Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

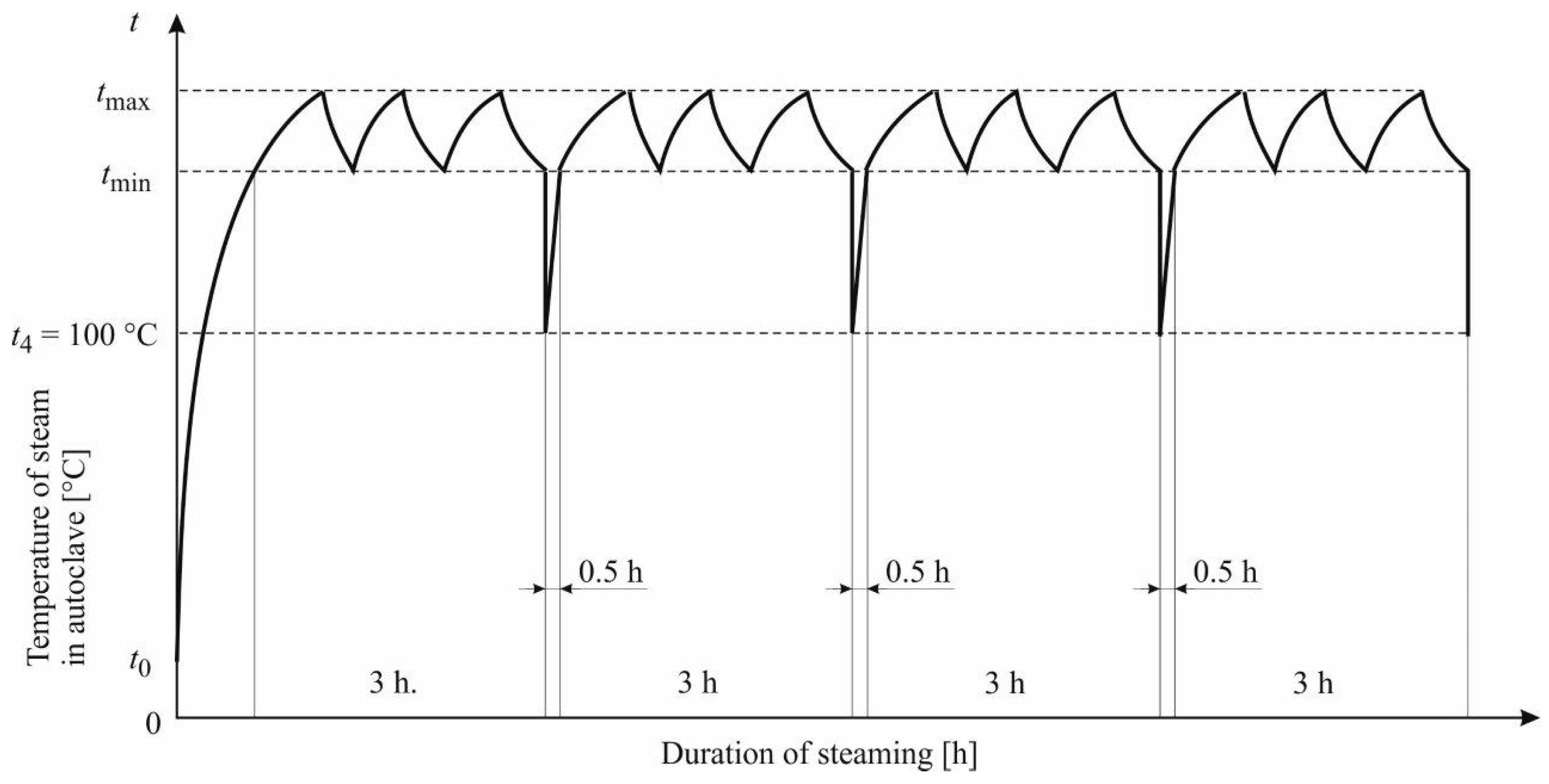

2.2. Thermal Treatment of Alder Wood

2.3. Determination of Alder Wood Density

2.4. Determination of Moisture Content before and after the Thermal Treatment Process

2.5. Measurement of Alder Wood Acidity

