Corrosion Behavior and Surface Treatment of Cladding Materials Used in High-Temperature Lead-Bismuth Eutectic Alloy: A Review

Abstract

1. Introduction

2. Candidate Cladding Materials for LBE-LFR

3. Surface Coatings of Cladding Materials for LBE-LFR

3.1. Al-Containing Coatings

3.2. Ceramic Coatings

3.3. Oxide Coatings

3.4. Amorphous and High-Entropy Alloy Coatings

4. Summary and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neumann, A.; Sorge, L.; von Hirschhausen, C.; Wealer, B. Democratic quality and nuclear power: Reviewing the global determinants for the introduction of nuclear energy in 166 countries. Energy Res. Soc. Sci. 2020, 63, 101389. [Google Scholar] [CrossRef]

- Omri, A.; Ben Mabrouk, N.; Sassi-Tmar, A. Modeling the causal linkages between nuclear energy, renewable energy and economic growth in developed and developing countries. Renew. Sustain. Energy Rev. 2015, 42, 1012–1022. [Google Scholar] [CrossRef]

- Meng, T.; Cheng, K.; Zeng, C.; He, Y.; Tan, S. Preliminary control strategies of megawatt-class gas-cooled space nuclear reactor with different control rod configurations. Prog. Nucl. Energy 2019, 113, 135–144. [Google Scholar] [CrossRef]

- Mu, R.; Zuo, J.; Yuan, X. China’s approach to nuclear safety—From the perspective of policy and institutional system. Energy Policy 2015, 76, 161–172. [Google Scholar] [CrossRef]

- Lorusso, P.; Bassini, S.; Del Nevo, A.; Di Piazza, I.; Giannetti, F.; Tarantino, M.; Utili, M. GEN-IV LFR development: Status & perspectives. Prog. Nucl. Energy 2018, 105, 318–331. [Google Scholar] [CrossRef]

- Alemberti, A.; Carlsson, J.; Malambu, E.; Orden, A.; Struwe, D.; Agostini, P.; Monti, S. European lead fast reactor—ELSY. Nucl. Eng. Des. 2011, 241, 3470–3480. [Google Scholar] [CrossRef]

- Smith, C.F.; Halsey, W.G.; Brown, N.W.; Sienicki, J.J.; Moisseytsev, A.; Wade, D.C. SSTAR: The US lead-cooled fast reactor (LFR). J. Nucl. Mater. 2008, 376, 255–259. [Google Scholar] [CrossRef]

- Abram, T.; Ion, S. Generation-IV nuclear power: A review of the state of the science. Energy Policy 2008, 36, 4323–4330. [Google Scholar] [CrossRef]

- Obara, T.; Miura, T.; Sekimoto, H. Fundamental study of polonium contamination by neutron irradiated lead–bismuth eutectic. J. Nucl. Mater. 2005, 343, 297–301. [Google Scholar] [CrossRef]

- Forgione, N.; Castelliti, D.; Gerschenfeld, A.; Polidori, M.; Del Nevo, A.; Hu, R. Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors; Elsevier: Amsterdam, The Netherlands, 2019; pp. 157–184. [Google Scholar]

- Alemberti, A.; Tuček, K.; Obara, T.; Moiseev, A.; Tocheny, L.; Hwang, I.; Smith, C.; Wu, Y.; Zhou, T. Status of Generation-IV Lead Fast Reactor Activities. 2017. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:51002820 (accessed on 22 October 2020).

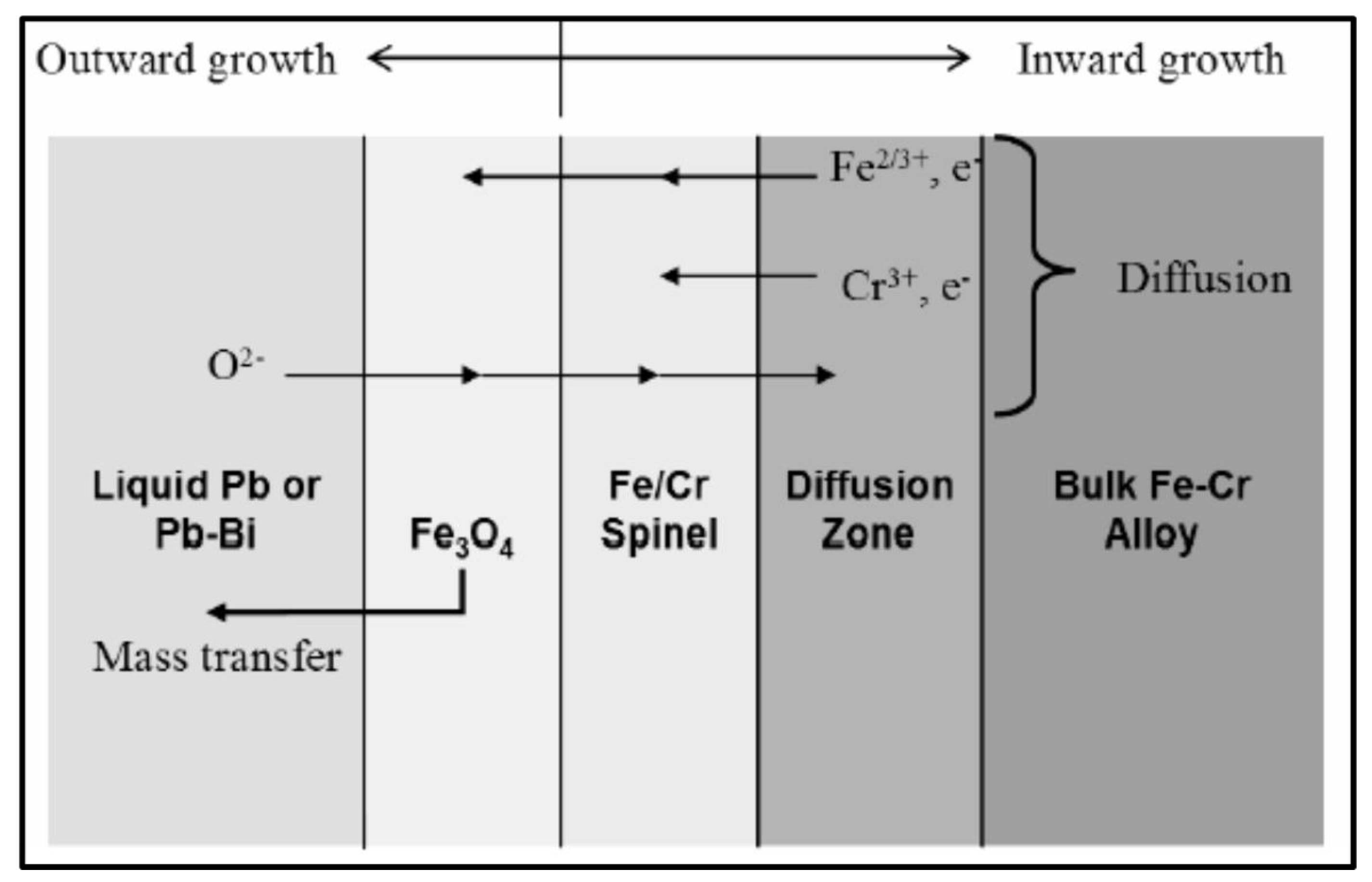

- Zhang, J. A review of steel corrosion by liquid lead and lead–bismuth. Corros. Sci. 2009, 51, 1207–1227. [Google Scholar] [CrossRef]

- Gong, X.; Chen, J.; Hu, F.; Xiang, C.; Yu, Z.; Xiao, J.; Wang, H.; Gong, H.; Wang, H.; Liu, C.; et al. Liquid metal embrittlement of an Fe10Cr4Al ferritic alloy exposed to oxygen-depleted and -saturated lead-bismuth eutectic at 350 °C. Corros. Sci. 2020, 165, 108364. [Google Scholar] [CrossRef]

