Microwave Absorption Properties of Fe3O4 Particles Coated with Al via Rotating Magnetic Field Method

Abstract

1. Introduction

2. Materials and Methods

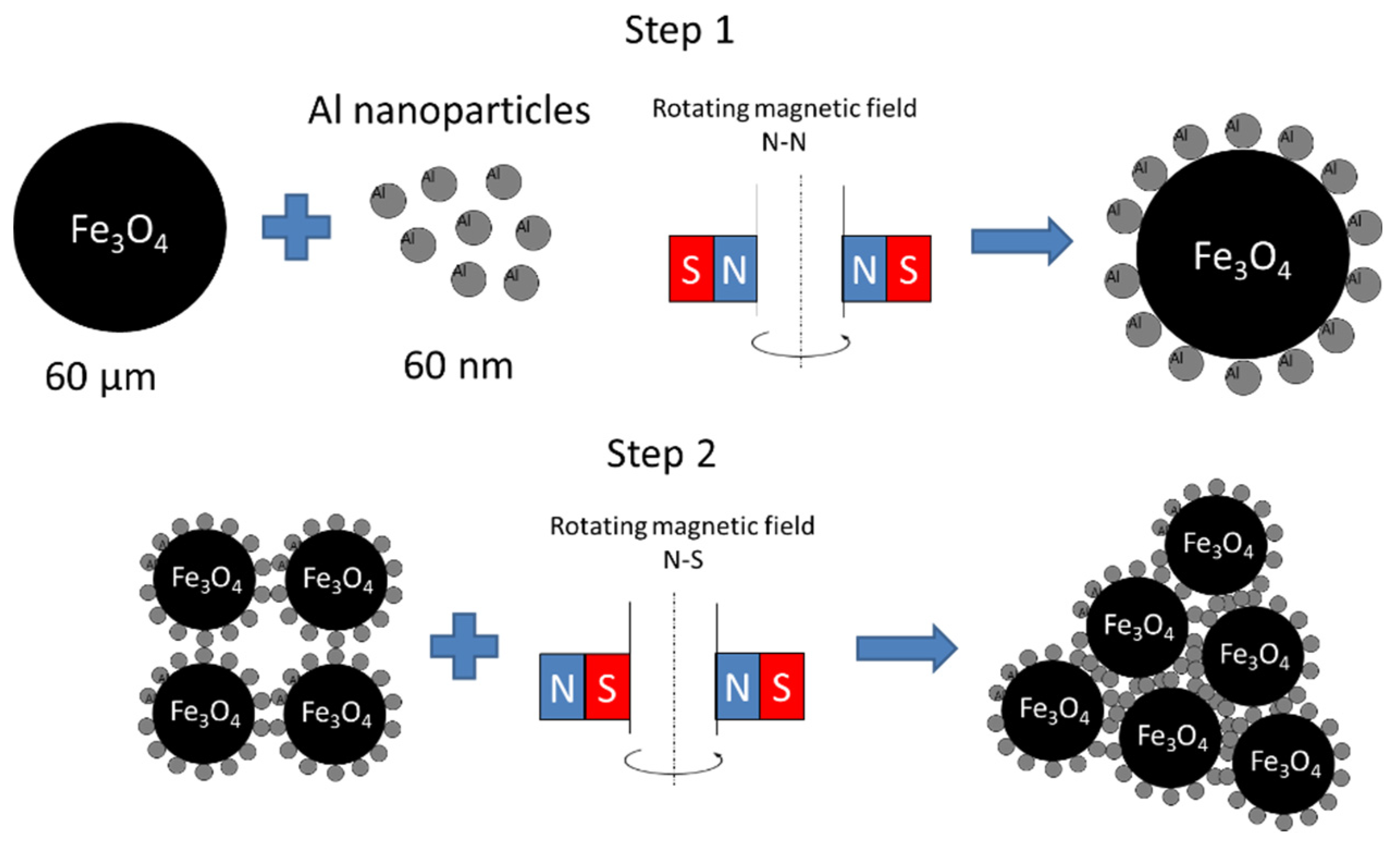

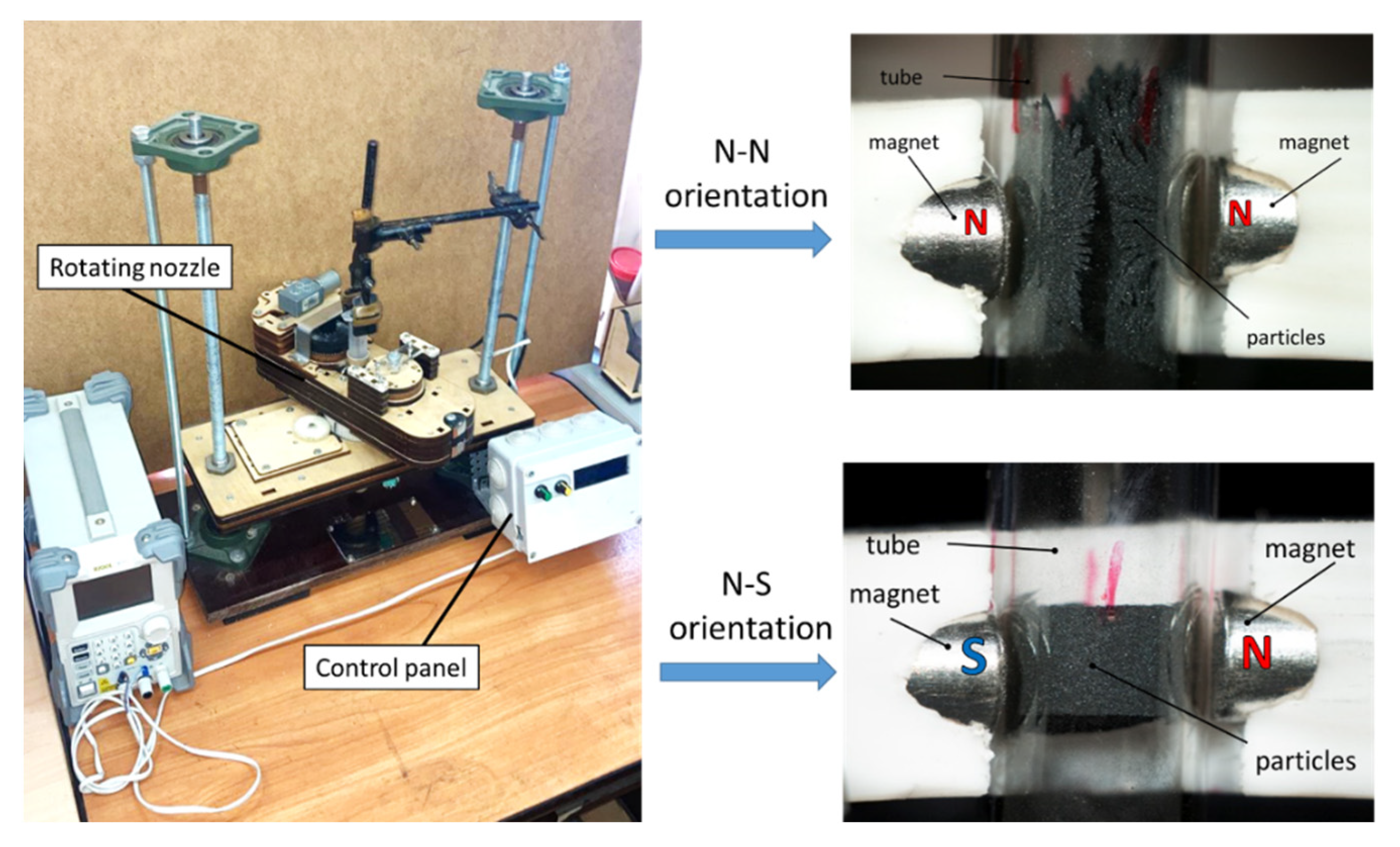

2.1. Preparation of Porous Fe3O4/Al Composite

2.2. Characterizations

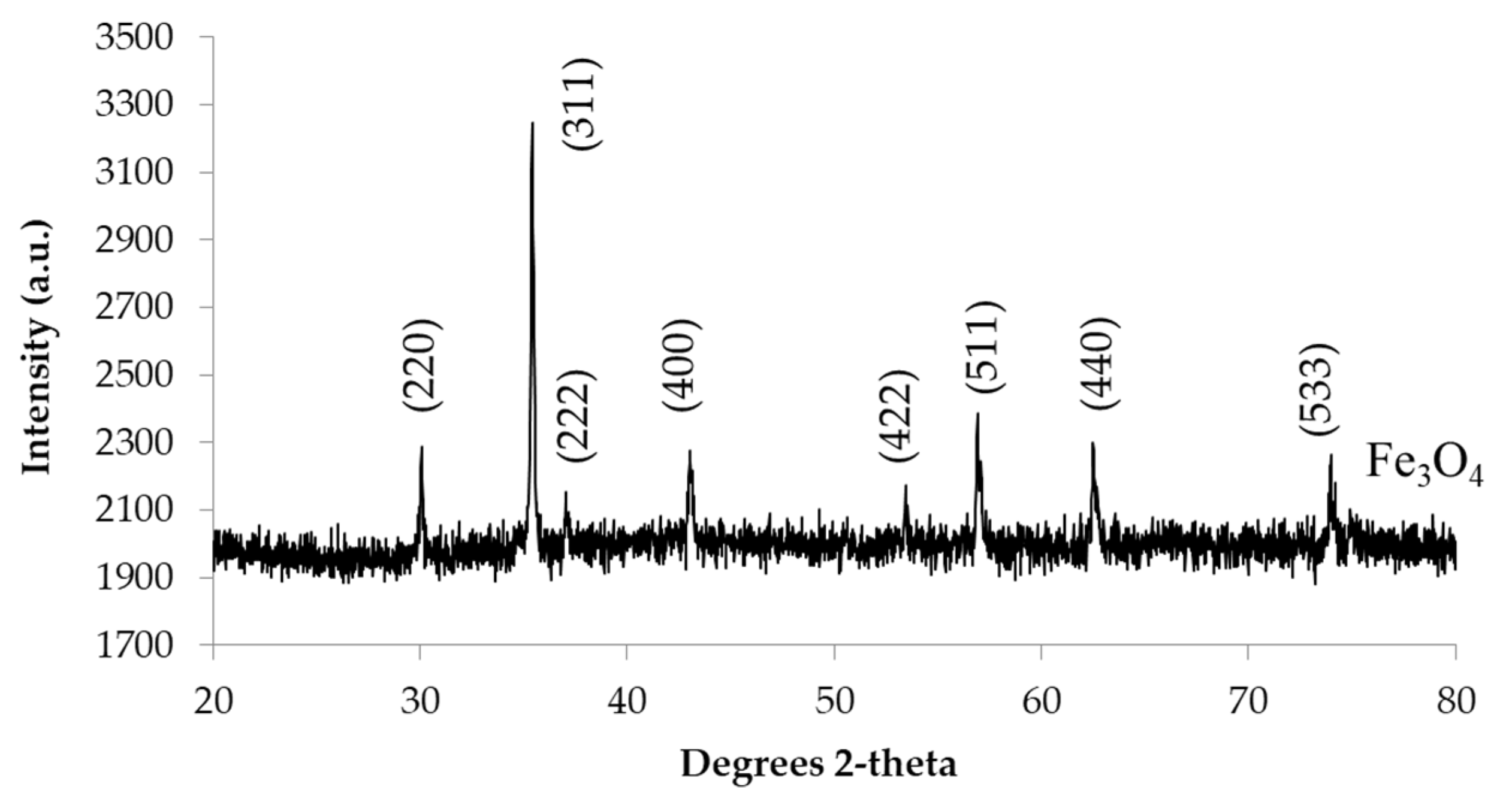

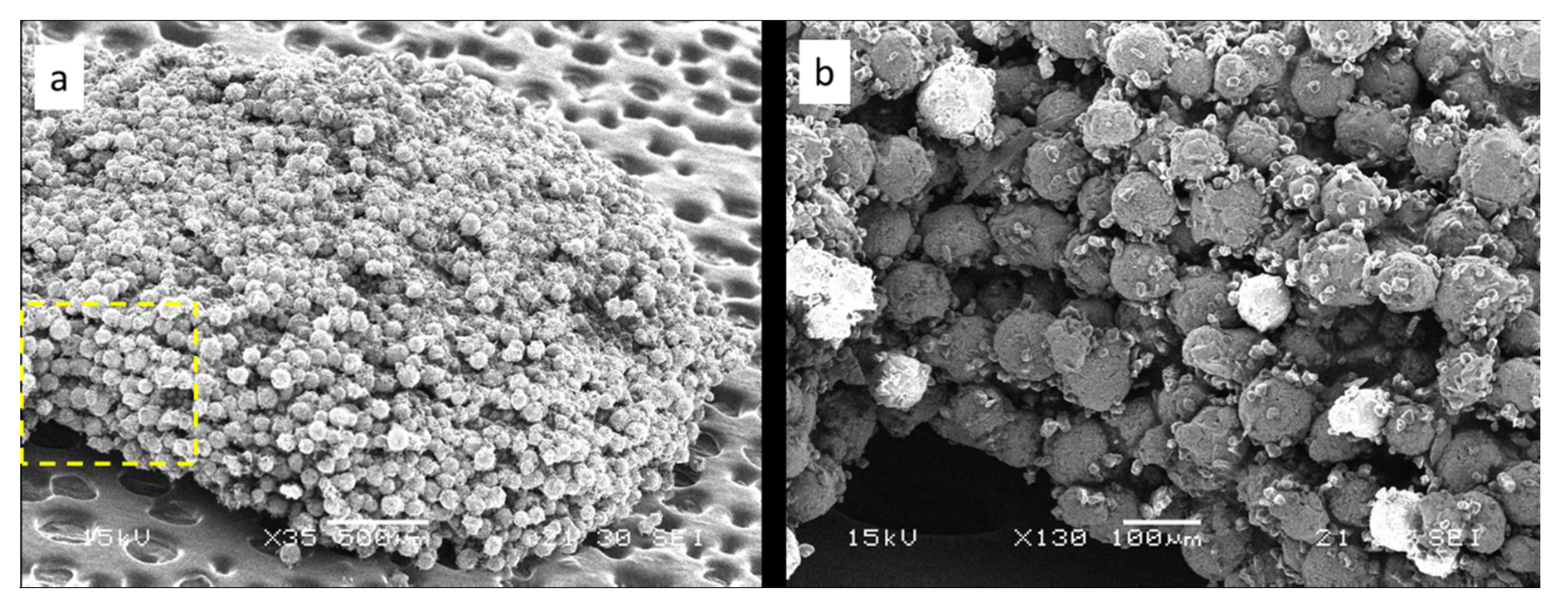

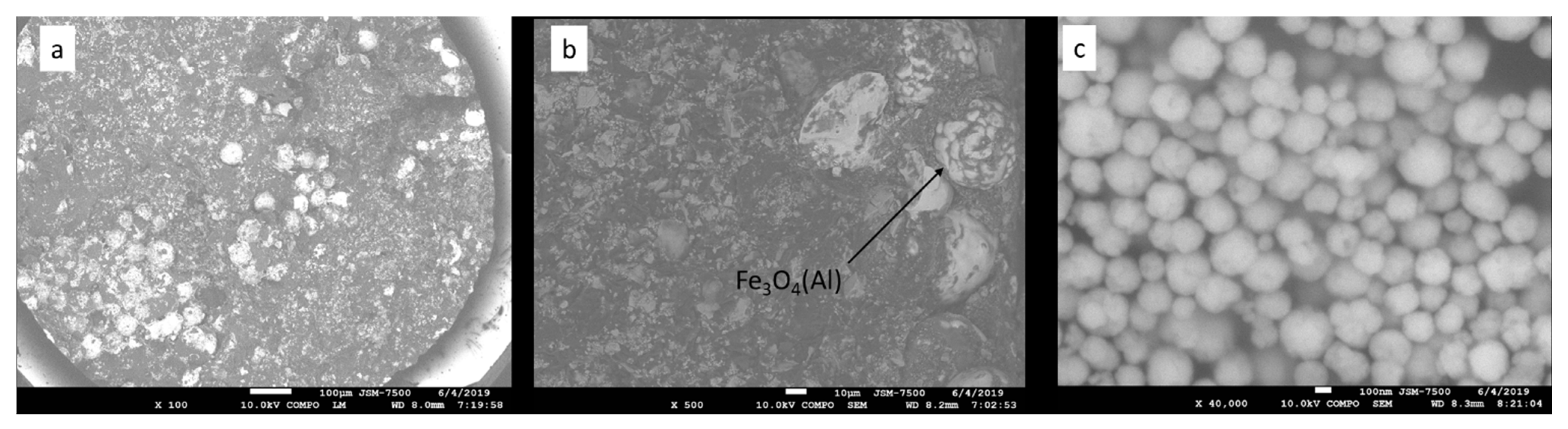

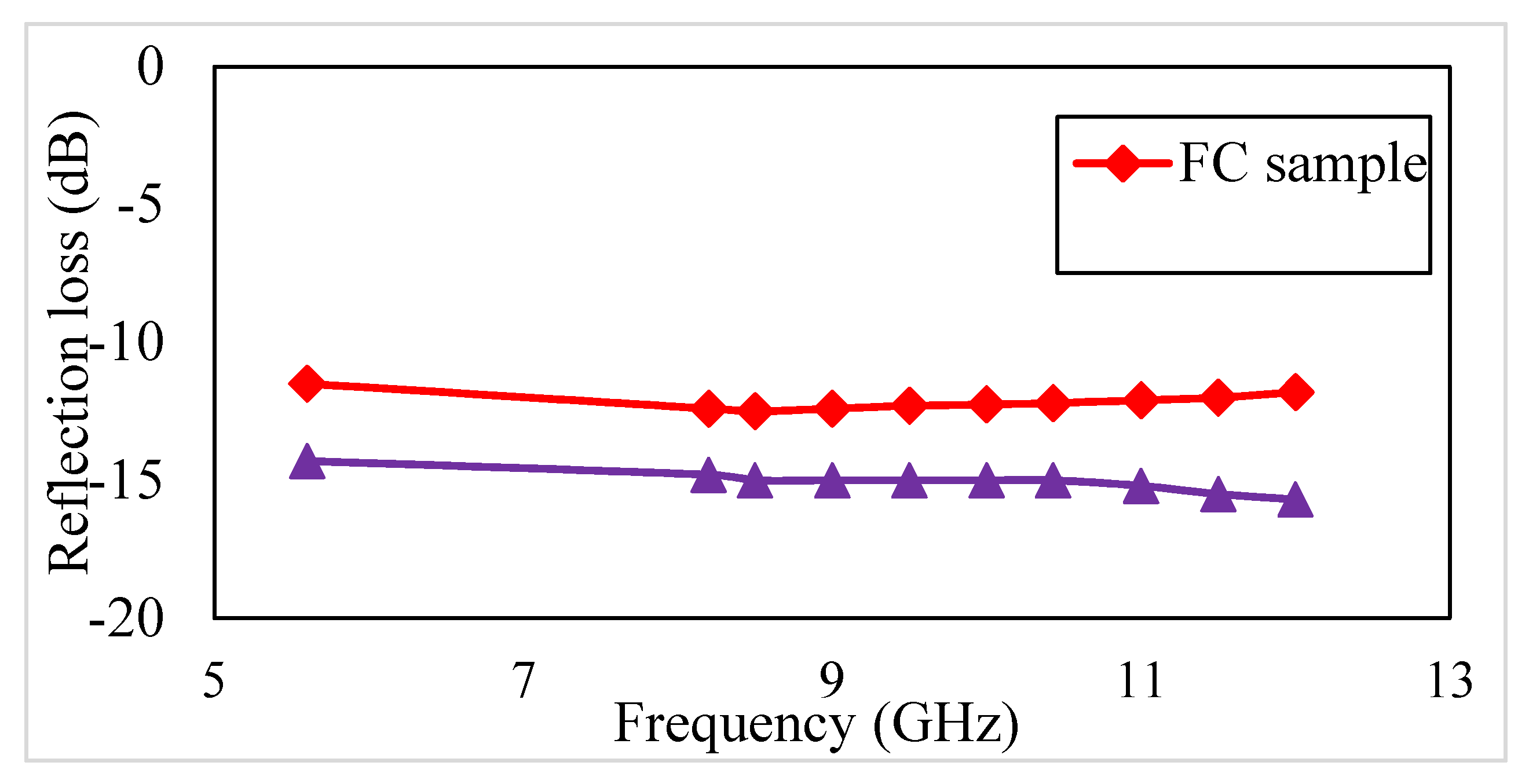

