Epitaxial Growth and Stoichiometry Control of Ultrawide Bandgap ZnGa2O4 Films by Pulsed Laser Deposition

Abstract

:1. Introduction

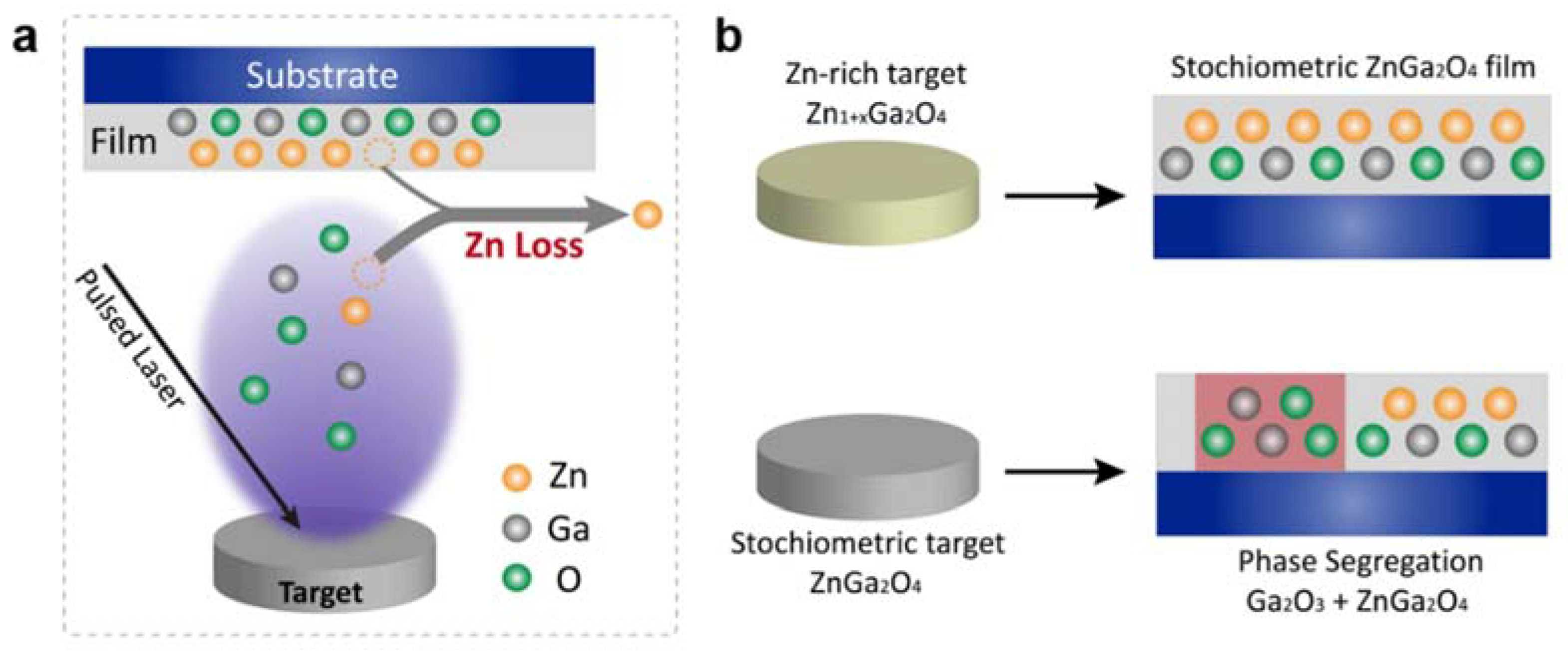

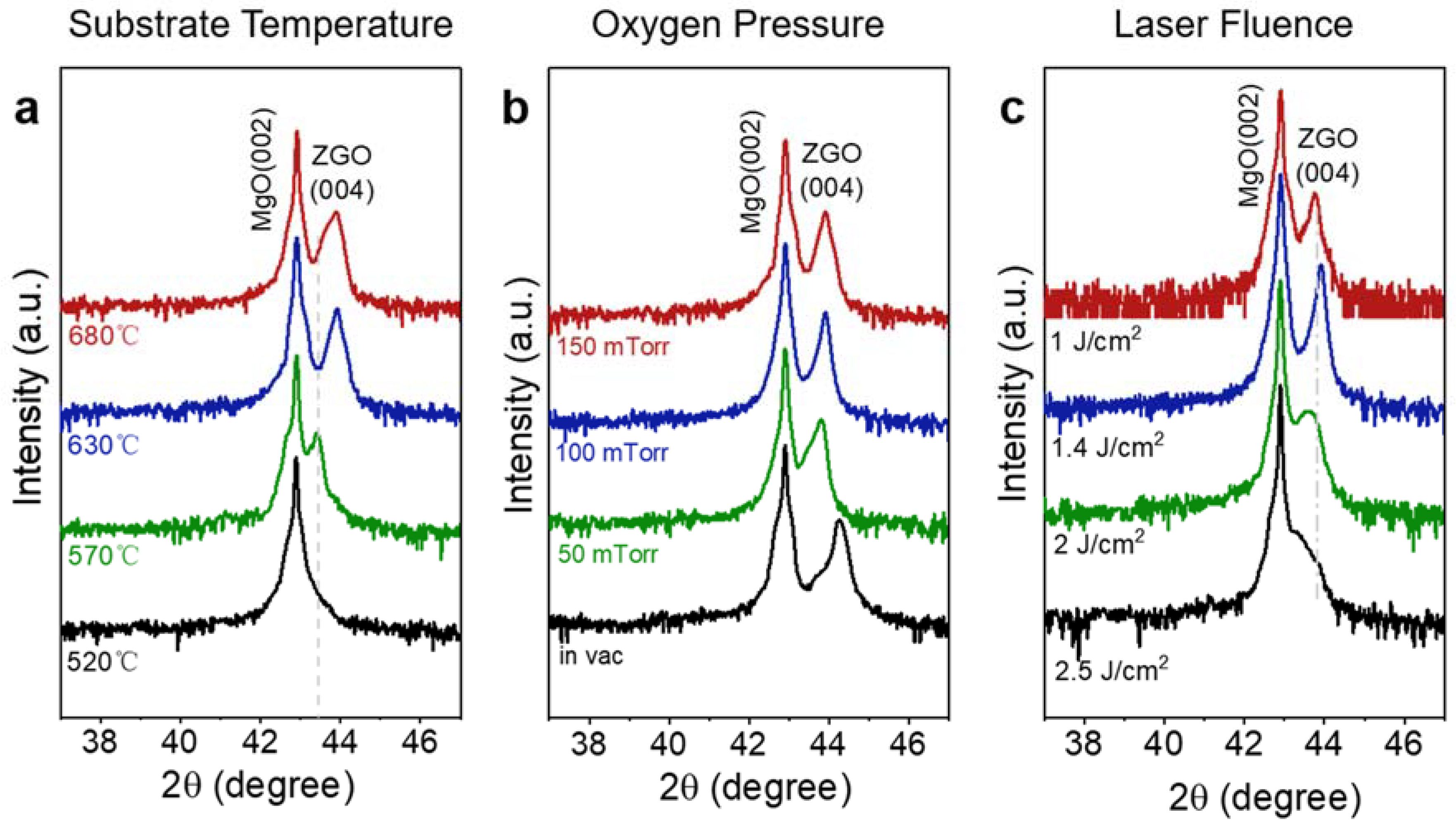

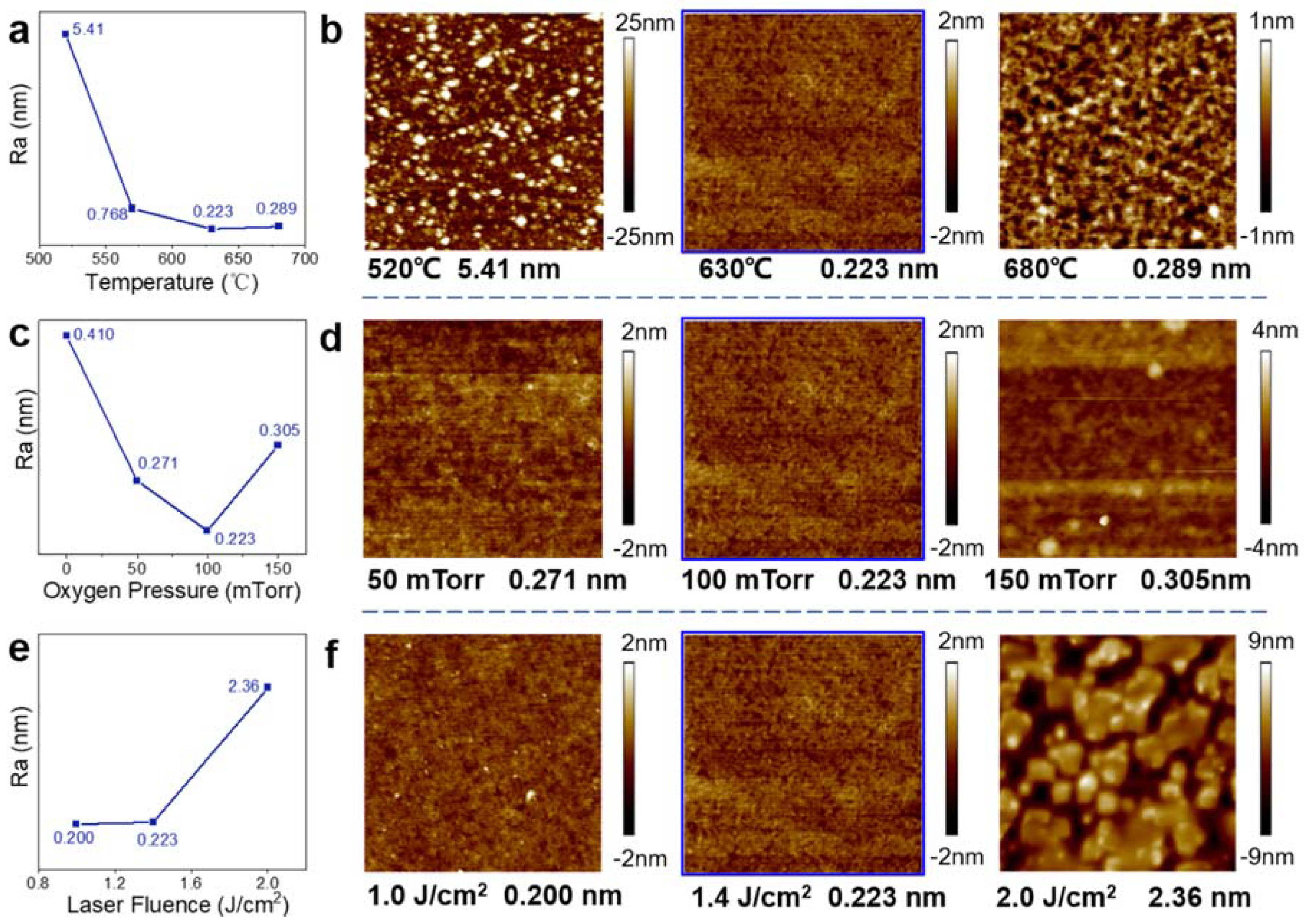

