Variable-Angle Spectroscopic Ellipsometry of Graphene-Based Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

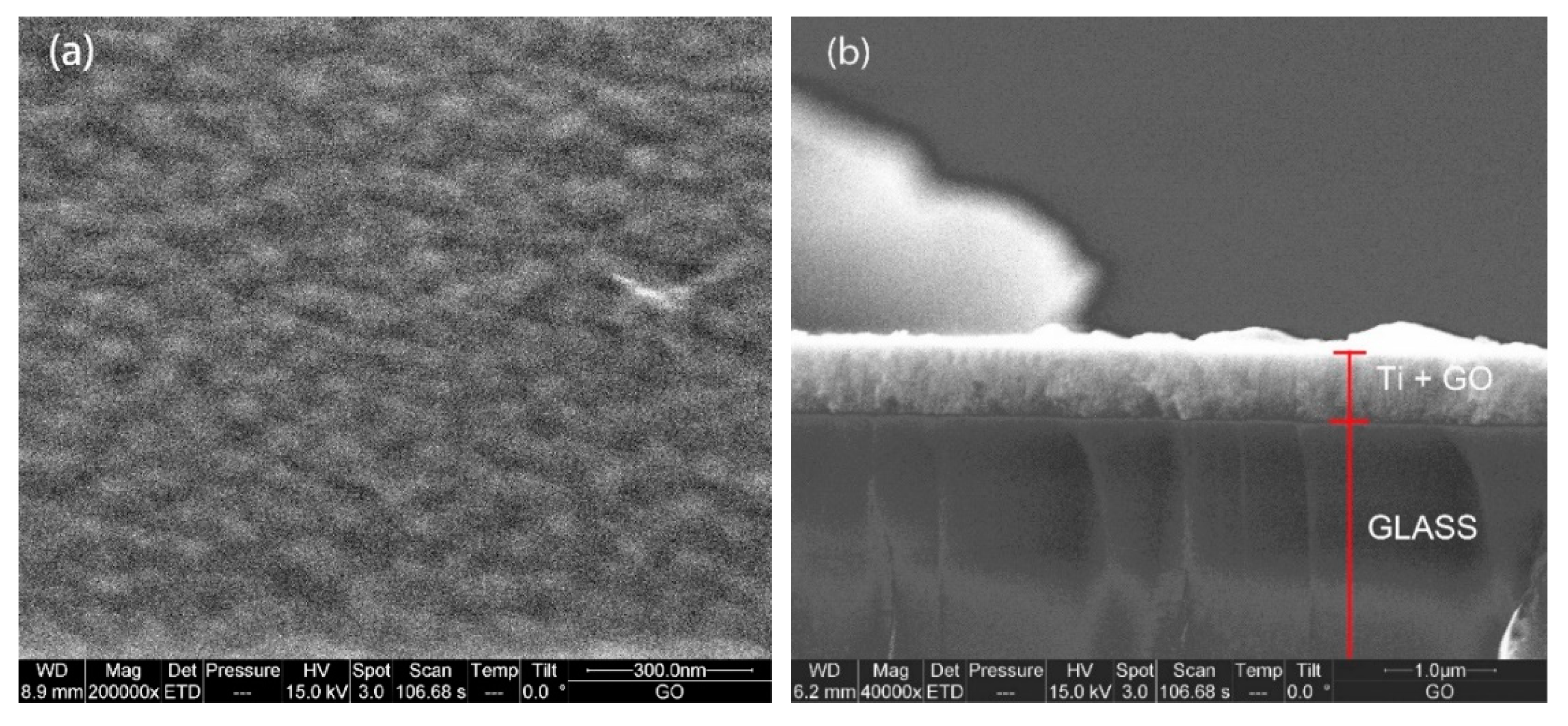

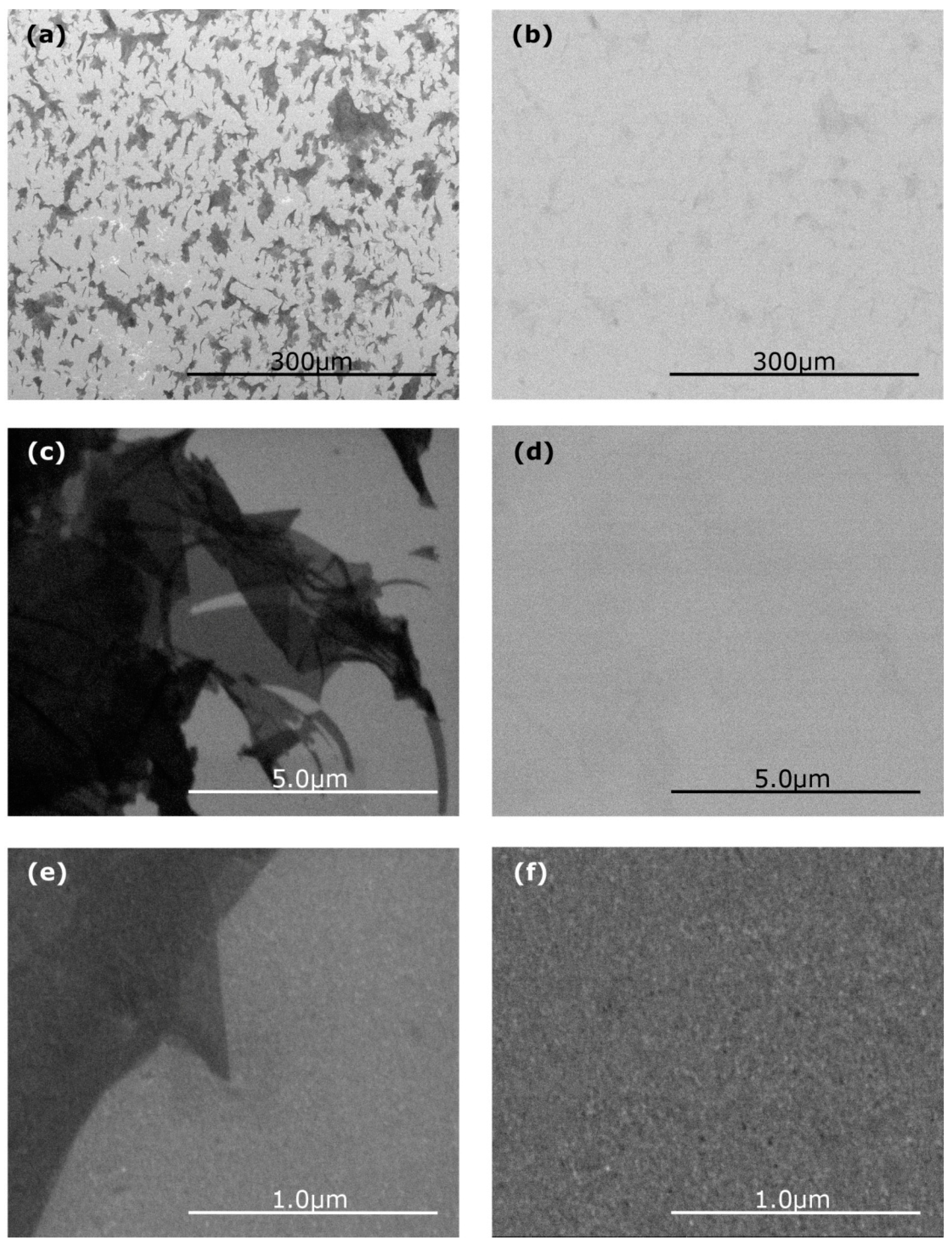

3.1. Interaction of Graphene Oxide with Magnetron-Sputtered Films

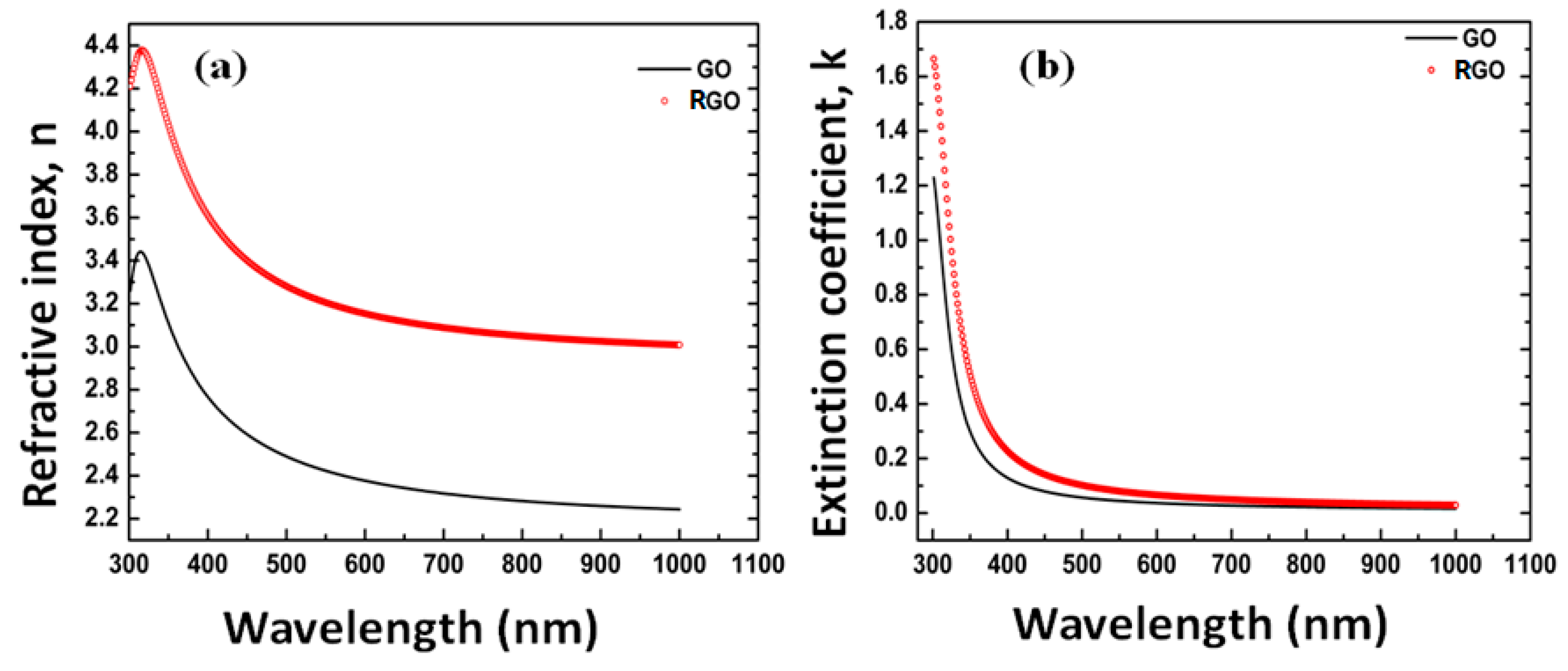

3.1.1. VASE Study of Electrophoretically Deposited Graphene Oxide and Reduced Graphene Oxide Thin Films