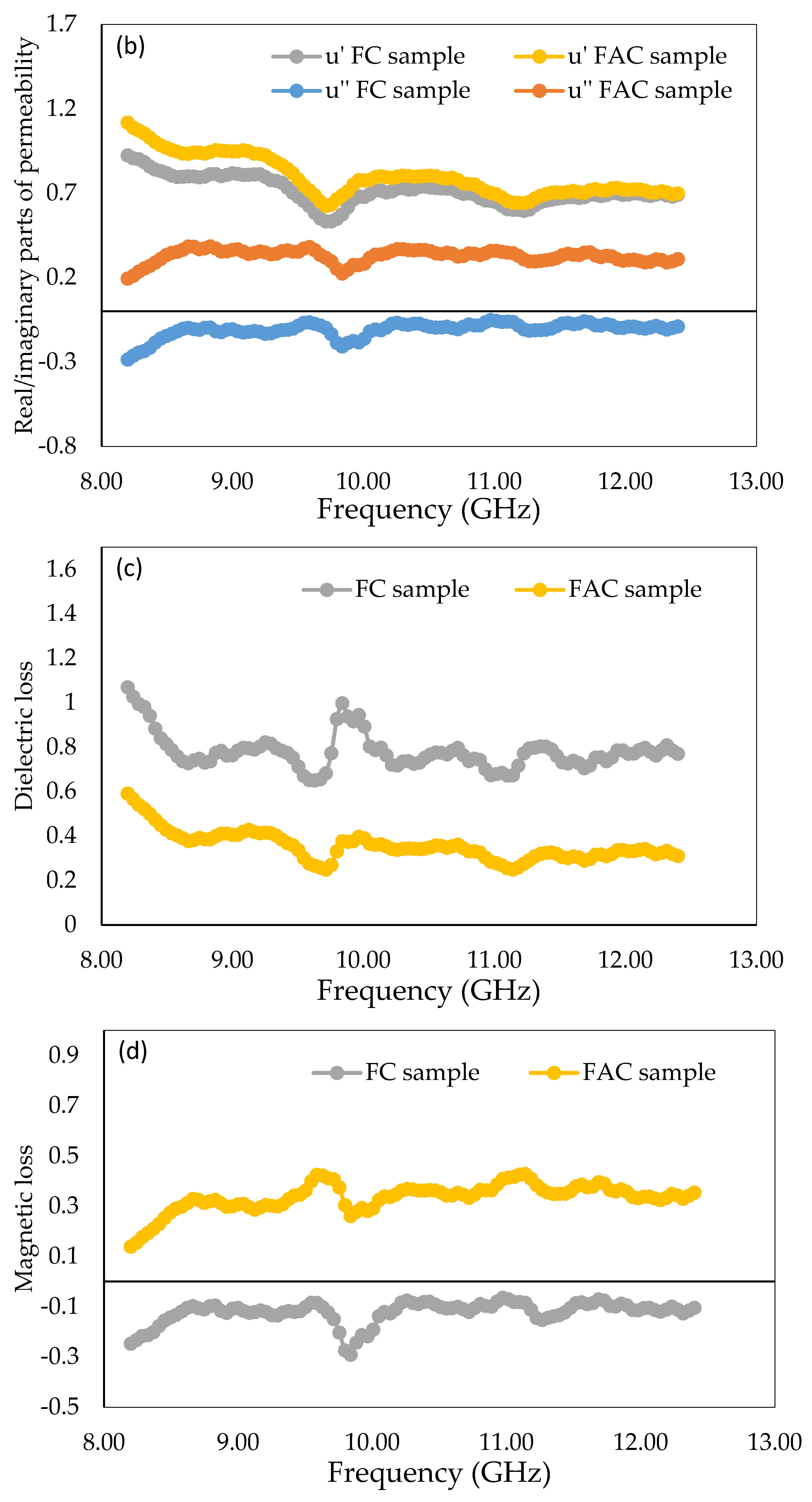

3. Results and Discussion

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, Y.; Nie, J.; Zhang, W.; Bao, C.; Ma, J.; Cao, Y. Preparation of soft magnetic composites for Fe particles coated with (NiZn)Fe2O4 via microwave treatment. J. Magn. Magn. Mater. 2015, 395, 245–250. [Google Scholar] [CrossRef]

- Jian, X.; Wu, B.; Wei, Y.; Dou, S.X.; Wang, X.; He, W.; Mahmood, N. Facile synthesis of Fe3O4/GCs composites and