Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C

Abstract

:1. Introduction

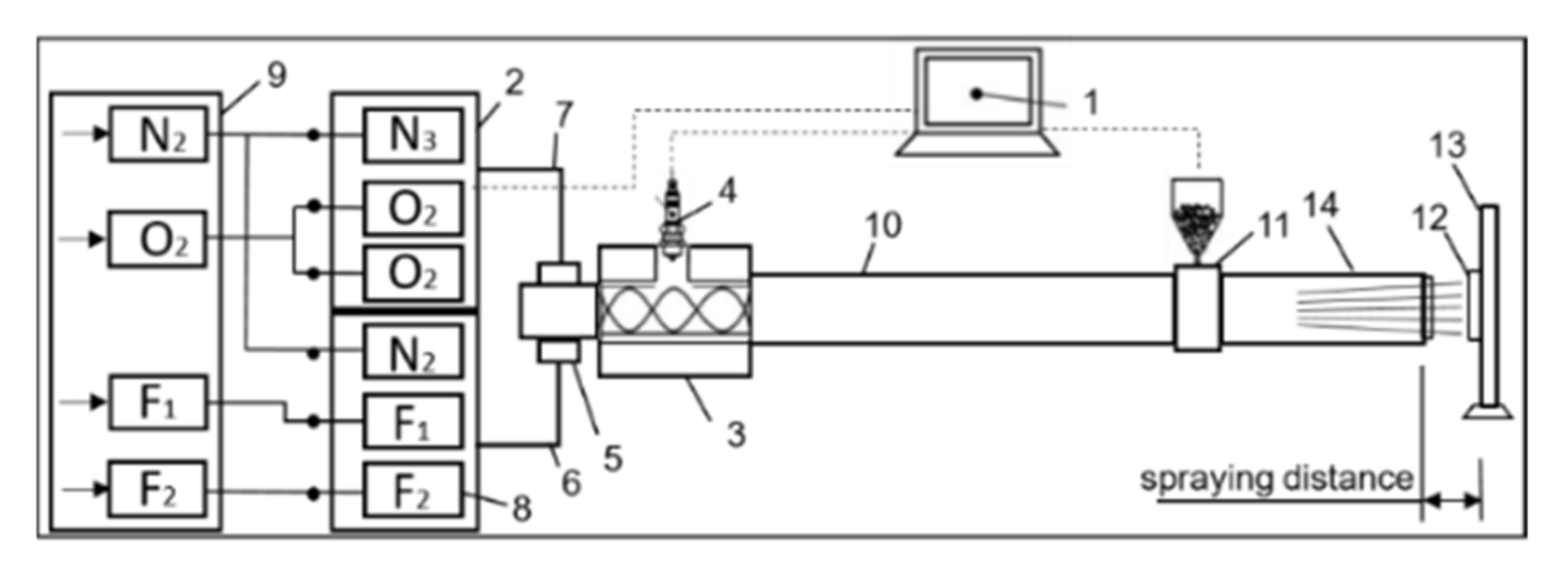

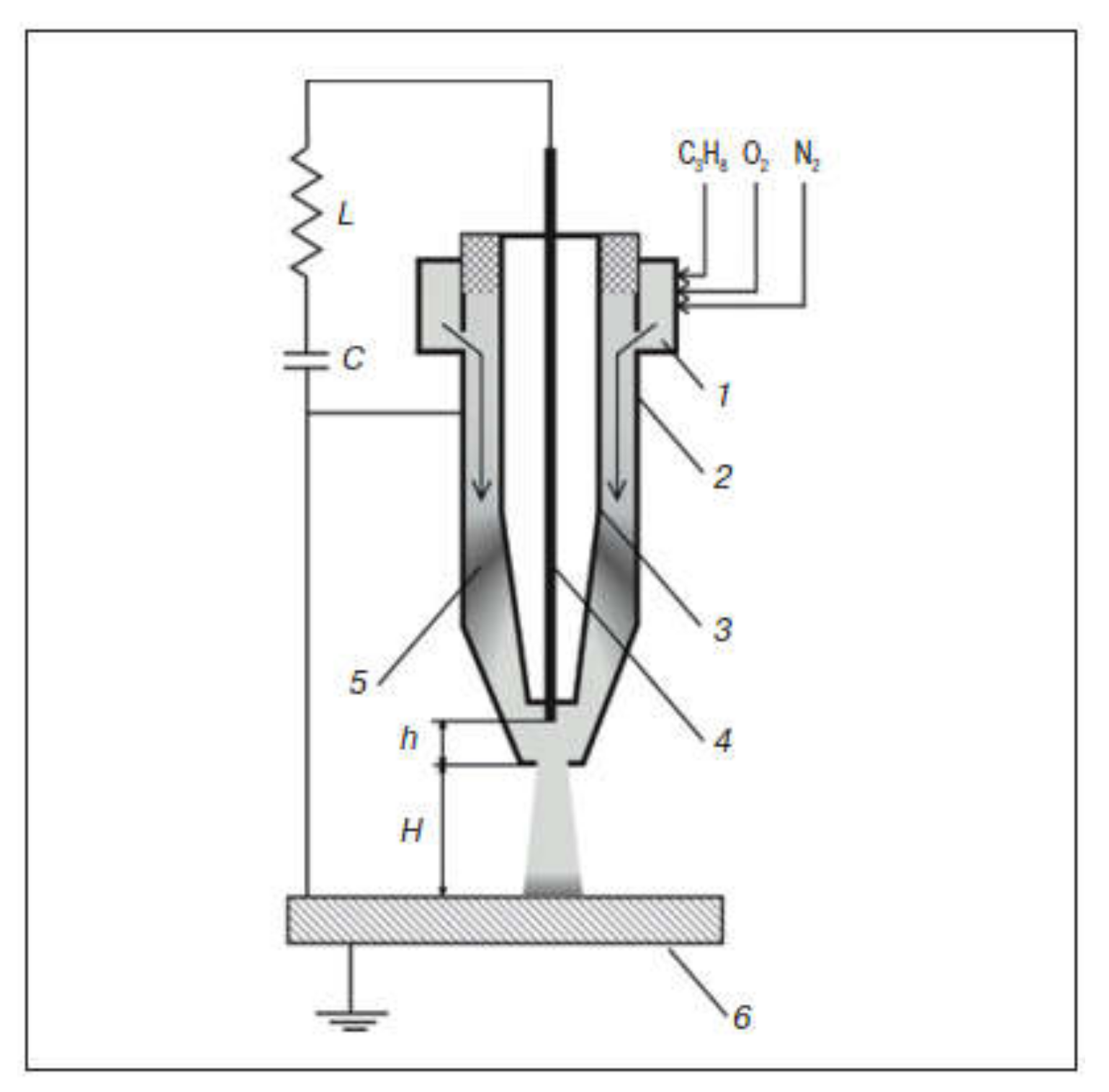

2. Materials and Methods

2.1. Experiment Setup

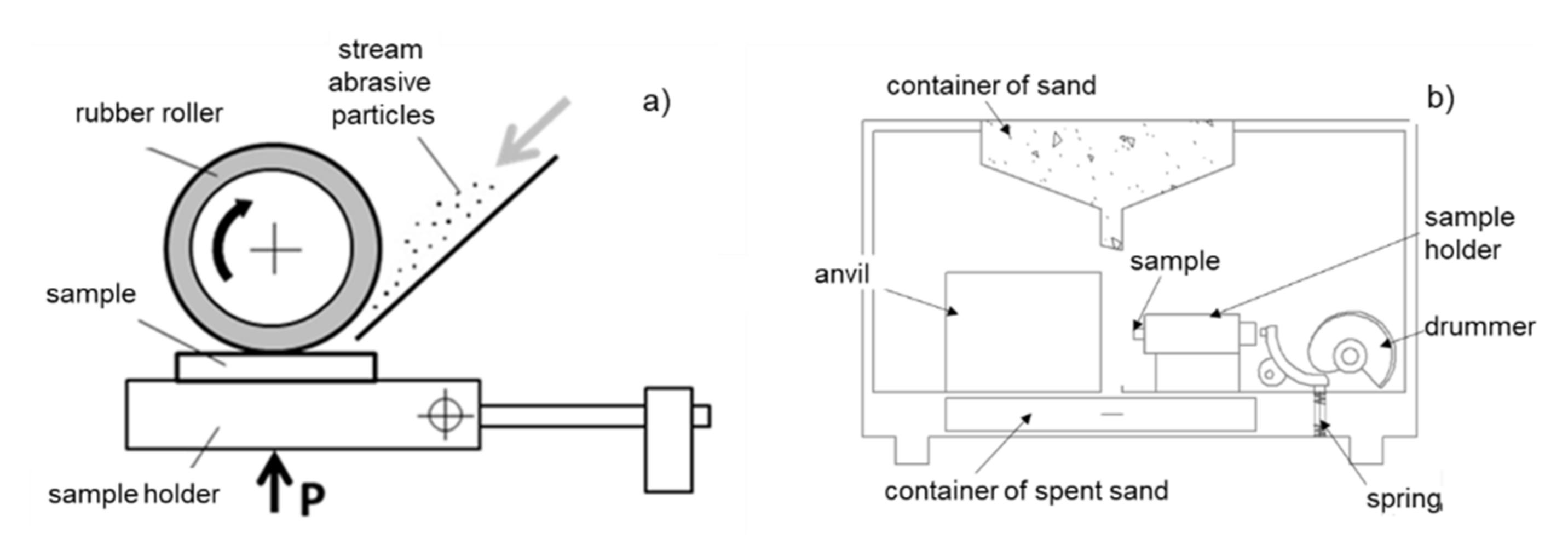

2.2. Stand for Testing Samples

2.3. Plan of Experiment

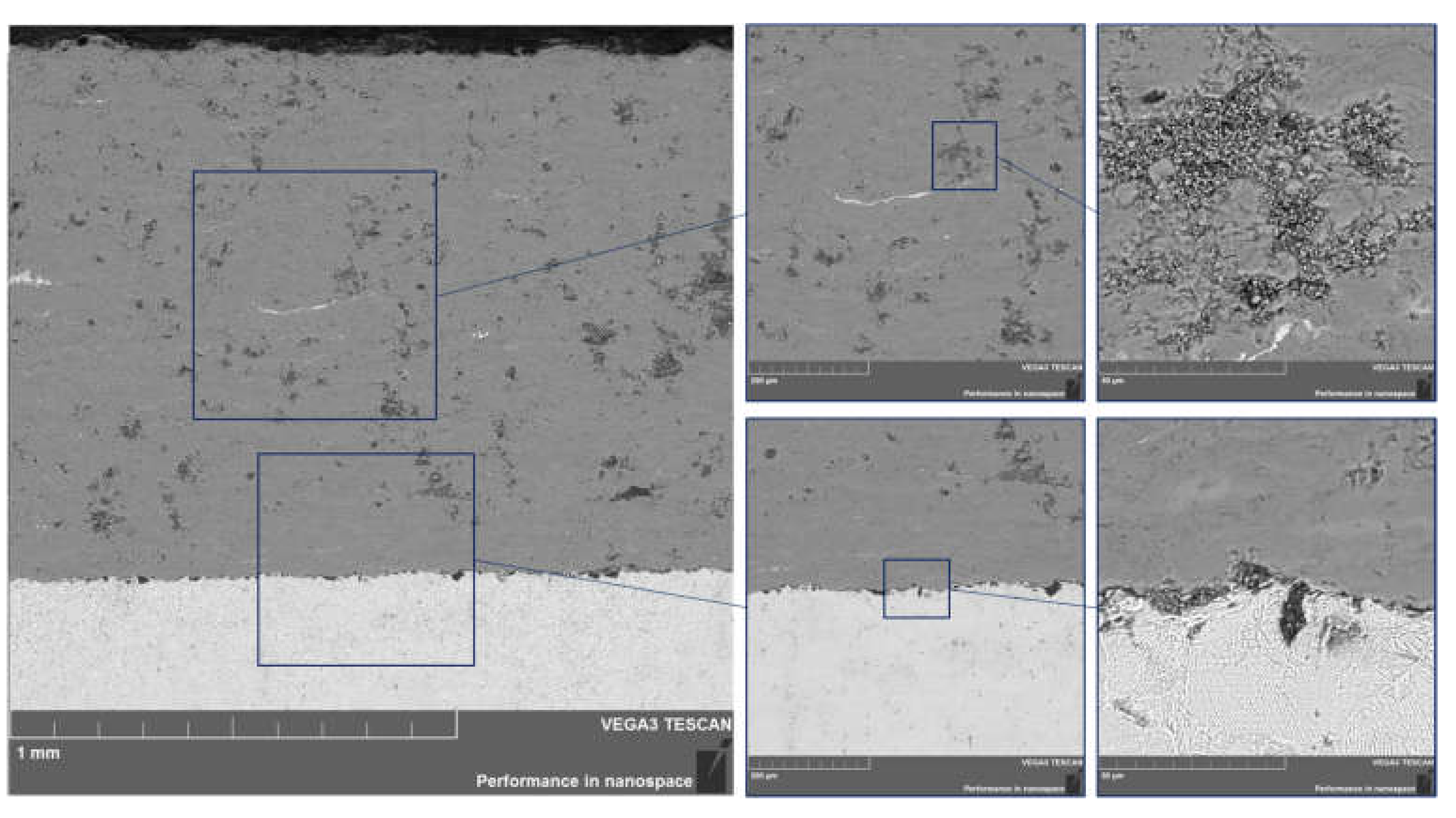

3. Results and Discussion

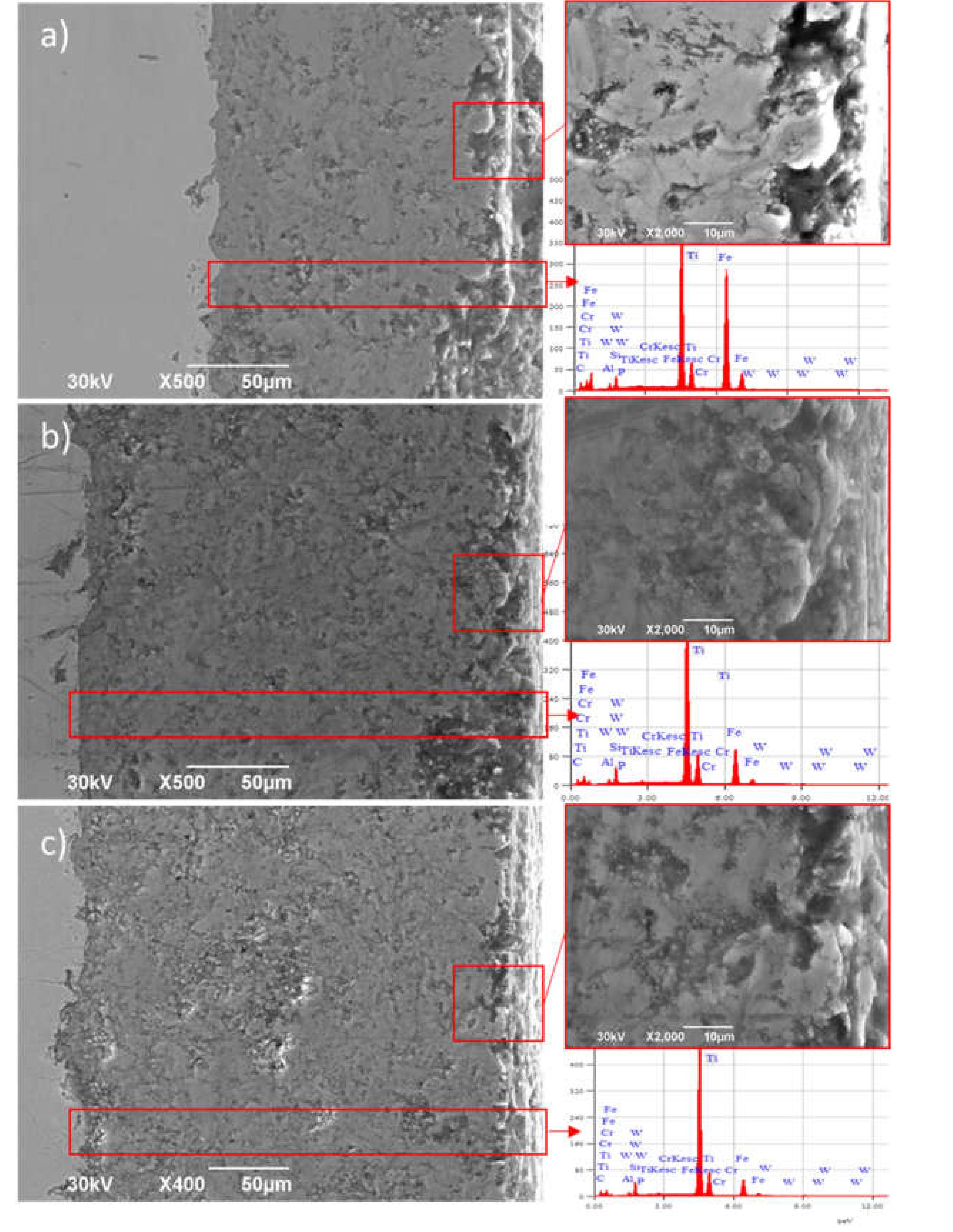

3.1. Coating Microstructure

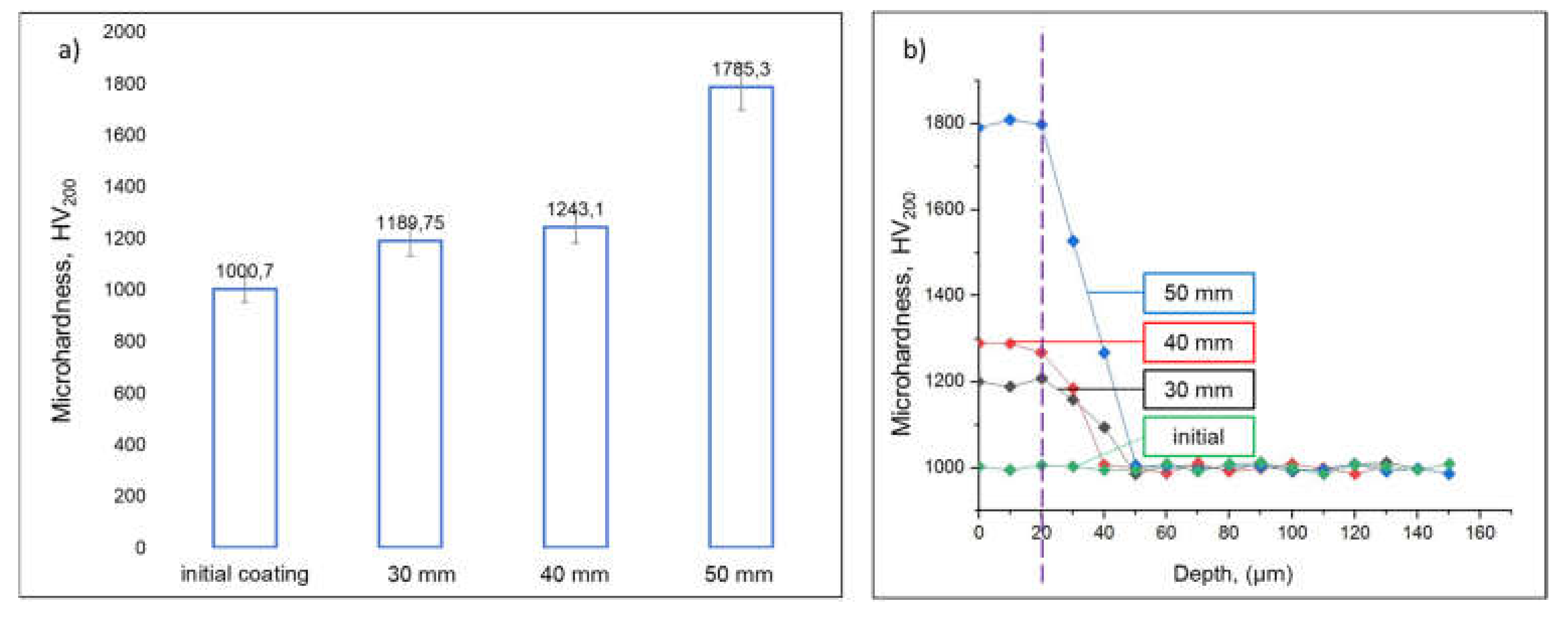

3.2. Microhardness HV

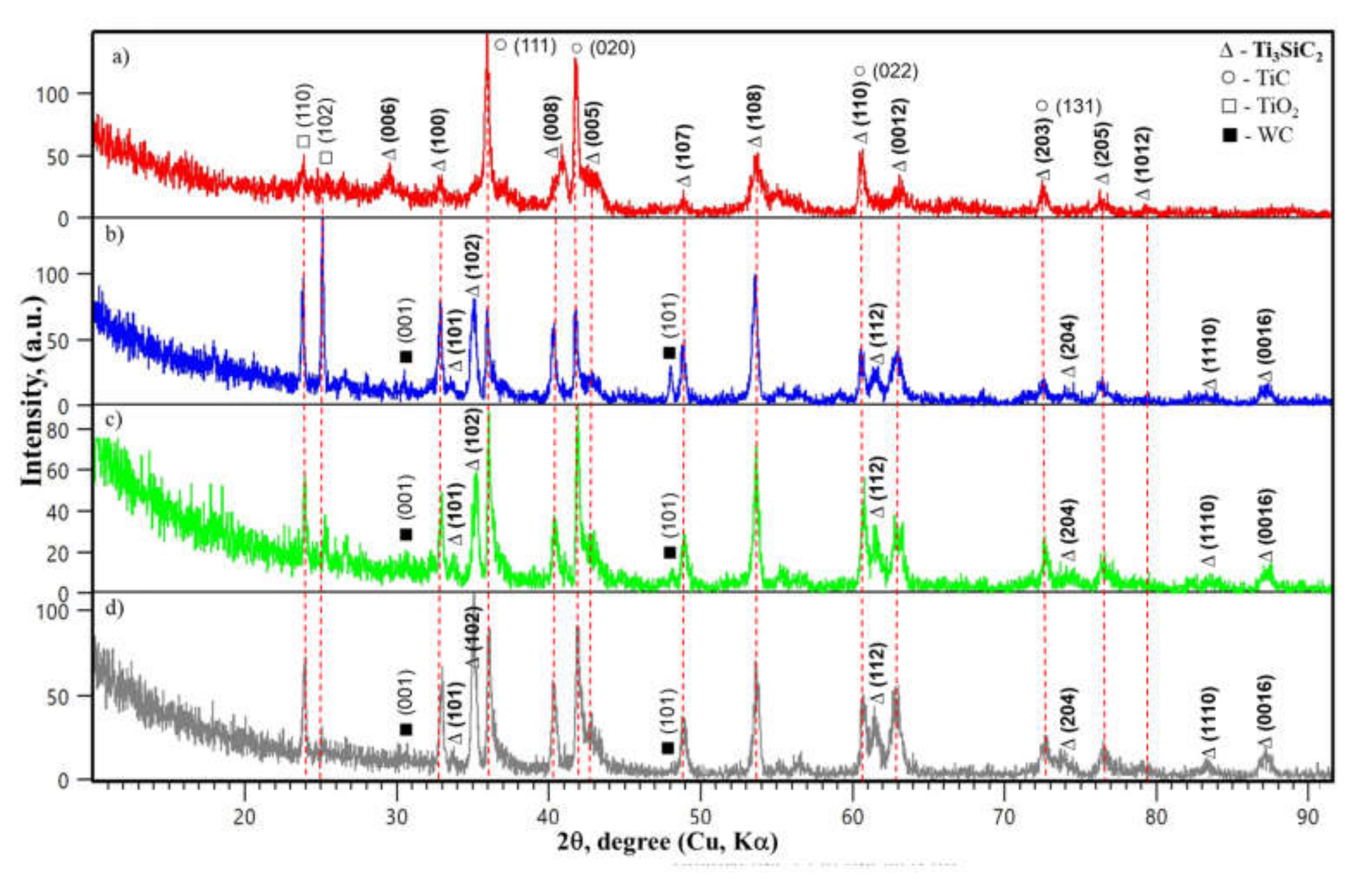