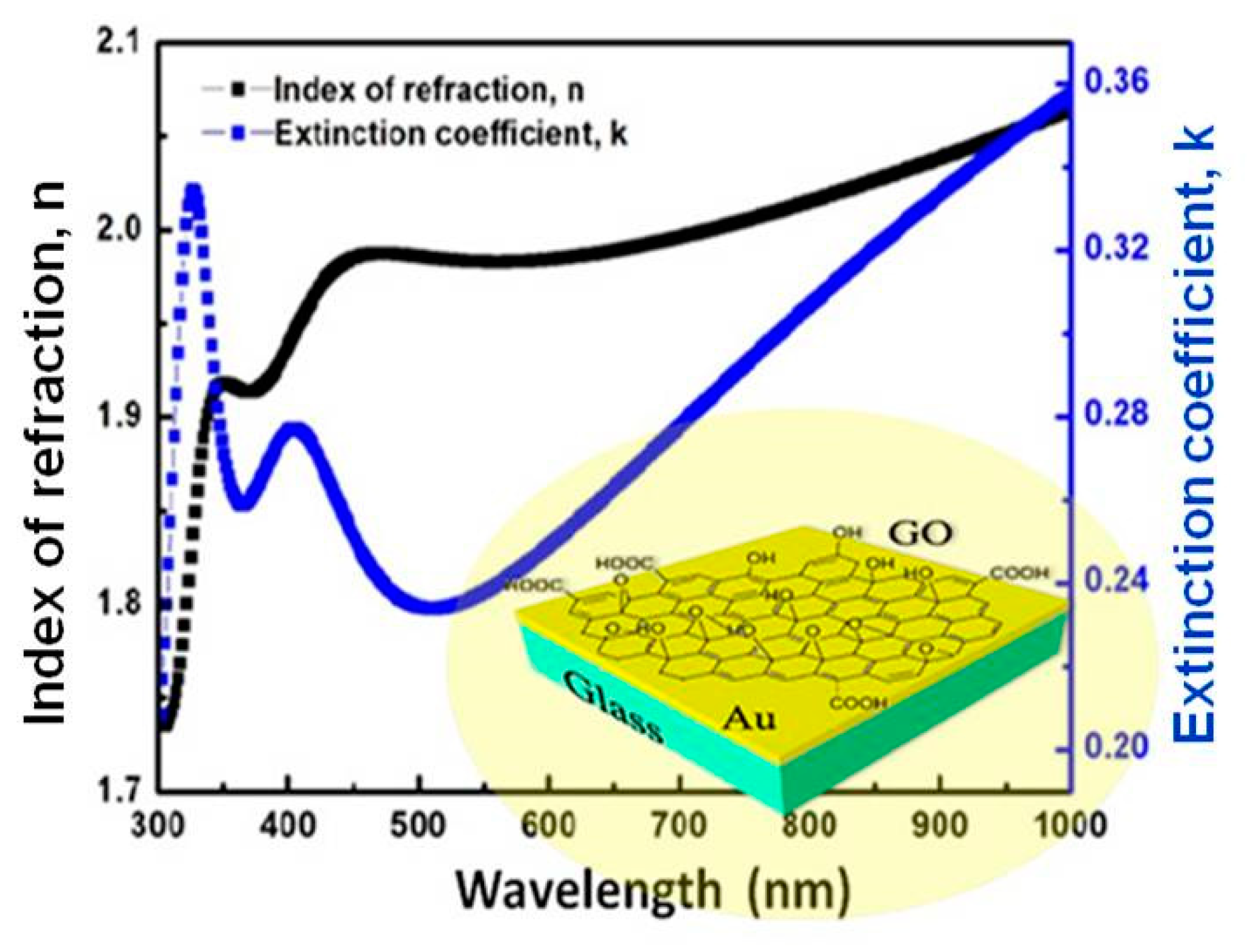

3.1.2. VASE Investigation of the Optical Properties of Graphene Oxide Dip-Coated on Magnetron-Sputtered Gold Thin Films

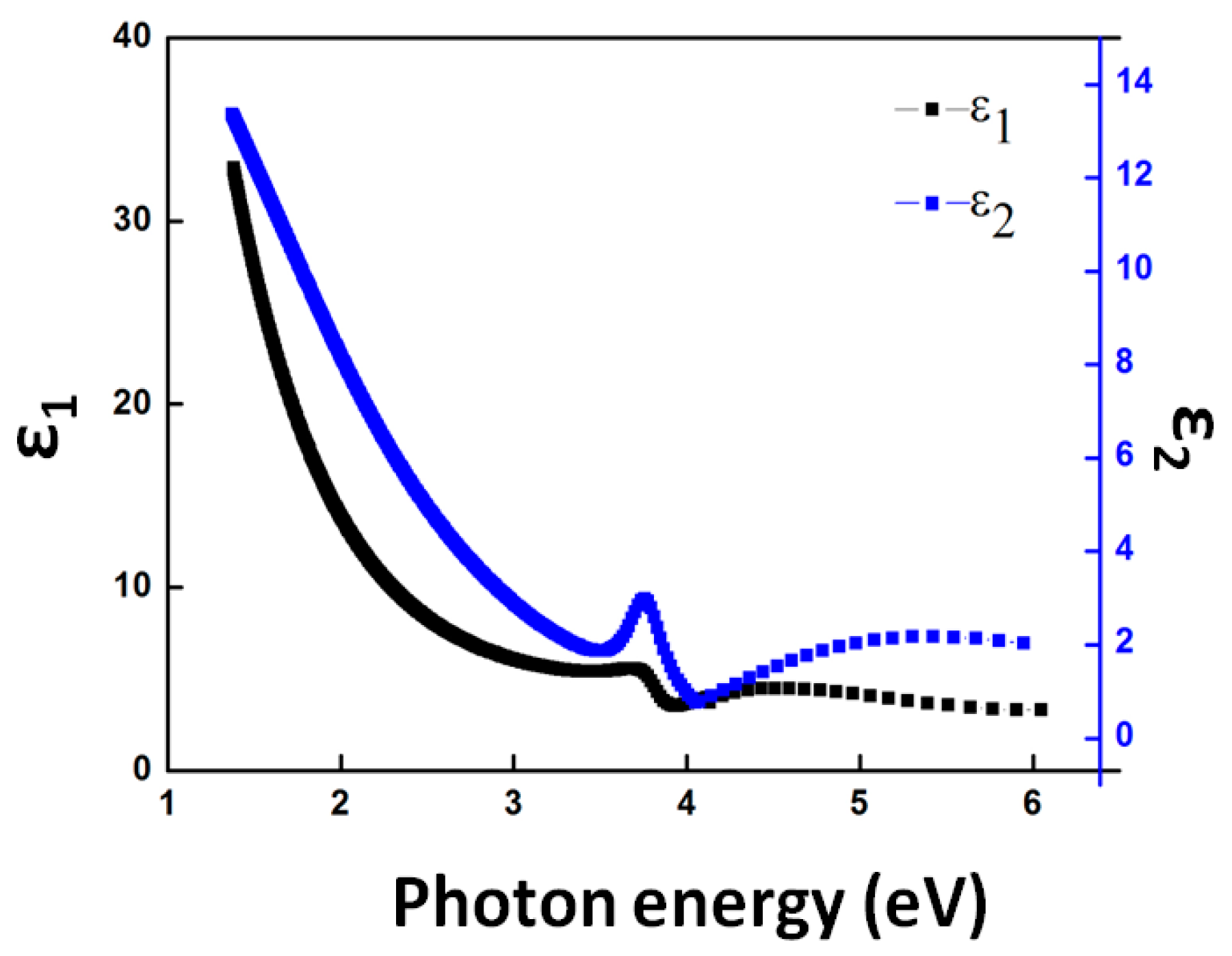

3.1.3. VASE Investigation of the Optical Properties of Graphene Oxide on Magnetron-Sputtered Silver Thin Films

