Author Contributions

Conceptualization, C.Z.; methodology, Q.L.; validation, T.Z.; formal analysis, T.Z.; investigation, C.Z.; resources, Y.B.; data curation, Q.L.; writing—original draft preparation, C.Z.; writing—review and editing, Y.B.; visualization, T.Z.; supervision, Y.B.; project administration, Y.B.; funding acquisition, Y.B. All authors have read and agreed to the published version of the manuscript.

Figure 1.

Riveting deformation process: (a) stage 1 of riveting process; (b) stage 2 of riveting process; (c) stage 3 of riveting process; (d) stage 4 of riveting process.

Figure 1.

Riveting deformation process: (a) stage 1 of riveting process; (b) stage 2 of riveting process; (c) stage 3 of riveting process; (d) stage 4 of riveting process.

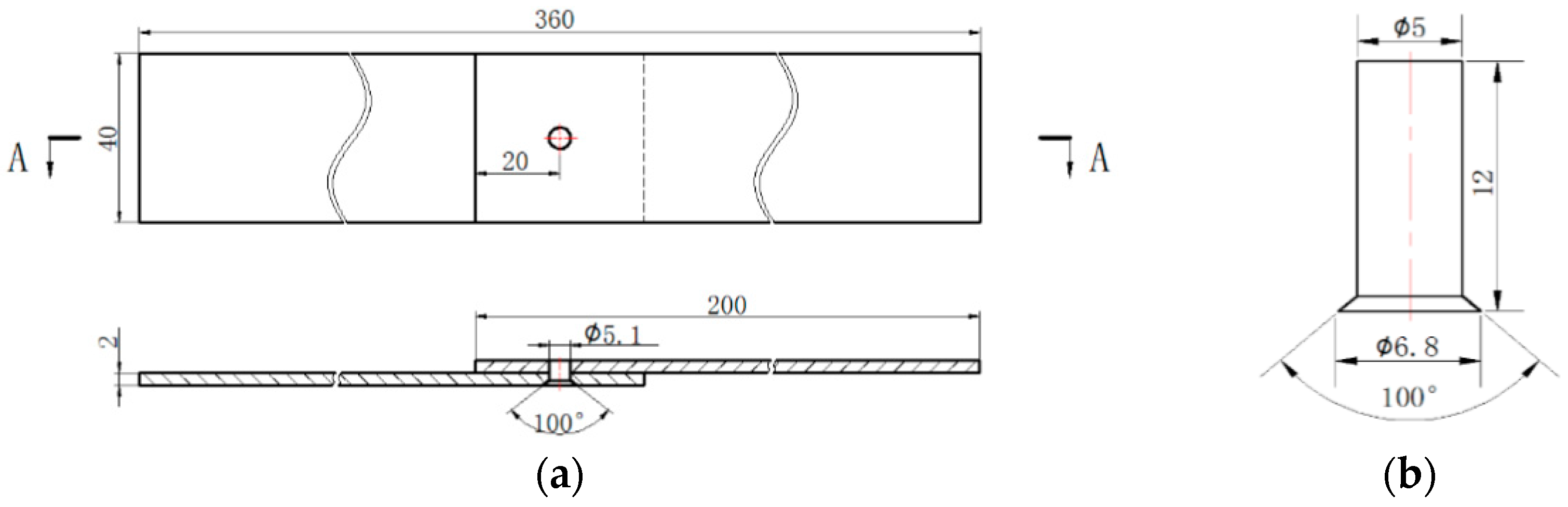

Figure 2.

Schematic diagram of riveted lap joint structure and size: (a) the structure and size of the joint plate; (b) the structure and size of the countersunk rivet.

Figure 2.

Schematic diagram of riveted lap joint structure and size: (a) the structure and size of the joint plate; (b) the structure and size of the countersunk rivet.

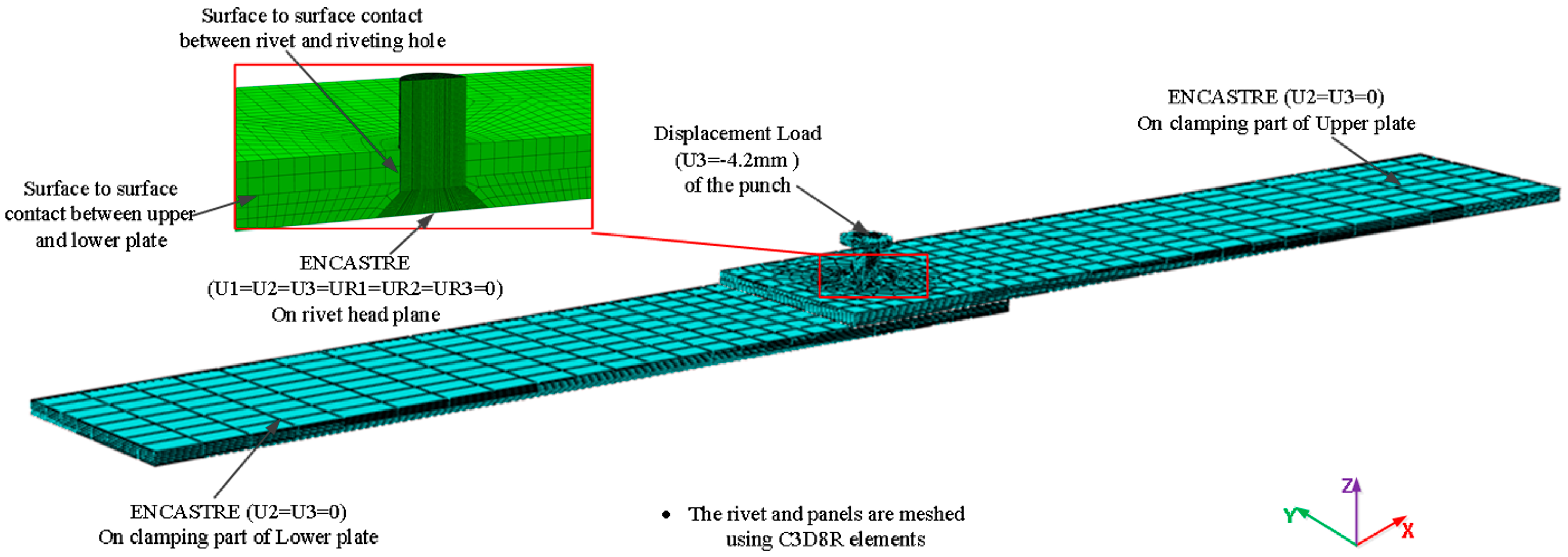

Figure 3.

Riveting model after finite element meshing.

Figure 3.

Riveting model after finite element meshing.

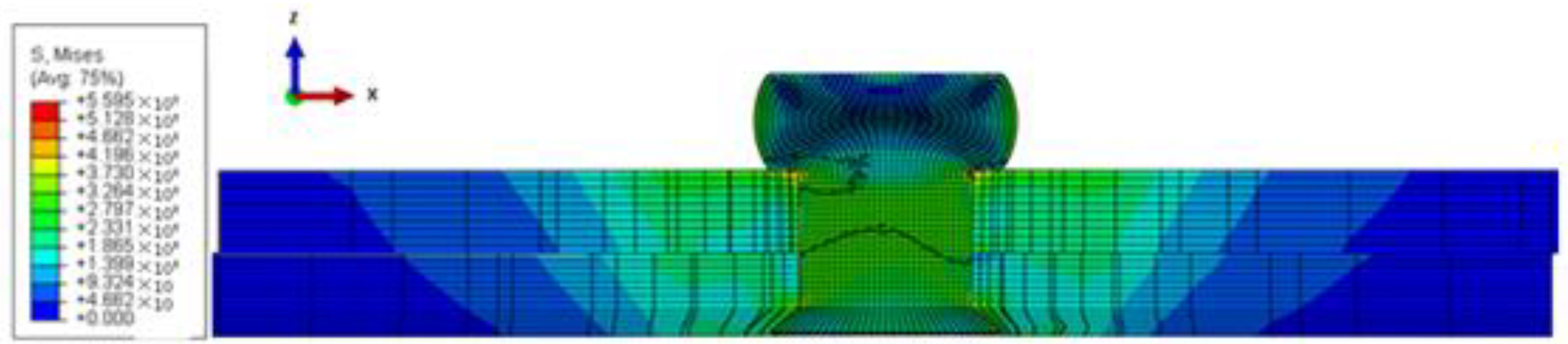

Figure 4.

Mises stress distribution of riveted parts (unit: MPa) (global).

Figure 4.

Mises stress distribution of riveted parts (unit: MPa) (global).