- Park, J.J.; Butt, D.P.; Beard, C.A. Review of liquid metal corrosion issues for potential containment materials for liquid lead and lead–bismuth eutectic spallation targets as a neutron source. Nucl. Eng. Des. 2000, 196, 315–325. [Google Scholar] [CrossRef]

- Ballinger, R.G.; Lim, J. An Overview of Corrosion Issues for the Design and Operation of High-Temperature Lead- and Lead-Bismuth-Cooled Reactor Systems. Nucl. Technol. 2004, 147, 418–435. [Google Scholar] [CrossRef]

- Lambrinou, K.; Charalampopoulou, E.; Van der Donck, T.; Delville, R.; Schryvers, D. Dissolution corrosion of 316L austenitic stainless steels in contact with static liquid lead-bismuth eutectic (LBE) at 500 °C. J. Nucl. Mater. 2017, 490, 9–27. [Google Scholar] [CrossRef]

- Serre, I.P.; Vogt, J.-B. Liquid metal embrittlement sensitivity of the T91 steel in lead, in bismuth and in lead-bismuth eutectic. J. Nucl. Mater. 2020, 531, 152021. [Google Scholar] [CrossRef]

- Tunca, B.; Lapauw, T.; Callaert, C.; Hadermann, J.; Delville, R.; Caspi, E.N.; Dahlqvist, M.; Rosén, J.; Marshal, A.; Pradeep, K.G.; et al. Compatibility of Zr2AlC MAX phase-based ceramics with oxygen-poor, static liquid lead–bismuth eutectic. Corros. Sci. 2020, 171, 108704. [Google Scholar] [CrossRef]

- Wu, Y. Design and R&D Progress of China Lead-Based Reactor for ADS Research Facility. Engineering 2016, 2, 124–131. [Google Scholar] [CrossRef]

- Gong, X.; Li, R.; Sun, M.; Ren, Q.; Liu, T.; Short, M.P. Opportunities for the LWR ATF materials development program to contribute to the LBE-cooled ADS materials qualification program. J. Nucl. Mater. 2016, 482, 218–228. [Google Scholar] [CrossRef]

- Konings, R.; Stoller, R. Comprehensive Nuclear Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 207–219. [Google Scholar]

- Pascal, Y. Structural Materials for Generation IV Nuclear Reactors; Elsevier: Amsterdam, The Netherlands, 2017; pp. 569–594. [Google Scholar]

- Xu, S.; Zhou, Z.; Long, F.; Jia, H.; Guo, N.; Yao, Z.; Daymond, M.R. Combination of back stress strengthening and Orowan strengthening in bimodal structured Fe–9Cr–Al ODS steel with high Al addition. Mater. Sci. Eng. A 2019, 739, 45–52. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, Z.; Long, F.; Jia, H.; Guo, N.; Sun, Y.; Yao, Z.; Daymond, M.R. Influence of al addition strategy on the microstructure of a low-cr oxide dispersion-strengthened (ODS) Ferritic Steel. Adv. Eng. Mater. 2020, 22, 1900879. [Google Scholar] [CrossRef]

- Wang, C.; Luo, J.; Guo, N.; Tu, J.; Ye, H.; Zhang, P.; Yan, Q. Effect of Yttrium Contents on the Microstructure of a Hot-Rolled Tantalum-Containing 12Cr-ODS Steel. Front. Mater. 2019, 6, 6. [Google Scholar] [CrossRef]

- Klueh, R.; Nelson, A. Ferritic/martensitic steels for next-generation reactors. J. Nucl. Mater. 2007, 371, 37–52. [Google Scholar] [CrossRef]

- Prasitthipayong, A.; Frazer, D.; Kareer, A.; Abad, M.D.; Garner, A.; Joni, B.; Ungar, T.; Ribarik, G.; Preuss, M.; Balogh, L.; et al. Micro mechanical testing of candidate structural alloys for Gen-IV nuclear reactors. Nucl. Mater. Energy 2018, 16, 34–45. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Lapauw, T.; Tunca, B.; Joris, J.; Jianu, A.; Fetzer, R.; Weisenburger, A.; Vleugels, J.; Lambrinou, K. Interaction of Mn+1AXn phases with oxygen-poor, static and fast-flowing liquid lead-bismuth eutectic. J. Nucl. Mater. 2019, 520, 258–272. [Google Scholar] [CrossRef]

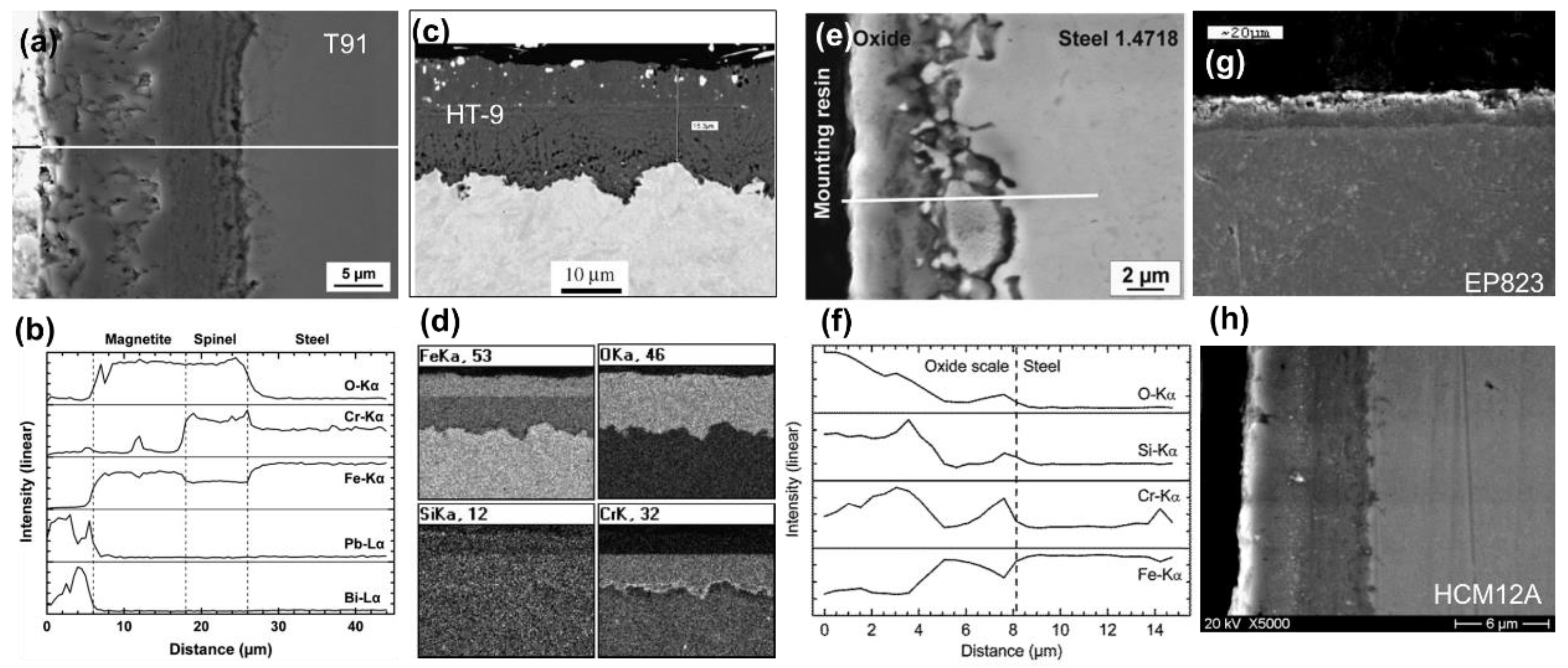

- Schroer, C.; Wedemeyer, O.; Skrypnik, A.; Novotny, J.; Konys, J. Corrosion kinetics of Steel T91 in flowing oxygen-containing lead–bismuth eutectic at 450 °C. J. Nucl. Mater. 2012, 431, 105–112. [Google Scholar] [CrossRef]

