1. Introduction

Complementary metal oxide semiconductors (CMOS) are field-effect transistors that are often used to build integrated circuit chips, such as readout integrated circuits (ROICs), image sensors, and other digital logic circuits. Over the past several decades, an unprecedented change has been noticed in the manufacturing of CMOS. Benefiting from advanced semiconductor manufacturing processes, silicon-based imagers with ultra-high performance (high resolution and wide dynamic response range) can be successfully prepared. Silicon-based imagers have a huge demand in deep learning [

1,

2], optoelectronic computing [

3,

4,

5], and neural network computing [

6]. The primary reason for the popularity of silicon-based imagers is their compatibility, allowing them to be manufactured on a large scale at a low cost. Due to the success of silicon-based imagers in visible imaging, the main focus of ongoing research is to break through the energy band gap limitation of silicon. Silicon-based CMOS imagers can extend the spectral sensing range for more expensive applications, and broad spectral imagers are important for a wide range of scientific and industrial processes.

Nowadays, the field of infrared silicon-based CMOS imagers is a major area of interest within the field of broad spectral imagers, as infrared contains a wide variety of information in comparison to visible light. The working principle of shortwave infrared imaging (SWIR) is similar to that of visible light imaging. In both processes, images are captured by reflected light, revealing the shadow information of objects. Therefore, information from SWIR imaging can be easily understood. Shortwave infrared can penetrate fog and dust; thus, it can be used in night vision, haze imaging, food selection, and semiconductor detection. In both mid-wave and long-wave infrared imaging, detection is carried out by thermal radiations emitted by targets; therefore, they are extensively applied to autonomous driving [

7], gas detection [

8], and remote sensing [

9]. Studies over the past five decades have provided important information on infrared imagers based on traditional bulk materials. However, traditional bulk materials still have some problems influenced by the imager, such as emerging materials appearing and being applied in the broad spectral imager.

Moreover, the semiconductor industry has also pushed the development of broad-spectrum infrared imagers, which has been noticed in recent years. Focal plane array readout integrated circuits have a better field and a more clever design. Large focal plane array imagers with high-resolution broad-spectrum sensing have attracted significant attention. Benefiting from the development of integrated microcircuits and precise microelectromechanical systems, visible sensing chips can be used in silicon-based broad-spectrum infrared imagers to broaden their sensing spectral range [

10]. A wide variety of emerging non-silicon-sensing materials has been successfully integrated with silicon-based readout integrated circuits (ROICs).

In this review, recent research progress on broad-spectrum infrared focal plane area imagers is summarized. The characterization of imager-based focal plane array ROICs is introduced. Then, the history of infrared imagers is simply described, and different infrared optoelectronics imagers are compared with traditional bulk material imagers and emerging material imagers. The current trend of emerging materials and imagers is simply introduced, and the application gap is analyzed. The future research direction of emerging material imagers is also outlooked.