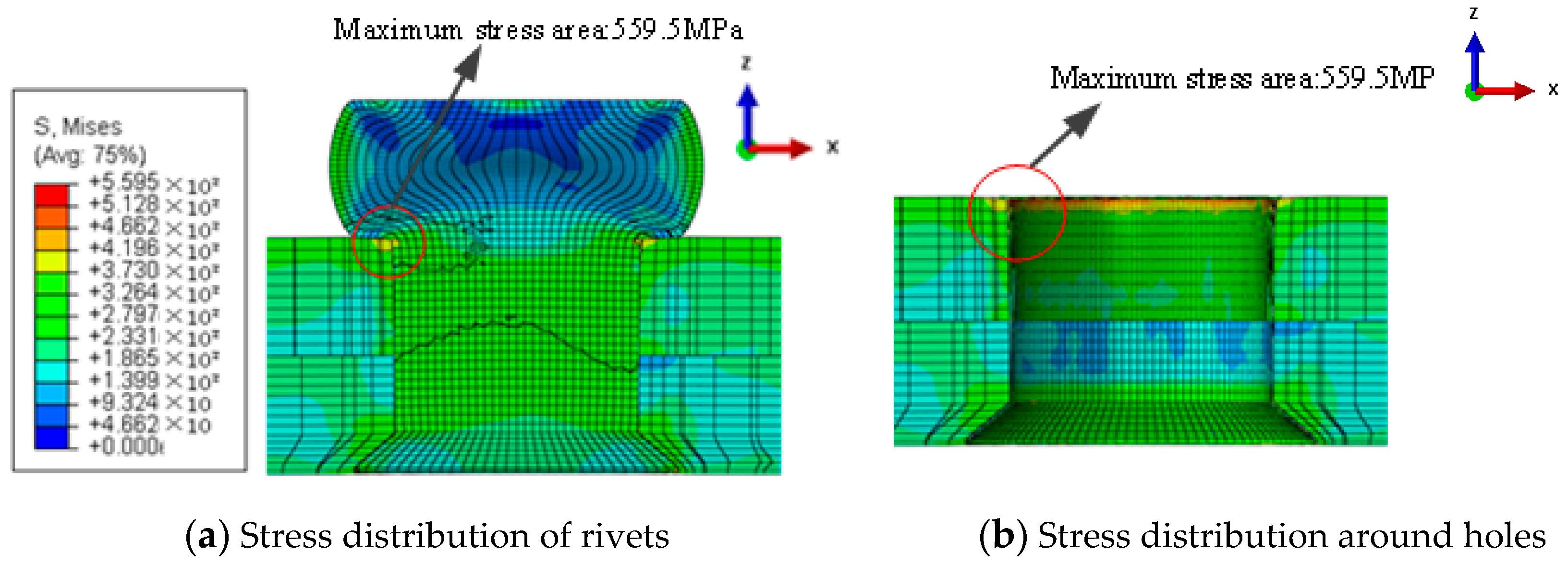

Figure 5.

Mises stress distribution of riveted parts (unit: MPa) (local).

Figure 5.

Mises stress distribution of riveted parts (unit: MPa) (local).

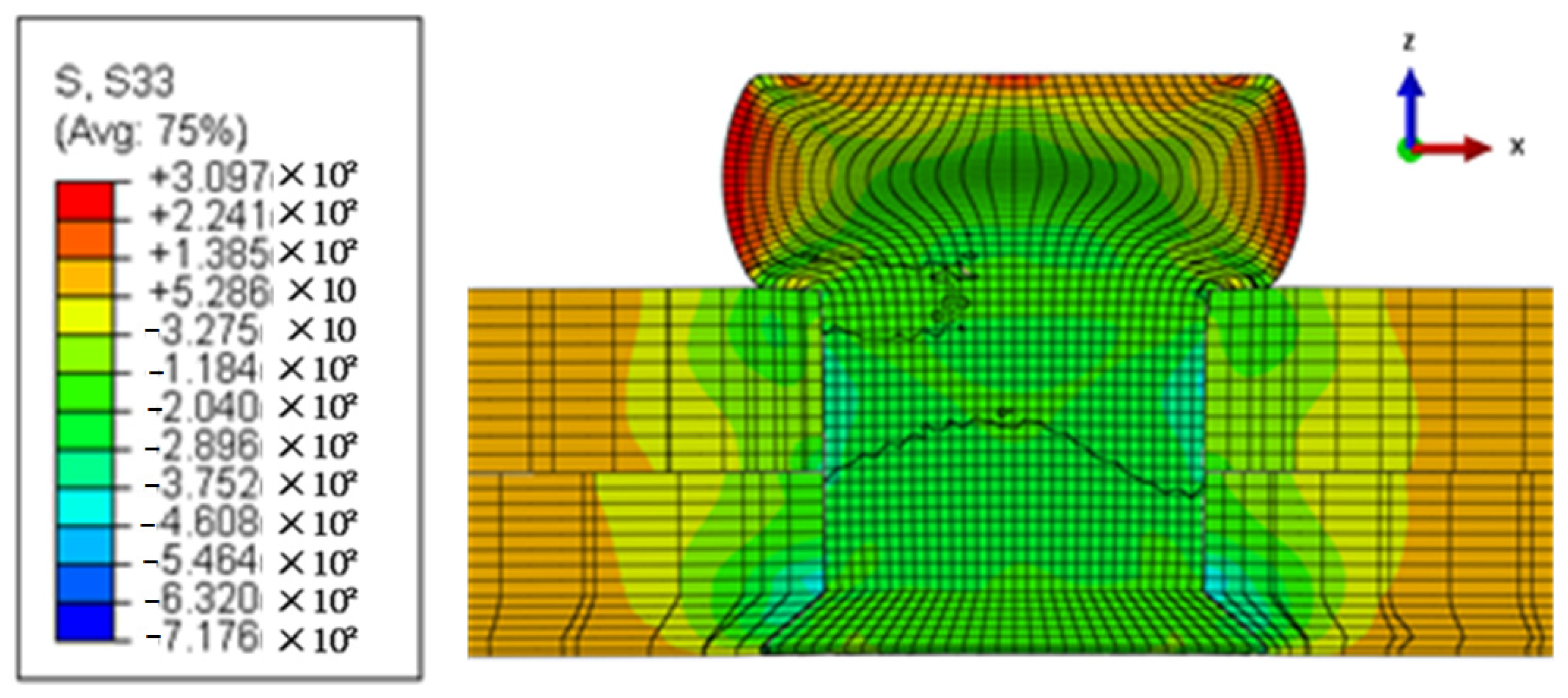

Figure 6.

Residual circumferential stress around rivet and hole (unit: MPa).

Figure 6.

Residual circumferential stress around rivet and hole (unit: MPa).

