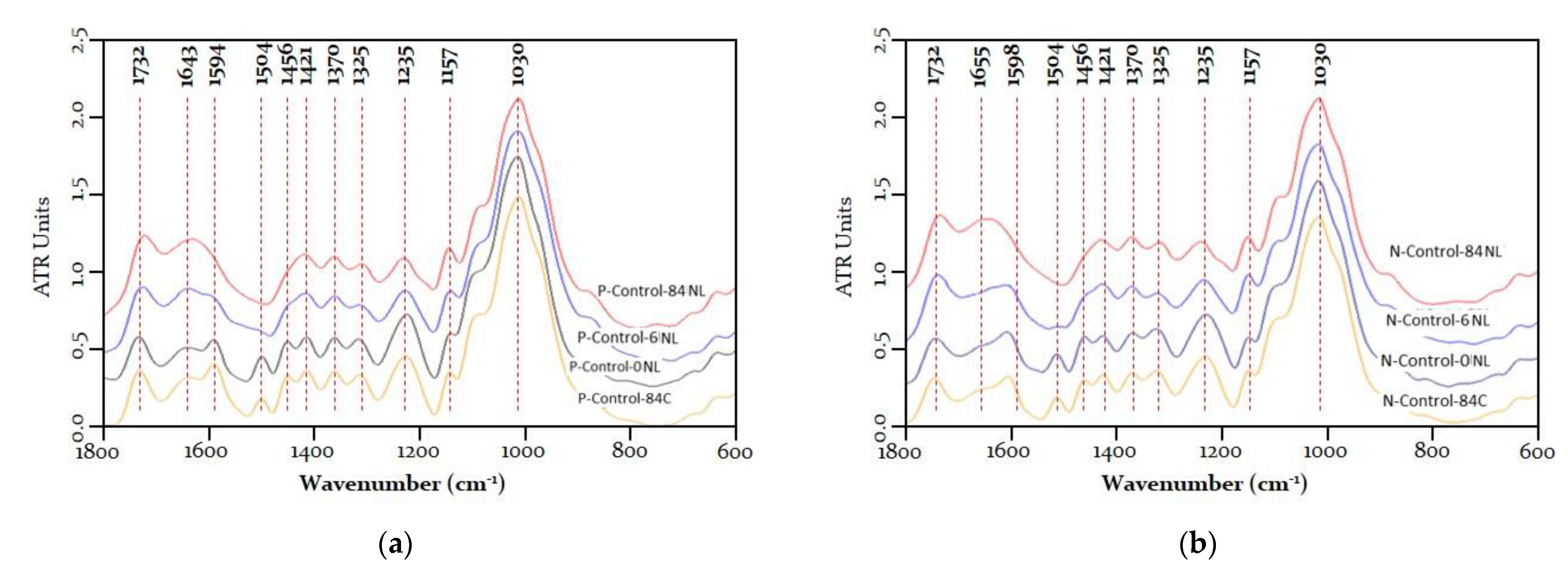

Figure 4 comparatively presents the FTIR spectra of the uncoated wood (a- European maple, b-European walnut) substrates (in the fingerprint region 2000–600 cm

−1) before (0NL) and after simulated natural ageing for 6 months (6NL) and 84 months (84NL) of exposure. Similarly, the spectra in