2. Characterization of Focal Plane Area Imagers

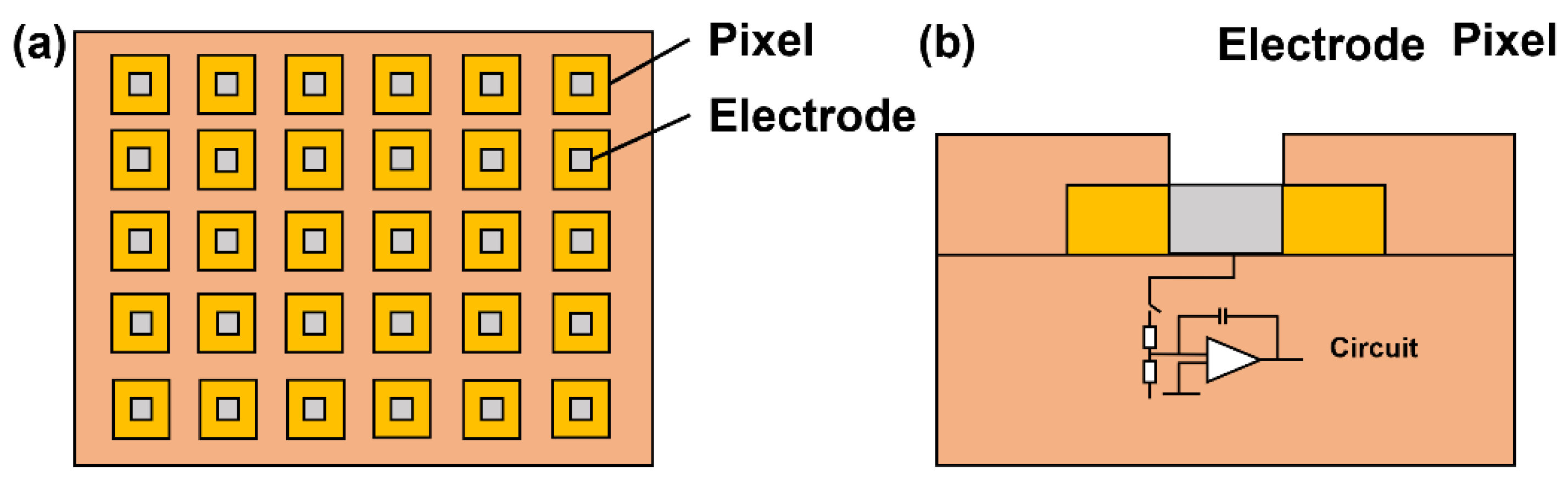

Focal plane array (FPA) imagers are special image sensors consisting of an array of optoelectronics-sensitive pixel units on silicon-based chips. Broad-spectrum optoelectronic materials can couple with FPA circuits to prepare broad-spectrum detectors. The pixel structure of a silicon-based FPA imager is displayed in

Figure 1, where the center of each pixel dot is a bare electrical connection point with a hole in the passivation layer. These pixel dots can easily transfer signals generated by the optoelectronics material to ROICs. The electronic signal is processed by the operational amplifier circuits and sample-hold devices. Then, the multiplexer selects the pixel data signals and provides an output. Nowadays, FPA ROICs have become a particularly useful choice in fabricating infrared imagers. Tang chose 640 × 512-pixel array ROICs to integrate PbS colloidal quantum dots (CQDs) and build an infrared imager [

11]. Anthony et al. designed a mid-wave infrared HgTe CQDs FPA detector [

12]. Emmanuel et al. prepared a cost-effective SWIR HgTe CQDs FPA imager [

13]. They all chose a similar method by coupling emerging materials and FPA ROICs to prepare their optoelectronic imagers.

Different from the characterization of single-point optoelectronic devices, FPA imagers use statistical analysis in order to gain insight into the quality of images. The photoresponsivity of imagers is characterized by different parameters, such as photocurrent, dark current, and detectivity. The main parameters of FPA imagers are array and pixel sizes, photoresponse nonuniformity (PRNU), and dead pixel rate. All these parameters are statistically calculated.

The detectivity of FPA imagers is generally affected by spectral responses, the signal-to-noise ratio, response time, and working temperature. Normalized detectivity is calculated as:

where

is the detectivity of an FPA imager,

is the effective size of a pixel,

is the integration time for each pixel,

is the photoresponsivity of the imager (volt), and

is the root mean square of noise.

The external quantum efficiency (EQE) of a photosensitive device is defined as the ratio of incident photons to converted electrons. Generally, a calibrated blackbody is used as a standard light source to irradiate silicon-based FPA imagers; therefore, the EQE of an FPA imager can be calculated as:

where

is the full well capacity,

is the photoresponsivity of the imager (volt),

is the maximum output voltage,

is the photon flux from the blackbody,

is the solid angle of the incident photon flux,

is the effective size of a pixel, and

is the integration time for each pixel.

Photoresponse nonuniformity (PRNU) is an overlooked fundamental difficulty in manufacturing broad-spectrum silicon-based detectors. The lower the PRUN, the better the image quality, because photoresponse uniformity across the sensing area is the prerequisite for imaging operations. The dead pixel ratio and the hot pixel ratio play vital roles in photoresponse nonuniformity.

In FPA imagers, each pixel on the focal plane is characterized by statistical methods. In order to visualize PRNU, statistical histograms are used to illustrate the response distribution of pixel units in FPA imagers. In statistical histograms, data are binned and summarized by counts or percentages. Each bar in statistical histograms represents a continuous range of data or the frequencies of characteristic data points.

3. Progress of the Infrared Focal Plane Array

With the development of silicon-based integrated circuits, silicon-based readout circuits are widely used in the detection field due to their increased reliability and reduced manufacturing cost. Rapidly advancing science has driven silicon-based integrated circuits into broad-spectrum infrared imaging technology, which has pushed the development of infrared FPA imagers. Readout circuits are designed to collect signals generated by photosensitive materials, ensuring photoresponse uniformity and image quality. In particular, FPA readout circuits have significantly raised the image resolution and detection performance of infrared imaging.

Figure 1a exhibits the pixel arrangement in a readout circuit, where hole electrodes are placed in the middle of pixels. A single-pixel integrated circuit is schematically presented in

Figure 1b.

