Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

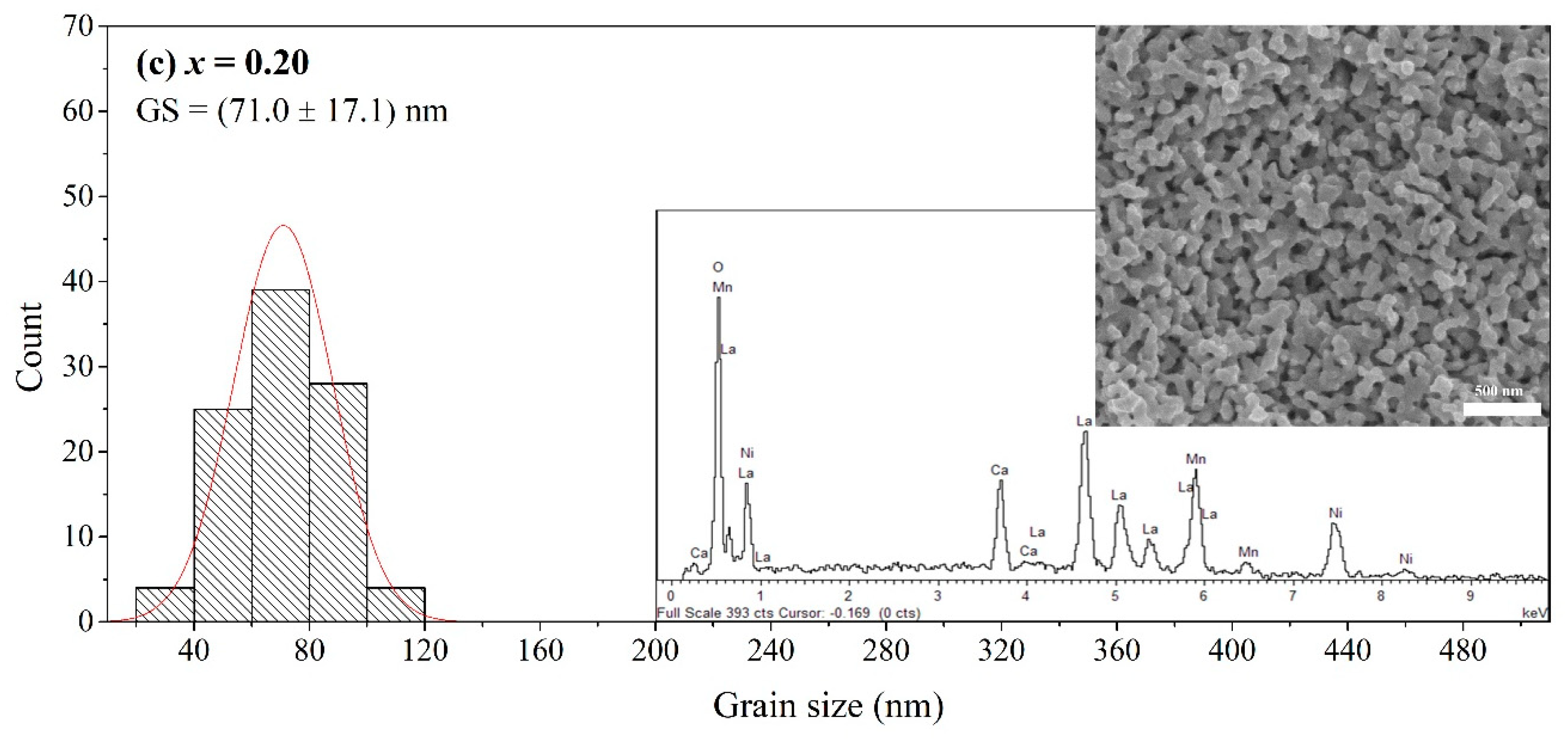

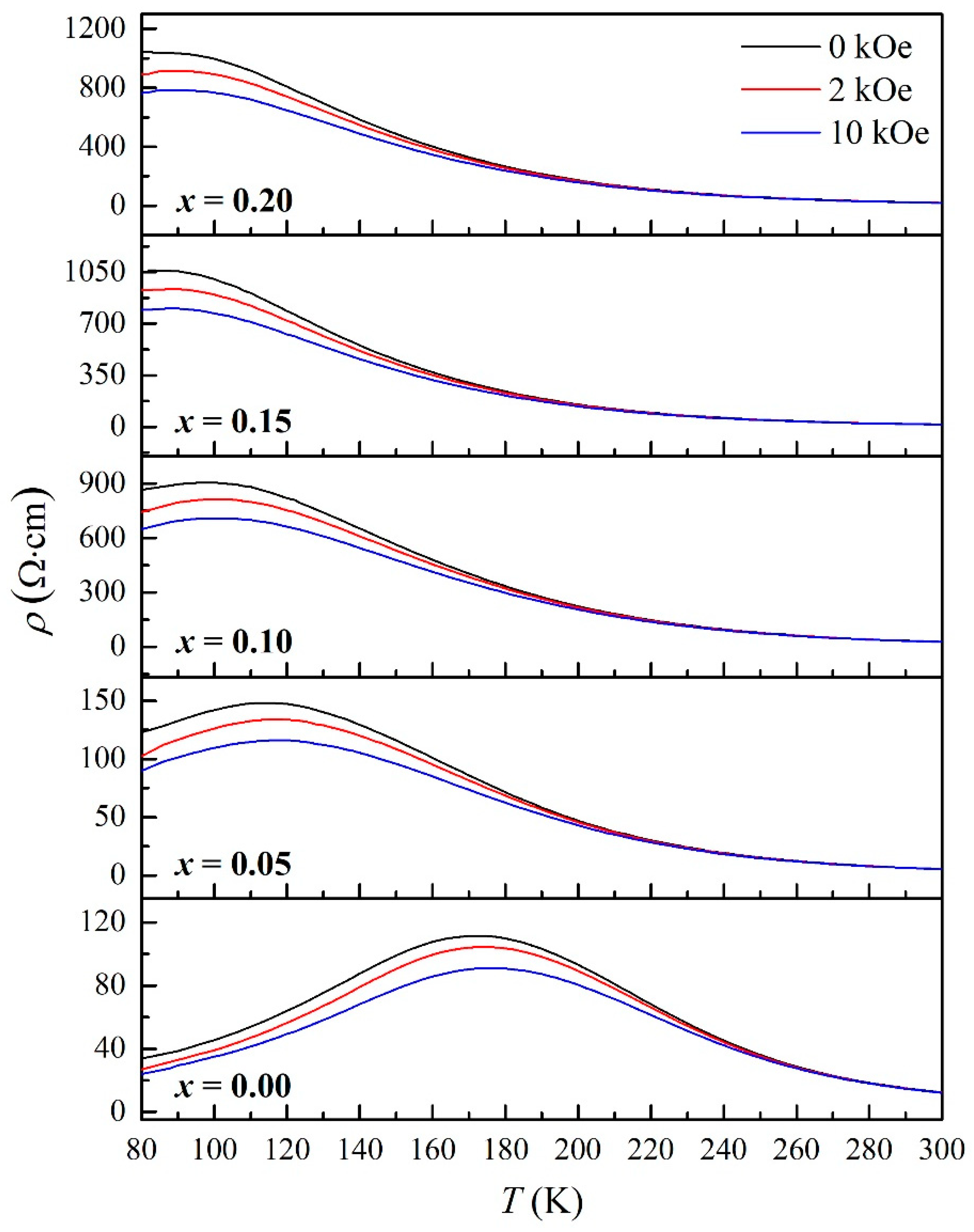

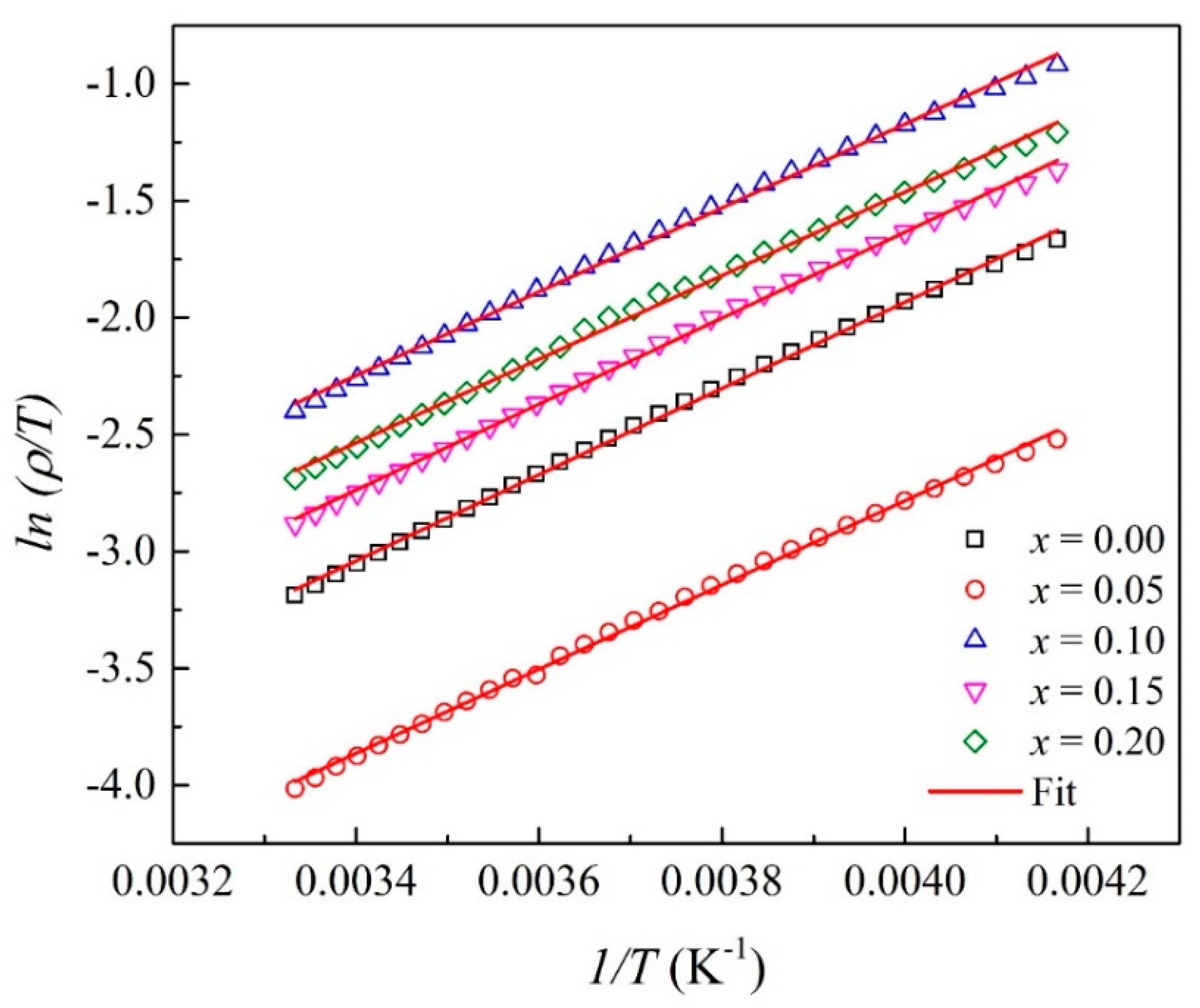

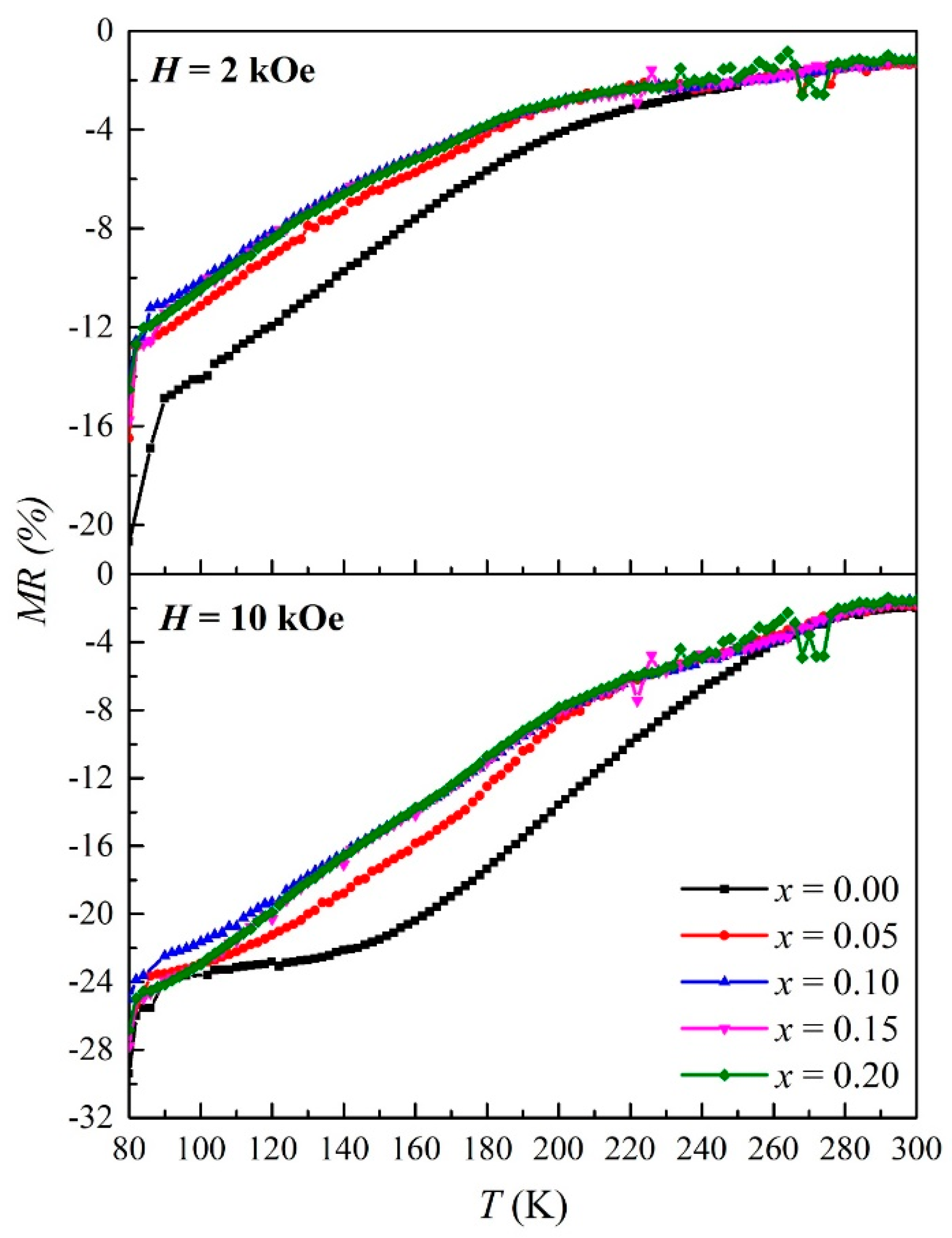

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishra, D.; Roul, B.; Singh, S.; Srinivasu, V. Possible observation of Griffith phase over large temperature range in plasma sintered La0.67Ca0.33MnO3. J. Magn. Magn. Mater. 2018, 448, 287–291. [Google Scholar] [CrossRef]