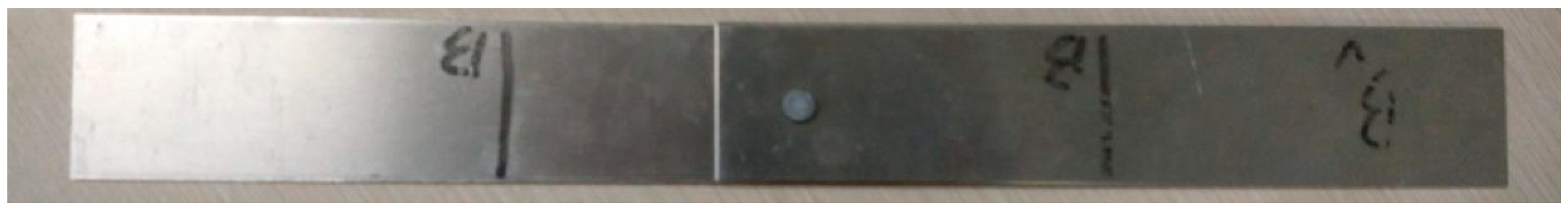

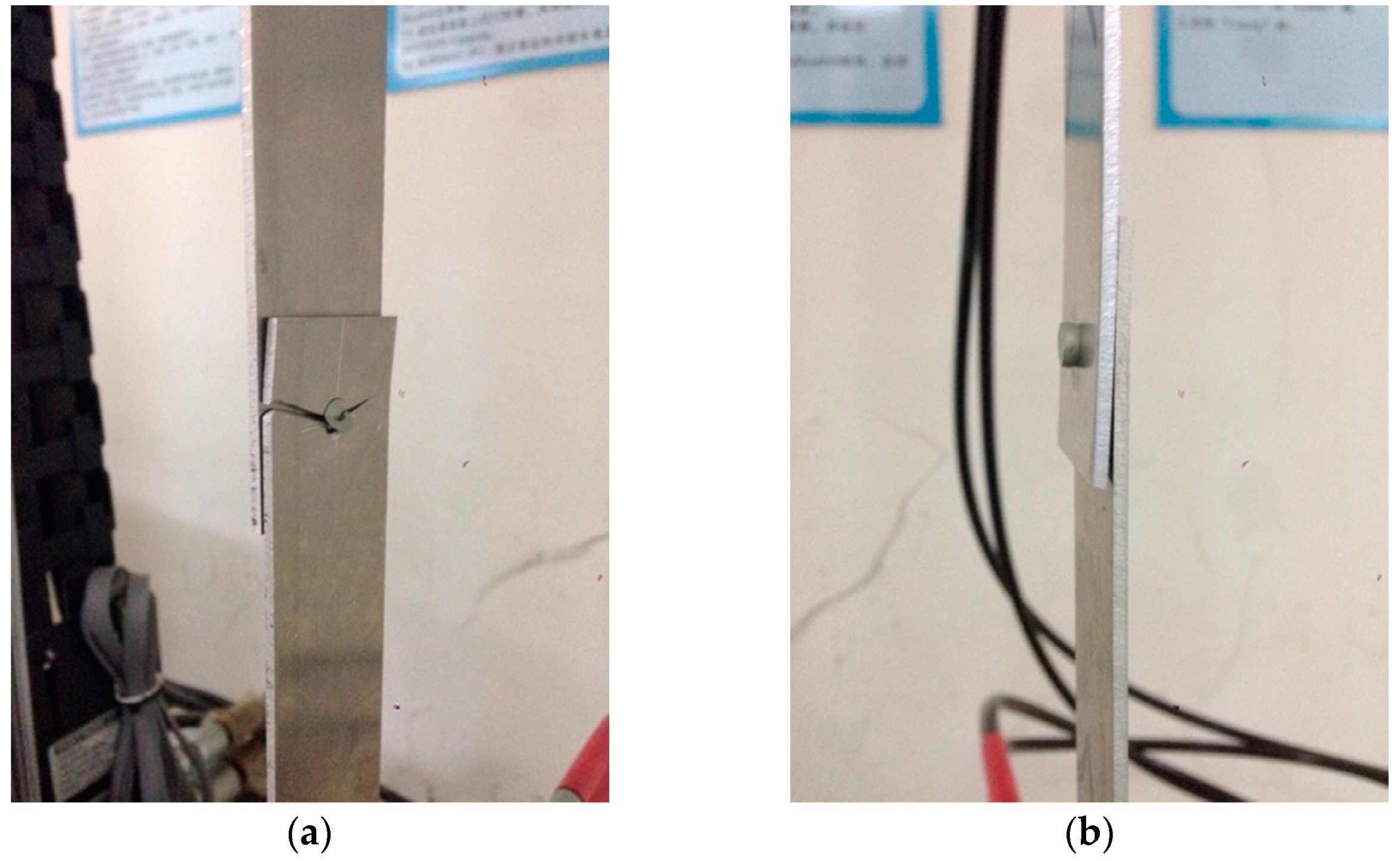

Figure 7.

Riveting test piece.

Figure 7.

Riveting test piece.

Figure 8.

Automatic drilling and riveting machine pressure riveting test.

Figure 8.

Automatic drilling and riveting machine pressure riveting test.

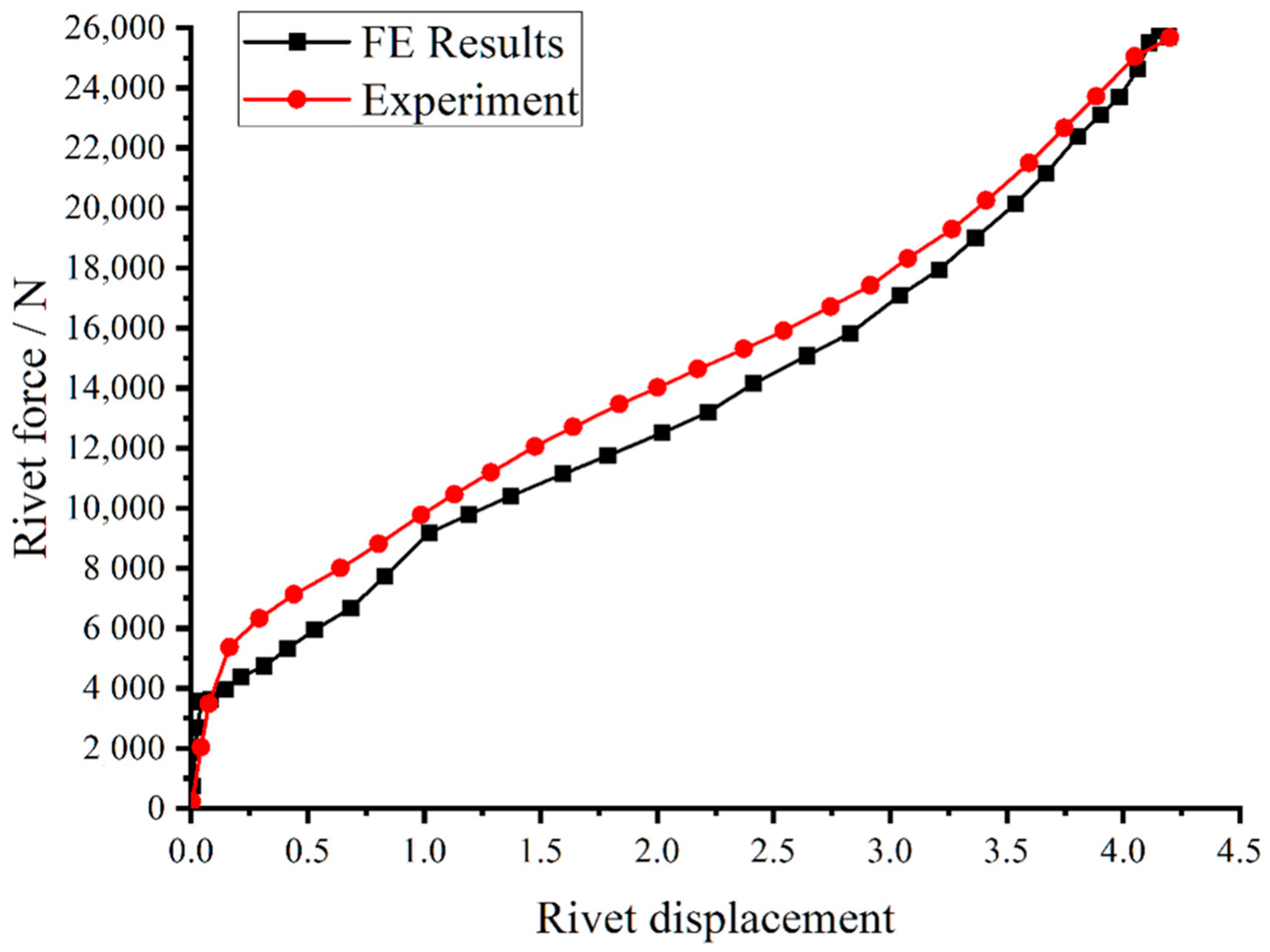

Figure 9.

Riveting force–displacement comparison curve obtained by finite element simulation and experiment.

Figure 9.

Riveting force–displacement comparison curve obtained by finite element simulation and experiment.

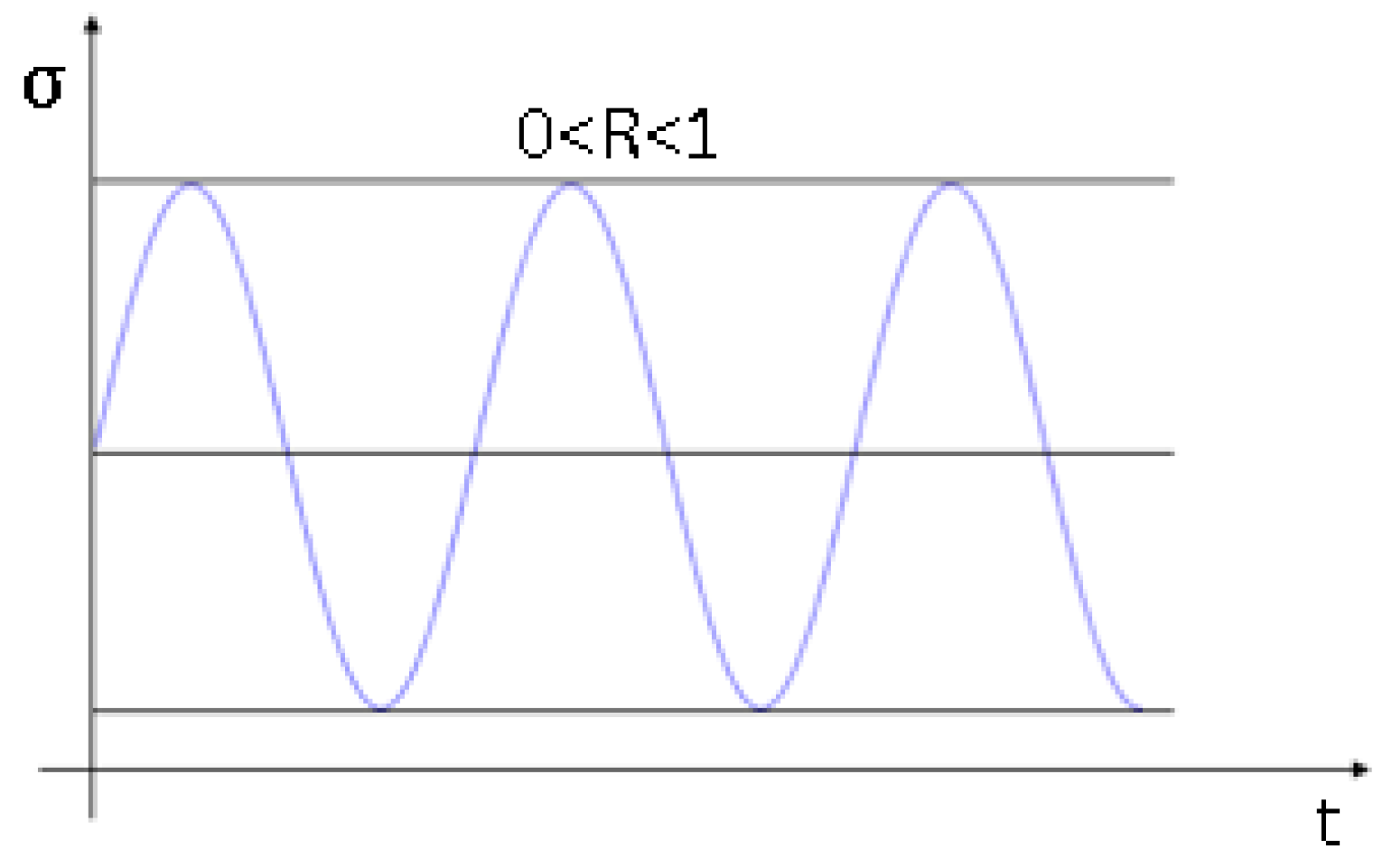

Figure 10.

