Solidification Microstructure Prediction of Ti-6Al-4V Alloy Produced by Laser Melting Deposition

Abstract

1. Introduction

2. Experiment

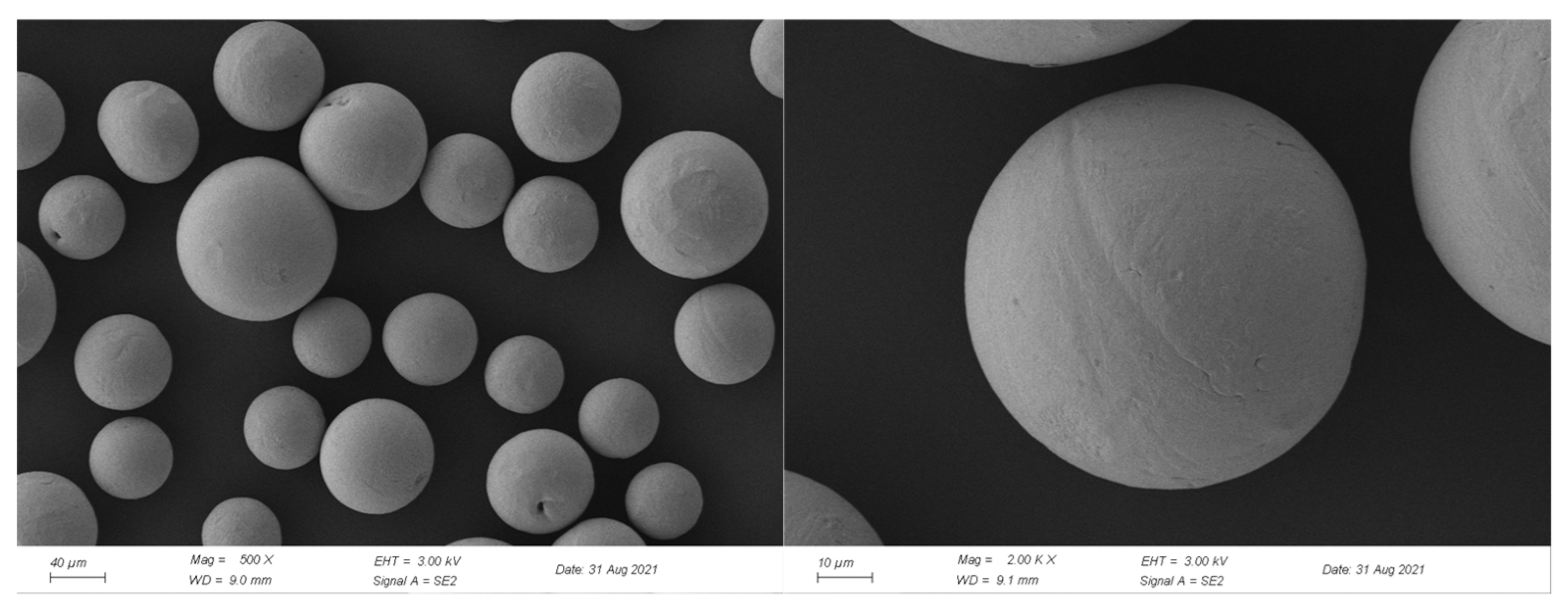

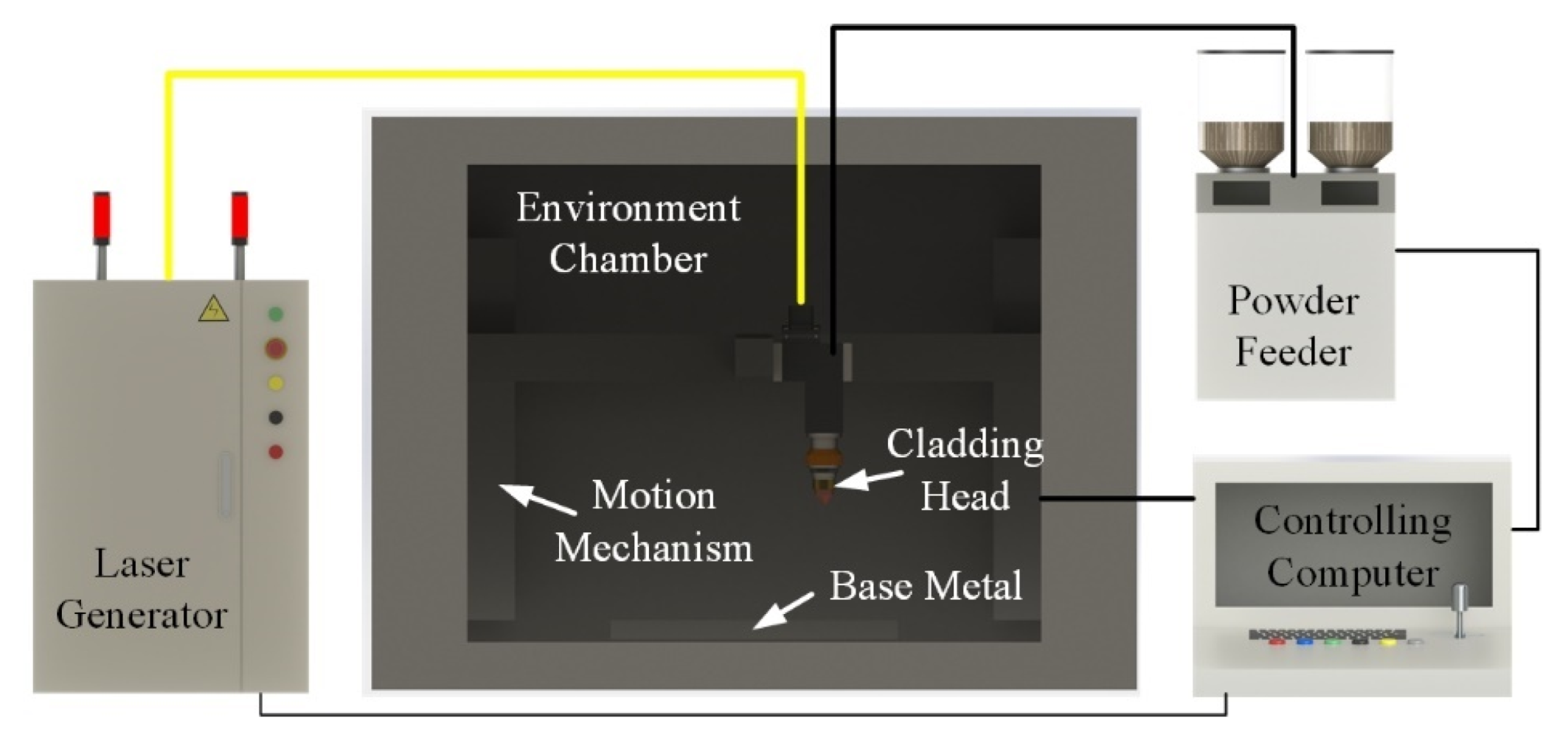

