Marine Biofilm Model Comprising a Loop-Type Biofilm Reactor and a Halomonas Strain HIG FST4 1, an Active Biofilm-Forming Bacterium

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bacterium and Its Preculture

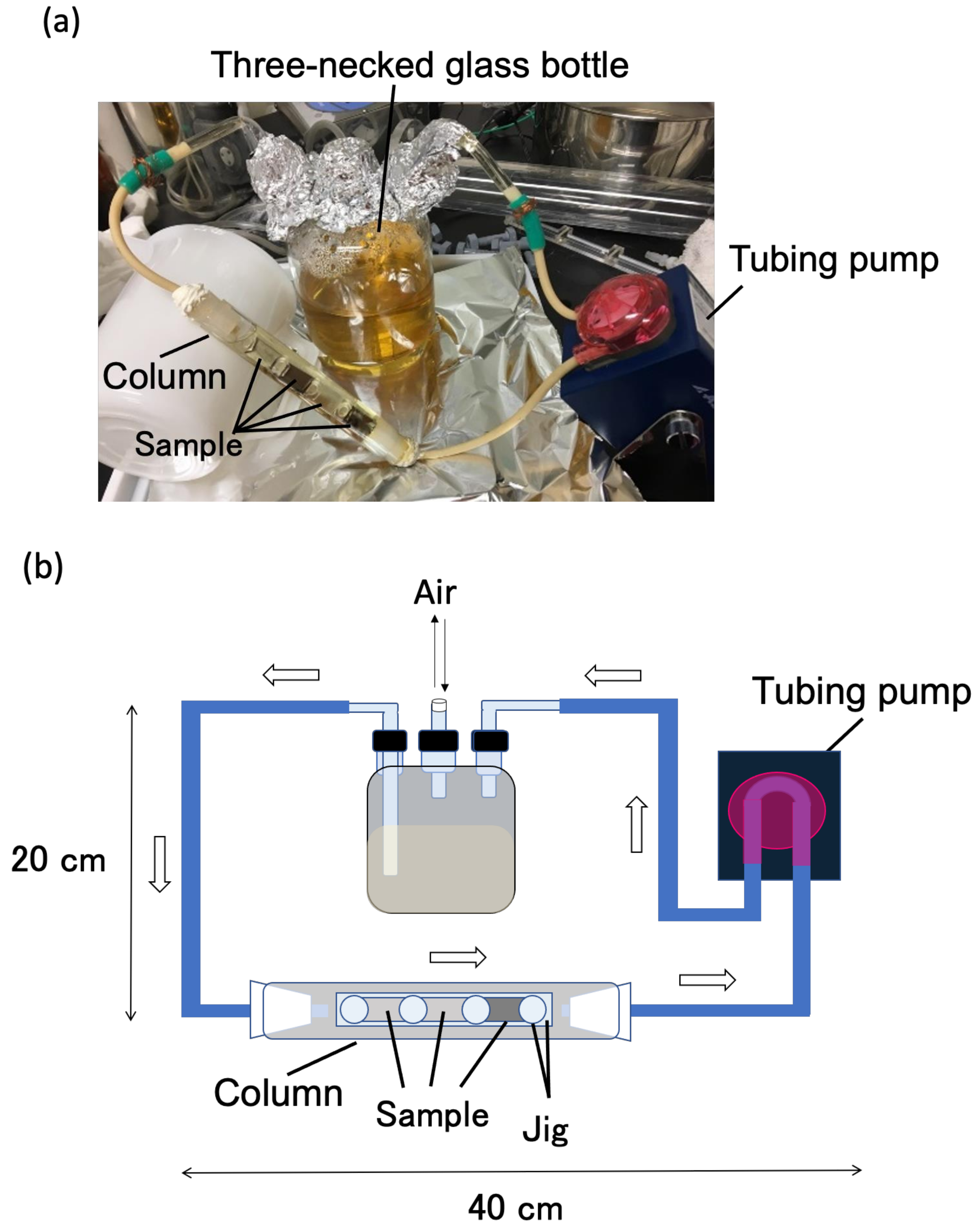

2.3. Biofilm Formation Tests