3.3. XRD Analysis

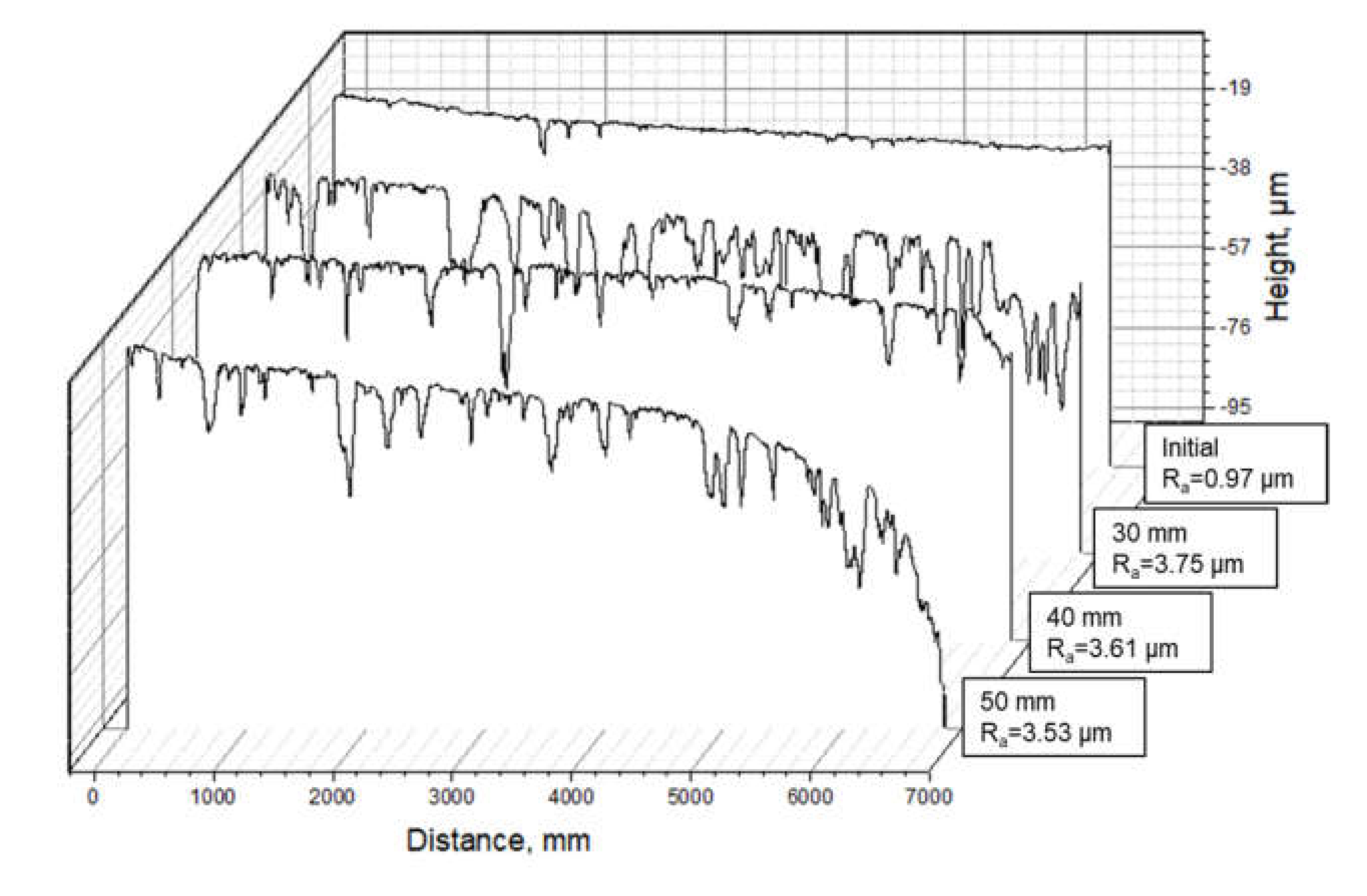

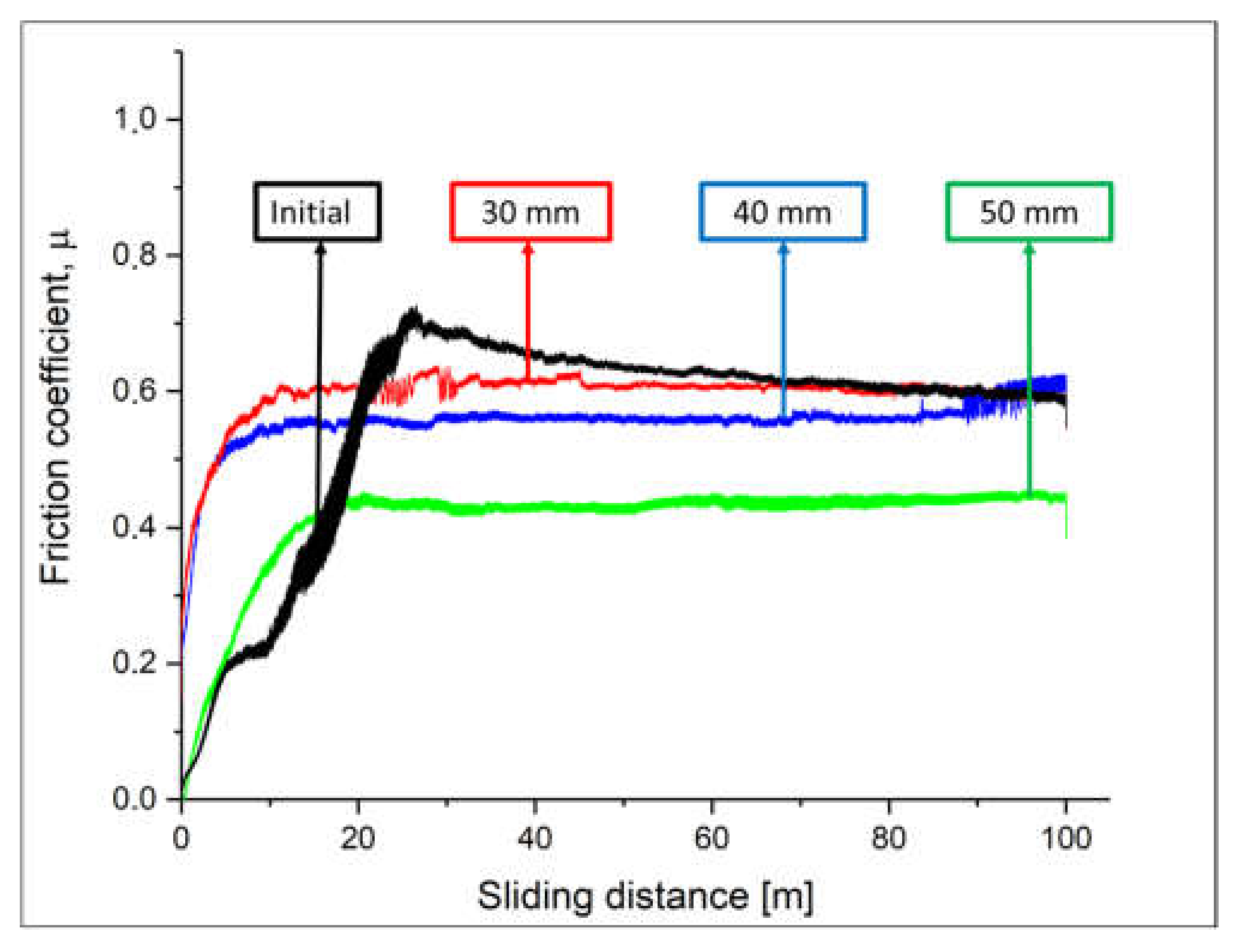

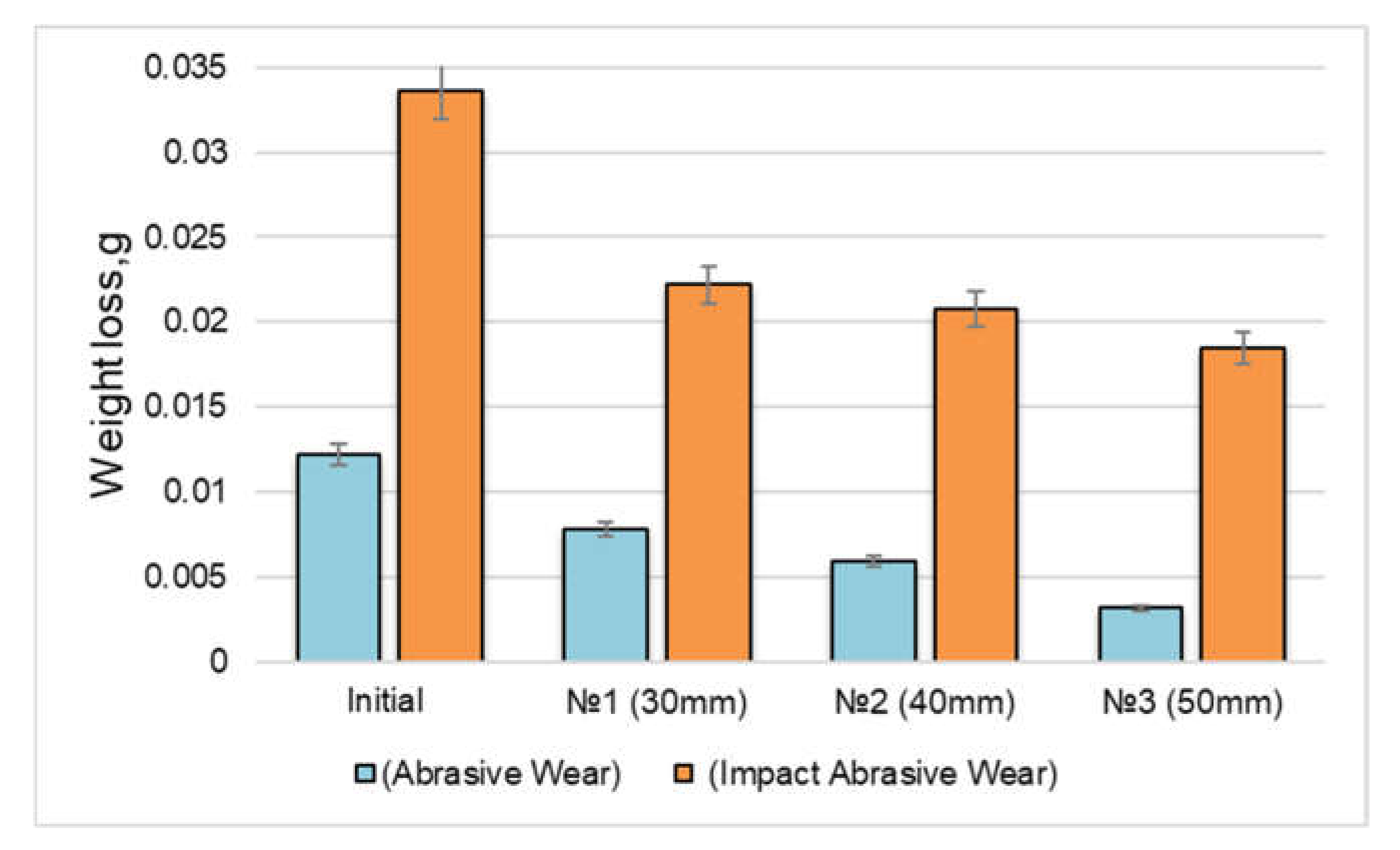

3.4. Wear Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuchumova, I.D.; Batraev, I.S.; Ulianitsky, V.Y.; Shtertser, A.A.; Gerasimov, K.B.; Ukhina, A.V.; Bulina, N.V.; Bataev, I.A.; Koga, G.Y.; Guo, Y.; et al. Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder. Metals 2019, 9, 846. [Google Scholar] [CrossRef] [Green Version]