2.1. Material and Equipment

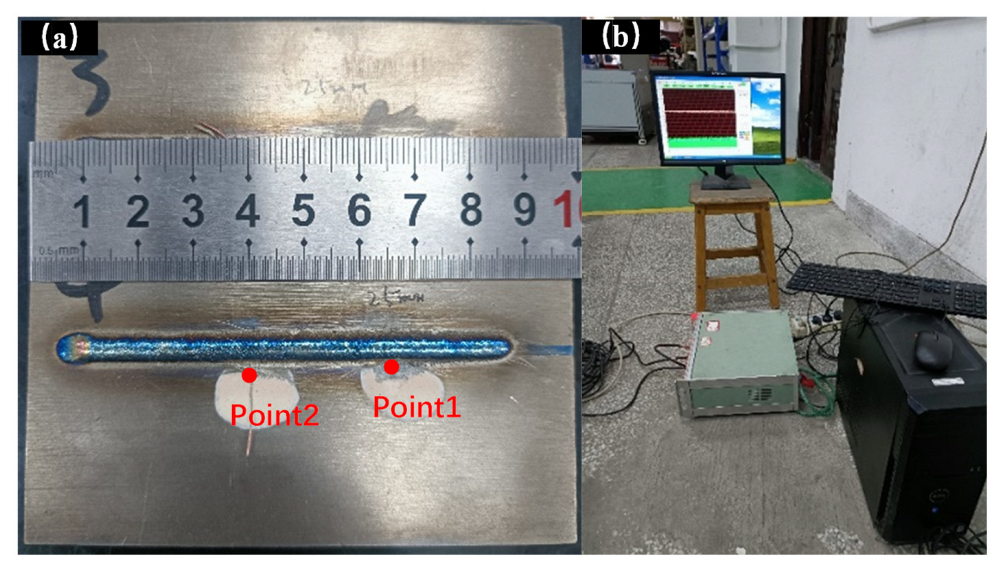

2.2. Experimental Procedures

3. Model Description

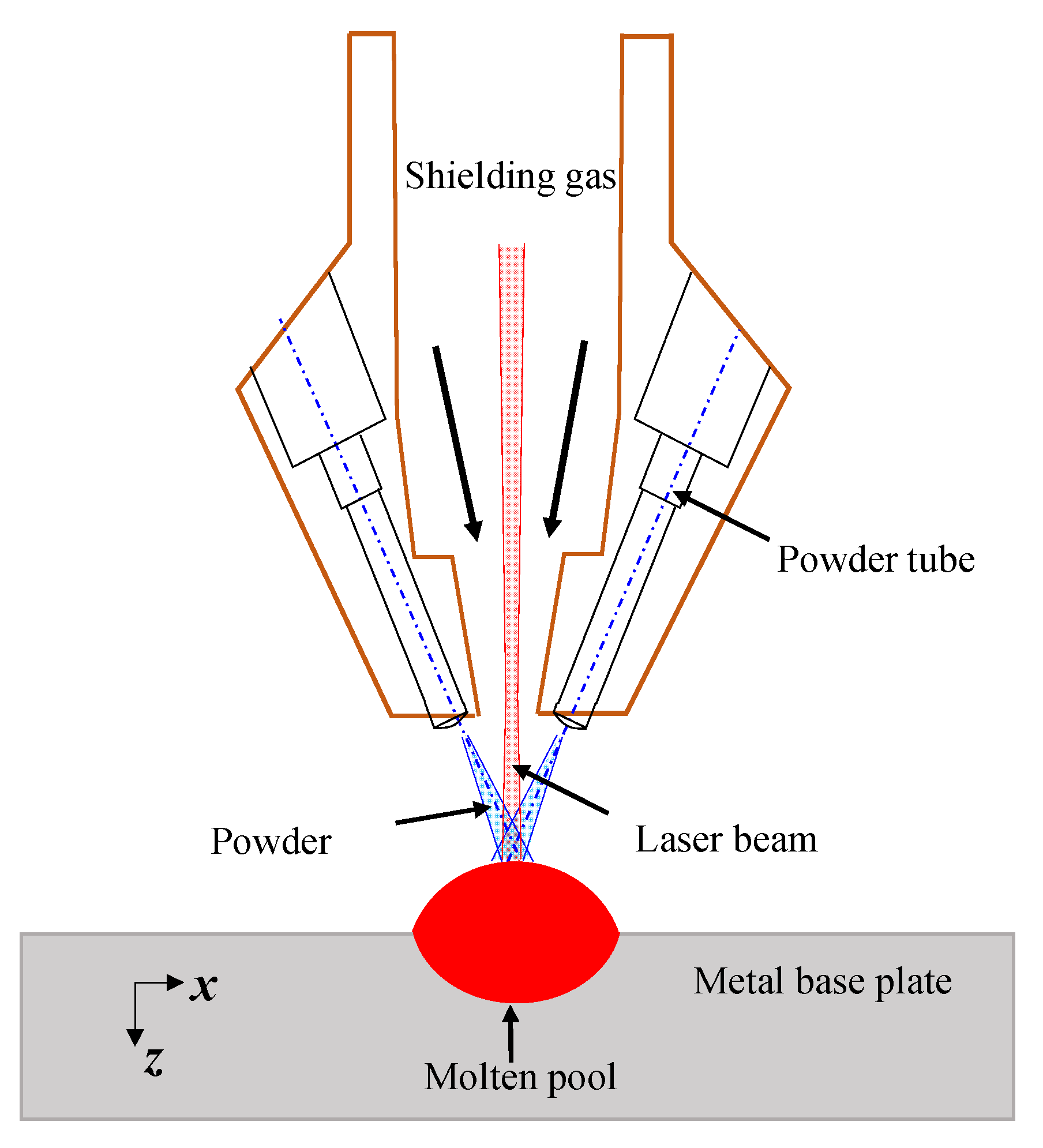

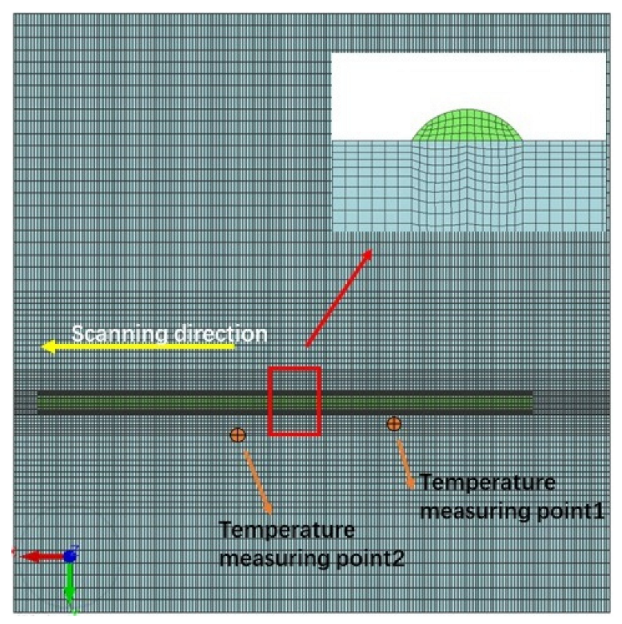

3.1. Physical Model