3.2. Optical Properties of Graphene-Based Thin Films

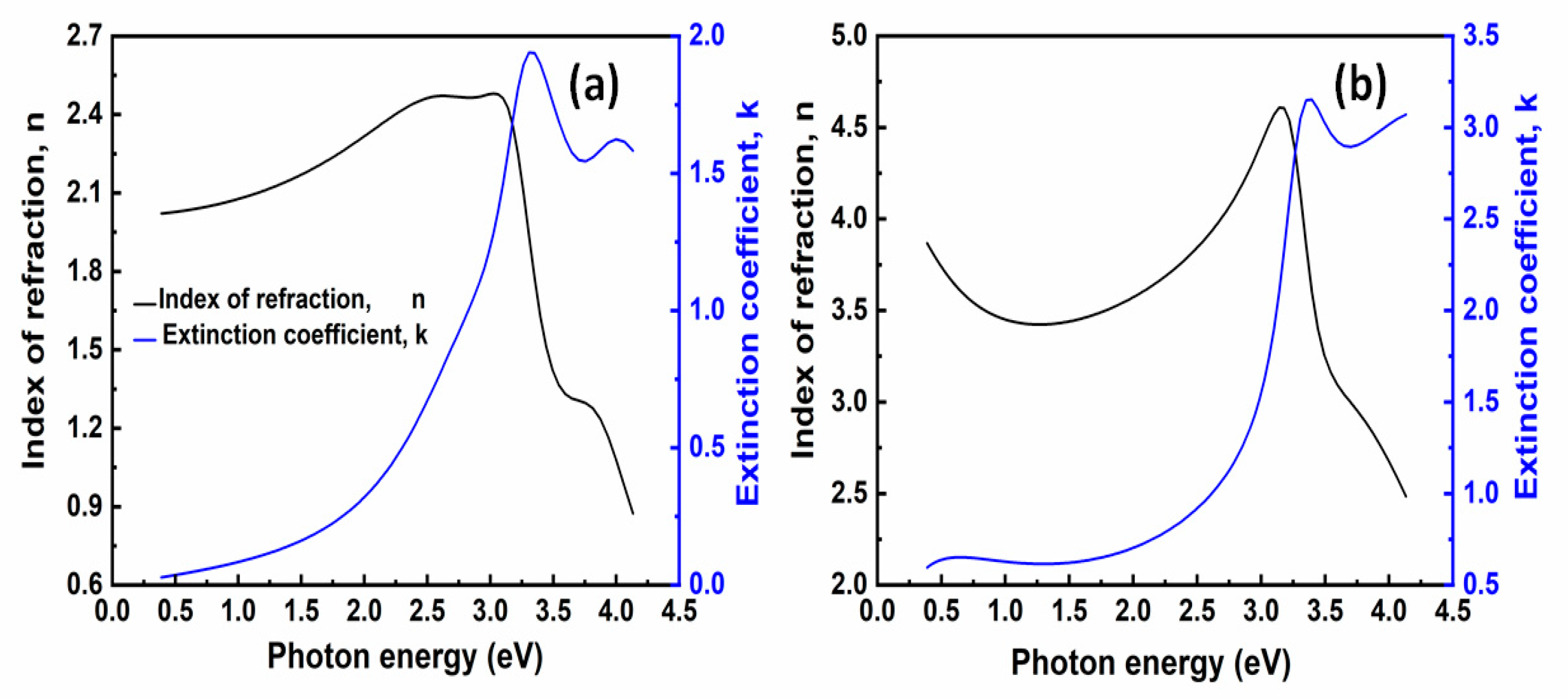

3.2.1. VASE Characterization of GO and Thermally Reduced RGO Thin Films on Si/SiO2 Substrates

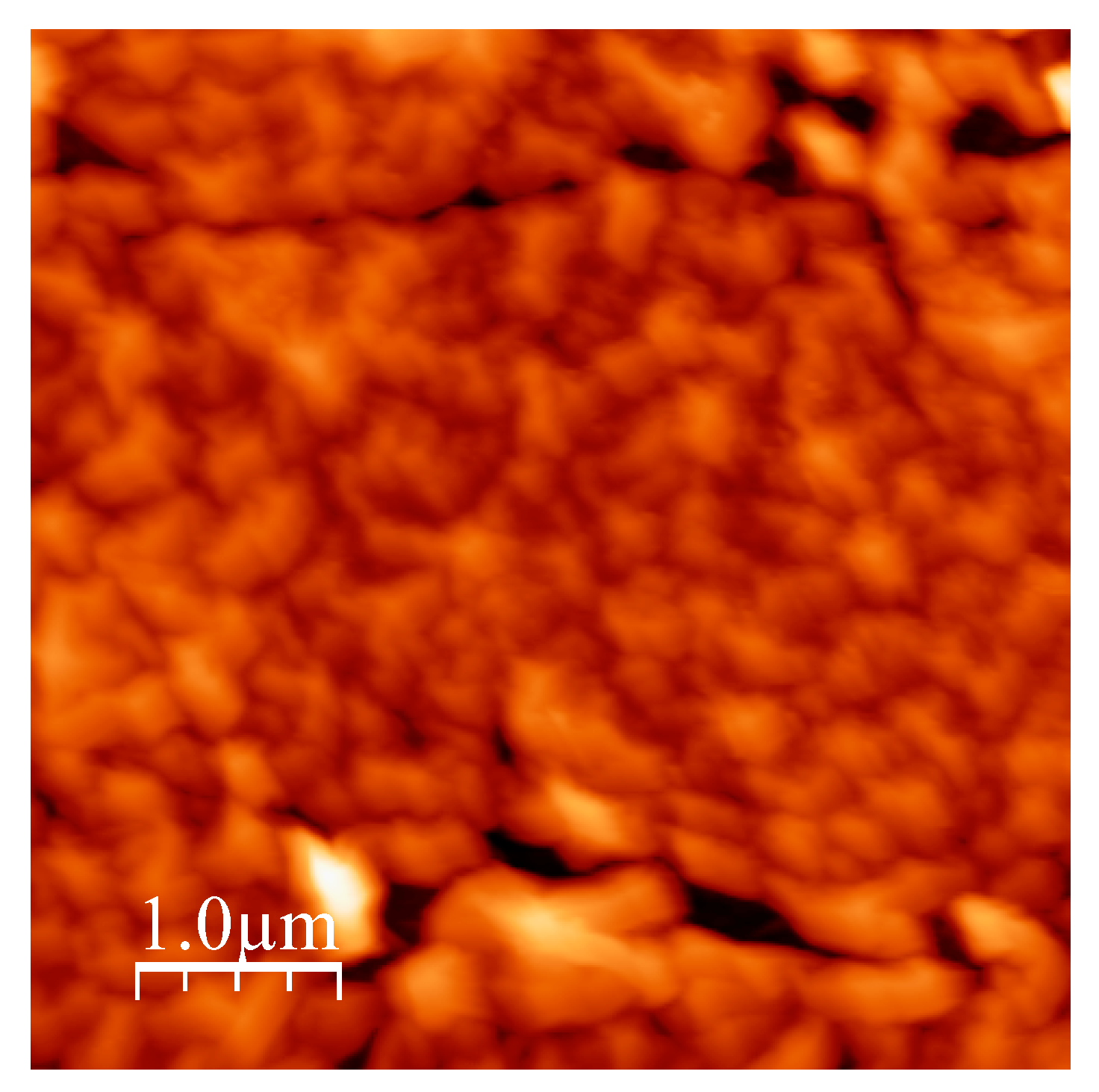

3.2.2. VASE Characterization of Reduced Graphene Oxide Stabilized with Poly(Sodium 4-Styrenesulfonate)

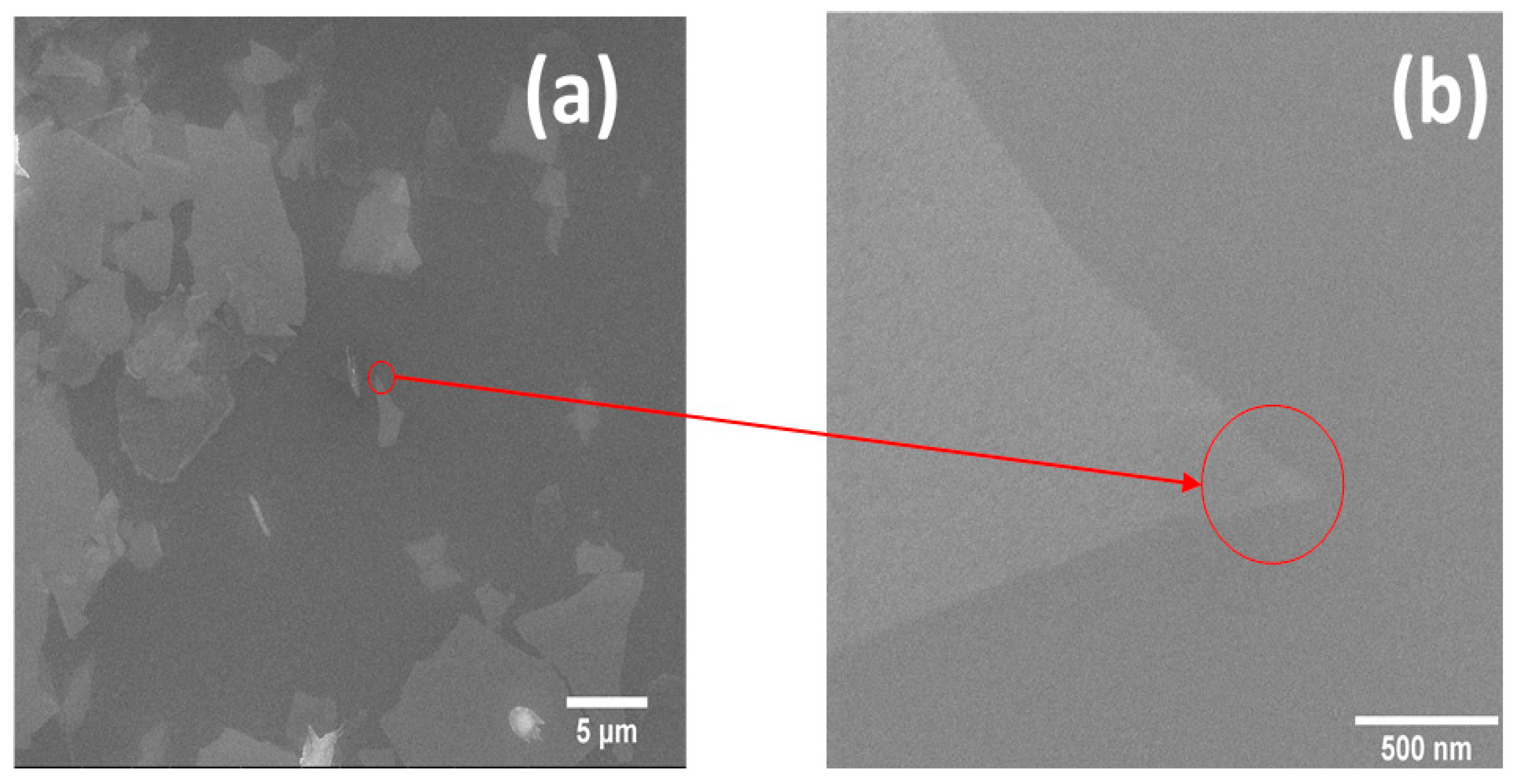