- Hosemann, P.; Hawley, M.; Koury, D.; Welch, J.; Johnson, A.; Mori, G.; Li, N.; Maloy, S. Nanoscale characterization of HT-9 exposed to lead bismuth eutectic at 550 °C for 3000 h. J. Nucl. Mater. 2008, 381, 211–215. [Google Scholar] [CrossRef]

- Schroer, C.; Koch, V.; Wedemeyer, O.; Skrypnik, A.; Konys, J. Silicon-containing ferritic/martensitic steel after exposure to oxygen-containing flowing lead–bismuth eutectic at 450 and 550 °C. J. Nucl. Mater. 2016, 469, 162–176. [Google Scholar] [CrossRef]

- Barbier, F.; Rusanov, A. Corrosion behavior of steels in flowing lead–bismuth. J. Nucl. Mater. 2001, 296, 231–236. [Google Scholar] [CrossRef]

- Tan, L.; Yang, Y.; Allen, T. Oxidation behavior of iron-based alloy HCM12A exposed in supercritical water. Corros. Sci. 2006, 48, 3123–3138. [Google Scholar] [CrossRef]

- Allen, T.R.; Sridharan, K.; Machut, M.T.; Tan, L. Surface Treatment to Improve Corrosion Resistance in Lead-Alloy Coolants; University of Wisconsin: Madison, WI, USA, 2007. [Google Scholar]

- Vogt, J.-B.; Serre, I.P. A Review of the Surface Modifications for Corrosion Mitigation of Steels in Lead and LBE. Coatings 2021, 11, 53. [Google Scholar] [CrossRef]

- Zeng, J.; Hu, J.; Yang, X.; Xu, H.; Li, H.; Guo, N. Evolution of the Microstructure and Properties of Pre-Boronized Coatings During Pack-Cementation Chromizing. Coatings 2020, 10, 159. [Google Scholar] [CrossRef]

- Lin, N.; Zhao, L.; Liu, Q.; Zou, J.; Xie, R.; Yuan, S.; Li, D.; Zhang, L.; Wang, Z.; Tang, B. Preparation of titanizing coating on AISI 316 stainless steel by pack cementation to mitigate surface damage: Estimations of corrosion resistance and tribological behavior. J. Phys. Chem. Solids 2019, 129, 387–400. [Google Scholar] [CrossRef]

- Zeng, J.; Hu, J.; Yang, X.; Xu, H.; Li, H.; Guo, N.; Dong, Q. Microstructure and formation mechanism of the Si-Cr dual-alloyed coating prepared by pack-cementation. Surf. Coat. Technol. 2020, 399, 126142. [Google Scholar] [CrossRef]

- Umretiya, R.V.; Elward, B.; Lee, D.; Anderson, M.; Rebak, R.B.; Rojas, J.V. Mechanical and chemical properties of PVD and cold spray Cr-coatings on Zircaloy-4. J. Nucl. Mater. 2020, 541, 152420. [Google Scholar] [CrossRef]

- Mouche, P.; Ang, C.; Koyanagi, T.; Doyle, P.; Katoh, Y. Characterization of PVD Cr, CrN, and TiN coatings on SiC. J. Nucl. Mater. 2019, 527, 151781. [Google Scholar] [CrossRef]

- Endrino, J.L.; Fox-Rabinovich, G.S.; Gey, C. Hard AlTiN, AlCrN PVD coatings for machining of austenitic stainless steel. Surf. Coat. Technol. 2006, 200, 6840–6845. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Chai, L.; Wu, H.; Zheng, Z.; Guan, H.; Pan, H.; Guo, N.; Song, B. Microstructural characterization and hardness variation of pure Ti surface-treated by pulsed laser. J. Alloys Compd. 2018, 741, 116–122. [Google Scholar] [CrossRef]

- Chai, L.; Chen, K.; Zhi, Y.; Murty, K.L.; Chen, L.-Y.; Yang, Z. Nanotwins induced by pulsed laser and their hardening effect in a Zr alloy. J. Alloys Compd. 2018, 748, 163–170. [Google Scholar] [CrossRef]

- Liu, F.; Shan, D.; Song, Y.; Han, E.-H.; Ke, W. Corrosion behavior of the composite ceramic coating containing zirconium oxides on AM30 magnesium alloy by plasma electrolytic oxidation. Corros. Sci. 2011, 53, 3845–3852. [Google Scholar] [CrossRef]

- Malinovschi, V.; Marin, A.; Negrea, D.; Andrei, V.; Coaca, E.; Mihailescu, C.; Lungu, C.P. Characterization of Al2O3/ZrO2 composite coatings deposited on Zr-2.5Nb alloy by plasma electrolytic oxidation. Appl. Surf. Sci. 2018, 451, 169–179. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Z.; Yao, Z.; Tang, H. Microstructure and corrosion resistance of ceramic coating on carbon steel prepared by plasma electrolytic oxidation. Surf. Coat. Technol. 2010, 204, 1685–1688. [Google Scholar] [CrossRef]

- Wan, Q.; Wu, Z.; Liu, Y.; Yang, B.; Liu, H.; Ren, F.; Wang, P.; Xiao, Y.; Zhang, J.; Zhang, G. Lead-bismuth eutectic (LBE) corrosion mechanism of nano-amorphous composite TiSiN coatings synthesized by cathodic arc ion plating. Corros. Sci. 2021, 183, 109264. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coatings Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Ferré, F.G.; Ormellese, M.; Di Fonzo, F.; Beghi, M. Advanced Al2O3 coatings for high temperature operation of steels in heavy liquid metals: A preliminary study. Corros. Sci. 2013, 77, 375–378. [Google Scholar] [CrossRef]

- Xu, S.; Long, F.; Persaud, S.Y.; Guo, N.; Yao, Z.; Daymond, M.R.; Gao, W.; Zhang, L.; Zhou, Z. Oxidation behavior of 9Cr-4.5Al ODS steel in 600 °C supercritical water and the effect of pre-oxidation. Corros. Sci. 2020, 165, 108380. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, Z.; Mo, K.; Wang, P.; Miao, Y.; Li, S.; Wang, M.; Liu, X.; Gong, M.; Almer, J.; et al. The microstructure and mechanical properties of Al-containing 9Cr ODS ferritic alloy. J. Alloys Compd. 2015, 648, 223–228. [Google Scholar] [CrossRef]

- Xiang, Z.D.; Burnell-Gray, J.S.; Datta, P.K. Aluminide coating formation on nickel-base superalloys by pack cementation process. J. Mater. Sci. 2001, 36, 5673–5682. [Google Scholar] [CrossRef]

- Kurata, Y.; Futakawa, M.; Saito, S. Corrosion behavior of Al-surface-treated steels in liquid Pb–Bi in a pot. J. Nucl. Mater. 2004, 335, 501–507. [Google Scholar] [CrossRef]

- Abdolahi, B.; Shahverdi, H.; Torkamany, M.; Emami, M. Improvement of the corrosion behavior of low carbon steel by laser surface alloying. Appl. Surf. Sci. 2011, 257, 9921–9924. [Google Scholar] [CrossRef]

- Engelko, V.; Mueller, G.; Rusanov, A.; Markov, V.; Tkachenko, K.; Weisenburger, A.; Kashtanov, A.; Chikiryaka, A.; Jianu, A. Surface modification/alloying using intense pulsed electron beam as a tool for improving the corrosion resistance of steels exposed to heavy liquid metals. J. Nucl. Mater. 2011, 415, 270–275. [Google Scholar] [CrossRef]

- Xu, J.; Liu, F.; Wang, F.; Yu, D.; Zhao, L. The corrosion resistance behavior of Al2O3 coating prepared on NiTi alloy by micro-arc oxidation. J. Alloys Compd. 2009, 472, 276–280. [Google Scholar] [CrossRef]

- Popovic, M.; Bolind, A.; Aussat, Y.; Gubser, A.; Hosemann, P. Oxidative passivation of Fe–Cr–Al steels in lead-bismuth eutectic under oxygen-controlled static conditions at 700° and 800 °C. J. Nucl. Mater. 2019, 523, 172–181. [Google Scholar] [CrossRef]