Extensive research on broad-spectrum FPA imagers has been executed in recent years. Focal plane detectors in the infrared band can be applied to gas sensing, autonomous driving, and remote sensing. Infrared detectors have high sensitivity to low light and can recognize chemical molecular vibrations and penetrate fog. The efficacy of traditional bulk materials in broad-spectrum infrared FPA imagers is well established. Hence, ongoing research is mainly focusing on infrared-sensitive materials for the preparation of FPA devices [

11,

12,

13,

14].

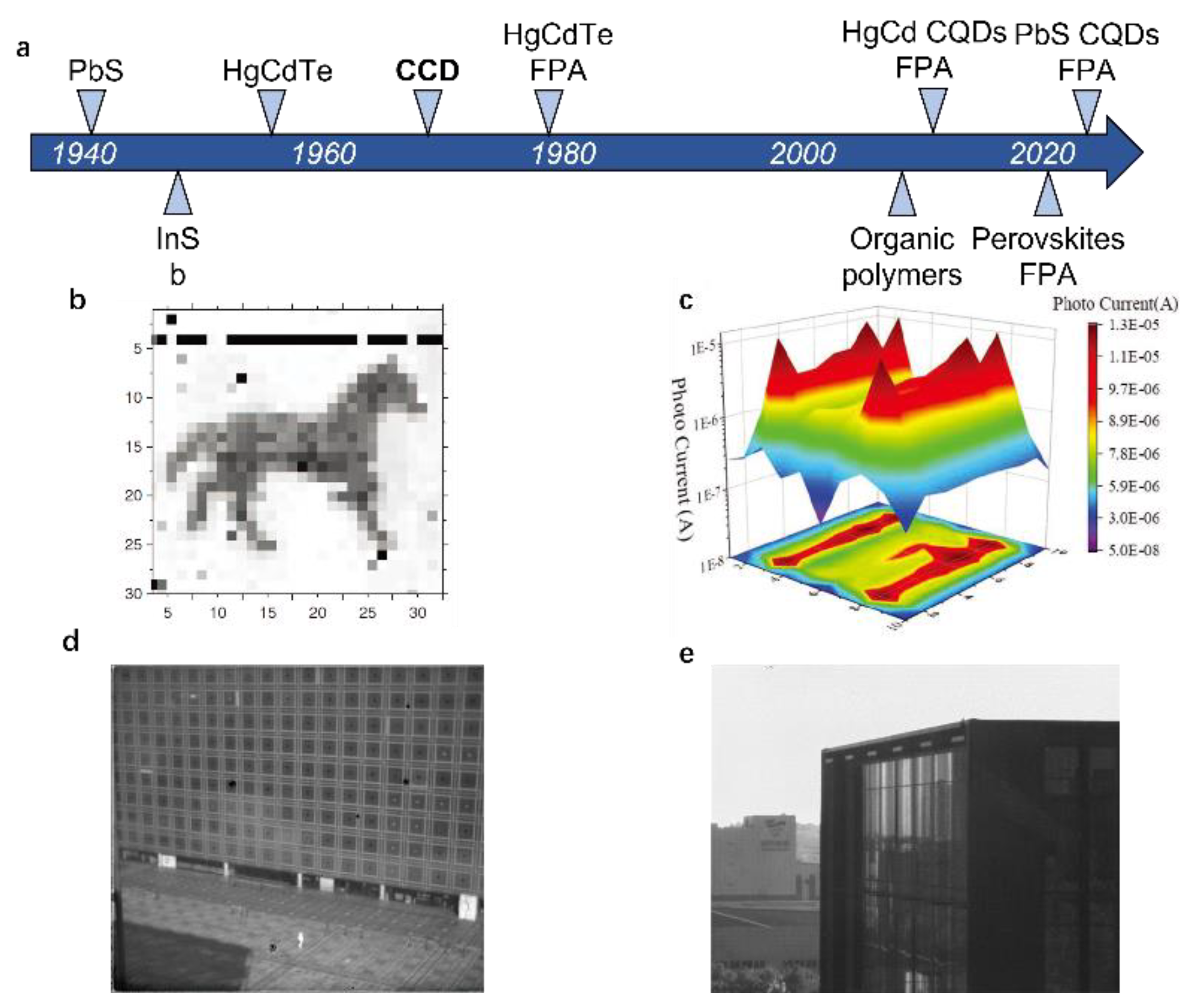

Figure 2a presents the invention timeline of different detectors. In 1873, Smith discovered the photoconductive effect of selenium and developed the first photon detector in the world. Kutzscher et al. produced a PbS infrared detector in 1933. PbS infrared detectors were first extensively used in the Second World War, and they could detect shortwave infrared signals of wavelengths up to 3 μm [

15]. In the 1950s, infrared detection technology was developed significantly. Cooled infrared detectors, such as lead selenide (PbSe) and indium antimonide (InSb), extended the infrared detect spectrum in the mid-wave infrared range of 3–5 μm. Binary semiconductor materials for infrared detection applications were developed rapidly in this period. In the 1960s, ternary semiconductor compounds emerged. Advanced microelectronics techniques, such as masking, microsoldering, and assembly, were gradually developed, and HgCdTe infrared detectors started to appear.