- Ulianitsky, V.; Batraev, I.; Dudina, D.; Smurov, I. Enhancing the properties of WC/ Co detonation coatings using two-component fuels. Surf. Coat. Technol. 2017, 318, 244–249. [Google Scholar] [CrossRef]

- Samodurova, M.; Shaburova, N.; Samoilova, O.; Moghaddam, A.O.; Pashkeev, K.; Ul’yanitckiy, V.; Trofimov, E. Properties of WC–10%Co–4%Cr Detonation Spray Coating Deposited on the Al–4%Cu–1%Mg Alloy. Materials 2021, 14, 1206. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Zhu, S.; Dong, W.; Ding, H.; Bai, Y.; Luo, Y.; Di, P. Geometric Influence of Hard Phase on Corrosion Performance between WC-Reinforced Coatings Prepared by High-Velocity Oxygen-Fuel Spray and Electric Contact Strengthening. Coatings 2021, 11, 694. [Google Scholar] [CrossRef]

- Barsoum, W. The Mn+1AXn: A new Class of Solids: Thermodynamically Stable Nanolaminates. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Shi, Q.; Zhu, H.; Li, C. The Effects of the Addition of Ti3SiC2 on the Microstructure and Properties of Laser Cladding Composite Coatings. Coatings 2020, 10, 498. [Google Scholar] [CrossRef]

- Xu, J.; Liu, L.L.; Jiang, L.; Munroe, P.; Xie, Z.H. Unraveling the mechanical and tribological