3.2. Governing Equations and Boundary Conditions

3.3. Heat Source Model

3.4. Cellular Automaton Model

4. Results and Discussion

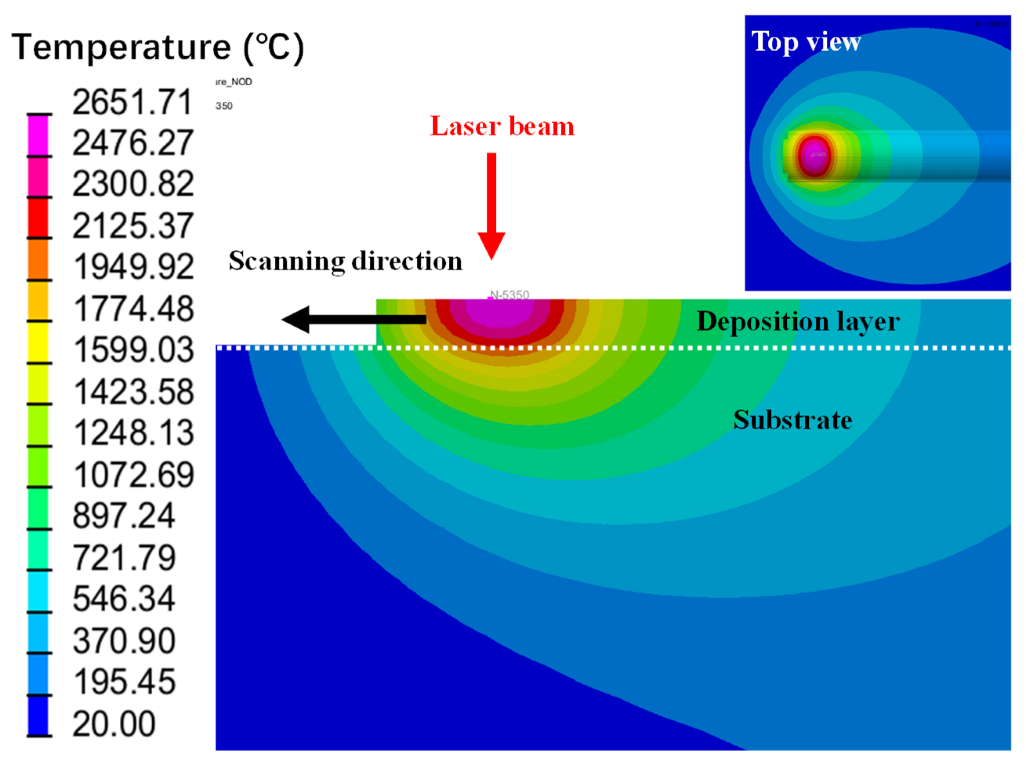

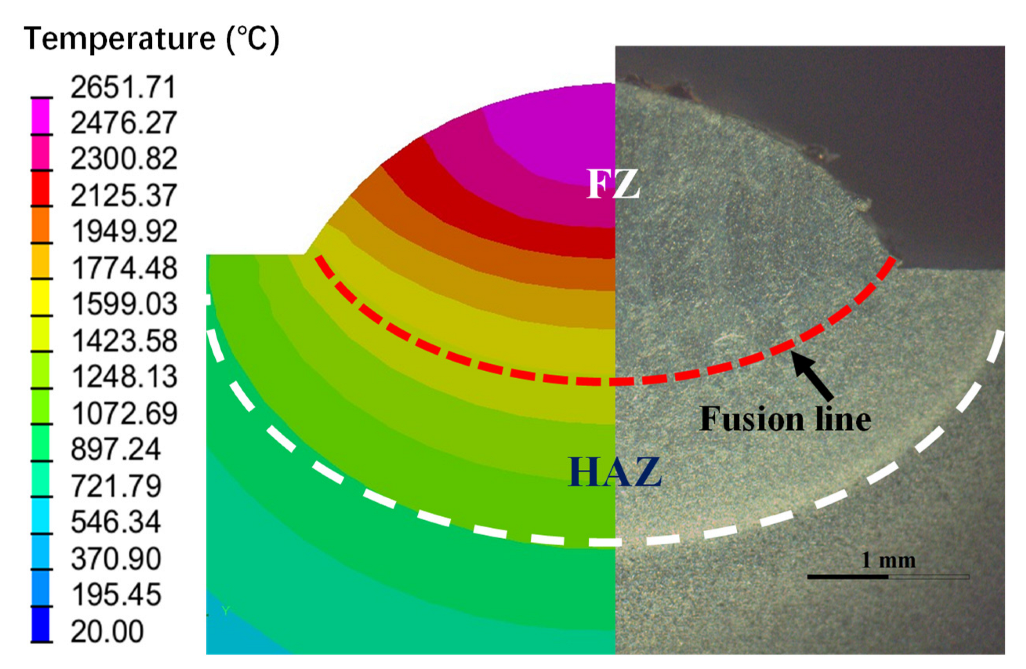

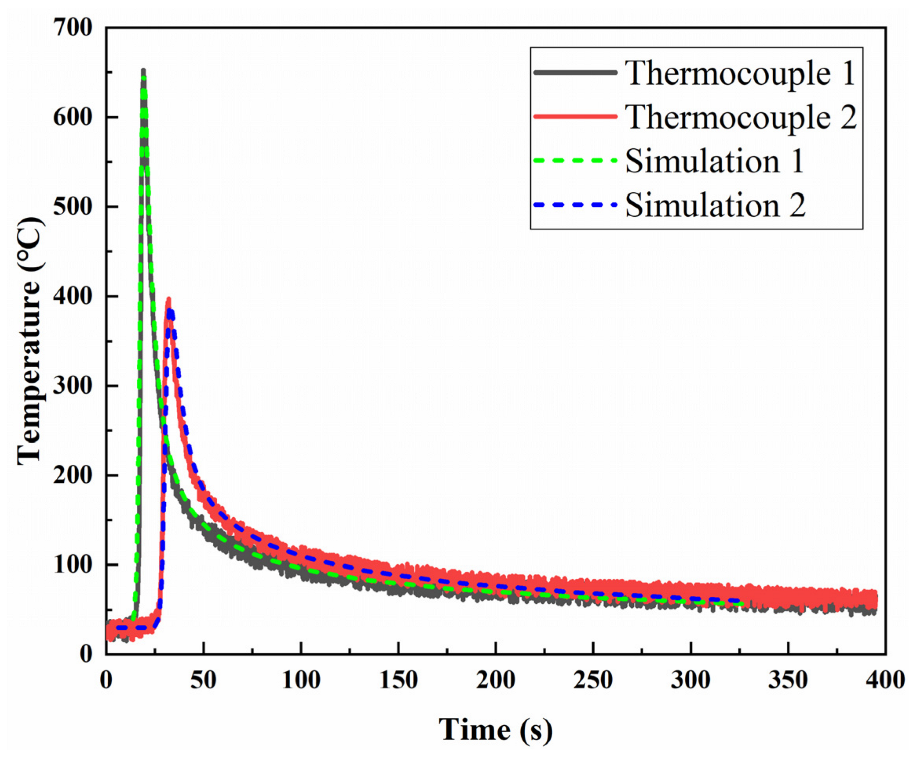