- Qiu, J.; Han, J.; Schoell, R.; Popovic, M.; Ghanbari, E.; Kaoumi, D.; Scully, J.R.; Macdonald, D.D.; Hosemann, P. Electrical properties of thermal oxide scales on pure iron in liquid lead-bismuth eutectic. Corros. Sci. 2020, 176, 109052. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Y.; Ge, H.; Li, L.; Ding, Y.; Meng, L.; Zhang, X. Microstructure evolution and corrosion behavior of Fe-Al-based intermetallic aluminide coatings under acidic condition. Trans. Nonferr. Metal Soc. 2018, 28, 2028–2043. [Google Scholar] [CrossRef]

- Liu, X.; Yang, D.; Yang, Y.; Chai, X.; Xiong, J.; Zhang, T.; Cheng, X. Computational fluid dynamics and subchannel analysis of lead–bismuth eutectic-cooled fuel assembly under various blockage conditions. Appl. Therm. Eng. 2020, 164, 114419. [Google Scholar] [CrossRef]

- Engelko, V.; Yatsenko, B.; Mueller, G.; Bluhm, H. Pulsed electron beam facility (GESA) for surface treatment of materials. Vacuum 2001, 62, 211–216. [Google Scholar] [CrossRef]

- Proskurovsky, D.; Rotshtein, V.; Ozur, G.; Markov, A.; Nazarov, D.; Shulov, V.; Ivanov, Y.F.; Buchheit, R. Pulsed electron-beam technology for surface modification of metallic materials. J. Vac. Sci. Technol. A 1998, 16, 2480–2488. [Google Scholar] [CrossRef]

- Heinzel, A.; Kondo, M.; Takahashi, M. Corrosion of steels with surface treatment and Al-alloying by GESA exposed in lead–bismuth. J. Nucl. Mater. 2006, 350, 264–270. [Google Scholar] [CrossRef]

- Glasbrenner, H.; Konys, J.; Mueller, G.; Rusanov, A. Corrosion investigations of steels in flowing lead at 400 °C and 550 °C. J. Nucl. Mater. 2001, 296, 237–242. [Google Scholar] [CrossRef]

- Cionea, C.; Abad, M.; Aussat, Y.; Frazer, D.; Gubser, A.; Hosemann, P. Oxide scale formation on 316L and FeCrAl steels exposed to oxygen controlled static LBE at temperatures up to 800 °C. Sol. Energy Mater. Sol. Cells 2016, 144, 235–246. [Google Scholar] [CrossRef]

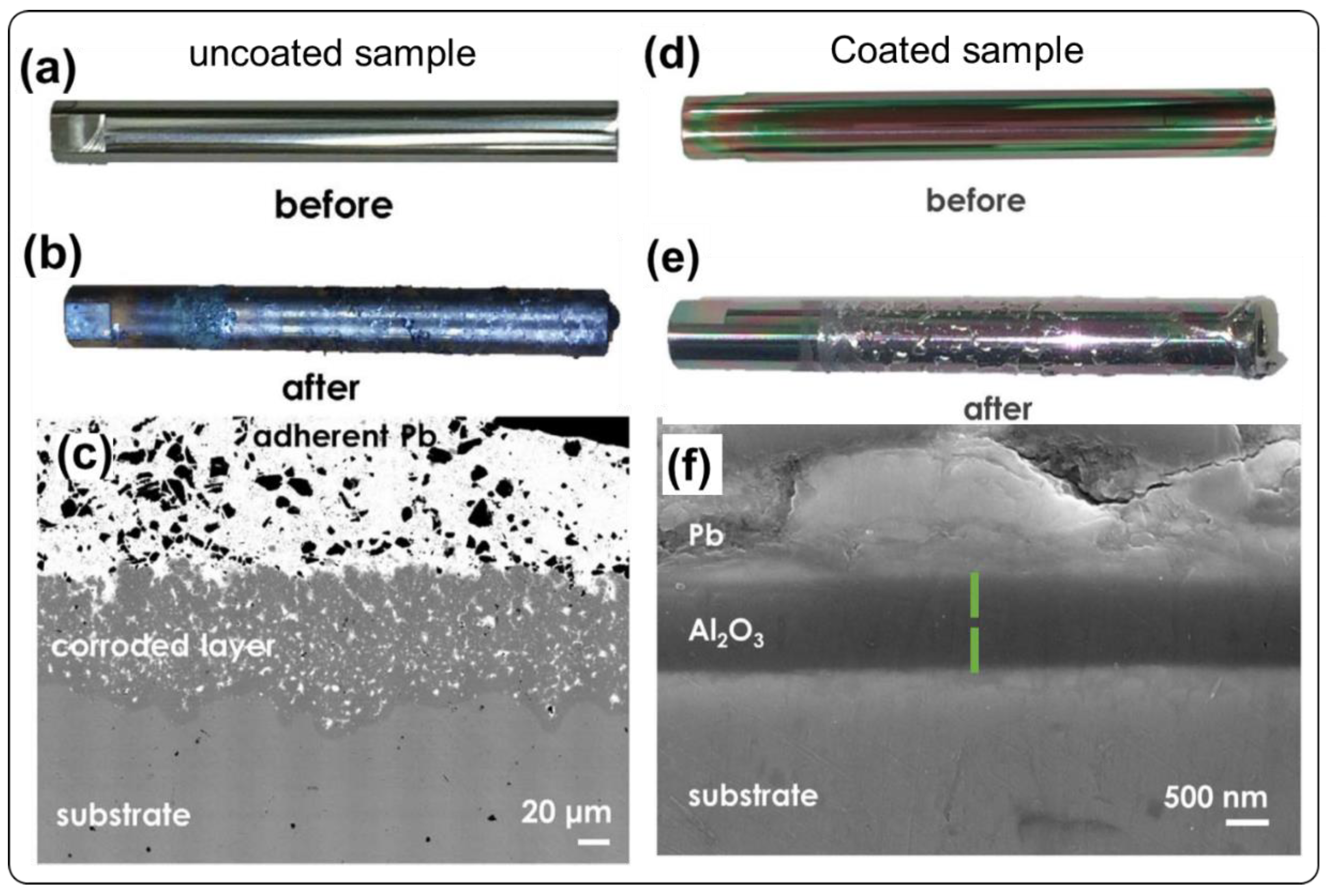

- Fetzer, R.; Weisenburger, A.; Jianu, A.; Müller, G. Oxide scale formation of modified FeCrAl coatings exposed to liquid lead. Corros. Sci. 2012, 55, 213–218. [Google Scholar] [CrossRef]

