The Influence of Nanostructured Alumina Coating on Bonding and Optical Properties of Translucent Zirconia Ceramics: In Vitro Evaluation

Abstract

:1. Introduction

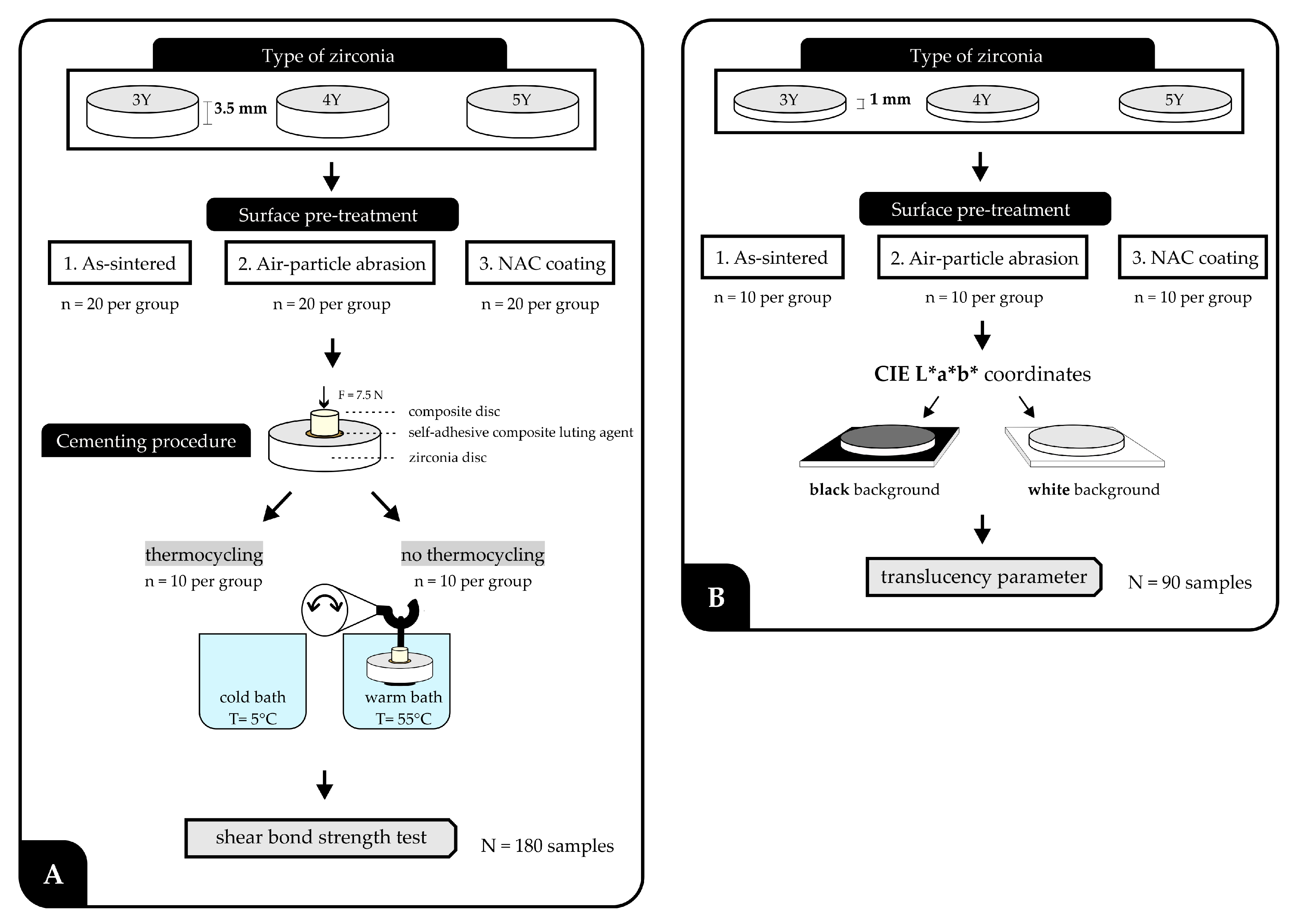

2. Materials and Methods

2.1. Specimen Preparation