Stress cycle diagram under fluctuation cycle.

Figure 10.

Stress cycle diagram under fluctuation cycle.

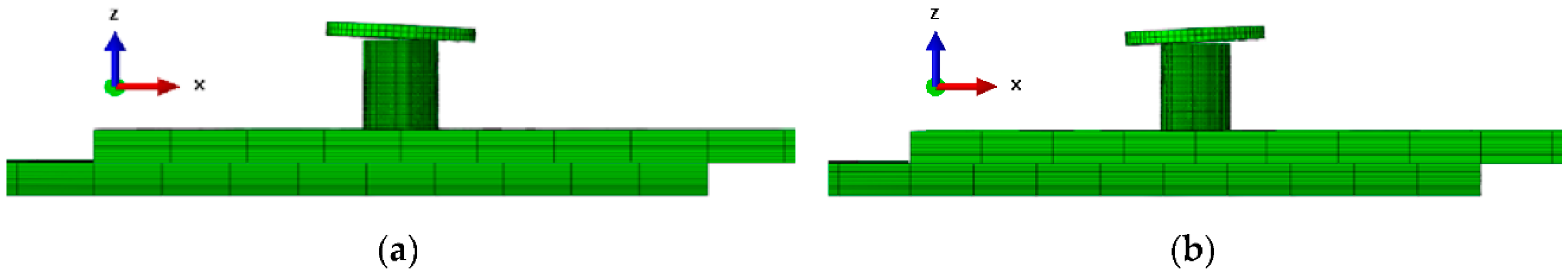

Figure 11.

Schematic diagram of the finite element model of different riveting angles and directions: (a) 0-3: a pressure riveting model with the punch deflected by 3° under the direction of 0°; (b) 180-3: a pressure riveting model with the punch deflected by 3° under the direction of 180°.

Figure 11.

Schematic diagram of the finite element model of different riveting angles and directions: (a) 0-3: a pressure riveting model with the punch deflected by 3° under the direction of 0°; (b) 180-3: a pressure riveting model with the punch deflected by 3° under the direction of 180°.

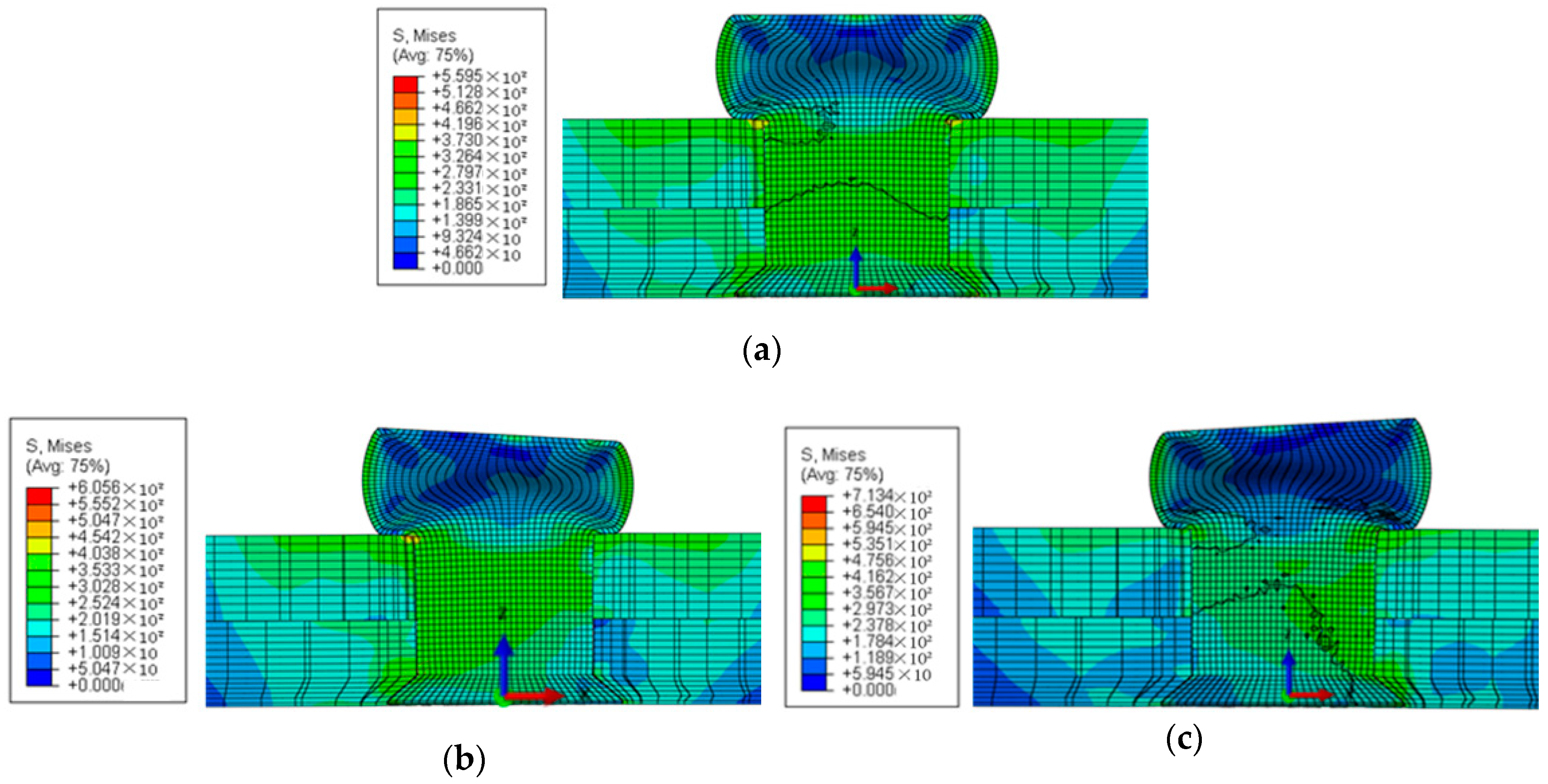

Figure 12.

Simulation results of riveted parts after pressing riveting at different angles in the same direction (0°) (unit: MPa): (a) the reference deformation and stress result of the punch at 0° when the punch is not deflected; (b) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 0°; (c) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 180°.

Figure 12.

Simulation results of riveted parts after pressing riveting at different angles in the same direction (0°) (unit: MPa): (a) the reference deformation and stress result of the punch at 0° when the punch is not deflected; (b) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 0°; (c) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 180°.

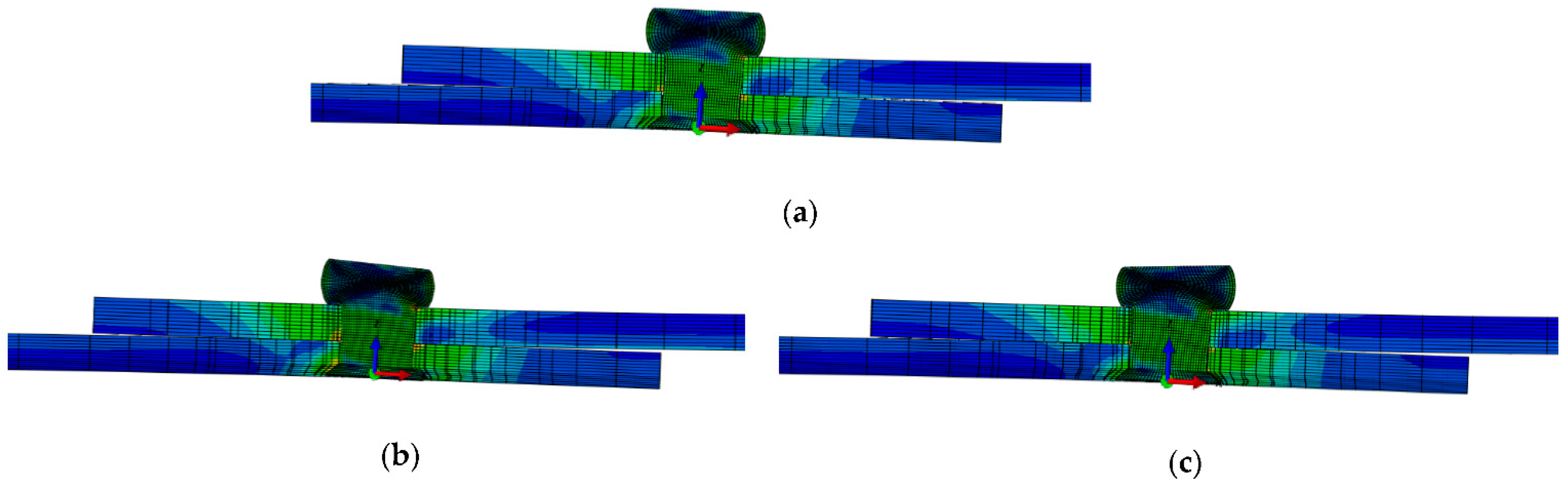

Figure 13.

