Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors

Abstract

:1. Introduction

2. The Effects of Deposition Parameters on the Microstructure of Multilayer Films

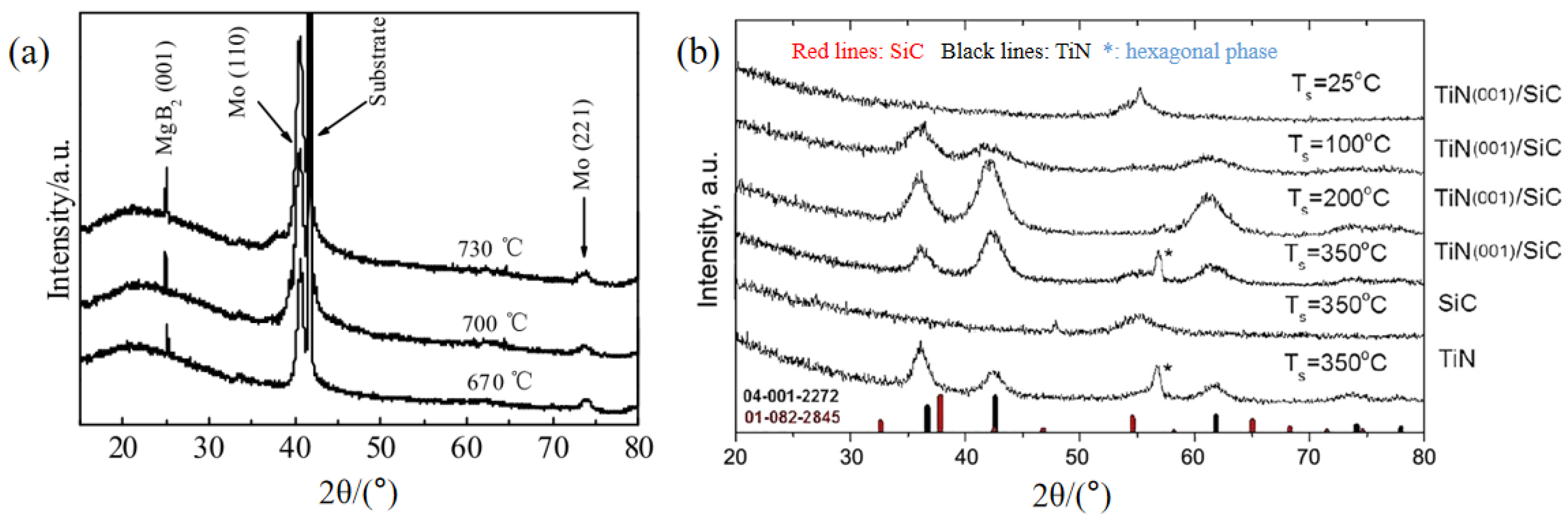

2.1. The Effect of Substrate Temperature

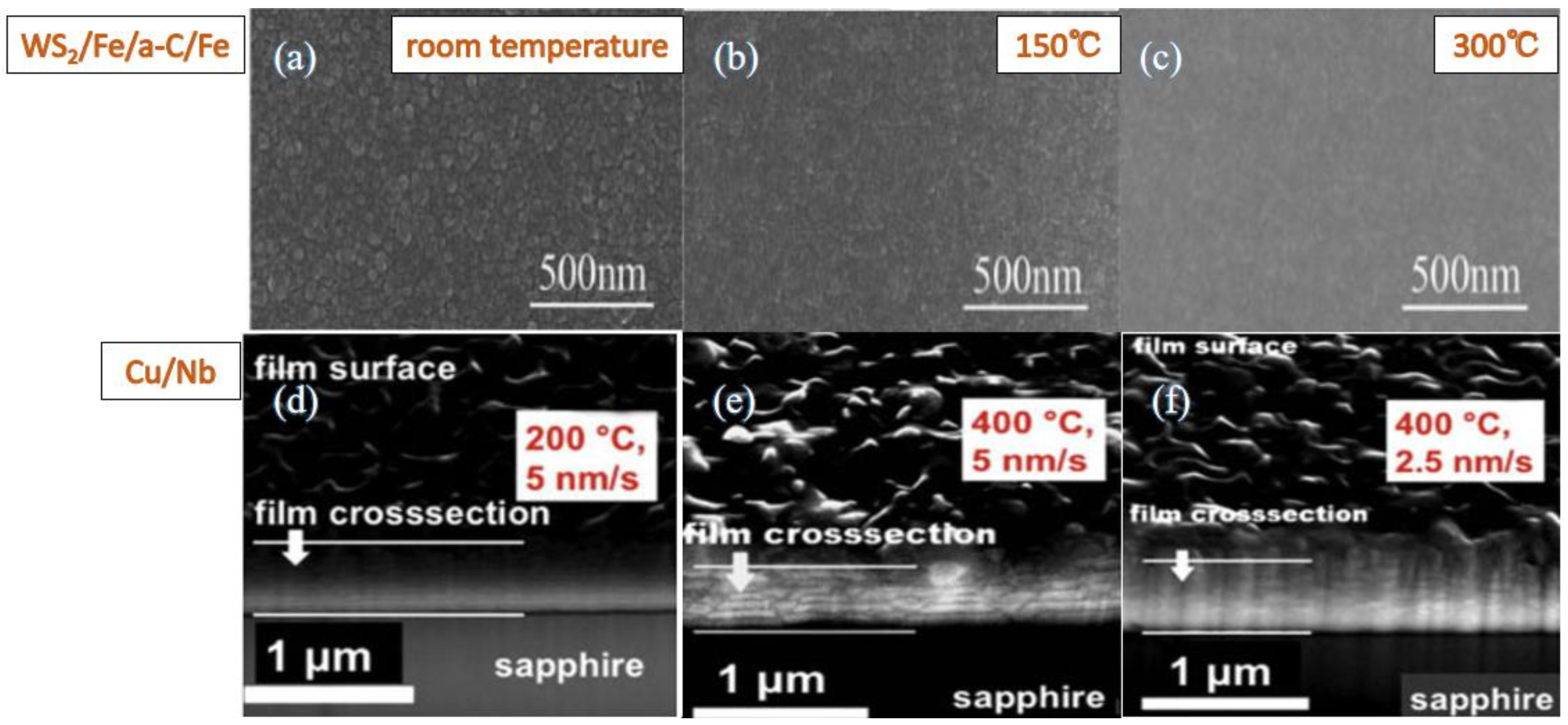

2.2. The Effect of Deposition Rate

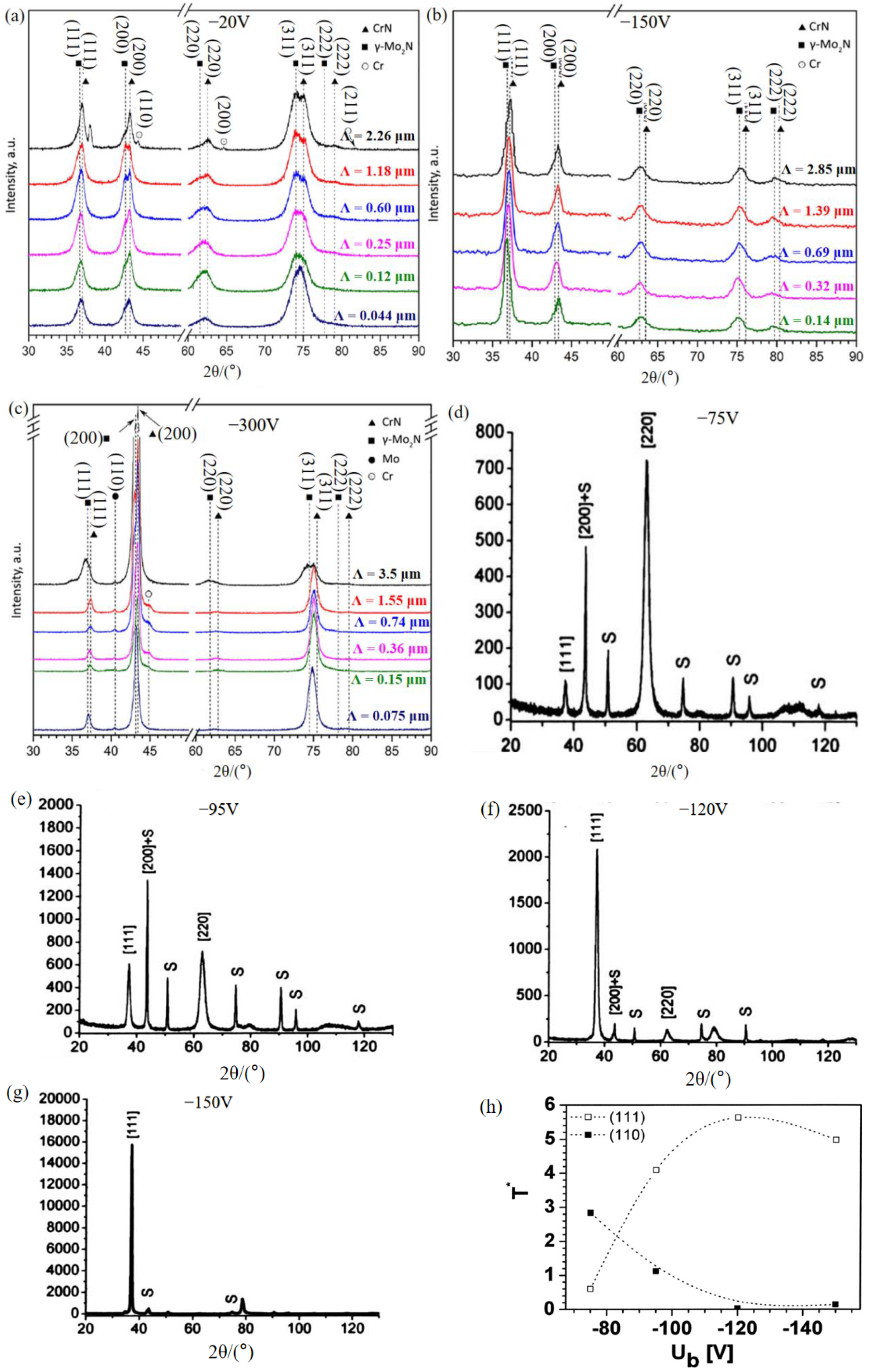

2.3. The Effect of Deposition Bias

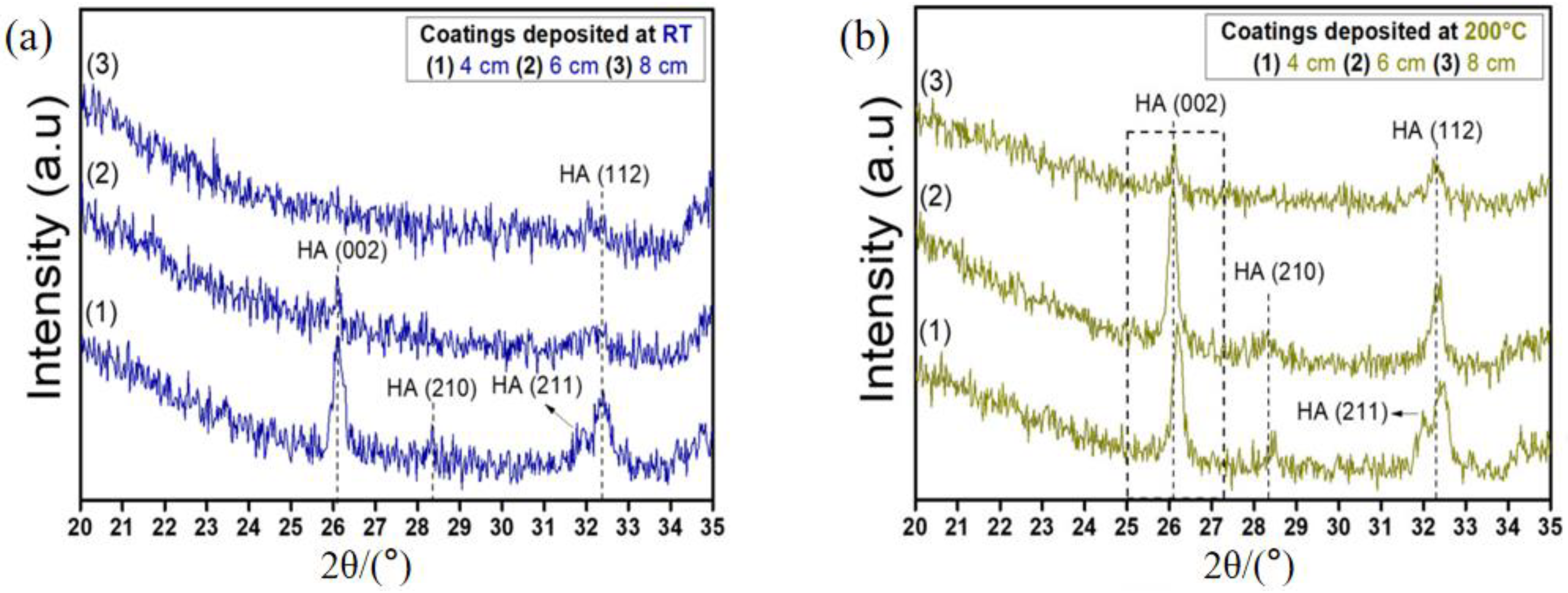