2.2. Shear Bond Strength Testing

2.2.1. Quantitative Assessment

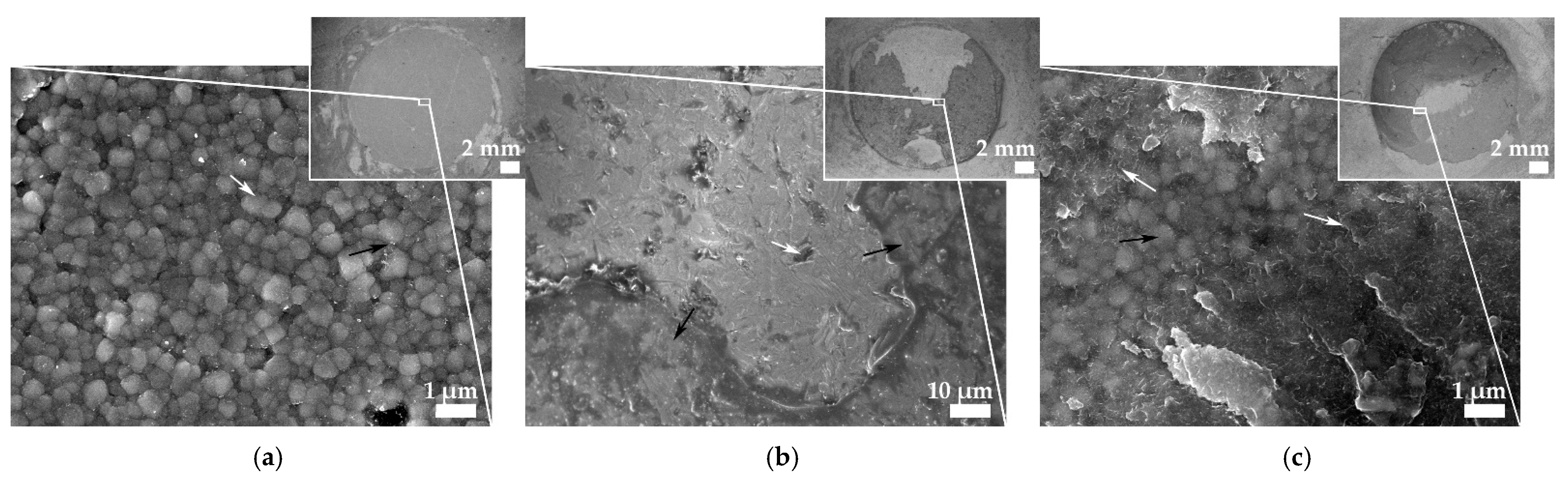

2.2.2. Qualitative Assessment

2.3. Translucency Measurement

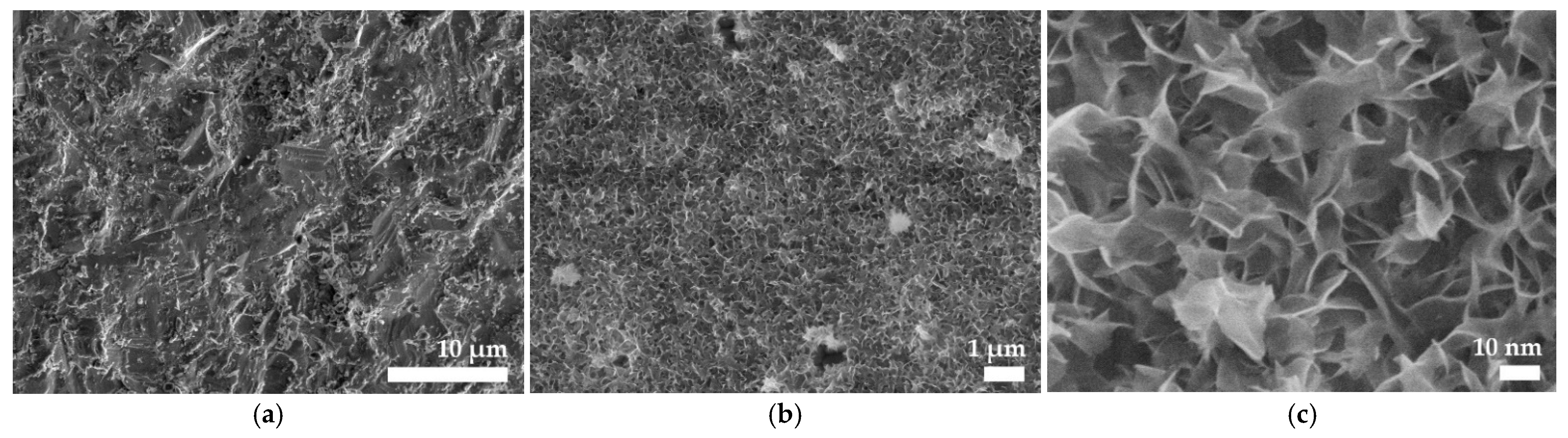

Grain Size Estimation