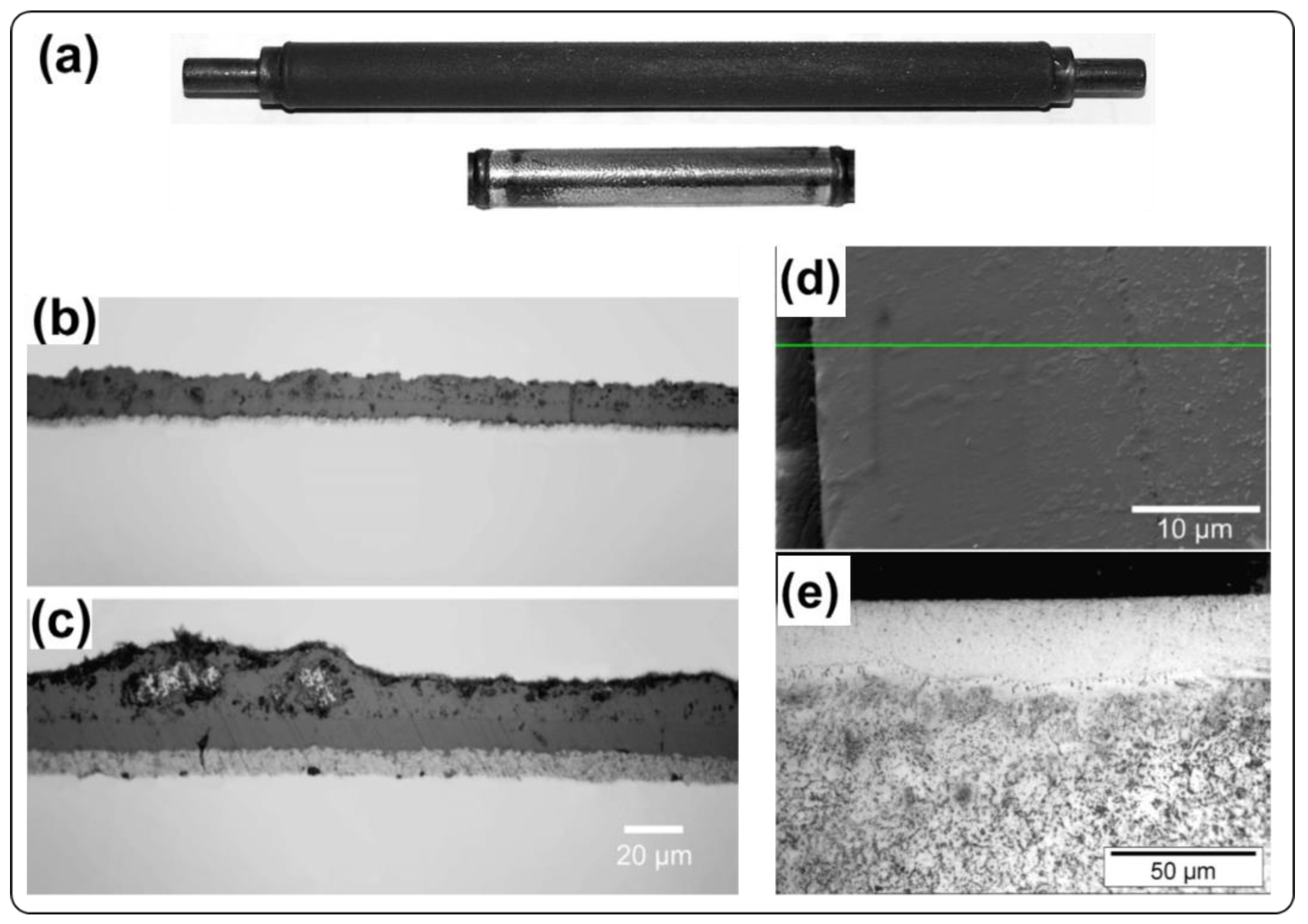

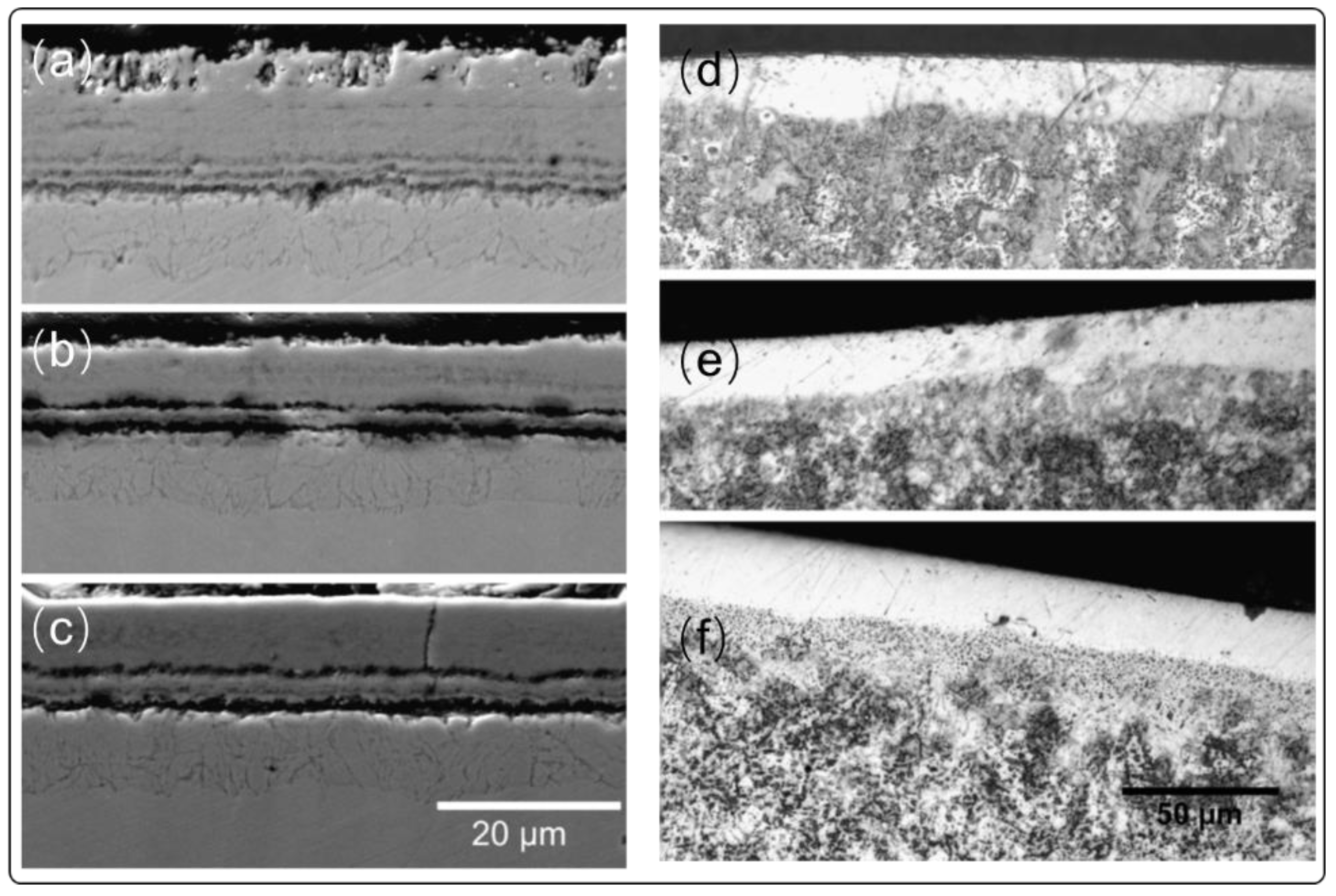

- Weisenburger, A.; Heinzel, A.; Müller, G.; Muscher, H.; Rousanov, A. T91 cladding tubes with and without modified FeCrAlY coatings exposed in LBE at different flow, stress and temperature conditions. J. Nucl. Mater. 2008, 376, 274–281. [Google Scholar] [CrossRef]

- Laidler, K.J. The development of the Arrhenius equation. J. Chem. Educ. 1984, 61, 494. [Google Scholar] [CrossRef]

- Chen, Y.; Qiu, C.; Hu, L.; Nong, Y.; Liu, Z.; He, B. The Corrosion Behavior of Multiphase Ceramic Protective Coatings on China Low Activation Martensitic Steel Surface in Flowing Liquid Lead-Bismuth Eutectic. Steel Res. Int. 2017, 88, 1600413. [Google Scholar] [CrossRef]

- Short, M.P.; Ballinger, R.G.; Hänninen, H.E. Corrosion resistance of alloys F91 and Fe–12Cr–2Si in lead–bismuth eutectic up to 715 °C. J. Nucl. Mater. 2013, 434, 259–281. [Google Scholar] [CrossRef]

- Gong, X.; Yang, Z.; Deng, Y.; Xiao, J.; Wang, H.; Yu, Z.; Yin, Y. Creep failure of a solution-annealed 15-15Ti steel exposed to stagnant lead-bismuth eutectic at 550 and 600 °C. Mater. Sci. Eng. A 2020, 798, 140230. [Google Scholar] [CrossRef]

- Rivai, A.K.; Takahashi, M. Compatibility of surface-coated steels, refractory metals and ceramics to high temperature lead–bismuth eutectic. Prog. Nucl. Energy 2008, 50, 560–566. [Google Scholar] [CrossRef]

- Cheng, P.; Chou, P.; Kim, Y.-J. Development of Mo-Based Accident Tolerant LWR Fuel Cladding. IAEA TECDOC Series 2016, 66. Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:47080122 (accessed on 22 October 2020).