In 1969, charge-coupled devices (CCDs) were invented. Subsequently, FPA readout circuits were developed for infrared imaging. In the 1970s, the first FPA infrared readout circuit chip was produced [

16]. Traditional infrared-sensitive materials have been progressively developed to build staring-vision infrared devices, such as mercury–cadmium–telluride (HgCdTe) devices. The quantum efficiency and array nonuniformity of HgCdTe FPA imagers ranged between 60% and 70% and between 10% and 30%, respectively [

17]. In a HgCdTe detector, an infrared detection signal is generated through a thin film of HgCdTe, which is coupled with a flip-chip-integrated readout circuit by molecular beam epitaxy sputtering. A focal plane array readout circuit chip then reads out the analog electrical signal. However, it is very difficult to grow indium columns at each pixel point on the focal plane array and align the HgCdTe material by external stress welding.

Multiquantum well infrared FPA imagers contain a single atomic layer of two different semiconductor materials. GaAs detectors with

> 10

10 Jones can be prepared at working temperatures less than 77 K [

18]. In contrast, GaAs multiquantum well infrared FPA imagers have faster response, lower operating power, and better response uniformity. GaAs detectors with large-area readout circuits have a greater potential in the long-wave infrared range than HgCdTe detectors.

The cut-off wavelength and response nonuniformity of InSb focal plane array detectors at 77 K are 5 µm and 10%, respectively. Generally, InSb films can be easily prepared in large-area readout circuits by a mature process. Although InSb FPA imagers and HgCdTe FPA detectors have a similar scale and pixel uniformity, HgCdTe detectors have a faster response and higher quantum efficiency during MWIR detection at low temperatures. However, InSb has good potential for MWIR detection because of its simple crystal growth process and fabrication reliability.

Nowadays, traditional bulk optoelectronic materials have been widely applied to broad-spectrum imagers. However, traditional infrared optoelectronics imagers still have some problems, which are that it is difficult to solve and influence the cost and yield of imagers, as traditional bulk semiconductor materials require lattice-matched substrates and complex flip-bonding processes to get attached to silicon-integrated readout circuits (ROICs), such as HgCdTe, InGaAs, and InSb. The detector manufacturing cost increases dramatically with larger arrays and smaller pixel sizes [

21]. Complex processes have impeded the development of high-resolution FPA detectors. In order to further expand the array scale and sensing range of Si-CMOS imagers, researchers are trying to replace the flip-bonding process with the copper–copper bonding technique and germanium–silicon technique [

22,

23]; however, this approach cannot yet solve the bonding problem between traditional block infrared-sensitive materials and silicon-based CMOS readout circuits.

The coupling of conventional block materials to readout circuits is mechanically unfeasible. The difficulty of integrating nonsilicon materials into silicon-integrated circuits has greatly hindered the development of Si-CMOS imagers beyond visible light. Emerging materials, such as inorganic–organic metal halide perovskites [

24,

25,

26,

27,

28], organic polymers [

19,

29,

30], and colloidal quantum dots (CQDs) [

12,

14,

31,

32,

33,

34,

35,

36,

37], can avoid complex flip-chip bonding processes to reduce the detector production cost and increase the portability of FPA readout circuit detectors. It is hoped that these emerging optoelectronic materials will contribute to solving the problem brought by traditional bulk materials and promote the application of infrared imagers.