Simulation results of riveted piece after transverse stretching: (a) the reference deformation and stress result of the punch at 0° when the punch is not deflected (0-0); (b) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 0° (0-3); (c) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 180° (180-3).

Figure 13.

Simulation results of riveted piece after transverse stretching: (a) the reference deformation and stress result of the punch at 0° when the punch is not deflected (0-0); (b) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 0° (0-3); (c) the deformation and stress result of the punch pressing down at an angle of 3° in the direction of 180° (180-3).

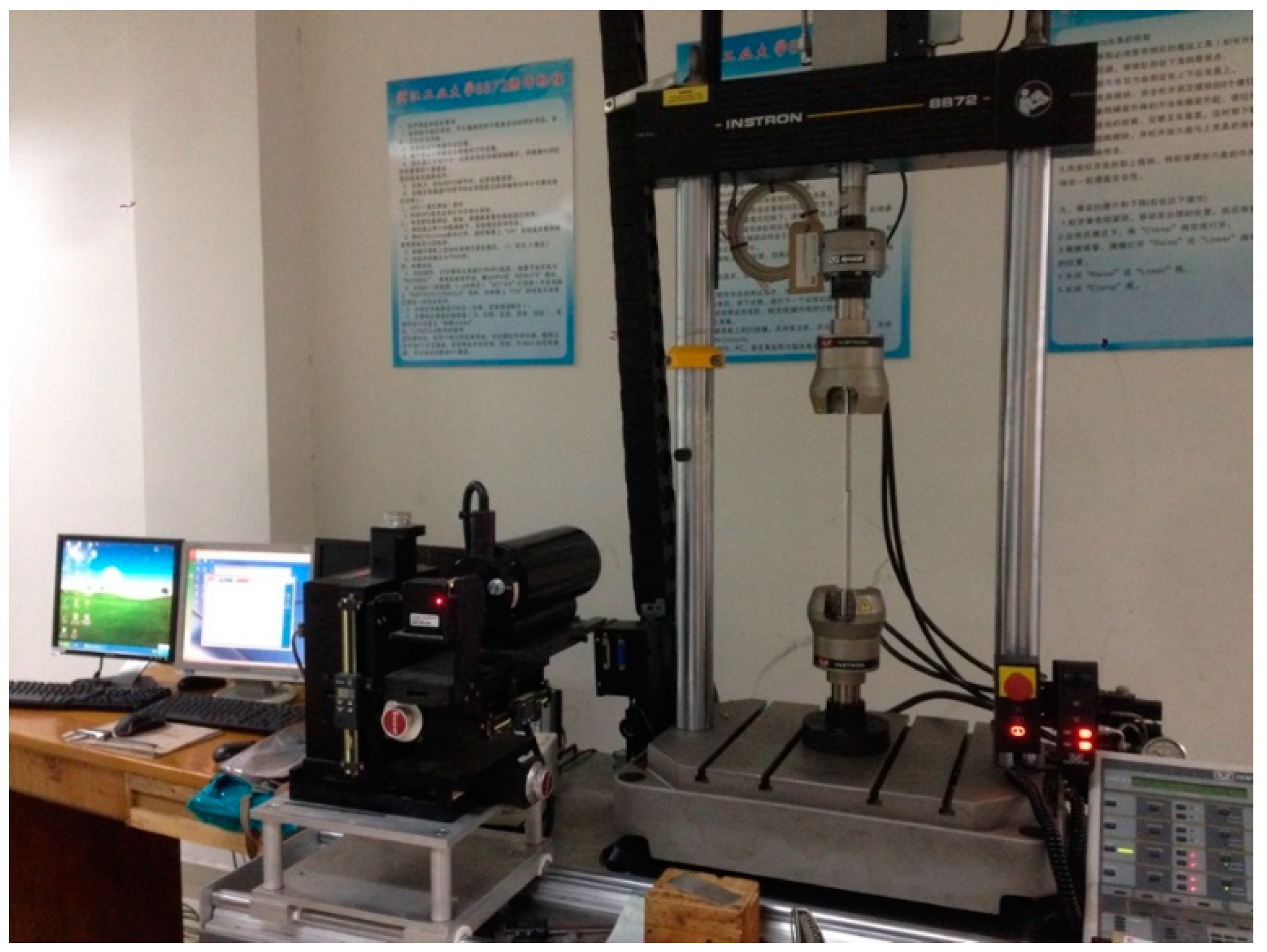

Figure 14.

Schematic diagram of fatigue test system: Instron 8872 Fatigue Test System.

Figure 14.

Schematic diagram of fatigue test system: Instron 8872 Fatigue Test System.

Figure 15.

High-cycle and low-cycle fatigue test results of riveted lap joints: (a) plate fractures with high-cycle fatigue failure; (b) rivet fracture with low-cycle fatigue failure.

Figure 15.

High-cycle and low-cycle fatigue test results of riveted lap joints: (a) plate fractures with high-cycle fatigue failure; (b) rivet fracture with low-cycle fatigue failure.

