Effect of Microcracks on the Tensile Properties of 3D Woven Composites

Abstract

:1. Introduction

2. Experimentation

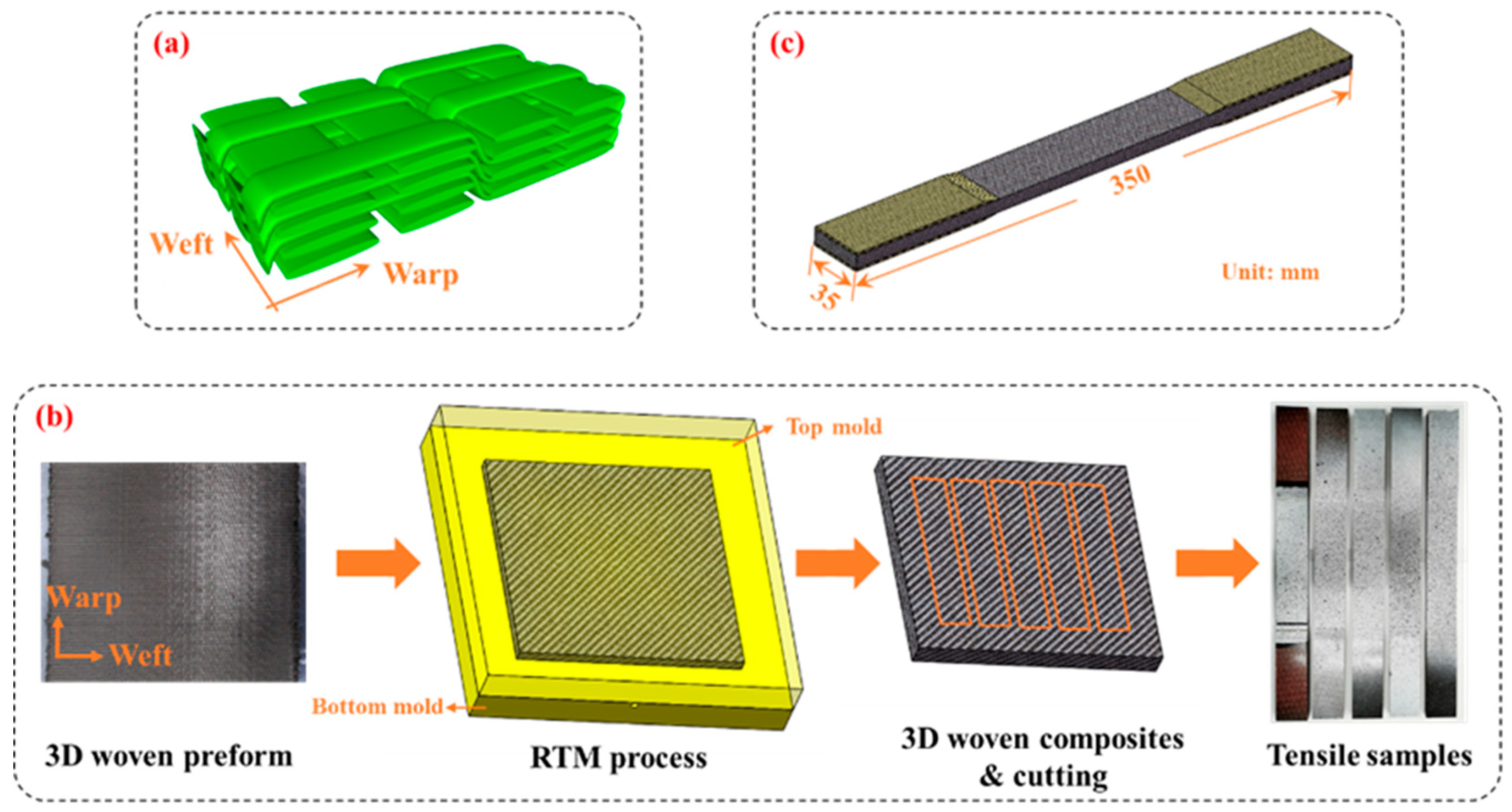

2.1. Materials and Specimens

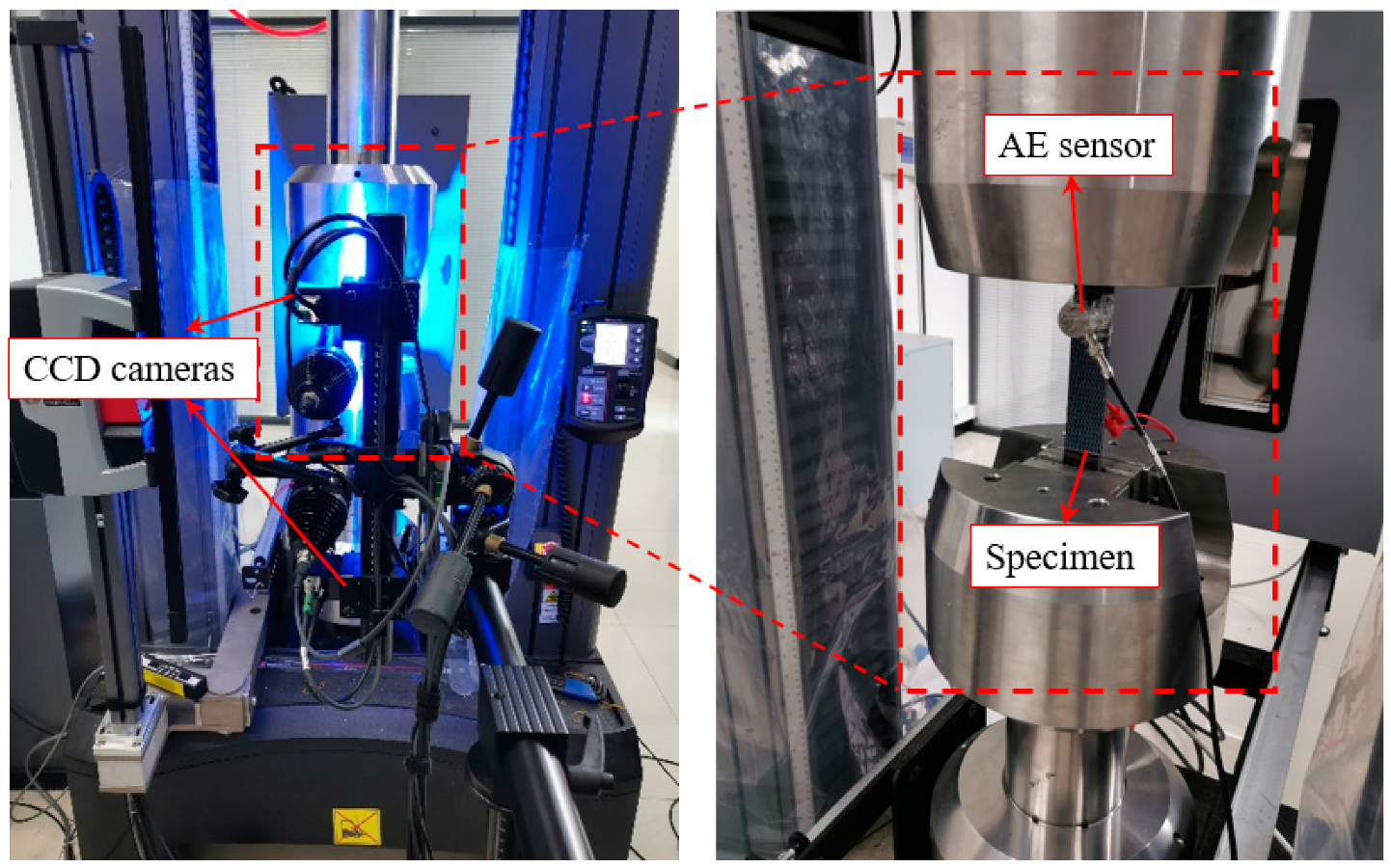