2.4. The Effect of Target–Substrate Distance

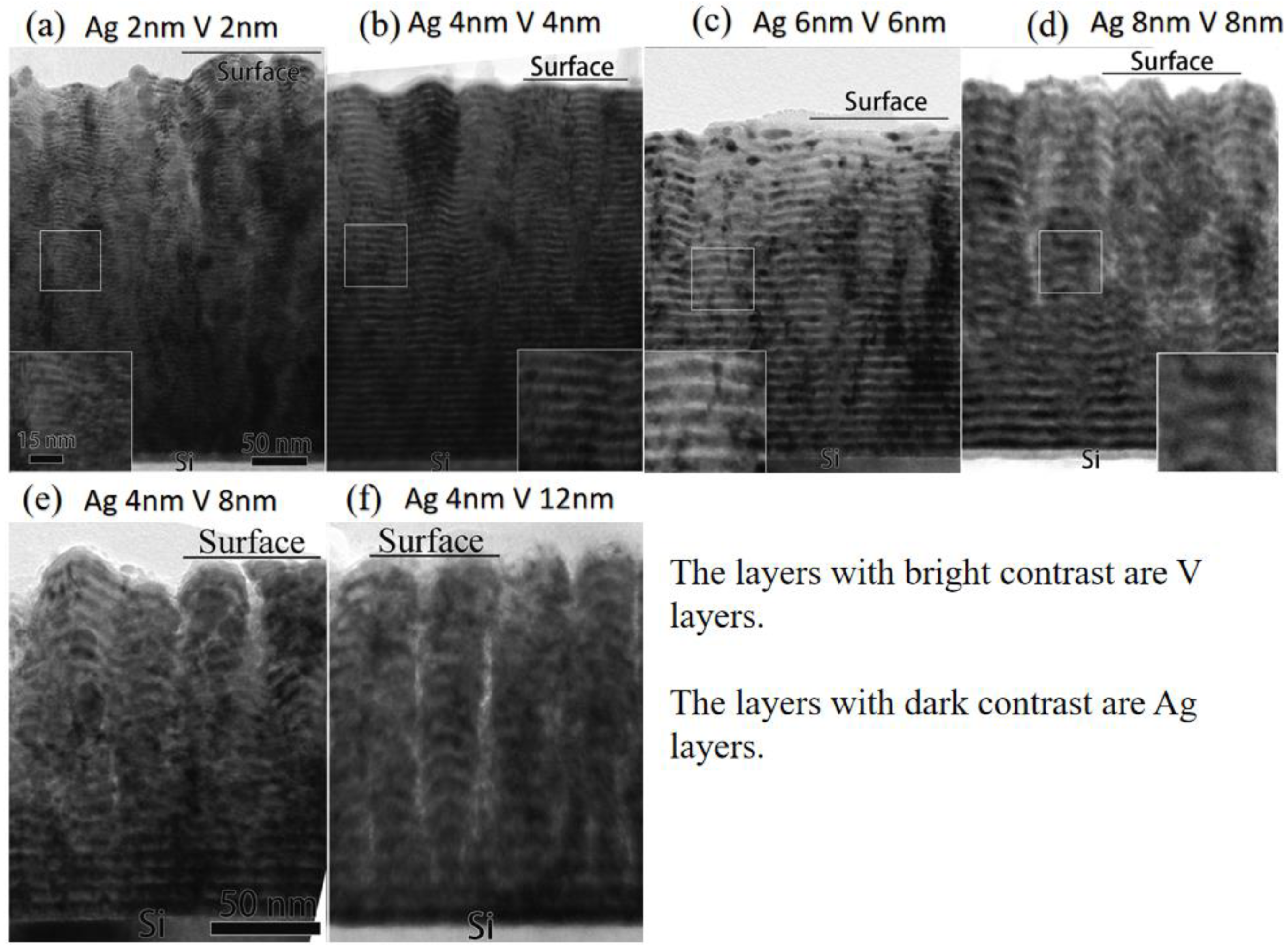

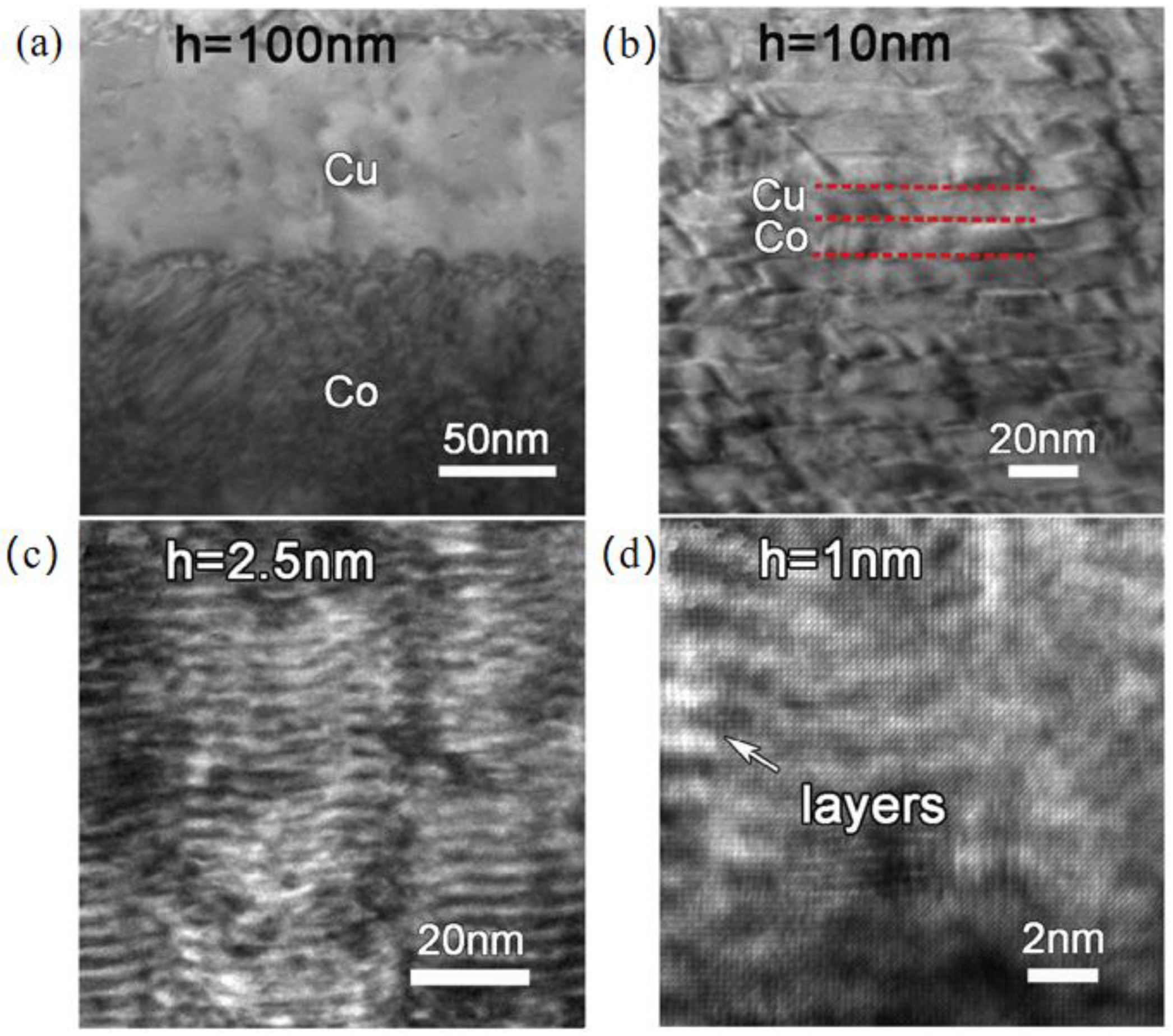

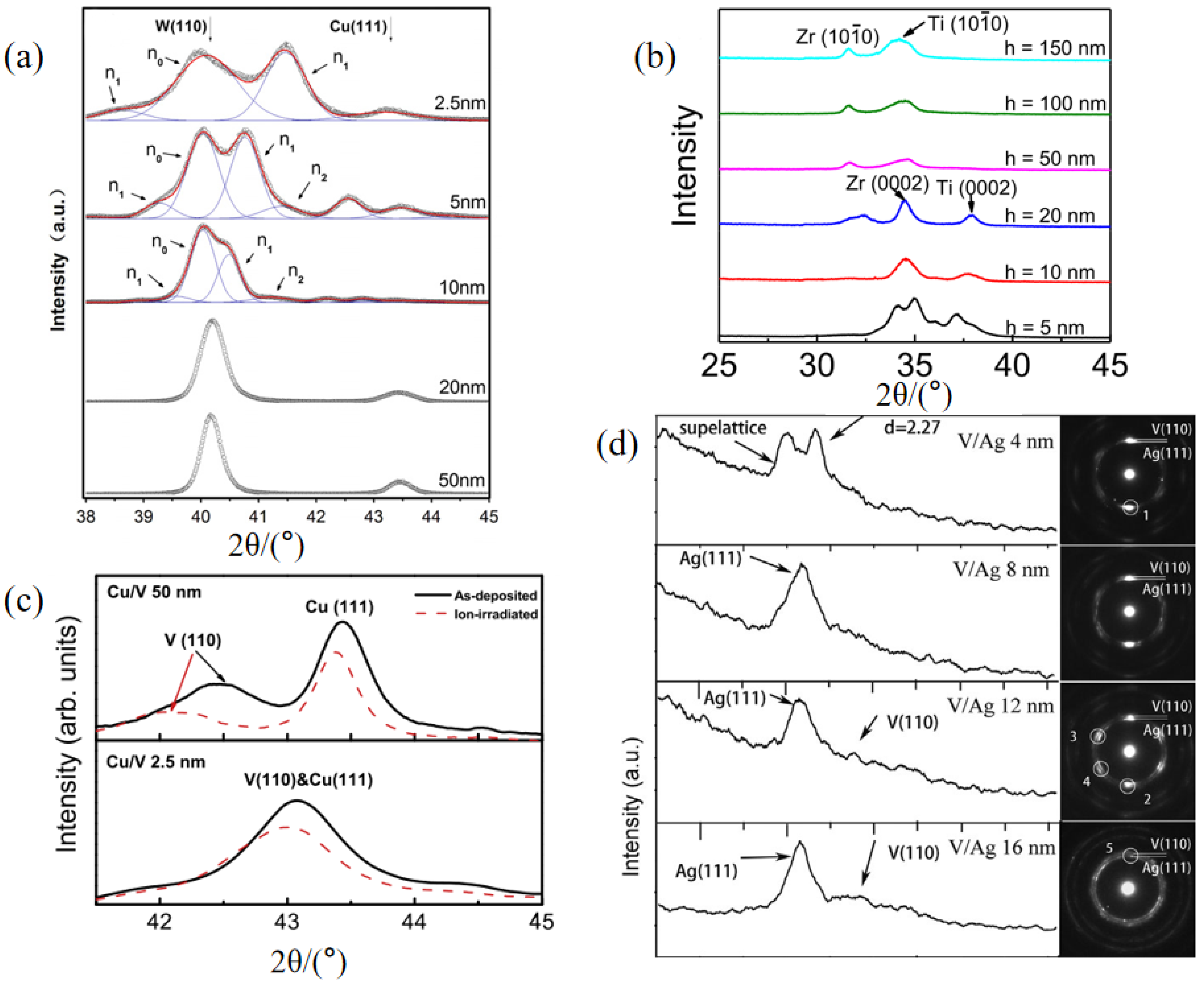

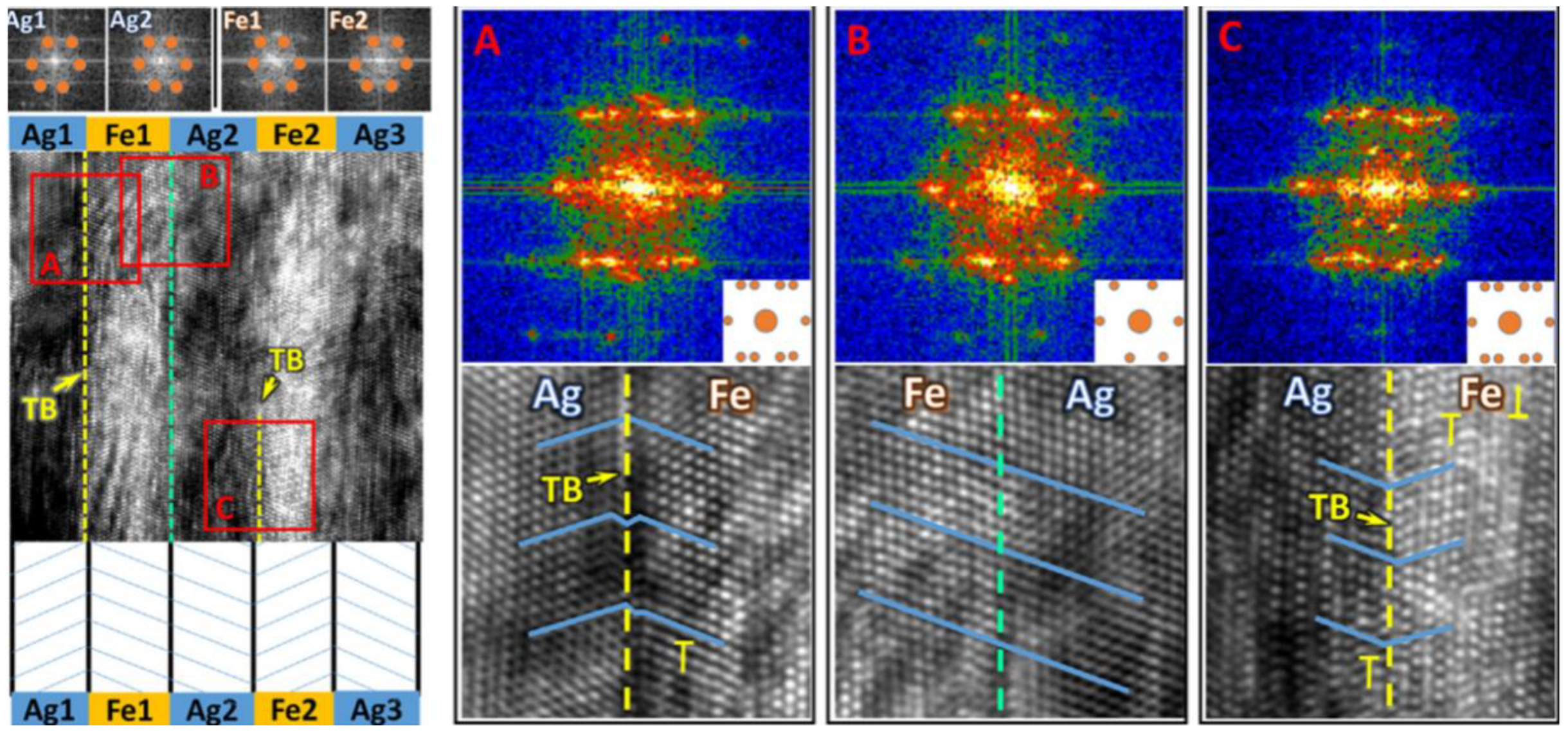

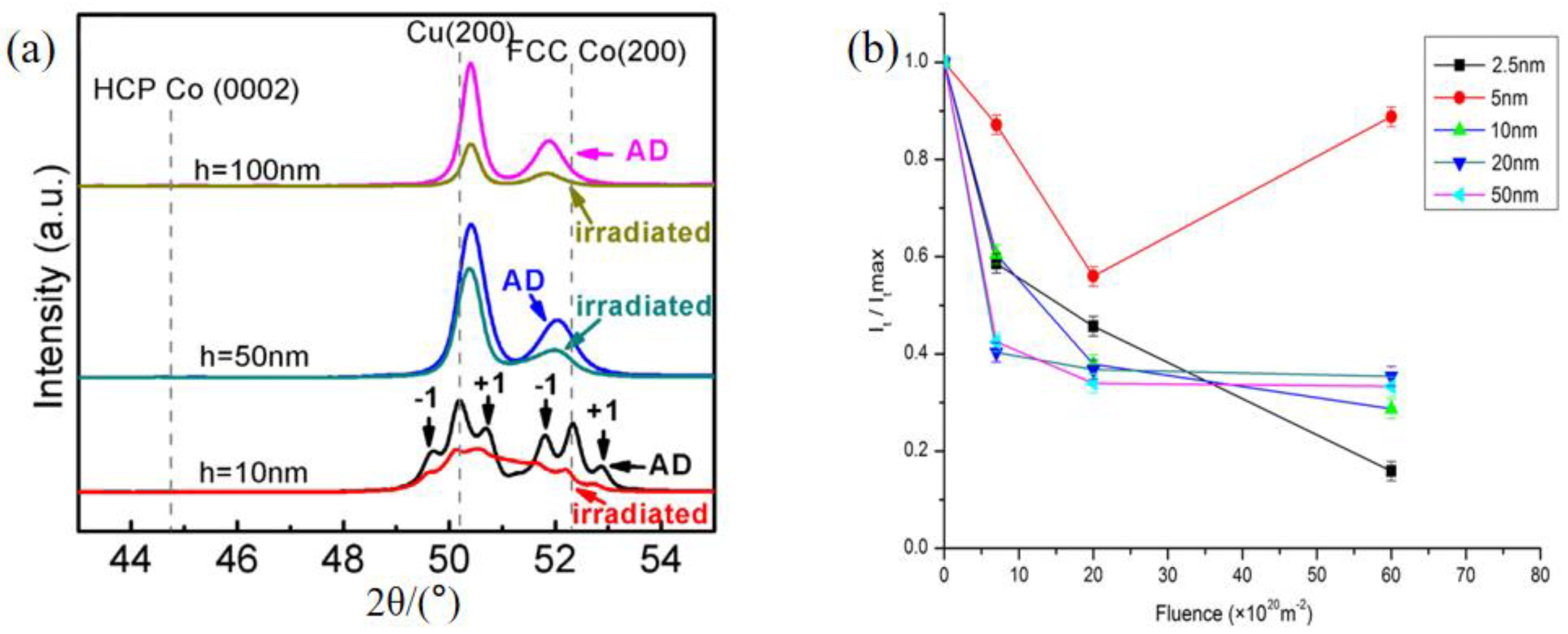

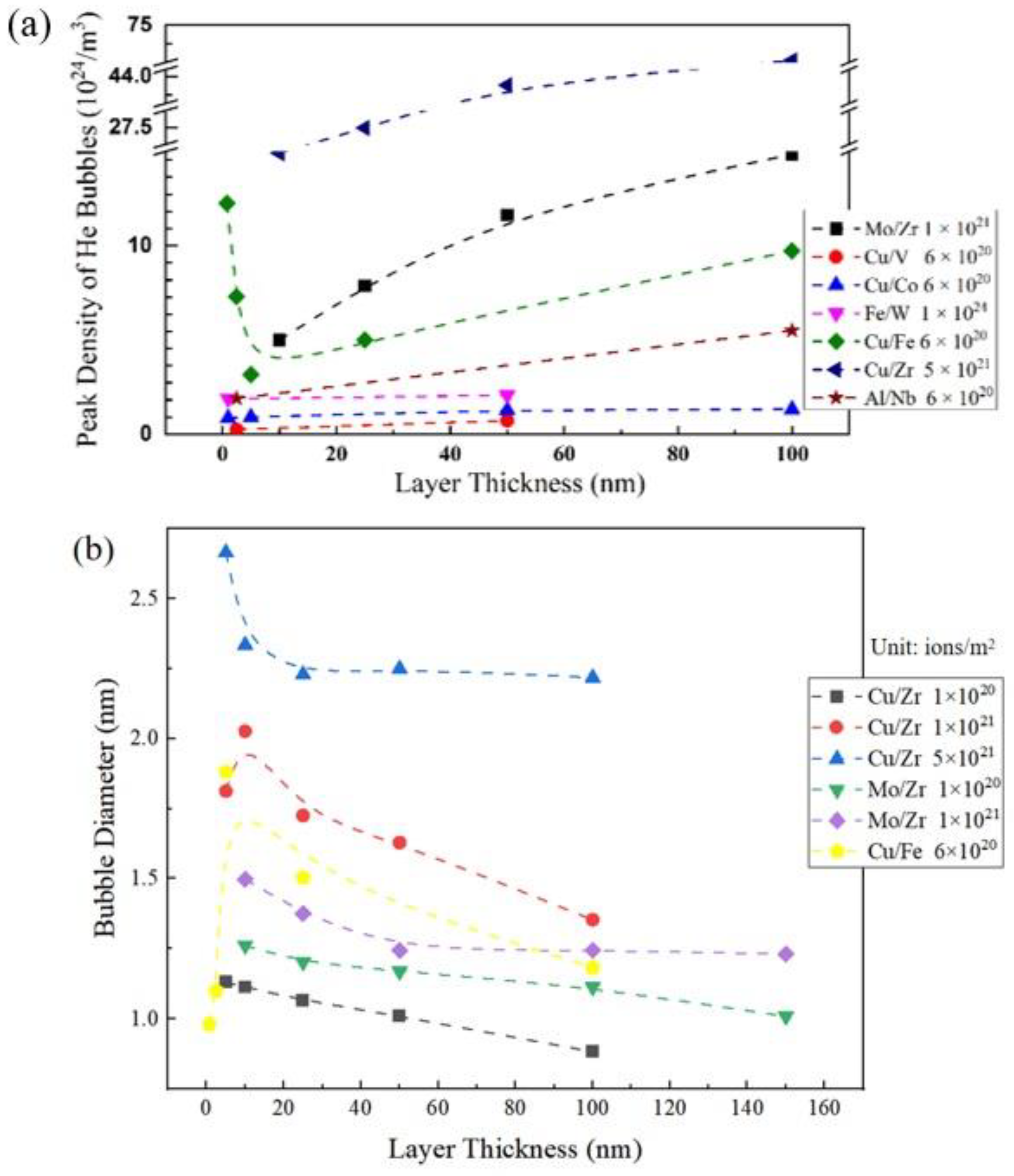

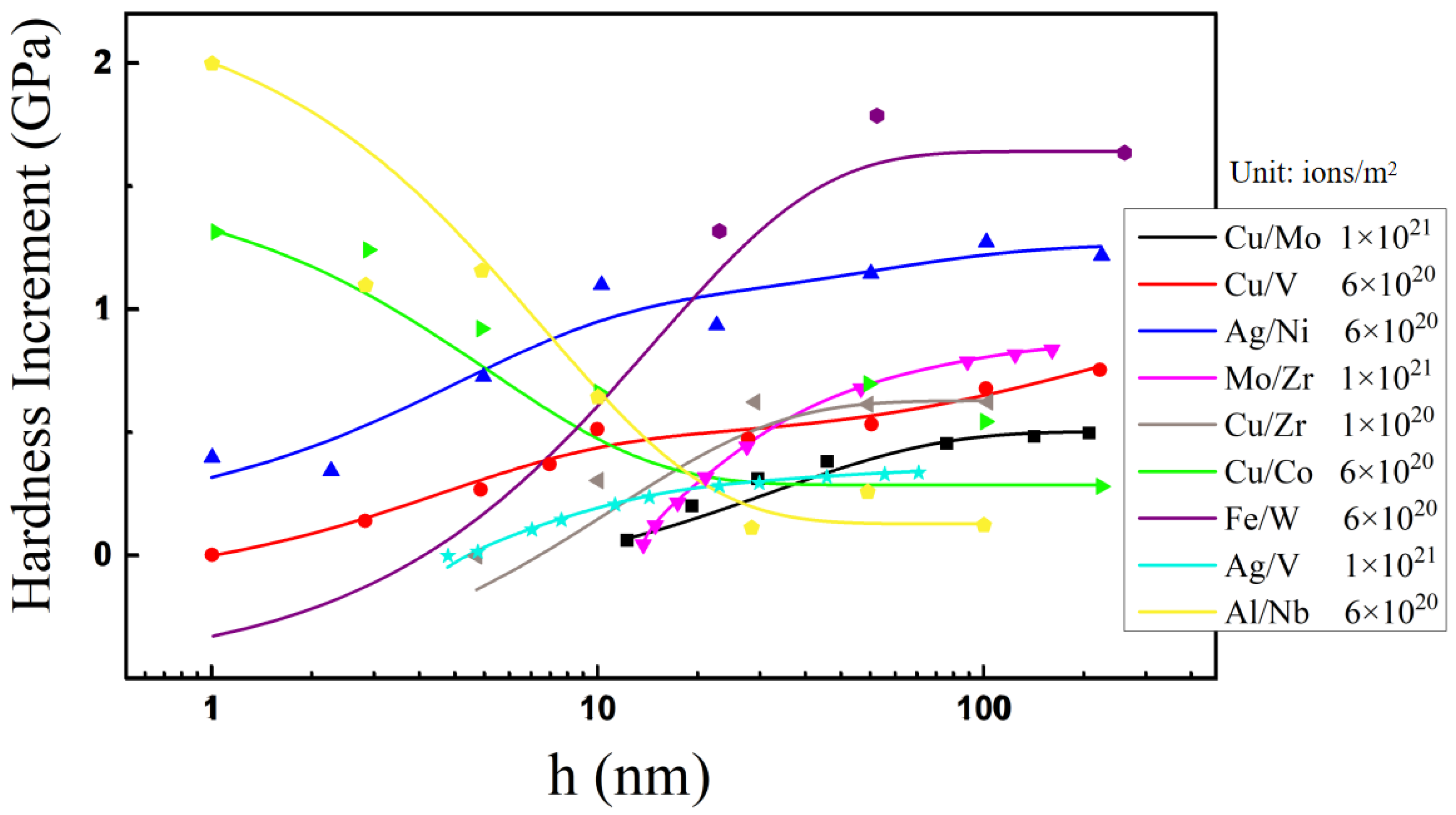

3. The Effect of Layer Thickness on the Microstructures of Multilayer Films

4. The Effect of Layer Thickness on the Irradiation Behaviors of Multilayer Films

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, W.; Lin, Y.; Zheng, J.; Zhang, S.; Liu, S.; Kwon, S. Preparation and characterization of CrAlN/TiAlSiN nano-multilayers by cathodic vacuum arc. Surf. Coat. Technol. 2015, 265, 205–211. [Google Scholar] [CrossRef]

- Budiman, A.; Li, N.; Wei, Q.; Baldwin, J.; Xiong, J.; Luo, H.; Trugman, D.; Jia, Q.; Tamura, N.; Kunz, M.; et al. Growth and structural characterization of epitaxial Cu/Nb multilayers. Thin Solid Films 2010, 519, 4137–4143. [Google Scholar] [CrossRef]

- Li, N.; Fu, E.; Wang, H.; Carter, J.; Shao, L.; Maloy, S.; Misra, A.; Zhang, X. He ion irradiation damage in Fe/W nanolayer films. J. Nucl. Mater. 2009, 389, 233–238. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, T.; Xue, J.; Yan, S.; Zhou, S.; Wang, Y.; Kwok, D.T.; Chu, P.; Zhang, Y. Radiation tolerance of Cu/W multilayered nanocomposites. J. Nucl. Mater. 2011, 413, 11–15. [Google Scholar] [CrossRef]