As shown in

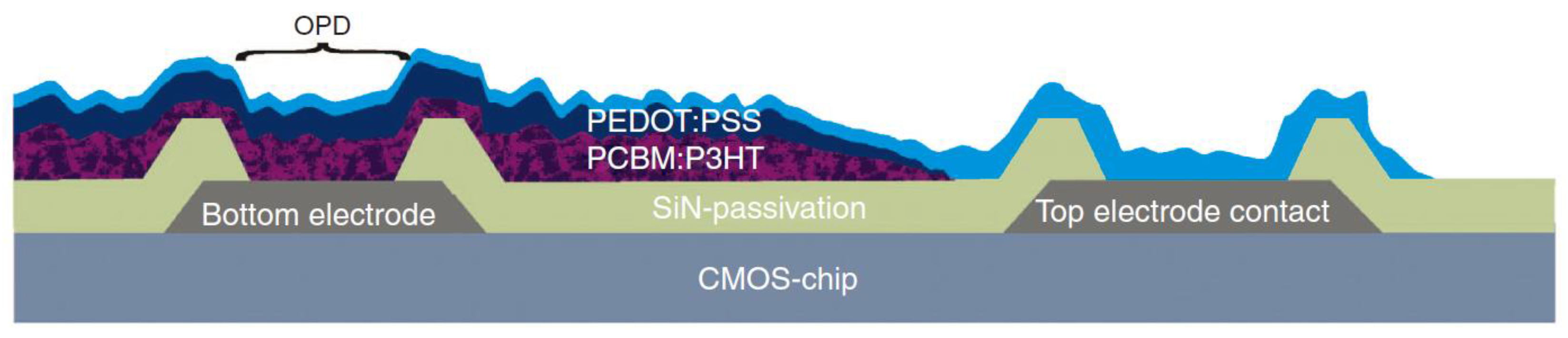

Figure 3, Daniela Baierl developed a hybrid CMOS detector based on a bulk heterojunction structure of PCBM–P3HT (poly(3-hexylthiophene)–[6, 6]-phenyl C61 butyric acid methylester) and squaraine to enable detection in the near-infrared range [

19]. The detector has a fill factor of 100% and an EQE of up to 50%.

Figure 2b displays a horse image taken by a hybrid CMOS imager under NIR light-emitting diode illumination at 850 nm. The hybrid CMOS detector is prepared by a low-cost spray-coating process to deposit the optoelectronic organic polymer film on the CMOS ROIC. It offers an effective method of coupling with integrated circuits. However, this organic polymer imager has some limitations in response range and detectivity. There is, therefore, a definite need for finding a great organic polymer material for application in the optoelectronics field.

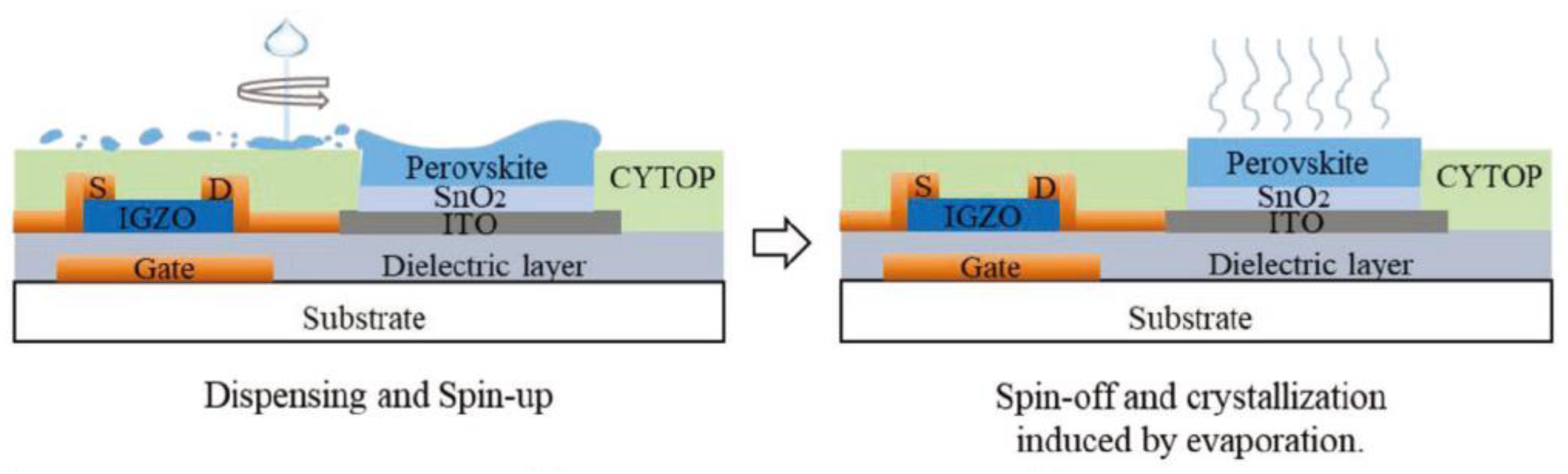

Inorganic–organic metal halide perovskites play an important role in infrared imaging. Wang fabricated an infrared imager by depositing a low-bandgap Sn-Pb-based perovskite photodiode on an indium gallium zinc oxide thin-film transistor (TFT) [

20]. A layer of hydrophobic perfluoro (1-butenyl vinyl ether) polymer (CYTOP) was printed on the TFT (