2.2. Instrumentation

2.2.1. Acoustic Emission (AE)

2.2.2. Digital Image Correlation

2.2.3. Micro-XCT

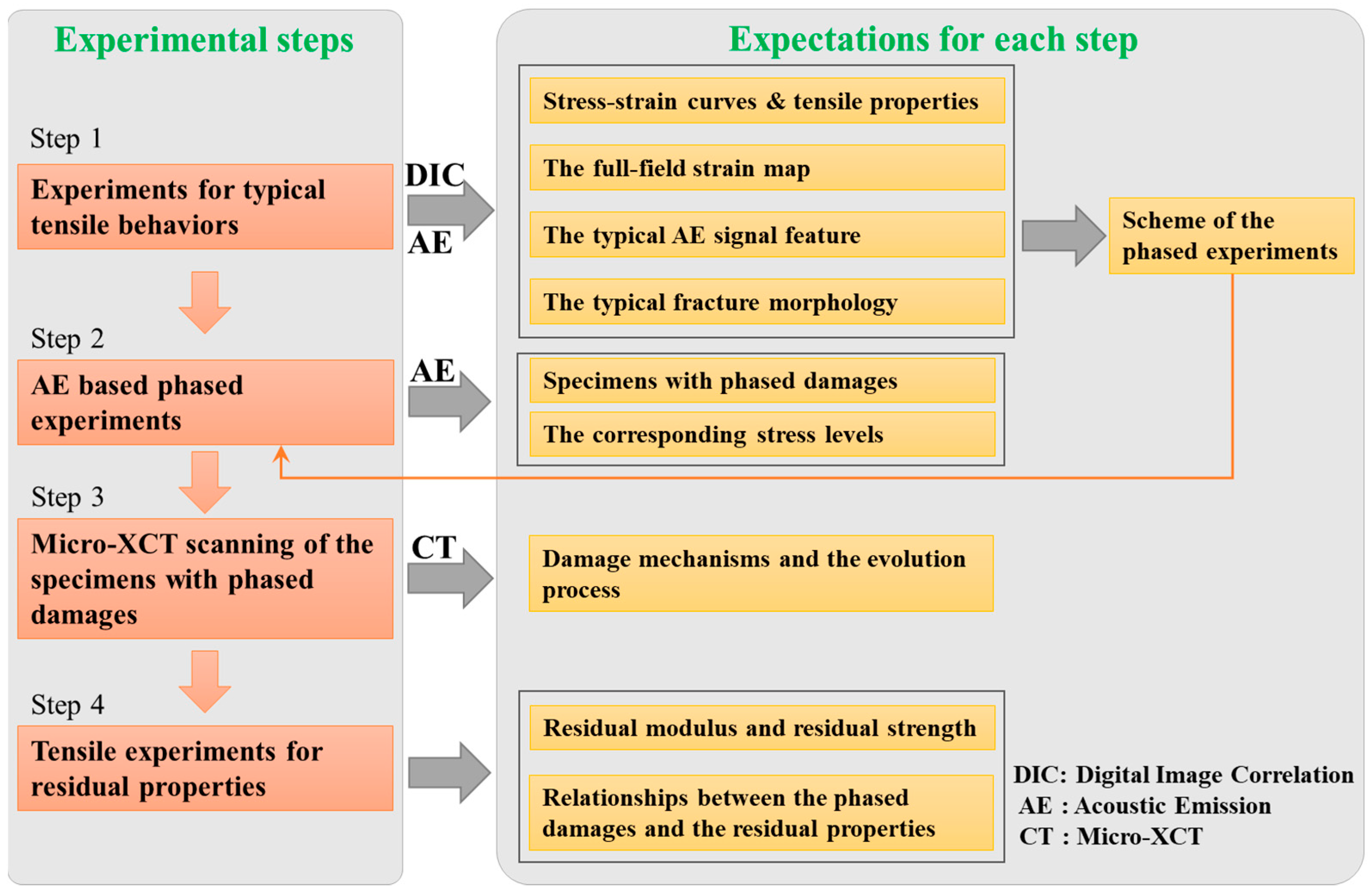

2.3. Experimental Procedures and Setups

3. Results and Discussions

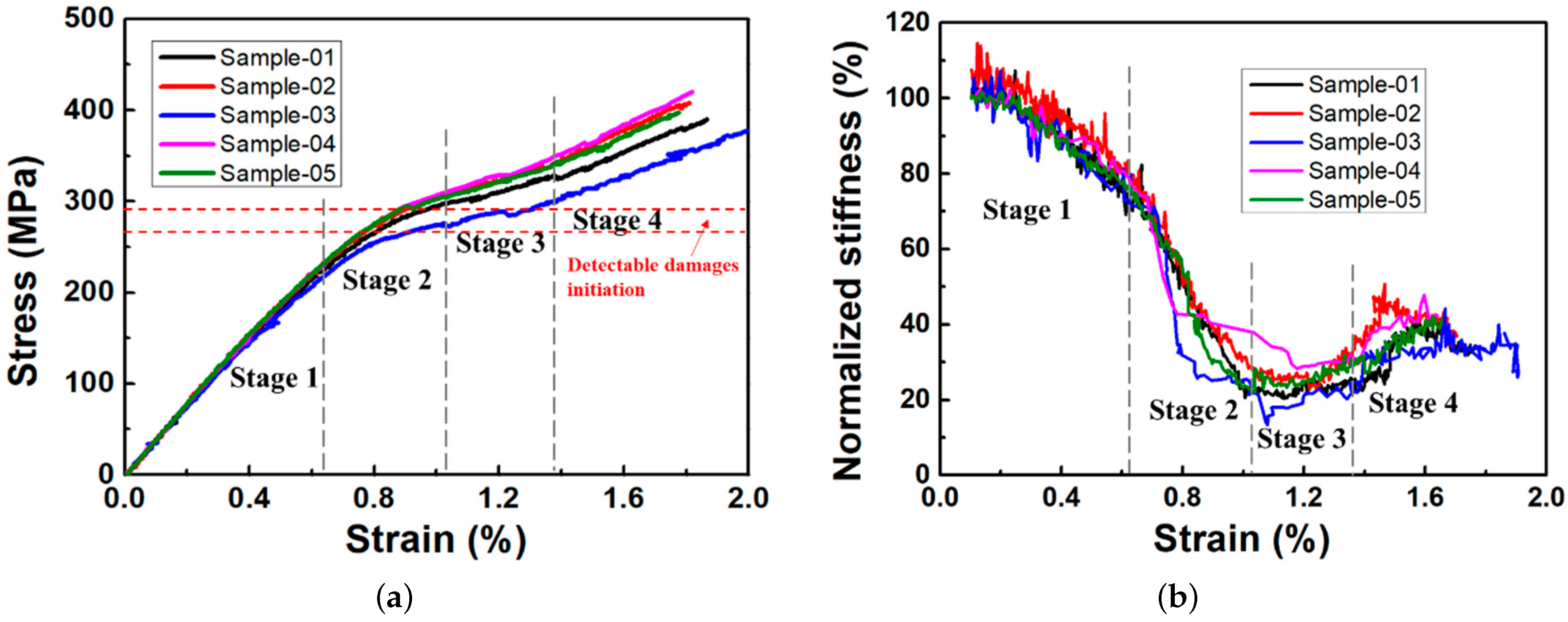