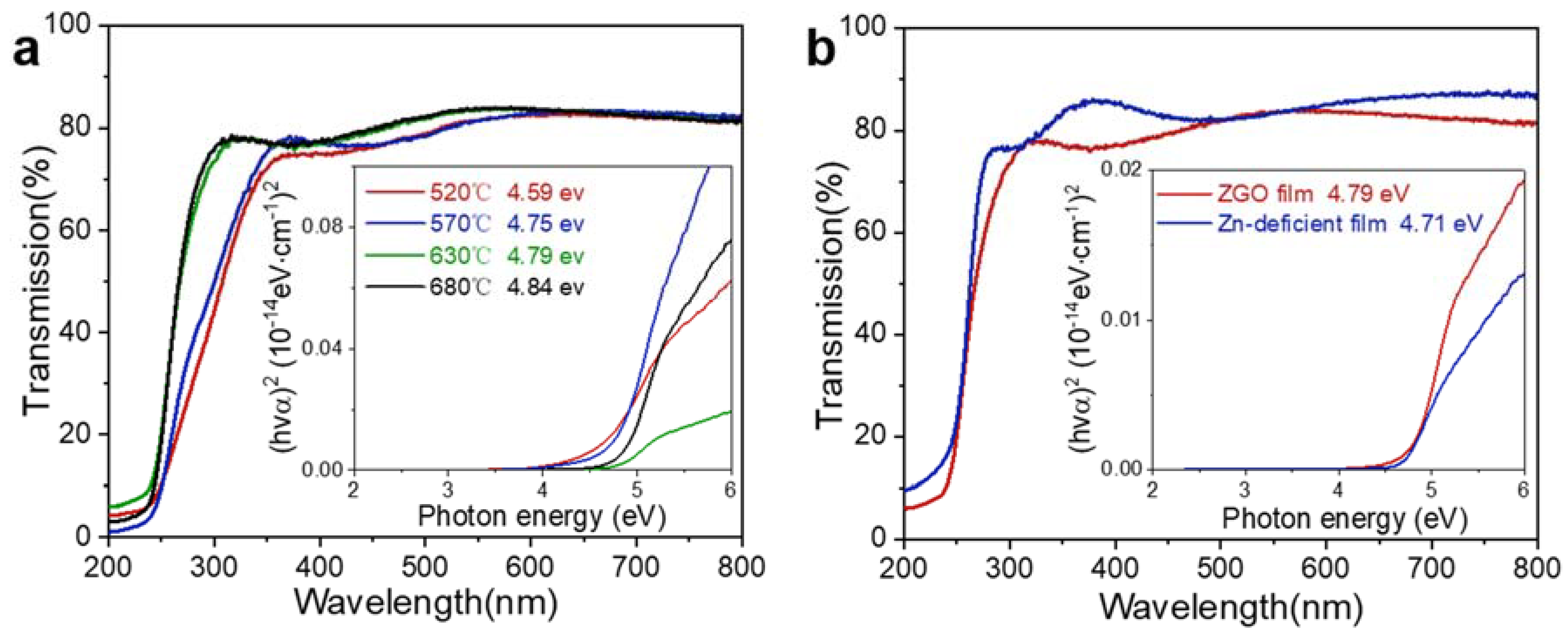

2. Result and Discussion

3. Conclusions

4. Experimental Section

4.1. Thin Film Deposition

4.2. Structural and Chemical Characterization

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kan, H.; Zheng, W.; Lin, R.; Li, M.; Fu, C.; Sun, H.; Dong, M.; Xu, C.; Luo, J.; Fu, Y.; et al. Ultrafast photovoltaic-type deep ultraviolet photodetectors using hybrid zero-/two-dimensional heterojunctions. ACS Appl. Mater. Interfaces 2019, 11, 8412–8418. [Google Scholar] [CrossRef] [Green Version]

- Xie, C.; Lu, X.-T.; Tong, X.-W.; Zhang, Z.-X.; Liang, F.-X.; Liang, L.; Luo, L.-B.; Wu, Y.-C. Recent progress in solar-blind deep-ultraviolet photodetectors based on inorganic ultrawide bandgap semiconductors. Adv. Funct. Mater. 2019, 29, 1806006. [Google Scholar] [CrossRef]

