Influence of Multi-Step Heating Methods on Properties of Al–Si Coating Boron Steel Sheet

Abstract

1. Introduction

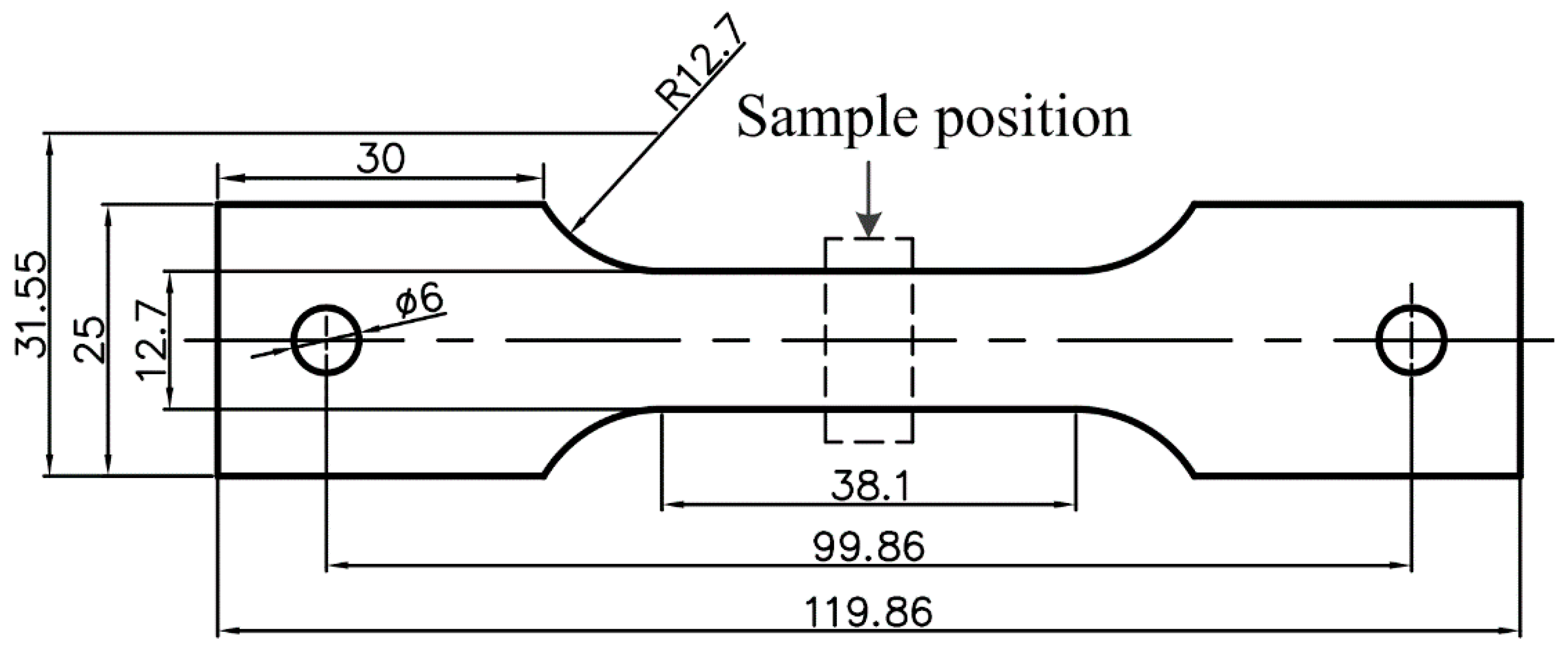

2. Experimental

2.1. Materials

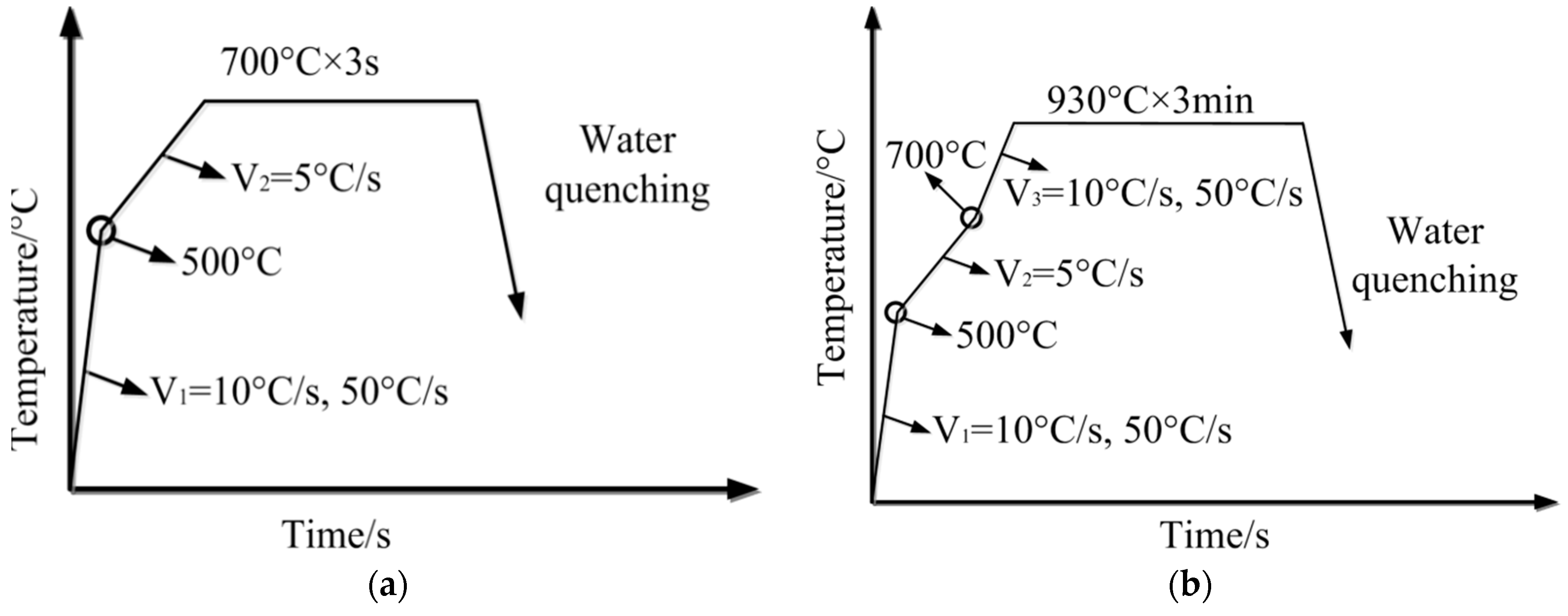

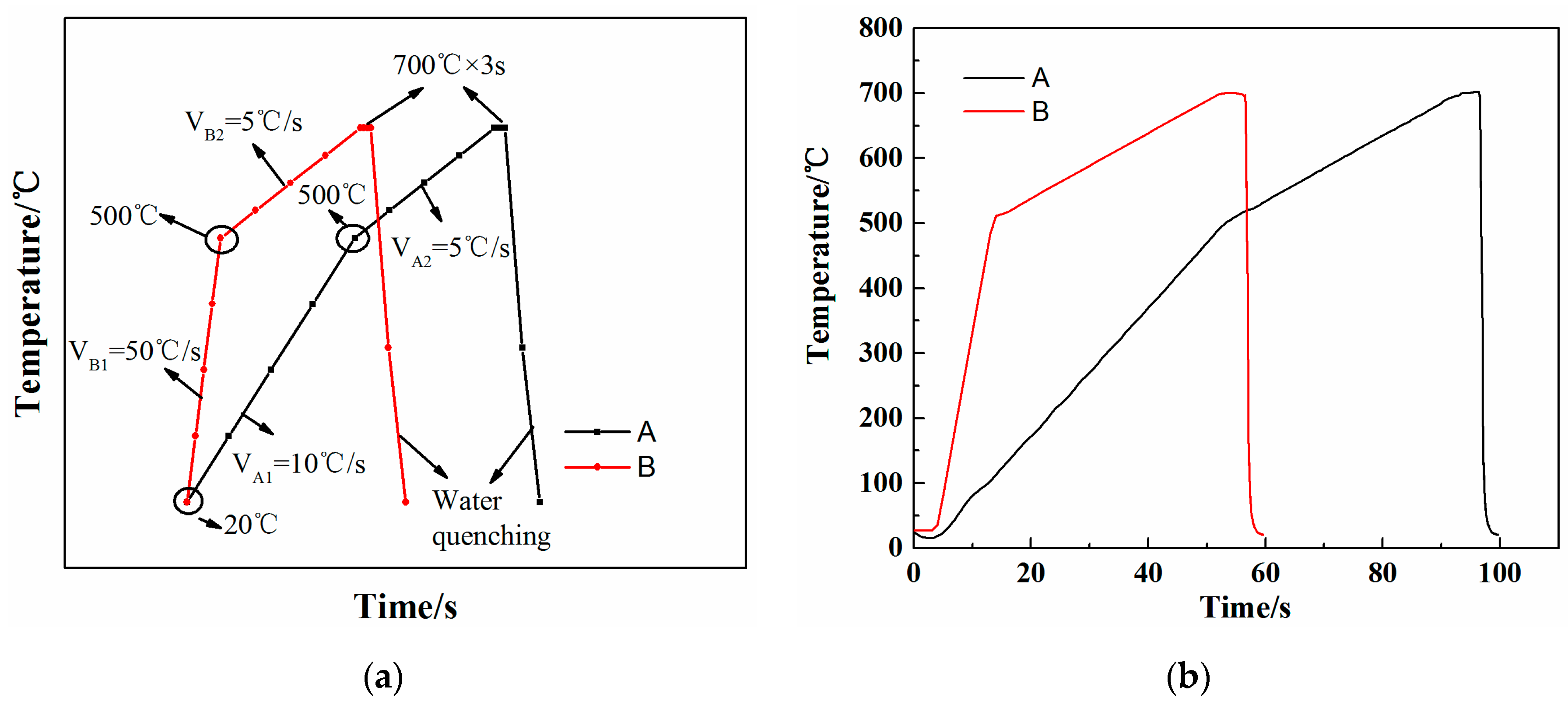

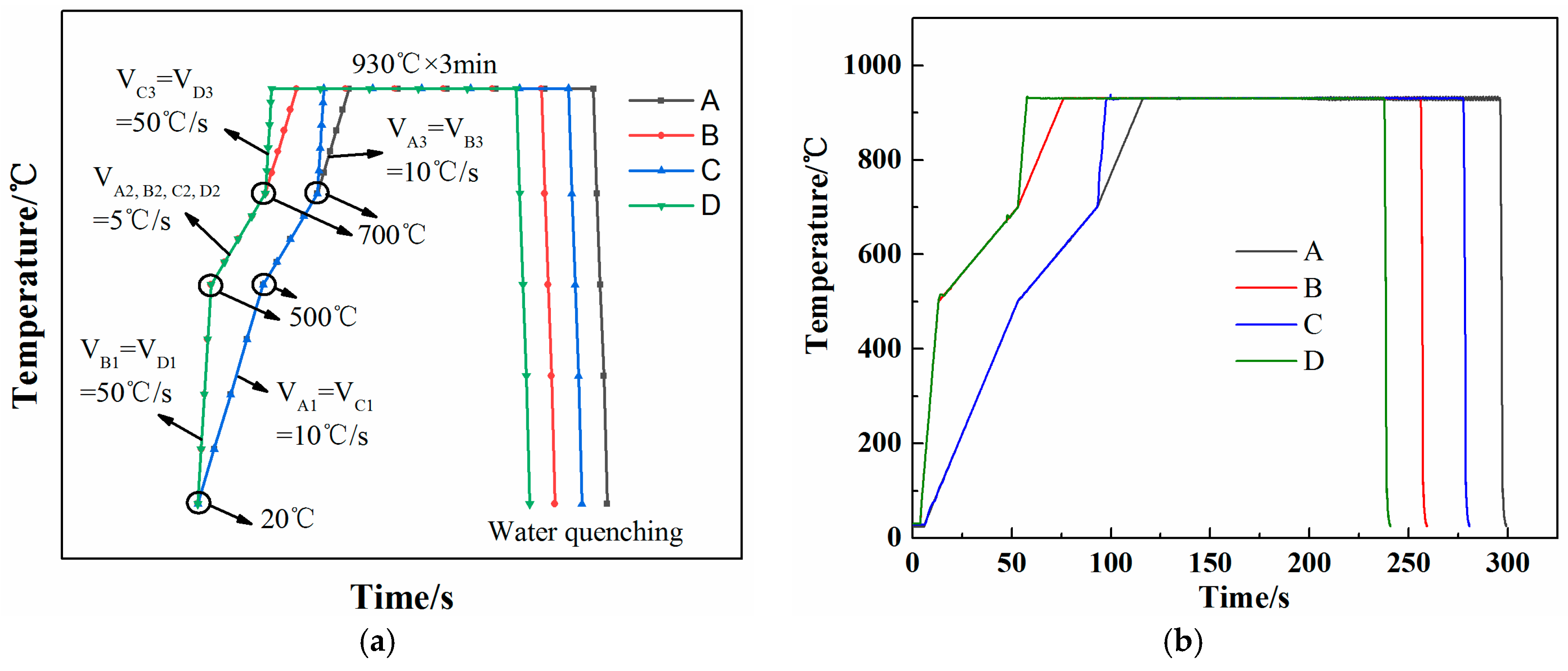

2.2. Experimental Schemes