- Fu, E.; Misra, A.; Wang, H.; Shao, L.; Zhang, X. Interface enabled defects reduction in helium ion irradiated Cu/V nanolayers. J. Nucl. Mater. 2010, 407, 178–188. [Google Scholar] [CrossRef]

- Ham, B.; Junkaew, A.; Arroyave, R.; Chen, J.; Wang, H.; Wang, P.; Majewski, J.; Park, J.; Zhou, H.C.; Arvapally, R.K.; et al. Hydrogen sorption in orthorhombic Mg hydride at ultra-low temperature. Int. J. Hydrogen Energy 2013, 38, 8328–8341. [Google Scholar] [CrossRef]

- Chen, P.; Zhu, M. Recent progress in hydrogen storage. Mater. Today 2008, 11, 36–43. [Google Scholar] [CrossRef]

- Piramanayagam, S. Perpendicular recording media for hard disk drives. J. Appl. Phys. 2007, 102, 011301. [Google Scholar] [CrossRef]

- Moser, A.; Takano, K.; Margulies, D.T.; Albrecht, M.; Sonobe, Y.; Ikeda, Y.; Sun, S.; Fullerton, E.E. Magnetic recording: Advancing into the future. J. Phys. D Appl. Phys. 2002, 35, R157–R167. Available online: https://iopscience.iop.org/article/10.1088/0022-3727/35/19/201/meta (accessed on 25 October 2021). [CrossRef]

- Hu, H.; Gao, W.; Zang, R.; Gao, J.; Tang, S.; Li, X.; Liang, L.; Zhang, H.; Cao, H.J.A.F.M. Direct growth of vertically orientated nanocavity arrays for plasmonic color generation. Adv. Funct. Mater. 2020, 30, 2002287. [Google Scholar] [CrossRef]

- Varghese, B.; Piramanayagam, S.; Yang, Y.; Wong, S.K.; Tan, H.K.; Lee, W.K.; Okamoto, I. Equiatomic CoPt thin films with extremely high coercivity. J. Appl. Phys. 2014, 115, 17. [Google Scholar] [CrossRef]

- Liang, J.; Liu, Q.; Li, T.; Luo, Y.; Lu, S.; Shi, X.; Zhang, F.; Asiri, A.M.; Sun, X. Magnetron sputtering enabled sustainable synthesis of nanomaterials for energy electrocatalysis. Green Chem. 2021, 23, 2834–2867. Available online: https://pubs.rsc.org/en/content/articlehtml/2021/gc/d0gc03994b (accessed on 25 October 2021). [CrossRef]

- Park, K.-I.; Xu, S.; Liu, Y.; Hwang, G.-T.; Kang, S.-J.L.; Wang, Z.L.; Lee, K.J. Piezoelectric BaTiO3 thin film nanogenerator on plastic substrates. Nano Lett. 2010, 10, 4939–4943. Available online: https://pubs.acs.org/doi/abs/10.1021/nl102959k (accessed on 25 October 2021). [CrossRef] [PubMed] [Green Version]

- Webb, J.B.; Lockwood, D.; Gnezdilov, V. Magnetron sputter epitaxy and characterization of InSb/In1−xAlxSb strained layer superlattices. J. Cryst. Growth 1994, 137, 405–414. [Google Scholar] [CrossRef]

- Wang, M.; Fan, Z. Optics coatings by magnetron sputtering deposition. In Proceedings of the Third International Conference on Thin Film Physics and Applications, Shanghai, China, 20 February 1998; pp. 130–132. Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/3175/0000/Optics-coatings-by-magnetron-sputtering-deposition/10.1117/12.300652.short (accessed on 25 October 2021).

- Ellmer, K. Magnetron sputtering of transparent conductive zinc oxide: Relation between the sputtering parameters and the electronic properties. J. Phys. D Appl. Phys. 2000, 33, R17–R32. [Google Scholar] [CrossRef]

- Tang, W.; Xu, K.W.; Wang, P.; Li, X. Characterization of the surface roughness and nanoindentation hardness of Au/NiCr/Ta multilayers. Acta Metall. Sinica. 2002, 38, 449–452. Available online: http://www.jmonline.org/article/doi/10.3321/j.issn:0412-1961.2002.05.001 (accessed on 25 October 2021).

- Lenis, J.; Gómez, M.; Bolívar, F.J.S.; Technology, C. Effect of deposition temperature and target-substrate distance on the structure, phases, mechanical and tribological properties of multi-layer HA-Ag coatings obtained by RF magnetron sputtering. Surf. Coat. Technol. 2019, 378, 124936. [Google Scholar] [CrossRef]

- Yang, J.; Wang, C.; Ouyang, K.; Tao, D.-P.; Yang, Y. Effects of Deposition Temperature and Growth Interruption on Ge/Si Multilayer Films Prepared by Ion Beam Sputtering. J. Synth. Cryst. 2010, 39, 945–950. [Google Scholar] [CrossRef]

- Safran, G.; Reinhard, C.; Ehiasarian, A.; Barna, P.B.; Szekely, L.; Geszti, O.; Hovsepian, P.E. Influence of the bias voltage on the structure and mechanical performance of nanoscale multilayer CrAlYN/CrN physical vapor deposition coatings. J. Vac. Sci. Technol. A 2009, 27, 174–182. [Google Scholar] [CrossRef]

- Monclús, M.A.; Karlik, M.; Callisti, M.; Frutos, E.; Llorca, J.; Polcar, T.; Molina-Aldareguía, J.M. Microstructure and mechanical properties of physical vapor deposited Cu/W nanoscale multilayers: Influence of layer thickness and temperature. Thin Solid Film. 2014, 571, 275–282. [Google Scholar] [CrossRef] [Green Version]

- Zheng, X.-H.; Liu, T.; Wang, G.-Q.; Yang, S.-Y.; Wang, Z.-S.; Yang, F.-E. Microstructure and tribological behaviors of magnetron sputtered WS2/Fe/aC/Fe multilayer films with various deposition temperatures. Vacuum 2020, 179, 109550. [Google Scholar] [CrossRef]

- Domínguez-Crespo, M.; Torres-Huerta, A.; Rodríguez, E.; González-Hernández, A.; Brachetti-Sibaja, S.; Dorantes-Rosales, H.; López-Oyama, A. Effect of deposition parameters on structural, mechanical and electrochemical properties in Ti/TiN thin films on AISI 316L substrates produced by r. f. magnetron sputtering. J. Alloys Compd. 2018, 746, 688–698. [Google Scholar] [CrossRef]

- Zhangyu, Z.; Han, X.; Song, W.; Qingzhu, Z.; Daigiang, W.; Yuqing, C.; Xinghua, F. Fabrication and superconducting property of MgB2/Mo multilayer films. Rare Met. Mater. Eng. 2019, 48, 2711–2715. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFDLAST2019&filename=COSE201908048&uniplatform=NZKPT&v=LXX2Z_7qkhlLYaXOlR70-NnWUME8B3wOSkD8APhZpBUc94GmFNZQ_ofnaXiuHpTl (accessed on 25 October 2021).

- Pogrebnjak, A.; Smyrnova, K.; Bondar, O. Nanocomposite multilayer binary nitride coatings based on transition and refractory metals: Structure and properties. Coatings 2019, 9, 155. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Liu, Y.; Lai, Z.Q. Technological parameters and electrical properties of Ti/TiN multilayer films prepared by magnetron sputtering. Mater. Sci. Forum 2010, 654–656, 1752–1755. [Google Scholar] [CrossRef]

- Yang, K.M.; Tang, P.Z.; Zhang, Q.; Ma, H.Y.; Liu, E.Q.; Li, M.; Zhang, X.; Li, J.; Liu, Y.; Fan, T.X. Enhanced defect annihilation capability of the graphene/copper interface: An in situ study. Scr. Mater. 2021, 203, 114001. [Google Scholar] [CrossRef]

- Zinkle, S.; Singh, B. Analysis of displacement damage and defect production under cascade damage conditions. J. Nucl. Mater. 1993, 199, 173–191. [Google Scholar] [CrossRef]

- Phythian, W.; Stoller, R.; Foreman, A.; Calder, A.; Bacon, D. A comparison of displacement cascades in copper and iron by molecular dynamics and its application to microstructural evolution. J. Nucl. Mater. 1995, 223, 245–261. [Google Scholar] [CrossRef]

- Jenkins, M.; Kirk, M.; Phythian, W. Experimental studies of cascade phenomena in metals. J. Nucl. Mater. 1993, 205, 16–30. [Google Scholar] [CrossRef] [Green Version]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 2016; Available online: https://sc.panda321.com/extdomains/books.google.com/books?hl=zh-CN&lr=&id=yDGmDAAAQBAJ&oi=fnd&pg=PR8&dq=Fundamentals+of+Radiation+Materials+Science:+Metals+and+Alloys&ots=FlfGekj1Sy&sig=LKY1-nVdYw6jOAD6weAWb16Ol8Q (accessed on 25 October 2021).