- Chen, H.; Liu, K.; Hu, L.; Al-Ghamdi, A.A.; Fang, X. New concept ultraviolet photodetectors. Mater. Today 2015, 18, 493–502. [Google Scholar] [CrossRef]

- Fan, M.M.; Liu, K.W.; Chen, X.; Wang, X.; Zhang, Z.Z.; Li, B.H.; Shen, D.Z. Mechanism of excellent photoelectric characteristics in mixed-phase ZnMgO ultraviolet photodetectors with single cutoff wavelength. ACS Appl. Mater. Interfaces 2015, 7, 20600–20606. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhang, Q.; Gan, L.; Li, X.; Li, H.; Zhang, Y.; Golberg, D.; Zhai, T. High-performance solar-blind deep ultraviolet photodetector based on individual single-crystalline Zn2GeO4 nanowire. Adv. Funct. Mater. 2016, 26, 704–712. [Google Scholar] [CrossRef]

- Liao, M.; Koide, Y. High-performance metal-semiconductor-metal deep-ultraviolet photodetectors based on homoepitaxial diamond thin film. Appl. Phys. Lett. 2006, 89, 113509. [Google Scholar] [CrossRef]

- Kaur, D.; Kumar, M. A strategic review on gallium oxide based deep—Ultraviolet photodetectors: Recent progress and future prospects. Adv. Opt. Mater. 2021, 9, 2002160. [Google Scholar] [CrossRef]

- Qin, Y.; Li, L.; Zhao, X.; Tompa, G.S.; Dong, H.; Jian, G.; He, Q.; Tan, P.; Hou, X.; Zhang, Z.; et al. Metal-semiconductor-metal ε-Ga2O3 solar-blind photodetectors with a record-high responsivity rejection ratio and their gain mechanism. ACS Photonics 2020, 7, 812–820. [Google Scholar] [CrossRef]

- Galazka, Z.; Ganschow, S.; Schewski, R.; Irmscher, K.; Klimm, D.; Kwasniewski, A.; Pietsch, M.; Fiedler, A.; Schulze-Jonack, I.; Albrecht, M.; et al. Ultra-wide bandgap, conductive, high mobility, and high quality melt-grown bulk ZnGa2O4 single crystals. APL Mater. 2019, 7, 022512. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.W.; Huang, S.Y.; Yuan, S.H.; Chen, Y.A.; Hsiao, P.W.; Wuu, D.S. Quasi-single-crystalline ZnGa2O4 films via solid phase epitaxy for enhancing deep—ultraviolet photoresponse. Adv. Mater. Interfaces 2019, 6, 1901075. [Google Scholar] [CrossRef]

- Noto, L.L.; Mbongo, M. Photoluminescence and thermoluminescence properties of ZnGa2O4 prepared by a microwave assisted solid state reaction. Phys. B Condens. Matter 2020, 578, 411768. [Google Scholar] [CrossRef]

- Horng, R.-H.; Huang, C.-Y.; Ou, S.-L.; Juang, T.-K.; Liu, P.-L. Epitaxial growth of ZnGa2O4: A new, deep ultraviolet semiconductor candidate. Cryst. Growth Des. 2017, 17, 6071–6078. [Google Scholar] [CrossRef]

- Oshima, T.; Niwa, M.; Mukai, A.; Nagami, T.; Suyama, T.; Ohtomo, A. Epitaxial growth of wide-band-gap ZnGa2O4 films by mist chemical vapor deposition. J. Cryst. Growth 2014, 386, 190–193. [Google Scholar] [CrossRef]

- Chen, H.; Yu, P.; Zhang, Z.; Teng, F.; Zheng, L.; Hu, K.; Fang, X. Ultrasensitive self-powered solar-blind deep-ultraviolet photodetector based on all-solid-state polyaniline/MgZnO bilayer. Small 2016, 12, 5809–5816. [Google Scholar] [CrossRef]