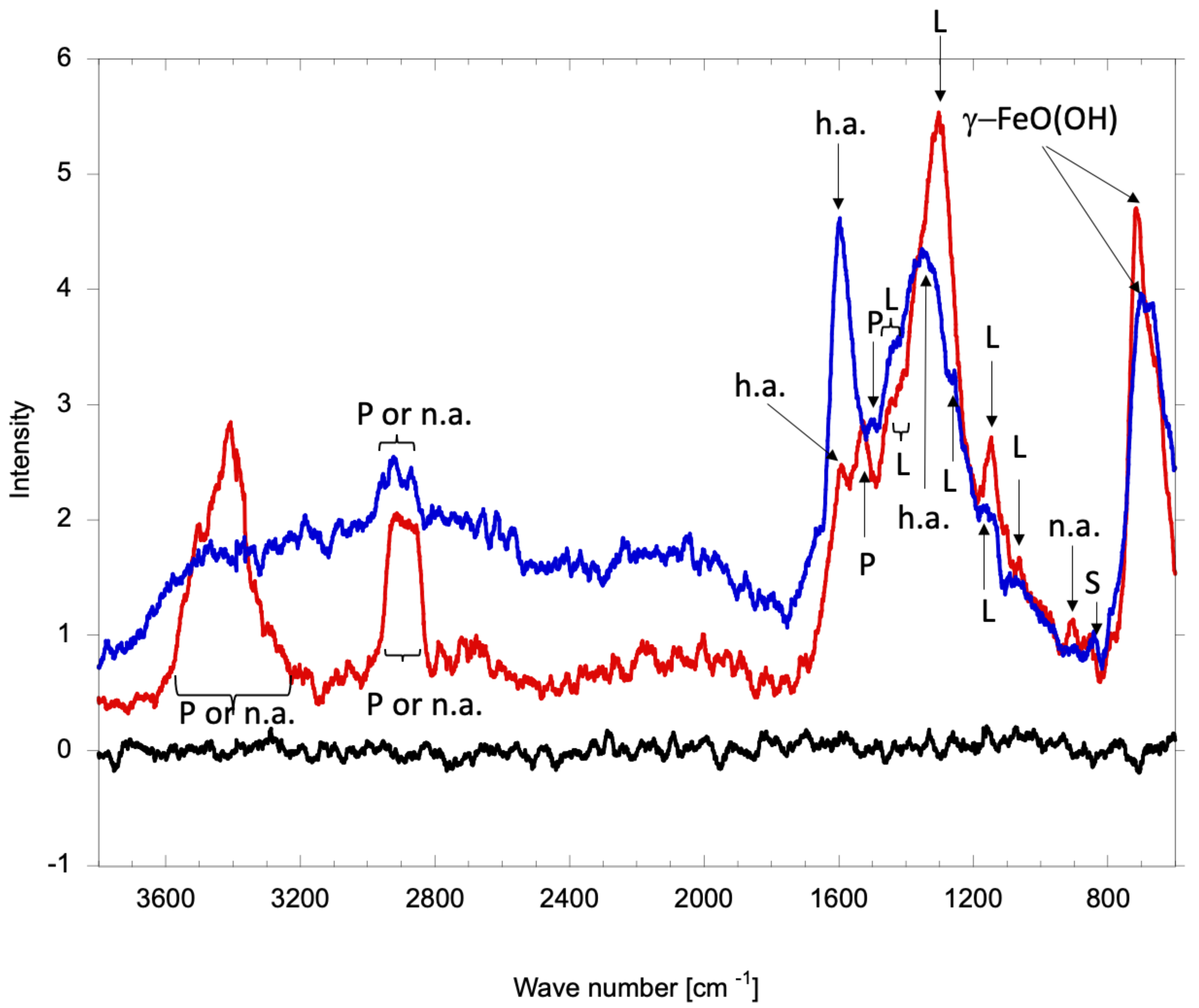

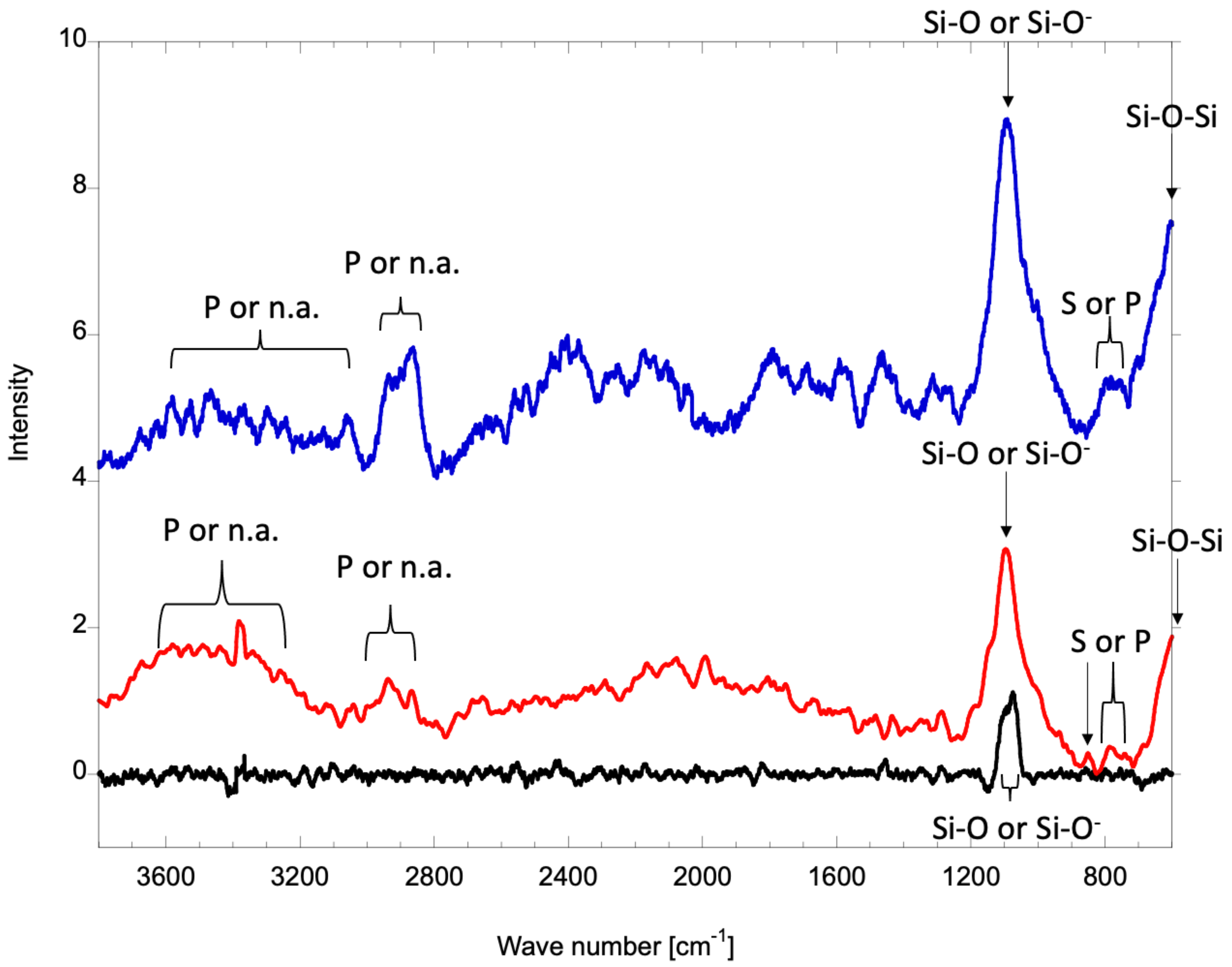

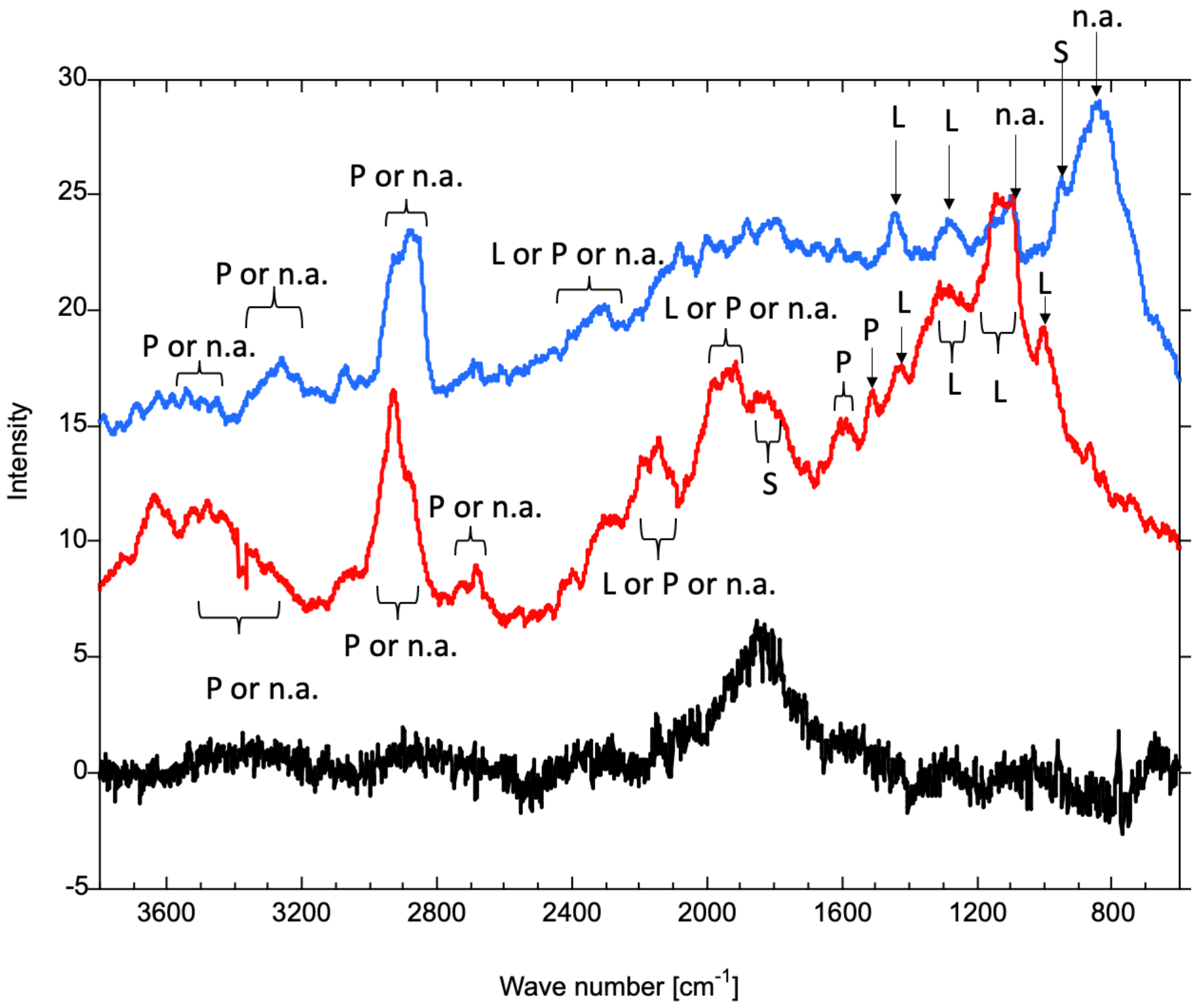

2.4. Raman Spectroscopy for Confirming Biofilm Formation

3. Results and Discussion

3.1. Differences in Surface of Materials before and after Slowly Rotating TTC and LBR Tests

3.2. Analysis of Raman Spectra

3.2.1. Pure Iron Samples

3.2.2. Soda Lime Glass Samples

3.2.3. Pure Aluminum Samples

3.2.4. Comparing Progression Biofilm Formation in LBR Test with That in Slowly Rotating TTC Test

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhury, M.R.; Hsieh, M.-K.; Vidic, R.D.; Dzombak, D.A. Corrosion management in power plant cooling systems using tertiary-treated municipal wastewater as makeup water. Corros. Sci. 2012, 61, 231–241. [Google Scholar] [CrossRef]

