Anti-Blocking Mechanism of Flocking Drainage Pipes in Tunnels Based on Mathematical Modeling Theory

Abstract

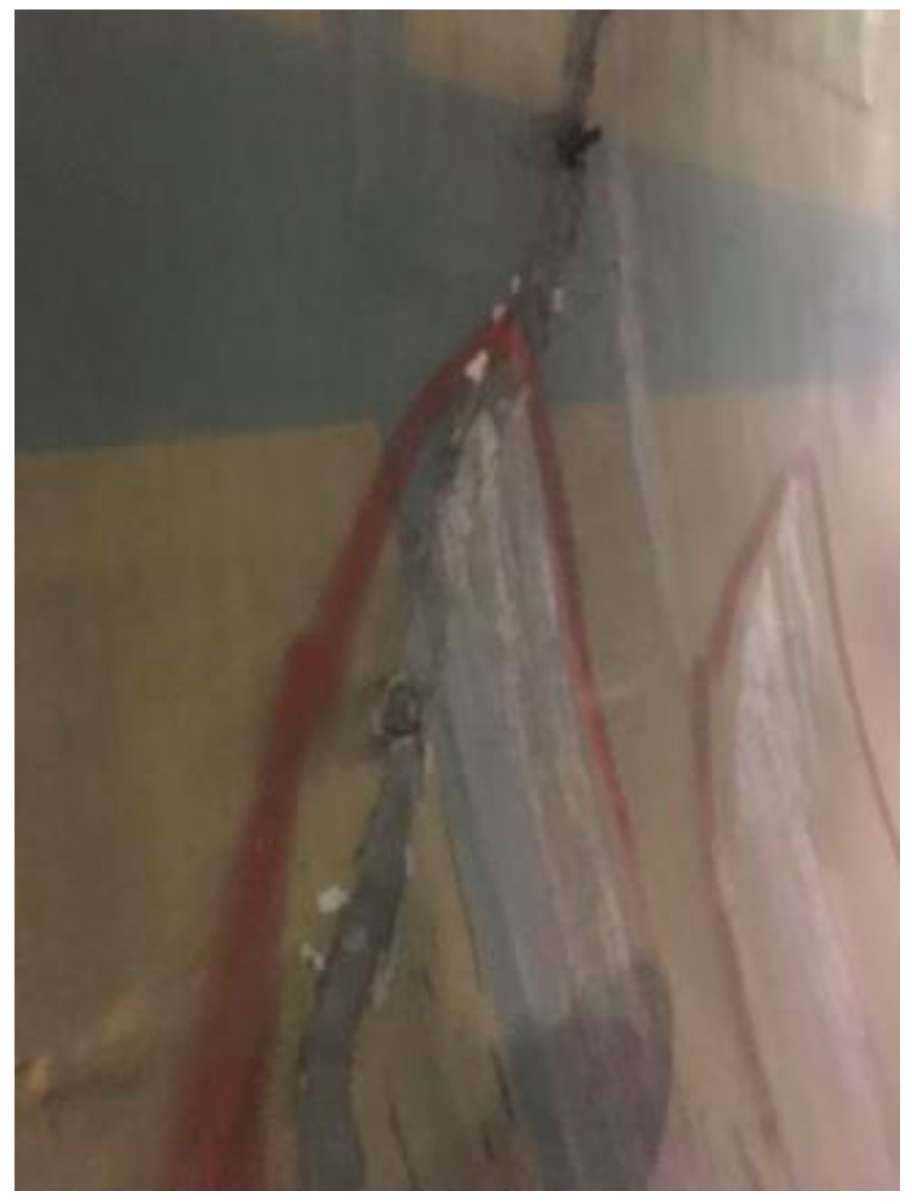

