Theoretical and Experimental Analysis of Surface Roughness and Adhesion Forces of MEMS Surfaces Using a Novel Method for Making a Compound Sputtering Target

Abstract

:1. Introduction

2. Materials and Methods

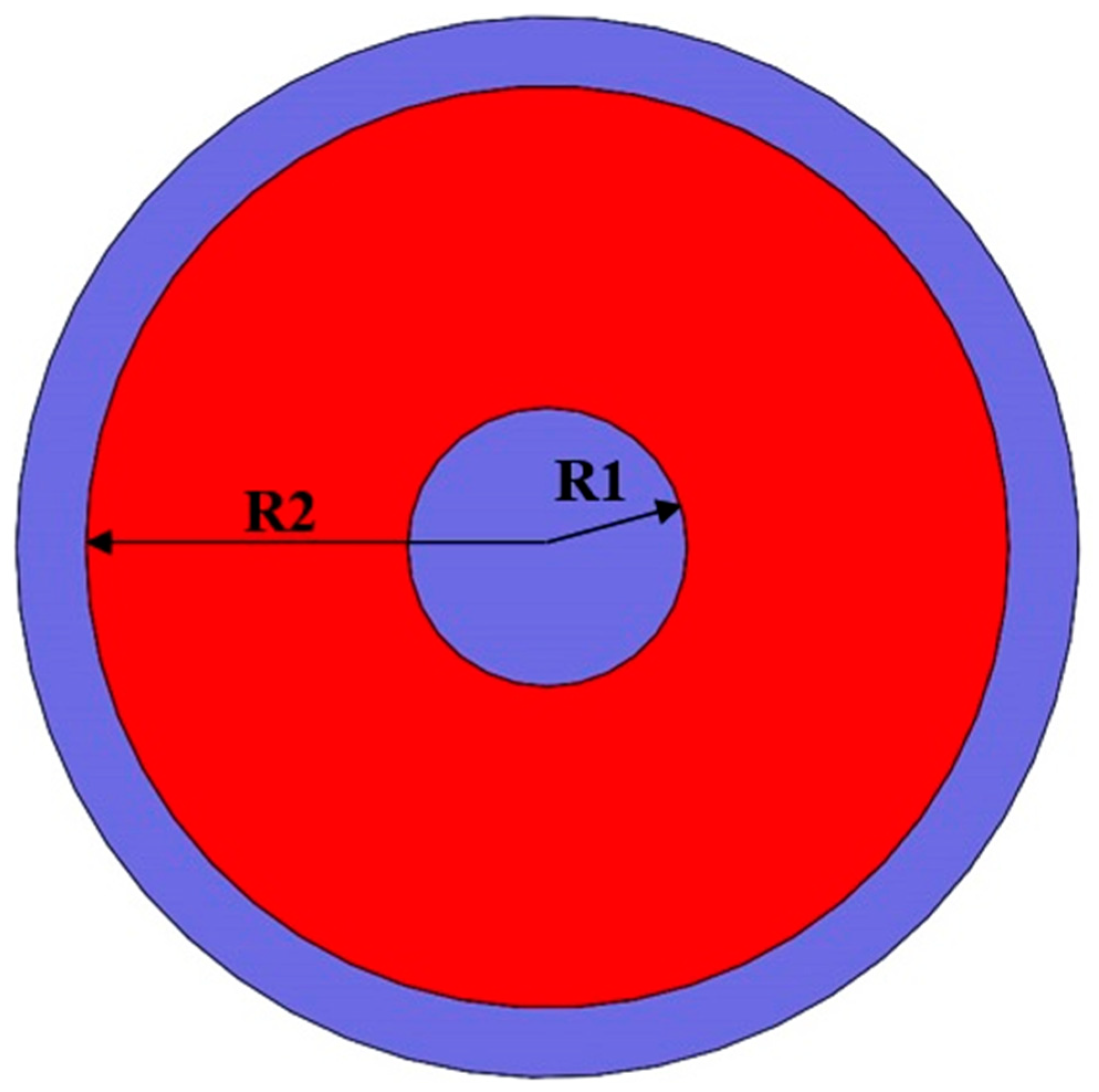

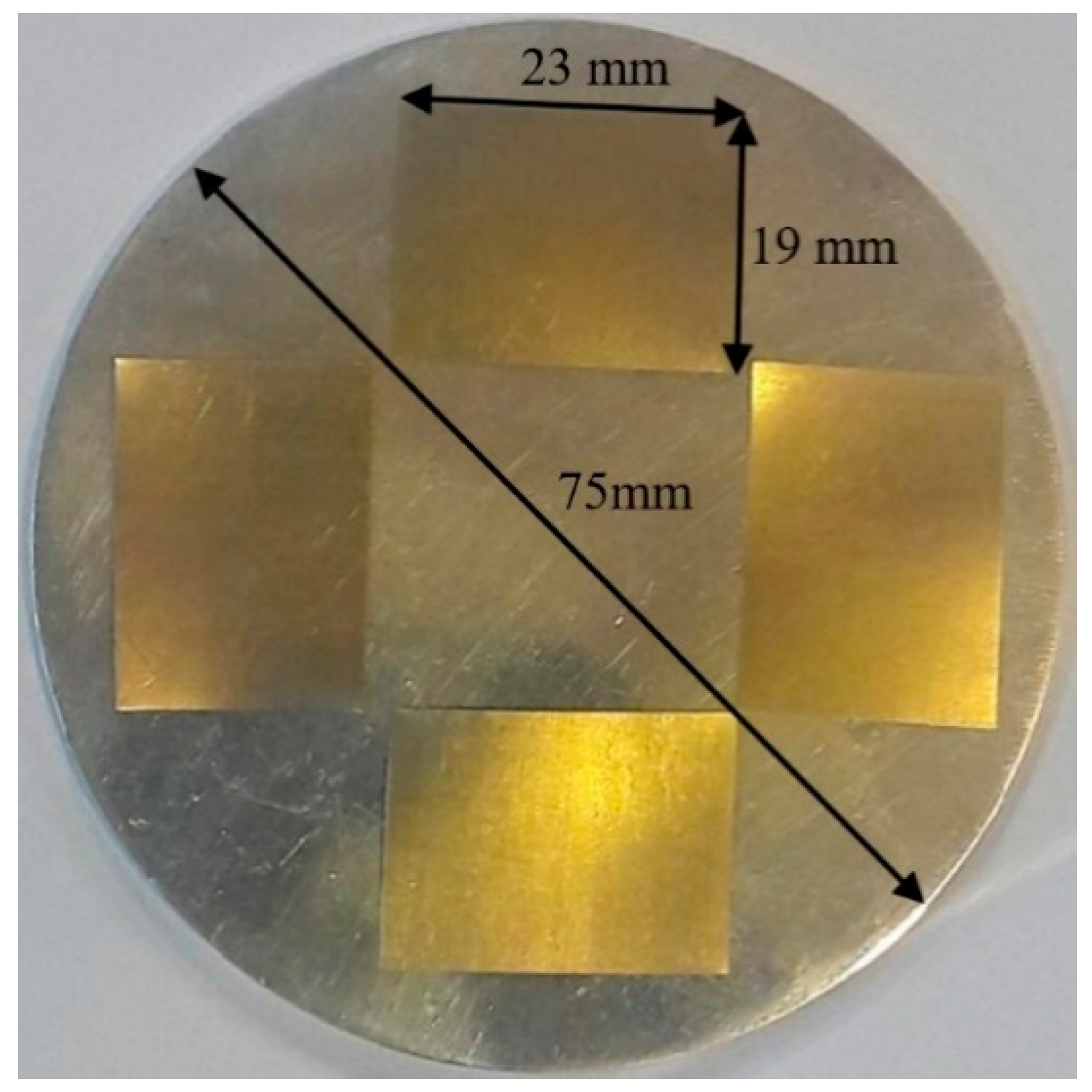

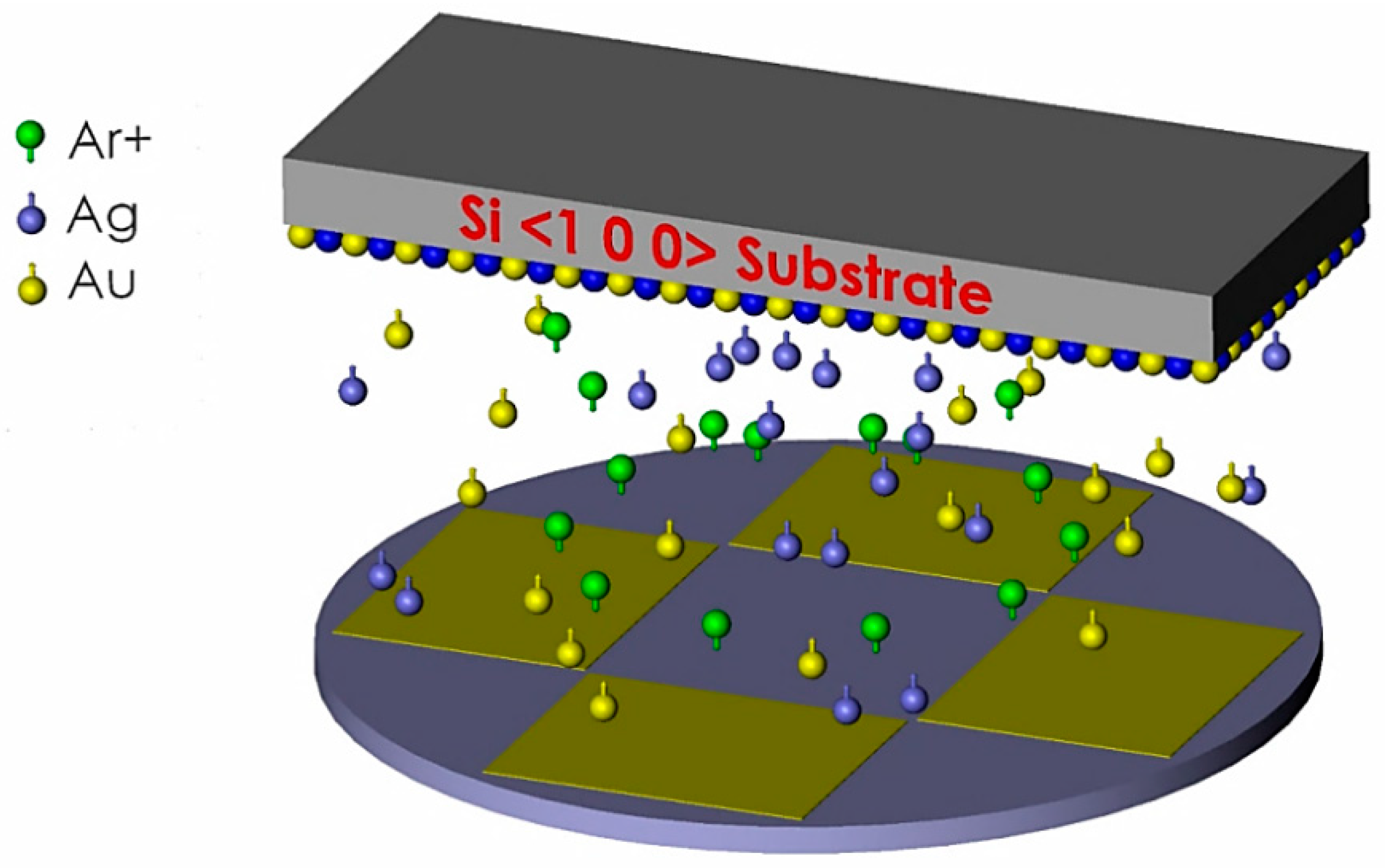

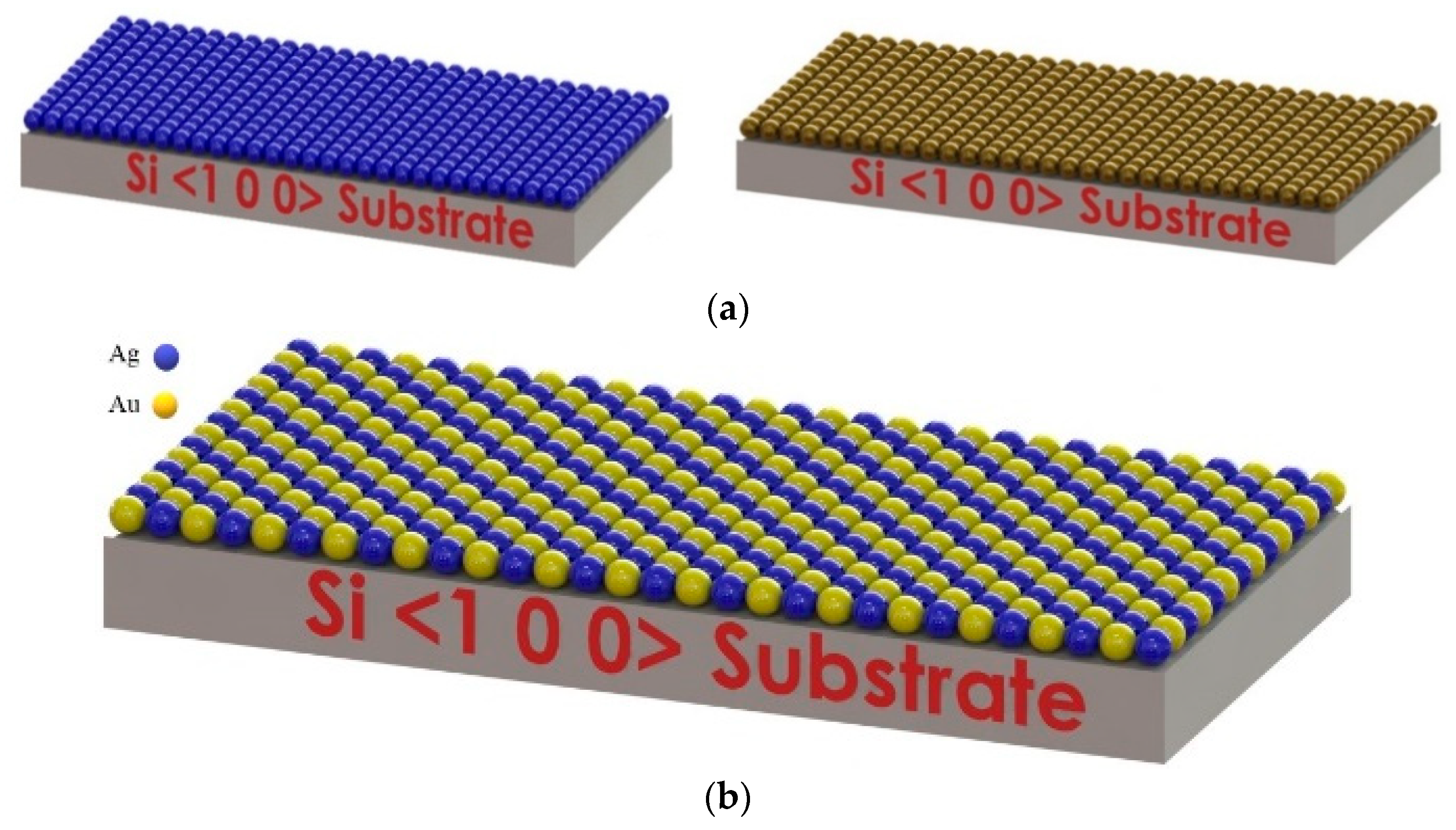

2.1. Manufacturing of Ag–Au Compound Target

