Deformation Mechanisms of NiP/Ni Composite Coatings on Ductile Substrates

Abstract

:1. Introduction

2. Experimental

2.1. Sample Preparation

2.2. Tensile Tests

2.3. Microstructure Characterization

2.4. MD Simulations

3. Results

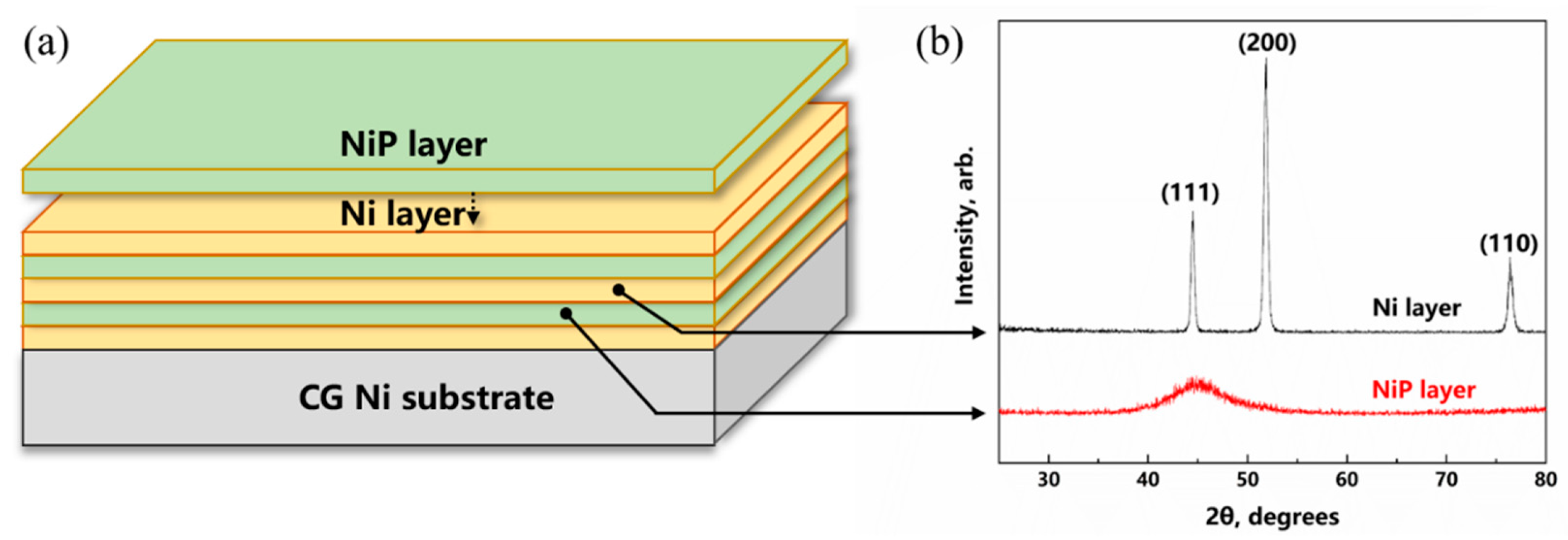

3.1. Microstructure of the Samples

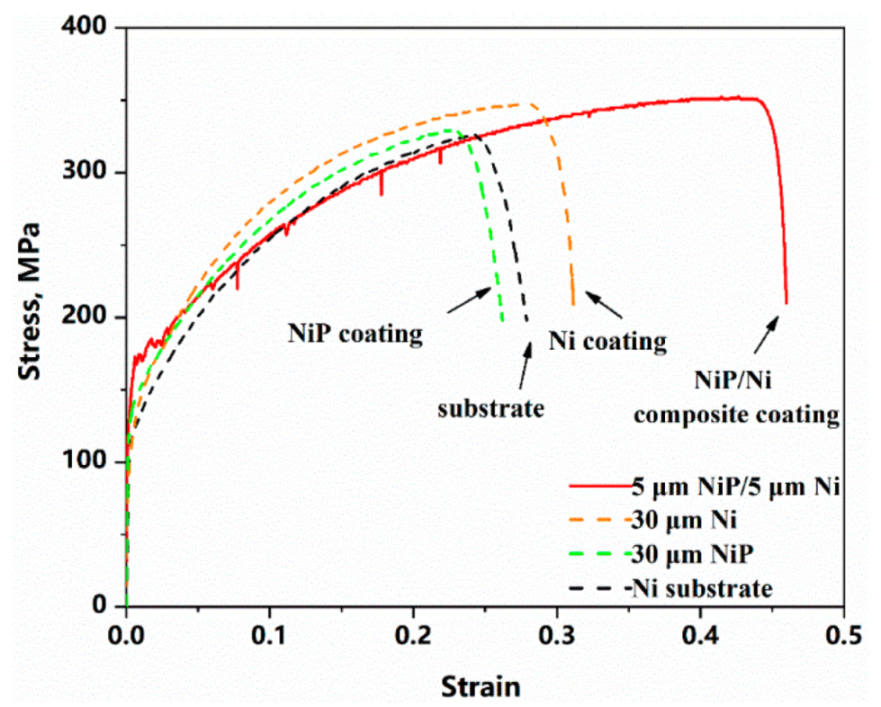

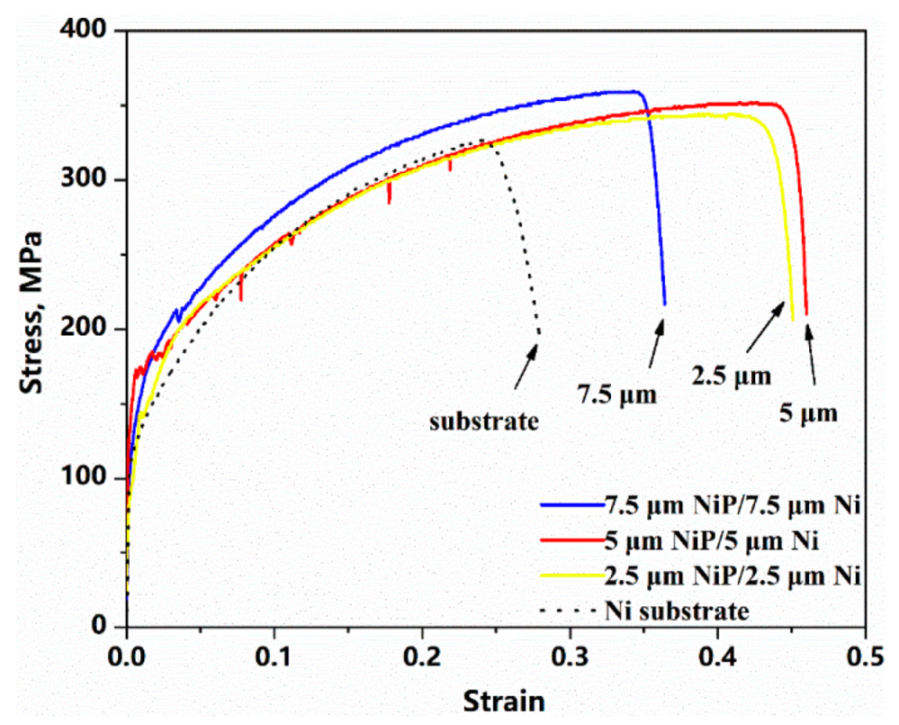

3.2. Mechanical Properties

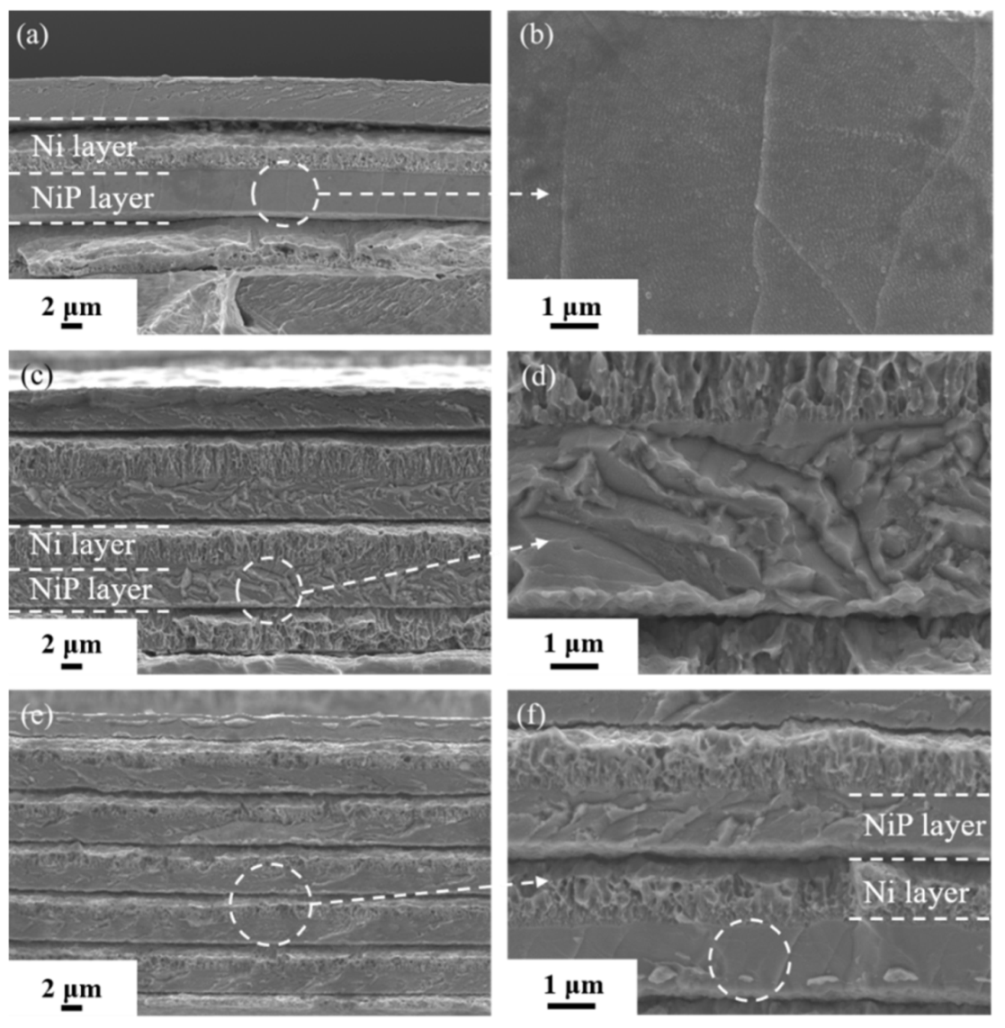

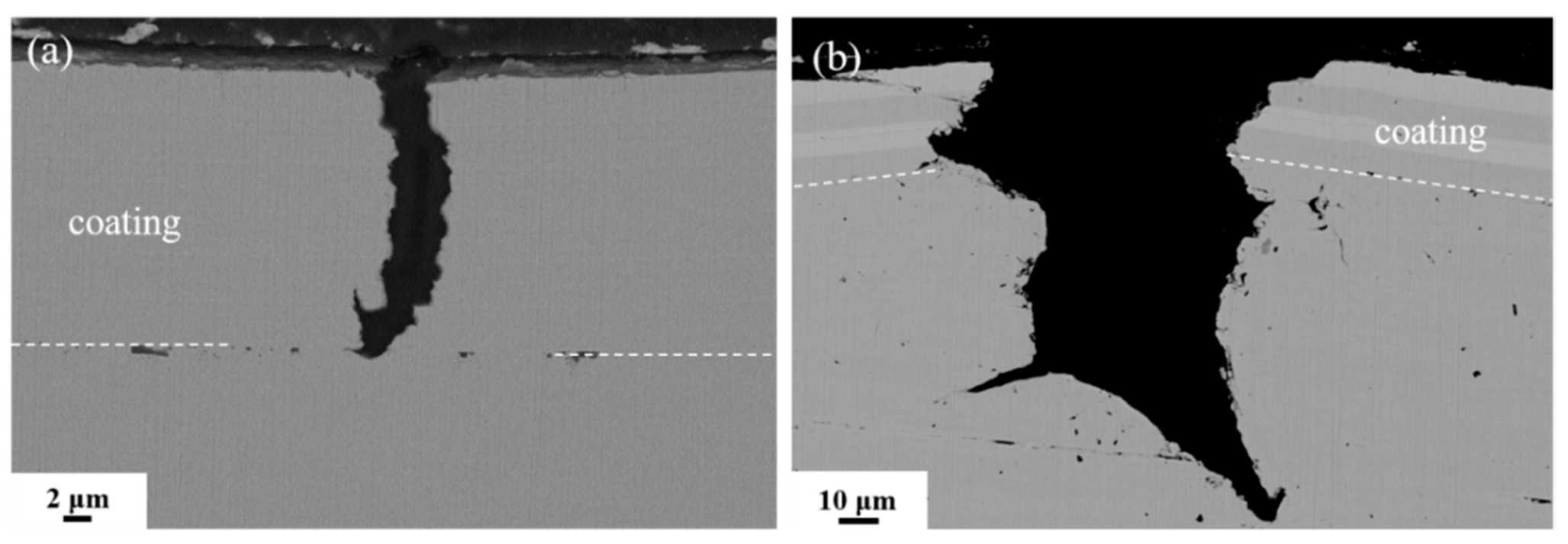

3.3. Fractography Analysis

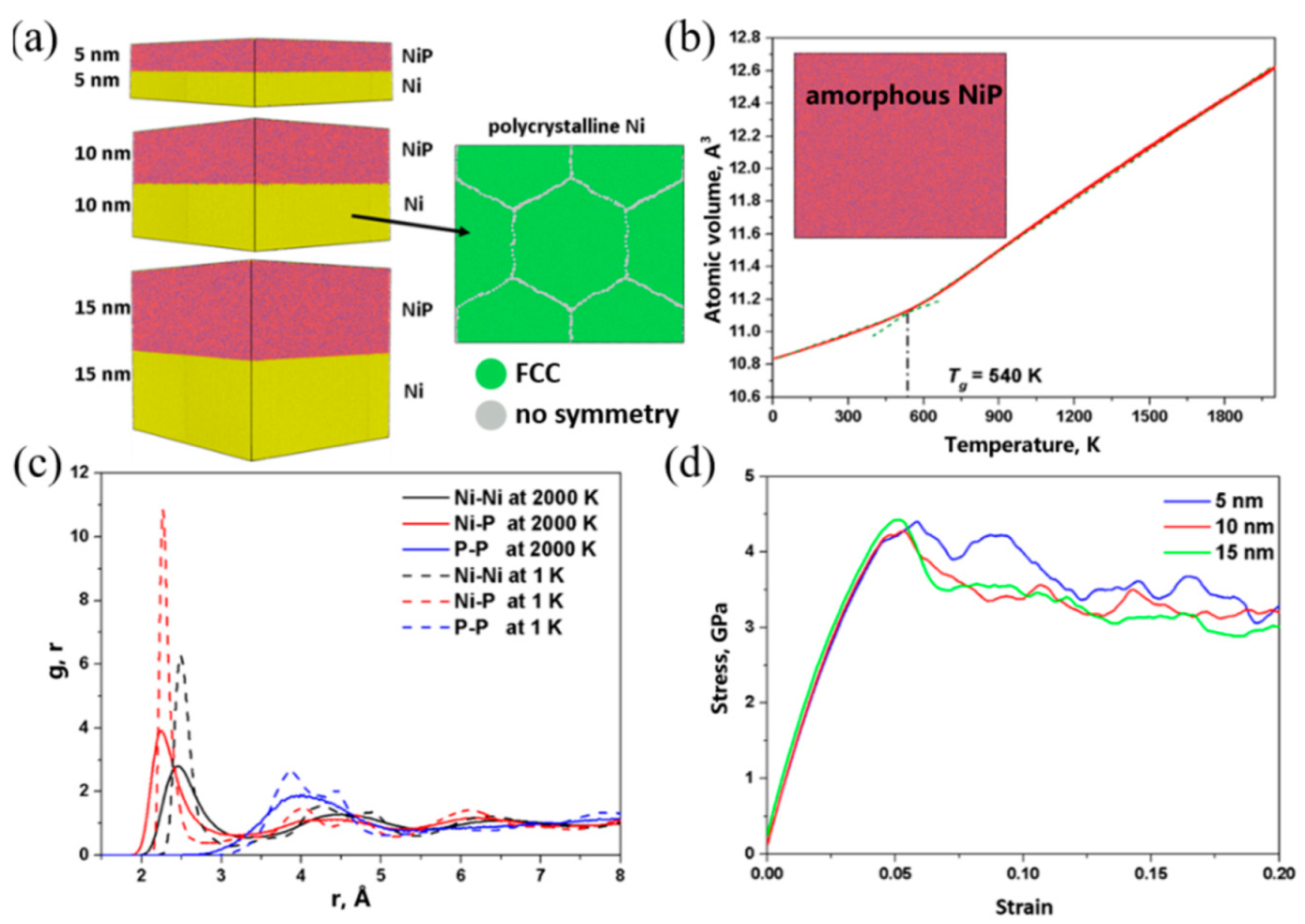