- Panchal, G.; Choudhary, R.J.; Phase, D.M. Magnetic properties of La0.7Sr0.3MnO3 film on ferroelectric BaTiO3 substrate. J. Magn. Magn. Mater. 2018, 448, 262–265. [Google Scholar] [CrossRef]

- Gong, J.; Zheng, D.; Li, D.; Jin, C.; Bai, H. Lattice distortion modified anisotropic magnetoresistance in epitaxial La0.67Sr0.33MnO3 thin films. J. Alloy. Compd. 2018, 735, 1152–1157. [Google Scholar] [CrossRef]

- Xia, W.; Pei, Z.; Leng, K.; Zhu, X. Research progress in rare earth-doped perovskite manganite oxide nanostructures. Nanoscale Res. Lett. 2020, 15, 1–55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ng, S.; Lim, K.; Halim, S.; Jumiah, H. Grain size effect on the electrical and magneto-transport properties of nanosized Pr0.67Sr0.33MnO3. Results Phys. 2018, 9, 1192–1200. [Google Scholar] [CrossRef]

- Zener, C. Interaction between the d-shells in the transition metals. II. Ferromagnetic compounds of manganese with perovskite structure. Phys. Rev. 1951, 82, 403. [Google Scholar] [CrossRef]

- Tang, T.; Tien, C.; Hou, B. Low-field magnetoresistance of Ag-substituted perovskite-type manganites. Phys. B Condens. Matter 2008, 403, 2111–2115. [Google Scholar] [CrossRef]

- Nagaev, E.L. Colossal-magnetoresistance materials: Manganites and conventional ferromagnetic semiconductors. Phys. Rep. 2001, 346, 387–531. [Google Scholar] [CrossRef]