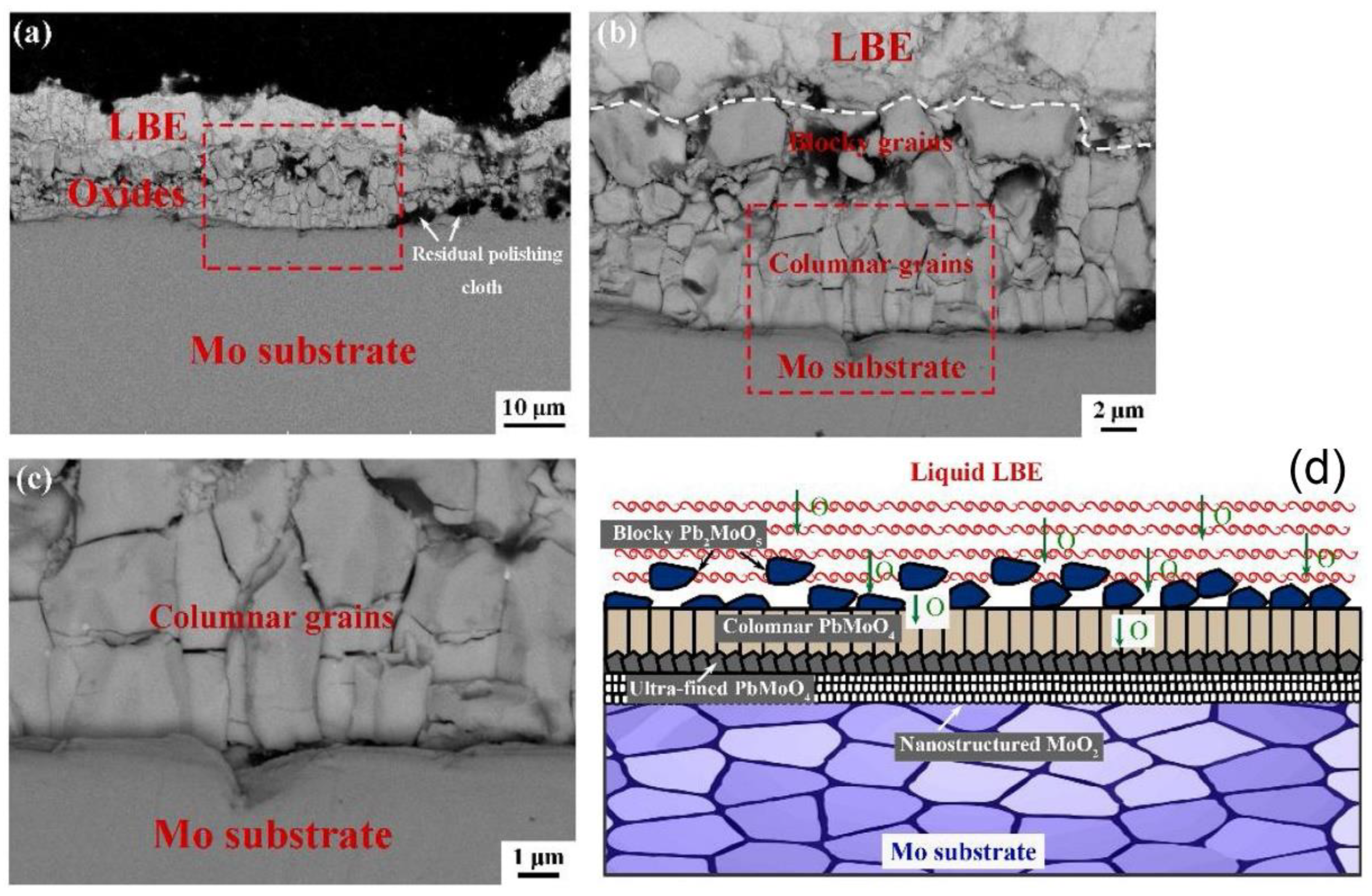

- Cairang, W.; Ma, S.; Gong, X.; Zeng, Y.; Yang, H.; Xue, D.; Qin, Y.; Ding, X.; Sun, J. Oxidation mechanism of refractory Molybdenum exposed to oxygen-saturated lead-bismuth eutectic at 600 °C. Corros. Sci. 2021, 179, 109132. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Prakash, M.S.; Jain, A.; Rajam, K. Structure, hardness and thermal stability of TiAlN and nanolayered TiAlN/CrN multilayer films. Vacuum 2005, 77, 169–179. [Google Scholar] [CrossRef]

- Jindal, P.; Santhanam, A.; Schleinkofer, U.; Shuster, A. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Zhou, Z.; Rainforth, W.; Luo, Q.; Hovsepian, P.; Ojeda, J.; Romero-Gonzalez, M. Wear and friction of TiAlN/VN coatings against Al2O3 in air at room and elevated temperatures. Acta Mater. 2010, 58, 2912–2925. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Miorin, E.; Montagner, F.; Zin, V.; Giuranno, D.; Ricci, E.; Pedroni, M.; Spampinato, V.; Vassallo, E.; Deambrosis, S.M. Al rich PVD protective coatings: A promising approach to prevent T91 steel corrosion in stagnant liquid lead. Surf. Coat. Technol. 2019, 377, 124890. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering (R-HiPIMS). J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