2.6. Color Measurement of Modified Alder Wood

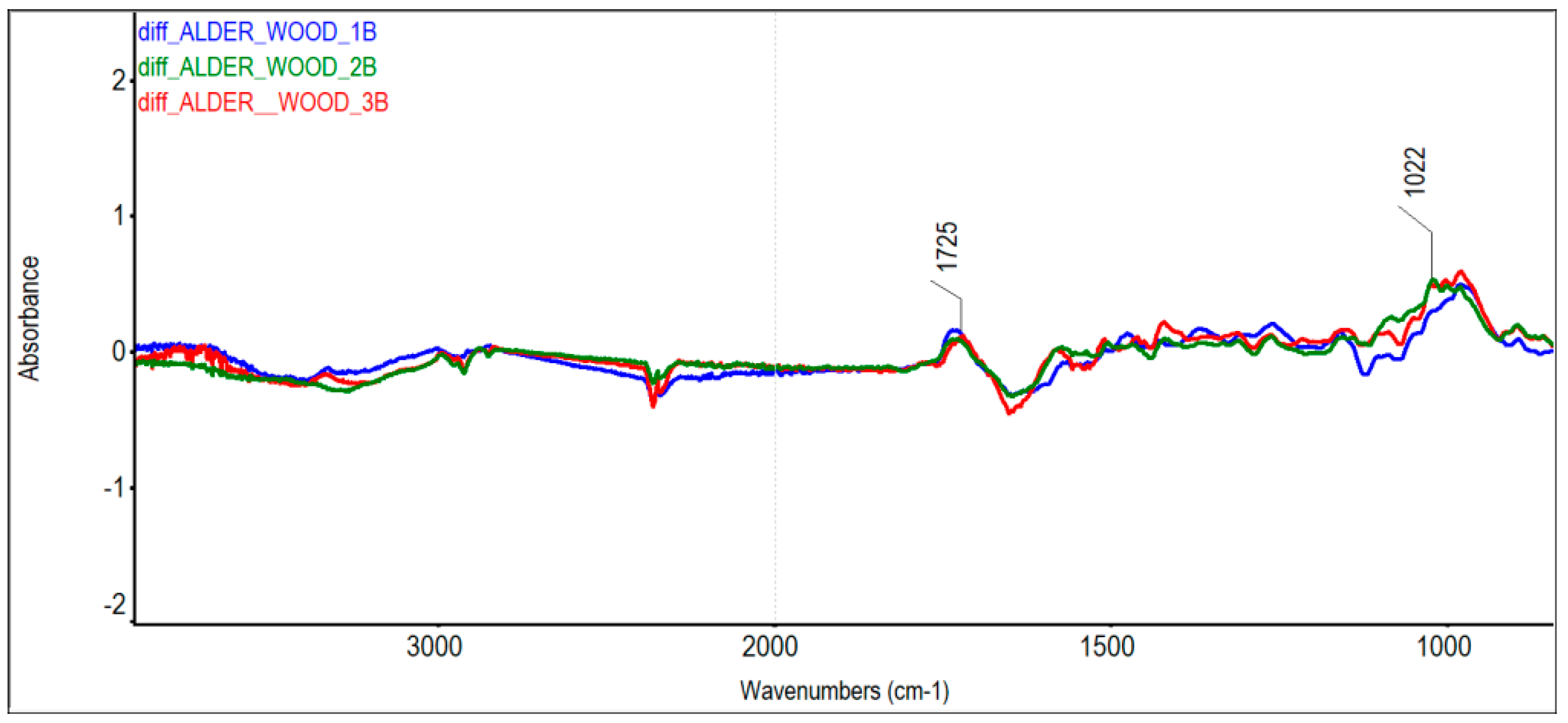

2.7. Analysis of Changes in Lignin-Cellulose Matrix of Wood ATR-FTIR Spectroscopy

2.8. Statistical Processing of Measured Data

3. Results and Discussion

4. Conclusions

- (1)