3. Results

3.1. Two-Step Heating Methods

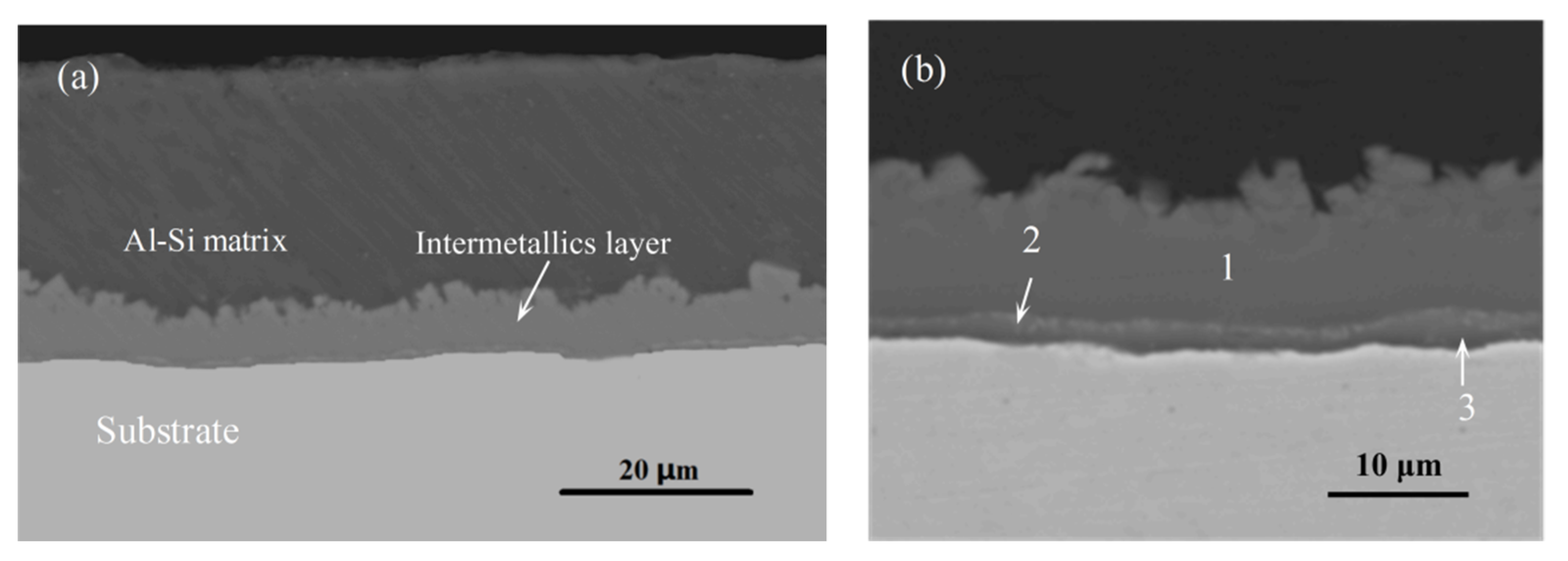

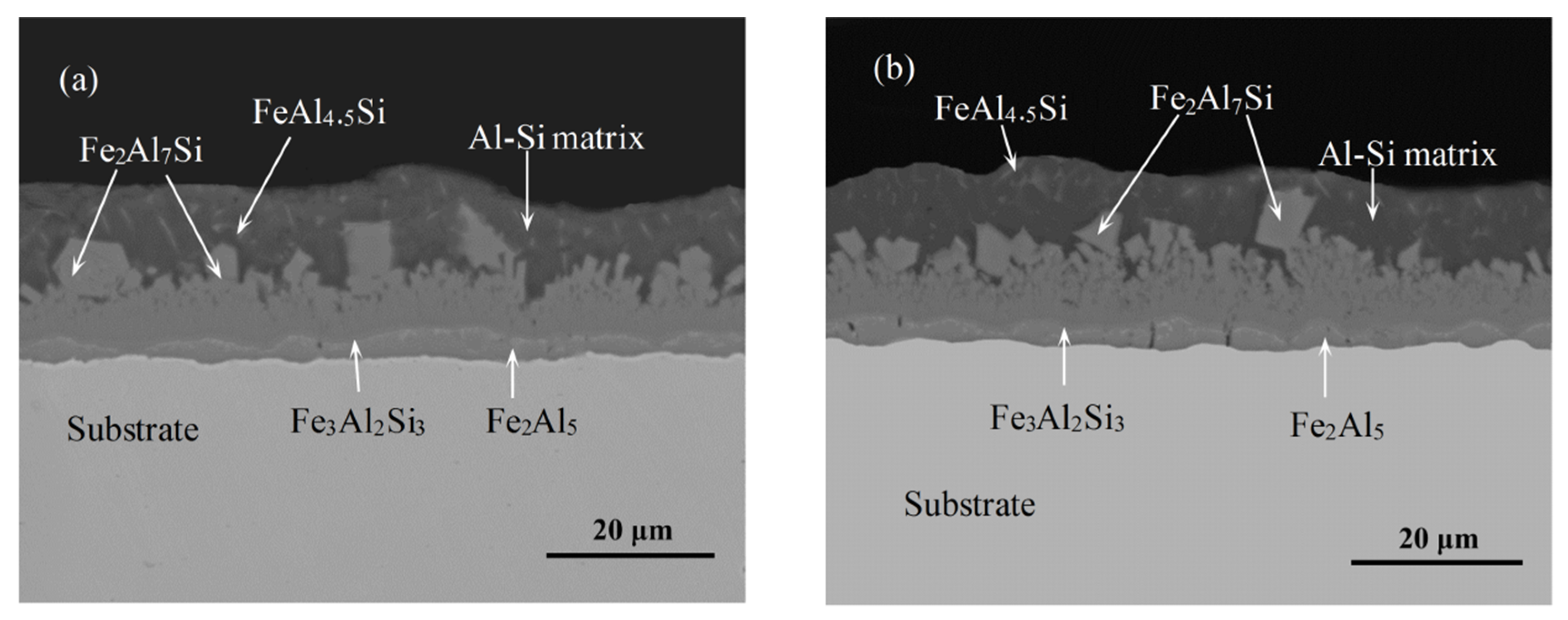

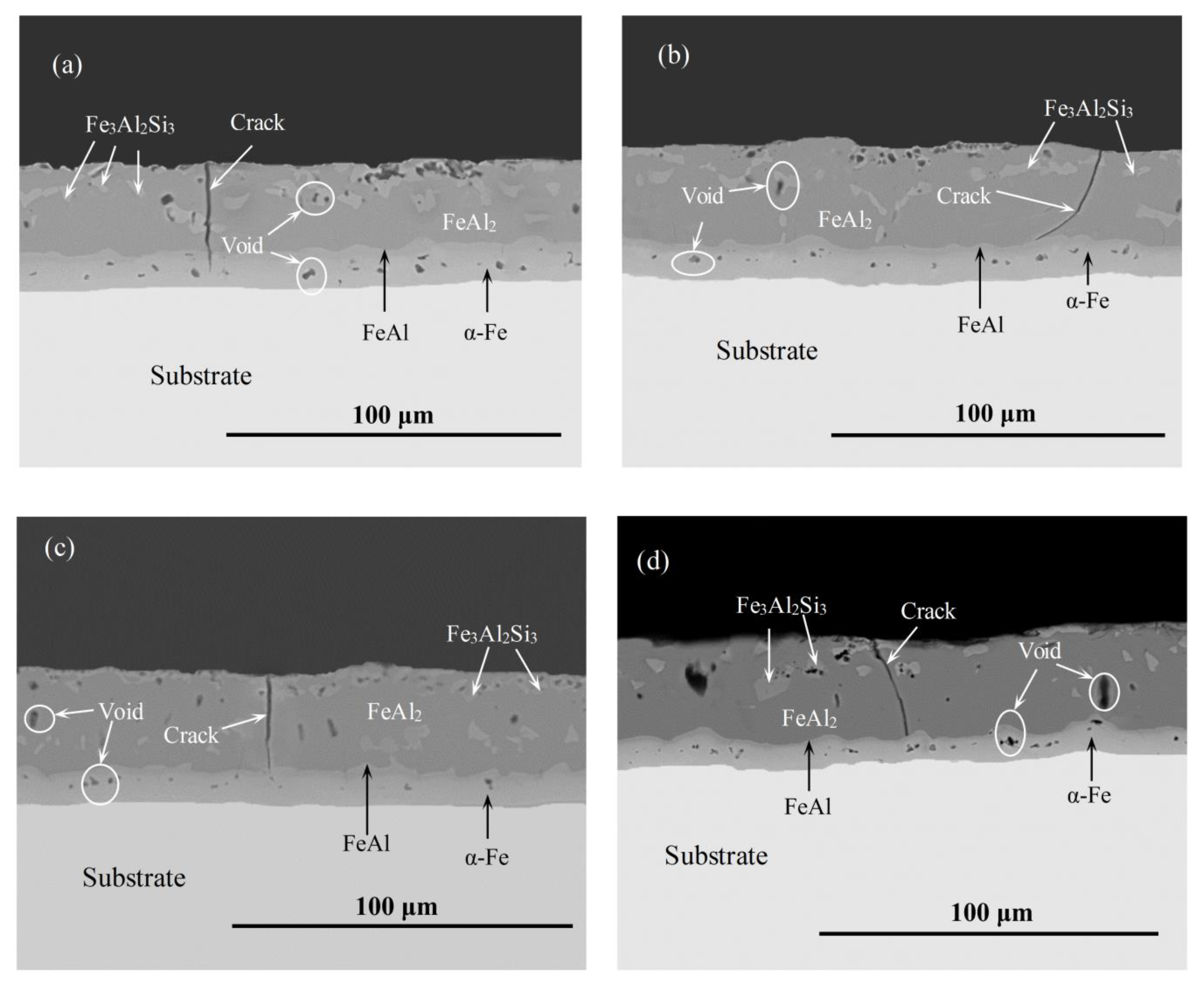

3.1.1. Microstructure Evolution of Al–Si Coating Boron Steel Sheet

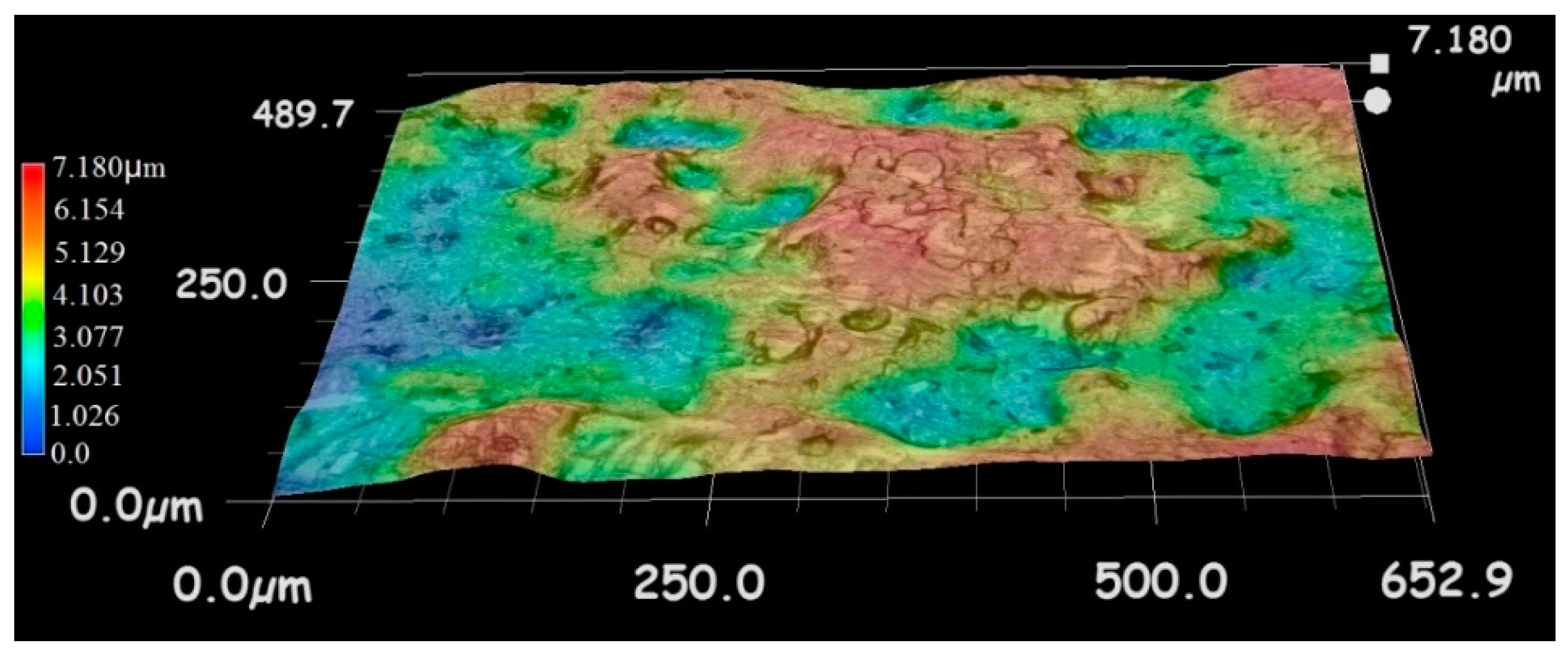

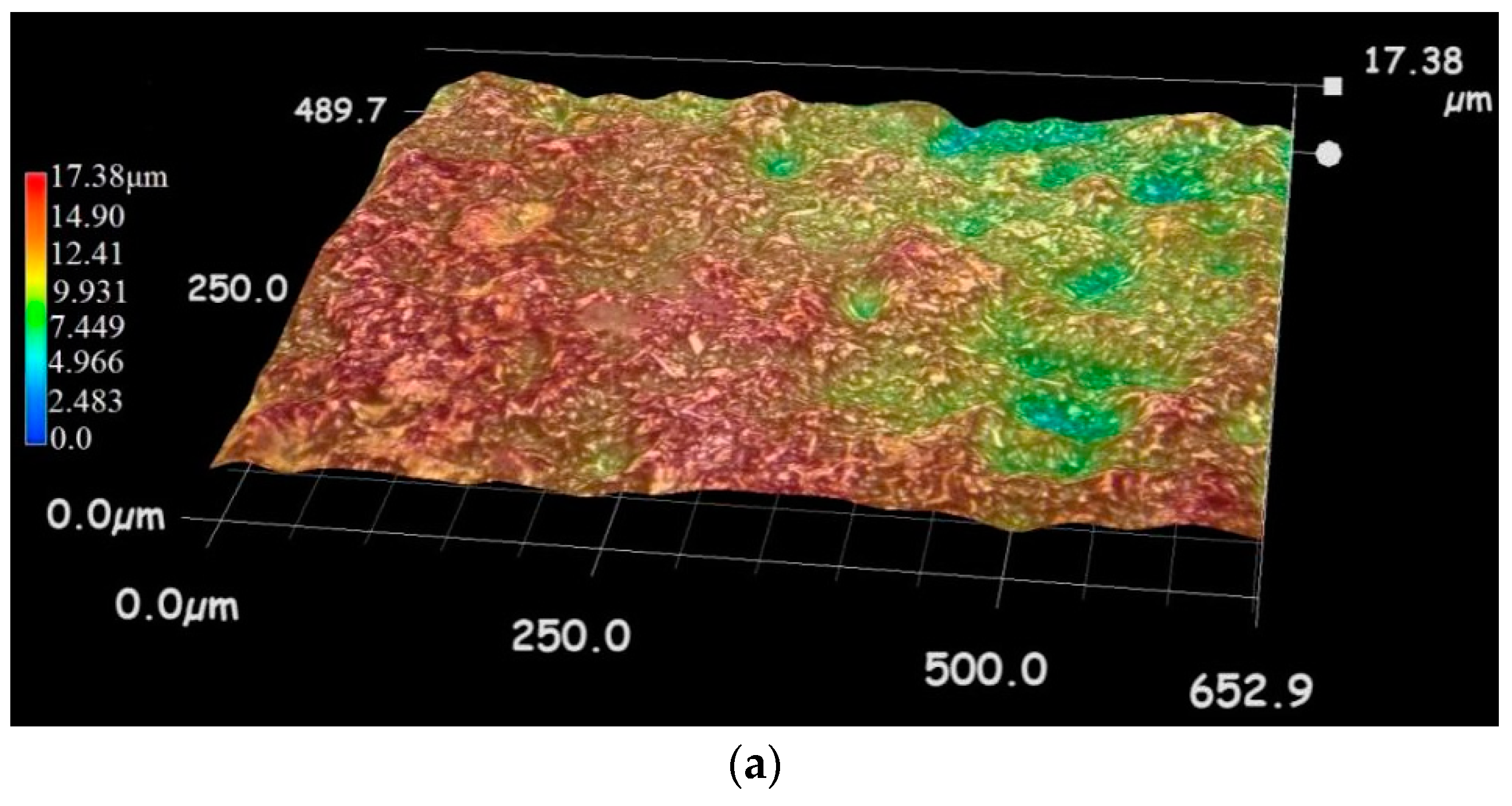

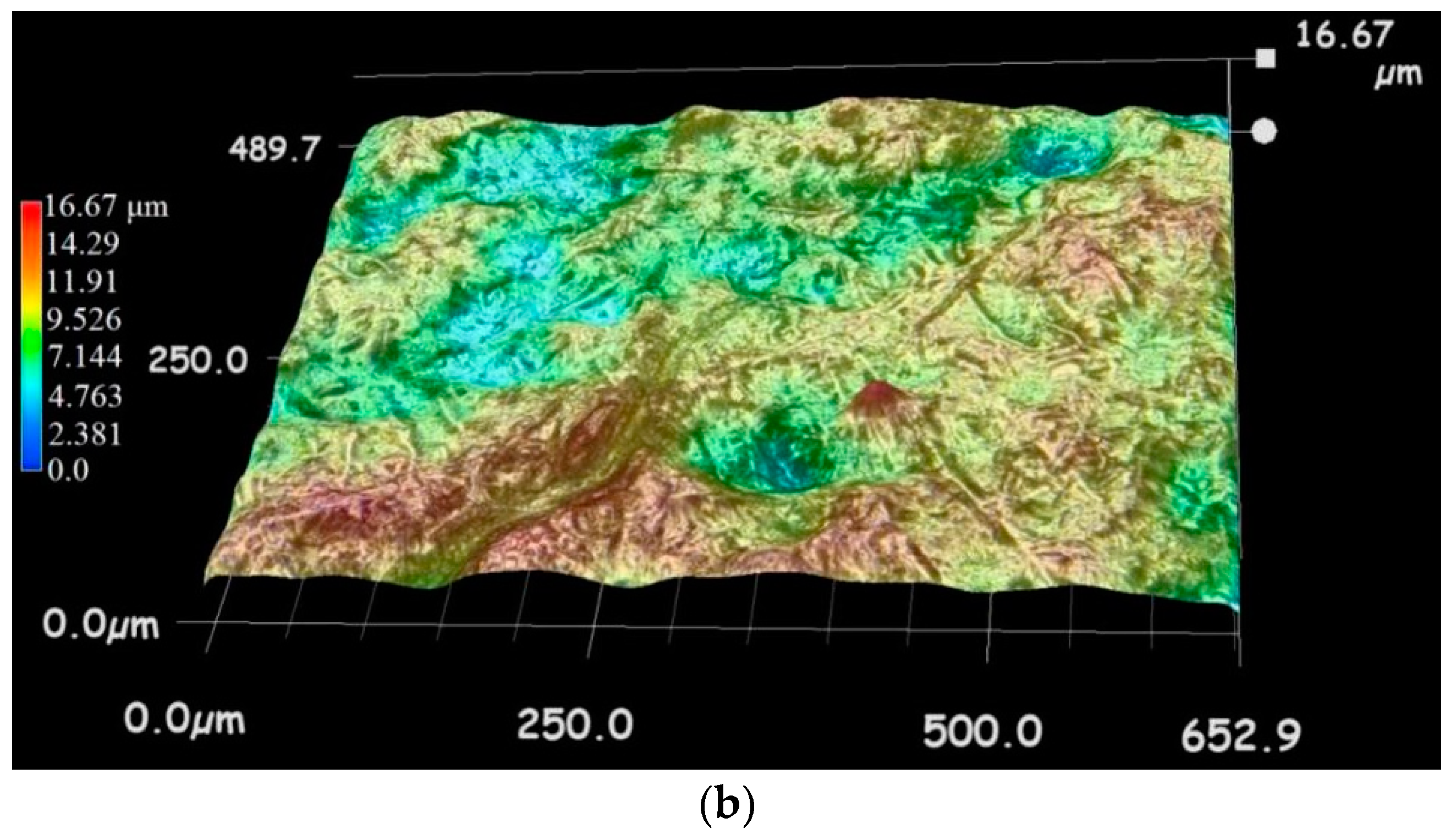