- Sadhu, A.; Bhattacharyya, S. Enhanced low-field magnetoresistance in La0.71Sr0.29MnO3 nanoparticles synthesized by the nonaqueous sol–gel route. Chem. Mater. 2014, 26, 1702–1710. [Google Scholar] [CrossRef]

- Phong, P.T.; Khiem, N.V.; Dai, N.V.; Manh, D.H.; Hong, L.V.; Phuc, N.X. Influence of Al2O3 on low-field spin-polarized tunneling magnetoresistance of (1−x) La0.7Ca0.3MnO3+x Al2O3 composites. Mater. Lett. 2009, 63, 353–356. [Google Scholar] [CrossRef]

- Hwang, H.; Cheong, S.; Ong, N.; Batlogg, a.B. Spin-polarized intergrain tunneling in La2/3Sr1/3MnO3. Phys. Rev. Lett. 1996, 77, 2041. [Google Scholar] [CrossRef]

- Eshraghi, M.; Salamati, H.; Kameli, P. The effect of NiO doping on the structure, magnetic and magnetotransport properties of La0.8Sr0.2MnO3 composite. J. Alloy. Compd. 2007, 437, 22–26. [Google Scholar] [CrossRef]

- Zi, Z.; Fu, Y.; Liu, Q.; Dai, J.; Sun, Y. Enhanced low-field magnetoresistance in LSMO/SFO composite system. J. Magn. Magn. Mater. 2012, 324, 1117–1121. [Google Scholar] [CrossRef]

- Li, J.; Chen, Q.; Yang, S.a.; Yan, K.; Zhang, H.; Liu, X. Electrical transport properties and enhanced broad-temperature-range low field magnetoresistance in LCMO ceramics by Sm2O3 adding. J. Alloy. Compd. 2019, 790, 240–247. [Google Scholar] [CrossRef]

- Dar, M.A.; Malla, M.; Solanki, J.; Varshney, D. Enhanced low field magnetoresistance in La0.7Ca0.2Sr0.1MnO3-MgO composites. In Proceedings of the AIP Conference Proceedings; American Institute of Physics: College Park, MA, USA, 2017; p. 140013. [Google Scholar]

- Thanh, T.D.; Phong, P.T.; Dai, N.V.; Manh, D.H.; Khiem, N.V.; Hong, L.V.; Phuc, N.X. Magneto-transport and magnetic properties of (1–x)La0.7Ca0.3MnO3+xAl2O3 composites. J. Magn. Magn. Mater. 2011, 323, 179–184. [Google Scholar] [CrossRef]

- Wang, C.B.; Liu, H.X.; Wu, L.; Shen, Q.; Zhang, L.M. Enhanced low-field magnetoresistance in LSMO/AZO composites prepared by plasma activated sintering. Ceram. Int. 2018, 44, 18048–18053. [Google Scholar] [CrossRef]

- Navin, K.; Kurchania, R. Structural, magnetic and transport properties of the La0.7Sr0.3MnO3-ZnO nanocomposites. J. Magn. Magn. Mater. 2018, 448, 228–235. [Google Scholar] [CrossRef]

- Gaur, A.; Varma, G.D. Magnetoresistance behaviour of La0.7Sr0.3MnO3/NiO composites. Solid State Commun. 2006, 139, 310–314. [Google Scholar] [CrossRef]

- Lim, K.P.; Shaari, A.H.; Chen, S.K.; Hassan, J.; Ng, S.W.; Wan Jusoh, W.N.W.; Fadin, N. Electrical Transport Properties and Magnetoresistance of Pr0.67Sr0.33MnO3-NiO Composites. In Proceedings of the Solid State Phenomena; Trans Tech Publications Ltd.: Bäch SZ, Switzerland, 2017; pp. 292–296. [Google Scholar]

- Ning, X.; Wang, Z.; Zhang, Z. Controllable self-assembled microstructures of La0.7Ca0.3MnO3: NiO nanocomposite thin films and their tunable functional properties. Adv. Mater. Interfaces 2015, 2, 1500302. [Google Scholar] [CrossRef]