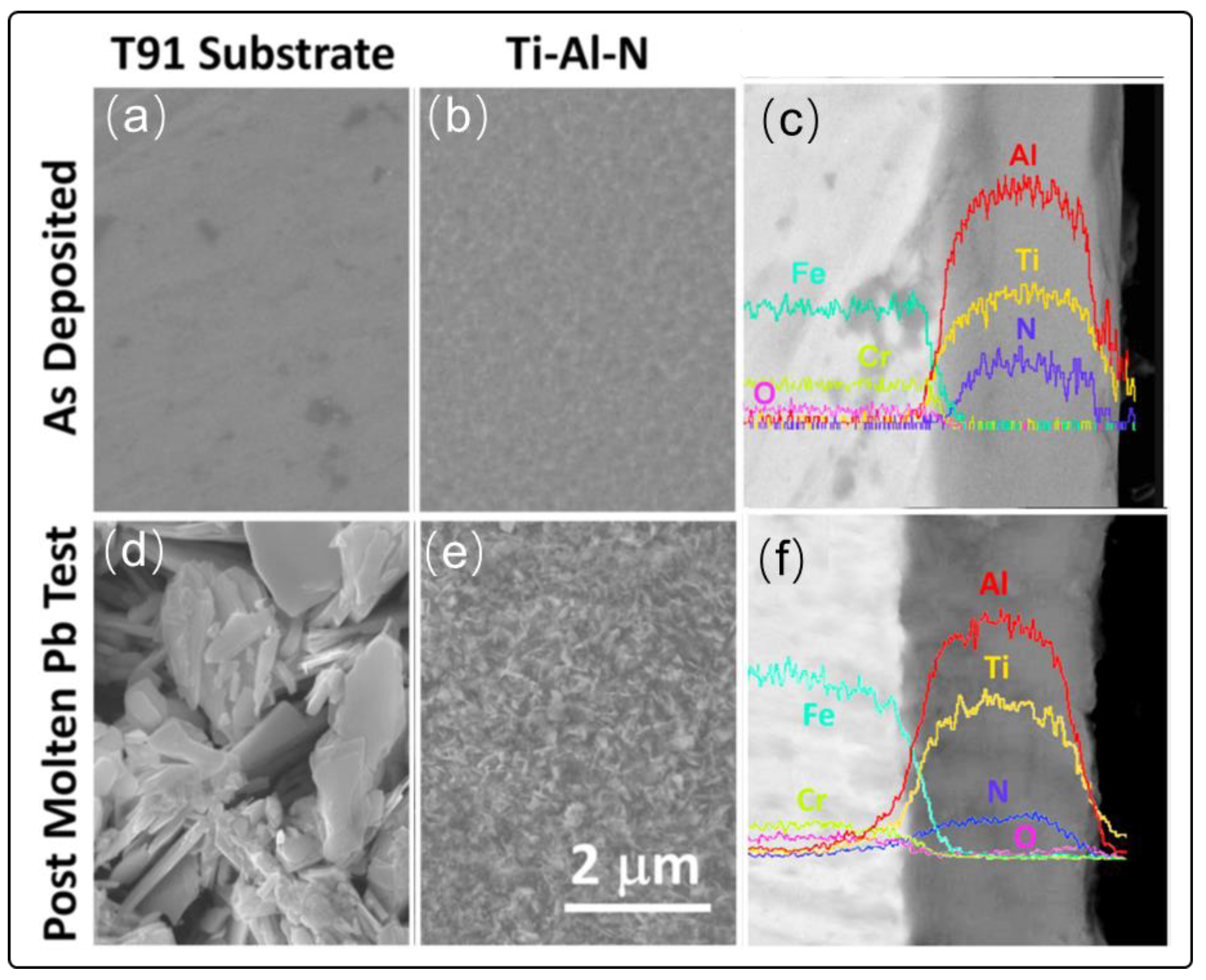

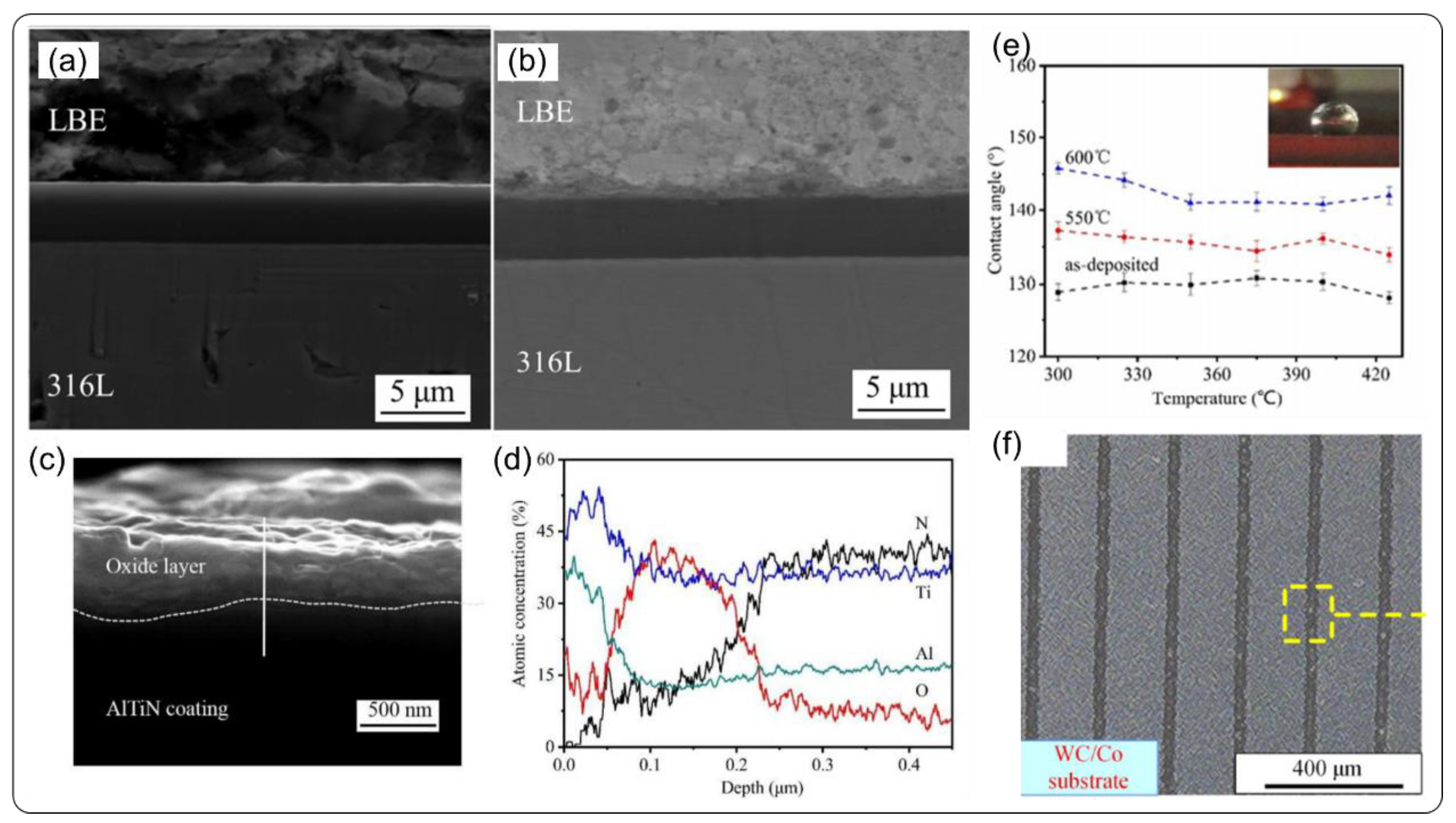

- Wu, Z.; Zhao, X.; Liu, Y.; Cai, Y.; Li, J.; Chen, H.; Wan, Q.; Yang, D.; Tan, J.; Liu, H.; et al. Lead-bismuth eutectic (LBE) corrosion behavior of AlTiN coatings at 550 and 600 °C. J. Nucl. Mater. 2020, 539, 152280. [Google Scholar] [CrossRef]

- Du, X.; Niu, F.; Zhu, H.; Ma, T.; Zhao, Y.; Xiong, W.; Zhang, H. Influence of oxide scale on the wettability of LBE on T91 steel. Fusion Eng. Des. 2017, 125, 378–383. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Guo, X.; Sun, L.; Lei, S. Study on the adhesion and tribological behavior of PVD TiAlN coatings with a multi-scale textured substrate surface. Int. J. Refract. Met. Hard Mater. 2018, 72, 292–305. [Google Scholar] [CrossRef]

- Ferré, F.G.; Mairov, A.; Iadicicco, D.; Vanazzi, M.; Bassini, S.; Utili, M.; Tarantino, M.; Bragaglia, M.; Lamastra, F.; Nanni, F.; et al. Corrosion and radiation resistant nanoceramic coatings for lead fast reactors. Corros. Sci. 2017, 124, 80–92. [Google Scholar] [CrossRef]

- Johnson, A.L.; Loewen, E.P.; Ho, T.T.; Koury, D.; Hosterman, B.; Younas, U.; Welch, J.; Farley, J.W. Spectroscopic and microscopic study of the corrosion of iron–silicon steel by lead–bismuth eutectic (LBE) at elevated temperatures. J. Nucl. Mater. 2006, 350, 221–231. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, L.; Qiu, C.; He, B.; Zhou, L.; Zhao, J.; Li, Y. Influence of LBE Temperatures on the Microstructure and Properties of Crystalline and Amorphous Multiphase Ceramic Coatings. Coatings 2019, 9, 543. [Google Scholar] [CrossRef]