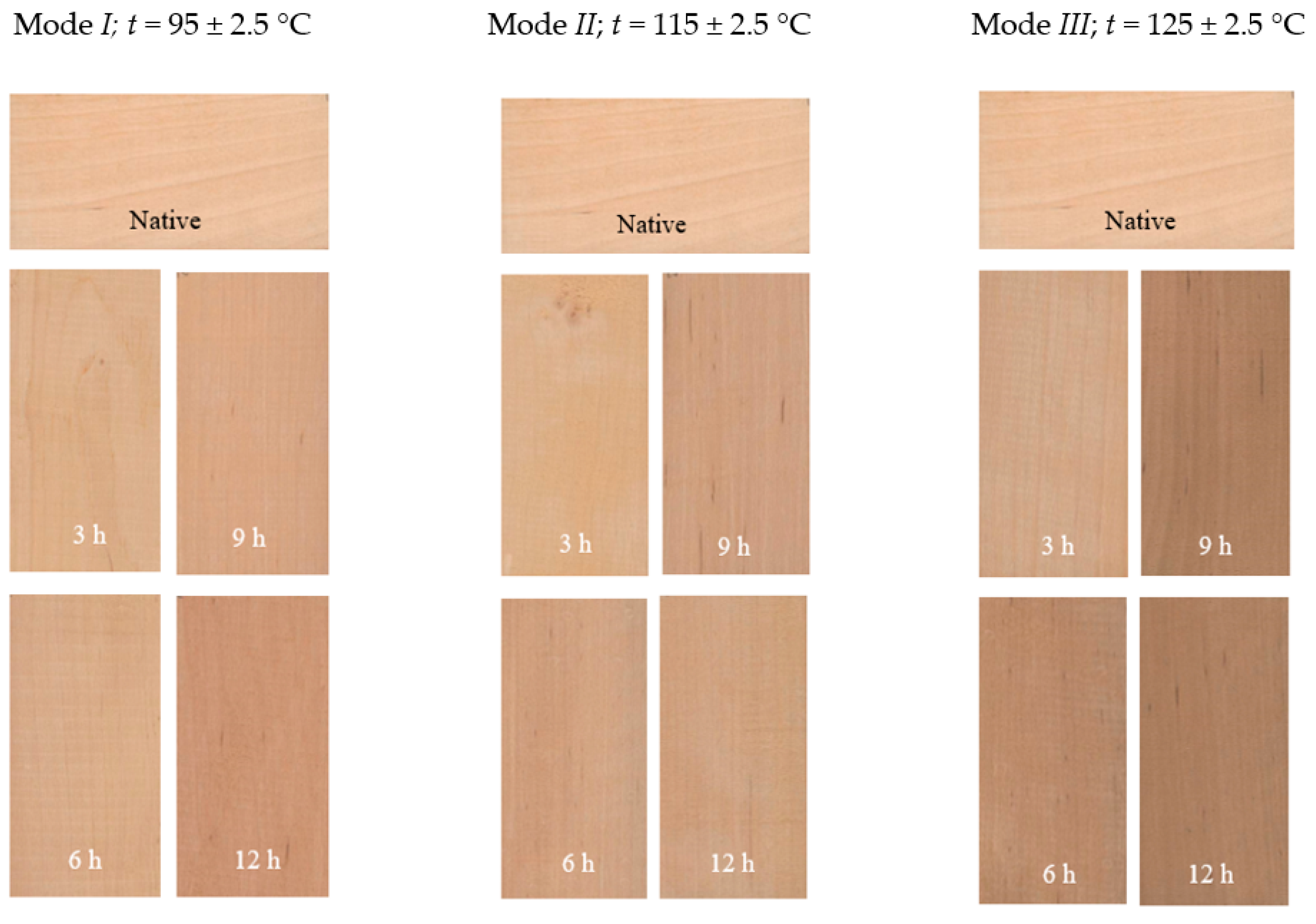

- The process of thermal treatment of alder wood changes the color from the original light white-gray color with the coordinates: L* = 76.8 ± 2.3; a* = 9.6 ± 1.6; b* = 22.3 ± 1.2 for soft reddish-brown tones with coordinates: L* = 57.4 ± 1.2; a* = 12.9 ± 0.5; b* = 18.3 ± 0.4 to dark brown shades with coordinates: L* = 47.4 ± 1.7; a* = 13.1 ± 0.6; b* = 16.3 ± 0.4.