- Wang, K.L.; Wu, Z.H.; Wang, Y.; Wang, C.Y.; Xu, Y. Mini-review: Antifouling natural products from marine microorganisms and their synthetic analogs. Mar. Drugs 2017, 15, 266. [Google Scholar] [CrossRef]

- Farkas, A.; Song, S.; Degiuli, N.; Martić, I.; Demirel, Y.K. Impact of biofilm on the ship propulsion characteristics and the speed reduction. Ocean. Eng. 2020, 199, 107033. [Google Scholar] [CrossRef]

- Zea-Obando, C.; Tunin-Ley, A.; Turquet, J.; Culioli, G.; Briand, J.F.; Bazire, A.; Rehel, K.; Fay, F.; Linossier, I. Anti-bacterial adhesion activity of tropical microalgae extracts. Molecules 2018, 23, 2180. [Google Scholar] [CrossRef]

- De Carvalho, C.C.C.R. Marine biofilms: A successful microbial strategy with economic implications. Front. Mar. Sci. 2018, 5, 126. [Google Scholar] [CrossRef]

- Tuck, B.; Watkin, E.; Somers, A.; Machuca, L.L. A critical review of marine biofilms on metallic materials. npj Mater. Degrad. 2022, 6, 1–12. [Google Scholar] [CrossRef]

- Selim, M.S.; Yang, H.; Wang, F.Q.; Fatthallah, N.A.; Huang, Y.; Kuga, S. Silicone/ZnO nanorod composite coating as a marine antifouling surface. Appl. Surf. Sci. 2019, 466, 40–50. [Google Scholar] [CrossRef]

- Gomes, I.B.; Simoes, M.; Simoes, L.C. Copper Surfaces in Biofilm Control. Nanomaterials 2020, 10, 2491. [Google Scholar] [CrossRef]

- Kanematsu, H.; Ikigai, H.; Yoshitake, M. Evaluation of various metallic coatings on steel to mitigate biofilm formation. Int. J. Mol. Sci. 2009, 10, 559–571. [Google Scholar] [CrossRef]

- Sandoval, K. The Isolation and Identification of Proteobacteria from USS Navy Ballast Tanks Capable of Biofilm Formation and Hydrocarbon Degradation; University of Oklahoma: Norman, OK, USA, 2015. [Google Scholar]

- Yuen, S.-N.; Choi, S.-M.; Phillips, D.L.; Ma, C.-Y. Raman and FTIR spectroscopic study of carboxymethylated non-starch polysaccharides. Food Chem. 2009, 114, 1091–1098. [Google Scholar] [CrossRef]

- Chao, Y.; Zhang, T. Surface-enhanced Raman scattering (SERS) revealing chemical variation during biofilm formation: From initial attachment to mature biofilm. Anal. Bioanal. Chem. 2012, 404, 1465–1475. [Google Scholar] [CrossRef]

- Czamara, K.; Majzner, K.; Pacia, M.Z.; Kochan, K.; Kaczor, A.; Baranska, M. Raman spectroscopy of lipids: A review. J. Raman Spectrosc. 2015, 46, 4–20. [Google Scholar] [CrossRef]

- Sano, K.; Kanematsu, H.; Kogo, T.; Hirai, N.; Tanaka, T. Corrosion and biofilm for a composite coated iron observed by FTIR-ATR and Raman spectroscopy. Trans. IMF 2016, 94, 139–145. [Google Scholar] [CrossRef]

- Benevides, J.M.; Overman, S.A.; Thomas, G.J. Raman, polarized Raman and ultraviolet resonance Raman spectroscopy of nucleic acids and their complexes. J. Raman Spectrosc. 2005, 36, 279–299. [Google Scholar] [CrossRef]

- Larkin, P. Chapter 7-General Outline and Strategies for IR and Raman Spectral Interpretation. In Infrared and Raman Spectroscopy; Larkin, P., Ed.; Elsevier: Oxford, UK, 2011; pp. 117–133. [Google Scholar]

- George, J.; Thomas, J. Raman spectroscopy of protein and nucleic acid assembles. Annu. Rev. Biophys. Biomol. Struct. 1999, 28, 1–27. [Google Scholar]