- Hou, Y.N.; Mei, Z.X.; Liang, H.L.; Ye, D.Q.; Gu, C.Z.; Du, X.L. Dual-band MgZnO ultraviolet photodetector integrated with Si. Appl. Phys. Lett. 2013, 102, 153510. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Misawa, S.; Gonda, S. Properties of AlxGa1−xN films prepared by reactive molecular beam epitaxy. J. Appl. Phys. 1982, 53, 6844–6848. [Google Scholar] [CrossRef]

- Cicek, E.; McClintock, R.; Cho, C.Y.; Rahnema, B.; Razeghi, M. AlxGa1-xN-based back-illuminated solar-blind photodetectors with external quantum efficiency of 89%. Appl. Phys. Lett. 2013, 103, 191108. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, W.; Huang, F. Gallium oxide solar-blind ultraviolet photodetectors: A review. J. Mater. Chem. C 2019, 7, 8753–8770. [Google Scholar] [CrossRef]

- Cheng, L.-C.; Huang, C.-Y.; Horng, R.-H. Thickness effect on operational modes of ZnGa2O4 MOSFETs. J. Electron Devices Soc. 2018, 6, 432–437. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, J.; Li, Y.; Chen, Z.; Wang, T. Preparation and optical properties of ZnGa2O4:Cr3+ thin films derived by sol–gel process. Appl. Surf. Sci. 2010, 256, 4702–4707. [Google Scholar] [CrossRef]

- Choi, H.-W.; Hong, B.-J.; Lee, S.-K.; Kim, K.-H.; Park, Y.-S. Cathode luminescence characteristics of ZnGa2O4 phosphor thin films with the doped activator. J. Lumin. 2007, 126, 359–364. [Google Scholar] [CrossRef]

- Yi, S.S.; Bae, J.S.; Shim, K.S.; Jeong, J.H.; Park, H.L.; Holloway, P.H. Photoluminescence behavior of ZnGa2O4−xSex: Mn2+ thin film phosphors. J. Cryst. Growth 2003, 259, 95–102. [Google Scholar] [CrossRef]

- Dazai, T.; Yasui, S.; Taniyama, T.; Itoh, M. Cation-deficiency-induced crystal-site engineering for ZnGa2O4: Mn(2+) thin film. Inorg. Chem. 2020, 59, 8744–8748. [Google Scholar] [CrossRef]

- Mini Krishna, K.; Nisha, M.; Reshmi, R.; Manoj, R.; Asha, A.S.; Jayaraj, M.K. Electrical and optical properties of ZnGa2O4 thin films deposited by pulsed laser deposition. Mater. Sci. Forum 2005, 29, 243–247. [Google Scholar]

- Zhang, W.; Lyons, J.L.; Cen, J.; Sfeir, M.Y.; Liu, M. Multicomponent oxynitride thin films: Precise growth control and excited state dynamics. Chem. Mater. 2019, 31, 3461–3467. [Google Scholar] [CrossRef]

- Yia, S.S.; Kim, I.W.; Park, H.L.; Bae, J.S.; Moon, B.K.; Jeong, J.H. Luminescence characteristics of pulsed laser deposited ZnGa2O4 thin film phosphors grown on various substrates. J. Cryst. Growth 2003, 247, 213–218. [Google Scholar] [CrossRef]

- Lee, Y.E.; Norton, D.P.; Park, C.; Rouleau, C.M. Blue photoluminescence in ZnGa2O4 thin-film phosphors. J. Appl. Phys. 2001, 89, 1653. [Google Scholar] [CrossRef]

- Lee, Y.E.; Norton, D.P.; Budai, J.D. Enhanced photoluminescence in epitaxial ZnGa2O4:Mn thin-film phosphors using pulsed-laser deposition. Appl. Phys. Lett. 1999, 74, 3155–3157. [Google Scholar] [CrossRef]