3.4. MD Simulation Results

4. Discussion

4.1. Composite Coating Effects on Deformation

4.2. Fracture Mechanism of NiP Layers in the Composite Coating

4.3. Effects of Coating Cracking on Substrate Deformation

5. Conclusions

- During the deformation process, the composite coating and the ductile substrate are constrained by each other and deform cooperatively. In this process, the geometrically necessary dislocations accumulate, resulting in long-range back stress, leading to strain hardening, showing synergetic strength and ductility.

- The critical fracture thickness of the amorphous NiP layer confined by the double Ni layer is larger than the amorphous NiP layer confined by a single Ni layer. With the decrease of the thickness, the distribution of shear strain becomes more uniform, and the expansion of STZ is restrained, which can prevent the formation of a large shear band. The deformation mode changes from shear fracture to the coexistence of uniform deformation and shear deformation.

- The multilayer structure interface increases the resistance of crack propagation, and the crack bends at the interface, which dissipates the energy of the crack and releases the stress concentration so that the substrate will not be damaged. The fracture energy of thicker coating is higher, and the crack easily expands into the matrix, which reduces the toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Chan, K.C.; Wu, Y.; Liu, L. Pitting initiation in Fe-based amorphous coatings. Acta Mater. 2012, 60, 4152–4159. [Google Scholar] [CrossRef]

- Ma, Y.; Cao, Q.P.; Qu, S.X.; Wang, X.D.; Jiang, J.Z. Effect of structural relaxation on plastic flow in a Ni-Nb metallic glassy film. Acta Mater. 2012, 60, 3667–3676. [Google Scholar] [CrossRef]

- Guo, H.; Yan, P.F.; Wang, Y.B.; Tan, J.; Zhang, Z.F.; Sui, M.L.; Ma, E. Tensile ductility and necking of metallic glass. Nat. Mater. 2007, 6, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Han, P.; Yin, S.; Niu, W.-J.; Zhai, L.; Li, X.; Mao, X.; Han, Y. Current research status on cold sprayed amorphous alloy coatings: A review. Coatings 2021, 11, 206. [Google Scholar] [CrossRef]

- Lelevic, A.; Walsh, F.C. Electrodeposition of NiP alloy coatings: A review. Surf. Coat. Technol. 2019, 369, 198–220. [Google Scholar] [CrossRef]