3.1. Typical Tensile Behaviors of 3D Woven Composites

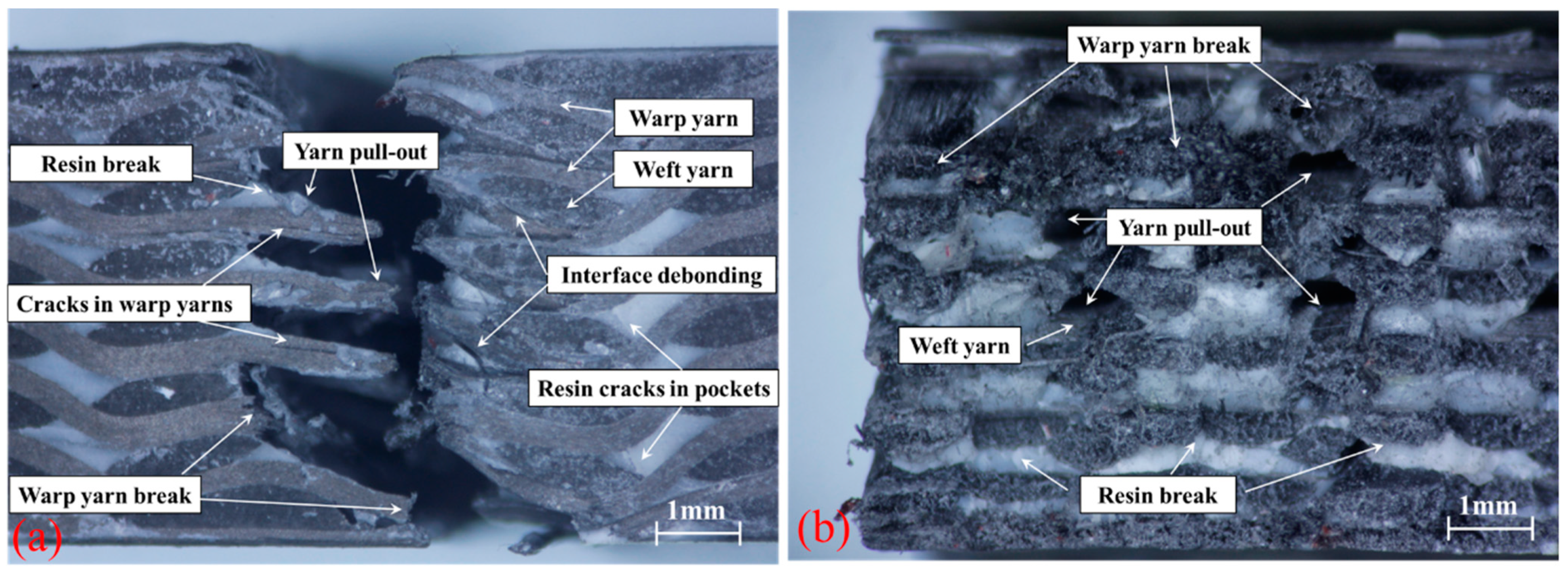

3.1.1. Tensile Properties and the Fracture Mechanisms

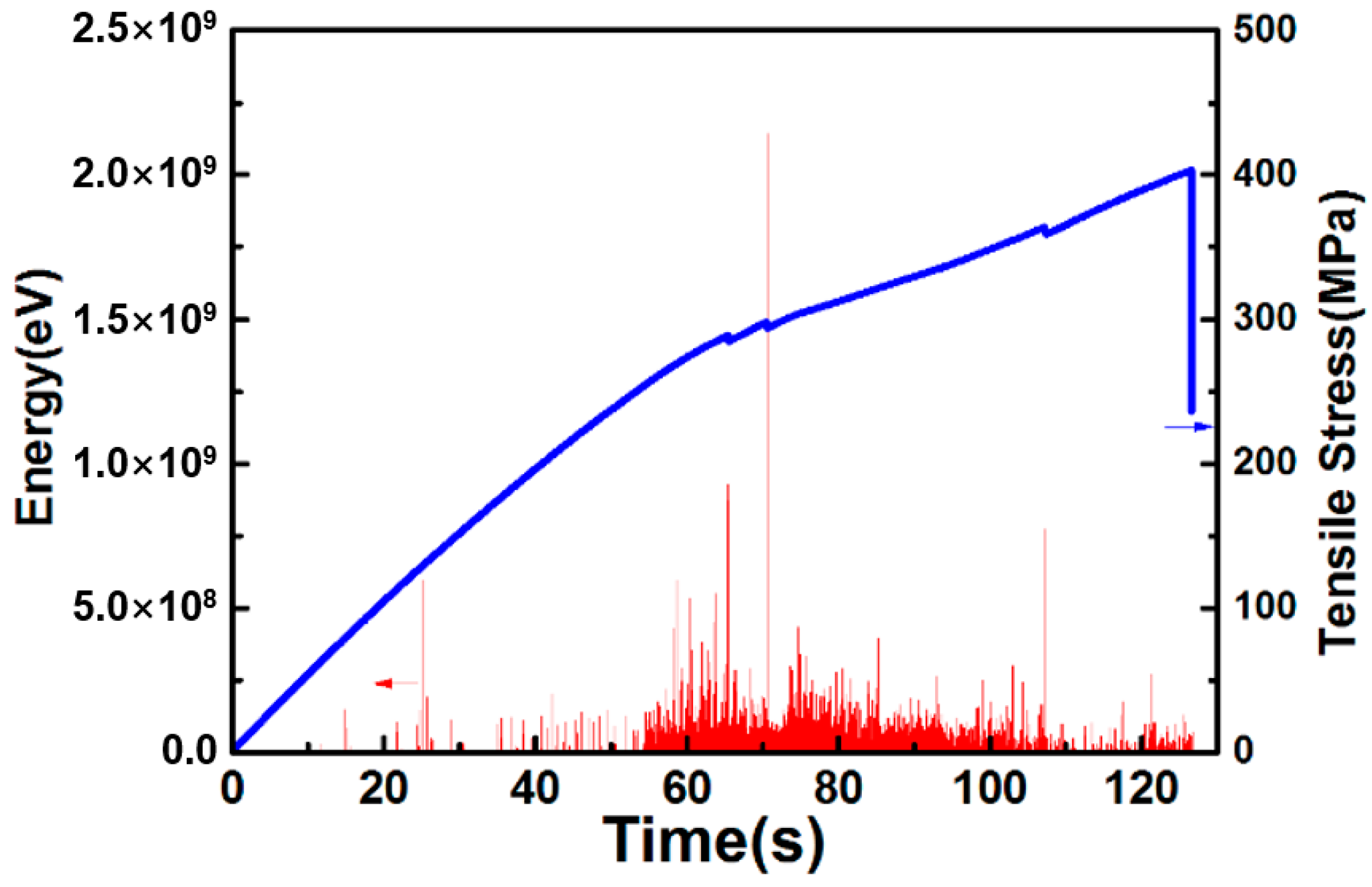

3.1.2. AE Monitoring and Damage Mechanisms Evolution