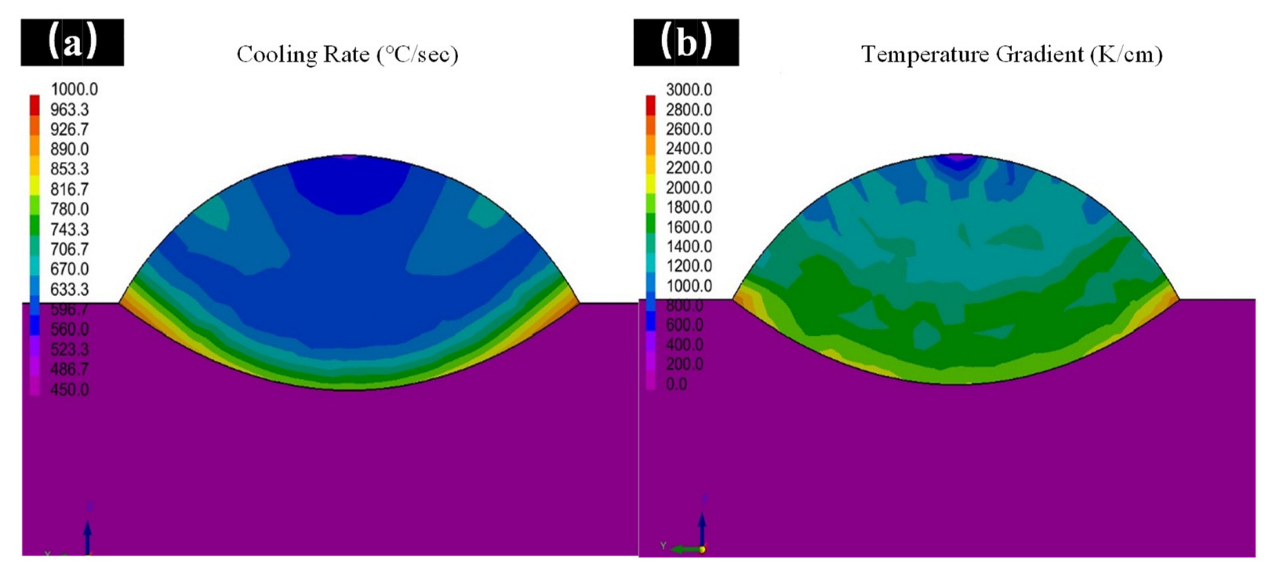

4.1. Temperature Field Analysis and Verification

4.2. Microstructure Analysis and Verification

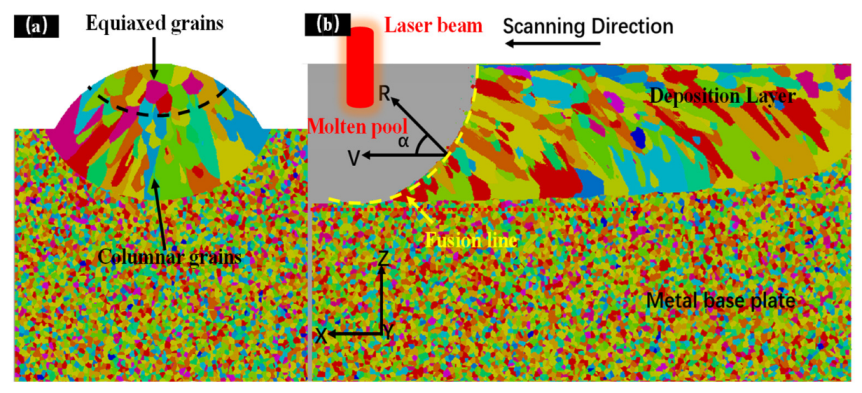

4.2.1. Solidification Microstructure Analysis