properties of a novel Ti5Si3/TiC nanocomposite coating synthesized by a double glow discharge plasma technique. Ceram. Int. 2013, 39, 9471–9481. [Google Scholar] [CrossRef]

- Benamor, A.; Hadji, Y.; Chiker, N.; Haddad, A.; Guedouar, B.; Labaiz, M.; Hakem, M.; Tricoteaux, A.; Nivot, C.; Erauw, J.P.; et al. Spark Plasma Sintering and tribological behavior of Ti3SiC2-Ti5Si3-TiC composites. Ceram. Int. 2019, 45, 21781–21792. [Google Scholar] [CrossRef]

- Rakhadilov, B.K.; Buitkenov, D.B.; Tuyakbaev, B.T.; Sagdoldina, Z.B.; Kenesbekov, A.B. Structure and properties of detonation coatings based on titanium carbosilicide. In Key Engineering Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2019; pp. 301–306. [Google Scholar]

- Islak, B.Y.; Ayas, E. Evaluation of properties of spark plasma sintered Ti3SiC2 and Ti3SiC2/SiC composites. Ceram. Int. 2019, 45, 12297–12306. [Google Scholar] [CrossRef]

- Buitkenov, D.B.; Rakhadilov, B.K.; Wieleba, W.; Kylyshkanov, M.K.; Yerbolatuly, D. Impact of the detonation gas spraying mode on the phase composition and adhesional strength of Ti–Si–C coatings. Bull. Univ. Karaganda Phys. 2020, 1, 59–64. [Google Scholar]

- Li, C.; Yan, S.; Zhang, F.; He, J. Fabrication and characterization of micro-laminated TiC-Ti5Si3-Ti3SiC2 composite coatings by atmosphere plasma spraying. Vacuum 2019, 161, 14–20. [Google Scholar] [CrossRef]

- Buitkenov, D.; Rakhadilov, B.; Erbolatuly, D.; Sagdoldina, Z. Influence of Heat Treatment on the Phase Composition and Microhardness of Coatings Based on Ti3SiC2/TiC. In Key Engineering Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2020; Volume 839, pp. 137–143. [Google Scholar]