- Lau, L.N.; Lim, K.P.; Ngai, L.M.; Ishak, A.N.; Kechik, M.M.A.; Chen, S.K.; Ibrahim, N.B.; Shaari, A.H. Influence of Al2O3 on the low-field magnetoresistance of sol–gel grown La0.67Ca0.33MnO3: Al2O3 nanocomposites. Appl. Phys. A 2020, 126, 1–7. [Google Scholar] [CrossRef]

- Amri, N.; Nasri, M.; Triki, M.; Dhahri, E. Synthesis and characterization of (1−x)(La0.6Ca0.4MnO3)/x (Sb2O3) ceramic composites. Phase Transit. 2019, 92, 52–64. [Google Scholar] [CrossRef]

- Lim, K.P.; Ng, S.W.; Lau, L.N.; Kechik, M.M.A.; Chen, S.K.; Halim, S.A. Unusual electrical behaviour in sol–gel-synthesised PKMO nano-sized manganite. Appl. Phys. A 2019, 125, 745. [Google Scholar] [CrossRef]

- Xia, W.; Li, L.; Wu, H.; Xue, P.; Zhu, X. Structural, morphological, and magnetic properties of sol-gel derived La0.7Ca0.3MnO3 manganite nanoparticles. Ceram. Int. 2017, 43, 3274–3283. [Google Scholar] [CrossRef]

- Arun, B.; Akshay, V.R.; Chandrasekhar, K.D.; Mutta, G.R.; Vasundhara, M. Comparison of structural, magnetic and electrical transport behavior in bulk and nanocrystalline Nd-lacunar Nd0.67Sr0.33MnO3 manganites. J. Magn. Magn. Mater. 2019, 472, 74–85. [Google Scholar] [CrossRef]

- Navin, K.; Kurchania, R. The effect of particle size on structural, magnetic and transport properties of La0.7Sr0.3MnO3 nanoparticles. Ceram. Int. 2018, 44, 4973–4980. [Google Scholar] [CrossRef]

- Chand, U.; Yadav, K.; Gaur, A.; Varma, G. Magnetic and Magnetotransport Properties of (Pr0.7Sr0.3MnO3)1−x/NiOx Composites. In Proceedings of the AIP Conference Proceedings; American Institute of Physics: College Park, MA, USA, 2011; pp. 1263–1264. [Google Scholar]

- Venkataiah, G.; Venugopal Reddy, P. Electrical behavior of sol–gel prepared Nd0.67Sr0.33MnO3 manganite system. J. Magn. Magn. Mater. 2005, 285, 343–352. [Google Scholar] [CrossRef]

- Staruch, M.; Gao, H.; Gao, P.-X.; Jain, M. Low-field magnetoresistance in La0.67Sr0.33MnO3:ZnO composite film. Adv. Funct. Mater. 2012, 22, 3591–3595. [Google Scholar] [CrossRef]

- Wang, T.; Chen, X.; Wang, F.; Shi, W. Low-field magnetoresistance in La0.7Sr0.3MnO3/CuCrO2 composites. Phys. B Condens. Matter 2010, 405, 3088–3091. [Google Scholar] [CrossRef]

- De Andres, A.; Garcia-Hernandez, M.; Martinez, J. Conduction channels and magnetoresistance in polycrystalline manganites. Phys. Rev. B 1999, 60, 7328. [Google Scholar] [CrossRef]

- Lau, L.N.; Lim, K.P.; Ishak, A.N.; Awang Kechik, M.M.; Chen, S.K.; Ibrahim, N.B.y.; Miryala, M.; Murakami, M.; Shaari, A.H. The physical properties of submicron and nano-grained La0.7Sr0.3MnO3 and Nd0.7Sr0.3MnO3 synthesised by sol–gel and solid-state reaction methods. Coatings 2021, 11, 361. [Google Scholar] [CrossRef]

- Thombare, B.; Dusane, P.; Kekade, S.; Salunkhe, A.; Choudhary, R.J.; Phase, D.M.; Devan, R.S.; Patil, S.I. Influence of nano-dimensionality on magnetotransport, magnetic and electrical properties of Nd1−xSrxMnO3−δ (0.3 ≤ x ≤ 0.7). J. Alloy. Compd. 2019, 770, 257–266. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Chen, Q.; Li, D.; Li, Z.; Zhang, Y. Effects of A-site cationic radius and cationic disorder on the electromagnetic properties of La0.7Ca0.3MnO3 ceramic with added Sr, Pb, and Ba. Ceram. Int. 2018, 44, 5378–5384. [Google Scholar] [CrossRef]