their enhanced microwave absorption properties. ACS Appl. Mater. Interfaces 2016, 8, 6101–6109. [Google Scholar] [CrossRef]

- Niu, M.; Pham-Huy, C.; He, H. Core-shell nanoparticles coated with molecularly imprinted polymers: A review. Microchim. Acta 2016, 10, 2677–2695. [Google Scholar] [CrossRef]

- Luo, F.; Luo, Z.; Hu, W.; Li, G.; Li, Y.; Liu, X.; Wang, J. Ultra-low inter-particle eddy current loss of Fe3Si/Al2O3 soft magnetic composites evolved from FeSiAl/Fe3O4 core-shell particles. J. Magn. Magn. Mater. 2019, 484, 218–224. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, H.; Ma, M.; Yang, Z. Facile synthesis of magnetically recoverable Fe3O4/Al2O3/molecularly imprinted TiO2 nanocomposites and its molecular recognitive photocatalytic degradation of target contaminant. J. Mol. Catal. A Chem. 2015, 402, 10–16. [Google Scholar] [CrossRef]

- Duan, W.; Li, X.; Wang, Y.; Qiang, R.; Tian, C.; Wang, N.; Du, Y. Surface functionalization of carbonyl iron with aluminum phosphate coating toward enhanced anti-oxidative ability and microwave absorption properties. Appl. Surf. Sci. 2018, 427, 594–602. [Google Scholar] [CrossRef]

- Liu, Q.; Cao, B.; Feng, C.; Zhang, W.; Zhu, S.; Zhang, D. High permittivity and microwave absorption of porous graphitic carbons encapsulating Fe nanoparticles. Compos. Sci. Technol. 2012, 13, 1632–1636. [Google Scholar] [CrossRef]

- Cui, C.K.; Du, Y.C.; Li, T.H.; Zheng, X.Y.; Wang, X.H.; Han, X.J. Synthesis of electromagnetic functionalized Fe3O4 microspheres/polyaniline composites by two-step oxidative polymerization. J. Phys. Chem. 2012, 116, 9523–9531. [Google Scholar] [CrossRef] [PubMed]

- Zong, M.; Huang, Y.; Zhao, Y.; Sun, X.; Qu, C.H.; Luo, D.D. Facile preparation, high microwave absorption and microwave absorbing mechanism of RGO-Fe3O4 composites. RSC Adv. 2013, 3, 23638–23648. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, D.Q.; Yang, Y.; Kang, F.Y.; Gu, J.L. Fe3O4/carbon composite nanofiber absorber with enhanced microwave absorption performance. Mater. Sci. Eng. B Adv. Funct. Solid State Mater. 2013, 178, 1–9. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Shi, Z.C.; Fan, R.H.; Gao, M.; Guo, J.Y.; Qi, X.G.; Sun, K.N. Microwave absorption properties of Fe@ Al2O3 nanoembedments prepared by mechanosynthesis. Mater. Chem. Phys. 2011, 130, 615–618. [Google Scholar] [CrossRef]