- Jang, Y.; Hong, S.; Seo, J.; Cho, H.; Char, K.; Galazka, Z. Thin film transistors based on ultra-wide bandgap spinel ZnGa2O4. Appl. Phys. Lett. 2020, 116, 202104. [Google Scholar] [CrossRef]

- Zhang, W.; Song, L.; Cen, J.; Liu, M. Mechanistic insights into defect-assisted carrier transport in bismuth vanadate photoanodes. J. Phys. Chem. C 2019, 123, 20730–20736. [Google Scholar] [CrossRef]

- Tsai, S.H.; Basu, S.; Huang, C.Y.; Hsu, L.C.; Lin, Y.G.; Horng, R.H. Deep-ultraviolet photodetectors based on epitaxial ZnGa2O4 thin films. Sci. Rep. 2018, 8, 14056. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.-C.; Huang, P.-H.; Tung, C.-Y.; Huang, C.-Y.; Tan, C.-S.; Huang, Y.-S.; Chen, L.-J.; He, J.-H.; Horng, R.-H. Power saving high performance deep-ultraviolet phototransistors made of ZnGa2O4 Epilayers. ACS Appl. Electron. Mater. 2020, 2, 590–596. [Google Scholar] [CrossRef]

- Kim, H.; Horwitz, J.S.; Kim, W.H.; Kafafi, Z.H.; Chrisey, D.B. Highly oriented indium tin oxide films for high efficiency organic light-emitting diodes. J. Appl. Phys. 2002, 91, 5371–5376. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, C.; Zhang, D.; Li, S.; Zhang, L.; Wang, W.; Zhang, J. Luminescence of Cr3+-doped ZnGa2O4 thin films deposited by pulsed laser ablation. Thin Solid Films 2012, 520, 6845–6849. [Google Scholar] [CrossRef]

- Yamaguchi, K. First principles study on electronic structure of β-Ga2O3. Solid State Commun. 2004, 131, 739–744. [Google Scholar] [CrossRef]

- Chikoidze, E.; Sartel, C.; Madaci, I.; Mohamed, H.; Vilar, C.; Ballesteros, B.; Belarre, F.; del Corro, E.; Vales-Castro, P.; Sauthier, G.; et al. P-type ultrawide-band-gap spinel ZnGa2O4: New perspectives for energy electronics. Cryst. Growth Des. 2020, 20, 2535–2546. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhang, W.; Liu, N.; Zhang, T.; Wang, Z.; Wu, S.; Zhan, Z.; Ye, J. Epitaxial Growth and Stoichiometry Control of Ultrawide Bandgap ZnGa2O4 Films by Pulsed Laser Deposition. Coatings 2021, 11, 782. https://doi.org/10.3390/coatings11070782

Wang L, Zhang W, Liu N, Zhang T, Wang Z, Wu S, Zhan Z, Ye J. Epitaxial Growth and Stoichiometry Control of Ultrawide Bandgap ZnGa2O4 Films by Pulsed Laser Deposition. Coatings. 2021; 11(7):782. https://doi.org/10.3390/coatings11070782

Chicago/Turabian StyleWang, Liu, Wenrui Zhang, Ningtao Liu, Tan Zhang, Zilong Wang, Simiao Wu, Zhaolin Zhan, and Jichun Ye. 2021. "Epitaxial Growth and Stoichiometry Control of Ultrawide Bandgap ZnGa2O4 Films by Pulsed Laser Deposition" Coatings 11, no. 7: 782. https://doi.org/10.3390/coatings11070782

APA StyleWang, L., Zhang, W., Liu, N., Zhang, T., Wang, Z., Wu, S., Zhan, Z., & Ye, J. (2021). Epitaxial Growth and Stoichiometry Control of Ultrawide Bandgap ZnGa2O4 Films by Pulsed Laser Deposition. Coatings, 11(7), 782. https://doi.org/10.3390/coatings11070782