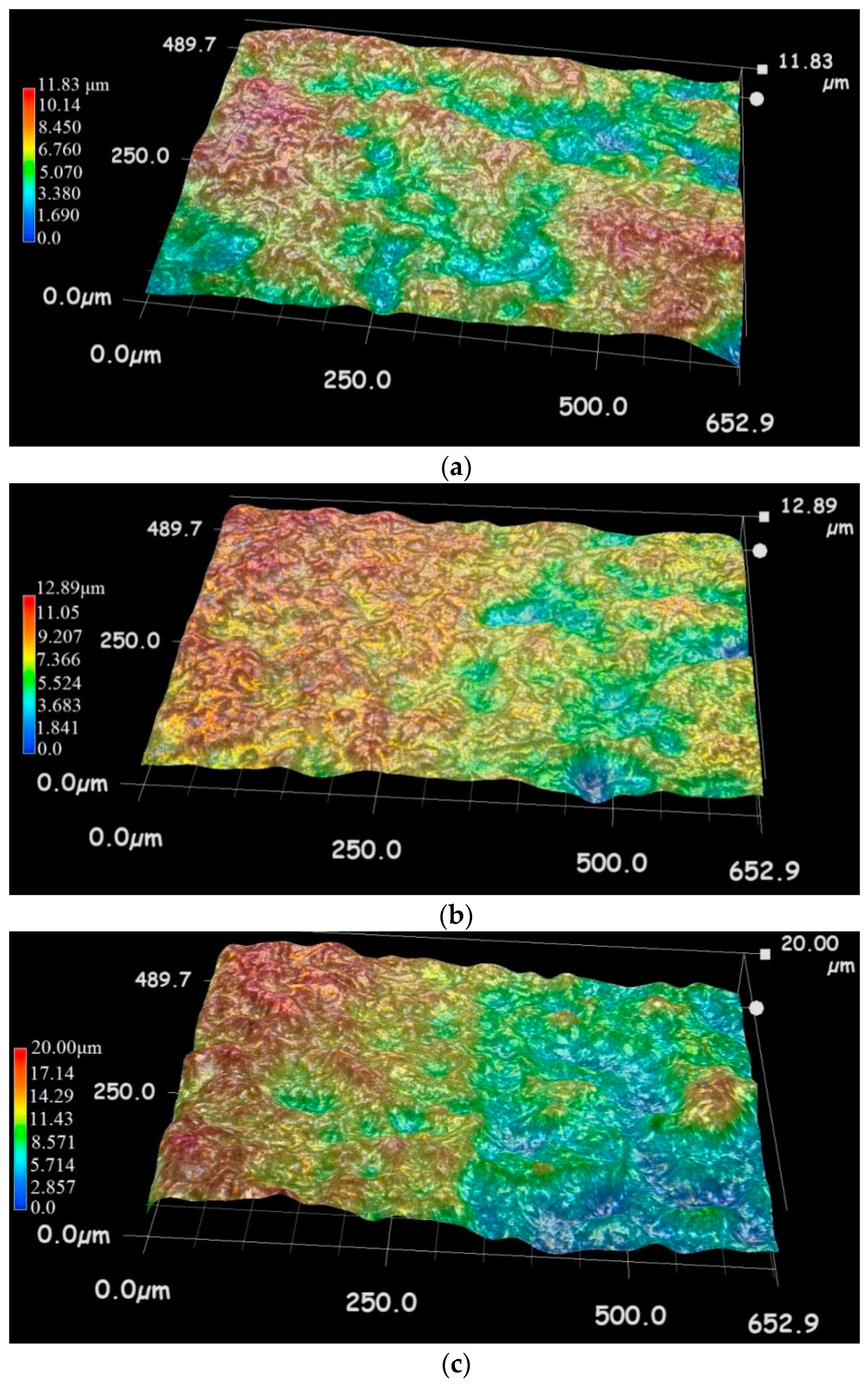

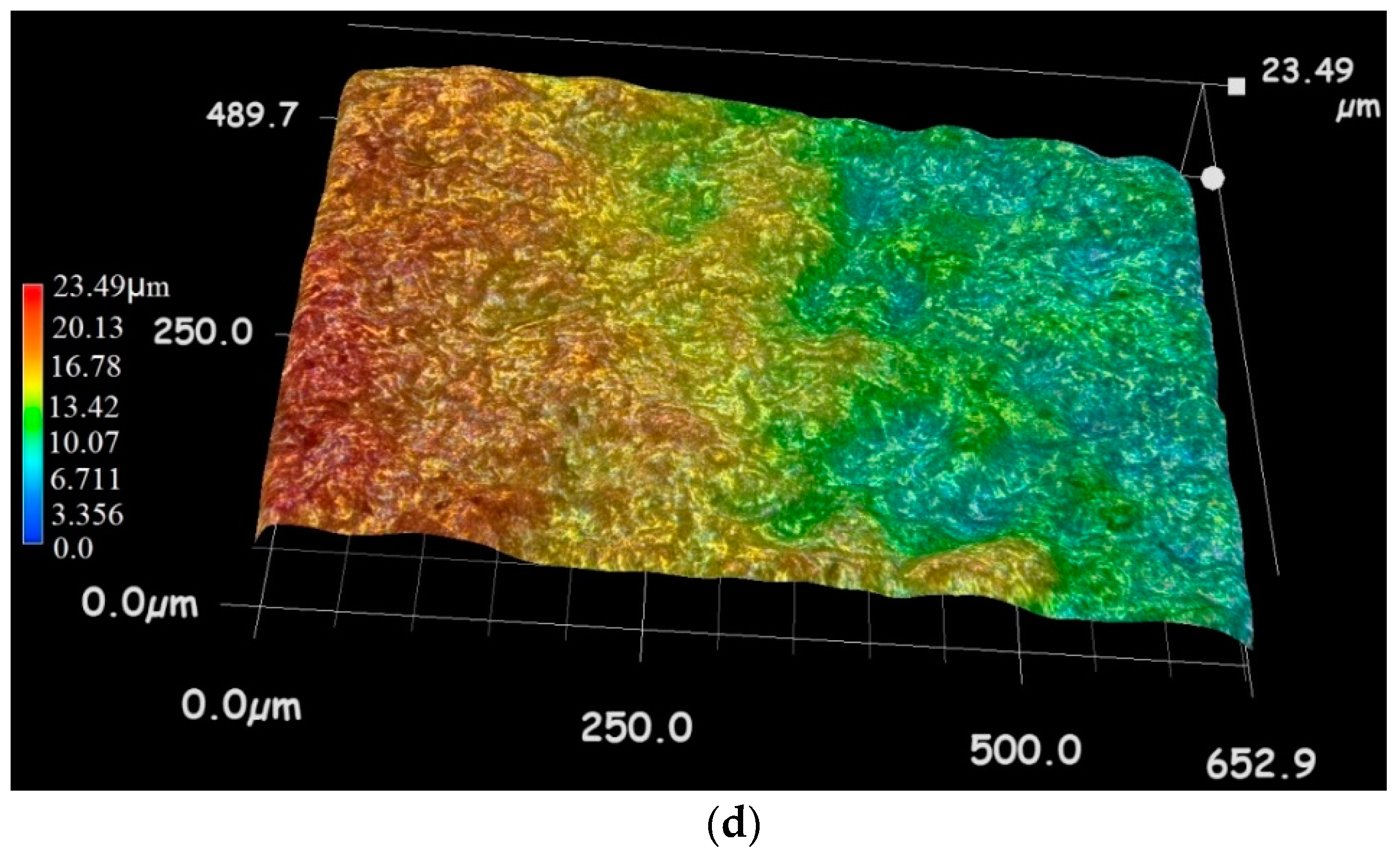

3.1.2. Variations of 3D Surface Topography of Al–Si Coating Boron Steel Sheet

3.2. Three-Step Heating Methods

3.2.1. Microstructure Evolution of Al–Si Coating Boron Steel Sheet

3.2.2. Variations of 3D Surface Topography of Al–Si Coating Boron Steel Sheet

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abe, Y.; Ohmi, T.; Mori, K.; Masuda, T. Improvement of formability in deep drawing of ultra-high strength steel sheets by coating of die. J. Mater. Process. Technol. 2014, 214, 1838–1843. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Zhou, J.; Mu, Y.; Wang, B.-Y. A damage-coupled unified viscoplastic constitutive model for prediction of forming limits of 22MnB5 at high temperatures. Int. J. Mech. Sci. 2017, 133, 457–468. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Chen, Y.; Han, G. Constitutive parameters identification based on DIC assisted thermo-mechanical tensile test for hot stamping of boron steel. J. Mater. Process. Technol. 2019, 271, 429–443. [Google Scholar] [CrossRef]

- Tang, B.; Wu, F.; Wang, Q.; Liu, J.; Guo, N.; Ge, H.; Wang, Q.; Liu, P. Damage prediction of hot stamped boron steel 22MnB5 with a microscopic motivated ductile fracture criterion: Experiment and simulation. Int. J. Mech. Sci. 2020, 169, 105302. [Google Scholar] [CrossRef]

