Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

2.2.1. Preparation of Shellac Polishes

2.2.2. Finishing of Wood Samples

2.2.3. Accelerated UV Ageing Procedure

2.3. Characterisation Methods

2.3.1. Colour Measurements

2.3.2. FTIR Investigations

3. Results

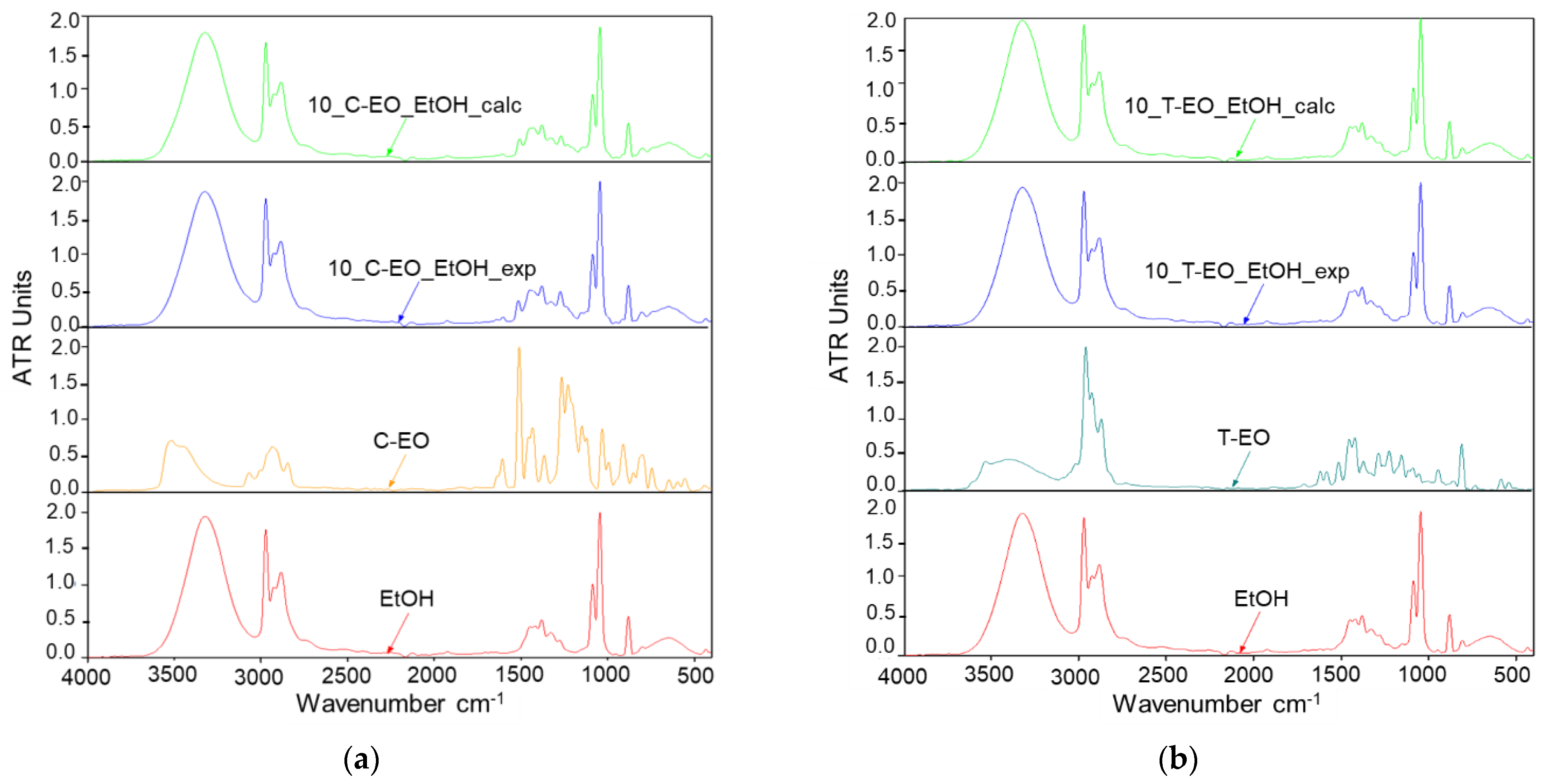

3.1. Modification of Shellac Solutions with EOs

3.2. Colour of Wood Surfaces

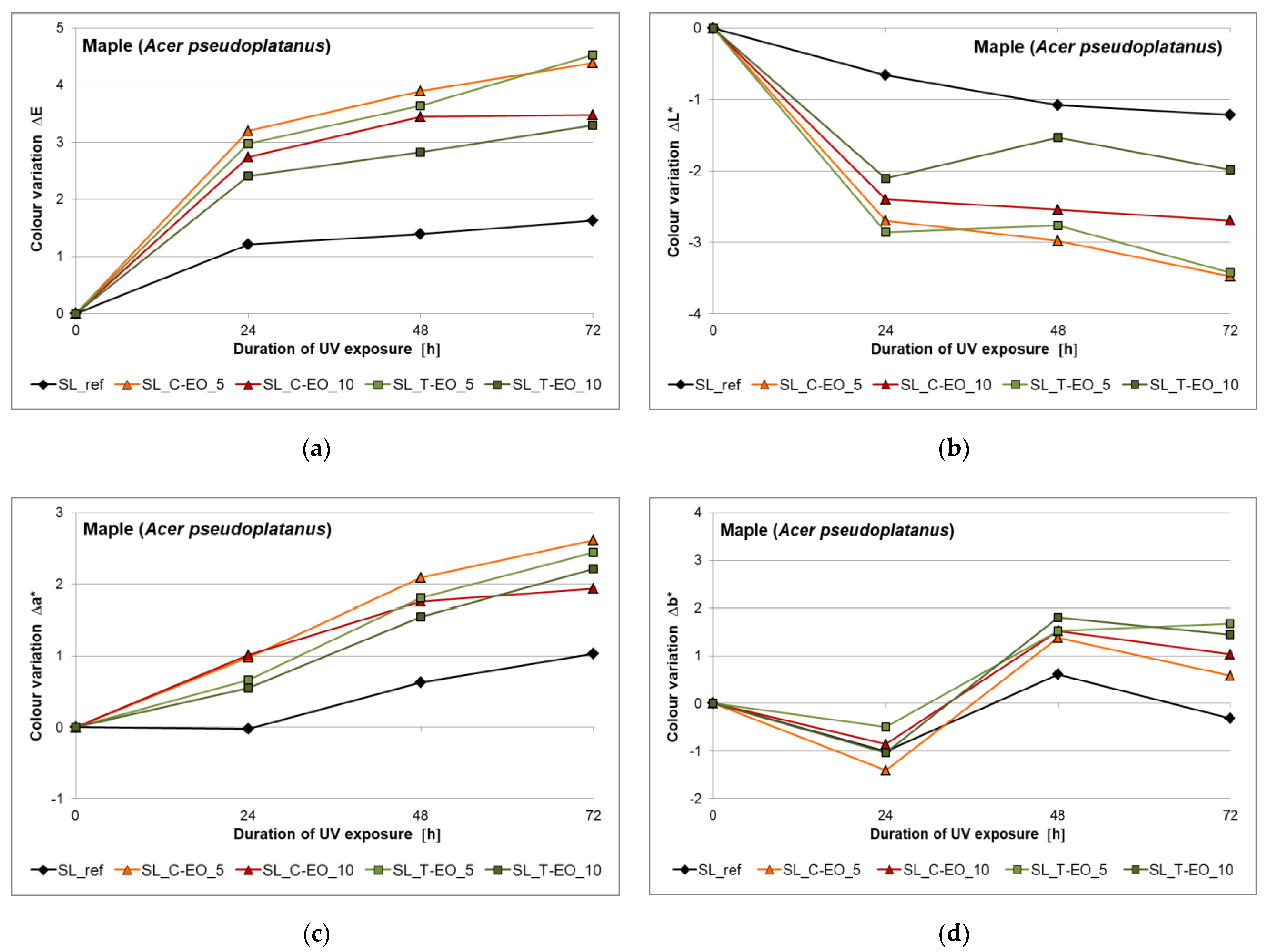

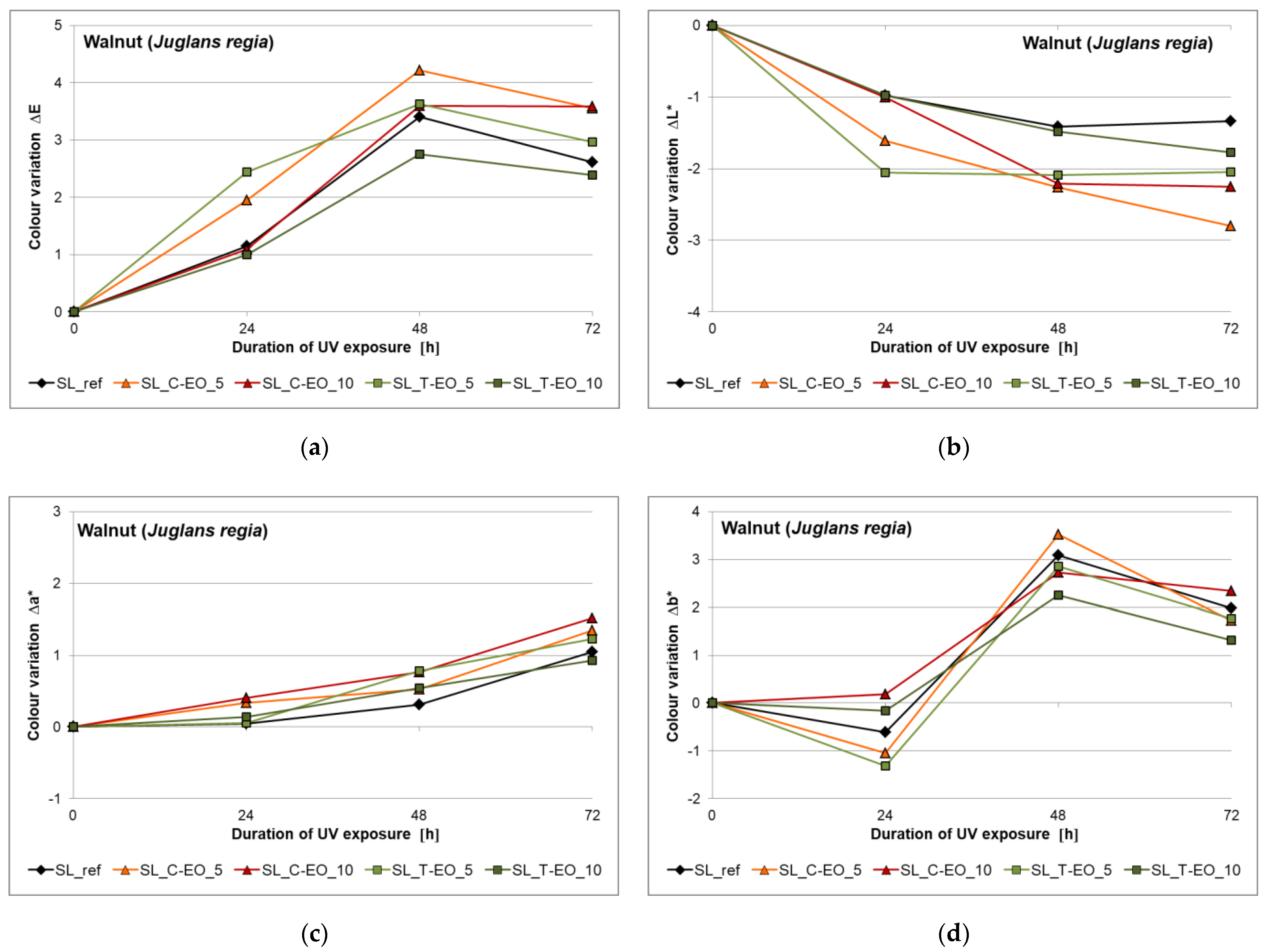

3.3. Colour Changes Induced by UV Ageing

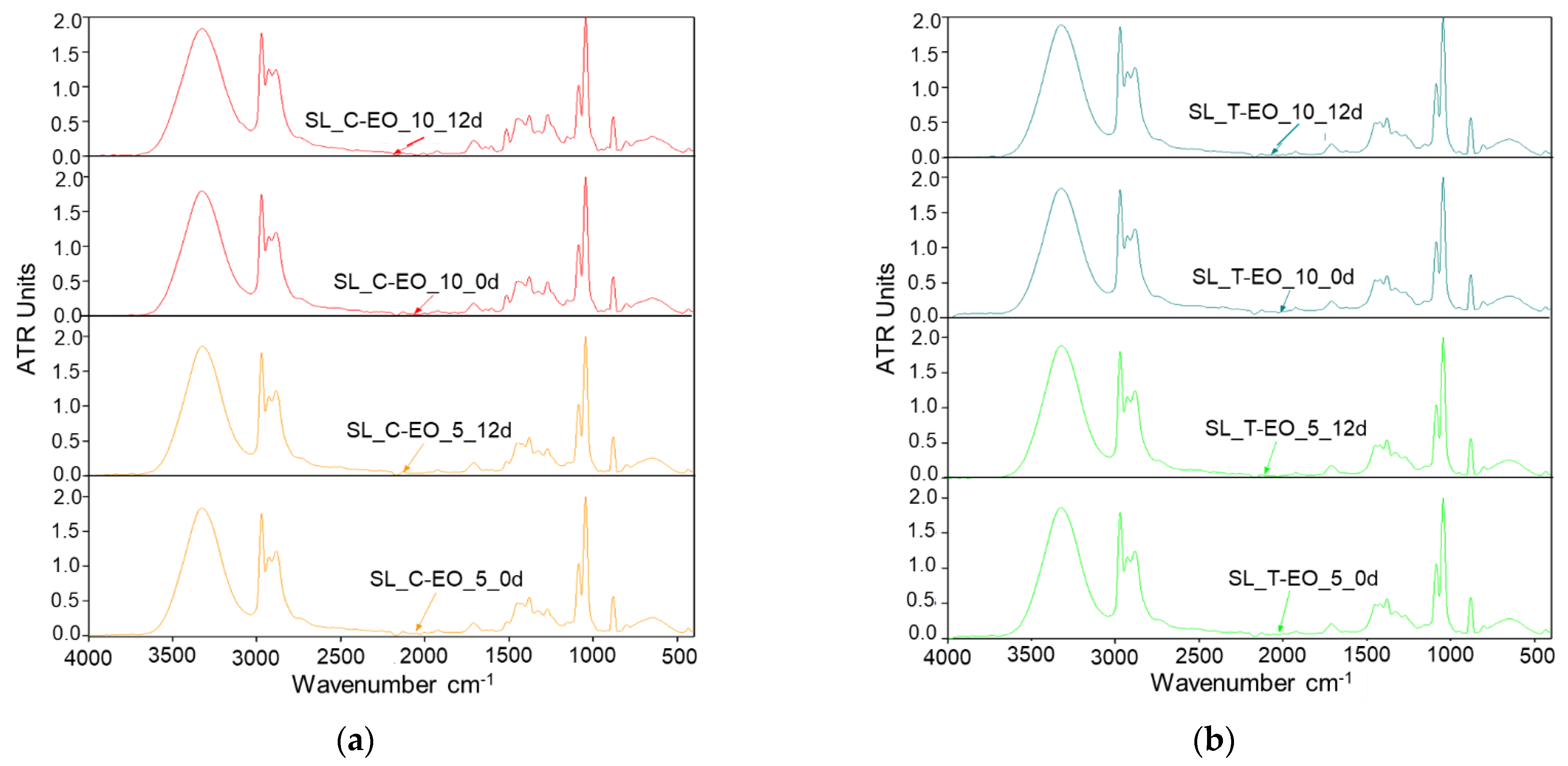

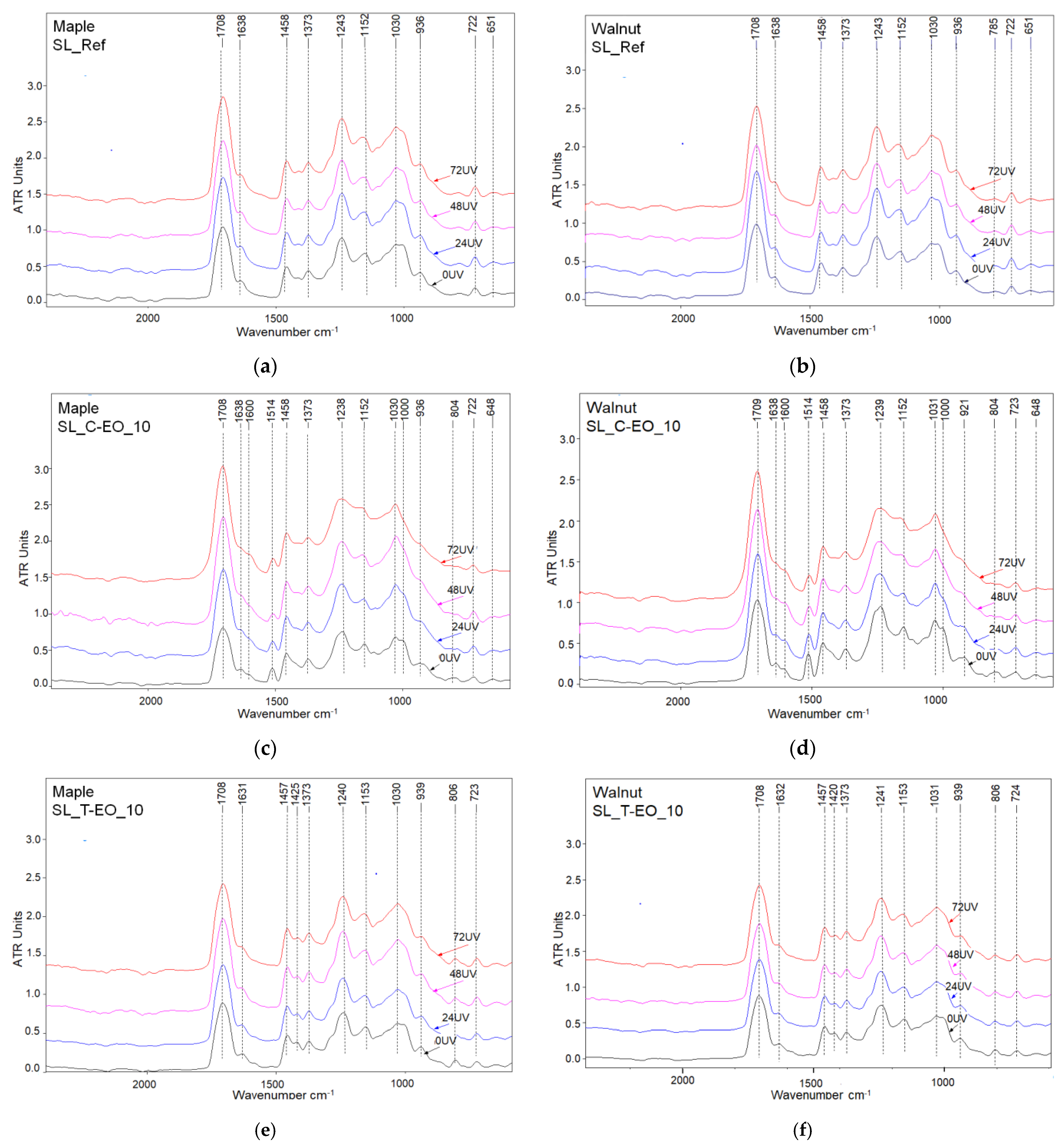

3.4. FTIR Investigation of UV Ageing Effects

4. Discussions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thombare, N.; Kumar, S.; Kumari, U.; Sakare, P.; Yogi, R.K.; Prasad, N.; Sharma, K.K. Shellac as a multifunctional biopolymer: A review on properties, applications and future potential. Int. J. Biol. Macromol. 2022, 215, 203–223. [Google Scholar] [CrossRef] [PubMed]