:1. Introduction

2. Method

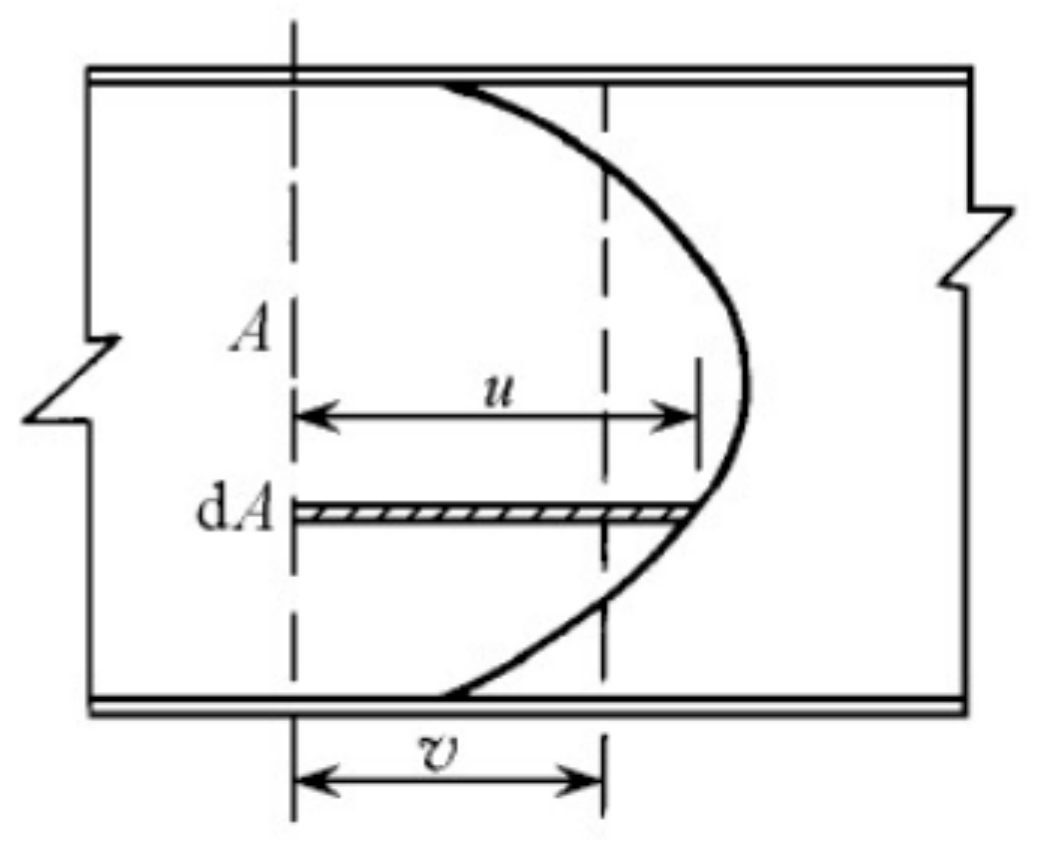

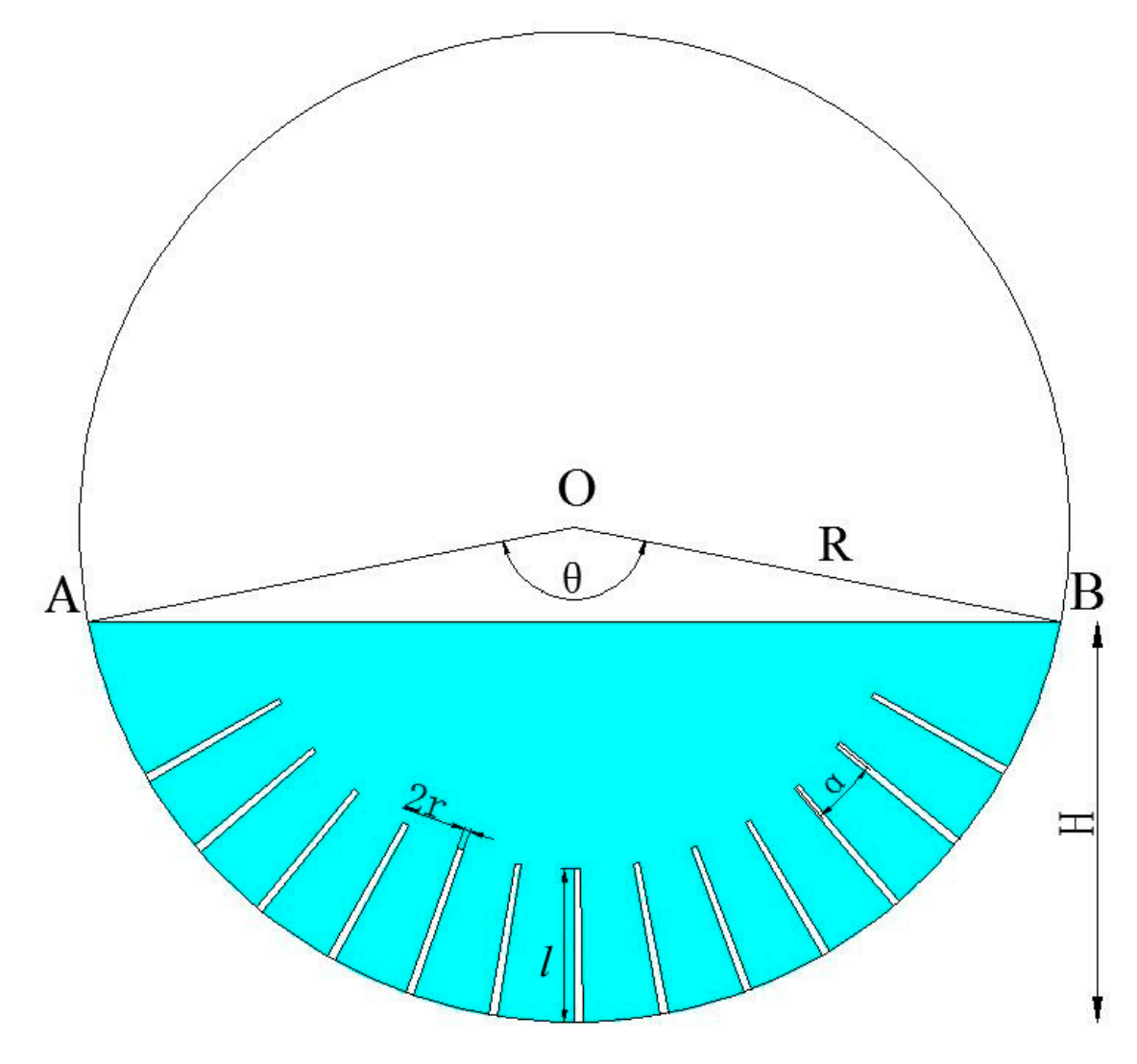

2.1. Average Flow Velocity of Flocking Drainage Pipe Section

- Q—Rate of flow;

- u—Flow velocity at a point in the pipe;

- Sectional area of water in the pipe;

- v—Average flow velocity in the pipe section.