Figure 4). A (FASnI

3)

0.6(MAPbI

3)

0.4 perovskite photodiode was deposited on the pixel electrode by spin coating, and the solution was self-assembled due to the hydrophobicity of the CYTOP layer. The inorganic–organic metal halide perovskite imager had 12 × 12 matrix arrays with an ITO/SnO

2/(FASnI

3)

0.6(MAPbI

3)

0.4/P3HT/Au multilayered photodiode structure. The low-bandgap perovskite imager had a wide response range of 300–1000 nm, and its EQE and detectivity at 850 nm were 45% and 10

11 Jones, respectively. However, the response of the perovskite imager was nonuniform, and only half of the pixel electrode worked as a photodiode in 12 × 12 matrix arrays, and this phenomenon could be attributed to the existence of the uneven perovskite film. The defected perovskite film provided a current leakage path. The number “11” shown in

Figure 2c is captured by a perovskite photodiode. Inorganic–organic metal halide perovskite coupling with TFT circuits is an interesting topic. This study contributes to our understanding of the application of halide perovskites on the imager. Inorganic–organic metal halide perovskite imagers should improve the uniformity and crystallinity of the perovskite layer to enhance the performance of the optoelectronic response, which increases the difficulty of the process, and the device interface between the perovskite film and circuit also influences the dark current and the uniformity of the pixel response. Greater efforts are needed to improve the interface morphology of TFT circuits and the uniformity of perovskite film.

The most surprising materials in the infrared emerging materials field are CQDs. A variety of CQDs are now available to extend the range of infrared detection [

38]. The development of low-cost FPA detectors based on CQDs is achieved by coupling CQDs with readout circuits [

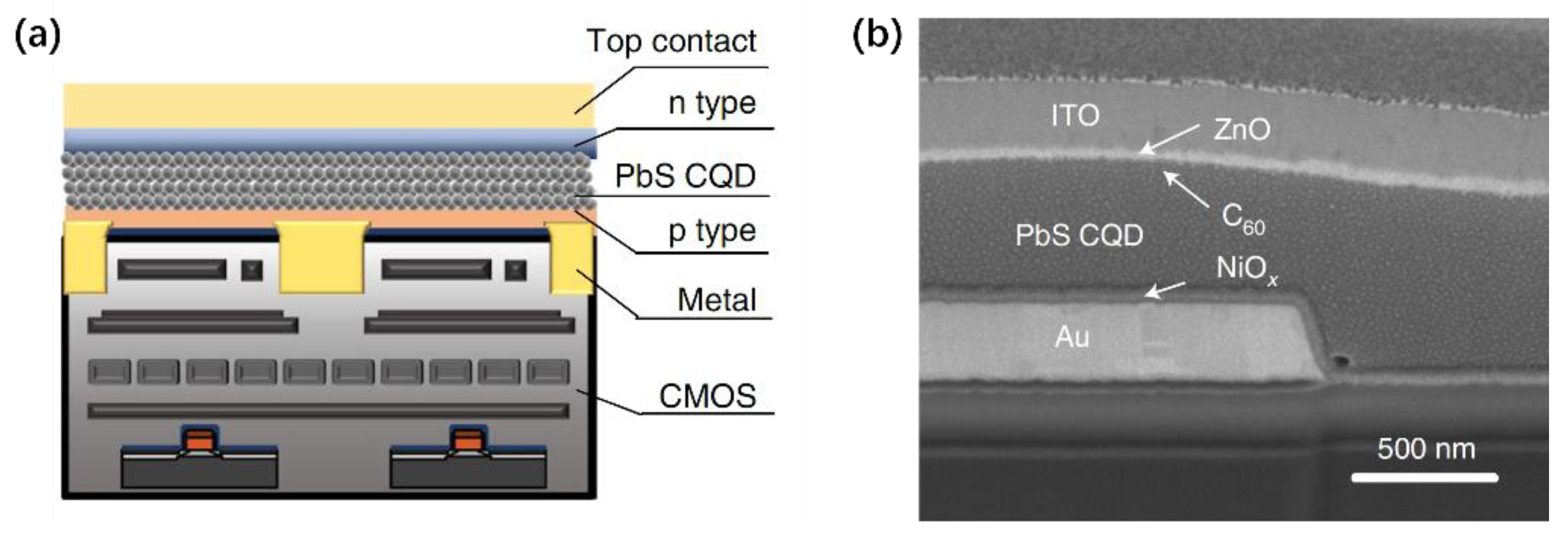

39]. Tang built an infrared imager by integrating PbS CQDs on the surface of a Si-CMOS readout circuit [