- Buitkenov, D.; Rakhadilov, B.; Erbolatuly, D.; Sagdoldina, Z. Reserach of the mechanic-tribological characteristics of Ti3SiC2/TiC coatings after annealing. Eurasian J. Phys. Funct. Mater. 2020, 4, 86–89. [Google Scholar] [CrossRef] [Green Version]

- Rakhadilov, B.; Buitkenov, D.; Sagdoldina, Z.; Seitov, B.; Kurbanbekov, S.; Adilkanova, M. Structural Features and Tribological Properties of Detonation Gun Sprayed Ti–Si–C Coating. Coatings 2021, 11, 141. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Tyurin, Y.N.; Kobzev, A.P. High-Speed Plasma Jet Modification and Doping of α-Fe. Tech. Phys. Lett. 2001, 27, 619–621. [Google Scholar] [CrossRef]

- Zhadkevich, M.L.; Tyurin, Y.N.; Kolisnichenko, O.V. Impul’sno-plazmennoye uprochneniye instrumenta. Oborudovaniye Instrum. 2004, 04, 40–43. (In Russia) [Google Scholar]

- Tyurin, Y.N.; Kolisnichenko, O.V. Plasma-detonation technology for modification of the surface layer of metal parts. Open Surf. Sci. J. 2009, 1, 13–19. [Google Scholar] [CrossRef]

- Ulianitsky, V.; Shtertser, A.; Zlobin, S.; Smurov, I. Computer-controlled detonation spraying: From process fundamentals toward advanced applications. J. Therm. Spray Technol. 2011, 20, 791–801. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Batraev, I.S.; Shtertser, A.A.; Dudina, D.V.; Bulina, N.V.; Smurov, I. Detonation spraying behaviour of refractory metals: Case studies for Mo and Ta-based powders. Adv. Powder Technol. 2018, 29, 1859–1864. [Google Scholar] [CrossRef]

- Ulianitsky, V.Y.; Rybin, D.K.; Ukhina, A.V.; Bokhonov, B.B.; Dudina, D.V.; Samodurova, M.N.; Trofimov, E.A. Structure and composition of Fe-Co-Ni and Fe-Co-Ni-Cu coatings obtained by detonation spraying of powder mixtures. Mater. Lett. 2021, 290, 129498. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Tyurin, Y.N. Modification of material properties and coating deposition using plasma jets. Physics-Uspekhi 2005, 48, 515–544. [Google Scholar]

- Berkovich, I.I.; Gromakovskiy, D.G. Tribologiya. Fizicheskiye osnovy, mekhanika i tekhnicheskiye prilozheniya: Uchebnik dlya vuzov.; Samar. Gos. Tekhnicheskiy Univ: Samara, Russia, 2000; Volume 268, ISBN 5-7964-0164-5. (In Russia) [Google Scholar]

| Coating | Number of Hardening Mode | Distance from Plasma Torch to Product, H, mm |

|---|---|---|

| Ti–Si–C | 1 | 30 |

| 2 | 40 | |

| 3 | 50 |

| Sample Name | Detected Phases | Phase Structure Data in the Powder Cell Database | Structure Type | Phase Content wt.% | |

|---|---|---|---|---|---|

| Grid Type | Spatial Group | ||||

| Ti3SiC2 | Ti3SiC2 | hexagonal | P63/mmc (194) | D6h4 | 39 |

| TiC | cubic | Fm-3m (196) | Oh5 | 57 | |

| TiO2 | tetragonal | I41amd (141) | D4h19 | 4 | |

| Ti3SiC2 after PPT (30 mm) | Ti3SiC2 | hexagonal | P63/mmc (194) | D6h4 | 52 |

| TiC | cubic | Fm-3m (196) | Oh5 | 29 | |

| TiO2 | tetragonal | I41amd (141) | D4h19 | 9 | |

| WC | hexagonal | P-6m2 (187) | D3h1 | 10 | |

| Ti3SiC2 after PPT (40 mm) | Ti3SiC2 | hexagonal | P63/mmc (194) | D6h4 | 59 |

| TiC | cubic | Fm-3m (196) | Oh5 | 27 | |

| TiO2 | tetragonal | I41amd (141) | D4h19 | 6 | |

| WC | hexagonal | P-6m2 (187) | D3h1 | 8 | |

| Ti3SiC2 after PPT (50 mm) | Ti3SiC2 | hexagonal | P63/mmc (194) | D6h4 | 62 |

| TiC | cubic | Fm-3m (196) | Oh5 | 27 | |

| TiO2 | tetragonal | I41amd (141) | D4h19 | 6 | |

| WC | hexagonal | P-6m2 (187) | D3h1 | 5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Buitkenov, D.; Idrisheva, Z.; Zhamanbayeva, M.; Pazylbek, S.; Baizhan, D. Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C. Coatings 2021, 11, 795. https://doi.org/10.3390/coatings11070795

Rakhadilov B, Buitkenov D, Idrisheva Z, Zhamanbayeva M, Pazylbek S, Baizhan D. Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C. Coatings. 2021; 11(7):795. https://doi.org/10.3390/coatings11070795

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Dastan Buitkenov, Zhanat Idrisheva, Manira Zhamanbayeva, Sapargali Pazylbek, and Daryn Baizhan. 2021. "Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C" Coatings 11, no. 7: 795. https://doi.org/10.3390/coatings11070795

APA StyleRakhadilov, B., Buitkenov, D., Idrisheva, Z., Zhamanbayeva, M., Pazylbek, S., & Baizhan, D. (2021). Effect of Pulsed-Plasma Treatment on the Structural-Phase Composition and Tribological Properties of Detonation Coatings Based on Ti–Si–C. Coatings, 11(7), 795. https://doi.org/10.3390/coatings11070795