- (2)

- The density of thermally treated alder wood decreases with increasing temperature in the range of average values ρ0 = 513.7–503.6 kg·m−3. The stated changes in the densities of color-modified alder wood do not exceed the tolerance limits of the densities of native alder wood, which is in the Central European area: ρ0 = 450–510–600 kg·m−3.

- (3)

- During the technological process of wood modification, the acidity of the wood changes, which is more pronounced at a higher saturated steam temperature and for a longer time. The change is from pH = 4.9 for native alder wood to pH = 3.1 in mode III after 12 h of modification.

- (4)

- The differential spectrum of alder wood samples showed significant changes in the extractives as well as degradation of hemicelluloses. A decrease in unconjugated bonds and an increase in conjugated carbonyls was observed at all steaming temperatures. The findings also confirmed changes in alder lignin.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kollmann, F.; Gote, W.A. Principles of wood sciences and technology. Solid Wood 1968, 1, 257–274. [Google Scholar]

- Sergovskij, P.S.; Rasev, A.I. Hydrothermal Treatment and Conservation of Wood; Lesnaja Promyšlennost: Moskva, Russia, 1987; p. 360. [Google Scholar]

- Trebula, P. Drying and Hydrothermal Treatment of Wood; Technical University in Zvolen: Zvolen, Slovakia, 1986; p. 255. [Google Scholar]

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions, 2nd ed.; Walter de Gruyter: Berlin, Germany, 1989; p. 613. [Google Scholar]

- Bučko, J. Hydrolysis Processes; Technical University in Zvolen: Zvolen, Slovakia, 1995; p. 116. [Google Scholar]

- Hon, D.S.N.; Shiraishi, N. Weathering and photochemistry in wood. In Wood and Cellulosic Chemistry, 2nd ed.; MarcelDekker: New York, NY, USA, 2001; pp. 513–546. [Google Scholar]

- Solár, R. Wood Chemistry; Technical University in Zvolen: Zvolen, Slovakia, 2004; p. 101. [Google Scholar]

- Sundqvist, B.; Karlsson, O.; Westremark, U. Determination of formic-acid and acid concentrations formed during hydrothermal treatment of birch wood and its relation to color, strength and hardness. Wood Sci. Technol. 2006, 40, 549–561. [Google Scholar] [CrossRef]

- Kačíková, D.; Kačík, F. Chemical and Mechanical Changes of Wood during Thermal Treatment; Technical University of Zvolen: Zvolen, Slovakia, 2011; p. 71. [Google Scholar]

- Výbohová, E.; Kučerová, V.; Andor, T.; Balážová, Ž.; Veľková, V. The effect of heat treatment on the chemical composition of ash wood. Bioresources 2018, 4, 8394–8408. [Google Scholar] [CrossRef]

- Geffert, A.; Výbohová, E.; Geffertová, J. Changes in the chemical composition of oak wood due to steaming. Acta Fac. Xylologiae Zvolen 2019, 1, 19–29. [Google Scholar]

- Molnar, S.; Tolvaj, L. Colour homogenisation of different wood species by steaming. In Interaction of Wood with Various Forms of Energy; Technical University in Zvolen: Zvolen, Slovakia, 2002; pp. 119–122. [Google Scholar]

- Tolvaj, L.; Nemeth, R.; Varga, D.; Molnar, S. Color homogenisation of beech wood by steam treatment. Drewno 2009, 52, 5–17. [Google Scholar]

- Dzurenda, L. Colouring of beech wood during thermal treatment using saturated water steams. Acta Fac. Xylologiae Zvolen 2014, 56, 13–22. [Google Scholar]

- Dzurenda, L. The shades of color of Quercus robur L. wood obtained through the processes of thermal treatment with saturated water vapor. BioResouces 2018, 13, 1525–1533. [Google Scholar] [CrossRef] [Green Version]