- Lin, M.H.; Shu, J.C.; Huang, H.Y.; Cheng, Y.C. Involvement of iron in biofilm formation by Staphylococcus aureus. PLoS ONE 2012, 7, e34388. [Google Scholar] [CrossRef]

- DePas, W.H.; Hufnagel, D.A.; Lee, J.S.; Blanco, L.P.; Bernstein, H.C.; Fisher, S.T.; James, G.A.; Stewart, P.S.; Chapman, M.R. Iron induces bimodal population development by Escherichia coli. Proc. Natl. Acad. Sci. USA 2013, 110, 2629–2634. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, X.; Wang, L.; Chen, L. Iron metabolism in Pseudomonas aeruginosa biofilm and the involved iron-targeted anti-biofilm strategies. J. Drug Target. 2021, 29, 249–258. [Google Scholar] [CrossRef]

- Marchetti, A.; Maldonado, M.T. Iron. In The Physiology of Microalgae; Borowitzka, M.A., Beardall, J., Raven, J.A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 233–279. [Google Scholar]

- Di Martino, P. Extracellular polymeric substances, a key element in understanding biofilm phenotype. AIMS Microbiol. 2018, 4, 274–288. [Google Scholar] [CrossRef]

- Suzuki, S. Characterization of formation of ferrous and ferric oxides in aqueous solution from a multidisciplinary viewpoint. Isij Int. 2022, 62, 800–810. [Google Scholar] [CrossRef]

- Pedrosa, J.; Costa, B.F.O.; Portugal, A.; Durães, L. Controlled phase formation of nanocrystalline iron oxides/hydroxides in solution–An insight on the phase transformation mechanisms. Mater. Chem. Phys. 2015, 163, 88–98. [Google Scholar] [CrossRef]

- De Melo, B.A.G.; Motta, F.L.; Santana, M.H.A. Humic acids: Structural properties and multiple functionalities for novel technological developments. Mater. Sci. Eng. C 2016, 62, 967–974. [Google Scholar] [CrossRef]

- Thornton, M. The Role of Gammaproteobacteria in Aerobic Alkane Degradation in Oilfield Production Water from the Barnett Shale; University of Oklahoma: Norman, OK, USA, 2017. [Google Scholar]

- Wang, M.; Cheng, J.; Li, M.; He, F. Raman spectra of soda–lime–silicate glass doped with rare earth. Phys. B Condens. Matter 2011, 406, 3865–3869. [Google Scholar] [CrossRef]

- Limoli, D.H.; Jones, C.J.; Wozniak, D.J. Bacterial extracellular polysaccharides in biofilm formation and function. Microbiol. Spectr. 2015, 3, 1–19. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogawa, A.; Hosaka, S.; Kanematsu, H.; Yoshitake, M. Marine Biofilm Model Comprising a Loop-Type Biofilm Reactor and a Halomonas Strain HIG FST4 1, an Active Biofilm-Forming Bacterium. Coatings 2022, 12, 1605. https://doi.org/10.3390/coatings12101605

Ogawa A, Hosaka S, Kanematsu H, Yoshitake M. Marine Biofilm Model Comprising a Loop-Type Biofilm Reactor and a Halomonas Strain HIG FST4 1, an Active Biofilm-Forming Bacterium. Coatings. 2022; 12(10):1605. https://doi.org/10.3390/coatings12101605

Chicago/Turabian StyleOgawa, Akiko, Shoya Hosaka, Hideyuki Kanematsu, and Michiko Yoshitake. 2022. "Marine Biofilm Model Comprising a Loop-Type Biofilm Reactor and a Halomonas Strain HIG FST4 1, an Active Biofilm-Forming Bacterium" Coatings 12, no. 10: 1605. https://doi.org/10.3390/coatings12101605

APA StyleOgawa, A., Hosaka, S., Kanematsu, H., & Yoshitake, M. (2022). Marine Biofilm Model Comprising a Loop-Type Biofilm Reactor and a Halomonas Strain HIG FST4 1, an Active Biofilm-Forming Bacterium. Coatings, 12(10), 1605. https://doi.org/10.3390/coatings12101605