- Ullmaier, H. The influence of helium on the bulk properties of fusion reactor structural materials. Nucl. Fusion 1984, 24, 1039–1083. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Ghetta, V. Microstructures and Mechanical Properties of Irradiated Metals and Alloys, Materials Issues for Generation IV Systems, Dordrecht, 2008; Ghetta, V., Gorse, D., Mazière, D., Pontikis, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 227–244. [Google Scholar]

- Odette, G.; Alinger, M.; Wirth, B. Recent Developments in Irradiation-Resistant Steels. Annu. Rev. Mater. Res. 2008, 38, 471–503. [Google Scholar] [CrossRef]

- Du, C.; Jin, S.; Fang, Y.; Li, J.; Hu, S.; Yang, T.; Zhang, Y.; Huang, J.; Sha, G.; Wang, Y.; et al. Ultrastrong nanocrystalline steel with exceptional thermal stability and radiation tolerance. Nat. Commun. 2018, 9, 5389. [Google Scholar] [CrossRef]

- Shang, Z.; Ding, J.; Fan, C.; Chen, D.; Li, J.; Zhang, Y.; Wang, Y.; Wang, H.; Zhang, X. He ion irradiation response of a gradient T91 steel. Acta Mater. 2020, 196, 175–190. [Google Scholar] [CrossRef]

- Shang, Z.; Fan, C.; Ding, J.; Xue, S.; Gabriel, A.; Shao, L.; Voisin, T.; Wang, Y.M.; Niu, T.; Li, J.; et al. Heavy ion irradiation response of an additively manufactured 316LN stainless steel. J. Nucl. Mater. 2021, 546, 152745. [Google Scholar] [CrossRef]

- Shang, Z.; Fan, C.; Xue, S.; Ding, J.; Li, J.; Voisin, T.; Wang, Y.M.; Wang, H.; Zhang, X. Response of solidification cellular structures in additively manufactured 316 stainless steel to heavy ion irradiation: An in situ study. Mater. Res. Lett. 2019, 7, 290–297. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Li, J.; Yu, K.; Wang, H.; Kirk, M.; Li, M.; Zhang, X. In situ studies on radiation tolerance of nanotwinned Cu. Acta Mater. 2016, 111, 148–156. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Chen, Y.; Wang, H.; Zhang, X. In situ studies on twin-thickness-dependent distribution of defect clusters in heavy ion-irradiated nanotwinned Ag. Met. Mater. Trans. A 2017, 48, 1466–1473. [Google Scholar] [CrossRef]

- Li, J.; Xie, D.; Xue, S.; Fan, C.; Chen, Y.; Wang, H.; Wang, J.; Zhang, X. Superior twin stability and radiation resistance of nanotwinned Ag solid solution alloy. Acta Mater. 2018, 151, 395–405. [Google Scholar] [CrossRef]

- Fan, C.; Xie, D.; Li, J.; Shang, Z.; Chen, Y.; Xue, S.; Wang, J.; Li, M.; El-Azab, A.; Wang, H.; et al. 9R phase enabled superior radiation stability of nanotwinned Cu alloys via in situ radiation at elevated temperature. Acta Mater. 2019, 167, 248–256. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Yu, K.Y.; Chen, Y.; Song, M.; Wang, H.; Kirk, M.A.; Li, M.; Zhang, X. In situ study of defect migration kinetics and self-healing of twin boundaries in heavy ion irradiated nanotwinned metals. Nano Lett. 2015, 15, 2922–2927. [Google Scholar] [CrossRef] [PubMed]

- Niu, T.; Li, J.; Zhang, Y.; Cho, J.; Ding, J.; Su, R.; Xue, S.; Fan, C.; Shang, Z.; Chen, D.; et al. In-situ studies on the mechanical properties of He ion irradiated nanotwinned Ag. J. Nucl. Mater. 2020, 540, 152392. [Google Scholar] [CrossRef]

- Yu, K.Y.; Fan, C.; Chen, Y.; Li, J.; Zhang, X. Recent Studies on the Microstructural Response of Nanotwinned Metals to In Situ Heavy Ion Irradiation. JOM 2020, 72, 160–169. [Google Scholar] [CrossRef]

- Fan, C.; Sreekar, A.; Shang, Z.; Li, J.; Li, M.; Wang, H.; El-Azab, A.; Zhang, X. Radiation induced nanovoid shrinkage in Cu at room temperature: An in situ study. Scr. Mater. 2019, 166, 112–116. [Google Scholar] [CrossRef]

- Fan, Z.; Li, Q.; Li, J.; Xue, S.; Wang, H.; Zhang, X. Tailoring plasticity of metallic glasses via interfaces in Cu/amorphous CuNb laminates. J. Mater. Res. 2017, 32, 2680–2689. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Wang, H.; Zhang, X. In situ study on enhanced heavy ion irradiation tolerance of porous Mg. Scr. Mater. 2018, 144, 13–17. [Google Scholar] [CrossRef]

- Li, J.; Fan, C.; Ding, J.; Xue, S.; Chen, Y.; Li, Q.; Wang, H.; Zhang, X. In situ heavy ion irradiation studies of nanopore shrinkage and enhanced radiation tolerance of nanoporous Au. Sci. Rep. 2017, 7, 39484. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fan, C.; Li, Q.; Wang, H.; Zhang, X. In situ studies on irradiation resistance of nanoporous Au through temperature-jump tests. Acta Mater. 2018, 143, 30–42. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Zhang, X. A review on the radiation response of nanoporous metallic materials. JOM 2018, 70, 2753–2764. [Google Scholar] [CrossRef]

- Niu, T.; Nasim, M.; Annadanam, R.G.S.; Fan, C.; Li, J.; Shang, Z.; Xue, Y.; El-Azab, A.; Wang, H.; Zhang, X. Recent studies on void shrinkage in metallic materials subjected to in situ heavy ion irradiations. JOM 2020, 72, 4008–4016. [Google Scholar] [CrossRef]

- Ackland, G. Controlling Radiation Damage. Science 2010, 327, 1587–1588. [Google Scholar] [CrossRef]

- Callisti, M.; Karlik, M.; Polcar, T. Bubbles formation in helium ion irradiated Cu/W multilayer nanocomposites: Effects on structure and mechanical properties. J. Nucl. Mater. 2016, 473, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Beyerlein, I.J.; Zhang, J.; Han, W.-Z. Defect-interface interactions in irradiated Cu/Ag nanocomposites. Acta Mater. 2018, 160, 211–223. [Google Scholar] [CrossRef]

- Chen, Y.; Fu, E.; Yu, K.; Song, M.; Liu, Y.; Wang, Y.; Wang, H.; Zhang, X. Enhanced radiation tolerance in immiscible Cu/Fe multilayers with coherent and incoherent layer interfaces. J. Mater. Res. 2015, 30, 1300–1309. Available online: https://www.cambridge.org/core/journals/journal-of-materials-research/article/enhanced-radiation-tolerance-in-immiscible-cufe-multilayers-with-coherent-and-incoherent-layer-interfaces/CC962813E8E65989C338C1A70039B38F (accessed on 25 October 2021). [CrossRef]

- Li, N.; Martin, M.; Anderoglu, O.; Misra, A.; Shao, L.; Wang, H.; Zhang, X. He ion irradiation damage in Al/Nb multilayers. J. Appl. Phys. 2009, 105, 123522. [Google Scholar] [CrossRef]

- Zhang, X.; Hattar, K.; Chen, Y.; Shao, L.; Li, J.; Sun, C.; Yu, K.; Li, N.; Taheri, M.L.; Wang, H.; et al. Radiation damage in nanostructured materials. Prog. Mater. Sci. 2018, 96, 217–321. [Google Scholar] [CrossRef]

- Chen, Y.; Li, N.; Bufford, D.C.; Li, J.; Hattar, K.; Wang, H.; Zhang, X. In situ study of heavy ion irradiation response of immiscible Cu/Fe multilayers. J. Nucl. Mater. 2016, 475, 274–279. [Google Scholar] [CrossRef] [Green Version]

- Niu, T.; Zhang, Y.; Cho, J.; Li, J.; Wang, H.; Zhang, X. Thermal stability of immiscible Cu-Ag/Fe triphase multilayers with triple junctions. Acta Mater. 2021, 208, 116679. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Kung, H. Single-dislocation-based strengthening mechanisms in nanoscale metallic multilayers. Philos. Mag. A 2002, 82, 2935–2951. [Google Scholar] [CrossRef]

- Clemens, B.; Kung, H.; Barnett, S. Structure and strength of multilayers. MRS Bull. 1999, 24, 20–26. [Google Scholar] [CrossRef]

- Zhang, Z.; Lagally Max, G. Atomistic processes in the early stages of thin-film growth. Science 1997, 276, 377–383. Available online: https://www.science.org/doi/full/10.1126/science.276.5311.377 (accessed on 25 October 2021). [CrossRef]

- Yamada, M.; Hotta, Y.; Yanagawa, T.; Ohtake, M.; Kirino, F.; Futamoto, M. Effect of substrate temperature on the ordered phase formation in Sm–Ni thin film deposited on Cu(111) underlayer. IEEE Trans. Magn. 2013, 50, 1–4. [Google Scholar] [CrossRef]

- Suzaki, Y.; Kawaguchi, A.; Murase, T.; Yuji, T.; Shikama, T.; Shin, D.-B.; Kim, Y.-K. Effect of substrate temperature on ZnO thin film fabrication by using an atmospheric pressure cold plasma generator. Phys. Status Solidi 2011, 8, 503–505. [Google Scholar] [CrossRef]

- Levi, A.C.; Kotrla, M. Theory and simulation of crystal growth. J. Phys. Condens. Matter 1997, 9, 299–344. [Google Scholar] [CrossRef]

- Sun, C.; Maloy, S.A.; Baldwin, K.; Wang, Y.; Valdez, J.A. Phase stability of Ni/Ni3Al multilayers under thermal annealing and irradiation. JOM 2020, 72, 3995–4001. Available online: https://link.springer.com/article/10.1007/s11837-020-04377-0 (accessed on 25 October 2021). [CrossRef]

- Pogrebnjak, A.D.; Ivashchenko, V.I.; Skrynskyy, P.L.; Bondar, O.V.; Konarski, P.; Załęski, K.; Jurga, S.; Coy, E. Experimental and theoretical studies of the physicochemical and mechanical properties of multi-layered TiN/SiC films: Temperature effects on the nanocomposite structure. Compos. Part B Eng. 2018, 142, 85–94. [Google Scholar] [CrossRef]

- Schürmann, U.; Takele, H.; Zaporojtchenko, V.; Faupel, F. Optical and electrical properties of polymer metal nanocomposites prepared by magnetron co-sputtering. Thin Solid Film. 2006, 515, 801–804. [Google Scholar] [CrossRef]

- Yanev, V.; Krischok, S.; Opitz, A.; Wurmus, H.; Schaefer, J.; Schwesinger, N.; Ahmed, S.-I.-U. Influence of the RF power on the deposition rate and the chemical surface composition of fluorocarbon films prepared in dry etching gas plasma. Surf. Sci. 2004, 566–568, 1229–1233. [Google Scholar] [CrossRef]

- Yamamoto, S.; Ichimura, H. Effect of substrate bias voltage on the properties of arc ion-plated TiN films onto high speed steels. J. Mater. Res. 1996, 11, 1149–1156. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Beresnev, V.; Bondar, O.; Postolnyi, B.; Załęski, K.; Coy, E.; Jurga, S.; Lisovenko, M.; Konarski, P.; Rebouta, L.; et al. Superhard CrN/MoN coatings with multilayer architecture. Mater. Des. 2018, 153, 47–59. [Google Scholar] [CrossRef]