- Dzurenda, L. Hues of Acer platanoides L. resulting from processes of thermal treatment with saturated steam. Drewno 2018, 61, 165–176. [Google Scholar]

- Dzurenda, L. Colour modification of Robinia pseudoacacia L. during the processes of heat treatment with saturated water steam. Acta Fac. Xylologiae Zvolen 2018, 60, 61–70. [Google Scholar]

- Barański, J.; Klement, I.; Vilkovská, T.; Konopka, A. High temperature drying process of beech wood (Fagus sylvatica L.) with different zones of sapwood and red false heartwood. Bioresources 2017, 12, 1861–1870. [Google Scholar] [CrossRef] [Green Version]

- STN EN 13183–1. Moisture Content of a Piece of Sawn Timber–Part1: Determination by Oven Dry Method; Slovenian Institute for Standardization: Ljubljana, Slovenia, 2003. [Google Scholar]

- Dudiak, M. Modification of maple wood colour during the process of thermal treatment with saturated water steam. Acta Fac. Xylologiae Zvolen 2021, 63, 25–34. [Google Scholar]

- Geffert, A.; Geffertová, J.; Dudiak, M. Direct method of measuring the ph value of wood. Forests 2019, 10, 852. [Google Scholar] [CrossRef] [Green Version]

- Požgaj, A.; Chovanec, D.; Kurjatko, S.; Babiak, M. Wood Structure and Properties; Bratislava: Príroda, Slovakia, 1997; p. 485. [Google Scholar]

- Makovíny, I. Useful Properties and Use of Different Types of Wood; Technical University in Zvolen: Zvolen, Slovakia, 2010; p. 104. [Google Scholar]

- Kuriatko, S. Wood Quality Parameters Determining Its Final Use; Technical University in Zvolen: Zvolen, Slovakia, 2010; p. 352. [Google Scholar]

- Dzurenda, L.; Deliiski, N. Analysis of moisture content changes in beech wood in the steaming process with saturated water steam. Wood Res. 2000, 45, 1–8. [Google Scholar]

- Dzurenda, L. The effect of moisture content of black locust wood on the heating in the saturated water steam during the process of colour modification. In Proceedings of the XXI International Scientific Conference—The Application of Experimental and Numerical Methods in Fluid Mechanics and Energy, Rajecke Teplice, Slovakia, 25–27 April 2018; Volume 168. [Google Scholar]

- Sanderman, W.; Rothkamm, M. The determination of pH values of woods and their practical importance. Holz Roh-Werkst. 1959, 17, 433–441. [Google Scholar]

- Irle, M. pH and Why You Need to Know It. Based Panels International. 2012. Available online: http://www.wbpionline.com/features/ph-and-why-you-need-to-know-it/ (accessed on 20 August 2012).

- Čudinov, B.S.; Stepanov, V.L. Phasenzusammensetzung der wassers in gefrorenem holz. Holztechnologie 1968, 9, 14–18. [Google Scholar]

- Blažej, A.; Šutý, L.; Košík, M.; Krkoška, P.; Golis, E. Chémia Dreva [Wood Chemistry]; ALFA: Bratislava, Slovakia, 1975; p. 221. [Google Scholar]

- Zevenhoven, M. Ash-Forming Matter in Biomass Fuels; Åbo Akademi University: Turku, Finland, 2001. [Google Scholar]

- Pňakovič, Ľ.; Dzurenda, L. Combustion characteristics of fallen fall leaves from ornamental trees in city and forest parks. Bioresources 2015, 10, 5563–5572. [Google Scholar] [CrossRef]

- Melcer, I.; Melcerová, A.; Solár, R.; Kačík, F. Chemistry of Hydrothermal Treatment of Deciduous Trees; College of Forestry and Wood Technology in Zvolen: Zvolen, Slovakia, 1989. [Google Scholar]

- Laurová, M.; Mamonová, M.; Kučerová, V. Process of Partial Hydrolysis of Beech Wood (Fagus sylvatica L.) by Steaming and Cooking; Technical University in Zvolen: Zvolen, Slovakia, 2004; p. 59. [Google Scholar]