2.4. Statistical Analysis

3. Results

3.1. Shear Bond Strength

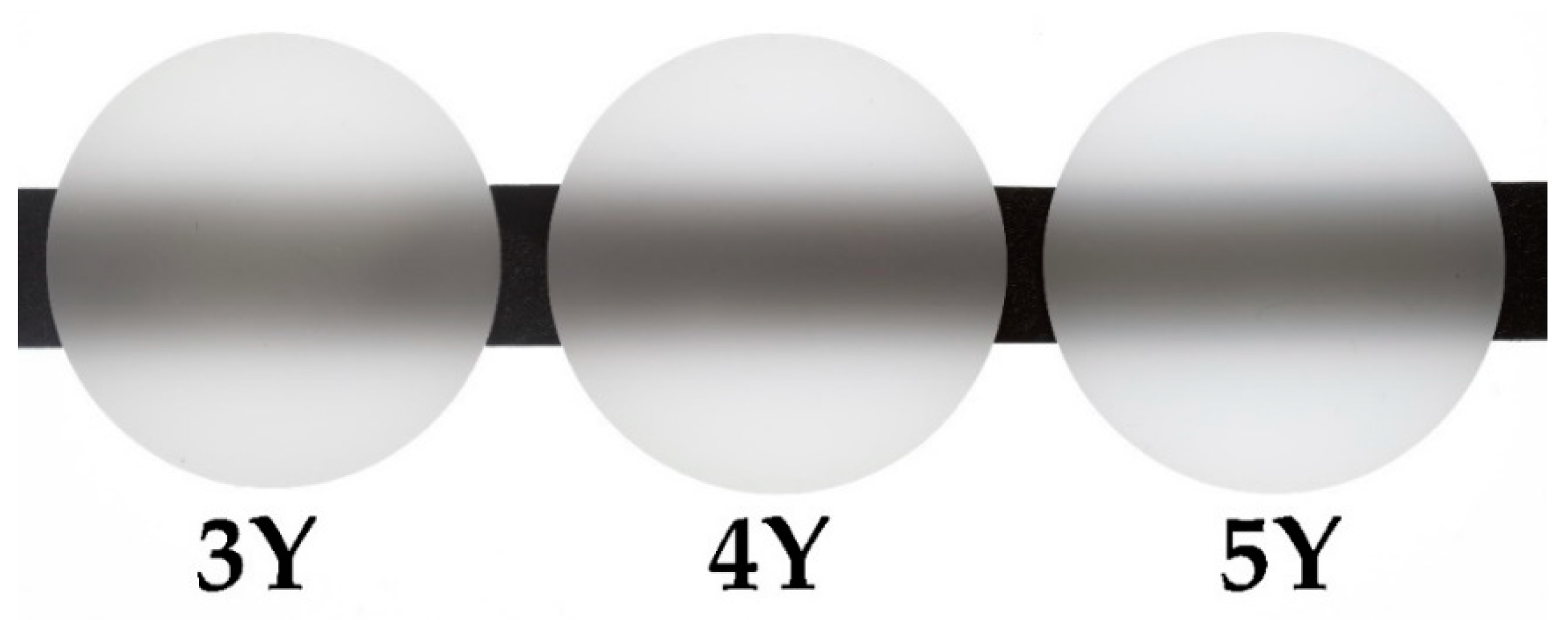

3.2. Translucency

4. Discussion

5. Conclusions

- NAC provided significantly higher SBS of resin cement to all types of translucent zirconia than APA.