- Mohamed, H. Influence of sodium doping on the electrical and magnetic properties of La0.90Li0.10MnO3 manganites. J. Magn. Magn. Mater. 2017, 424, 44–52. [Google Scholar] [CrossRef]

- Wang, C.B.; Shen, Y.J.; Zhu, Y.X.; Zhang, L.M. Transport properties of La1−xSrxMnO3 ceramics above metal–insulator transition temperature. Phys. B Condens. Matter 2015, 461, 57–60. [Google Scholar] [CrossRef]

- Varshney, D.; Dodiya, N. Electrical resistivity of alkali metal doped manganites LaxAyMnwO3 (A = Na, K, Rb): Role of electron–phonon, electron–electron and electron–magnon interactions. Curr. Appl. Phys. 2013, 13, 1188–1198. [Google Scholar] [CrossRef]

- Ehsani, M.H.; Kameli, P.; Ghazi, M.E. Influence of grain size on the electrical properties of the double-layered LaSr2Mn2O7 manganite. J. Phys. Chem. Solids 2012, 73, 744–750. [Google Scholar] [CrossRef]

- De Teresa, J.; Ibarra, M.; Blasco, J.; Garcia, J.; Marquina, C.; Algarabel, P.; Arnold, Z.; Kamenev, K.; Ritter, C.; Von Helmolt, R. Spontaneous behavior and magnetic field and pressure effects on La2/3Ca1/3MnO3 perovskite. Phys. Rev. B 1996, 54, 1187. [Google Scholar] [CrossRef]

- Ning, X.; Wang, Z.; Zhang, Z. Large, Temperature-tunable low-field magnetoresistance in La0.7Sr0.3MnO3: NiO nanocomposite films modulated by microstructures. Adv. Funct. Mater. 2014, 24, 5393–5401. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, X.; Li, S. Structure, magnetic, electrical transport and magnetoresistance properties of La0.67Sr0.33Mn1−xFexO3 (x = 0–0.15) doped manganite coatings. Ceram. Int. 2017, 43, 3679–3687. [Google Scholar] [CrossRef]

- Modi, A.; Bhat, M.A.; Pandey, D.K.; Tarachand; Bhattacharya, S.; Gaur, N.K.; Okram, G.S. Structural, magnetotransport and thermal properties of Sm substituted La0.7−xSmxBa0.3MnO3 (0 ≤ x ≤ 0.2) manganites. J. Magn. Magn. Mater. 2017, 424, 459–466. [Google Scholar] [CrossRef]

- Xiong, C.; Huang, Q.; Xiong, Y.; Ren, Z.; Wei, L.; Zhu, Y.; Li, X.; Sun, C. Electro-magnetic transport behavior of La0.7Ca0.3MnO3/SnO2 composites. Mater. Res. Bull. 2008, 43, 2048–2054. [Google Scholar] [CrossRef]