- Licchelli, M.; Malagodi, M.; Somaini, M.; Weththimuni, M.; Zanchi, C. Surface treatments of wood by chemically modified shellac. Surf. Eng. 2013, 29, 121–127. [Google Scholar] [CrossRef]

- Šimůnková, K.; Pánek, M.; Zeidler, A. Comparison of selected properties of shellac varnish for restoration and polyurethane varnish for reconstruction of historical artefacts. Coatings 2018, 8, 119. [Google Scholar] [CrossRef]

- Sözen, E. Determination of changes in the mechanical and color properties of some wood species treated with shellac. BioResources 2022, 17, 1703–1716. [Google Scholar] [CrossRef]

- Derry, J. Documenting the Process, Defining the Product. A Study on the Processing Methods of Shellac and the Analysis of Selected Physical and Chemical characteristics. Master’s Thesis, Institute of Archeology, Conservation and History, University of Oslo, 2012. Available online: https://www.duo.uio.no/handle/10852/34480 (accessed on 18 October 2022).

- Timar, M.C.; Varodi, A.M.; Liu, X.Y. The influence of artificial ageing on selected properties of wood surfaces finished with traditional materials—An assessment for conservation purposes. Ser. II For. Wood Ind. Agric. Food Eng. 2020, 13, 81–94. [Google Scholar] [CrossRef]

- Bercea, A.; Mitu, B.; Matei, A.; Marascu, V.; Brajnicov, S. Esterification process induced by UV irradiation of shellac thin films deposited by matrix assisted pulsed laser evaporation. Rev. De Chim. 2019, 70, 2982–2984. [Google Scholar] [CrossRef]

- Ghosh, M.; Gupta, S.; Kumar, V.K. Studies on the loss of gloss of shellac and polyurethane finishes exposed to UV. Maderas Cienc. Y Tecnol. 2015, 17, 39–44. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Capsoni, D.; Malagodi, M.; Milanese, C.; Licchelli, M. Shellac/nanoparticles dispersions as protective materials for wood. Appl. Phys. A 2016, 122, 1058. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Capsoni, D.; Malagodi, M.; Licchelli, M. Improving wood resistance to decay by nanostructured ZnO-based treatments. J. Nanomater. 2019, 2019, 6715756. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Milanese, C.; Licchelli, M.; Malagodi, M. Improving the protective properties of shellac-based varnishes by functionalized nanoparticles. Coatings 2021, 11, 419. [Google Scholar] [CrossRef]

- Capobianco, G.; Calienno, L.; Pelosi, C.; Scacchi, M.; Bonifazi, G.; Agresti, G.; Picchio, R.; Santamaria, U.; Serranti, S.; Monaco, A.L. Protective behaviour monitoring on wood photo-degradation by spectroscopic techniques coupled with chemometrics. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 172, 34–42. [Google Scholar] [CrossRef]

- Miranda, M.; Sun, X.; Ference, C.; Plotto, A.; Bai, J.; Wood, D.; Assis, O.B.G.; Ferreira, M.D.; Baldwin, E. Nano- and micro- carnauba wax emulsions versus shellac protective coatings on postharvest citrus quality. J. Am. Soc. Hortic. Sci. 2021, 146, 40–49. [Google Scholar] [CrossRef]