2.2. The Coating Process

3. Results and Discussion

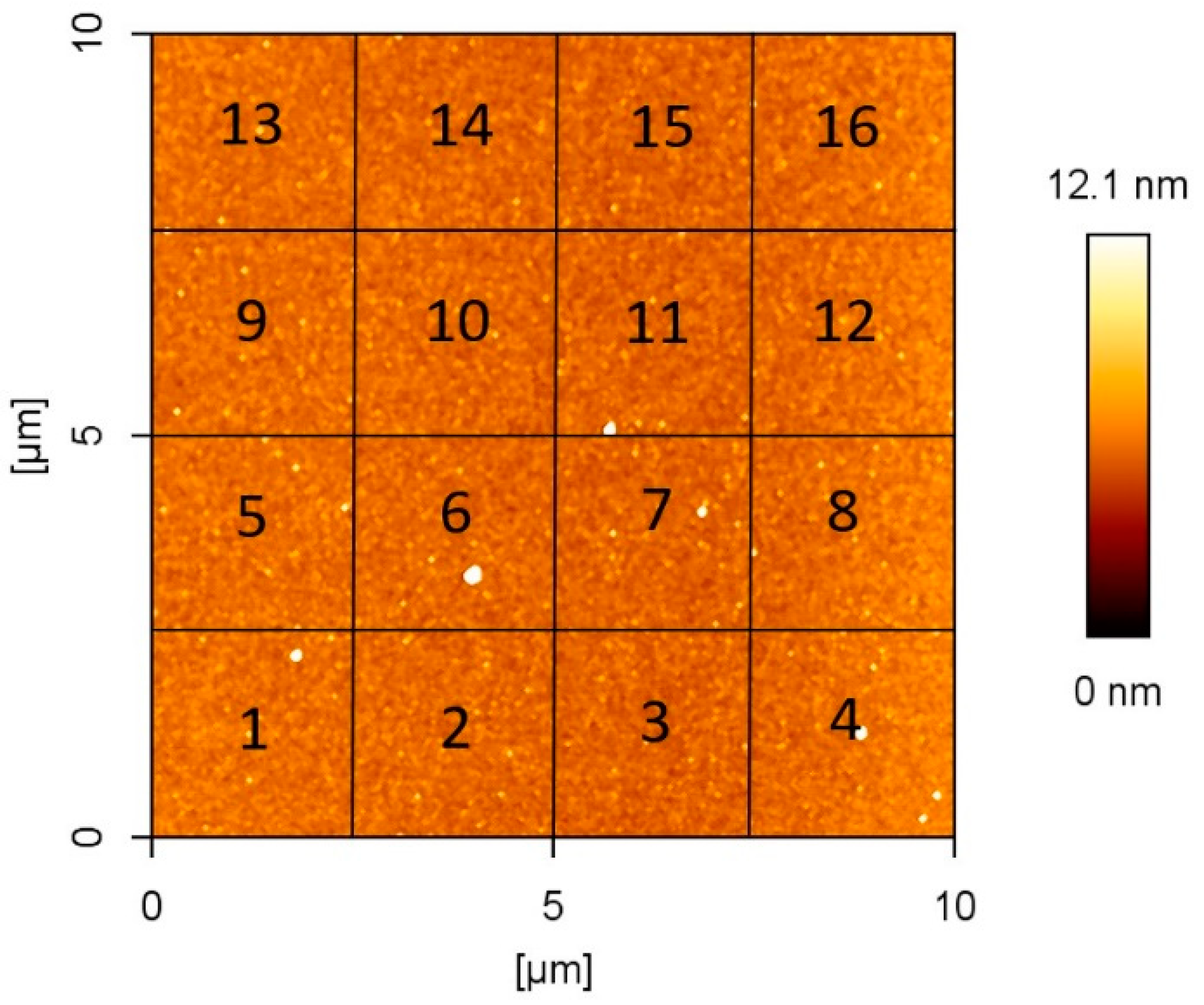

3.1. Surface Topography

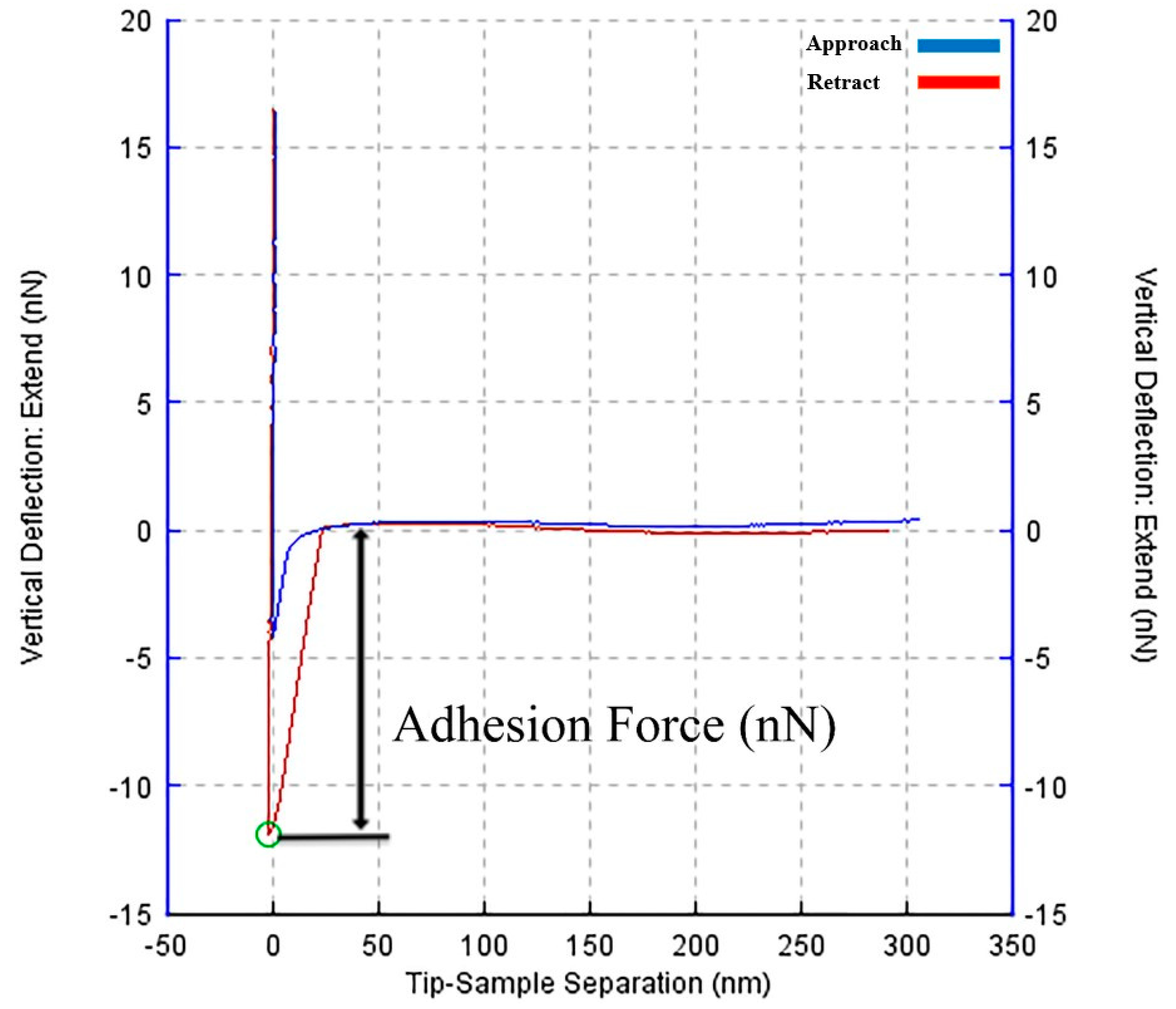

3.2. Experiemental Adhesion Force

3.3. Theoretical Models

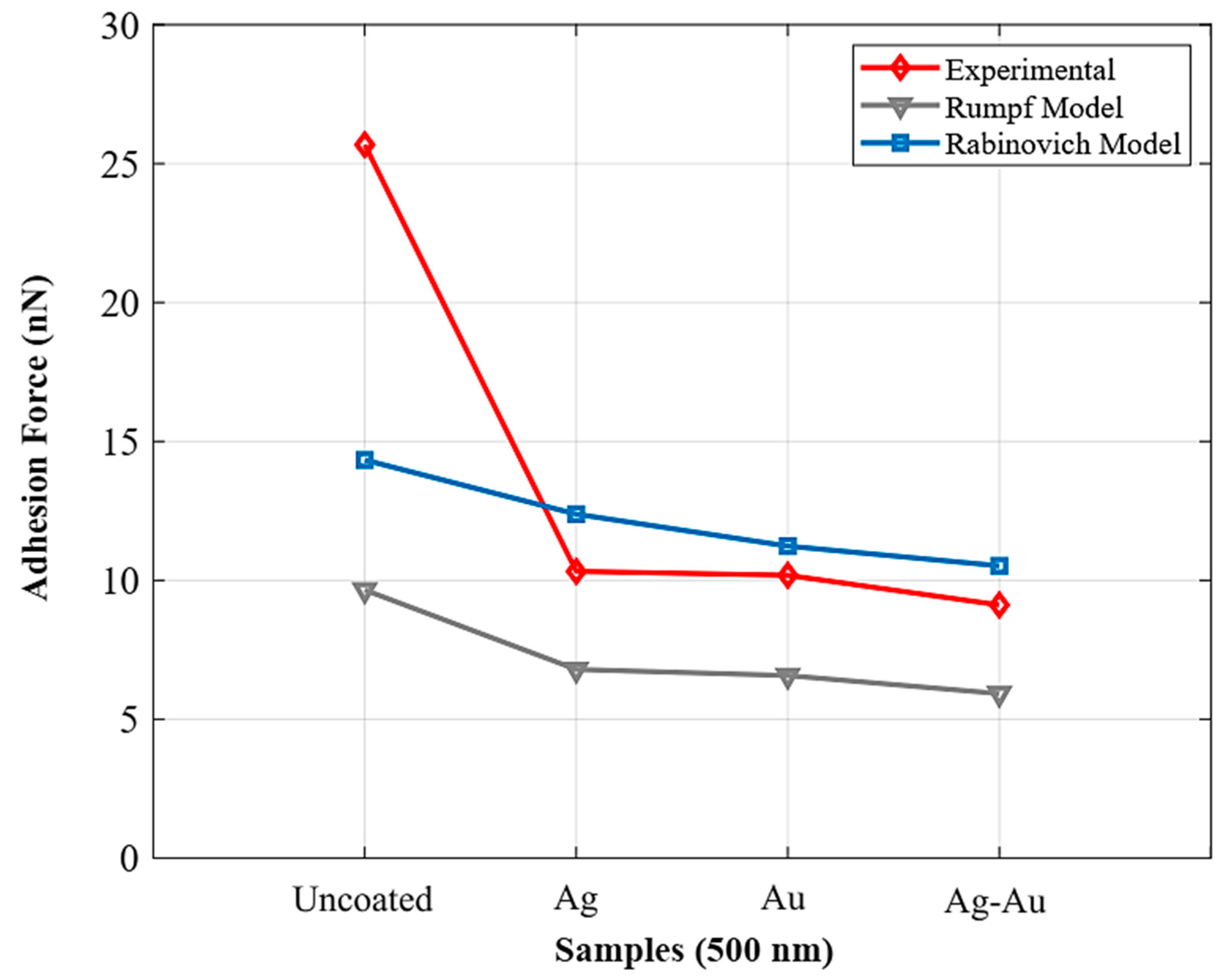

- Comparing all coated samples with the non-coated ones suggests that reducing the adhesion force in all coated specimens is due to the reduction of surface energy and increased surface roughness. The surface energy of the gold on a silicon substrate is 1 J/mm2, and this value for silver on the silicon is 1.25 J/m2 [42,43]. According to the results, the highest roughness is related to the gold surface, which is an effective parameter in reducing adhesion due to the reduction of the contact surface [44,45]. In addition, the surface energy of gold is less than that of silver, which is a reason for the impact of surface energy on adhesion.

- Theoretical and experimental adhesion values revealed that the compound thin films (500 nm) compared with the single thin films with the same thickness have higher surface roughness and the lowest adhesion force.

- Both approaches indicated that gold coatings (single layer with thicknesses of 120 and 500 nm) compared to silver coatings with the same thicknesses have a drop in the adhesion force because of a reduction in surface energy and more surface roughness.

- Comparing the adhesion values of Rumpf and Rabinovich models with the experimental ones revealed that the results achieved from the Rabinovich model were closer to the experimental values compared with the Rumpf model. This is due to moderately high surface energy and “soft” elastic materials with large tip radii.