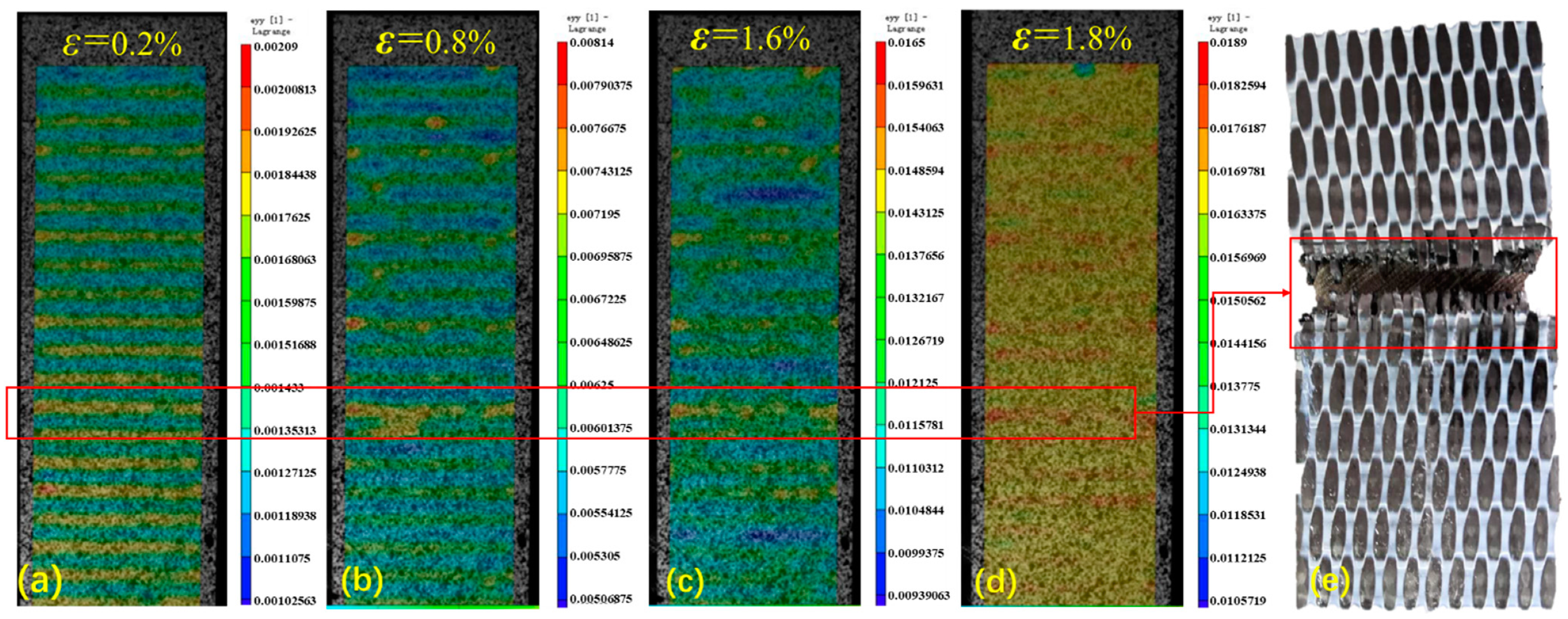

3.1.3. DIC Monitoring and Damage Mechanisms Evolution

3.2. AE Energy Based Phased Experiments

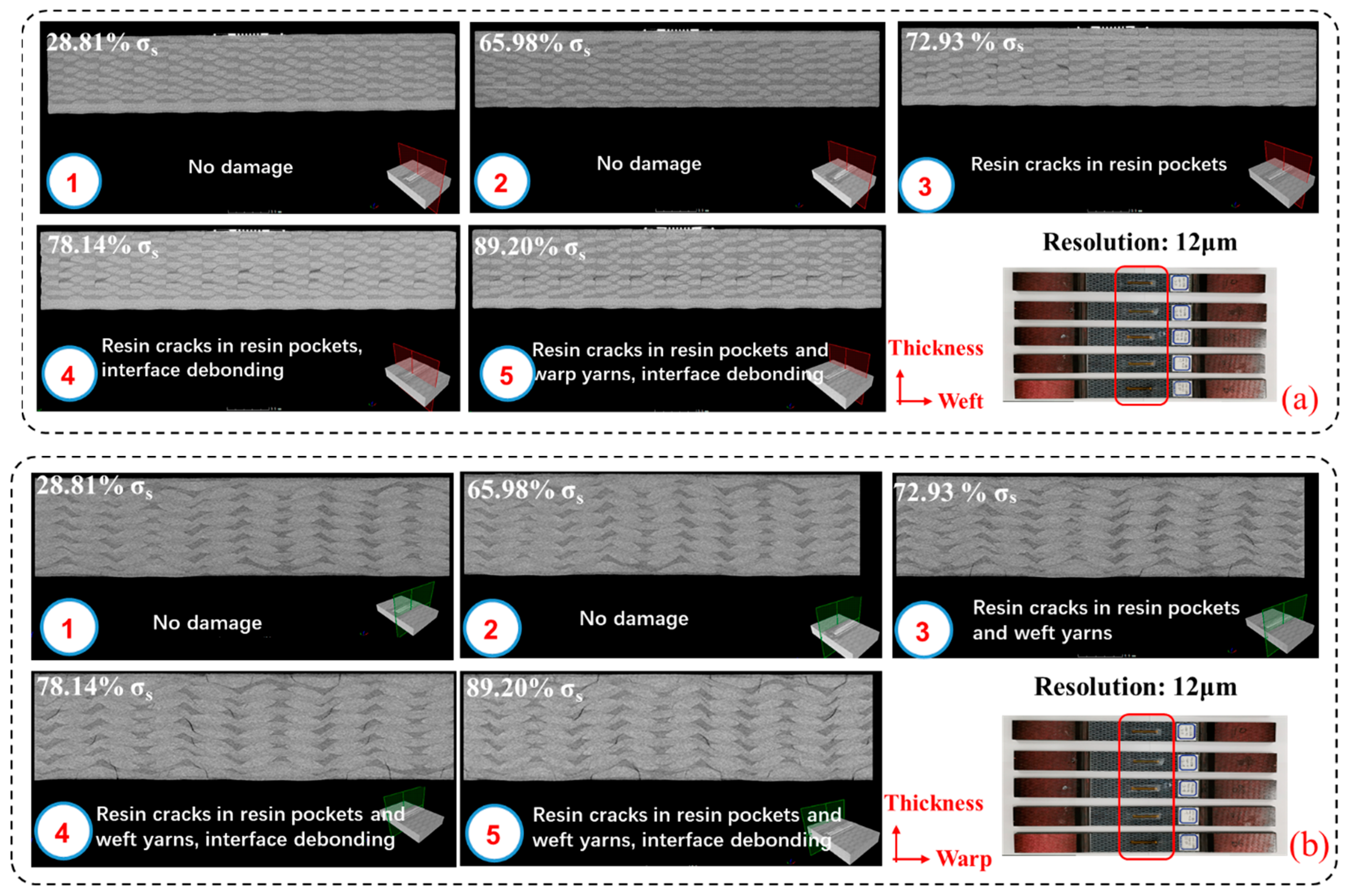

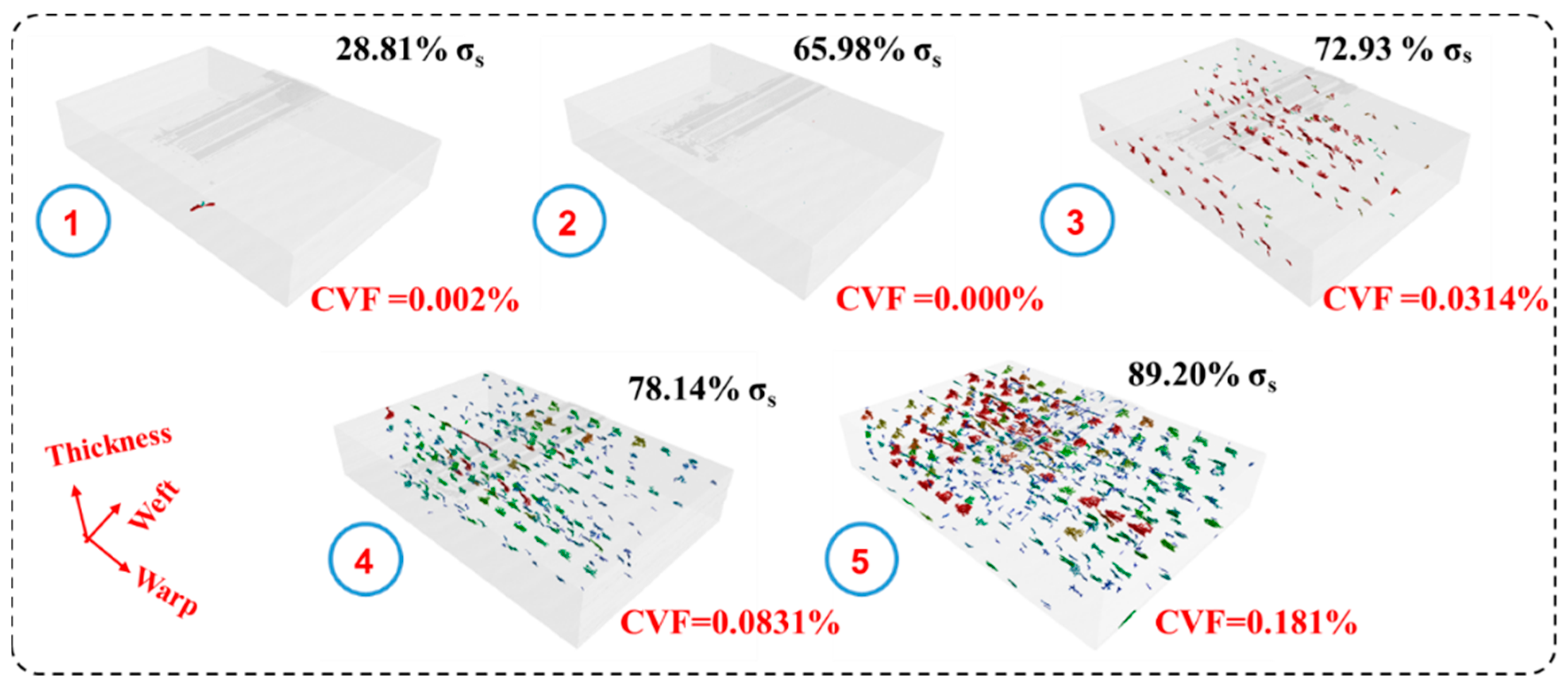