- NAC did not affect the optical properties, while APA significantly lowered the translucency of translucent zirconia.

- NAC, not impairing mechanical nor optical properties of translucent zirconia, should be regarded as a zirconia pretreatment alternative to APA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manicone, P.F.; Rossi Iommetti, P.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef]

- Della Bona, A.; Kelly, J.R. The clinical success of all-ceramic restorations. J. Am. Dent. Assoc. 2008, 139, 8S–13S. [Google Scholar] [CrossRef] [Green Version]

- Al-Amleh, B.; Lyons, K.; Swain, M. Clinical trials in zirconia: A systematic review. J. Oral Rehabil. 2010, 37, 641–652. [Google Scholar] [CrossRef]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lawn, B.R. Novel zirconia materials in dentistry. J. Dent. Res. 2018, 97, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, M.; Bernasconi, M. Adhesion to zirconia used for dental restorations: A systematic review and meta-analysis. J. Adhes. Dent. 2015, 17, 7–26. [Google Scholar] [PubMed]

- Chen, J.; Cai, H.; Ren, X.; Suo, L.; Pei, X.; Wan, Q. A Systematic review of the survival and complication rates of all-ceramic resin-bonded fixed dental prostheses. J. Prosthodont. 2018, 27, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Quigley, N.P.; Loo, D.S.S.; Choy, C.; Ha, W.N. Clinical efficacy of methods for bonding to zirconia: A systematic review. J. Prosthet. Dent. 2021, 125, 231–240. [Google Scholar] [CrossRef] [PubMed]

- Atsu, S.S.; Kilicarslan, M.A.; Kucukesmen, H.C.; Aka, P.S. Effect of zirconium-oxide ceramic surface treatments on the bond strength to adhesive resin. J. Prosthet. Dent. 2006, 95, 430–436. [Google Scholar] [CrossRef]

- Derand, T.; Molin, M.; Kvam, K. Bond strength of composite luting cement to zirconia ceramic surfaces. Dent. Mater. 2005, 21, 1158–1162. [Google Scholar] [CrossRef]

- Lung, C.Y.; Kukk, E.; Matinlinna, J.P. The effect of silica-coating by sol-gel process on resin-zirconia bonding. Dent. Mater. J. 2013, 32, 165–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Everson, P.; Addison, O.; Palin, W.M.; Burke, F.J. Improved bonding of zirconia substructures to resin using a “glaze-on” technique. J. Dent. 2012, 40, 347–351. [Google Scholar] [CrossRef]

- Phark, J.H.; Duarte, S., Jr.; Blatz, M.; Sadan, A. An in vitro evaluation of the long-term resin bond to a new densely sintered high-purity zirconium-oxide ceramic surface. J. Prosthet. Dent. 2009, 101, 29–38. [Google Scholar] [CrossRef]

- Egilmez, F.; Ergun, G.; Cekic-Nagas, I.; Vallittu, P.K.; Ozcan, M.; Lassila, L.V. Effect of surface modification on the bond strength between zirconia and resin cement. J. Prosthodont. 2013, 22, 529–536. [Google Scholar] [CrossRef]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Selective infiltration-etching technique for a strong and durable bond of resin cements to zirconia-based materials. J. Prosthet. Dent. 2007, 98, 379–388. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y. Influence of different surface treatments on zirconia/resin shear bond strength using one-bottle universal adhesive. Adv. Appl. Ceram. 2018, 118, 70–77. [Google Scholar] [CrossRef]

- Wolfart, M.; Lehmann, F.; Wolfart, S.; Kern, M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent. Mater. 2007, 23, 45–50. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Barloi, A.; Kern, M. Influence of air-abrasion on zirconia ceramic bonding using an adhesive composite resin. Dent. Mater. 2010, 26, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lawn, B.R.; Rekow, E.D.; Thompson, V.P. Effect of sandblasting on the long-term performance of dental ceramics. J. Biomed. Mater. Res. B Appl. Biomater. 2004, 71, 381–386. [Google Scholar] [CrossRef]