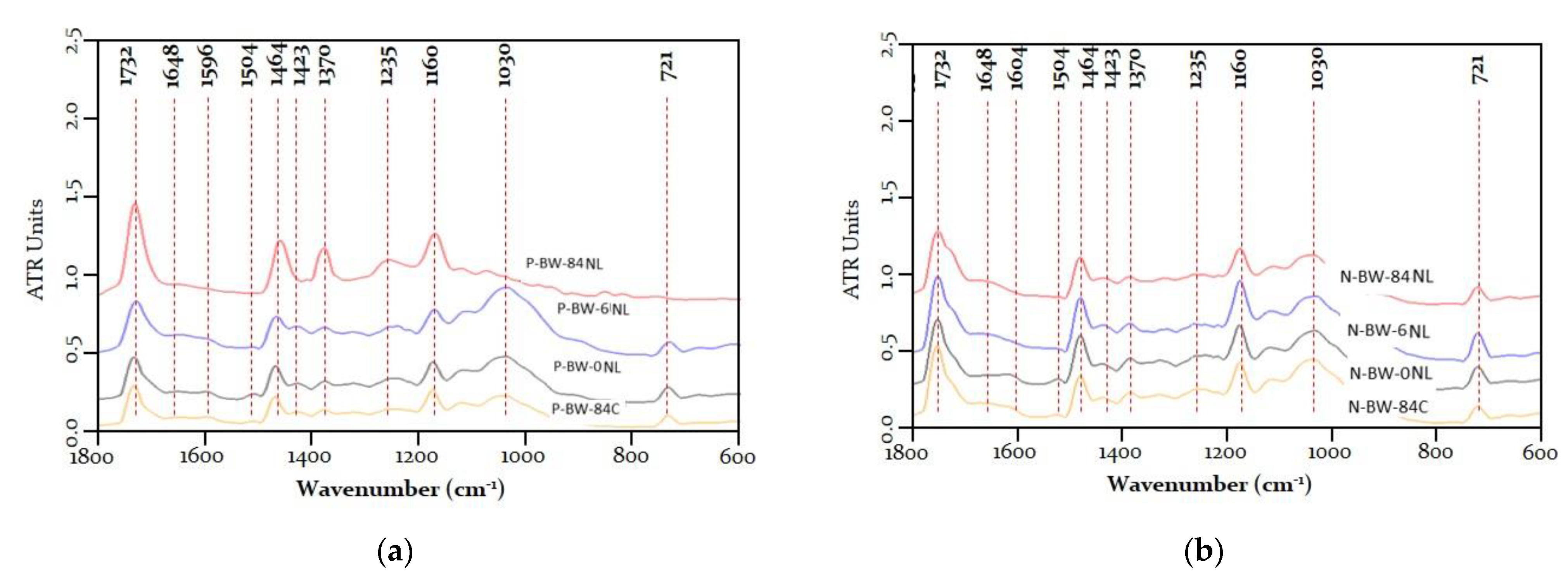

Figure 5 and

Figure 6 comparatively present the influence of indoor natural simulated ageing on the surface chemistry of the wood samples coated with the two types of waxes.

For both types of uncoated wood samples, the FTIR spectra clearly highlighted important chemical changes due to light-induced natural ageing, revealed by changes in some of the specific absorption bands of the main wood components. These changes were visible after 6 months of exposure and evolved after 84 months. The most evident modifications were the decrease up to complete disappearance of the lignin-associated bands at around 1504 cm

−1 and 1594 cm

−1, assigned to lignin C=C stretching vibrations of the aromatic rings [

35]. They occurred in parallel with increase of the absorption intensity of the bands at around 1732 cm

−1, assigned to unconjugated carbonyl groups and that at around 1643 cm

−1, assigned to conjugated and aromatic carbonyls, which also slightly shifted to lower values after 84 months. These carbonyl peaks may be associated with chromophores resulting from lignin photo-degradation. Additionally, it could be noticed the decrease of the peak at around 1235 cm

−1, assigned to syringyl ring and C–O stretch in lignin and xylan [

61], and an increase of peaks at around 1157 cm

−1, assigned to asymmetric C–O–C stretching associated with cellulose and hemicelluloses, indicating an apparent increase of cellulose content, mainly due to lignin degradation. These chemical changes are in good accordance with the literature [

11,

13,

15,

23,

47,

54]. It is noteworthy that for the sample specimens covered with black cardboard, ageing resulted in only very slight changes in the absorption intensity of the peaks at 1732 cm

−1, 1370 cm

−1, and 1504 cm

−1.