- One of the Rumpf model problems compared to Rabinovich is not determining the surface asperity radius, which was thought not feasible experimentally. Also, the Rumpf model cannot precisely measure the geometry of nanoscale surfaces [28].

- Surface roughness and adhesion force results indicate that uncoated surfaces have higher adhesion force values than deposited surfaces. The increase in adhesion values is due to the atomic accumulation on the surface and the formation of asperities after the deposition process. The asperities lessen the tip contact with the surface. Consequently, the adhesion force decreases when the contact between tip and surface minimizes. In addition, the inverse effect of roughness on adhesion reduction can be observed when the roughness of the uncoated silicon surface is compared to the considerably lower adhesion of deposited surfaces.

- As shown in Figure 10 and Table 4, the film with 500 nm thickness has less adhesion force than the sample with 120 nm thickness. The growth of atomic accumulation in the thickness of 500 nm has led to increased surface roughness and reduced adhesion. In other words, the change in the deposition thickness, surface energy, and roughness has a notable impact on the adhesion force.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ejeian, F.; Azadi, S.; Razmjou, A.; Orooji, Y.; Kottapalli, A.; Ebrahimi Warkiani, M.; Asadnia, M. Design and applications of MEMS flow sensors: A review. Sens. Actuators Phys. 2019, 295, 483–502. [Google Scholar] [CrossRef]

- Nastro, A.; Ferrari, M.; Ferrari, V. Double-actuator position-feedback mechanism for adjustable sensitivity in electrostatic-capacitive MEMS force sensors. Sens. Actuators Phys. 2020, 312, 112127. [Google Scholar] [CrossRef]

- Ali, W.R.; Prasad, M. Piezoelectric MEMS based acoustic sensors: A review. Sens. Actuators A Phys. 2020, 301, 111756. [Google Scholar] [CrossRef]

- Basu, A.K.; Basu, A.; Bhattacharya, S. Micro/Nano fabricated cantilever based biosensor platform: A review and recent progress. Enzyme Microb. Technol. 2020, 139, 109558. [Google Scholar] [CrossRef]

- Di Barba, P.; Wiak, S. MEMS: Field Models and Optimal Design; Springer International Publishing: New York, NY, USA, 2020; Volume 573, ISBN 978-3-030-21495-1. [Google Scholar]

- Paulasto-Kröckel, M.; Tilli, M.; Ross, G.; Kuisma, H. Where is silicon based MEMS heading to? In Handbook of Silicon Based MEMS Materials and Technologies, 3rd ed.; Micro and Nano Technologies; Tilli, M., Paulasto-Krockel, M., Petzold, M., Theuss, H., Motooka, T., Lindroos, V., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. xxi–xxix. ISBN 978-0-12-817786-0. [Google Scholar]

- Janioud, P.; Poulain, C.; Koumela, A.; Armani, J.M.; Dupret, A.; Rey, P.; Berthelot, A.; Jourdan, G.; Morfouli, P. Effects of gamma radiation on suspended silicon nanogauges bridge used for MEMS transduction. Microelectron. Reliab. 2020, 114, 113736. [Google Scholar] [CrossRef]

- Das, T.K.; Shirinzadeh, B.; Ghafarian, M.; Al-Jodah, A.; Zhong, Y.; Smith, J. Design, analysis and experimental investigations of a high precision flexure-based microgripper for micro/nano manipulation. Mechatronics 2020, 69, 102396. [Google Scholar] [CrossRef]

- Alogla, A.F.; Amalou, F.; Balmer, C.; Scanlan, P.; Shu, W.; Reuben, R.L. Corrigendum to “Micro-tweezers: Design, fabrication, simulation and testing of a pneumatically actuated micro-gripper for micromanipulation and microtactile sensing. Sens. Actuators Phys. 2018, 273, 324. [Google Scholar] [CrossRef]

- Verotti, M.; Dochshanov, A.; Belfiore, N.P. A comprehensive survey on microgrippers design: Mechanical structure. J. Mech. Des. Trans. ASME 2017, 139, 1–46. [Google Scholar] [CrossRef]

- Van Nguyen, P.; Luu, Q.K.; Takamura, Y.; Ho, V.A. Wet Adhesion of Micro-Patterned Interfaces for Stable Grasping of Deformable Objects. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October–24 January 2021; pp. 9213–9219. [Google Scholar]

- Feng, Y.Y.; Chen, S.J.; Hsieh, P.H.; Chu, W.T. Fabrication of an electro-thermal micro-gripper with elliptical cross-sections using silver-nickel composite ink. Sens. Actuators Phys. 2016, 245, 106–112. [Google Scholar] [CrossRef]

- Ardito, R.; Frangi, A.; Rizzini, F.; Corigliano, A. Evaluation of adhesion in microsystems using equivalent rough surfaces modeled with spherical caps. Eur. J. Mech. A/Solids 2016, 57, 121–131. [Google Scholar] [CrossRef]

- Llewellyn-Evans, H.; Griffiths, C.A.; Fahmy, A. Microgripper design and evaluation for automated µ-wire assembly: A survey. Microsyst. Technol. 2020, 26, 1745–1768. [Google Scholar] [CrossRef] [Green Version]

- Delrio, F.W.; Carraro, C.; Maboudian, R. Small-scale surface engineering problems. Tribol. Dyn. Engine Powertrain Fundam. Appl. Futur. Trends 2010, 960–989. [Google Scholar] [CrossRef]

- Demaghsi, H.; Mirzajani, H.; Ghavifekr, H.B. Design and simulation of a novel metallic microgripper using vibration to release nano objects actively. Microsyst. Technol. 2014, 20, 65–72. [Google Scholar] [CrossRef]