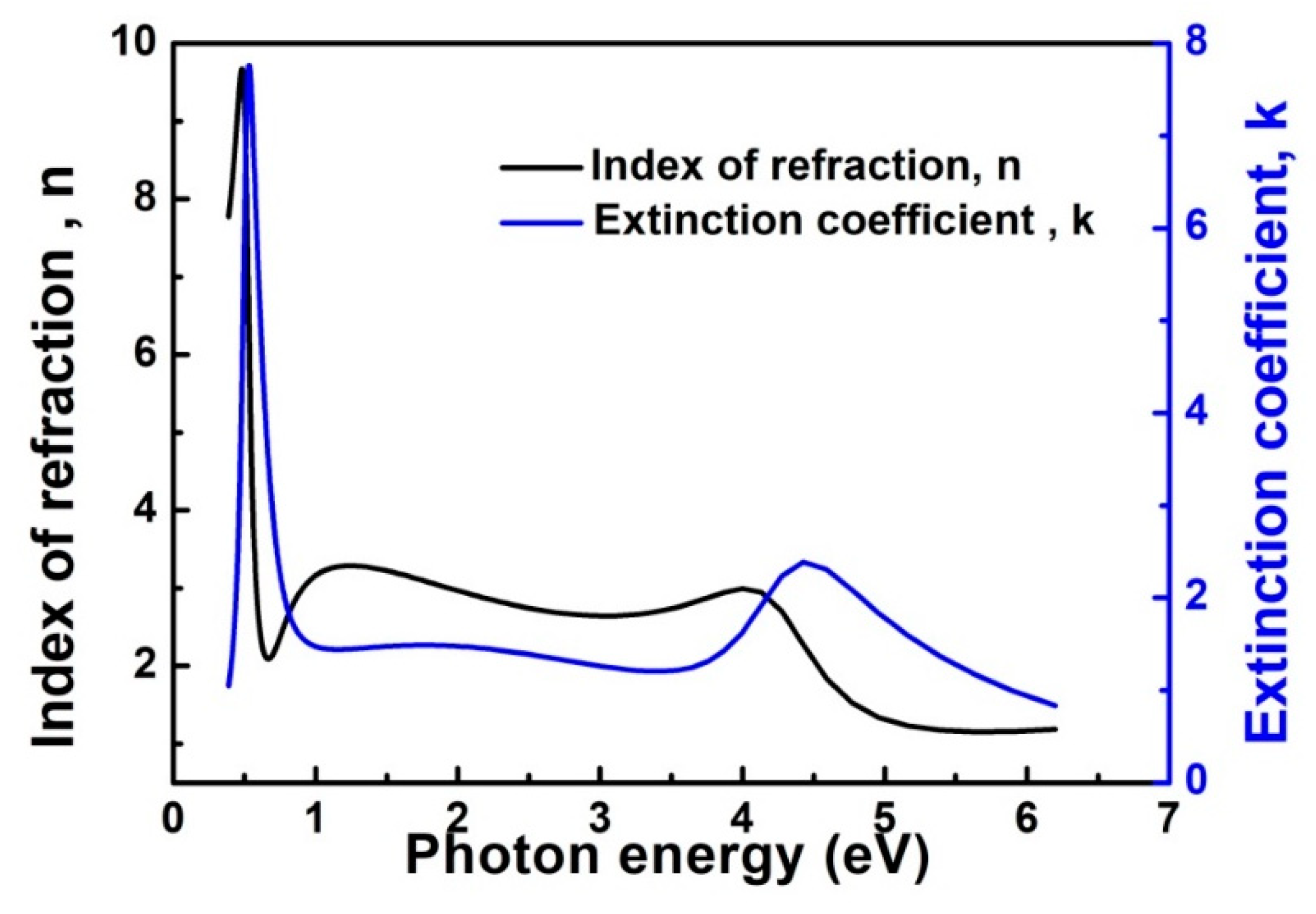

3.2.3. VASE Study of Graphene Nanoplatelets Thin Films on Si/SiO2 Substrates

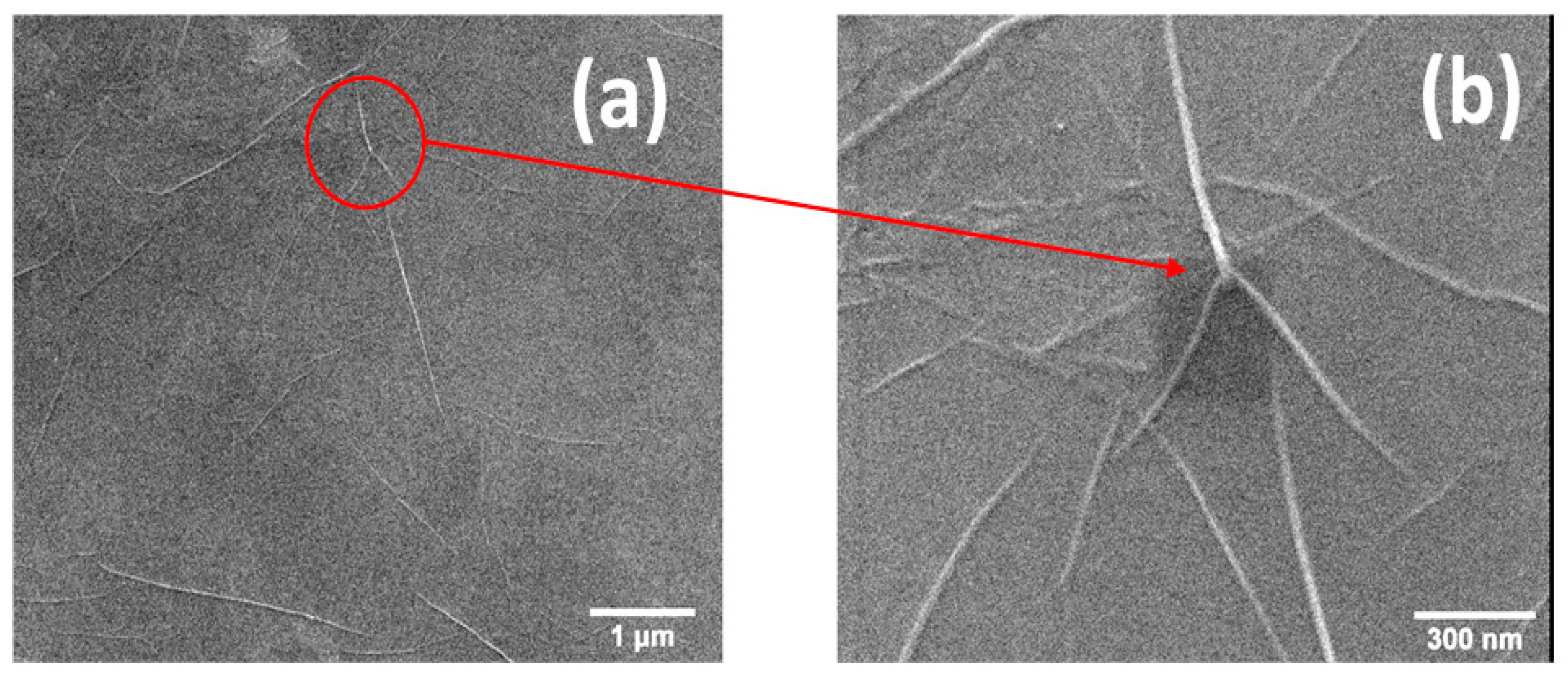

3.3. Optical Properties of CVD-Grown Monolayer, Bilayer, and Trilayer Graphene

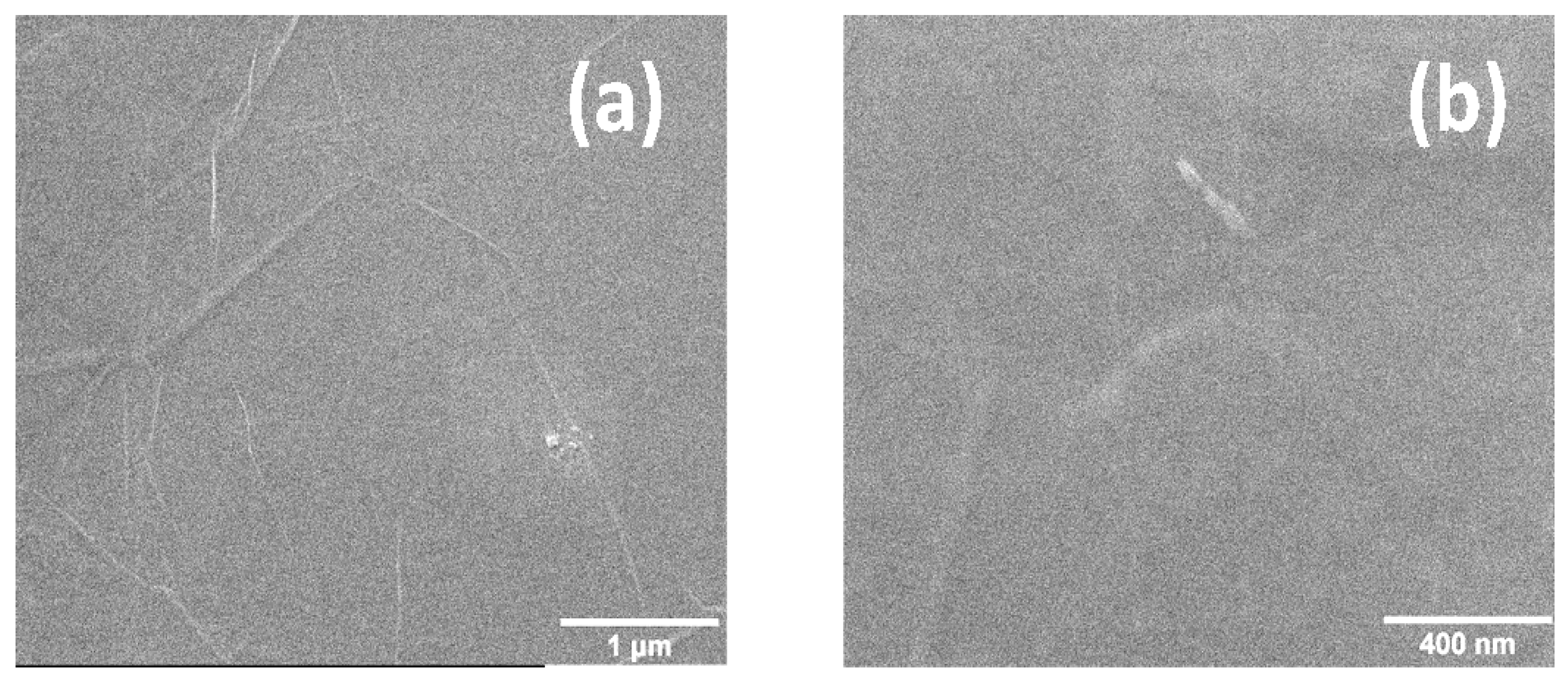

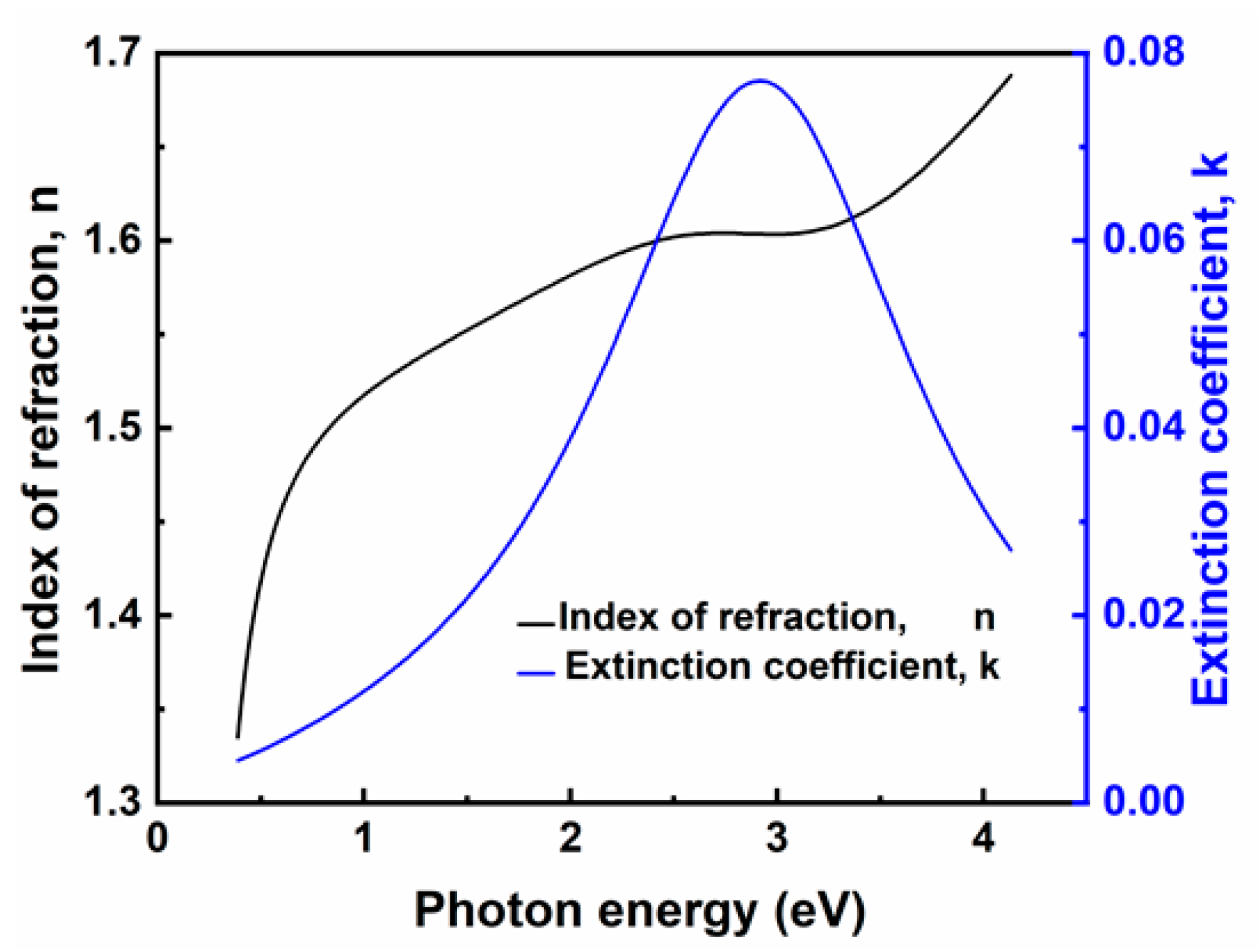