11]. The photodetector was integrated into a CMOS ROIC with a 640 × 512-pixel array, a pixel size of 15 μm, an EQE of 60%, and a spatial resolution of 40 line pairs per millimeter at a modulation transfer function of 50%. The detector was composed of a multilayered indium tin oxide (ITO)/NiO

x/PbS CQD/C

60/ZnO/ITO (

Figure 5a,b). Generally, photodiodes of PbS CQDs FPA imagers are composed of NiO

x/PbS CQD/C

60/ZnO. Charge transport layers (NiO

x and ZnO) are prepared by sputtering, and a protective layer of fullerene (C

60) is deposited on the PbS CQD/ZnO interface. NiO

x and ZnO act as hole transport and electron transport layers, respectively, to provide suitable energy band positions and high stability. In order to improve reproducibility, hole transport layers and electron transport layers are prepared by mild sputtering. Fullerene protective layers, with their strong C-C bonding and mechanical properties, can prevent damage during sputtering. In the PbS imager shown in

Figure 5a, a transparent conductive oxide (ITO) is used as the electrode. The device could collect more charges in the top-illuminated mode than in the back-illuminated mode. The depletion region of the photodiode close to the illumination side has prompted the efficient drift of photogenerated carriers by the built-in electric field.

Figure 2e exhibits an image of outdoor buildings at nightfall captured by a PbS quantum dot device. The most obvious finding to emerge from this study is that the CQD imager can take clear images, and CQD material has more mature applications coupling with ROICs. However, one source of weakness in this study, which could have affected the measurements of infrared, was the PbS CQD imager exhibits a spectral range of 400–1300 nm, which cannot fully cover the range of SWIR.

Further, HgTe CQDs are band gap tunable quantum dot materials. The special properties of HgTe CQDs reduce complexities in manufacturing and extend the spectral response range. Controlling the quantum dot size, HgTe CQDs can be used to detect a wide range of infrared wavelengths, such as shortwave infrared, mid-wave infrared, and long-wave infrared [

31]. HgTe CQDs FPA infrared detectors can operate at higher temperatures than traditional detectors based on HgCdTe, PbTe, and In(Ga)AsSb [

40]. Guyot and Sionnest invented a very sophisticated technique to synthesize HgTe CQDs using cheap precursors in less than two hours [

12]. Colloidal suspensions of HgTe CQDs can be synthesized by the bench-top method and directly coupled with readout circuits by spraying, dripping, and spin coating, avoiding complex molecular epitaxial growth and flip-bonding processes. Anthony designed a mid-wave infrared HgTe CQDs FPA detector. The QE,

, and NEDT of the MWIR HgTe CQD FPA imager at 95 K were 0.30%, 1.46 × 10

9 Jones, and 2.319, respectively. Defects in CQD films can greatly reduce the performance of detectors. However, ROIC modification and CQD deposition processes still need to be improved to enhance the performance of detectors.