- Guo, T.; Chen, Y.; Cao, R.; Pang, X.; He, J.; Qiao, L. Cleavage cracking of ductile-metal substrates induced by brittle coating fracture. Acta Mater. 2018, 152, 77–85. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Hamza, A.V.; Barbee, T.W. Ductile crystalline–amorphous nanolaminates. Proc. Natl. Acad. Sci. USA 2007, 104, 11155–11160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, X.L.; Li, Y.; Lu, L. Co-existence of homogeneous flow and localized plastic deformation in tension of amorphous Ni-P films on ductile substrate. Acta Mater. 2016, 106, 182–192. [Google Scholar] [CrossRef] [Green Version]

- Ren, L.W.; Yang, F.Q.; Jiao, Z.M.; Yang, H.J.; Wang, Z.H.; Qiao, J.W. Plasticity enhancement in Ni-P amorphous alloy/Ni/Zr-based metallic glass composites with a sandwich structure. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 643, 175–182. [Google Scholar] [CrossRef]

- Wang, Y.C.; Luo, X.M.; Chen, L.J.; Yang, H.W.; Zhang, B.; Zhang, G.P. Enhancement of shear stability of a Fe-based amorphous alloy using electrodeposited Ni layers. J. Mater. Sci. Technol. 2018, 34, 2283–2289. [Google Scholar] [CrossRef]

- Pan, Z.; Rupert, T.J. Amorphous intergranular films as toughening structural features. Acta Mater. 2015, 89, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Brandl, C.; Germann, T.C.; Misra, A. Structure and shear deformation of metallic crystalline–amorphous interfaces. Acta Mater. 2013, 61, 3600–3611. [Google Scholar] [CrossRef]

- Arman, B.; Brandl, C.; Luo, S.N.; Germann, T.C.; Misra, A.; Cagin, T. Plasticity in Cu(111)/Cu46Zr54 glass nanolaminates under uniaxial compression. J. Appl. Phys. 2011, 110. [Google Scholar] [CrossRef]

- Cui, Y.; Shibutani, Y.; Li, S.; Huang, P.; Wang, F. Plastic deformation behaviors of amorphous-Cu50Zr50/crystalline-Cu nanolaminated structures by molecular dynamics simulations. J. Alloy. Compd. 2017, 693, 285–290. [Google Scholar] [CrossRef]

- Cheng, B.; Trelewicz, J.R. Design of crystalline-amorphous nanolaminates using deformation mechanism maps. Acta Mater. 2018, 153, 314–326. [Google Scholar] [CrossRef]

- Guo, W.; Jägle, E.; Yao, J.; Maier, V.; Korte-Kerzel, S.; Schneider, J.M.; Raabe, D. Intrinsic and extrinsic size effects in the deformation of amorphous CuZr/nanocrystalline Cu nanolaminates. Acta Mater. 2014, 80, 94–106. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Liu, G.; Lei, S.Y.; Niu, J.J.; Sun, J. Transition from homogeneous-like to shear-band deformation in nanolayered crystalline Cu/amorphous Cu–Zr micropillars: Intrinsic vs. extrinsic size effect. Acta Mater. 2012, 60, 7183–7196. [Google Scholar] [CrossRef]

- Luan, Y.W.; Li, C.H.; Zhang, D.; Li, J.; Han, X.J.; Li, J.G. Plastic deformation mechanisms and size effect of Cu50Zr50/Cu amorphous/crystalline nanolaminate: A molecular dynamics study. Comput. Mater. Sci. 2017, 129, 137–146. [Google Scholar] [CrossRef]

- Cuan, X.; Pan, J.; Cao, R.; Lin, Y.; Yao, J.; Wang, Y.; Li, Y. Effect of amorphous layer thickness on the tensile behavior of bulk-sized amorphous Ni-P/crystalline Ni laminates. Mater. Lett. 2018, 218, 150–153. [Google Scholar] [CrossRef]

- Sheng, H.W.; Ma, E.; Kramer, M.J. Relating dynamic properties to atomic structure in metallic glasses. JOM 2012, 64, 856–881. [Google Scholar] [CrossRef] [Green Version]