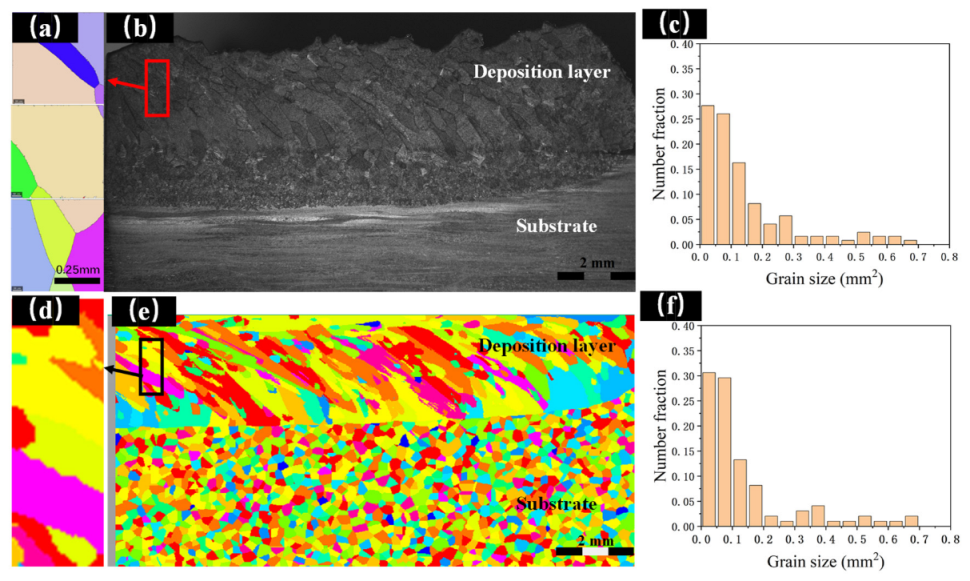

4.2.2. Solidification Microstructure Verification

4.3. Grain Morphologies Simulation

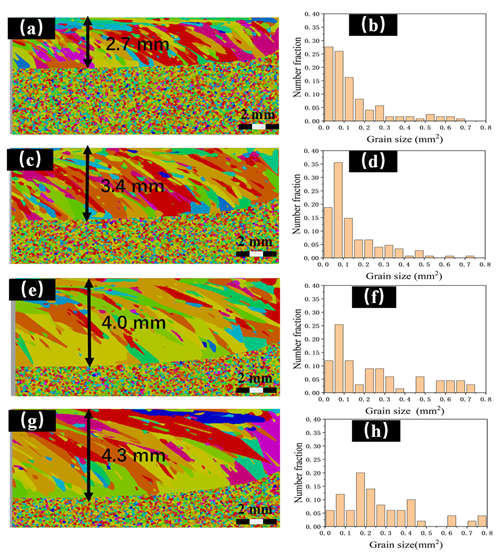

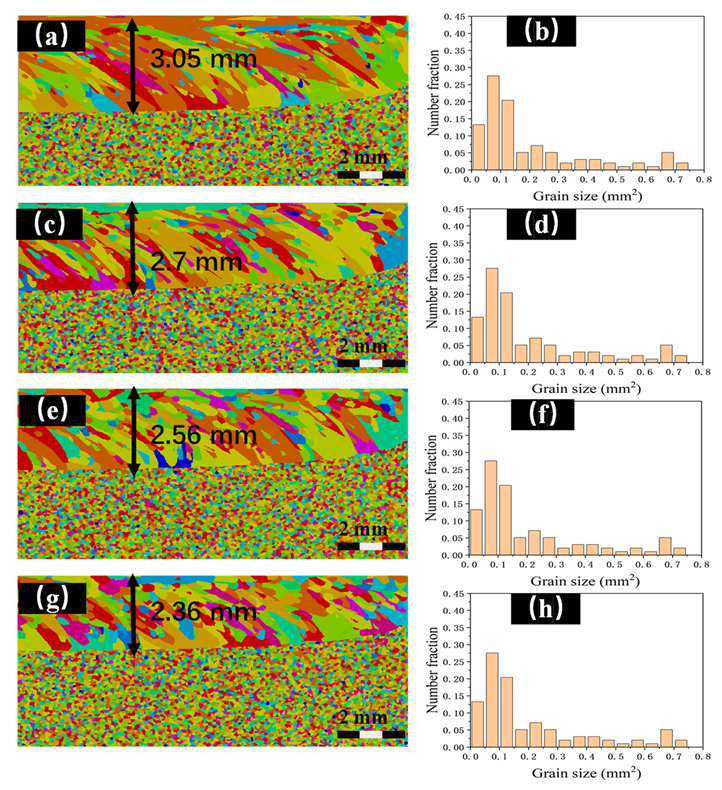

4.3.1. Effect of Laser Power

4.3.2. Effect of Laser Scanning Speed

5. Conclusions

- (1)

- Both the thermal cycles and transverse cross-sections of the molten pool simulated by the FE model were in good agreement with the experimental results.