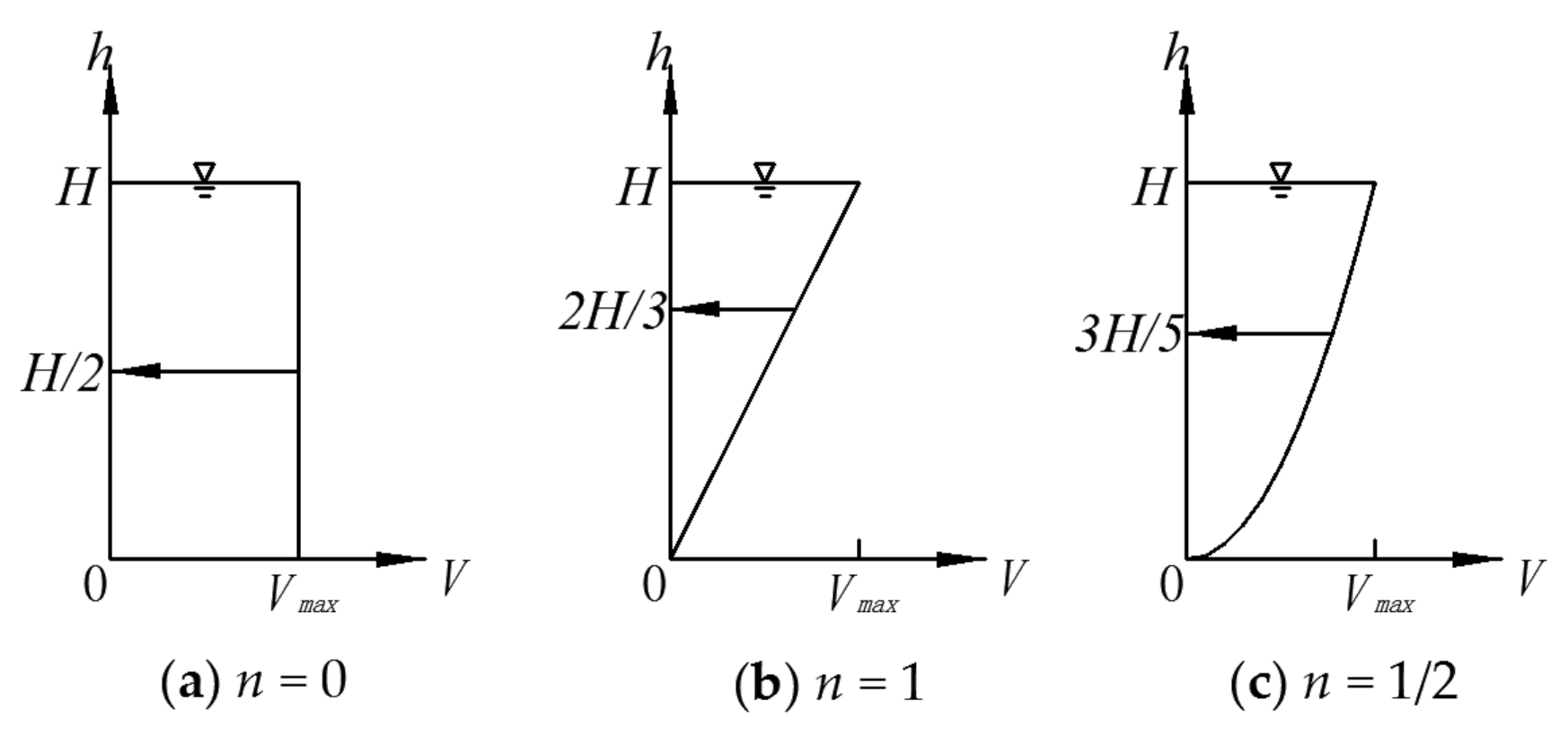

2.2. Rule of the Flow Velocity Distribution of Flocking Drainage Pipe

- V—flow velocity at any depth of vertical surface;

- Vmax—flow velocity of water surface;

- H—water depth;

- h—water depth at any point;

- n—constant, which was determined by the nature of water flow and the interior wall of the drainage pipe.

3. Results and Discussion

3.1. Analysis of the Flow Velocity of Flocking Drainage Pipes

- v—average flow velocity of flocking drainage pipe section (mm/s);

- Q—groundwater flow in flocking drainage pipe (mL/s);

- R—radius of flocking drainage pipe (mm);

- H—cross-section height of groundwater in flocked drainage pipe (mm);

- α—flocking circular spacing of flocked drainage pipe (°);

- r—radius of fluff of flocking drainage pipe (mm);

- l—length of fluff of flocking drainage pipe (mm); N—amount of fluff of flocking drainage pipe section.

3.2. Analysis of the Fluff Stress of Flocking Drainage Pipe

- FW—standard value of flowing water pressure (kN);

- γ—unit weight of groundwater (kN/m3);

- v—average flow velocity of flocking drainage pipe section (m/s);

- water resistance area by fluff (m2),

- A = 2rl, g—acceleration of gravity, g = 9.81 m/s2;

- K—coefficient of fluff shape, which was 0.8 for round fluff, 1.3 for rectangular fluff.

3.3. Analysis of the Interaction between the Fluff, the Crystal and the Groundwater

- τ1—adhesion force between the crystal and the fluff (kN/m2);

- τ2—adhesion force between the crystals (kN/m2);

- r′—fixed thickness of crystal on the fluff (m).

- (1)

- When the flowing water pressure was greater than the adhesion force between the crystals and the fluff, namely:

- (2)

- When the water pressure is greater than the adhesion force between the crystals and less than the adhesion between the crystals and the fluff, namely:

3.4. Analysis of the Changing Law of Crystals in Flocking Drainage Pipes over Time

4. Conclusions

- (1)

- When the groundwater velocity v0 in the pipe met v2 ≤ 4gπ(r + r′)lτ2/γKA, crystals were attached to the fluff. When the running time of groundwater in the drainage pipe was t > (Q/C2α1)((1/v0) − (γKA/(4gπ(r + r′)l·τ2))1/2), the crystals attached to the fluff, maintain dynamic balance.