- Zhang, Y.; Lawn, B.R.; Malament, K.A.; Van Thompson, P.; Rekow, E.D. Damage accumulation and fatigue life of particle-abraded ceramics. Int. J. Prosthodont. 2006, 19, 442–448. [Google Scholar]

- Wang, H.; Aboushelib, M.N.; Feilzer, A.J. Strength influencing variables on CAD/CAM zirconia frameworks. Dent. Mater. 2008, 24, 633–638. [Google Scholar] [CrossRef] [PubMed]

- Oblak, C.; Verdenik, I.; Swain, M.V.; Kosmac, T. Survival-rate analysis of surface treated dental zirconia (Y-TZP) ceramics. J. Mater. Sci. Mater. Med. 2014, 25, 2255–2264. [Google Scholar] [CrossRef]

- Oblak, C.; Kocjan, A.; Jevnikar, P.; Kosmač, T. The effect of mechanical fatigue and accelerated ageing on fracture resistance of glazed monolithic zirconia dental bridges. J. Eur. Ceram. Soc. 2017, 37, 4415–4422. [Google Scholar] [CrossRef]

- Guth, J.F.; Stawarczyk, B.; Edelhoff, D.; Liebermann, A. Zirconia and its novel compositions: What do clinicians need to know? Quintessence Int. 2019, 50, 512–520. [Google Scholar] [PubMed]

- Lawson, N.C.; Jurado, C.A.; Huang, C.T.; Morris, G.P.; Burgess, J.O.; Liu, P.R.; Kinderknecht, K.E.; Lin, C.P.; Givan, D.A. Effect of Surface Treatment and Cement on Fracture Load of Traditional Zirconia (3Y), Translucent Zirconia (5Y), and Lithium Disilicate Crowns. J. Prosthodont. 2019, 28, 659–665. [Google Scholar] [CrossRef]

- Malgaj, T.; Kocjan, A.; Jevnikar, P. The effect of firing protocols on the resin-bond strength to alumina-coated zirconia ceramics. Adv. Appl. Ceram. 2019, 119, 267–275. [Google Scholar] [CrossRef]

- Jevnikar, P.; Golobič, M.; Kocjan, A.; Kosmač, T. The effect of nano-structured alumina coating on the bond strength of resin-modified glass ionomer cements to zirconia ceramics. J. Eur. Ceram. Soc. 2012, 32, 2641–2645. [Google Scholar] [CrossRef]

- Kocjan, A. The hydrolysis of AlN powder–a powerful tool in advanced materials engineering. Chem. Rec. 2018, 18, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Malgaj, T.; Plut, A.; Eberlinc, A.; Drevensek, M.; Jevnikar, P. Anterior esthetic rehabilitation of an alveolar cleft using novel minimally invasive prosthodontic techniques: A case report. Cleft Palate Craniofac. J. 2021, 58, 912–918. [Google Scholar] [CrossRef] [PubMed]

- Malgaj, T.; Abram, A.; Kocjan, A.; Jevnikar, P. Influence of nanostructured alumina coating on the clinical performance of zirconia cantilevered resin-bonded fixed dental prostheses: Up to 3-year results of a prospective, randomized, controlled clinical trial. J. Prosthet. Dent. 2021, in press. [Google Scholar] [CrossRef]

- Jevnikar, P.; Krnel, K.; Kocjan, A.; Funduk, N.; Kosmac, T. The effect of nano-structured alumina coating on resin-bond strength to zirconia ceramics. Dent. Mater. 2010, 26, 688–696. [Google Scholar] [CrossRef] [PubMed]

- Hummel, M.; Kern, M. Durability of the resin bond strength to the alumina ceramic Procera. Dent. Mater. 2004, 20, 498–508. [Google Scholar] [CrossRef]

- Finger, W.J.; Lee, K.S.; Podszun, W. Monomers with low oxygen inhibition as enamel/dentin adhesives. Dent. Mater. 1996, 12, 256–261. [Google Scholar] [CrossRef]