- (2)

- The results suggested that the grain size of the LMD-produced Ti-6Al-4V alloy was strongly affected by the incident energy. A high incident energy (higher laser power/lower laser scanning speed) resulted in a lower cooling rate and a larger grain size. Conversely, a low incident energy effectively refined the microstructure.

- (3)

- The columnar-to-equiaxed transformation (CET) was achieved by reducing the laser incident energy.

- (4)

- The cellular automata model coupled with the finite element model (CA–FE) was an effective approach for studying the evolution of the solidification microstructure during the LMD process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Napoli, G.; Paura, M.; Vela, T.; di Schino, A. Colouring titanium alloys by anodic oxidation. Metalurgija 2018, 57, 111–113. [Google Scholar]

- Kobryn, P.A.; Semiatin, S.L. Microstructure and texture evolution during solidification processing of Ti-6Al-4V. J. Mater. Processing Technol. 2003, 135, 330–339. [Google Scholar] [CrossRef]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V. Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Comput. Mater. Sci. 2018, 141, 207–220. [Google Scholar] [CrossRef]

- Gandin, C.A.; Desbiolles, J.L.; Rappaz, M.; Thevoz, P. A three-dimensional cellular automaton-finite element model for the prediction of solidification grain structures. Metall. Mater. Trans. A 1999, 30, 3153–3165. [Google Scholar] [CrossRef]

- Gandin, C.A.; Rappaz, M.; Tintillier, R. 3-Dimensional simulation of the grain formation in investment castings. Metall. Mater. Trans. A 1994, 25, 629–635. [Google Scholar] [CrossRef]

- Saluja, R.S.; Narayanan, R.G.; Das, S. Cellular automata finite element (CAFE) model to predict the forming of friction stir welded blanks. Comput. Mater. Sci. 2012, 58, 87–100. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Akbari, M.; Khalkhali, A.; Asadi, P.; Parivar, A.H. Optimization of microstructural and mechanical properties of friction stir welding using the cellular automaton and Taguchi method. Mater. Des. 2014, 64, 660–666. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of grain structure during laser additive manufacturing. Simulation by a cellular automata method. Mater. Des. 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Li, X.; Tan, W. Numerical investigation of effects of nucleation mechanisms on grain structure in metal additive manufacturing. Comput. Mater. Sci. 2018, 153, 159–169. [Google Scholar] [CrossRef]

- Koepf, J.A.; Gotterbarm, M.R.; Markl, M.; Körner, C. 3D multi-layer grain structure simulation of powder bed fusion additive manufacturing. Acta Mater. 2018, 152, 119–126. [Google Scholar] [CrossRef]

- Yin, H.; Felicelli, S.D. Dendrite growth simulation during solidification in the LENS process. Acta Mater. 2010, 58, 1455–1465. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F.; Seufzer, W.; Taminger, K. A coupled finite element cellular automaton model to predict thermal history and grain morphology of Ti-6Al-4V during direct metal deposition (DMD). Addit. Manuf. 2016, 11, 32–39. [Google Scholar] [CrossRef]

- Lian, Y.; Gan, Z.; Yu, C.; Kats, D.; Liu, W.K.; Wagner, G.J. A cellular automaton finite volume method for microstructure evolution during additive manufacturing. Mater. Des. 2019, 169, 107672. [Google Scholar] [CrossRef]

- Dezfoli, A.R.A.; Hwang, W.; Huang, W.; Tsai, T. Determination and controlling of grain structure of metals after laser incidence: Theoretical approach. Sci. Rep. 2017, 7, 41527. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.; Anderson, M.J.; Sovani, Y.; Turner, R.P.; Attallah, M.M.; Brooks, J.W.; Basoalto, H.C. Mesoscale modelling of selective laser melting: Thermal fluid dynamics and microstructural evolution. Comput. Mater. Sci. 2017, 126, 479–490. [Google Scholar] [CrossRef]

- Xiong, F.; Huang, C.; Kafka, O.L.; Lian, Y.; Yan, W.; Chen, M.; Fang, D. Grain growth prediction in selective electron beam melting of Ti-6Al-4V with a cellular automaton method. Mater. Des. 2021, 199, 109410. [Google Scholar] [CrossRef]

- Chew, Y.; Pang, J.H.L.; Bi, G.; Song, B. Thermo-mechanical model for simulating laser cladding induced residual stresses with single and multiple clad beads. J. Mater. Processing Technol. 2015, 224, 89–101. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yang, H.; Li, F.; Wang, Z.; Zeng, X. Prediction of microstructure in selective laser melted Ti 6Al 4V alloy by cellular automaton. J. Alloys Compd. 2018, 748, 281–290. [Google Scholar] [CrossRef]

- Jin, Y.Z.; Song, Y.L.; Liu, Y.H.; Sun, C.; Liu, H.F.; Liu, J. Effect of Rare Earth Refinement on the Microstructure Simulation of an AlSi7Cu3Mg Alloy Based on the Cellular Automata Method. Strength Mater 2021, 53, 73–82. [Google Scholar] [CrossRef]