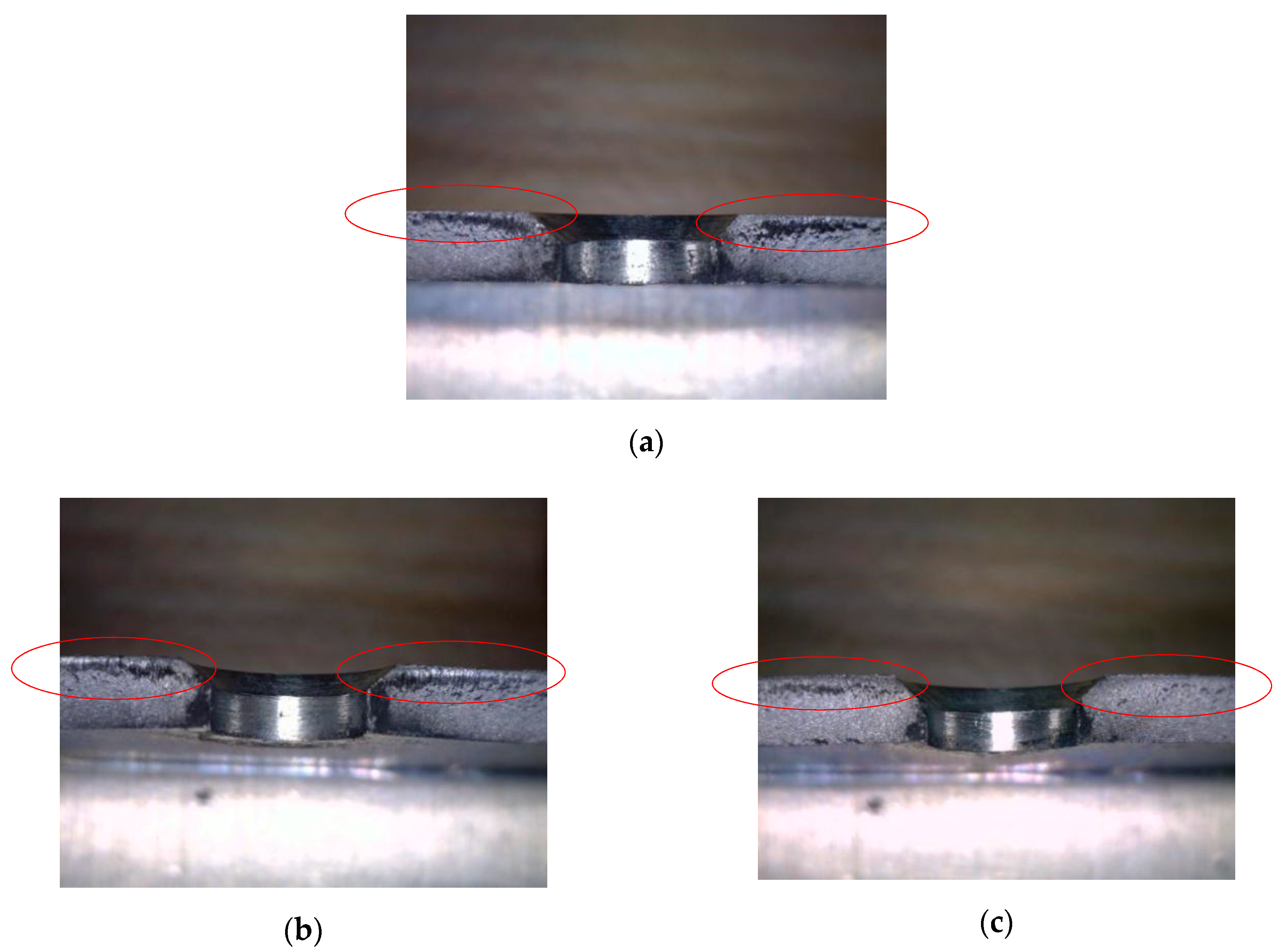

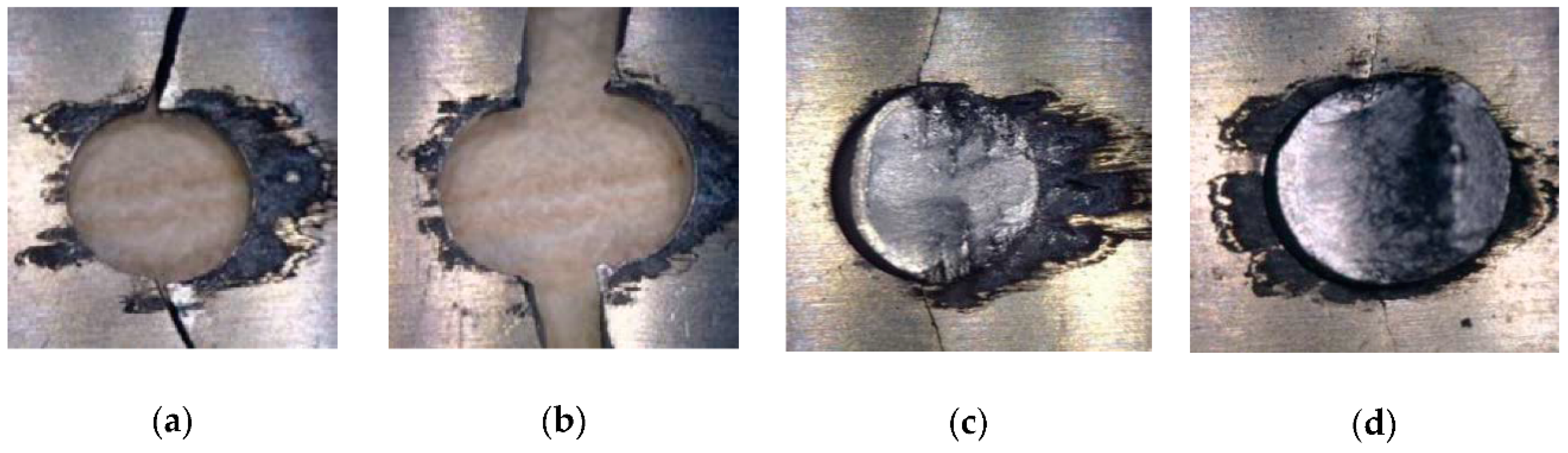

Figure 16.

Fatigue fracture section of riveted lap joint: (a) fatigue fracture section of 0° standard part (0-0); (b) fatigue fracture section of riveted lap joint with 1° in the 0° direction (0-1); (c) fatigue fracture section of riveted lap joint with 1° in the 180° direction (180-1).

Figure 16.

Fatigue fracture section of riveted lap joint: (a) fatigue fracture section of 0° standard part (0-0); (b) fatigue fracture section of riveted lap joint with 1° in the 0° direction (0-1); (c) fatigue fracture section of riveted lap joint with 1° in the 180° direction (180-1).

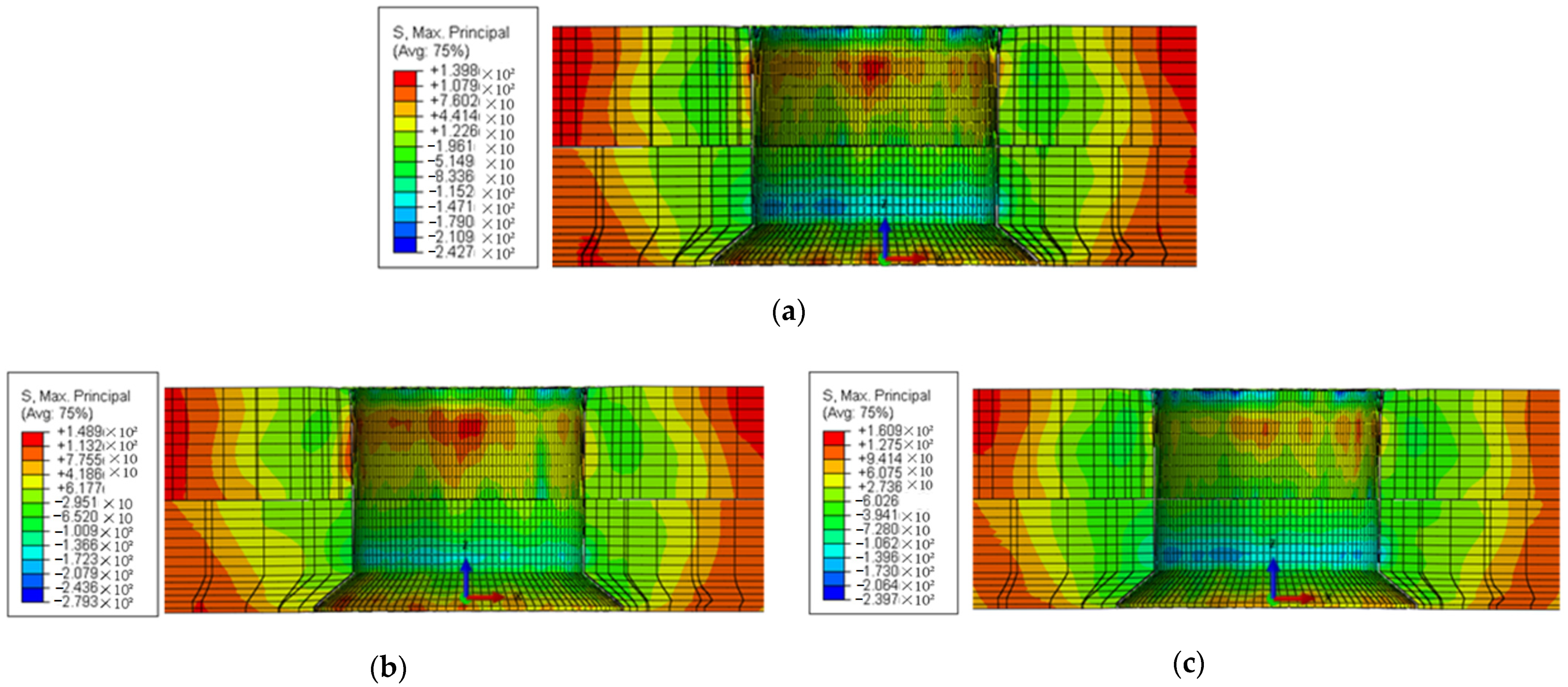

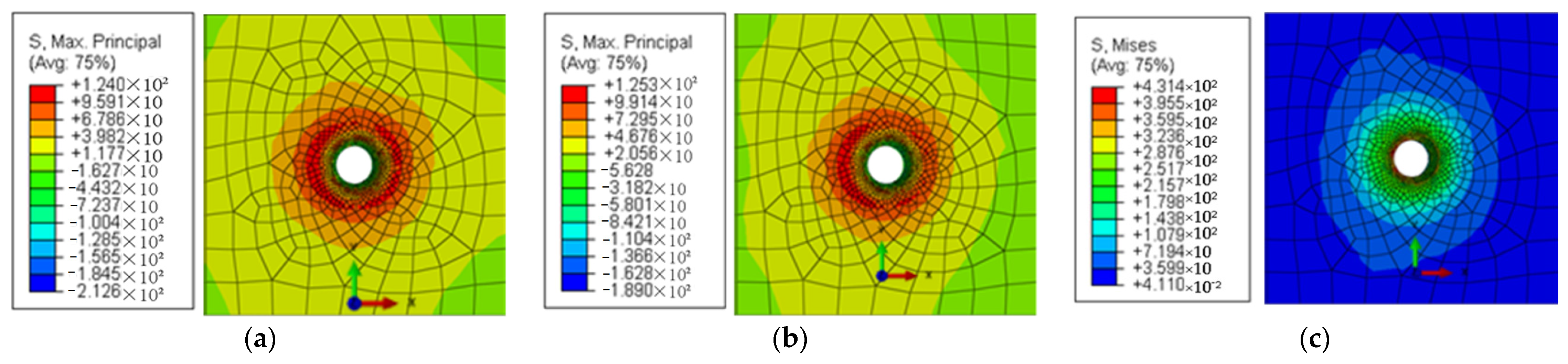

Figure 17.

Distribution diagram of maximum principal stress around the hole of riveted parts (unit: MPa): (a) distribution of maximum principal stress of 0° standard part (0-0); (b) distribution of maximum principal stress of riveted parts of 1° in the 0° direction (0-1); (c) distribution of maximum principal stress of riveted parts of 1° in the 180° direction (180-1).

Figure 17.

Distribution diagram of maximum principal stress around the hole of riveted parts (unit: MPa): (a) distribution of maximum principal stress of 0° standard part (0-0); (b) distribution of maximum principal stress of riveted parts of 1° in the 0° direction (0-1); (c) distribution of maximum principal stress of riveted parts of 1° in the 180° direction (180-1).