- Commission Internationale de l’Eclairage. CIE Technical Report: Colorimetry; CIE Publication: Paris, France, 2004. [Google Scholar]

- Della Bona, A.; Nogueira, A.D.; Pecho, O.E. Optical properties of CAD-CAM ceramic systems. J. Dent. 2014, 42, 1202–1209. [Google Scholar] [CrossRef] [Green Version]

- Klimke, J.; Trunec, M.; Krell, A. Transparent tetragonal yttria-stabilized zirconia ceramics: Influence of scattering caused by birefringence. J. Am. Ceram. Soc. 2011, 94, 1850–1858. [Google Scholar] [CrossRef]

- Krell, A.; Hutzler, T.; Klimke, J. Transmission physics and consequences for materials selection, manufacturing, and applications. J. Eur. Ceram. Soc. 2009, 29, 207–221. [Google Scholar] [CrossRef]

- Fathy, S.M.; Al-Zordk, W.; Grawish, M.E.; Swain, M.V. Flexural strength and translucency characterization of aesthetic monolithic zirconia and relevance to clinical indications: A systematic review. Dent. Mater. 2021, 37, 711–730. [Google Scholar] [CrossRef]

- Zhang, F.; Reveron, H.; Spies, B.C.A. Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019, 91, 24–34. [Google Scholar] [CrossRef]

- Ruales-Carrera, E.; Cesar, P.F.; Henriques, B.; Fredel, M.C.; Ozcan, M.; Volpato, C.A.M. Adhesion behavior of conventional and high-translucent zirconia: Effect of surface conditioning methods and aging using an experimental methodology. J. Esthet. Restor. Dent. 2019, 31, 388–397. [Google Scholar] [CrossRef]

- Heikkinen, T.T.; Matinlinna, J.P.; Vallittu, P.K.; Lassila, L.V. Long term water storage deteriorates bonding of composite resin to alumina and zirconia short communication. Open Dent. J. 2013, 7, 123–125. [Google Scholar] [CrossRef] [Green Version]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Valente, F.; Mavriqi, L.; Traini, T. Effects of 10-MDP based primer on shear bond strength between zirconia and new experimental resin cement. Materials 2020, 13, 235. [Google Scholar] [CrossRef] [Green Version]

- Kern, M.; Barloi, A.; Yang, B. Surface conditioning influences zirconia ceramic bonding. J. Dent. Res. 2009, 88, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Aung, S.; Takagaki, T.; Lyann, S.K.; Ikeda, M.; Inokoshi, M.; Sadr, A.; Nikaido, T.; Tagami, J. Effects of alumina-blasting pressure on the bonding to super/ultra-translucent zirconia. Dent. Mater. 2019, 35, 730–739. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, W.; Jiang, F.; Wang, Z.; Zhao, J.; Zhou, C.; Wu, J. Effects of air-abrasion pressure on mechanical and bonding properties of translucent zirconia. Clin. Oral Investig. 2021, 25, 1979–1988. [Google Scholar] [CrossRef]

- Papia, E.; Larsson, C.; du Toit, M.; Vult von Steyern, P. Bonding between oxide ceramics and adhesive cement systems: A systematic review. J. Biomed. Mater. Res. B Appl. Biomater. 2014, 102, 395–413. [Google Scholar] [CrossRef] [PubMed]

- Van Meerbeek, B.; Peumans, M.; Poitevin, A.; Mine, A.; Van Ende, A.; Neves, A.; De Munck, J. Relationship between bond-strength tests and clinical outcomes. Dent. Mater. 2010, 26, e100–e121. [Google Scholar] [CrossRef]

- Yoshida, K. Influence of alumina air-abrasion for highly translucent partially stabilized zirconia on flexural strength, surface properties, and bond strength of resin cement. J. Appl. Oral Sci. 2020, 28, e20190371. [Google Scholar] [CrossRef] [PubMed]

- Keuper, M.; Berthold, C.; Nickel, K.G. Long-time aging in 3 mol.% yttria-stabilized tetragonal zirconia polycrystals at human body temperature. Acta Biomater. 2014, 10, 951–959. [Google Scholar] [CrossRef] [PubMed]