- Yuan, Y.; He, N.; Dong, L.; Guo, Q.; Zhang, X.; Li, B.; Li, L. Multiscale shellac-based delivery systems: From macro- to nanoscale. ACS Nano 2021, 15, 18794–18821. [Google Scholar] [CrossRef]

- Liao, W.; Badri, W.; Dumas, E.; Ghnimi, S.; Elaissari, A.; Saurel, R.; Gharsallaoui, A. Nanoencapsulation of essential oils as natural food antimicrobial agents: An overview. Appl. Sci. 2021, 11, 5778. [Google Scholar] [CrossRef]

- Bonda, A.F.; Candiani, A.; Pertile, M.; Giovannelli, L.; Segale, L. Shellac gum/carrageenan alginate-based core–shell systems containing peppermint essential oil formulated by mixture design approach. Gels 2021, 7, 162. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L. Preparation of shellac resin microcapsules coated with urea formaldehyde resin and properties of waterborne paint films for tilia amurensis rupr. Membranes 2020, 10, 278. [Google Scholar] [CrossRef]

- Tao, Y.; Yan, X.X.; Chang, Y.J. Effect of coating process on mechanical, optical, and self-healing properties of waterborne coating on basswood surface with MF-coated shellac core microcapsule. Polymers 2021, 13, 4228. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Yan, X.X.; Tao, Y.; Chang, Y.J. Effect of shellac waterborne coating microcapsules on the optical, mechanical and self-healing properties of waterborne primer on Tilia europaea L. wood. Coatings 2021, 11, 785. [Google Scholar] [CrossRef]

- Yan, X.X.; Li, W.B.; Han, Y.; Yin, T.Y. Preparation of melamine/rice husk powder coated shellac microcapsules and effect of different rice husk powder content in wall material on properties of wood waterborne primer. Polymers 2021, 14, 72. [Google Scholar] [CrossRef]

- Gupta, S.; John, A.; Kumar, V.S.K. Studies on effect of coat thickness on the moisture uptake by a hardwood substrate. Maderas Cienc. Y Tecnol. 2016, 18, 443–456. [Google Scholar] [CrossRef][Green Version]

- Liu, M.; Xu, G.L.; Wang, J.A.; Tu, X.W.; Liu, X.Y.; Wu, Z.H.; Lv, J.F.; Xu, W. Effects of shellac treatment on wood hygroscopicity, dimensional stability and thermostability. Coatings 2020, 10, 881. [Google Scholar] [CrossRef]

- Haro-González, J.N.; Castillo-Herrera, G.A.; Martínez-Velázquez, M.; Espinosa-Andrews, H. Clove essential oil (Syzygium aromaticum L. myrtaceae): Extraction, chemical composition, food applications, and essential bioactivity for human health. Molecules 2021, 26, 6387. [Google Scholar] [CrossRef]

- Bimbiraitė-Survilienė, K.; Stankevičius, M.; Šuštauskaitė, S.; Gęgotek, A.; Maruška, A.; Skrzydlewska, E.; Barsteigienė, Z.; Akuņeca, I.; Ragažinskienė, O.; Lukošius, A. Evaluation of chemical composition, radical scavenging and antitumor activities of Satureja hortensis L. herb extracts. Antioxidants 2021, 10, 53. [Google Scholar] [CrossRef]

- Dhifi, W.; Bellili, S.; Jazi, S.; Bahloul, N.; Mnif, W. Essential oils’ chemical characterization and investigation of some biological activities: A critical review. Medicines 2016, 3, 25. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, Z.; Huang, Q.; Zhang, D. Antifungal activity of several essential oils and major components against wood-rot fungi. Ind. Crops Prod. 2017, 108, 278–285. [Google Scholar] [CrossRef]

- Mutlu-Ingok, A.; Devecioglu, D.; Dikmetas, D.N.; Karbancioglu-Guler, F.; Capanoglu, E. Antibacterial, antifungal, antimycotoxigenic, and antioxidant activities of essential oils: An updated review. Molecules 2020, 25, 4711. [Google Scholar] [CrossRef]

- Perumal, A.B.; Huang, L.; Nambiar, R.B.; He, Y.; Li, X.; Sellamuthu, P.S. Application of essential oils in packaging films for the preservation of fruits and vegetables: A review. Food Chem. 2022, 375, 131810. [Google Scholar] [CrossRef]

- Pánek, M.; Reinprecht, L.; Hulla, M. Ten essential oils for beech wood protection—Efficacy against wood-destroying fungi and moulds, and effect on wood discoloration. BioResources 2014, 9, 5588–5603. [Google Scholar] [CrossRef]

- Stupar, M.; Grbić, M.L.; Džamić, A.; Unković, N.; Ristić, M.; Jelikić, A.; Vukojević, J. Antifungal activity of selected essential oils and biocide benzalkonium chloride against the fungi isolated from cultural heritage objects. S. Afr. J. Bot. 2014, 93, 118–124. [Google Scholar] [CrossRef]

- Kakakhel, M.A.; Wu, F.; Gu, J.-D.; Feng, H.; Shah, K.; Wang, W. Controlling biodeterioration of cultural heritage objects with biocides: A review. Int. Biodeterior. Biodegradation 2019, 143, 104721. [Google Scholar] [CrossRef]

- Morsy, N.F.S. Chemical structure, quality indices and bioactivity of essential oil constituents. In Active Ingredients from Aromatic and Medicinal Plants; El-Shemy, A.H., Ed.; Cairo University: Cairo, Egypt, 2017; Available online: https://www.intechopen.com/chapters/53045 (accessed on 26 August 2022).