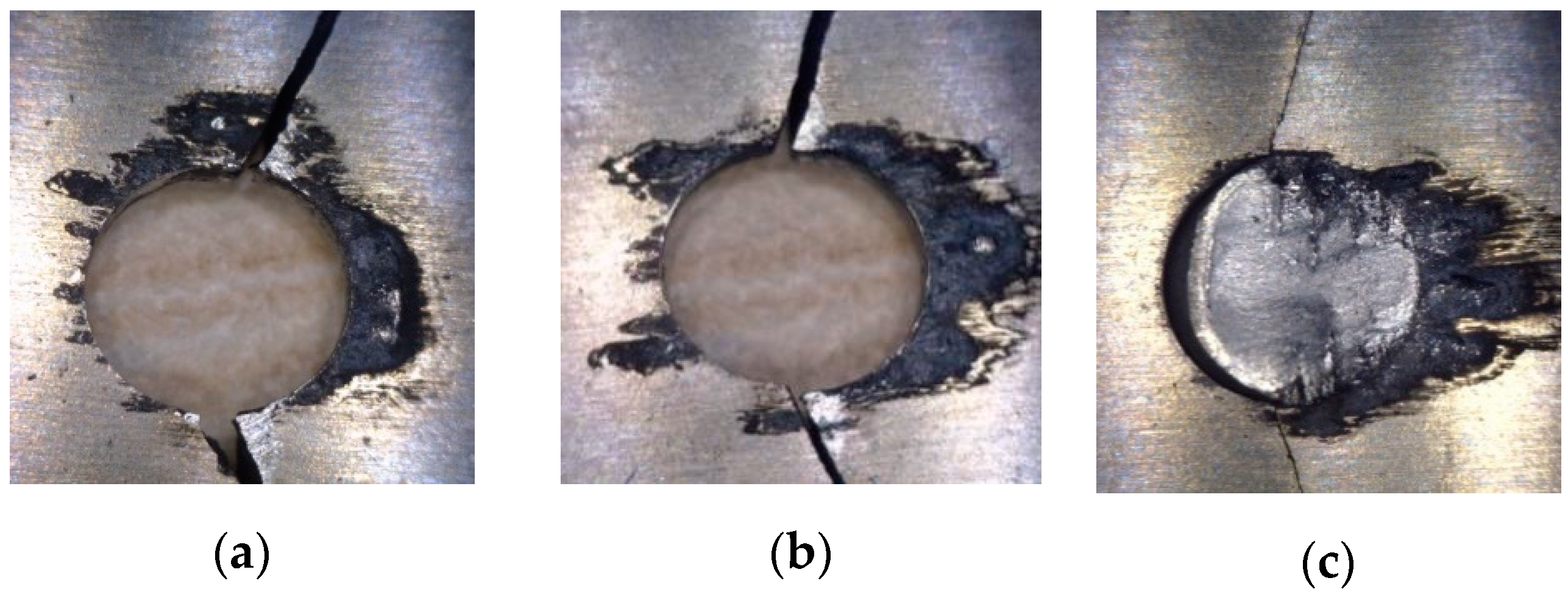

Figure 18.

Fatigue failure morphology of riveted lap joints at different riveting angles: (a) fatigue failure morphology of 0° standard part (0-0); (b) fatigue failure morphology of riveted joints of 1° in the 0° direction (0-1); (c) fatigue failure morphology of riveted joints of 2° in the 0° direction (0-2).

Figure 18.

Fatigue failure morphology of riveted lap joints at different riveting angles: (a) fatigue failure morphology of 0° standard part (0-0); (b) fatigue failure morphology of riveted joints of 1° in the 0° direction (0-1); (c) fatigue failure morphology of riveted joints of 2° in the 0° direction (0-2).

Figure 19.

Distribution diagram of maximum principal stress of riveted joints of different riveting angles (unit: MPa): (a) distribution of maximum principal stress of 0° standard part (0-0); (b) distribution of maximum principal stress of riveted parts of 1° in the 0° direction (0-1); (c) distribution of maximum principal stress of 2° in the 0° direction (0-2).

Figure 19.

Distribution diagram of maximum principal stress of riveted joints of different riveting angles (unit: MPa): (a) distribution of maximum principal stress of 0° standard part (0-0); (b) distribution of maximum principal stress of riveted parts of 1° in the 0° direction (0-1); (c) distribution of maximum principal stress of 2° in the 0° direction (0-2).

Figure 20.

Fatigue failure morphology of riveted lap joints in different riveting directions: (a) fatigue failure morphology of riveted joints of 1° in the 0° direction (0-1); (b) fatigue failure morphology of riveted joints of 1° in the 180° direction (180-1); (c) fatigue failure morphology of riveted joints of 2° in the 0° direction (0-2); (d) fatigue failure morphology of riveted joints of 2° in the 180° direction (180-2).

Figure 20.

Fatigue failure morphology of riveted lap joints in different riveting directions: (a) fatigue failure morphology of riveted joints of 1° in the 0° direction (0-1); (b) fatigue failure morphology of riveted joints of 1° in the 180° direction (180-1); (c) fatigue failure morphology of riveted joints of 2° in the 0° direction (0-2); (d) fatigue failure morphology of riveted joints of 2° in the 180° direction (180-2).

Figure 21.

Distribution diagram of maximum principal stress of riveted joints in different riveting directions (unit: MPa): (a) distribution of maximum principal stress of riveted joints of 1° in the 0° direction (0-1); (b) distribution of maximum principal stress of riveted joints of 1° in the 180° direction (180-1); (c) distribution of maximum principal stress of 2° in the 0° direction (0-2); (d) distribution of maximum principal stress of 2° in the 180° direction (180-2).

Figure 21.

Distribution diagram of maximum principal stress of riveted joints in different riveting directions (unit: MPa): (a) distribution of maximum principal stress of riveted joints of 1° in the 0° direction (0-1); (b) distribution of maximum principal stress of riveted joints of 1° in the 180° direction (180-1); (c) distribution of maximum principal stress of 2° in the 0° direction (0-2); (d) distribution of maximum principal stress of 2° in the 180° direction (180-2).

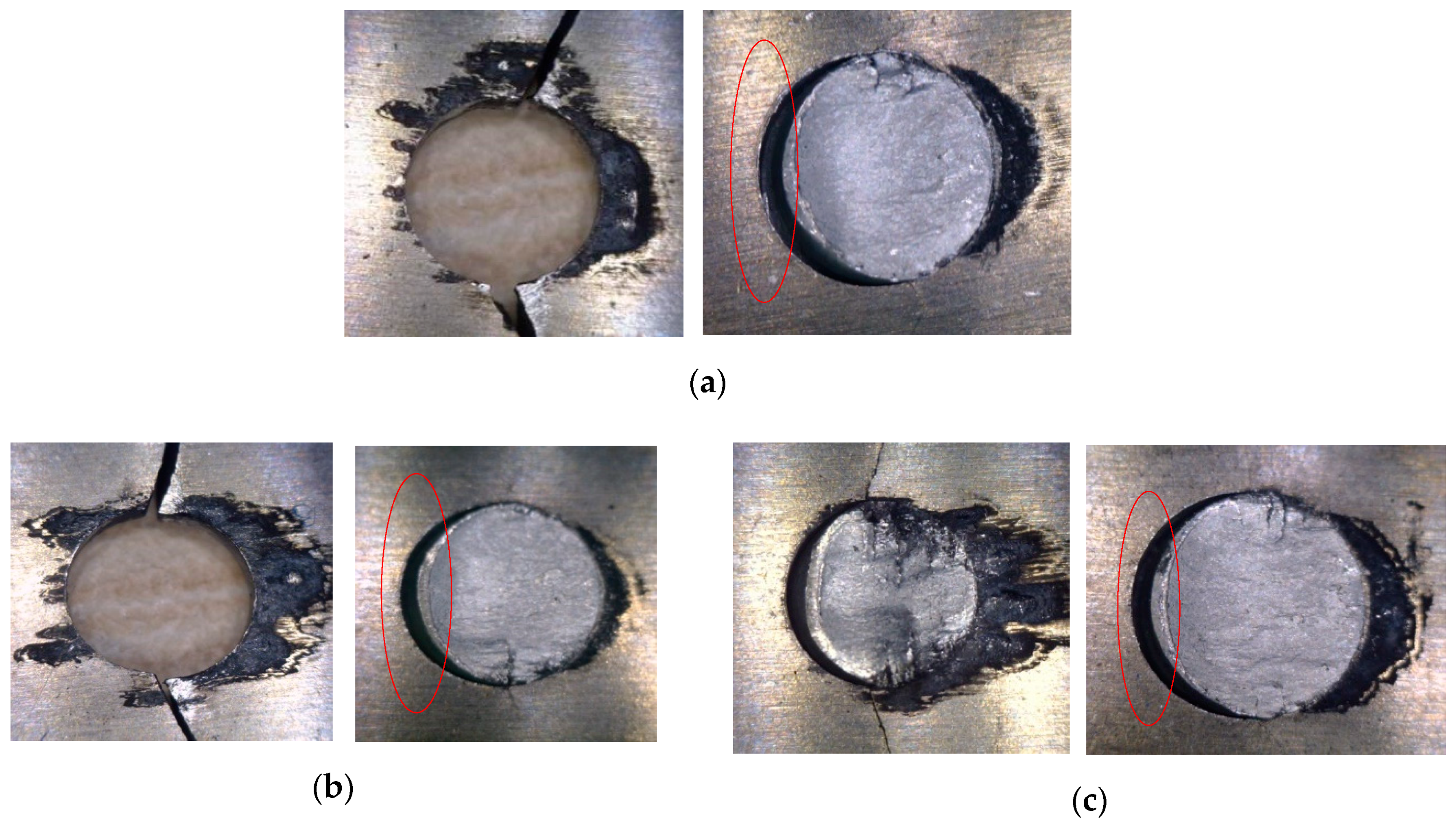

Figure 22.