3.3.1. VASE Investigation of CVD-Grown Monolayer Graphene

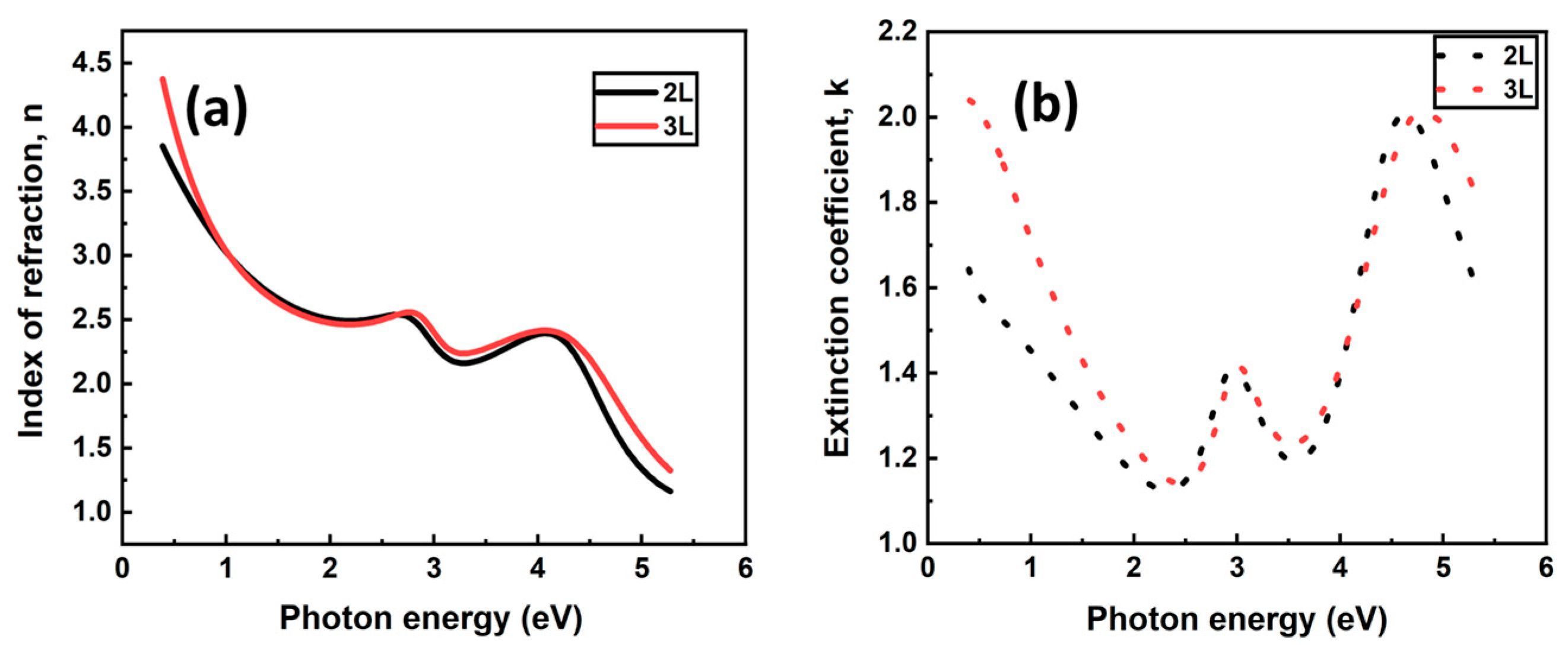

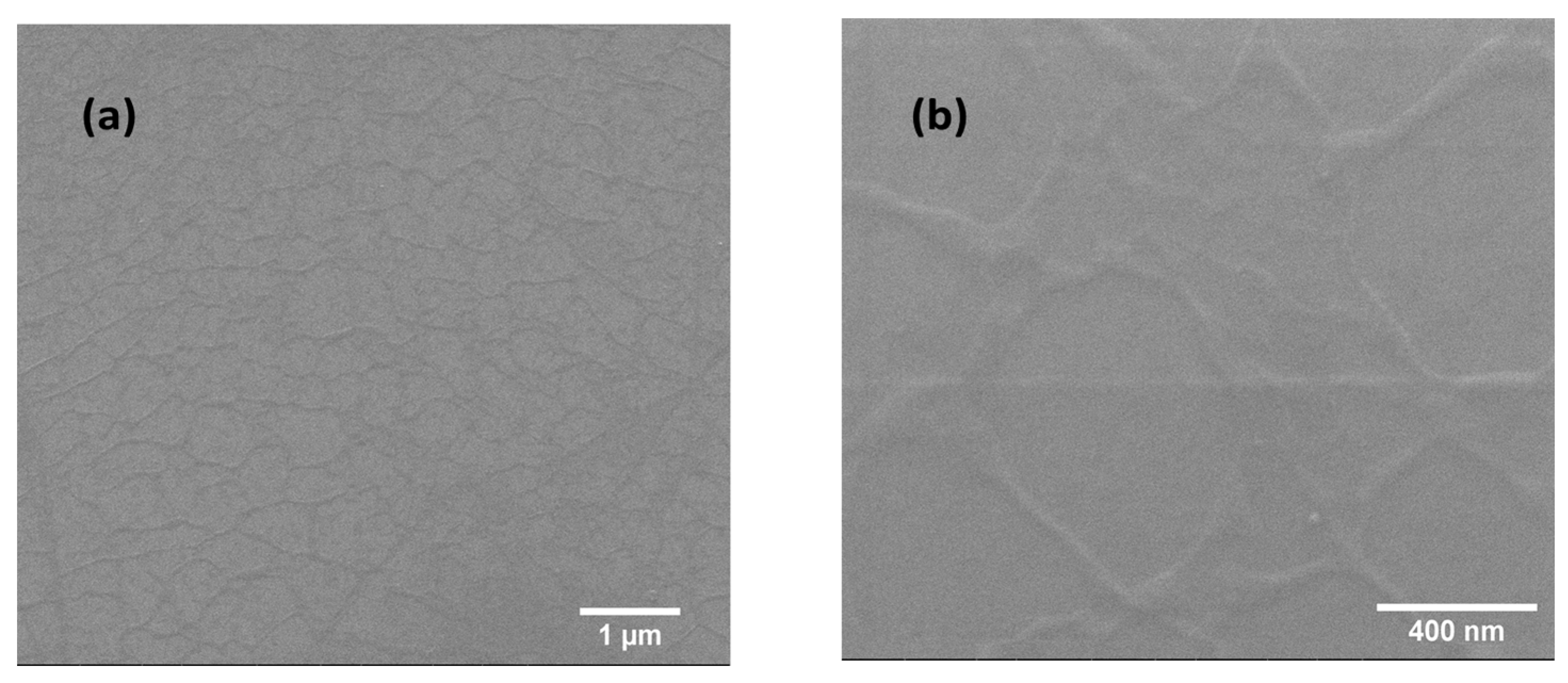

3.3.2. VASE Characterization of Turbostratic CVD-Grown Bilayer and Trilayer Graphene on Si/SiO2

3.3.3. VASE Characterization of Turbostratic CVD-Grown Monolayer, Bilayer and Trilayer Graphene on PET

4. Conclusions and Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zheng, Q.; Li, Z.; Yang, J.; Kim, J.-K. Graphene oxide-based transparent conductive films. Prog. Mater. Sci. 2014, 64, 200–247. [Google Scholar] [CrossRef]

- Bouten, P.C.P.; Slikkerveer, P.J.; Leterrier, Y. Mechanics of ITO on plastic substrates for flexible displays. Flex. Flat Panel Displays 2005, 99–120. [Google Scholar] [CrossRef]