- Liang, W.-K.; Liu, Y.; Zhu, B.; Zhou, M.-L.; Zhang, Y.-S. Conduction heating of boron alloyed steel in application for hot stamping. Int. J. Precis. Eng. Man. 2015, 16, 1983–1992. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.-S.; Tian, X.-W.; Li, J. Thermal contact conductance estimation and experimental validation in hot stamping process. Sci. China Tech. Sci. 2012, 55, 1852–1857. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Mori, K.; Ito, D. Prevention of oxidation in hot stamping of quenchable steel sheet by oxidation preventive oil. CIRP Ann. 2009, 58, 267–270. [Google Scholar] [CrossRef]

- Kondratiuk, J.; Kuhn, P. Tribological investigation on friction and wear behaviour of coatings for hot sheet metal forming. Wear 2011, 270, 839–849. [Google Scholar] [CrossRef]

- Hu, P.; Ying, L.; Li, Y.; Liao, Z. Effect of oxide scale on temperature-dependent interfacial heat transfer in hot stamping process. J. Mater. Process. Technol. 2013, 213, 1475–1483. [Google Scholar] [CrossRef]

- Suehiro, M.; Kusumi, K.; Maki, J.; Ohgami, M. Properties of aluminium steels for hot-forming. Nippon Steel Tech. Rep. 2003, 88, 16–21. [Google Scholar]

- Azushima, A.; Uda, K.; Yanagida, A. Friction behavior of aluminum-coated 22MnB5 in hot stamping under dry and lubricated conditions. J. Mater. Process. Technol. 2012, 212, 1014–1021. [Google Scholar] [CrossRef]

- Jeon, Y.P.; Seo, H.-Y.; Kim, J.-D.; Kang, C.G. Experimental analysis of coating layer behavior of Al–Si-coated boron steel in a hot bending process for IT applications. Int. J. Adv. Manuf. Technol. 2013, 67, 1693–1700. [Google Scholar] [CrossRef]

- Wu, C.-W.; Huang, C.; Chen, G. Interface delamination of the thermal barrier coating subjected to local heating. Sci. China Ser. E: Technol. Sci. 2010, 53, 3168–3174. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Sgarabotto, F.; Bariani, P. Tribological performances of Zn-based coating in direct hot stamping. Tribol. Int. 2014, 78, 142–151. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Medea, F. Comparison of tribological and wear performances of AlSi and Zn coatings in hot stamping of boron steel sheets. Wear 2015, 332, 810–821. [Google Scholar] [CrossRef]

- Chakraborty, A.; Mondal, A.; Halder, A.-K.; Dutta, M.; Singh, S.B. Evolution of microstructure of zinc-nickel alloy coating during hot stamping of boron added steels. J. Alloys Compd. 2019, 794, 672–682. [Google Scholar] [CrossRef]

- Chang, J.-K.; Lin, C.-S.; Cheng, W.-J.; Lo, I.-H.; Wang, W.-R. Oxidation resistant silane coating for hot-dip galvanized hot stamping steel. Corros. Sci. 2020, 164, 108307. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, B.; Wang, Z.; Liu, Y.; Wang, L.; Zhang, Y.; Li, S. Successive phase and morphology evolution of galvannealed coating in hot stamping and diffusion modeling of α-Fe(Zn)/steel system considering the effect of Zn concentration. Surf. Coat. Technol. 2019, 380, 125036. [Google Scholar] [CrossRef]

- Chang, J.-K.; Lin, C.-S.; Wang, W.-R.; Jian, S.-Y. High temperature deformation behaviors of hot dip 55 wt % Al-Zn coated steel. Appl. Surf. Sci. 2020, 511, 145550. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, S.-M.; Zhang, Q.-F.; Liu, C.-S. Effect of temperature on microstructure and formability of Al-10 mass% Si coatings. J. Iron Steel Res. Int. 2016, 23, 270–275. [Google Scholar] [CrossRef]

- Ighodaro, O.; Biro, E.; Zhou, Y. Comparative effects of Al-Si and galvannealed coatings on the properties of resistance spot welded hot stamping steel joints. J. Mater. Process. Technol. 2016, 236, 64–72. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, L.; Tan, C.; Zhou, W.; Chen, B.; Song, X.; Zhao, H.; Feng, J. Influence of Al-Si coating on microstructure and mechanical properties of fiber laser welded 22MnB5 steel. Opt. Laser Technol. 2019, 116, 117–127. [Google Scholar] [CrossRef]

- Drillet, P.; Spehner, D.; Kefferstein, R. Coated Steel Strips, Methods of Making the Same, Methods of Using the Same, Stamping Blanks Prepared from the Same, Stamped Products Prepared from the Pame, and Prticles of Manufacture Which Contain Such a Stamped Product. Google Patents US8307680B2, 13 November 2012. [Google Scholar]

- Jenner, F.; Walter, M.-E.; Iyengar, R.-M.; Hughes, R. Evolution of phases, microstructure, and surface roughness during heat treatment of aluminized low carbon steel. Metall. Mater. Trans. A. 2010, 41A, 1554–1563. [Google Scholar] [CrossRef]

- Windmann, M.; Röttger, A.; Theisen, W. Formation of intermetallic phases in Al-coated hot-stamped 22MnB5 sheets in terms of coating thickness and Si content. Surf. Coat. Technol. 2014, 246, 17–25. [Google Scholar] [CrossRef]

- Windmann, M.; Röttger, A.; Theisen, W. Phase formation at the interface between a boron alloyed steel substrate and an Al-rich coating. Surf. Coat. Technol. 2013, 226, 130–139. [Google Scholar] [CrossRef]

- Yuan, X.-H.; Zhang, Q.-F. Microstructure Evolution of Hot-Dip Al-10%Si Coating during the Austenitization of 22MnB5 Hot Stamping Steel. Acta Metall. Sin. 2017, 53, 1495–1503. (In Chinese) [Google Scholar]

- Fan, D.W.; Kim, H.S.; Oh, J.-K.; Chin, K.-G.; De Cooman, B.C. Coating Degradation in Hot Press Forming. ISIJ Int. 2010, 50, 561–568. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, C. Microstructural evolution of intermetallic layer in hot-dipped aluminide mild steel with silicon addition. Surf. Coat. Technol. 2011, 205, 4726–4731. [Google Scholar] [CrossRef]

- Wang, K.; Jin, Y.; Zhu, B.; Zhang, Y. Investigation on cracking characteristics of Al–Si coating on hot stamping boron steel parts based on surface strain analysis. Surf. Coat. Technol. 2017, 309, 282–294. [Google Scholar] [CrossRef]

- Pontevichi, S.; Bosselet, F.; Barbeau, F.; Peronnet, M.; Viala, J.-C. Solid-liquid phase equilibria in the Al-Fe-Si system at 727 °C. J. Phase Equilib. Diffus. 2004, 25, 528–537. [Google Scholar] [CrossRef]

- Achar, D.-R.-G.; Ruge, J.; Sundaresan, S. Joining aluminum and steel, especially by means of welding. In Aluminum Monography; Aluminum-Verlag: Düsseldorf, Germany, 1980. [Google Scholar]

- Pelcastre, L.; Hardell, J.; Rolland, A.; Prakash, B. Influence of microstructural evolution of Al-Si coated UHSS on its tribological behaviour against tool steel at elevated temperatures. J. Mater. Process. Technol. 2016, 228, 117–124. [Google Scholar] [CrossRef]