- Fadel, H.H.M.; El-Ghorab, A.H.; Hussein, A.M.; El-Massry, K.F.; Lotfy, S.N.; Ahmed, M.Y.S.; Soliman, T.N. Correlation between chemical composition and radical scavenging activity of 10 commercial essential oils: Impact of microencapsulation on functional properties of essential oils. Arab. J. Chem. 2020, 13, 6815–6827. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of oils: A comprehensive review of benefits, techniques, and applications. Compr. Rev. Food Sci. Food Saf. 2015, 15, 143–182. [Google Scholar] [CrossRef] [PubMed]

- Dupuis, V.; Cerbu, C.; Witkowski, L.; Potarniche, A.-V.; Timar, M.C.; Żychska, M.; Sabliov, C.M. Nanodelivery of essential oils as efficient tools against antimicrobial resistance: A review of the type and physical-chemical properties of the delivery systems and applications. Drug Deliv. 2022, 29, 1007–1024. [Google Scholar] [CrossRef] [PubMed]

- Khorram, F.; Ramezanian, A. Cinnamon essential oil incorporated in shellac, a novel bio-product to maintain quality of ‘Thomson navel’ orange fruit. J. Food Sci. Technol. 2020, 58, 2963–2972. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, J.; Hu, C.; Deng, L.; Ritenour, M.A. Use of carvacrol and thymol in shellac coating to control stem-end rot on ‘ruby red’ grapefruit and maintain fruit quality during simulated storage and marketing. Sci. Hortic. 2020, 272, 109606. [Google Scholar] [CrossRef]

- Sharma, S.; Barkauskaite, S.; Duffy, B.; Jaiswal, A.K.; Jaiswal, S. Characterization and antimicrobial activity of biodegradable active packaging enriched with clove and thyme essential oil for food packaging application. Foods 2020, 9, 1117. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Gelatin/agar-based functional film integrated with pickering emulsion of clove essential oil stabilized with nanocellulose for active packaging applications. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127220. [Google Scholar] [CrossRef]

- Pop, D.M.; Varodi, A.M.; Timar, M.C. Essential oils as potential ecological wood preservatives—A preliminary test on thyme essential oil. Innov. Woodwork. Ind. Eng. Des. 2019, 15, 28–36. Available online: https://www.scjournal-inno.com/bg/author-278-dana-mihaela-pop.htm (accessed on 18 October 2022).

- Reiprecht, L.; Pop, D.M.; Vidholdova, Z.; Timar, M.C. Anti-decay potential of five essential oils against the wood-decaying fungi Serpula lacrymans and Trametes versicolor. Acta Fac. Xylologiae Zvolen 2019, 61, 63–72. [Google Scholar] [CrossRef]

- Pop, D.M.; Timar, M.C.; Beldean, E.C.; Varodi, A.M. Combined testing approach to evaluate the antifungal efficiency of clove (Eugenia caryophyllata) essential oil for potential application in wood conservation. BioResources 2020, 15, 9474–9489. [Google Scholar] [CrossRef]

- Pop, D.-M.; Timar, M.C.; Varodi, A.M.; Beldean, E.C. An evaluation of clove (Eugenia caryophyllata) essential oil as a potential alternative antifungal wood protection system for cultural heritage conservation. Maderas Cienc. Y Tecnol. 2022, 11, 1–16. [Google Scholar] [CrossRef]

- Complex Art: Creative Hobby Timisoara. Available online: https://complexart.ro/ (accessed on 27 August 2022).

- Steaua divina—produse naturale. Available online: https://www.steauadivina.ro/en/ (accessed on 27 August 2022).

- Chemical Company SA—Romania. Available online: https://www.chemical.ro/en/products-index/ethyl-alcohol/ethyl-alcohol-abs-99-3_p247/ (accessed on 27 August 2022).

- Timar, M.C.; Varodi, A.M.; Gurău, L. Comparative study of photodegradation of six wood species after short-time UV exposure. Wood Sci. Technol. 2015, 50, 135–163. [Google Scholar] [CrossRef]

- Evans, P.; Chowdhury, M.J.; Mathews, B.; Schmalzl, K.; Ayer, S.; Kiguchi, M.; Kataoka, Y. Weathering and UV protection of wood surfaces (chapter 14). In Handbook of Environmental Degradation of Materials, 1st ed.; Myer, K., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2005; pp. 277–297. ISBN 9780815517498. [Google Scholar]

- Kataoka, Y.; Kiguchi, M.; Williams, R.; Evans, D. Violet light causes photodegradation of wood beyond the zone affected by ultraviolet radiation. Holzforschung 2007, 61, 23–27. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M. A comparative study on the artificial UV and natural ageing of beeswax and Chinese wax and influence of wax finishing on the ageing of Chinese Ash (Fraxinus mandshurica) wood surfaces. J. Photochem. Photobiol. B Biol. 2019, 201, 111607. [Google Scholar] [CrossRef]

- Allegretti, O.; Cividini, R.; Travan, L. Drying process for white beech. Pro Ligno 2008, 4, 11–19. [Google Scholar]

- Liu, X.Y. Contributions to the Study of Ageing Phenomena of Wooden Substrate and Traditional Materials for Transparent Finishes—A Comparative Approach for Europe and China with Applicability in Furniture Conservation/Restoration. Ph.D. Thesis, Transilvania University of Brasov, Brasov, Romania, 2017. [Google Scholar]

- Tarhan, I.; Bakır, M.R.; Kalkan, O.; Yöntem, M.; Kara, H. Rapid determination of adulteration of clove essential oil with benzyl alcohol and ethyl acetate: Towards quality control analysis by FTIR with chemometrics. Vib. Spectrosc. 2022, 118, 103339. [Google Scholar] [CrossRef]

- Valderrama, A.C.S.; Rojas De, G.C. Traceability of active compounds of essential oils in antimicrobial food packaging using a chemometric method by ATR-FTIR. Am. J. Anal. Chem. 2017, 8, 726–741. [Google Scholar] [CrossRef]