- Camposilvan, E.; Leone, R.; Gremillard, L.; Sorrentino, R.; Zarone, F.; Ferrari, M.; Chevalier, J. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent. Mater. 2018, 34, 879–890. [Google Scholar] [CrossRef] [PubMed]

- Kocjan, A.; Ambrožič, M.; Kosmač, T. Stereometric analysis of nanostructured boehmite coatings synthesized by aluminum nitride powder hydrolysis. Ceram. Int. 2012, 38, 4853–4859. [Google Scholar] [CrossRef]

- Liu, G.L.; Huang, Z.R.; Liu, X.J.; Jiang, D.L. Effect of density and surface roughness on optical properties of silicon carbide optical components. Chin. Phys. Lett. 2008, 25, 1135–1137. [Google Scholar]

- Guinneton, F.; Valmalette, J.C.; Gavarri, J.R. Nanocrystalline vanadium dioxide: Synthesis and mid-infrared properties. Opt. Mater. 2000, 15, 111–114. [Google Scholar] [CrossRef]

- Guinneton, F.; Sauques, L.; Valmalette, J.C.; Cros, F.; Gavarri, J.R. Role of surface defects and microstructure in infrared optical properties of thermochromic VO2 materials. J. Phys. Chem. Solids 2005, 66, 63–73. [Google Scholar] [CrossRef]

- Salas, M.; Lucena, C.; Herrera, L.J.; Yebra, A. Translucency thresholds for dental materials. Dent. Mater. 2018, 34, 1168–1174. [Google Scholar] [CrossRef]

- Gherlone, E.; Polizzi, E.; Tete, G.; Cappare, P. Dentistry and Covid-19 pandemic: Operative indications post-lockdown. New Microbiol. 2021, 44, 1–11. [Google Scholar] [PubMed]

- Tecco, S.; Parisi, M.R.; Gastaldi, G.; Polizzi, E.; D’Amicantonio, T.; Zilocchi, I.; Gardini, I.; Gherlone, E.F.; Lazzarin, A.; Cappare, P. Point-of-care testing for hepatitis C virus infection at an Italian dental clinic: Portrait of the pilot study population. New Microbiol. 2019, 42, 133–138. [Google Scholar] [PubMed]

- D’Orto, B.; Tete, G.; Polizzi, E. Osseointegrated dental implants supporting fixed prostheses in patients affected by Sjogren’s Sindrome: A narrative review. J. Biol. Regul. Homeost. Agents 2020, 34, 91–93. [Google Scholar] [PubMed]

- Moritz, J.; Abram, A.; Čekada, M.; Gabor, U.; Garvas, M.; Zdovc, I.; Dakskobler, A.; Cotič, J.; Ivičak-Kocjan, K.; Kocjan, A. Nanoroughening of sandblasted 3Y-TZP surface by alumina coating deposition for improved osseointegration and bacteria reduction. J. Eur. Ceram. Soc. 2019, 39, 4347–4357. [Google Scholar] [CrossRef]

- Tete, G.; D’Orto, B.; Nagni, M.; Agostinacchio, M.; Polizzi, E.; Agliardi, E. Role of induced pluripotent stem cells (IPSCS) in bone tissue regeneration in dentistry: A narrative review. J. Biol. Regul. Homeost. Agents 2020, 34, 1–10. [Google Scholar]

- Cappare, P.; Tete, G.; Sberna, M.T.; Panina-Bordignon, P. The emerging role of stem cells in regenerative dentistry. Curr. Gene Ther. 2020, 20, 259–268. [Google Scholar] [CrossRef] [PubMed]

- Crespi, R.; Cappare, P.; Gherlone, E. Sinus floor elevation by osteotome: Hand mallet versus electric mallet. A prospective clinical study. Int. J. Oral Maxillofac. Implants 2012, 27, 1144–1150. [Google Scholar]

- Sterzenbach, G.; Tunjan, R.; Rosentritt, M.; Naumann, M. Increased tooth mobility because of loss of alveolar bone support: A hazard for zirconia two-unit cantilever resin-bonded FDPs in vitro? J. Biomed. Mater. Res. B Appl. Biomater. 2014, 102, 244–249. [Google Scholar] [CrossRef] [PubMed]