- Shao, G.; Ware, H.O.T.; Huang, J.; Hai, R.; Li, L.; Sun, C. 3D printed magnetically-actuating micro-gripper operates in air and water. Addit. Manuf. 2021, 38, 101834. [Google Scholar] [CrossRef]

- Adachi, H.; Wasa, K. Thin Films and Nanomaterials. In Handbook of Sputter Deposition Technology: Fundamentals and Applications for Functional Thin Films, Nano-Materials and MEMS, 2nd ed.; William Andrew: New York, NY, USA, 2012; pp. 3–39. [Google Scholar] [CrossRef]

- Behera, R.R.; Das, A.; Hasan, A.; Pamu, D.; Pandey, L.M.; Sankar, M.R. Effect of TiO2 addition on adhesion and biological behaviour behavior of BCP-TiO2 composite films deposited by magnetron sputtering. Mater. Sci. Eng. C 2020, 114, 111033. [Google Scholar] [CrossRef] [PubMed]

- Barajas-Valdes, U.; Suárez, O.M. Nanomechanical properties of thin films manufactured via magnetron sputtering from pure aluminum and aluminum-boron targets. Thin Solid Films 2020, 693, 137670. [Google Scholar] [CrossRef]

- Butt, H.J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef] [Green Version]

- Giessibl, F.J. Seizo Morita Noncontact Atomic Force Microscopy; Springer: Cham, Switzerland, 2015; Volume 3, ISBN 9783319155876. [Google Scholar]

- Ono, K.; Mizushima, Y.; Furuya, M.; Kunihisa, R.; Tsuchiya, N.; Fukuma, T.; Iwata, A.; Matsuki, A. Direct measurement of adhesion force of individual aerosol particles by atomic force microscopy. Atmosphere 2020, 11, 489. [Google Scholar] [CrossRef]

- Leite, F.L.; Bueno, C.C.; Da Róz, A.L.; Ziemath, E.C.; Oliveira, O.N. Theoretical models for surface forces and adhesion and their measurement using atomic force microscopy. J. Mol. Sci. 2012, 23, 12773–12856. [Google Scholar] [CrossRef]

- Prokopovich, P.; Perni, S. Comparison of JKR- and DMT-based multi-asperity adhesion model: Theory and experiment. Colloids Surf. Physicochem. Eng. Asp. 2011, 383, 95–101. [Google Scholar] [CrossRef]

- Prokopovich, P.; Starov, V. Adhesion models: From single to multiple asperity contacts. Adv. Colloid Interface Sci. 2011, 168, 210–222. [Google Scholar] [CrossRef]

- Rabinovich, Y.I.; Adler, J.J.; Ata, A.; Singh, R.K.; Moudgil, B.M. Adhesion between nanoscale rough surfaces. I. Role of asperity geometry. J. Colloid Interface Sci. 2000, 232, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Beach, E.R.; Tormoen, G.W.; Drelich, J.; Han, R. Pull-off force measurements between rough surfaces by atomic force microscopy. J. Colloid Interface Sci. 2002, 247, 84–99. [Google Scholar] [CrossRef] [PubMed]

- Rumpf, H. Particle Technology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 1, ISBN 9401179441. [Google Scholar]

- Buranich, V.; Pogrebnjak, A.; Budzynski, P.; Shelest, I.; Prószyński, A.; Chocyk, D.; Goncharov, A.; Yunda, A. Mechanical and tribological characterization of nanostructured HfB2 films deposited from compound target. SN Appl. Sci. 2020, 2, 563. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.L.; Liu, H.Y.; Deng, Q.Y.; Yang, W.M.; Silins, K.; Huang, N.; Leng, Y.X. Optimal target sputtering mode for aluminum nitride thin film deposition by high power pulsed magnetron sputtering. Vacuum 2019, 160, 410–417. [Google Scholar] [CrossRef]

- Baolong, G.; Deyi, L.; Jiajun, Z.; Wulin, Y.; Licai, F.; Lingping, Z. Construction of magnetron sputtering non-equilibrium Miedema’s model for application in Ag-Mo thin films. Phys. B Condens. Matter 2021, 602, 412541. [Google Scholar] [CrossRef]

- Vladkova, T.; Angelov, O.; Stoyanova, D.; Gospodinova, D.; Gomes, L.; Soares, A.; Mergulhao, F.; Ivanova, I. Magnetron co-sputtered TiO2/SiO2/Ag nanocomposite thin coatings inhibiting bacterial adhesion and biofilm formation. Surf. Coat. Technol. 2020, 384, 125322. [Google Scholar] [CrossRef]

- Francq, R.; Snyders, R.; Cormier, P.A. Structural and Morphological study of ZnO-Ag thin films synthesized by reactive magnetron co-sputtering. Vacuum 2017, 137, 1–7. [Google Scholar] [CrossRef]

- Mertin, S.; Länzlinger, T.; Sandu, C.S.; Scartezzini, J.-L.; Muralt, P. Combinatorial study of low-refractive Mg–F–Si–O nano-composites deposited by magnetron co-sputtering from compound targets. Appl. Surf. Sci. 2018, 435, 170–177. [Google Scholar] [CrossRef]

- Mazur, M.; Domaradzki, J.; Wojcieszak, D.; Kaczmarek, D. Investigations of elemental composition and structure evolution in (Ti, Cu)-oxide gradient thin films prepared using (multi) magnetron co-sputtering. Surf. Coat. Technol. 2018, 334, 150–157. [Google Scholar] [CrossRef]