- Geim, A.K.N.; Novoselov, K.S. The Rise of Graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Manasoglu, G.; Celen, R.; Kanik, M.; Ulcay, Y. An investigation on the thermal and solar properties of graphene-coated polyester fabrics. Coatings 2021, 11, 125. [Google Scholar] [CrossRef]

- Abakah, R.R.; Huang, F.; Hu, Q.; Wang, Y.; Jing, L. Comparative study of corrosion properties of different graphene nanoplate/epoxy composite coatings for enhanced surface barrier protection. Coatings 2021, 11, 285. [Google Scholar] [CrossRef]

- Dou, B.; Xiao, H.; Lin, X.; Zhang, Y.; Zhao, S.; Duan, S.; Gao, X.; Fang, Z. Investigation of the anti-corrosion properties of fluorinated graphene-modified waterborne epoxy coatings for carbon steel. Coatings 2021, 11, 254. [Google Scholar] [CrossRef]

- Baibarac, M.; Daescu, M.; Fejer, S.N. Optical evidence for the assembly of sensors based on reduced graphene oxide and polydiphenylamine for the detection of epidermal growth factor receptor. Coatings 2021, 11, 258. [Google Scholar] [CrossRef]

- Imae, I. Reduction of graphene oxide using an environmentally friendly method and its application to energy-related materials. Coatings 2021, 11, 297. [Google Scholar] [CrossRef]

- Zhou, Z.-M.; Wang, K.; Wang, Y.-H. High Performance of thermoplastic polyurethane-graphene oxide self-healing composite film. coatings 2021, 11, 128. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Li, S.; Geng, Y.; Hou, D. Influence of a new type of graphene oxide/silane composite emulsion on the permeability resistance of damaged concrete. Coatings 2021, 11, 208. [Google Scholar] [CrossRef]

- Yung, T.-Y.; Lu, Y.-C.; Chen, J.-S.; Cheng, Y.-W.; Liu, T.-Y.; Chen, P.-T. Reinforcement of epoxy resin by additives of amine-functionalized graphene nanosheets. Coatings 2021, 11, 35. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zhou, C. Review of chemical vapor deposition of graphene and related applications. Acc. Chem. Res. 2013, 46, 2329–2339. [Google Scholar] [CrossRef] [PubMed]

- Ahmadivand, A.; Gerislioglu, B.; Ramezani, Z. Gated graphene island-enabled tunable charge transfer plasmon terahertz metamodulator. Nanoscale 2019, 11, 8091–8095. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Uzlu, B.; Shaygan, M.; Otto, M.; Ribeiro, M.; Marín, E.G.; Iannaccone, G.; Fiori, G.; Elsayed, M.S.; Negra, R.; et al. Flexible one-dimensional metal–insulator–graphene diode. ACS Appl. Electron. Mater. 2019, 1, 945–950. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, J.-H. Graphene for flexible and wearable device applications. Carbon N. Y. 2017, 120, 244–257. [Google Scholar] [CrossRef]

- Zhu, M.; Li, X.; Guo, Y.; Li, X.; Sun, P.; Zang, X.; Wang, K.; Zhong, M.; Wu, D.; Zhu, H. Vertical junction photodetectors based on reduced graphene oxide/silicon Schottky diodes. Nanoscale 2014, 6, 4909–4914. [Google Scholar] [CrossRef]

- Naumov, A.V. Optical properties of graphene oxide. In Graphene Oxide: Fundamentals and Applications; Dimiev, A.M., Eigler, S., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 147–174. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon N. Y. 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Chua, C.K.; Pumera, M. Chemical reduction of graphene oxide: A synthetic chemistry viewpoint. Chem. Soc. Rev. 2014, 43, 291–312. [Google Scholar] [CrossRef]

- Jung, I.; Dikin, D.A.; Piner, R.D.; Ruoff, R.S. Tunable electrical conductivity of individual graphene oxide sheets reduced at “low” temperatures. Nano Lett. 2008, 8, 4283–4287. [Google Scholar] [CrossRef]

- MAunkor, T.H.; Mahbubul, I.M.; Saidur, R.; Metselaar, H.S.C. The green reduction of graphene oxide. RSC Adv. 2016, 6, 27807–27828. [Google Scholar] [CrossRef]

- Yan, W.; Yu, W.-J.; Wang, L.; Zhang, D.; Ge, X.-Q.; Hang, J.-Z.; Deng, W.; Shi, L.-Y. Preparation of partially reduced graphene oxide nanosheets/poly(sodium 4-styrenesulfonate) composite with high capacitance. Electrochim. Acta 2014, 147, 257–264. [Google Scholar] [CrossRef]

- Moosa, A.A.; Sa, A.R.; Ibrahim, M. Mechanical and electrical properties of graphene nanoplates and carbon-nanotubes hybrid epoxy. Nanocomposites 2016, 6, 157–165. [Google Scholar] [CrossRef]

- Laurenzi, S.; Santonicola, M.G. 7—Impact Response of Advanced Composite Structures Reinforced by Carbon Nanoparticles; Lopresto, V., Langella, A., Abrate, S., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 217–235. [Google Scholar] [CrossRef]

- Li, W.; Cheng, G.; Liang, Y.; Tian, B.; Liang, X.; Peng, L.; Walker, A.R.H.; Gundlach, D.J.; Nguyen, N.V. Broadband optical properties of graphene by spectroscopic ellipsometry. Carbon N. Y. 2016, 99, 348–353. [Google Scholar] [CrossRef]

- Tompkins, H.; Irene, E.A. Handbook of Ellipsometry; William Andrew: Norwich, NY, USA, 2005. [Google Scholar]

- Weber, J.W.; Calado, V.E.; van de Sanden, M.C.M. Optical constants of graphene measured by spectroscopic ellipsometry. Appl. Phys. Lett. 2010, 97, 91904. [Google Scholar] [CrossRef]

- Nelson, F.J.; Kamineni, V.K.; Zhang, T.; Comfort, E.S.; Lee, J.U.; Diebold, A.C. Optical properties of large-area polycrystalline chemical vapor deposited graphene by spectroscopic ellipsometry. Appl. Phys. Lett. 2010, 97, 253110. [Google Scholar] [CrossRef]

- Matković, A.; Beltaos, A.; Milićević, M.; Ralević, U.; Vasić, B.; Jovanović, D.; Gajić, R. Spectroscopic imaging ellipsometry and Fano resonance modeling of graphene. J. Appl. Phys. 2012, 112, 123523. [Google Scholar] [CrossRef]

- Schöche, S.; Hong, N.; Khorasaninejad, M.; Ambrosio, A.; Orabona, E.; Maddalena, P.; Capasso, F. Optical properties of graphene oxide and reduced graphene oxide determined by spectroscopic ellipsometry. Appl. Surf. Sci. 2017, 421, 778–782. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, P.; Sun, Q.Q.; Wan, L.; Li, J.; Chen, L.Y.; Zhang, D.W.; Wang, X.B. Optical investigation of reduced graphene oxide by spectroscopic ellipsometry and the band-gap tuning. Appl. Phys. Lett. 2011, 99, 141911. [Google Scholar] [CrossRef]

- Politano, G.; Vena, C.; Desiderio, G.; Versace, C. Variable angle spectroscopic ellipsometry characterization of reduced graphene oxide stabilized with poly(sodium 4-styrenesulfonate). Coatings 2020, 743. [Google Scholar] [CrossRef]

- Politano, G.G.; Vena, C.; Desiderio, G.; Versace, C. Variable angle spectroscopic ellipsometry characterization of turbostratic CVD-grown bilayer and trilayer graphene. Opt. Mater. 2020, 107, 110165. [Google Scholar] [CrossRef]

- Politano, G.G.; Nucera, A.; Castriota, M.; Desiderio, G.; Vena, C.; Versace, C. Spectroscopic and morphological study of graphene nanoplatelets thin films on Si/SiO2 substrates. Mater. Res. Express. 2019, 6, 106432. [Google Scholar] [CrossRef]

- Politano, G.G.; Cazzanelli, E.; Versace, C.; Castriota, M.; Desiderio, G.; Davoli, M.; Vena, C.; Bartolino, R. Micro-Raman investigation of Ag/graphene oxide/Au sandwich structure. Mater. Res. Express. 2019, 6, 075605. [Google Scholar] [CrossRef]

- Castriota, M.; Politano, G.G.; Vena, C.; de Santo, M.P.; Desiderio, G.; Davoli, M.; Cazzanelli, E.; Versace, C. Variable Angle Spectroscopic Ellipsometry investigation of CVD-grown monolayer graphene. Appl. Surf. Sci. 2019, 467–468. [Google Scholar] [CrossRef]

- Politano, G.G.; Cazzanelli, E.; Versace, C.; Vena, C.; de Santo, M.P.; Castriota, M.; Ciuchi, F.; Bartolino, R. Graphene oxide on magnetron sputtered silver thin films for SERS and metamaterial applications. Appl. Surf. Sci. 2018, 427, 927–933. [Google Scholar] [CrossRef]