- (2)

- When the groundwater velocity v0 in the pipe met 4gπ(r + r′)lτ2/γKA < v2 < 4gπrlτ1/γKA, crystals were still attached to the fluff. When the running time of groundwater in the drainage pipe was t > (Q/C2α2)((−1/v0) + (γKA/(4gπ(r + r′)l·τ2))1/2), the crystals attached to the fluff, maintaining dynamic balance.

- (3)

- When the groundwater velocity v0 in the pipe met v2 ≥ 4gπrlτ1/γKA, crystals did not adhere to the fluff.

- (4)

- The adhesion between crystals and fluff and between crystals of the flocking drainage pipe needs to be determined by more in-depth experimental research, so as to improve the calculation model of the flocking anti-crystallization blocking mechanism of drainage pipes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Transport of the People’s Republic of China. Statistical Bulletin on the Development of Transportation Industry in 2020 [EB/OL]. Available online: https://xxgk.mot.gov.cn/2020/jigou/zhghs/202105/t20210517_3593412.html (accessed on 19 May 2021).

- Duau, H.; Chen, F.; Yao, C.; Wang, B.; Shu, W. The phenomenon of crystal pipe blocking in karst tunnel and its induced risk. China Civ. Eng. J. 2020, 53, 332–335. [Google Scholar]

- Zhao, P.; Guo, X.; Ma, W. Research and application of dredge equipment for drainage pipeline in railway tunnel. Railw. Eng. 2018, 58, 30–32+66. [Google Scholar]

- Zhang, X.; Zhou, Y.; Zhang, B.; Zhou, Y.; Liu, S.; Li, Y. Investigation and analysis on crystallization of tunnel drainage pipes in chongqing. Adv. Mater. Sci. Eng. 2018, 2018, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Guo, X. Crystallization mechanism and countermeasures of drainage system for railway tunnel. China Railw. Sci. 2020, 41, 71–77. [Google Scholar]

- Lei, L.; Hua, Y.; Li, G.; Qi, J.; Li, D. Analysis and treatment of blind pipe blockage in humaling tunnel on lanzhou-chongqing railway. Mod. Tunn. Technol. 2020, 57, 149–153. [Google Scholar]

- Wu, Y.; Li, G.; Jia, Q.; Qi, H.; Li, D. Study on characteristics and sources of crystal components of leakage water in the loess tunnel. Mod. Tunn. Technol. 2020, 57, 154–159. [Google Scholar]

- Ye, F.; Tian, C.; He, B.; Zhao, M.; Wang, J.; Han, X.; Song, G. Experimental study on scaling and cloggingin drainage system of tunnels under construction. China J. Highw. Transp. 2021, 34, 159–170. [Google Scholar]

- Jiang, Y.; Du, K.; Tao, L.; Zhao Jumei Xiao, H. Investigation and discussion on blocking mechanism of drainage system in karst tunnels. Railw. Stand. Des. 2019, 63, 131–135. [Google Scholar]

- Tian, C.; Ye, F.; Song, G.; Wang, Q.; Zhao, M.; He, B.; Wang, J.; Han, X. On mechanism of crystal blockage of tunnel drainage system and preventive countermeasures. Mod. Tunn. Technol. 2020, 57, 77–83. [Google Scholar]

- Zhou, W.; Wang, Y.; Li, Y.; Wang, L.; Jia, X. Research on the influence factors of crystallization and sedimentation of tunnel drainage pipeline in karst area. Highway 2021, 66, 347–352. [Google Scholar]

- Xiang, K.; Zhou, J.; Zhang, X.; Huang, C.; Song, L.; Liu, S. Experimental Study on Crystallization Rule of Tunnel Drainpipe in Alkaline Environment. Tunn. Constr. 2019, 39, 207–212. [Google Scholar]

- Zhou, Y.; Zhang, X.; Wei, L.; Liu, S.; Zhang, B.; Zhou, C. Experimental Study on Prevention of Calcium Carbonate Crystallizing in Drainage Pipe of Tunnel Engineering. Adv. Civ. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Du, K.; Liao, J.; Chen, X.; Xiao, H. Experimental research on maintainability of drainage facilities in lining construction joints of karst tunnel. Railw. Stand. Des. 2019, 63, 91–96. [Google Scholar]

- Ye, F.; Tian, C.; Zhao Meng He, B.; Wang, J.; Han, X. The disease of scaling and cloging in the drainage pipes of a tunnel under construction in Yunnan. China Civ. Eng. J. 2020, 53, 336–341. [Google Scholar]