3.3. Micro-XCT Detection and the Damages Evolution Process

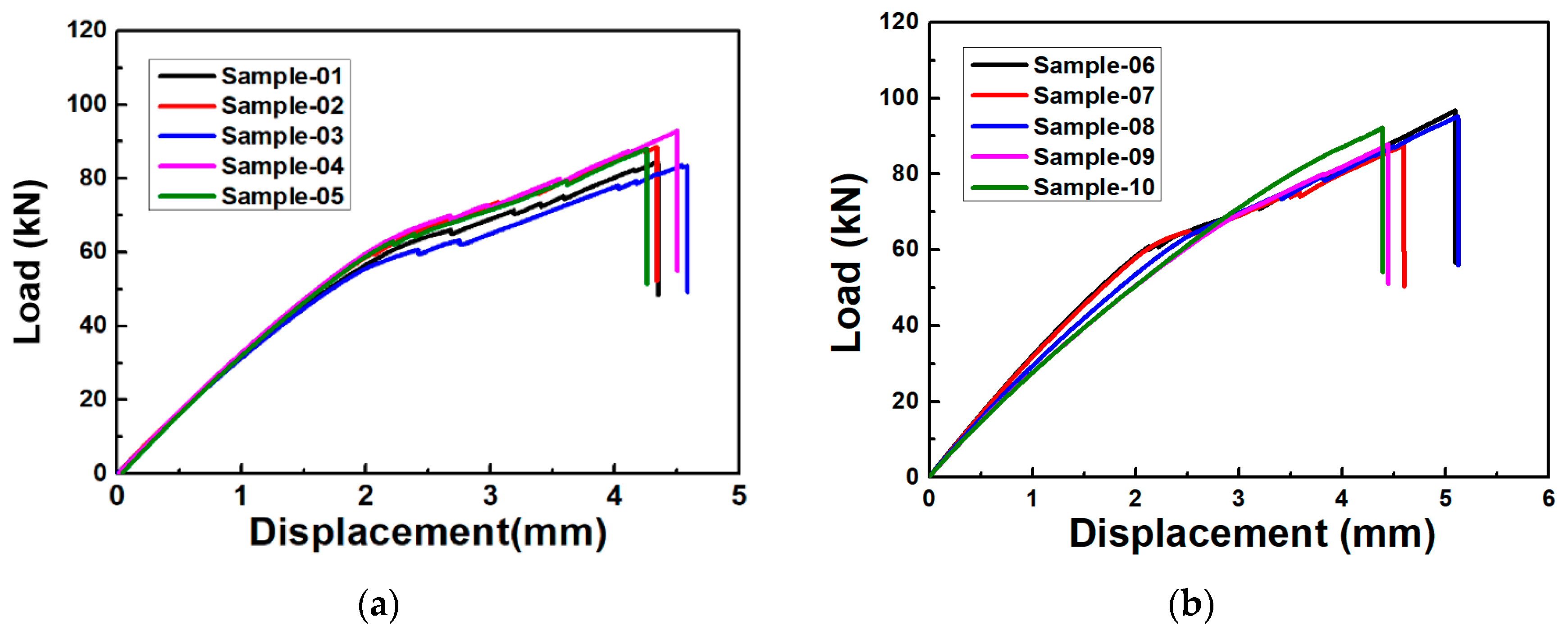

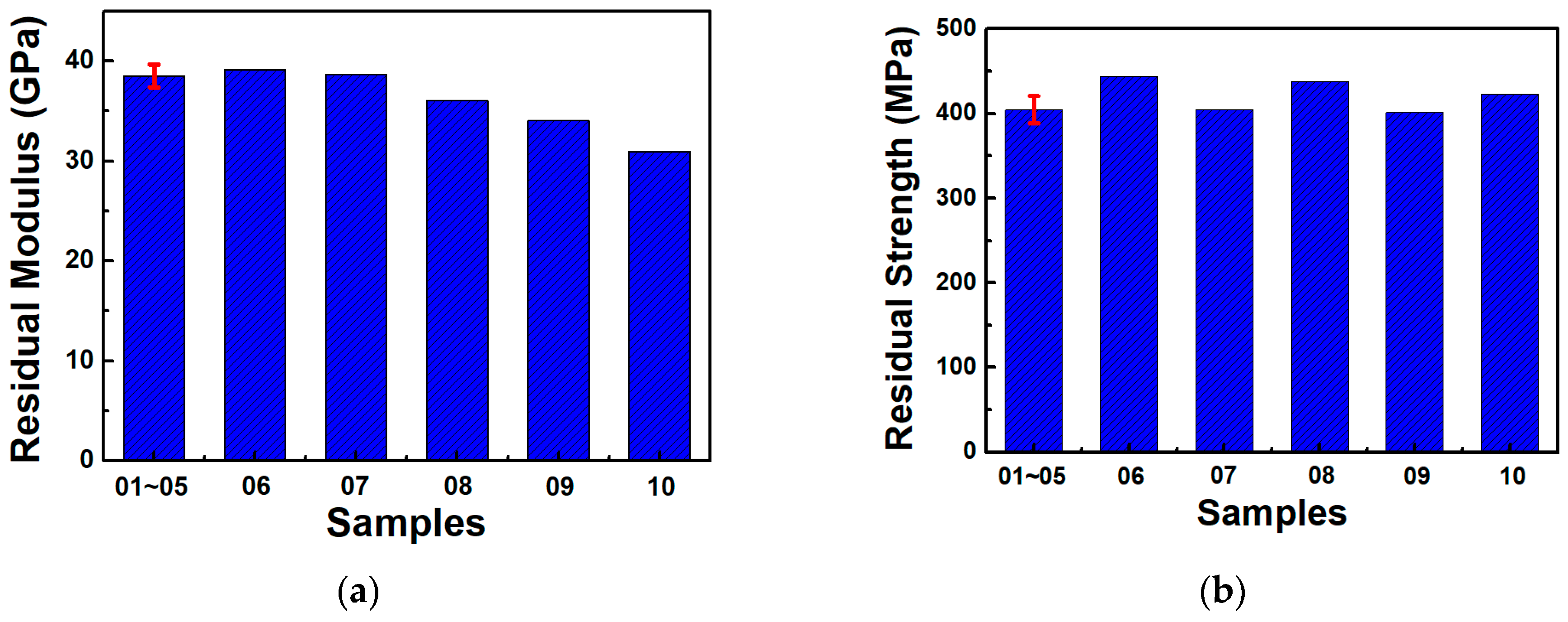

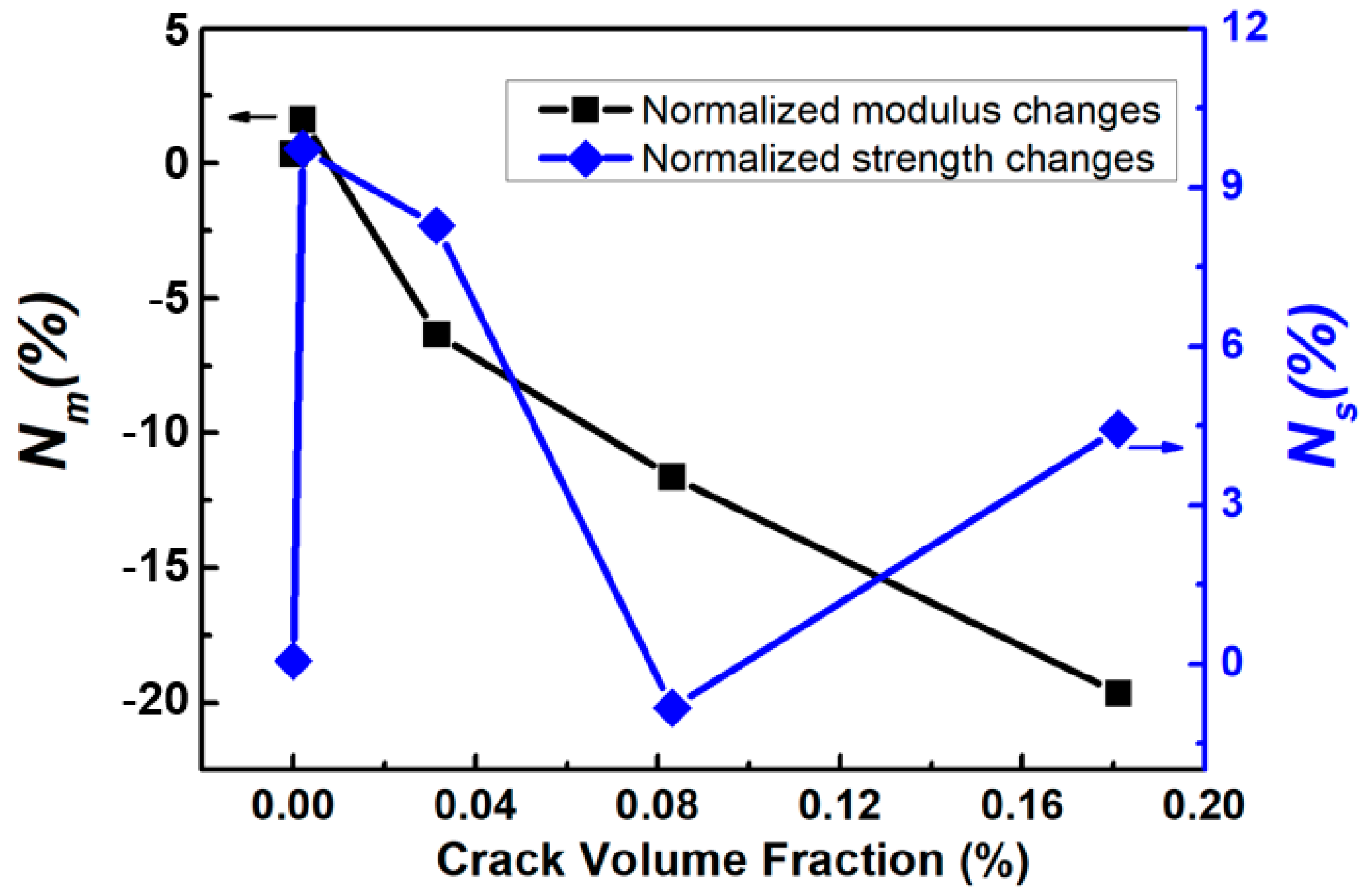

3.4. Residual Properties and the Effect of Microcracks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mouritz, A.P.; Bannister, M.K.; Falzon, P.J.; Leong, K.H. Review of applications for advanced three-dimensional fibre textile composites. Compos. Part A Appl. Sci. 1999, 30, 1445–1461. [Google Scholar] [CrossRef]