- Politano, G.G.; Vena, C.; Desiderio, G.; Versace, C. Spectroscopic ellipsometry investigation of the optical properties of graphene oxide dip-coated on magnetron sputtered gold thin films. J. Appl. Phys. 2018, 123, 055303. [Google Scholar] [CrossRef]

- Politano, G.G.; Versace, C.; Vena, C.; Castriota, M.; Ciuchi, F.; Fasanella, A.; Desiderio, G.; Cazzanelli, E. Physical investigation of electrophoretically deposited graphene oxide and reduced graphene oxide thin films. J. Appl. Phys. 2016, 120, 195307. [Google Scholar] [CrossRef]

- Losurdo, M.; Giangregorio, M.M.; Bianco, G.V.; Capezzuto, P.; Bruno, G. How spectroscopic ellipsometry can aid graphene technology? Thin Solid Films 2014, 571, 389–394. [Google Scholar] [CrossRef]

- Moré, J.J. The Levenberg-Marquardt algorithm: Implementation and theory. In Proceedings of the Biennial Conference, Dundee, UK, 28 June–1 July 1977; pp. 105–116. [Google Scholar] [CrossRef]

- Lee, V.; Whittaker, L.; Jaye, C.; Baroudi, K.M.; Fischer, D.A.; Banerjee, S. Large-area chemically modified graphene films: Electrophoretic deposition and characterization by soft x-ray absorption spectroscopy. Chem. Mater. 2009, 21, 3905–3916. [Google Scholar] [CrossRef]

- An, S.J.; Zhu, Y.; Lee, S.H.; Stoller, M.D.; Emilsson, T.; Park, S.; Velamakanni, A.; An, J.; Ruoff, R.S. Thin film fabrication and simultaneous anodic reduction of deposited graphene oxide platelets by electrophoretic deposition. J. Phys. Chem. Lett. 2010, 1, 1259–1263. [Google Scholar] [CrossRef]

- Chavez-Valdez, A.; Shaffer, M.S.P.; Boccaccini, A.R. Applications of graphene electrophoretic deposition. A review. J. Phys. Chem. B 2013, 117, 1502–1515. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, S.; Zhou, P.; Sun, Q.; Wang, P.; Wan, L.; Li, J.; Chen, L.; Wang, X.; Ding, S.; et al. Evolution of the band-gap and optical properties of graphene oxide with controllable reduction level. Carbon N. Y. 2013, 62, 157–164. [Google Scholar] [CrossRef]

- Kravets, V.G.; Grigorenko, A.N.; Nair, R.R.; Blake, P.; Anissimova, S.; Novoselov, K.S.; Geim, A.K. Spectroscopic ellipsometry of graphene and an exciton-shifted van Hove peak in absorption. Phys. Rev. B 2010, 81, 155413. [Google Scholar] [CrossRef]

- Johari, P.; Shenoy, V.B. Modulating optical properties of graphene oxide: Role of prominent functional groups. ACS Nano 2011, 5, 7640–7647. [Google Scholar] [CrossRef] [PubMed]

- Chae, D.-H.; Utikal, T.; Weisenburger, S.; Giessen, H.; Klitzing, K.V.; Lippitz, M.; Smet, J. Excitonic fano resonance in free-standing graphene. Nano Lett. 2011, 11, 1379–1382. [Google Scholar] [CrossRef]

- Stebunov, Y.V.; Aftenieva, O.A.; Arsenin, A.V.; Volkov, V.S. Highly sensitive and selective sensor chips with graphene-oxide linking layer. ACS Appl. Mater. Interfaces 2015, 7, 21727–21734. [Google Scholar] [CrossRef] [PubMed]

- Scriven, L.E. Physics and applications of dip coating and spin coating. MRS Proc. 1988, 121, 717. [Google Scholar] [CrossRef]

- Luo, Z.; Lu, Y.; Somers, L.A.; Johnson, A.T.C. High yield preparation of macroscopic graphene oxide membranes. J. Am. Chem. Soc. 2009, 131, 898–899. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.V.; Bardhan, N.M.; Tongay, S.; Wu, J.; Belcher, A.M.; Grossman, J.C. Scalable enhancement of graphene oxide properties by thermally driven phase transformation. Nat. Chem. 2014, 6, 151–158. [Google Scholar] [CrossRef]

- Zacharias, P.; Kliewer, K.L. Dispersion relation for the 3.8 eV volume plasmon of silver. Solid State Commun. 1976, 18, 23–26. [Google Scholar] [CrossRef]

- Liou, S.C.; Shie, C.-S.; Chen, C.H.; Breitwieser, R.; Pai, W.W.; Guo, G.Y.; Chu, M.-W. π-plasmon dispersion in free-standing graphene by momentum-resolved electron energy-loss spectroscopy. Phys. Rev. B 2015, 91, 45418. [Google Scholar] [CrossRef]

- Kubo, R.; Ichimura, M. Kramers-Kronig relations and sum rules. J. Math. Phys. 1972, 13, 1454–1461. [Google Scholar] [CrossRef]

- Boukhvalov, D.W.; Katsnelson, M.I. Modeling of graphite oxide. J. Am. Chem. Soc. 2008, 130, 10697–10701. [Google Scholar] [CrossRef]

- Bansal, T.; Mohite, A.D.; Shah, H.M.; Galande, C.; Srivastava, A.; Jasinski, J.B.; Ajayan, P.M.; Alphenaar, B.W. New insights into the density of states of graphene oxide using capacitive photocurrent spectroscopy. Carbon N. Y. 2012, 50, 808–814. [Google Scholar] [CrossRef]

- Eda, G.; Lin, Y.-Y.; Mattevi, C.; Yamaguchi, H.; Chen, H.-A.; Chen, I.-S.; Chen, C.-W.; Chhowalla, M. Blue photoluminescence from chemically derived graphene oxide. Adv. Mater. 2010, 22, 505–509. [Google Scholar] [CrossRef]

- Liang, H.F.; Smith, C.T.G.; Mills, C.A.; Silva, S.R.P. The band structure of graphene oxide examined using photoluminescence spectroscopy. J. Mater. Chem. C 2015, 3, 12484–12491. [Google Scholar] [CrossRef]

- J. A. Woollam Co. WVASE Manual “Guide to Using WVASE32”; J. A. Woollam Co.: Lincoln, NE, USA, 2010. [Google Scholar]

- Tosatti, E.; Fuchs, H. Unoccupied electronic states of a graphite surface as observed by local tunnelling spectroscopy. EPL 1987, 3, 745. [Google Scholar]

- Kumar, D.; Singh, K.; Verma, V.; Bhatti, H.S. Microwave assisted synthesis and characterization of graphene nanoplatelets. Appl. Nanosci. 2016, 6, 97–103. [Google Scholar] [CrossRef]

- Yang, L.; Deslippe, J.; Park, C.-H.; Cohen, M.L.; Louie, S.G. Excitonic effects on the optical response of graphene and bilayer graphene. Phys. Rev. Lett. 2009, 103, 186802. [Google Scholar] [CrossRef] [PubMed]

- Hadipour, H.; Jafari, S. The importance of electron correlation in graphene and hydrogenated graphene. Eur. Phys. J. B 2015. [Google Scholar] [CrossRef]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Liu, C.-H.; Liu, C.-H.; Zhong, Z.; Norris, T.B. Extracting the complex optical conductivity of mono- and bilayer graphene by ellipsometry. Appl. Phys. Lett. 2014, 104, 261909. [Google Scholar] [CrossRef]

- Ke, F.; Chen, Y.; Yin, K.; Yan, J.; Zhang, H.; Liu, Z.; Tse, J.S.; Wu, J.; Mao, H.-K.; Chen, B. Large bandgap of pressurized trilayer graphene. Proc. Natl. Acad. Sci. USA 2019, 116, 9186–9190. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.-M.; Lin, I.-T. Graphene Photonics; Cambridge University Press: Cambridge, UK, 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Politano, G.G.; Versace, C. Variable-Angle Spectroscopic Ellipsometry of Graphene-Based Films. Coatings 2021, 11, 462. https://doi.org/10.3390/coatings11040462

Politano GG, Versace C. Variable-Angle Spectroscopic Ellipsometry of Graphene-Based Films. Coatings. 2021; 11(4):462. https://doi.org/10.3390/coatings11040462

Chicago/Turabian StylePolitano, Grazia Giuseppina, and Carlo Versace. 2021. "Variable-Angle Spectroscopic Ellipsometry of Graphene-Based Films" Coatings 11, no. 4: 462. https://doi.org/10.3390/coatings11040462

APA StylePolitano, G. G., & Versace, C. (2021). Variable-Angle Spectroscopic Ellipsometry of Graphene-Based Films. Coatings, 11(4), 462. https://doi.org/10.3390/coatings11040462