- Sinjari, B.; Santilli, M.; D’Addazio, G.; Rexhepi, I.; Gigante, A.; Caputi, S.; Traini, T. Influence of dentine pre-treatment by sandblasting with aluminum oxide in adhesive restorations. An in vitro study. Materials 2020, 13, 3026. [Google Scholar] [CrossRef] [PubMed]

- Braga, R.R.; Meira, J.B.; Boaro, L.C.; Xavier, T.A. Adhesion to tooth structure: A critical review of “macro” test methods. Dent. Mater. 2010, 26, e38–e49. [Google Scholar] [CrossRef] [PubMed]

| Type of ZrO2 | Treatment | No Thermocycling | 37,500 Thermocycles | ||||

|---|---|---|---|---|---|---|---|

| Mean | SD | P < 0.05 | Mean | SD | P < 0.05 | ||

| 3Y | AS | 11.88 | 2.44 | A | 0.00 | ds | A |

| APA | 18.16 | 2.24 | C, D, E | 14.25 | 4.00 | B | |

| NAC | 22.19 | 5.82 | E, F | 21.52 | 2.63 | C | |

| 4Y | AS | 14.00 | 3.11 | A, B, C | 0.00 | ds | A |

| APA | 17.30 | 2.59 | B, C, D | 15.27 | 4.05 | B | |

| NAC | 23.43 | 1.52 | F | 20.10 | 4.63 | C | |

| 5Y | AS | 12.93 | 2.72 | A, B | 0.00 | ds | A |

| APA | 15.81 | 4.16 | A, B, C | 12.17 | 2.21 | B | |

| NAC | 21.57 | 2.46 | D, E, F | 23.06 | 3.74 | C | |

| Type of ZrO2 | Treatment | Mean TP | SD | P < 0.05 |

|---|---|---|---|---|

| 3Y | AS | 23.4 | 0.64 | A |

| NAC | 23.6 | 0.21 | A | |

| APA | 21.4 | 0.13 | B | |

| 4Y | AS | 25.7 | 0.39 | C |

| NAC | 25.6 | 0.56 | C | |

| APA | 24.4 | 0.18 | D | |

| 5Y | AS | 31.9 | 1.05 | E |

| NAC | 31.8 | 0.54 | E | |

| APA | 29.9 | 0.76 | F |

| ΔTPab | 3Y | 4Y | 5Y | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAC | P | APA | P | NAC | P | APA | P | NAC | P | APA | P | |

| AS | −0.26 | 0.55 | 1.92 | <0.001 | 0.07 | 0.96 | 1.24 | 0.001 | 0.19 | 0.93 | 2.05 | 0.005 |

| NAC | - | - | 2.18 | <0.001 | - | - | 1.16 | 0.002 | - | - | 1.86 | 0.009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malgaj, T.; Mirt, T.; Kocjan, A.; Jevnikar, P. The Influence of Nanostructured Alumina Coating on Bonding and Optical Properties of Translucent Zirconia Ceramics: In Vitro Evaluation. Coatings 2021, 11, 1126. https://doi.org/10.3390/coatings11091126

Malgaj T, Mirt T, Kocjan A, Jevnikar P. The Influence of Nanostructured Alumina Coating on Bonding and Optical Properties of Translucent Zirconia Ceramics: In Vitro Evaluation. Coatings. 2021; 11(9):1126. https://doi.org/10.3390/coatings11091126

Chicago/Turabian StyleMalgaj, Tine, Tadej Mirt, Andraž Kocjan, and Peter Jevnikar. 2021. "The Influence of Nanostructured Alumina Coating on Bonding and Optical Properties of Translucent Zirconia Ceramics: In Vitro Evaluation" Coatings 11, no. 9: 1126. https://doi.org/10.3390/coatings11091126

APA StyleMalgaj, T., Mirt, T., Kocjan, A., & Jevnikar, P. (2021). The Influence of Nanostructured Alumina Coating on Bonding and Optical Properties of Translucent Zirconia Ceramics: In Vitro Evaluation. Coatings, 11(9), 1126. https://doi.org/10.3390/coatings11091126