| Sample | LCMO | ||||

|---|---|---|---|---|---|

| Ref. code | 98-006-5295 | ||||

| Structure type | Orthorhombic | ||||

| Space group | Pnma (62) | ||||

| NiO content, x | 0.00 | 0.05 | 0.10 | 0.15 | 0.20 |

| a (Å) | 5.454 | 5.454 | 5.453 | 5.452 | 5.454 |

| b (Å) | 7.710 | 7.704 | 7.717 | 7.705 | 7.706 |

| c (Å) | 5.462 | 5.473 | 5.458 | 5.467 | 5.473 |

| V (Å3) | 229.688 | 229.975 | 229.676 | 229.684 | 230.334 |

| Mn1-O1 (Å) | 1.930 (19) | 1.932(14) | 1.929 (22) | 1.931 (17) | 1.932 (18) |

| Mn1-O1 (Å) | 1.974 (19) | 1.977 (14) | 1.973 (23) | 1.975 (17) | 1.977 (19) |

| Mn1-O2 (Å) | 1.954 (13) | 1.952 (5) | 1.955 (19) | 1.953 (8) | 1.953 (8) |

| Mn1-O1-Mn1 (°) | 162.6 (3) | 162.6 (4) | 162.5 (6) | 162.6 (6) | 162.58 (6) |

| Mn1-O2-Mn1 (°) | 161.2 (7) | 161.1 (9) | 161.2 (7) | 161.2 (7) | 161.1 (7) |

| REXP (%) | 4.625 | 4.178 | 3.843 | 3.757 | 3.511 |

| RP (%) | 3.578 | 3.324 | 3.064 | 3.003 | 2.853 |

| RWP (%) | 4.628 | 4.317 | 3.917 | 3.818 | 3.546 |

| Goodness of fit, χ2 | 1.001 | 1.068 | 1.039 | 1.032 | 1.020 |

| Sample | NiO | ||||

| Ref. code | 98-000-8168 | ||||

| Structure type | Cubic | ||||

| Space group | Fm-3m (225) | ||||

| a (Å) | - | 4.179 | 4.177 | 4.177 | 4.179 |

| b (Å) | - | 4.179 | 4.177 | 4.177 | 4.179 |

| c (Å) | - | 4.179 | 4.177 | 4.177 | 4.179 |

| V (Å3) | - | 72.97 | 72.86 | 72.86 | 72.96 |

| x | D (nm) | TC1 (K) | TC2 (K) | TMI (K) | ΔT (K) | MR (%) at 80 K | |

|---|---|---|---|---|---|---|---|

| 2 kOe | 10 kOe | ||||||

| 0.00 | 35.8 | 289 | - | 172 | 117 | 20.70 | 29.41 |

| 0.05 | 35.9 | 293 | 179 | 116 | 177 | 16.48 | 26.70 |

| 0.10 | 37.5 | 287 | 173 | 98 | 189 | 14.09 | 25.04 |

| 0.15 | 38.7 | 291 | 174 | <80 | - | 15.76 | 27.84 |

| 0.20 | 35.3 | 292 | 175 | <80 | - | 14.53 | 26.83 |

| NiO Content, x | H (kOe) | ||||||

|---|---|---|---|---|---|---|---|

(Ω cm) | (Ω cm K−2) | (Ω cm K−4.5) | R2 | Ea (meV) | R2 | ||

| 0.00 | 0 | −0.131 | 0.0047 | −9.81 × 10−10 | 0.998 | 1.589 | 0.999 |

| 10 | −1.373 | 0.0037 | −9.00 × 10−10 | 0.998 | - | - | |

| 0.05 | 0 | 50.840 | 0.0133 | −4.20 × 10−8 | 0.999 | 1.552 | 0.998 |

| 10 | 37.576 | 0.0102 | −3.01 × 10−8 | 0.999 | - | - | |

| 0.10 | 0 | 607.812 | 0.0534 | −2.40 × 10−7 | 0.999 | 1.545 | 0.998 |

| 10 | 250.109 | 0.0845 | −3.87 × 10−7 | 0.997 | - | - | |

| 0.15 | 0 | - | - | - | - | 1.585 | 0.999 |

| 10 | - | - | - | - | - | - | |

| 0.20 | 0 | - | - | - | - | 1.540 | 0.997 |

| 10 | - | - | - | - | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lau, L.N.; Lim, K.P.; Chok, S.Y.; Ishak, A.N.; Hon, X.T.; Wong, Y.J.; Awang Kechik, M.M.; Chen, S.K.; Ibrahim, N.B.; Miryala, M.; et al. Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites. Coatings 2021, 11, 835. https://doi.org/10.3390/coatings11070835

Lau LN, Lim KP, Chok SY, Ishak AN, Hon XT, Wong YJ, Awang Kechik MM, Chen SK, Ibrahim NB, Miryala M, et al. Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites. Coatings. 2021; 11(7):835. https://doi.org/10.3390/coatings11070835

Chicago/Turabian StyleLau, Lik Nguong, Kean Pah Lim, See Yee Chok, Amirah Natasha Ishak, Xiao Tong Hon, Yan Jing Wong, Mohd Mustafa Awang Kechik, Soo Kien Chen, Noor Baa’yah Ibrahim, Muralidhar Miryala, and et al. 2021. "Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites" Coatings 11, no. 7: 835. https://doi.org/10.3390/coatings11070835

APA StyleLau, L. N., Lim, K. P., Chok, S. Y., Ishak, A. N., Hon, X. T., Wong, Y. J., Awang Kechik, M. M., Chen, S. K., Ibrahim, N. B., Miryala, M., Murakami, M., & Shaari, A. H. (2021). Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites. Coatings, 11(7), 835. https://doi.org/10.3390/coatings11070835