- Mahieu, S.; Ghekiere, P.; Depla, D.; De Gryse, R. Biaxial alignment in sputter deposited thin films. Thin Solid Films 2006, 515, 1229–1249. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Ren, F.; Hong, M.; Xiao, X.; Cai, G.; Jiang, C. Structure and growth mechanism of V/Ag multilayers with differ-ent periodic thickness fabricated by magnetron sputtering deposition. J. Mater. Sci. Technol. 2014, 30, 1012–1019. [Google Scholar] [CrossRef]

- Fu, E.G.; Carter, J.; Swadener, G.; Misra, A.; Shao, L.; Wang, H.; Zhang, X. Size dependent enhancement of helium ion irradiation tolerance in sputtered Cu/V nanolaminates. J. Nucl. Mater. 2009, 385, 629–632. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Fu, E.; Sun, C.; Yu, K.; Song, M.; Li, J.; Wang, Y.; Wang, H.; Zhang, X. Unusual size-dependent strengthening mechanisms in helium ion-irradiated immiscible coherent Cu/Co nanolayers. Acta Mater. 2015, 84, 393–404. [Google Scholar] [CrossRef] [Green Version]

- Hou, Z.; Zhang, J.; Zhang, P.; Wu, K.; Li, J.; Wang, Y.; Liu, G.; Zhang, G.; Sun, J. Modulation-dependent deformation behavior and strengthening response in nanostructured Ti/Zr multilayers. Appl. Surf. Sci. 2020, 502, 144118. [Google Scholar] [CrossRef]

- Xu, J.; Kamiko, M.; Zhou, Y.; Yamamoto, R.; Li, G.; Gu, M. Superhardness effects of heterostructure NbN/TaN nanostructured multilayers. J. Appl. Phys. 2001, 89, 3674–3678. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Xue, S.; Wang, H.; Zhang, X. Comparison of size dependent strengthening mechanisms in Ag/Fe and Ag/Ni multilayers. Acta Mater. 2016, 114, 154–163. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Wan, L.; Yu, X.-X.; Vogel, F.; Thompson, G.B. Influence of phase stability on the in situ growth stresses in Cu/Nb multilayered films. Acta Mater. 2017, 132, 149–161. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.H.; Wei, M.Z.; Ma, Y.J.; Sun, C.; Lu, H.M.; Fan, Z.; Meng, X.K. Cyclic deformation induced strengthening and unusual rate sensitivity in Cu/Ru nanolayered films. Int. J. Plast. 2017, 99, 43–57. [Google Scholar] [CrossRef]

- Heinisch, H.; Gao, F.; Kurtz, R. The effects of interfaces on radiation damage production in layered metal composites. J. Nucl. Mater. 2004, 329–333, 924–928. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, J.; Wang, F.; Huang, P.; Xu, K.; Lu, T. Strain rate sensitivity of Cu/Ta multilayered films: Comparison between grain boundary and heterophase interface. Scr. Mater. 2016, 111, 123–126. [Google Scholar] [CrossRef]

- Liang, X.Q.; Wang, Y.Q.; Zhao, J.T.; Wu, S.H.; Wu, K.; Liu, G.; Sun, J. Size- and ion-dose-dependent microstructural evolution and hardening in He-irradiated miscible Cu/Zr crystalline/crystalline nanolaminates. Surf. Coat. Technol. 2019, 366, 255–265. [Google Scholar] [CrossRef]

- Guo, Z.B.; Mi, W.B.; Li, J.Q.; Cheng, Y.; Zhang, X.X. Enhancement in anomalous Hall resistivity of Co/Pd multilayer and CoPd alloy by Ga + ion irradiation. EPL Europhys. Lett. 2014, 105, 46005. [Google Scholar] [CrossRef]

- Spasova, M.; Wiedwald, U.; Ramchal, R.; Farle, M.; Jergel, M.; Majkova, E.; Luby, S.; Senderak, R. Magnetization and Magnetic Anisotropy of Co/W Multilayers. Phys. Status Solidi 2001, 225, 449–457. [Google Scholar] [CrossRef]

- Hillebrands, B.; Dutcher, J.R. Origin of very large in-plane anisotropies in (110)-oriented Co/Pd and Co/Pt coherent super-lattices. Phys. Rev. B 1993, 47, 6126–6129. Available online: https://journals.aps.org/prb/abstract/10.1103/PhysRevB.47.6126 (accessed on 25 October 2021). [CrossRef]

- Majková, E.; Spasova, M.; Jergel, M.; Luby, S.; Okayasu, S.; Luches, A.; Martino, M.; Zubarev, E.; Brunel, M. Formation of granular-like structure of Ag/Co multilayers by excimer laser irradiation. Thin Solid Films 1999, 343–344, 214–217. [Google Scholar] [CrossRef]

- Yu, K.; Liu, Y.; Fu, E.; Wang, Y.; Myers, M.; Wang, H.; Shao, L.; Zhang, X. Comparisons of radiation damage in He ion and proton irradiated immiscible Ag/Ni nanolayers. J. Nucl. Mater. 2013, 440, 310–318. [Google Scholar] [CrossRef]

- Kim, C.; Qadri, S.B.; Yu, H.Y.; Kim, K.H.; Maruyama, B.; Edelstein, A.S. Synthesis and structure of ion-beam sputtered multilayer Fe/Ni films. J. Vac. Sci. Technol. A 1990, 8, 1407–1410. [Google Scholar] [CrossRef]

- Wu, Z.L.; Peng, T.X.; Cao, B.S.; Lei, M.K. X-ray diffraction and high resolution transmission electron microscopy charac-terization of intermetallics formed in Fe/Ti nanometer-scale multilayers during thermal annealing. Thin Solid Film. 2009, 517, 6553–6557. [Google Scholar] [CrossRef]

- Wu, S.; Cheng, P.; Wu, K.; Hou, Z.; Wang, Y.; Liang, X.; Li, J.; Kuang, J.; Zhang, J.; Liu, G.; et al. Effect of He-irradiation fluence on the size-dependent hardening and deformation of nanostructured Mo/Zr multilayers. Int. J. Plast. 2018, 111, 36–52. [Google Scholar] [CrossRef]

- Laptev, R.; Lomygin, A.; Krotkevich, D.; Syrtanov, M.; Kashkarov, E.; Bordulev, Y.; Siemek, K.; Kobets, A. Effect of Proton Irradiation on the Defect Evolution of Zr/Nb Nanoscale Multilayers. Metals 2020, 10, 535. [Google Scholar] [CrossRef] [Green Version]

- Hou, Z.Q.; Zhang, J.Y.; Li, J.; Wang, Y.Q.; Wu, K.; Liu, G.; Zhang, G.J.; Sun, J. Phase transformation-induced strength sof-tening in Ti/Ta nanostructured multilayers: Coherent interface vs. phase boundary. Mater. Sci. Eng. A 2017, 684, 78–83. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, S.; Li, Q.; Li, J.; Ding, J.; Niu, T.; Su, R.; Wang, H.; Zhang, X. Size dependent strengthening in high strength nanotwinned Al/Ti multilayers. Acta Mater. 2019, 175, 466–476. [Google Scholar] [CrossRef]

- Zinkle, S.J. Radiation-Induced Effects on Microstructure. Compr. Nucl. Mater. 2020, 1, 91–129. Available online: https://www.researchgate.net/publication/255249921 (accessed on 25 October 2021).

- He, X.; Liang, S.-H.; Li, J.-H.; Liu, B.-X. Atomistic mechanism of interfacial reaction and asymmetric growth kinetics in an immiscible Cu/Ru system at equilibrium. Phys. Rev. B 2007, 75, 045431. Available online: https://journals.aps.org/prb/abstract/10.1103/PhysRevB.75.045431 (accessed on 25 October 2021). [CrossRef]

- Demkowicz, M.J.; Hoagland, R.G.; Hirth, J.P. Interface structure and radiation damage resistance in Cu-Nb multilayer nanocomposites. Phys. Rev. Lett. 2008, 100, 136102. [Google Scholar] [CrossRef]

- Abdolrahim, N.; Zbib, H.M.; Bahr, D.F. Multiscale modeling and simulation of deformation in nanoscale metallic multi-layer systems. Int. J. Plast. 2014, 52, 33–50. [Google Scholar] [CrossRef]

- Misra, A.; Demkowicz, M.J.; Zhang, X.; Hoagland, R.G. The radiation damage tolerance of ultra-high strength nanolayered composites. JOM 2007, 59, 62–65. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.P. The stopping and range of ions in matter. In Treatise on Heavyion Science; Springer: Berlin/Heidelberg, Germany, 1985; pp. 93–129. Available online: https://link.springer.com/chapter/10.1007/978-1-4615-8103-1_3 (accessed on 25 October 2021).