- Novak, N.; Dobnik Dubrovski, P.; Borovinšek, M.; Vesenjak, M.; Ren, Z. Deformation behaviour of advanced textile composites with auxetic structure. Compos. Struct. 2020, 252, 112761. [Google Scholar] [CrossRef]

- Yao, L.; Jiang, M.; Zhou, D.; Xu, F.; Zhao, D.; Zhang, W. Fabrication and characterization of microstrip array antennas integrated in the three dimensional orthogonal woven composite. Compos. Part B Eng. 2011, 42, 885–890. [Google Scholar] [CrossRef]

- Abbasi, S.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Improving the delamination resistance of fibre reinforced polymer composites using 3D woven metal Z-Filaments. Compos. Sci. Technol. 2020, 198, 108301. [Google Scholar] [CrossRef]

- Gerlach, R.; Siviour, C.R.; Wiegand, J.; Petrinic, N. In-plane and through-thickness properties, failure modes, damage and delamination in 3D woven carbon fibre composites subjected to impact loading. Compos. Sci. Technol. 2012, 72, 397–411. [Google Scholar] [CrossRef]

- Pankow, M.; Salvi, A.; Waas, A.M.; Yen, C.F.; Ghiorse, S. Resistance to delamination of 3D woven textile composites evaluated using end notch flexure (ENF) tests: Experimental results. Compos. Part A Appl. Sci. 2011, 42, 1463–1476. [Google Scholar] [CrossRef]

- Petersen, R.; Liu, P.R. 3D-woven fiber-reinforced composite for CAD/CAM dental application. SAMPE J. 2016, 2016, LB15–0138. [Google Scholar] [PubMed]

- Zhang, D.; Chen, L.; Sun, Y.; Zhang, Y.; Qian, K. Multi-Scale modeling of an integrated 3D braided composite with applications to helicopter arm. Appl. Compos. Mater. 2017, 24, 1233–1250. [Google Scholar] [CrossRef]

- Wang, Y.; Soutis, C. Fatigue behaviour of composite t-joints in wind turbine blade applications. Appl. Compos. Mater. 2017, 24, 461–475. [Google Scholar] [CrossRef]

- Yan, S.; Zeng, X.; Long, A. Experimental assessment of the mechanical behaviour of 3D woven composite T-joints. Compos. Part B Eng. 2018, 154, 108–113. [Google Scholar] [CrossRef] [Green Version]

- Limmer, L.; Weissenbach, G.; Brown, D.; McIlhagger, R.; Wallace, E. The potential of 3-D woven composites exemplified in a composite component for a lower-leg prosthesis. Compos. Part A Appl. Sci. 1996, 27, 271–277. [Google Scholar] [CrossRef]

- Karahan, M.; Lomov, S.V.; Bogdanovich, A.E.; Verpoest, I. Fatigue tensile behavior of carbon/epoxy composite reinforced with non-crimp 3D orthogonal woven fabric. Compos. Sci. Technol. 2011, 71, 1961–1972. [Google Scholar] [CrossRef]

- Kuo, W.-S.; Ko, T.-H.; Chen, C.-P. Effect of weaving processes on compressive behavior of 3D woven composites. Compos. Part A Appl. Sci. 2007, 38, 555–565. [Google Scholar] [CrossRef]

- Li, Z.; Guo, L.; Zhang, L.; Wang, Q. In situ experimental investigation on the out-plane damage evolution of 3D woven carbon-fiber reinforced composites. Compos. Sci. Technol. 2018, 162, 101–109. [Google Scholar] [CrossRef]

- Mounien, R.; Fagiano, C.; Paulmier, P.; Tranquart, B.; Irisarri, F.X. Experimental characterization of the bearing behavior of 3D woven composites. Compos. Part B Eng. 2017, 116, 369–376. [Google Scholar] [CrossRef]

- Rudov-Clark, S.; Mouritz, A.P. Tensile fatigue properties of a 3D orthogonal woven composite. Compos. Part A Appl. Sci. 2008, 39, 1018–1024. [Google Scholar] [CrossRef]

- Pierreux, G.; Van Hemelrijck, D.; Massart, T.J. Automated generation of 3D orthogonal woven composites RVEs including yarn cross-section variations. Compos. Sci. Technol. 2019, 176, 90–102. [Google Scholar] [CrossRef] [Green Version]

- Zheng, T.; Guo, L.; Huang, J.; Liu, G. A novel mesoscopic progressive damage model for 3D angle-interlock woven composites. Compos. Sci. Technol. 2020, 185, 107894. [Google Scholar] [CrossRef]

- Ansar, M.; Xinwei, W.; Chouwei, Z. Modeling strategies of 3D woven composites: A review. Compos. Struct. 2011, 93, 1947–1963. [Google Scholar] [CrossRef]

- Gereke, T.; Cherif, C. A review of numerical models for 3D woven composite reinforcements. Compos. Struct. 2019, 209, 60–66. [Google Scholar] [CrossRef]

- Bahei-El-Din, Y.A.; Zikry, M.A. Impact-induced deformation fields in 2D and 3D woven composites. Compos. Sci. Technol. 2003, 63, 923–942. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Sachan, Y.; Ahmad, S.; Alagirusamy, R.; Bhatnagar, N. On the mechanical response of 2D plain woven and 3D angle-interlock fabrics. Compos. Part B Eng. 2017, 118, 135–148. [Google Scholar] [CrossRef]

- Hart, K.R.; Chia, P.X.L.; Sheridan, L.E.; Wetzel, E.D.; Sottos, N.R.; White, S.R. Mechanisms and characterization of impact damage in 2D and 3D woven fiber-reinforced composites. Compos. Part A Appl. Sci. 2017, 101, 432–443. [Google Scholar] [CrossRef]

- Saeedifar, M.; Saleh, M.N.; El-Dessouky, H.M.; Teixeira De Freitas, S.; Zarouchas, D. Damage assessment of NCF, 2D and 3D woven composites under compression after multiple-impact using acoustic emission. Compos. Part A Appl. Sci. 2020, 132, 105833. [Google Scholar] [CrossRef]

- Saleh, M.N.; El-Dessouky, H.M.; Saeedifar, M.; De Freitas, S.T.; Scaife, R.J.; Zarouchas, D. Compression after multiple low velocity impacts of NCF, 2D and 3D woven composites. Compos. Part A Appl. Sci. 2019, 125, 105576. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage characterization of laminated composites using acoustic emission: A review. Compos. Part B Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

- Li, L.; Yentl, S.; Ilya, S.; Xiong, Y.; Stepan, V.L. Cluster analysis of acoustic emission signals for 2D and 3D woven carbon fiber/epoxy composites. J. Compos. Mater. 2016, 50, 1921–1935. [Google Scholar] [CrossRef] [Green Version]