- Schulz, H.; Ozkan, G.; Baranska, M.; Krüger, H.; Özcan, M. Characterisation of essential oil plants from Turkey by IR and Raman spectroscopy. Vib. Spectrosc. 2005, 39, 249–256. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood—Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany; New York, NY, USA, 1984. [Google Scholar]

- William, R.S. Weathering of wood. In Handbook of Wood Chemistry and Wood Composites, 1st ed.; Roger, M.R., Ed.; CRD Press: London, UK; New York, NY, USA, 2005; pp. 9–32. ISBN 0-8493-1588-3. [Google Scholar]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef]

- Persze, L.; Tolvaj, L. Photodegradation of wood at elevated temperature: Colour change. J. Photochem. Photobiol. B Biol. 2012, 108, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Chang, S.-T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Lin, H.-Y.; Chang, S.-T. Stabilizing effect of extractives on the photo-oxidation of Acacia confusa wood. Polym. Degrad. Stab. 2010, 95, 1518–1522. [Google Scholar] [CrossRef]

- Chang, T.-C.; Lin, H.-Y.; Wang, S.-Y.; Chang, S.-T. Study on inhibition mechanisms of light-induced wood radicals by Acacia confusa heartwood extracts. Polym. Degrad. Stab. 2014, 105, 42–47. [Google Scholar] [CrossRef]

- Evans, P.D.; Haase, J.G.; Seman, B.M.; Kiguchi, M. The search for durable exterior clear coatings for wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef]

- Pánek, M.; Oberhofnerová, E.; Hýsek; Šedivka, P.; Zeidler, A. Colour stabilization of oak, spruce, larch and douglas fir heartwood treated with mixtures of nanoparticle dispersions and UV-stabilizers after exposure to UV and VIS-radiation. Materials 2018, 11, 1653. [Google Scholar] [CrossRef]

- Elgendy, E.M.; Khayyat, S. Oxidation reactions of some natural volatile aromatic compounds: Anethole and eugenol. Russ. J. Org. Chem. 2008, 44, 823–829. [Google Scholar] [CrossRef]

- Gülçin, I. Antioxidant activity of eugenol: A structure—Activity relationship study. J. Med. Food 2011, 14, 975–985. [Google Scholar] [CrossRef]

- Yildiz, G.; Aydogmus, Z.; Cinar, M.E.; Senkal, F.; Ozturk, T. Electrochemical oxidation mechanism of eugenol on graphene modified carbon paste electrode and its analytical application to pharmaceutical analysis. Talanta 2017, 173, 1–8. [Google Scholar] [CrossRef]

- Alfieri, M.L.; Panzella, L.; Crescenzi, O.; Napolitano, A.; D’Ischia, M. Nature-inspired functional chromophores from biomimetic o-quinone chemistry. Eur. J. Org. Chem. 2021, 2021, 2982–2989. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Pánek, M.; Böhm, M. Effect of surface pretreatment with natural essential oils on the weathering performance of spruce wood. BioResources 2018, 13, 7053–7070. [Google Scholar] [CrossRef]

| No | Type of SL Polish | Composition (Volumetric Proportions) | Research Code (Coating Variant) | ||

|---|---|---|---|---|---|

| SL_Ref (13.2% *) | C-EO 100% | T-EO 100% | |||

| 1 | Reference SL | 100 | - | - | SL_Ref |

| 2 | Modified SL-C-EO | 95 | 5 | - | SL_C-EO_5 |

| 3 | 90 | 10 | - | SL_C-EO_10 | |

| 4 | Modified SL-T-EO | 95 | - | 5 | SL_T-EO_5 |

| 5 | 90 | - | 10 | SL_T-EO_10 | |

| Colour Parameter | Type of Surface/Coating | |||||

|---|---|---|---|---|---|---|

| Uncoated | SL_Ref | SL_C-EO_5 | SL_C-EO_10 | SL_T-EO_5 | SL_T-EO_10 | |

| Maple (Acer pseudoplatanus) | ||||||

| L* | 85.14 (1.37) | 70.31 (2.51) a | 73.26 (1.96) b | 72.39 (2.96) b | 74.11 (1.52) b | 71.39 (2.73) a |

| a* | 3.65 (0.47) | 11.06 (1.38) a | 8.34 (1.26) b | 8.69 (1.59) b | 8.32 (0.97) b | 9.53 (1.50) b |

| b* | 14.89 (0.96) | 41.12 (1.14) a | 38.98 (2.99) b | 39.29 (2.51) b | 38.43 (1.64) b | 40.97 (2.32) a |

| ΔE | - | 31.03 | 4.54 | 3.65 | 5.41 | 1.88 |

| Walnut (Juglans regia) | ||||||

| L* | 56.81 (2.68) | 45.35 (2.55) a | 45.25 (2.40) a | 43.59 (2.08) b | 44.15 (2.15) a | 43.59 (3.21) b |

| a* | 6.33 (0.97) | 10.81 (1.72) a | 9.55 (1.57) b | 9.84 (1.06) a | 9.35 (0.97) b | 9.03 (1.29) b |

| b* | 13.29 (1.69) | 17.50 (3.47) a | 16.97 (3.01) a | 16.60 (2.98) a | 15.84 (3.08) a | 15.18 (4.04) a |

| ΔE | - | 13.00 | 1.36 | 2.20 | 2.52 | 3.41 |

| Type of Surface/Finish | Colour Parameter | Maple (Acer pseudoplatanus) | Walnut (Juglans regia) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 UV | 24 UV | 48 UV | 72 UV | 0 UV | 24 UV | 48 UV | 72 UV | ||

| Uncoated (Control C) | L* | 85.86 (1.44) | 84.70 (0.85) | 82.92 (0.93) | 81.14 (0.81) | 58.95 (0.90) | 56.92 (1.02) | 55.90 (0.92) | 55.02 (2.00) |