Ageing effects revealed by colour modifications of wood surfaces coated with the two types of waxes, increased as compared with the uncoated control in the case of European walnut, must be associated to chemical changes occurring in the transparent wax layer and the wood support under it. However, the FTIR spectra of the finished samples (presented in

Figure 5 and

Figure 6) by the ATR technique reflect almost exclusively the chemical features of the top wax layers. Only some limited transparency of wood chemical features, such as small absorptions of lignin at around 1600 and 1504 cm

−1 and C–O absorptions in the range 1103–1030 cm

−1, associated to hollocelluloses, could be observed in the spectra of the coated specimens prior to ageing.

The spectra of the finished surfaces, almost similar for both wood species, revealed only minor changes as result of ageing. Still, the total disappearance of the small lignin associated band at 1504 and 1596 cm

−1 could be observed. Furthermore, the absorption at around 721 cm

−1, assigned to CH

2 rocking vibrations and characteristic for waxes [

35,

62], decreased as a result of ageing. For European maple wood samples coated with BW, this peak totally disappeared after 84 months of exposure. These changes proved that photo-degradation of lignin and some minor degradation of the waxes top layers occurred during the simulated indoor natural ageing of coated samples. These findings are in line with colour measurements. Degradation of lignin must have occurred under the action of UV-A and visible violet radiation [

48] of natural light passing through the window glass and should be correlated with the increase of yellowness [

9,

11,

13,

62,

63], which was more rapid and advanced in the first 6 months of ageing.

Comparing the spectra of coated samples after 6 and 84 months of exposure, only minor other changes could be observed. This clearly indicated that the waxes remained on the wood surfaces, suffering very little chemical changes during the 7 years test, in accordance with the reported remarkable chemical stability of waxes (BW) identified on ancient objects [

25,

26,

27,

28,

29]. However, the increased absorption at around 1030 cm

−1, associated to the wood substrate, observed in the spectra of the 7-years-aged coated samples indicated thinning of the wax layers, possibly as a result of temperature-induced softening and absorption into the substrate. In conclusion, it can therefore be assumed that both beeswax and Chinese wax have a role of protective coatings for wood surfaces, though they are transparent to natural light filtered by window glass, including UV light, and colour changes of wood surfaces, influenced mostly by the wood species, will occur.

4. Conclusions

A long-term (7 years) simulated indoor natural ageing test, under the action of natural light filtered by window glass, highlighted the comparative behaviour of two wood species: European maple (Acer pseudoplatanus) and European walnut (Juglans regia) and the effect of their coating with beeswax (BW) and Chinese wax (CW) on the evolution of colour and surface chemistry changes, providing new research-based data important for the scientific conservation of historic furniture/wood cultural heritage.

Colour changes of uncoated wood samples was rapid in the first 6 months, and slowed down until 84 months, though differences in the dynamics and actual changes were observed among the two wood species: European maple darkened (ΔL = −13.03), while European walnut lightened during this process (ΔL = +11.66). A sharp increase of yellowness in the first 5–6 months, combined with the results of FTIR, highlighted that degradation of lignin was mainly responsible for colour change in the early stages of natural ageing, while the bleaching of extractives might have played an essential role in later stages, especially in the case of walnut.

Coating of maple wood with waxes was associated with only small, statistically not significant colour changes, while a slight increased colour stability against light-induced ageing was obtained. Contrarily, coating with waxes brought about more evident and statistically significant colour changes in the case of European walnut, but could not impede colour changes as result of light-induced ageing, which were higher when compared with uncoated walnut wood.

Statistial analysis of colour data by two-way Anova showed that ageing condition (not aged, aged under the direct action of light, aged protected) was a significant factor influencing the colour of wood samples, regardless of wood species and surface type (uncoated, coated with BW, coated with CW). On the other hand, the combined action of surface type and ageing condition was found statistically significant in the case of maple and not significant in the case of walnut. FTIR investigation of the coated samples proved that photo-degradation of lignin and some minor degradation of the waxes top layers occurred during the 7 years of simulated indoor natural ageing.

Future research should focus on the role of extractives in the particular behaviour of the different wood species, the utilisation of mixtures of waxes, and their modification with UV absorbing additives in order to improve their protective effect against light-induced ageing.