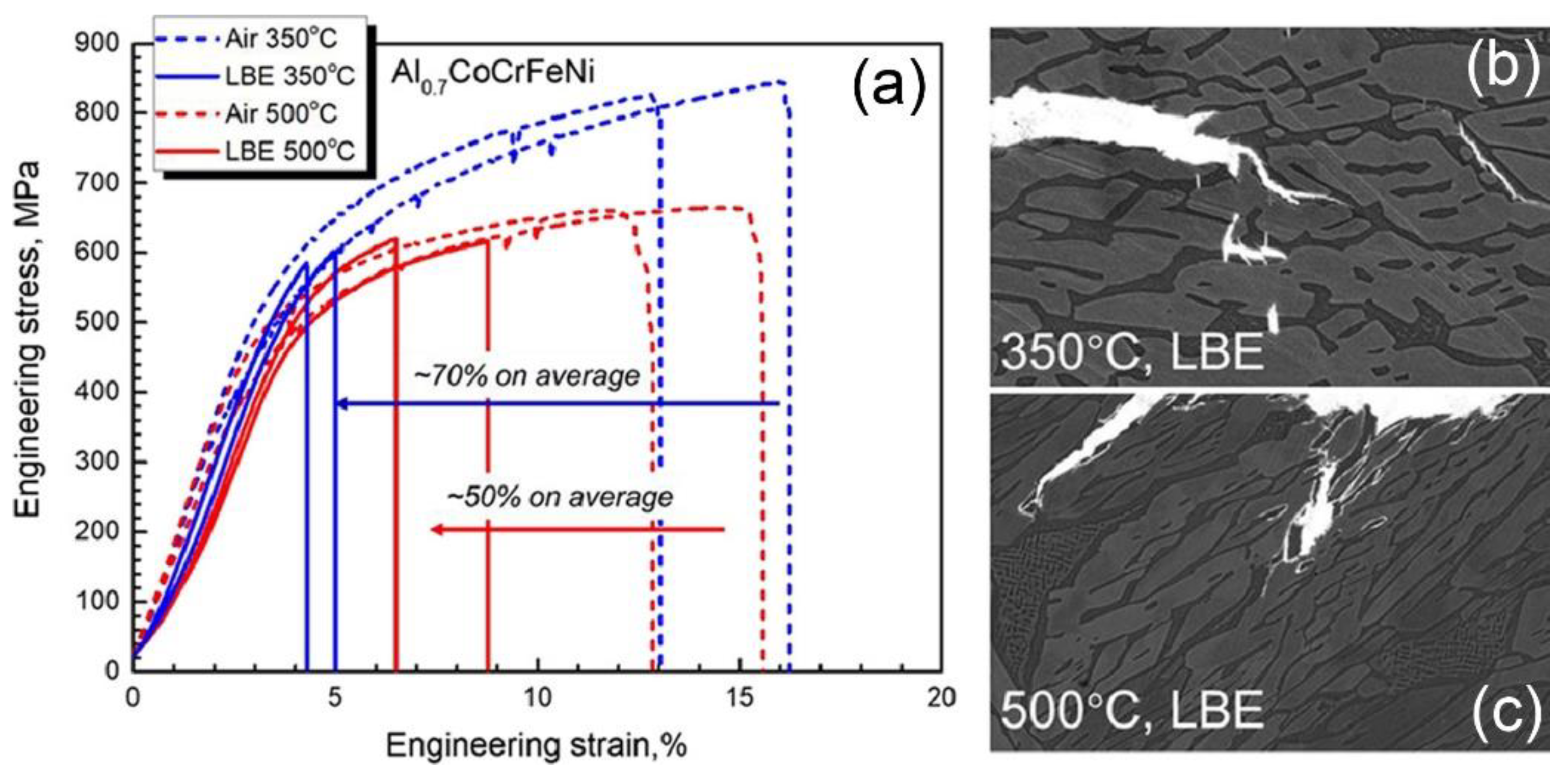

- Gong, X.; Xiang, C.; Auger, T.; Chen, J.; Liang, X.; Yu, Z.; Short, M.P.; Song, M.; Yin, Y. Liquid metal embrittlement of a dual-phase Al0.7CoCrFeNi high-entropy alloy exposed to oxygen-saturated lead-bismuth eutectic. Scr. Mater. 2021, 194, 113652. [Google Scholar] [CrossRef]

- Xiang, K.; Chai, L.; Wang, Y.; Wang, H.; Guo, N.; Ma, Y.; Murty, K.L. Microstructural characteristics and hardness of CoNiTi medium-entropy alloy coating on pure Ti substrate prepared by pulsed laser cladding. J. Alloys Compd. 2020, 849, 156704. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Z.; Wu, M.; Weng, F.; Liu, T.; Zhan, X. Influence of Specific Energy on Microstructure and Properties of Laser Cladded FeCoCrNi High Entropy Alloy. Metals 2020, 10, 1464. [Google Scholar] [CrossRef]

- Li, Y.; Liang, H.; Nie, Q.; Qi, Z.; Deng, D.; Jiang, H.; Cao, Z. Microstructures and Wear Resistance of CoCrFeNi2V0.5Tix High-Entropy Alloy Coatings Prepared by Laser Cladding. Crystals 2020, 10, 352. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chung, C.-H. Tribological and mechanical properties of multicomponent CrVTiNbZr(N) coatings. Coatings 2021, 11, 41. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Hunger, R.; Berger, R.; Lampke, T. Precipitation Hardening of the HVOF Sprayed Single-Phase High-Entropy Alloy CrFeCoNi. Coatings 2020, 10, 701. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Y.; Yang, X.; Li, H.; Xu, H.; Ma, C.; Dong, Q.; Guo, N.; Yao, Z. Effect of pack-chromizing temperature on microstructure and performance of AISI 5140 steel with Cr-coatings. Surf. Coat. Technol. 2018, 344, 656–663. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, J.; Li, H.; Yang, X.; Xu, H.; Jin, Y.; Ma, C.; Dong, Q.; Guo, N. Effect of Annealing Treatment on Microstructure and Properties of Cr-Coatings Deposited on AISI 5140 Steel by Brush-Plating. Coatings 2018, 8, 193. [Google Scholar] [CrossRef]

- Hu, J.; Pei, Y.; Liu, Y.; Yang, X.; Li, H.; Xu, H.; Guo, N. Microstructure and Properties of Cr-Fe2B Composite Coatings Prepared by Pack-Preboronizing Combined with Electro Brush-Plating. Coatings 2020, 10, 519. [Google Scholar] [CrossRef]

- Chaus, A.S.; Pokorný, P.; Čaplovič, Ľ.; Sitkevich, M.V.; Peterka, J. Complex fine-scale diffusion coating formed at low temperature on high-speed steel substrate. Appl. Surf. Sci. 2018, 437, 257–270. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, J.; Lu, K. Chromizing behaviors of a low carbon steel processed by means of surface mechanical attrition treatment. Acta Mater. 2005, 53, 2081–2089. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N. Enhanced PVD process control by online substrate temperature measurement. Surf. Coatings Technol. 2018, 354, 383–389. [Google Scholar] [CrossRef]

- Tauveron, N. Thermal fluctuations in the lower plenum of a high temperature reactor. Nucl. Eng. Des. 2003, 222, 125–137. [Google Scholar] [CrossRef]

- Shi, Q.-Q.; Yan, W.; Sha, W.; Wang, W.; Shan, Y.-Y.; Yang, K. Corrosion resistance of self-growing TiC coating on SIMP steel in LBE at 600 °C. Mater. Corros. 2016, 67, 1204–1212. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Xiao, J.; Wang, H.; Chen, Y.; Yin, X.; Guo, N. Corrosion Behavior and Surface Treatment of Cladding Materials Used in High-Temperature Lead-Bismuth Eutectic Alloy: A Review. Coatings 2021, 11, 364. https://doi.org/10.3390/coatings11030364

Wang H, Xiao J, Wang H, Chen Y, Yin X, Guo N. Corrosion Behavior and Surface Treatment of Cladding Materials Used in High-Temperature Lead-Bismuth Eutectic Alloy: A Review. Coatings. 2021; 11(3):364. https://doi.org/10.3390/coatings11030364

Chicago/Turabian StyleWang, Hao, Jun Xiao, Hui Wang, Yong Chen, Xing Yin, and Ning Guo. 2021. "Corrosion Behavior and Surface Treatment of Cladding Materials Used in High-Temperature Lead-Bismuth Eutectic Alloy: A Review" Coatings 11, no. 3: 364. https://doi.org/10.3390/coatings11030364

APA StyleWang, H., Xiao, J., Wang, H., Chen, Y., Yin, X., & Guo, N. (2021). Corrosion Behavior and Surface Treatment of Cladding Materials Used in High-Temperature Lead-Bismuth Eutectic Alloy: A Review. Coatings, 11(3), 364. https://doi.org/10.3390/coatings11030364