- Xuan, S.; Hao, L.; Jiang, W.; Gong, X.; Hu, Y.; Chen, Z. A facile method to fabricate carbon-encapsulated Fe3O4 core/shell composites. Nanotechnology 2007, 18, 035602. [Google Scholar] [CrossRef] [PubMed]

- Barbey, R.; Lavanant, L.; Paripovic, D.; Schuwer, N.; Sugnaux, C.; Tugulu, S.; Klok, H.A. Polymer brushes via surface-initiated controlled radical polymerization: Synthesis, characterization, properties and applications. Chem. Rev. 2009, 109, 5437–5527. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.Z.; Ding, J.; Jiang, H.B.; Neo, C.P.; Chen, L.F.; Ong, C.K. High frequency complex permeability of iron particles in a nonmagnetic matrix. J. Appl. Phys. 2006, 99, 083905. [Google Scholar] [CrossRef]

- Ding, D.; Wang, Y.; Li, X.; Qiang, R.; Xu, P.; Chu, W.; Han, X.; Du, Y. Rational design of core-shell Co@C microspheres for high-performance microwave absorption. Carbon 2017, 111, 722–732. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, L.; Wang, E. Influence of External Static Magnetic Fields on Properties of Metallic Functional Materials. Crystals 2017, 7, 374. [Google Scholar] [CrossRef]

- Milyutin, V.A.; Gervasyeva, I.V. Thermally activated transformations in alloys with different type of magnetic ordering under high magnetic field. J. Magn. Magn. Mater. 2019, 492, 165654. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, J.H.; Han, K.; Zhong, H.G.; Li, R.X.; Zhai, Q.J. Effect of Coil Configuration Design on Al Solidified Structure Refinement. Metals 2020, 10, 153. [Google Scholar] [CrossRef]

- Shorstkii, I.; Yakovlev, N. Synthesis of magnetically controlled Fe3O4 composites and their enhanced microwave absorption properties. Mater. Res. Express 2019, 6, 046104. [Google Scholar] [CrossRef]

- Shorstkii, I.; Yakovlev, N. Method of absorbing material formation based on magnetically controlled Fe3O4 particles. Inorg. Mater. Appl. Res. 2020, 11, 78–84. [Google Scholar] [CrossRef]

- Nicolson, A.M.; Ross, G.F. Measurement of the intrinsic properties of materials by time-domain techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Weir, W.B. Automatic measurement of complex dielectric constant and permeability at microwave frequencies. Proc. IEEE 1974, 62, 33–36. [Google Scholar] [CrossRef]

- Vonsovskyi, S.V. Magnetism. Moskow Sci. 1984, 22–67. (In Russian) [Google Scholar] [CrossRef]

- Getzlaff, M. Fundamentals of Magnetism; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; pp. 304–337. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shorstkii, I.; Sosnin, M. Microwave Absorption Properties of Fe3O4 Particles Coated with Al via Rotating Magnetic Field Method. Coatings 2021, 11, 621. https://doi.org/10.3390/coatings11060621

Shorstkii I, Sosnin M. Microwave Absorption Properties of Fe3O4 Particles Coated with Al via Rotating Magnetic Field Method. Coatings. 2021; 11(6):621. https://doi.org/10.3390/coatings11060621

Chicago/Turabian StyleShorstkii, Ivan, and Maxim Sosnin. 2021. "Microwave Absorption Properties of Fe3O4 Particles Coated with Al via Rotating Magnetic Field Method" Coatings 11, no. 6: 621. https://doi.org/10.3390/coatings11060621

APA StyleShorstkii, I., & Sosnin, M. (2021). Microwave Absorption Properties of Fe3O4 Particles Coated with Al via Rotating Magnetic Field Method. Coatings, 11(6), 621. https://doi.org/10.3390/coatings11060621