- Babiak, M.; Kubovský, I.; Mamoňová, M. Color Space of Selected Domestic Trees. In Interaction of Wood with Various Forms of Energy; Technical University in Zvolen: Zvolen, Slovakia, 2004; pp. 113–117. [Google Scholar]

- Meints, T.; Teischinger, A.; Stingl, R.; Hassmann, C. Wood colour of central European wood species: CIELAB characterisation and colour intensification. Eur. J. Wood Prod. 2017, 75, 499–509. [Google Scholar] [CrossRef]

- Dzurenda, L.; Geffert, A.; Geffertová, J.; Dudiak, M. Evaluation of the process thermal treatment of maple wood saturated water steam in terms of change of pH and color of wood. Bioresources 2020, 15, 2550–2559. [Google Scholar]

- Varga, D.; Van der Zee, M.E. Influence of steaming on selected wood properties of four hardwood species. HolzRoh. Werkst. 2008, 66, 11–18. [Google Scholar] [CrossRef]

- Hadjiski, M.; Deliiski, N. Advanced control of the wood thermal treatment processing. Cybern. Inf. Technol. Bulg. Acad. Sci. 2016, 16, 176–197. [Google Scholar] [CrossRef] [Green Version]

- Banski, A.; Dudiak, M. Dependence of color on the time and temperature of saturated water steam in the process of thermal modification of beech wood. In AIP Conference Proceedings; AIP: College Park, MD, USA, 2019. [Google Scholar]

- Dzurenda, L.; Dudiak, M. Cross-correlation of color and acidity of wet beech wood in the process of thermal treatment with saturated steam. Wood Res. 2021, 66, 105–116. [Google Scholar] [CrossRef]

- Klement, I.; Marko, P. Colour changes of beech wood (Fagus sylvatica L.) during high temperature drying process. Wood Res. 2009, 54, 45–54. [Google Scholar]

- Geffert, A.; Geffertová, J.; Výbohová, E.; Dudiak, M. Impact of steaming mode on chemical characteristics and color of birch wood. Forests 2020, 11, 478. [Google Scholar] [CrossRef] [Green Version]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Structural differences between wood species: Evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J. Appl. Polym. Sci. 2012, 126, E336–E343. [Google Scholar] [CrossRef]

- Zhang, P.; Wei, Y.; Liu, Y.; Gao, J.; Chen, Y.; Fan, Y. Heat-induced discoloration of chromophore structures in Eucalyptus lignin. Materials 2018, 11, 1686. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Tshabalala, M.A.; Gao, J.M.; Stark, N.M.; Fan, Y.M. Color and surface chemistry changes of extracted wood flour after heating at 120 °C. Wood Sci. Technol. 2014, 48, 137–150. [Google Scholar] [CrossRef]

| Modes | tmin (°C) | tmax (°C) | t4 (°C) | Length of Time Wood Is Exposed to Color Modification | |||

|---|---|---|---|---|---|---|---|

| Mode I | 92.5 | 97.5 | - | τ1 = 3 h | τ2 = 6 h * | τ3 = 9 h * | τ4 = 12 h * |

| Mode II | 112.5 | 117.5 | 100 | ||||

| Mode III | 122.5 | 127.5 | 100 | ||||

| Wood | Dry Alder Wood | Wet Alder Wood | ||||

|---|---|---|---|---|---|---|

| Density Wood | Coordinates of Color Space CIE L*a*b* | Moisture Content | Acidity | |||

| ρ0 (kg·m−3) | L* | a* | b* | w (%) | pH (-) | |

| Alder | 522.8 ± 30.4 | 78.3 ± 2.3 | 9.2 ± 1.6 | 22.6 ± 1.2 | 62.9 ± 2.3 | 4.9 ± 0.2 |