- Thévoz, P.; Desbiolles, J.L.; Rappaz, M. Modeling of equiaxed microstructure formation in casting. Metall. Trans. A 1989, 20, 311–322. [Google Scholar] [CrossRef]

- Liu, S.; Hong, K.; Katinas, C.; Shin, Y.C. Multiphysics modeling of phase transformation and microhardness evolution in laser direct deposited Ti6Al4V. J. Manuf. Processes 2019, 45, 579–587. [Google Scholar] [CrossRef]

- Li, J.; Zhou, X.; Brochu, M.; Provatas, N.; Zhao, Y.F. Solidification microstructure simulation of Ti-6Al-4V in metal additive manufacturing: A review. Addit. Manuf. 2020, 31, 100989. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Thermal process maps for predicting solidification microstructure in laser fabrication of thin-wall structures. J. Mater. Processing Technol. 2006, 178, 135–142. [Google Scholar] [CrossRef]

- Gäumann, M.; Henry, S.; Cléton, F.; Wagnière, J.D.; Kurz, W. Epitaxial laser metal forming: Analysis of microstructure formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Zhan, X.; Lin, X.; Gao, Z.; Qi, C.; Zhou, J.; Gu, D. Modeling and simulation of the columnar-to-equiaxed transition during laser melting deposition of Invar alloy. J. Alloys Compd. 2018, 755, 123–134. [Google Scholar] [CrossRef]

- Tian, F.; Li, Z.; Song, J. Solidification of laser deposition shaping for TC4 alloy based on cellular automation. J. Alloys Compd. 2016, 676, 542–550. [Google Scholar] [CrossRef]

- Ma, P.; Wu, Y.; Zhang, P.; Chen, J. Solidification prediction of laser cladding 316L by the finite element simulation. Int. J. Adv. Manuf. Technol. 2019, 103, 957–969. [Google Scholar] [CrossRef]

- Ao, X.; Xia, H.; Liu, J.; He, Q. Simulations of microstructure coupling with moving molten pool by selective laser melting using a cellular automaton. Mater. Des. 2020, 185, 108230. [Google Scholar] [CrossRef]

| Material | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| Powder | 6.11 | 3.97 | 0.30 | 0.005 | 0.006 | 0.0028 | 0.062 | Bal. |

| Substrate | 5.6~6.5 | 3.5~4.5 | 0.3 | 0.08 | 0.05 | 0.015 | 0.2 | Bal. |

| Item | Value |

|---|---|

| Laser generator manufacturer | Raycus (China, Wuhan) |

| Laser wavelength | 1064 nm |

| Spot diameter | 3 mm |

| Maximum output power | 6000 W |

| Laser power | 1200 W |

| Scanning speed | 120 mm/min |

| Shielding gas flow | 40 L/min |

| Powder feeding rate | 8.1 g/min |

| Temperature (°C) | Thermal Conductivity (W/m·K) | Specific Heat Capacity (J/kg·K) | Density (kg/m3) |

|---|---|---|---|

| 20 | 7.0 | 540 | 4420 |

| 100 | 7.45 | 550 | 4406 |

| 200 | 8.75 | 575 | 4395 |

| 400 | 11.35 | 625 | 4366 |

| 800 | 17.8 | 700 | 4309 |

| 1000 | 19.3 | 760 | 4283 |

| 1200 | 22.9 | 800 | 4252 |

| 1500 | 25.8 | 875 | 4205 |

| 1700 | 34.6 | 930 | 3886 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Lv, H.; Xie, S.; Han, R.; Zhang, Z.; Liu, Y.; Chen, H.; Chen, Y.; She, J.; He, D. Solidification Microstructure Prediction of Ti-6Al-4V Alloy Produced by Laser Melting Deposition. Coatings 2022, 12, 1610. https://doi.org/10.3390/coatings12111610

Liu J, Lv H, Xie S, Han R, Zhang Z, Liu Y, Chen H, Chen Y, She J, He D. Solidification Microstructure Prediction of Ti-6Al-4V Alloy Produced by Laser Melting Deposition. Coatings. 2022; 12(11):1610. https://doi.org/10.3390/coatings12111610

Chicago/Turabian StyleLiu, Jin, Hang Lv, Shao Xie, Ruipeng Han, Zhenlin Zhang, Yan Liu, Hui Chen, Yong Chen, Jian She, and Dupeng He. 2022. "Solidification Microstructure Prediction of Ti-6Al-4V Alloy Produced by Laser Melting Deposition" Coatings 12, no. 11: 1610. https://doi.org/10.3390/coatings12111610

APA StyleLiu, J., Lv, H., Xie, S., Han, R., Zhang, Z., Liu, Y., Chen, H., Chen, Y., She, J., & He, D. (2022). Solidification Microstructure Prediction of Ti-6Al-4V Alloy Produced by Laser Melting Deposition. Coatings, 12(11), 1610. https://doi.org/10.3390/coatings12111610