High-cycle fatigue failure and low-cycle fatigue failure of riveted joints of different riveting angles: (a) comparison of high-cycle fatigue and low-cycle fatigue failures of 0° standard part (0-0); (b) comparison of high-cycle fatigue and low-cycle fatigue failures of riveted parts of 1° in the 0° direction (0-1); (c) comparison of high-cycle fatigue and low-cycle fatigue failures of riveted parts of 2° in the 0° direction (0-2).

Figure 22.

High-cycle fatigue failure and low-cycle fatigue failure of riveted joints of different riveting angles: (a) comparison of high-cycle fatigue and low-cycle fatigue failures of 0° standard part (0-0); (b) comparison of high-cycle fatigue and low-cycle fatigue failures of riveted parts of 1° in the 0° direction (0-1); (c) comparison of high-cycle fatigue and low-cycle fatigue failures of riveted parts of 2° in the 0° direction (0-2).

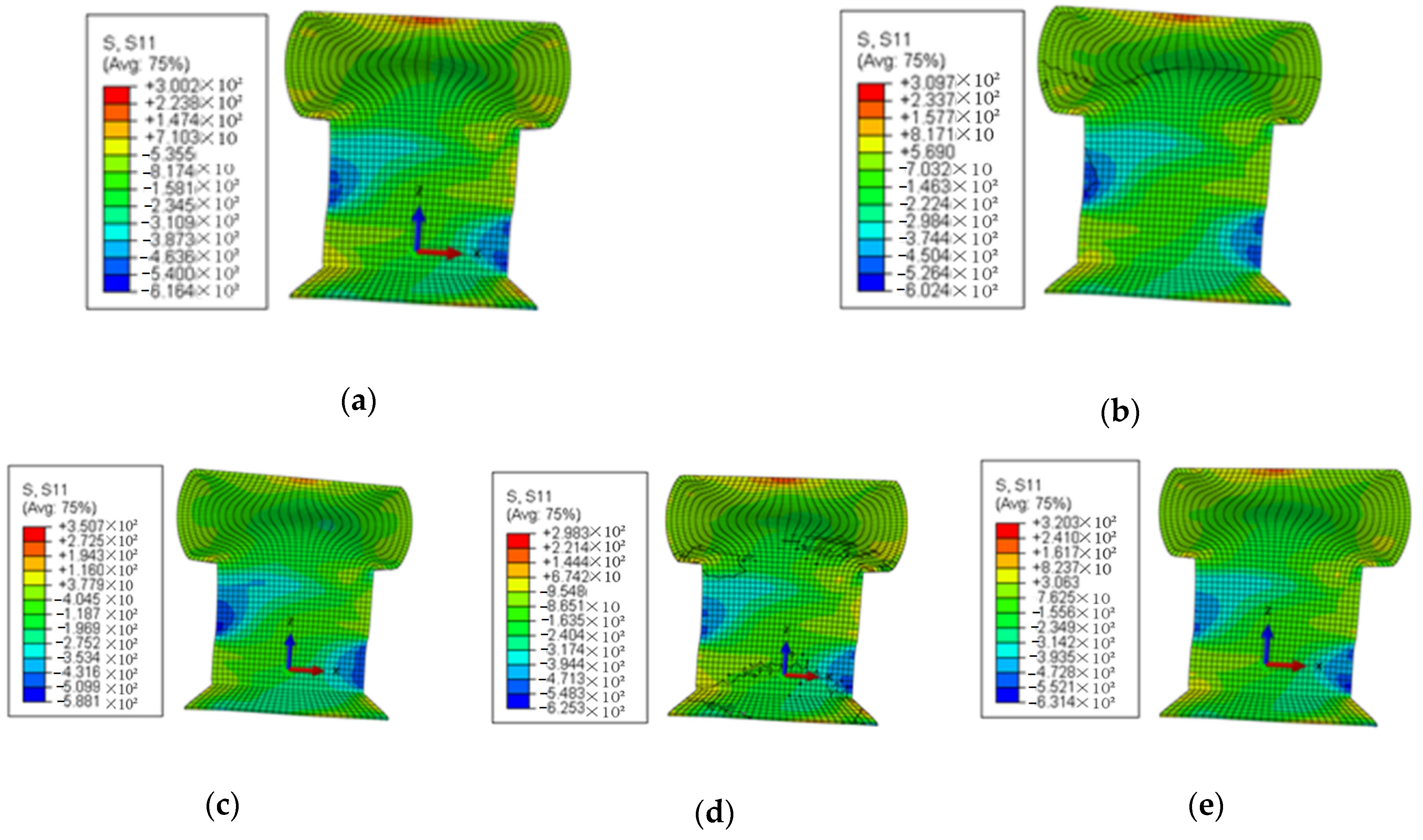

Figure 23.

Stress distribution diagram of rivet under shearing force (unit: MPa): (a) stress distribution of rivet of 0° standard part (0-0); (b) stress distribution of rivet of joints of 1° in the 0° direction (0-1); (c) stress distribution of rivet of joints of 2° in the 0° direction (0-2); (d) stress distribution of rivet of joints of 1° in the 180° direction (180-1); (e) stress distribution of rivet of joints of 2° in the 180° direction (180-2).

Figure 23.

Stress distribution diagram of rivet under shearing force (unit: MPa): (a) stress distribution of rivet of 0° standard part (0-0); (b) stress distribution of rivet of joints of 1° in the 0° direction (0-1); (c) stress distribution of rivet of joints of 2° in the 0° direction (0-2); (d) stress distribution of rivet of joints of 1° in the 180° direction (180-1); (e) stress distribution of rivet of joints of 2° in the 180° direction (180-2).

Table 1.

Material parameters of 2117-T4 aluminum alloy rivets.

Table 1.

Material parameters of 2117-T4 aluminum alloy rivets.

| Material Parameter | 2117-T4 Aluminum Alloy Rivets |

|---|

| Density, ρ | 2830 Kg/m3 |

| Young’s modulus, E | 74 GPa |

| Poisson’s ratio, ν | 0.33 |

| Yield stress, σS | 172 MPa |

| Strength coefficient, C 1(0.02 ≤ εtrue ≤ 0.10) | 544 MPa |

| Strength coefficient, C 1(0.10 ≤ εtrue ≤ 1.0) | 551 MPa |

| Hardening exponent, m 1(0.02 ≤ εtrue ≤ 0.10) | 0.23 |

| Hardening exponent, m 1(0.10 ≤ εtrue ≤ 1.0) | 0.15 |

Table 2.

Material parameters of 7050 aluminum alloy plates.

Table 2.

Material parameters of 7050 aluminum alloy plates.

| Material Parameter | 7050 Aluminum Alloy Rivets |

|---|

| Density, ρ | 2690 Kg/m3 |

| Young’s modulus, E | 71.7 GPa |

| Poisson’s ratio, ν | 0.33 |

| Yield stress, σS | 310 MPa |

| Strength coefficient, C 1(εy ≤ εtrue ≤ 0.02) | 676 MPa |

| Strength coefficient, C 1(0.02 ≤ εtrue ≤ 0.1) | 745 MPa |

| Hardening exponent, m 1(εy ≤ εtrue ≤ 0.02) | 0.14 |

| Hardening exponent, m 1(0.02 ≤ εtrue ≤ 0.1) | 0.164 |

Table 3.

Driven head size data comparison between simulation and riveting test.

Table 3.

Driven head size data comparison between simulation and riveting test.

| Parameters | Data |

|---|

| Diameter of driven head from simulation | 7.843 mm |

| Diameter of driven head from test | 8.021 mm |

| Driven head diameter difference | 0.178 mm |

| Deviation | 2.2% |

Table 4.

Fatigue life of riveted lap joints at different riveting angles.

Table 4.

Fatigue life of riveted lap joints at different riveting angles.

| Riveting Angle | 0° | 1° | 2° |

|---|

| High-cycle fatigue life (cycle) | 163,793 | 212,862 | 144,572 |

| Low-cycle fatigue life (cycle) | 11,212 | 13,039 | 14,161 |

Table 5.

High-cycle fatigue life of riveted joints at different riveting angles and directions.

Table 5.

High-cycle fatigue life of riveted joints at different riveting angles and directions.

| Riveting Directions | 0° | 1° | 2° |

|---|

| High-cycle fatigue life of 0° direction (cycle) | 163,793 | 212,862 | 144,572 |

| High-cycle fatigue life of 180° direction (cycle) | 131,878 | 87,141 |

Table 6.

Low-cycle fatigue life of riveted joints at different riveting angles and directions.

Table 6.

Low-cycle fatigue life of riveted joints at different riveting angles and directions.

| Riveting Angles | 0° | 1° | 2° |

|---|

| Low-cycle fatigue life of 0° direction (cycle) | 11,212 | 13,039 | 14,161 |

| Low-cycle fatigue life of 180° direction (cycle) | 10,469 | 13,453 |

Table 7.

Maximum shear stress of rivet at different riveting angles and directions.

Table 7.

Maximum shear stress of rivet at different riveting angles and directions.

| Riveting Angles | 0° | 1° | 2° |

|---|

| Maximum shear stress of 0° direction (MPa) | 616.4 | 602.4 | 588.1 |

| Maximum shear stress of 180° direction (MPa) | 625.3 | 631.4 |