- Holmes, J.; Das, R.; Stachurski, Z.; Compston, P.; Kalyanasundaram, S. Development of an S-specimen geometry for shear testing of woven thermoplastic composites. Compos. Part B Eng. 2020, 203, 108485. [Google Scholar] [CrossRef]

- Montesano, J.; Selezneva, M.; Levesque, M.; Fawaz, Z. Modeling fatigue damage evolution in polymer matrix composite structures and validation using in-situ digital image correlation. Compos. Struct. 2015, 125, 354–361. [Google Scholar] [CrossRef]

- Guo, L.; Huang, J.; Zhang, L.; Sun, X. Damage evolution of 3D woven carbon/epoxy composites under tension-tension fatigue loading based on synchrotron radiation computed tomography (SRCT). Int. J. Fatigue 2020, 142, 105913. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Ballistic impact mechanisms—A review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Gigliotti, M.; Pannier, Y.; Gonzalez, R.A.; Lafarie-Frenot, M.C.; Lomov, S.V. X-ray micro-computed-tomography characterization of cracks induced by thermal cycling in non-crimp 3D orthogonal woven composite materials with porosity. Compos. Part A Appl. Sci. 2018, 112, 100–110. [Google Scholar] [CrossRef]

- Seltzer, R.; González, C.; Muñoz, R.; Llorca, J.; Blanco-Varela, T. X-ray microtomography analysis of the damage micromechanisms in 3D woven composites under low-velocity impact. Compos. Part A Appl. Sci. 2013, 45, 49–60. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Sun, L.; Zhu, L.; Yang, S.; Hui, D.; Qiu, Y. X-ray 3D microscopy analysis of fracture mechanisms for 3D orthogonal woven E-glass/epoxy composites with drilled and moulded-in holes. Compos. Part B Eng. 2018, 133, 193–202. [Google Scholar] [CrossRef]

- Brault, R.; Germaneau, A.; Dupré, J.C.; Doumalin, P.; Mistou, S. In-situ analysis of laminated composite materials by X-ray micro-computed tomography and digital volume correlation. Exp. Mech. 2013, 53, 1143–1151. [Google Scholar] [CrossRef] [Green Version]

- Garcea, S.C.; Sinclair, I.; Spearing, S.M. In situ synchrotron tomographic evaluation of the effect of toughening strategies on fatigue micromechanisms in carbon fibre reinforced polymers. Compos. Sci. Technol. 2015, 109, 32–39. [Google Scholar] [CrossRef]

- Hülsbusch, D.; Mrzljak, S.; Walther, F. In situ computed tomography for the characterization of the fatigue damage development in glass fiber-reinforced polyurethane. Mater. Test. 2019, 61, 821–828. [Google Scholar] [CrossRef]

- Tan, P.; Tong, L.; Steven, G.P.; Ishikawa, T. Behavior of 3D orthogonal woven CFRP composites. Part I. Experimental investigation. Compos. Part A Appl. Sci. 2000, 31, 259–271. [Google Scholar] [CrossRef]

- Pascoe, J.A.; Zarouchas, D.S.; Alderliesten, R.C.; Benedictus, R. Using acoustic emission to understand fatigue crack growth within a single load cycle. Eng. Fract. Mech. 2018, 194, 281–300. [Google Scholar] [CrossRef] [Green Version]

- Fotouhi, M.; Heidary, H.; Ahmadi, M.; Pashmforoush, F. Characterization of composite materials damage under quasi-static three-point bending test using wavelet and fuzzy C-means clustering. J. Compos. Mater. 2012, 46, 1795–1808. [Google Scholar] [CrossRef]

- Oskouei, A.R.; Ahmadi, M. Acoustic emission characteristics of mode I delamination in glass/polyester composites. J. Compos. Mater. 2009, 44, 793–807. [Google Scholar] [CrossRef]

- Lissek, F.; Haeger, A.; Knoblauch, V.; Hloch, S.; Pude, F.; Kaufeld, M. Acoustic emission for interlaminar toughness testing of CFRP: Evaluation of the crack growth due to burst analysis. Compos. Part B Eng. 2018, 136, 55–62. [Google Scholar] [CrossRef]

- Nikbakht, M.; Yousefi, J.; Hosseini-Toudeshky, H.; Minak, G. Delamination evaluation of composite laminates with different interface fiber orientations using acoustic emission features and micro visualization. Compos. Part B Eng. 2017, 113, 185–196. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.A.; Zarouchas, D.; Toudeshky, H.H.; Jalalvand, M. Clustering of interlaminar and intralaminar damages in laminated composites under indentation loading using acoustic emission. Compos. Part B Eng. 2018, 144, 206–219. [Google Scholar] [CrossRef] [Green Version]

- Warren, K.C.; Lopez-Anido, R.A.; Goering, J. Experimental investigation of three-dimensional woven composites. Compos. Part A Appl. Sci. 2015, 73, 242–259. [Google Scholar] [CrossRef]

| Materials | Tensile Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| Carbon fiber | 275 | 5120 | 1.72 |

| Epoxy resin | 3.5 | 102 | 5.6 |

| Mechanical Properties | Sample-01 | Sample-02 | Sample-03 | Sample-04 | Sample-05 | Average Value | CoV (%) |

|---|---|---|---|---|---|---|---|

| Tensile modulus (GPa) | 38.47 | 37.62 | 37.22 | 39.42 | 39.91 | 38.53 | 2.97 |

| Tensile strength (MPa) | 403.46 | 427.54 | 386.50 | 411.75 | 393.80 | 404.61 | 3.95 |

| Elongation at break (%) | 1.87 | 1.81 | 2.08 | 1.82 | 1.78 | 1.87 | 6.45 |

| Phase Points | Corresponding Samples | Stress Levels (σ/σs) |

|---|---|---|

| ① | Sample-06 | 28.81% |

| ② | Sample-07 | 65.98% |

| ③ | Sample-08 | 72.93% |

| ④ | Sample-09 | 78.14% |

| ⑤ | Sample-10 | 89.20% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Zhao, Q.; Feng, Y.; Zhou, H.; Sun, F.; Wang, K.; Li, C.; Zhang, L.; Sun, X. Effect of Microcracks on the Tensile Properties of 3D Woven Composites. Coatings 2021, 11, 794. https://doi.org/10.3390/coatings11070794

Huang J, Zhao Q, Feng Y, Zhou H, Sun F, Wang K, Li C, Zhang L, Sun X. Effect of Microcracks on the Tensile Properties of 3D Woven Composites. Coatings. 2021; 11(7):794. https://doi.org/10.3390/coatings11070794

Chicago/Turabian StyleHuang, Jian, Qian Zhao, Yubo Feng, Haili Zhou, Fangfang Sun, Kun Wang, Chao Li, Liquan Zhang, and Xuekun Sun. 2021. "Effect of Microcracks on the Tensile Properties of 3D Woven Composites" Coatings 11, no. 7: 794. https://doi.org/10.3390/coatings11070794

APA StyleHuang, J., Zhao, Q., Feng, Y., Zhou, H., Sun, F., Wang, K., Li, C., Zhang, L., & Sun, X. (2021). Effect of Microcracks on the Tensile Properties of 3D Woven Composites. Coatings, 11(7), 794. https://doi.org/10.3390/coatings11070794