| Thermal Treatment Mode | Statistical Characteristics of Dry Wood Density | |||

|---|---|---|---|---|

| ρ0 (kg·m−3) | s (kg·m−3) | vx (%) | N (-) | |

| Mode I | 513.7 | 25.1 | 4.9 | 20 |

| Mode II | 510.4 | 22.5 | 4.4 | 20 |

| Mode III | 503.6 | 21.7 | 4.3 | 20 |

| Thermal Treatment Mode | Time of Thermal Modification of Alder Wood | |||

|---|---|---|---|---|

| 3 h | 6 h | 9 h | 12 h | |

| w (%) | w (%) | w (%) | w (%) | |

| Mode I | 58.6 ± 1.9 | 59.2 ± 1.2 | 58.5 ± 1.0 | 57.9 ± 1.1 |

| Mode II | 59.3 ± 1.2 | 58.9 ± 1.4 | 58.2 ± 1.2 | 56.9 ± 1.1 |

| Mode III | 58.5 ± 1.6 | 57.0 ± 1.1 | 56.1 ± 1.1 | 53.8 ± 0.9 |

| Modes Thermal Treatment | Time of Thermal Modification of Alder Wood | |||

|---|---|---|---|---|

| 3 h | 6 h | 9 h | 12 h | |

| pH | pH | pH | pH | |

| Mode I | 4.8 ± 0.2 | 4.7 ± 0.1 | 4.5 ± 0.3 | 4.4 ± 0.2 |

| Mode II | 4.0 ± 0.2 | 3.8 ± 0.3 | 3.7 ± 0.2 | 3.5 ± 0.2 |

| Mode III | 3.9 ± 0.3 | 3.4 ± 0.2 | 3.1 ± 0.2 | 3.1 ± 0.1 |

| Thermal Treatment Temperature | Coordinates CIE L*a*b* | Time of Thermal Modification of Alder Wood | |||

|---|---|---|---|---|---|

| 3 h | 6 h | 9 h | 12 h | ||

| tI = 95 ± 2.5 °C | L* | 76.1 ± 1.8 | 73.3 ± 1.4 | 70.5 ± 1.9 | 68.6 ± 0.8 |

| a* | 10.4 ± 1.1 | 11.7 ± 0.8 | 12.2 ± 1.0 | 12.5 ± 0.7 | |

| b* | 22.0 ± 0.9 | 21.5 ± 0.7 | 20.8 ± 0.8 | 20.5 ± 0.7 | |

| ∆E* | 1.1 | 4.2 | 7.0 | 8.9 | |

| tII = 115 ± 2.5 °C | L* | 72.2 ± 1.6 | 65.9 ± 1.2 | 61.7 ± 1.1 | 57.4 ± 1.2 |

| a* | 11.4 ± 0.8 | 12.6 ± 0.6 | 12.8 ± 0.6 | 12.9 ± 0.5 | |

| b* | 19.2 ± 0.7 | 18.6 ± 0.5 | 18.4 ± 0.6 | 18.3 ± 0.4 | |

| ∆E* | 5.8 | 11.9 | 15.9 | 20.1 | |

| tIII = 125 ± 2.5 °C | L* | 64.8 ± 1.7 | 57.4 ± 1.2 | 51.2 ± 1.1 | 47.4 ± 1.7 |

| a* | 11.8 ± 0.7 | 12.3 ± 0.6 | 12.5 ± 0.5 | 13.1 ± 0.6 | |

| b* | 19.3 ± 0.6 | 17.2 ± 0.5 | 16.6 ± 0.5 | 16.3 ± 0.4 | |

| ∆E* | 12.6 | 20.2 | 26.4 | 30.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudiak, M.; Dzurenda, L. Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam. Coatings 2021, 11, 898. https://doi.org/10.3390/coatings11080898

Dudiak M, Dzurenda L. Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam. Coatings. 2021; 11(8):898. https://doi.org/10.3390/coatings11080898

Chicago/Turabian StyleDudiak, Michal, and Ladislav Dzurenda. 2021. "Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam" Coatings 11, no. 8: 898. https://doi.org/10.3390/coatings11080898

APA StyleDudiak, M., & Dzurenda, L. (2021). Changes in the Physical and Chemical Properties of Alder Wood in the Process of Thermal Treatment with Saturated Water Steam. Coatings, 11(8), 898. https://doi.org/10.3390/coatings11080898