- Annesi, F.; Pane, A.; Pezzi, L.; Pagliusi, P.; Losso, M.A.; Stamile, B.; Qualtieri, A.; Desiderio, G.; Contardi, M.; Athanassiou, A.; et al. Biocompatible and biomimetic keratin capped Au nanoparticles enable the inactivation of mesophilic bacteria via photo-thermal therapy. Colloids Surf. Physicochem. Eng. Asp. 2021, 625, 126950. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, H.Z. Influence of Au doping concentration on structural and optical properties of ZnO:Au films fabricated through magnetron sputtering. Opt. Mater. 2020, 108, 110433. [Google Scholar] [CrossRef]

- Moghayedi, M.; Goharshadi, E.K.; Ghazvini, K.; Ahmadzadeh, H.; Jorabchi, M.N. Antibacterial activity of Ag nanoparticles/phosphomolybdate/reduced graphene oxide nanocomposite: Kinetics and mechanism insights. Mater. Sci. Eng. B 2020, 262, 114709. [Google Scholar] [CrossRef]

- Huang, W.; Tao, F.; Li, F.; Mortimer, M.; Guo, L.-H. Antibacterial nanomaterials for environmental and consumer product applications. NanoImpact 2020, 20, 100268. [Google Scholar] [CrossRef]

- Eichenlaub, S.; Chan, C.; Beaudoin, S.P. Hamaker constants in integrated circuit metalization. J. Colloid Interface Sci. 2002, 248, 389–397. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.-M.; Ma, F.; Xu, K.-W. Calculation of the surface energy of FCC metals with modified embedded-atom method. Appl. Surf. Sci. 2004, 229, 34–42. [Google Scholar] [CrossRef]

- Maugis, D. Adhesion of spheres: The JKR-DMT transition using a dugdale model. J. Colloid Interface Sci. 1992, 150, 243–269. [Google Scholar] [CrossRef]

- Rusu, F.; Pustan, M.; Bîrleanu, C.; Müller, R.; Voicu, R.; Baracu, A. Analysis of the surface effects on adhesion in MEMS structures. Appl. Surf. Sci. 2015, 358, 634–640. [Google Scholar] [CrossRef]

- Katainen, J.; Paajanen, M.; Ahtola, E.; Pore, V.; Lahtinen, J. Adhesion as an interplay between particle size and surface roughness. J. Colloid Interface Sci. 2006, 304, 524–529. [Google Scholar] [CrossRef]

| Final Pressure (mbar) | Argon Pressure (mbar) | Voltage (V) | Temperature (°C) | Target-Substrate Distance (mm) | Substrate Dimensions (mm2) |

|---|---|---|---|---|---|

| 2.5 × 10−5 | 9 × 10−3 | 600 | 70 | 130 | 10 × 10 |

| Samples | Ra (nm) | Rms (nm) | Height of Asperities (nm) | |||

|---|---|---|---|---|---|---|

| 120 | 500 | 120 | 500 | 120 | 500 | |

| Ag | 0.456 | 1.03 | 0.817 | 1.984 | 12.8 | 1.984 |

| Au | 0.533 | 1.09 | 0.825 | 2.994 | 12.1 | 2.994 |

| Ag–Au | 0.878 | 1.23 | 1.296 | 3.564 | 16.6 | 3.564 |

| Si (uncoated) | 0.395 | 0.824 | 8.4 | |||

| Surface | Hamaker Coefficient |

|---|---|

| Si-Si | 31.60 |

| Ag-Ag | 50.00 |

| Au-Au | 40.00 |

| Si-Ag | 39.75 |

| Si-Au | 35.55 |

| Ag-Au | 44.72 |

| Samples | Thickness (nm) | Experimental Adhesion Force (nN) | Mean Values of Theoretical Adhesion Force (nN) | |

|---|---|---|---|---|

| Rumpf | Rabinovich | |||

| uncoated | - | 25.68 | 9.65 | 14.33 |

| Ag | 120 | 13.89 | 7.42 | 12.10 |

| Au | 120 | 12.28 | 6.73 | 11.39 |

| Ag–Au | 120 | 11.60 | 6.44 | 11.03 |

| Ag | 500 | 10.32 | 6.79 | 12.38 |

| Au | 500 | 10.18 | 6.57 | 11.23 |

| Ag–Au | 500 | 9.11 | 5.92 | 10.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salehi, M.; Heidari, P.; Ruhani, B.; Kheradmand, A.; Purcar, V.; Căprărescu, S. Theoretical and Experimental Analysis of Surface Roughness and Adhesion Forces of MEMS Surfaces Using a Novel Method for Making a Compound Sputtering Target. Coatings 2021, 11, 1551. https://doi.org/10.3390/coatings11121551

Salehi M, Heidari P, Ruhani B, Kheradmand A, Purcar V, Căprărescu S. Theoretical and Experimental Analysis of Surface Roughness and Adhesion Forces of MEMS Surfaces Using a Novel Method for Making a Compound Sputtering Target. Coatings. 2021; 11(12):1551. https://doi.org/10.3390/coatings11121551

Chicago/Turabian StyleSalehi, Majid, Pedram Heidari, Behrooz Ruhani, Amanj Kheradmand, Violeta Purcar, and Simona Căprărescu. 2021. "Theoretical and Experimental Analysis of Surface Roughness and Adhesion Forces of MEMS Surfaces Using a Novel Method for Making a Compound Sputtering Target" Coatings 11, no. 12: 1551. https://doi.org/10.3390/coatings11121551

APA StyleSalehi, M., Heidari, P., Ruhani, B., Kheradmand, A., Purcar, V., & Căprărescu, S. (2021). Theoretical and Experimental Analysis of Surface Roughness and Adhesion Forces of MEMS Surfaces Using a Novel Method for Making a Compound Sputtering Target. Coatings, 11(12), 1551. https://doi.org/10.3390/coatings11121551