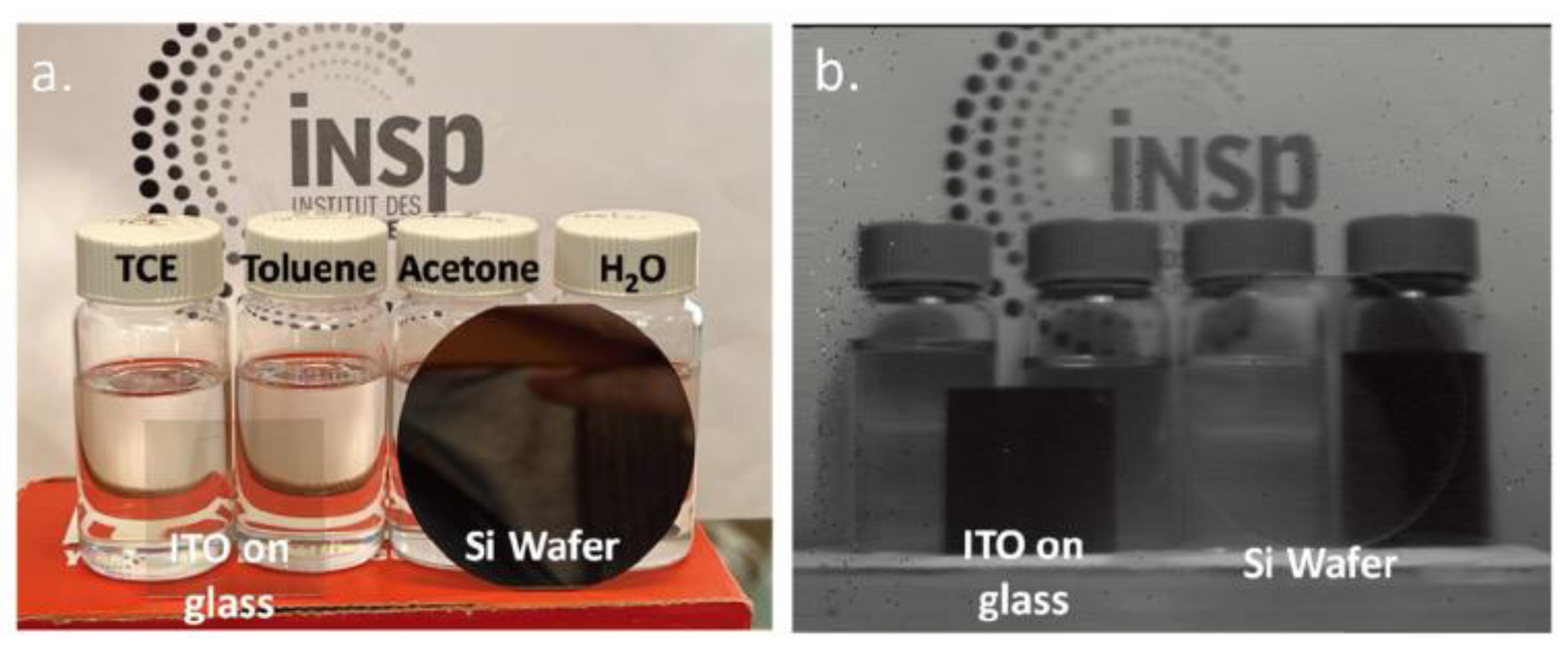

Emmanuel prepared a cost-effective HgTe CQDs focal plane array by a single-step fabrication route [

13].

Figure 2d displays an image of a building captured by an SWIR HgTe CQDs device. The HgTe CQDs film deposited on a 15 μm pixel FPA readout circuit has an EQE of 4%–5% and a cut-off wavelength of 1.8 μm in the Peltier cooling condition. In

Figure 6a, an ITO-covered glass and a silicon wafer are placed in front of different reagent vials. However, in

Figure 6b, an opaque image of the ITO glass and the reagents and a transparent image of the silicon wafer are exhibited. This is because absorption bands of silicon range between 0.4 and 1.1 μm, and the transmissivity of the ITO glass ranges between 0.4 and 0.9 μm. A single imager generally costs EUR 70. This single-step fabrication route can avoid the expensive molecular beam epitaxy method.

Table 1 lists the parameters of infrared detectors based on emerging materials. Compared with the other emerging materials, HgTe CQDs as band gap tunable material can extend spectral the range of response spectral by controlling the condition of the experiment, and HgTe CQDs can be uniformly modified on FPA circuits, which improves the quality of images and decrease the cost of the process. However, there are some problems that should be solved, such as the agglomeration of CQDs influencing the response of pixels. Notwithstanding these limitations, the study suggests that HgTe CQDs will make an important contribution to the field of broad-spectrum optoelectronic imagers.

4. Outlook

Si-CMOS technology can successfully fabricate high-performance and low-cost detectors with high reliability. Si-CMOS readout circuits facilitate the development of infrared FPA imagers. Staring-vision readout circuits are extensively used in the infrared field. Current research mainly focuses on the development of large-array infrared detectors with high resolution and low noise. Infrared CMOS-compatible optoelectronic imagers have a wide application in the electronics industry, ranging from vibrating chemical molecule detection to haze imaging. Broad-spectrum infrared imagers are used in semiconductor detection, medical drug screening, and agricultural product observation. However, infrared imagers have some major issues that need to be resolved before their mass rollout.

Traditional infrared FPA imagers are maturing; however, complex fabrication processes and high manufacturing cost limit their development. Generally, indium columns are grown in the center of pixel electrodes. Block materials are then coupled to focal plane array readout circuits under external pressure. This process seriously affects the product quality of infrared imagers. When readout circuits are scaled up, the difficulty of manufacturing significantly increases. New encapsulation methods might increase the portability of block materials.

New optoelectronic materials, such as perovskites, organic films, and colloidal quantum dots, are impetuses to the development of infrared FPA imagers. Due to their flowability, these new optoelectronic materials can easily flow to each pixel electrode on the surface of FPA readout circuits, and this simple coupling method avoids complex processes. In comparison to bulk materials, these new materials can reduce manufacturing costs and extend the application field of detectors. Therefore, significant research is being carried out on these new optoelectronic materials to build infrared FPA imagers with high stability and strong sensitivity. However, coupling processes between these new materials and readout circuits need further investigation.