- Liang, W.; Tao, W.; Zhu, B.; Zhang, Y. Influence of heating parameters on properties of the Al-Si coating applied to hot stamping. Sci. China Ser. E: Technol. Sci. 2017, 60, 1088–1102. [Google Scholar] [CrossRef]

- Dinh, K.-A.; Hong, S.-T.; Luu, T.-V.; Kim, M.-J.; Han, H.N. Intermetallic Evolution of Al–Si-Coated Hot Stamping Steel During Modified Electrically Assisted Rapid Heating. Acta Metall. Sin. 2018, 31, 1327–1333. [Google Scholar] [CrossRef]

- Gui, Z.-X.; Liang, W.-K.; Liu, Y.; Zhang, Y. Thermo-mechanical behavior of the Al–Si alloy coated hot stamping boron steel. Mater. Des. 2014, 60, 26–33. [Google Scholar] [CrossRef]

- Siebert, P.; Alsmann, M.; Watermeier, H.-J. Influence of different heating technologies on the coating properties of hot-dip aluminized 22MnB5. In Proceedings of the 3rd International Conference on Hot Sheet Metal Forming of High Performance Steel, CHS2, Kassel, Germany, 13–17 June 2011; pp. 457–464. [Google Scholar]

- Han, Y.; Chen, X.; Li, L.; Zhang, X.; Zhou, D. Effect of Si on the Formation and Growth of Intermetallic Compounds at Roll-Bonded Aluminum-Steel (Al-St) Interface. J. Mater. Eng. Perform. 2018, 27, 333–343. [Google Scholar] [CrossRef]

- Barros, J.; Ros-Yáñez, T.; Houbaert, Y. Chemical and physical interactions of Si-rich steel substrates during hot dipping experiments in a molten Al-(25 wt%) Si alloy. In Defect and Diffusion Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2005; Volume 237, pp. 1115–1120. [Google Scholar]

- Grigorieva, R.; Drillet, P.; Mataigne, J.-M.; Redjaïmia, A. Phase transformations in the Al-Si coating during the austenitization step. In Solid State Phenomena; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 172, pp. 784–790. [Google Scholar]

- He, H.; Gou, W.; Wang, S.; Hou, Y.; Ma, C.; Mendez, P.F. Kinetics of intermetallic compound layers during initial period of reaction between mild steel and molten aluminum. Int. J. Mater. Res. 2019, 110, 194–201. [Google Scholar] [CrossRef]

- Liu, Z.-K.; Chang, Y.-A. Thermodynamic assessment of the Al-Fe-Si system. Metall. Mater. Trans. A 1999, 30, 1081–1095. [Google Scholar] [CrossRef]

- Raghavan, V, Al-Fe-Si (Aluminum-Iron-Silicon). JPE 2002, 23, 362–366. [CrossRef]

- Azimaee, H.; Sarfaraz, M.; Mirjalili, M.; Aminian, K. Effect of silicon and manganese on the kinetics and morphology of the intermetallic layer growth during hot-dip aluminizing. Surf. Coat. Technol. 2019, 357, 483–496. [Google Scholar] [CrossRef]

- Gui, Z.-X.; Wang, K.; Zhang, Y.-S.; Zhu, B. Cracking and interfacial debonding of the Al–Si coating in hot stamping of pre-coated boron steel. Appl. Surf. Sci. 2014, 316, 595–603. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni | Cr | Mo | Ti | V | Nb | W | Cu | B |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.24 | 0.22 | 1.49 | 0.012 | 0.13 | 0.005 | 0.03 | 0.004 | 0.013 | 0.034 | 0.009 | 0.002 |

| Regions | Chemical Compositions in at % | Intermetallic Compounds | ||

|---|---|---|---|---|

| Fe | Al | Si | ||

| 1 | 22.56 | 64.98 | 12.46 | Fe2Al7Si |

| 2 | 33.36 | 45.21 | 21.43 | Fe3Al2Si3 |

| 3 | 25.65 | 62.08 | 12.27 | Fe2Al5 |

| Intermetallic Compounds | Chemical Compositions in at % | ||

|---|---|---|---|

| Fe | Al | Si | |

| FeAl4.5Si | 15.81 | 68.13 | 16.06 |

| Fe2Al7Si | 21.73 | 69.67 | 8.6 |

| Fe3Al2Si3 | 33.36 | 45.21 | 21.43 |

| Fe2Al5 | 25.35 | 60.98 | 13.67 |

| Intermetallic Compounds | Chemical Compositions in at % | ||

|---|---|---|---|

| Fe | Al | Si | |

| FeAl2 | 35.55 | 61.36 | 3.09 |

| 32.57 | 62.93 | 4.5 | |

| 35.43 | 62.62 | 1.95 | |

| Fe3Al2Si3 | 40.65 | 38.54 | 20.81 |

| FeAl | 50.82 | 40.17 | 9.01 |

| 46.46 | 45.62 | 7.92 | |

| 43.15 | 45.38 | 1.47 | |

| α-Fe | 87.19 | 11.34 | 1.47 |

| Numbers | Mean Thickness of the Al–Si Coating | Mean Thickness of α-Fe Phase | Volume Fraction of α-Fe Phase | Volume Fraction of Fe3Al2Si3 Intermetallic Compound | Volume Fraction of FeAl Intermetallic Compound | Porosity |

|---|---|---|---|---|---|---|

| A | 39.4 μm | 9.7 μm | 22.68% | 11.53% | 9.92% | 2.92% |

| B | 40.3 μm | 8.8 μm | 20.53% | 9.85% | 8.75% | 2.53% |

| C | 39.8 μm | 7.6 μm | 21.32% | 7.69% | 6.19% | 2.96% |

| D | 37.5 μm | 6.8 μm | 14.06% | 4.97% | 3.71% | 3.31% |

| Intermetallic Compounds | Density (g/cm3) |

|---|---|

| Fe2Al7Si | 3.58 |

| Fe2Al8Si | 3.62 |

| FeAl3 | 3.9 |

| Fe2Al5 | 4.11 |

| Fe3(AlSi)5 | 5.06 |

| FeAl | 5.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, W.; Duan, J.; Wang, Q.; Dong, J.; Liu, Q.; Lin, C.; Zhang, Y. Influence of Multi-Step Heating Methods on Properties of Al–Si Coating Boron Steel Sheet. Coatings 2021, 11, 164. https://doi.org/10.3390/coatings11020164

Liang W, Duan J, Wang Q, Dong J, Liu Q, Lin C, Zhang Y. Influence of Multi-Step Heating Methods on Properties of Al–Si Coating Boron Steel Sheet. Coatings. 2021; 11(2):164. https://doi.org/10.3390/coatings11020164

Chicago/Turabian StyleLiang, Weikang, Jinchang Duan, Qianting Wang, Junhao Dong, Qiong Liu, Chen Lin, and Yisheng Zhang. 2021. "Influence of Multi-Step Heating Methods on Properties of Al–Si Coating Boron Steel Sheet" Coatings 11, no. 2: 164. https://doi.org/10.3390/coatings11020164

APA StyleLiang, W., Duan, J., Wang, Q., Dong, J., Liu, Q., Lin, C., & Zhang, Y. (2021). Influence of Multi-Step Heating Methods on Properties of Al–Si Coating Boron Steel Sheet. Coatings, 11(2), 164. https://doi.org/10.3390/coatings11020164