- Su, Y.; Yang, H.; Shi, W.; Guo, H.; Zhao, Y.; Wang, D. Crystallization and morphological control of calcium carbonate by functionalized triblock copolymers. Colloids Surf. A Physicochem. Eng. Asp. 2009, 355, 158–162. [Google Scholar] [CrossRef]

- Semra, K.; Mualla, O.; Emel, A. The effect of ultrasonication on calcium carbonate crystallization in the presence of biopolymer. J. Cryst. Growth 2014, 401, 266–270. [Google Scholar]

- Su, M.; Han, J.; Li, Y.; Chen, J.; Zhao, Y.; Keith, C. Ultrasonic crystallization of calcium carbonate in presence of seawater ions. Desalination 2015, 369, 85–90. [Google Scholar] [CrossRef]

- Rayane, M.; Samira, G.; Mohamed, T. Calcium carbonate inhibition by green inhibitors: Thiamine and pyridoxine. Desalination 2017, 404, 147–154. [Google Scholar]

- Hong, Y.; Qian, X.; Li, J.; Yang, H.; Zhang, P. On scavenging performances of cleaning solvents for the clogging in the drainage system of karst tunnels. Mod. Tunn. Technol. 2020, 57, 160–170. [Google Scholar]

- Liu, S.; Zhang, X.; Lü, H.; Liu, Q.; Wang, B. The effect of flocking pvc pipe on the prevention and crystallization of tunnel drains. Sci. Technol. Eng. 2018, 18, 313–319. [Google Scholar]

- Liu, S.; Zhang, X.; Lü, H.; Liu, Q.; Wang, B. The effect of anti-crystallization of tunnel plumage drain pipe under different water filling state. Sci. Technol. Eng. 2018, 18, 156–163. [Google Scholar]

- Liu, S.; Gao, F.; Zhou, Y.; Liu, Q.; Lü, H.; Wang, B.; Xiang, K.; Xiao, D. Effect of fuzz length on the prevention of crystallization of tunnel flocking drainpipes. Sci. Technol. Eng. 2019, 19, 234–239. [Google Scholar]

- Liu, S.; Gao, F.; Zhang, X.; Han, F.; Zhou, Y.; Xiang, K.; Xiao, D. Experimental study on anti-crystallization law of tunnel transverse flocking drainpipe at different velocities. Asia-Pac. J. Chem. Eng. 2020, 15, 1–9. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, X.; Gao, F.; Wei, L.; Liu, Q.; Lü, H.; Wang, B. Two-dimensional flow field distribution characteristics of flocking drainage pipes in tunnel. Open Phys. 2020, 18, 139–148. [Google Scholar] [CrossRef]

- Zhou, Y. Calculation of bridge water pressure. East China Highw. 1992, 5, 24–25. [Google Scholar]

- JTG D60-2015 General Specifications for Design of Highway Bridges and Culverts; People’s Communications Publishing House Co., Ltd.: Beijing, China, 1 December 2015. Available online: https://xxgk.mot.gov.cn/2020/jigou/glj/202006/t20200623_3312312.html (accessed on 10 October 2015).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhang, X.; Gao, F. Anti-Blocking Mechanism of Flocking Drainage Pipes in Tunnels Based on Mathematical Modeling Theory. Coatings 2021, 11, 961. https://doi.org/10.3390/coatings11080961

Liu S, Zhang X, Gao F. Anti-Blocking Mechanism of Flocking Drainage Pipes in Tunnels Based on Mathematical Modeling Theory. Coatings. 2021; 11(8):961. https://doi.org/10.3390/coatings11080961

Chicago/Turabian StyleLiu, Shiyang, Xuefu Zhang, and Feng Gao. 2021. "Anti-Blocking Mechanism of Flocking Drainage Pipes in Tunnels Based on Mathematical Modeling Theory" Coatings 11, no. 8: 961. https://doi.org/10.3390/coatings11080961

APA StyleLiu, S., Zhang, X., & Gao, F. (2021). Anti-Blocking Mechanism of Flocking Drainage Pipes in Tunnels Based on Mathematical Modeling Theory. Coatings, 11(8), 961. https://doi.org/10.3390/coatings11080961