- Song, X.T.; Guo, R.P.; Wang, Z.; Wang, X.J.; Yang, H.J.; Qiao, J.W.; Han, L.N.; Liaw, P.K.; Wu, Y.C. Deformation mechanisms in amorphous Ni-Mo-P films coated on CoCrFeNi high-entropy alloys. Intermetallics 2019, 114. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Dolgov, N.A. Analytical methods to determine the stress state in the substrate-coating system under mechanical loads. Strength Mater. 2016, 48, 658–667. [Google Scholar] [CrossRef]

- Cramer, T.; Wanner, A.; Gumbsch, P. Energy dissipation and path instabilities in dynamic fracture of silicon single crystals. Phys. Rev. Lett. 2000, 85, 788–791. [Google Scholar] [CrossRef]

- Shimizu, F.; Ogata, S.; Li, J. Theory of shear banding in metallic glasses and molecular dynamics calculations. Mater. Trans. 2007, 48, 2923–2927. [Google Scholar] [CrossRef] [Green Version]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 2154–2162. [Google Scholar] [CrossRef]

- Takasugi, T.; Izumi, O. Surface strengthening in aluminium single crystals coated with electro-deposited nickel film. Acta Metall. 1975, 23, 1111–1120. [Google Scholar] [CrossRef]

- Song, X.T.; Shi, X.H.; Xia, Z.H.; Yang, H.J.; Wu, Y.C.; Liaw, P.K.; Qiao, J.W. Effects of Ni–P coating on mechanical properties of Al0.3CoCrFeNi high-entropy alloys. Mater. Sci. Eng. A 2019, 752, 152–159. [Google Scholar] [CrossRef]

- Yang, M.; Pan, Y.; Yuan, F.; Zhu, Y.; Wu, X. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, X.; Yuan, F.; Kan, Q.; Qu, S.; Kang, G.; Zhang, X. Multiple mechanism based constitutive modeling of gradient nanograined material. Int. J. Plast. 2020, 125, 314–330. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Vecchio, K. Non-equiatomic FeNiCoAl-based high entropy alloys with multiscale heterogeneous lamella structure for strength and ductility. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2019, 743, 361–371. [Google Scholar] [CrossRef]

- Kundu, A.; Field, D.P. Influence of plastic deformation heterogeneity on development of geometrically necessary dislocation density in dual phase steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 667, 435–443. [Google Scholar] [CrossRef]

- Cao, R.Q.; Pan, J.; Lin, Y.; Li, Y. Mechanical properties and optimum layer thickness in an amorphous Ni-P/coarse-grained Ni bi-layered structure. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 760, 458–468. [Google Scholar] [CrossRef]

- Kelly, R.G.; Frost, A.J.; Shahrabi, T.; Newman, R.C. Brittle fracture of an Au/Ag alloy induced by a surface film. Metall. Trans. A 1991, 22, 531–541. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xu, H.; Zhou, X.; Guo, T.; Pang, X.; Volinsky, A.A. Deformation Mechanisms of NiP/Ni Composite Coatings on Ductile Substrates. Coatings 2021, 11, 834. https://doi.org/10.3390/coatings11070834

Zhang Z, Xu H, Zhou X, Guo T, Pang X, Volinsky AA. Deformation Mechanisms of NiP/Ni Composite Coatings on Ductile Substrates. Coatings. 2021; 11(7):834. https://doi.org/10.3390/coatings11070834

Chicago/Turabian StyleZhang, Zhendi, Hang Xu, Xiaoye Zhou, Tao Guo, Xiaolu Pang, and Alex A. Volinsky. 2021. "Deformation Mechanisms of NiP/Ni Composite Coatings on Ductile Substrates" Coatings 11, no. 7: 834. https://doi.org/10.3390/coatings11070834

APA StyleZhang, Z., Xu, H., Zhou, X., Guo, T., Pang, X., & Volinsky, A. A. (2021). Deformation Mechanisms of NiP/Ni Composite Coatings on Ductile Substrates. Coatings, 11(7), 834. https://doi.org/10.3390/coatings11070834