| a* | 3.36 (0.53) | 3.45 (0.41) | 4.52 (0.37) | 5.07 (0.90) | 6.81 (0.26) | 7.98 (0.56) | 8.30 (0.84) | 8.45 (0.89) | |

| b* | 14.44 | 17.53 | 20.79 | 22.50 | 12.22 | 13.35 | 16.66 | 16.94 | |

| (0.11) | (0.54) | (0.54) | (0.52) | (0.64) | (0.94) | (0.74) | (0.95) | ||

| ΔE | - | 3.30 | 7.09 | 9.49 | - | 2.60 | 5.59 | 6.36 | |

| SL_Ref | L* | 68.18 | 67.52 | 67.10 | 66.96 | 44.09 | 43.11 | 42.68 | 42.75 |

| (1.01) | (0.96) | (0.91) | (0.91) | (1.80) | (1.24) | (0.96) | (1.45) | ||

| a* | 12.20 | 12.17 | 12.83 | 13.23 | 10.09 | 10.14 | 10.41 | 11.14 | |

| (0.52) | (0.58) | (0.54) | (0.56) | (1.47) | (1.34) | (1.43) | (1.46) | ||

| b* | 41.37 | 40.36 | 41.98 | 41.06 | 14.71 | 14.10 | 17.80 | 16.69 | |

| (1.08) | (0.57) | (1.04) | (1.61) | (1.84) | (2.09) | (1.97) | (1.85) | ||

| ΔE | - | 1.21 | 1.39 | 1.63 | - | 1.15 | 3.41 | 2.61 | |

| SL_C-EO_5 | L* | 72.57 | 69.87 | 69.58 | 69.09 | 45.48 | 43.87 | 43.22 | 42.68 |

| (1.48) | (2.26) | (1.21) | (1.27) | (1.99) | (1.56) | (1.61) | (2.07) | ||

| a* | 9.15 | 10.13 | 11.24 | 11.77 | 9.70 | 10.03 | 10.22 | 11.04 | |

| (0.81) | (0.70) | (0.63) | (0.47) | (1.24) | (1.34) | (1.20) | (1.43) | ||

| b* | 39.76 | 38.34 | 41.14 | 40.34 | 15.32 | 14.26 | 18.84 | 17.04 | |

| (1.85) | (1.64) | (1.58) | (1.27) | (2.32) | (2.16) | (1.93) | (1.88) | ||

| ΔE | - | 3.20 | 3.90 | 4.39 | - | 1.95 | 4.22 | 3.55 | |

| SL_C-EO_10 | L* | 71.08 | 68.68 | 68.54 | 68.38 | 44.33 | 43.33 | 42.13 | 42.08 |

| (3.66) | (4.09) | (3.76) | (3.88) | (1.97) | (1.63) | (1.41) | (1.84) | ||

| a* | 9.52 | 10.53 | 11.27 | 11.45 | 10.16 | 10.56 | 10.93 | 11.68 | |

| (1.91) | (1.81) | (1.70) | (1.96) | (0.96) | (1.08) | (1.11) | (1.55) | ||

| b* | 37.66 | 36.81 | 39.18 | 38.70 | 15.81 | 16.00 | 18.54 | 18.15 | |

| (2.05) | (1.96) | (1.60) | (1.93) | (3.15) | (2.29) | (1.99) | (2.65) | ||

| ΔE | - | 2.74 | 3.45 | 3.48 | - | 1.10 | 3.59 | 3.58 | |

| SL_T-EO_5 | L* | 73.63 | 70.77 | 70.86 | 70.21 | 43.30 | 41.24 | 41.21 | 41.25 |

| (1.46) | (2.19) | (1.33) | (1.16) | (1.71) | (2.31) | (1.83) | (1.76) | ||

| a* | 8.61 | 9.27 | 10.42 | 11.05 | 9.02 | 9.08 | 9.81 | 10.25 | |

| (1.08) | (0.98) | (0.94) | (0.89) | (1.01) | (1.00) | (1.06) | (1.17) | ||

| b* | 38.64 | 38.14 | 40.16 | 40.31 | 14.02 | 12.70 | 16.88 | 15.79 | |

| (0.89) | (1.14) | (0.86) | (1.39) | (1.98) | (2.34) | (2.63) | (1.91) | ||

| ΔE | - | 2.98 | 3.64 | 4.53 | - | 2.44 | 3.63 | 2.97 | |

| SL_T-EO_10 | L* | 72.16 | 70.05 | 70.63 | 70.17 | 42.13 | 41.15 | 40.65 | 40.35 |

| (1.64) | (2.14) | (1.11) | (1.36) | (2.86) | (2.01) | (2.22) | (2.58) | ||

| a* | 8.83 | 9.38 | 10.37 | 11.04 | 8.67 | 8.81 | 9.22 | 9.60 | |

| (0.61) | (0.84) | (0.63) | (0.83) | (1.08) | (0.99) | (1.34) | (1.39) | ||

| b* | 39.19 | 38.15 | 41.00 | 40.63 | 12.88 | 12.71 | 15.13 | 14.18 | |

| (1.41) | (2.35) | (1.24) | (1.57) | (3.79) | (2.08) | (3.20) | (2.77) | ||

| ΔE | - | 2.41 | 2.83 | 3.30 | - | 1.00 | 2.75 | 2.39 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Timar, M.C.; Beldean, E.C. Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces. Coatings 2022, 12, 1591. https://doi.org/10.3390/coatings12101591

Timar MC, Beldean EC. Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces. Coatings. 2022; 12(10):1591. https://doi.org/10.3390/coatings12101591

Chicago/Turabian StyleTimar, Maria Cristina, and Emanuela Carmen Beldean. 2022. "Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces" Coatings 12, no. 10: 1591. https://doi.org/10.3390/coatings12101591

APA StyleTimar, M. C., & Beldean, E. C. (2022). Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces. Coatings, 12(10), 1591. https://doi.org/10.3390/coatings12101591