- Mao, S.; Shu, S.; Zhou, J.; Averback, R.S.; Dillon, S.J. Quantitative comparison of sink efficiency of Cu–Nb, Cu–V and Cu–Ni interfaces for point defects. Acta Mater. 2015, 82, 328–335. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Carter, J.; Misra, A.; Shao, L.; Wang, H.; Zhang, X. The influence of interfaces on the formation of bubbles in He-ion-irradiated Cu/Mo nanolayers. Philos. Mag. Lett. 2011, 91, 18–28. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, R.; Hou, J.; Zhao, B.; Sun, M.; Hao, T.; Xie, Z.; Liu, R.; Wang, X.; Fang, Q.; et al. Study on thermal stability and irradiation response of copper/iron nano-multilayer composite fabricated by cross accumulative roll bonding. J. Nucl. Mater. 2021, 543, 152548. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, J.; Wang, Y.; Wu, S.; Zeng, F.; Wu, K.; Liu, G.; Zhang, G.; Sun, J. Tuning the size-dependent He-irradiated tolerance and strengthening behavior of crystalline/amorphous Cu/Ta nanostructured multilayers. Mater. Sci. Eng. A 2016, 672, 153–160. [Google Scholar] [CrossRef]

- Suharyadi, E.; Natsume, S.; Kato, T.; Tsunashima, S.; Iwata, S. Modification of the microstructure and magnetic properties of Ga-Ion-Irradiated Co/Pd multilayer film for future planar media. Trans. Magn. Soc. Jpn. 2005, 5, 125–130. [Google Scholar] [CrossRef]

- Bagchi, S.; Anwar, S.; Lalla, N. Effect of swift heavy ion irradiation in W/Co multilayer structures. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1601–1606. [Google Scholar] [CrossRef]

- Kavita, S.; Reddy, V.R.; Amirthapandian, S.; Gupta, A.; Panigrahi, B.K. Si+ ion irradiation in a Co/Pt multilayer system. J. Phys. Condens. Matter 2009, 21, 096003. [Google Scholar] [CrossRef] [PubMed]

- Amirthapandian, S.; Panigrahi, B.K.; Srivastava, A.K.; Gupta, A.; Nair, K.G.M.; Nandedkar, R.V.; Narayanasamy, A. Irra-diation induced metastable phase formation in thermally immiscible Co–Ag multilayers. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 212, 140–145. [Google Scholar] [CrossRef]

- Yu, K.; Sun, C.; Chen, Y.; Liu, Y.; Wang, H.; Kirk, M.; Li, M.; Zhang, X. Superior tolerance of Ag/Ni multilayers against Kr ion irradiation: An in situ study. Philos. Mag. 2013, 93, 3547–3562. [Google Scholar] [CrossRef]

- Milosavljević, M.; Stojanović, N.; Perusko, D.; Timotijević, B.; Toprek, D.; Kovač, J.; Dražič, G.; Jeynes, C. Ion irradiation induced Al–Ti interaction in nano-scaled Al/Ti multilayers. Appl. Surf. Sci. 2012, 258, 2043–2046. [Google Scholar] [CrossRef]

- Srivastava, S.; Kumar, R.; Gupta, A.; Patel, R.S.; Majumdar, A.; Avasthi, D. Swift heavy ion induced mixing in Fe/Ni multilayer. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2006, 243, 304–312. [Google Scholar] [CrossRef]

- Padiyath, J.; Stahn, J.; Horisberger, M.; Ay, M.; Böni, P. Polarizing neutron monochromator with reduced higher-order contributions. Appl. Phys. Lett. 2006, 89, 253111. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Tang, X.; Huang, H.; Liu, J.; Li, H.; Qiu, Y.; Chen, D. Surface damage and mechanical properties degradation of Cr/W multilayer films irradiated by Xe20+. Appl. Surf. Sci. 2015, 357, 1225–1230. [Google Scholar] [CrossRef]

- Milosavljević, M.; Milinović, V.; Peruško, D.; Grce, A.; Stojanović, M.; Pjević, D.; Mitrić, M.; Kovač, J.; Homewood, K.P. Sta-bility of nano-scaled Ta/Ti multilayers upon argon ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2011, 269, 2090–2097. [Google Scholar] [CrossRef]

- Lu, Y.; Kotoka, R.; Ligda, J.; Cao, B.; Yarmolenko, S.; Schuster, B.; Wei, Q. The microstructure and mechanical behavior of Mg/Ti multilayers as a function of individual layer thickness. Acta Mater. 2014, 63, 216–231. [Google Scholar] [CrossRef]

- Grimes, R.W.; Konings, R.J.M.; Edwards, L. Greater tolerance for nuclear materials. Nat. Mater. 2008, 7, 683–685. [Google Scholar] [CrossRef]

- Garner, F.A.; Toloczko, M.B.; Sencer, B.H. Comparison of swelling and irradiation creep behavior of fcc-austenitic and bcc-ferritic/martensitic alloys at high neutron exposure. J. Nucl. Mater. 2000, 276, 123–142. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, Y.; Nastasi, M.; Misra, A. Nucleation and growth of bubbles in He ion-implanted V/Ag multilayers. Philos. Mag. 2011, 91, 553–573. [Google Scholar] [CrossRef]

- Li, N.; Nastasi, M.; Misra, A. Defect structures and hardening mechanisms in high dose helium ion implanted Cu and Cu/Nb multilayer thin films. Int. J. Plast. 2012, 32–33, 1–16. [Google Scholar] [CrossRef]

- El-Atwani, O.; Hattar, K.; Hinks, J.; Greaves, G.; Harilal, S.; Hassanein, A. Helium bubble formation in ultrafine and nanocrystalline tungsten under different extreme conditions. J. Nucl. Mater. 2015, 458, 216–223. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Li, N.; Anderoglu, O.; Wang, H.; Swadener, J.G.; Höchbauer, T.; Misra, A.; Hoagland, R. Nanostructured Cu/Nb multilayers subjected to helium ion-irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 261, 1129–1132. [Google Scholar] [CrossRef]

- Reed, D.J. A review of recent theoretical developments in the understanding of the migration of helium in metals and its interaction with lattice defects. Radiat. Eff. 1977, 31, 129–147. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M.; Liu, Y. Strengthening mechanisms of the nanolayered polycrystalline metallic multilayers assisted by twins. Int. J. Plast. 2015, 72, 168–184. [Google Scholar] [CrossRef]

- Anderson, P.M.; Bingert, J.F.; Misra, A.; Hirth, J.P. Rolling textures in nanoscale Cu/Nb multilayers. Acta Mater. 2003, 51, 6059–6075. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Q.; Shao, S.; Misra, A. Strength and plasticity of nanolaminated materials. Mater. Res. Lett. 2017, 5, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Misra, A.; Hirth, J.P.; Hoagland, R.G. Length-scale-dependent deformation mechanisms in incoherent metallic multi-layered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Hoagland, R.; Kurtz, R.; Henager, C. Slip resistance of interfaces and the strength of metallic multilayer composites. Scr. Mater. 2004, 50, 775–779. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zeng, F.L.; Wu, K.; Wang, Y.Q.; Liang, X.Q.; Liu, G.; Zhang, G.J.; Sun, J. Size-dependent plastic deformation characteristics in He-irradiated nanostructured Cu/Mo multilayers: Competition between dislocation-boundary and dislocation-bubble interactions. Mater. Sci. Eng. A 2016, 673, 530–540. [Google Scholar] [CrossRef]

- Wei, Q.; Li, N.; Mara, N.; Nastasi, M.; Misra, A. Suppression of irradiation hardening in nanoscale V/Ag multilayers. Acta Mater. 2011, 59, 6331–6340. [Google Scholar] [CrossRef]

| Layer | T/°C | FWMH/(°) | d/nm |

|---|---|---|---|

| Mo (110) | 670 | 0.845 | 0.2229 |

| 700 | 0.743 | 0.2232 | |

| 730 | 0.642 | 0.2236 | |

| MgB2 (001) | 670 | 0.105 | 0.3531 |

| 700 | 0.063 | 0.3530 | |

| 730 | 0.044 | 0.3532 |

| Deposition Temperatures | Cu Deposition Rates | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 nm/s | 2.5 nm/s | 5 nm/s | |||||

| FWHM /(°) | SNR | FWHM /(°) | SNR | FWHM /(°) | SNR | ||

| 750 °C | Cu | 0.6 | 1663 | 0.5 | 596 | 0.5 | 588 |

| Nb | 0.8 | 521 | 0.9 | 292 | 0.8 | 1012 | |

| 600 °C | Cu | 0.9 | 1226 | 0.9 | 886 | 0.8 | 488 |

| Nb | 1.1 | 489 | 1.2 | 327 | 1.1 | 224 | |

| 400 °C | Cu | 1.6 | 309 | 1.7 | 256 | 1.4 | 226 |

| Nb | 1.5 | 131 | 1.7 | 122 | 1.7 | 54 | |

| 250 °C | Cu | 1.3 | 211 | 1.3 | 112 | 2.2 | 179 |

| Nb | 1.5 | 106 | 1.6 | 89 | 3.6 | 124 | |

| 200 °C | Cu | 3.4 | 128 | ||||

| Nb | 4.6 | 122 | |||||

| 150 °C | Cu | 5.2 | 116 | ||||

| Nb | 5.8 | 68 | |||||

| Sample | Crystallite Size (nm) | |

|---|---|---|

| Coatings Deposited at: | ||

| RT | 200 °C | |

| 4 cm | 26.22 | 29.38 |

| 6 cm | 17.64 | 30.24 |

| 8 cm | Amorphous coating | 19.79 |

| Metallic Nanolayers | Researched Layer Thickness (T) | Coherency |

|---|---|---|

| Cu/Nb [80] | 1–20 nm | Coherent at T ≤ 2 nm |

| Cu/W [54] | 2.5–50 nm | Incoherent at T = 2.5–50 nm |

| Cu/Fe [56] | 0.75–100 nm | Coherent at T ≤ 5 nm |

| Cu/Ag [55] | 50–150 nm | Semi-coherent at T ≥ 50 nm |

| Cu/Ru [81] | 2–100 nm | Coherent at 2 nm and semi-coherent at 10 nm |

| Cu/Ni [82] | 1–10 nm | Coherent at T ≤ 1–4 nm |

| Cu/Co [76] | 1–100 nm | Coherent at T = 1–100 nm |

| Cu/Ta [83] | 2–200 nm | Incoherent at T = 2–200 nm |

| Cu/Zr [84] | 5–100 nm | Incoherent at T = 5–100 nm |

| Co/Pd [85] | 1–28 nm (Pd) | Coherent at T = 1–27 nm |

| Co/W [86] | 1–7 nm (W) | Coherent at T = 1–7 nm |

| Co/Pt [87] | 1–28 nm (Pt) | Coherent at T = 1–27 nm |

| Co/Ag [88] | 1–6 nm (Ag) | Coherent at T = 1–6 nm |

| Ag/V [74] | 2–8 nm | Incoherent at T = 2–8 nm |

| Ag/Ni [89] | 1–200 nm | Incoherent at T = 1–200 nm |

| Ag/Fe [79] | 1–200 nm | Coherent at T ≤ 5 nm |

| Fe/Ni [90] | 2–4.5 nm | Coherent at T = 2–4.5 nm |

| Fe/W [3] | 1–200 nm | Incoherent at T = 1–200 nm |

| Fe/Ti [91] | 8 nm | Incoherent at T = 8 nm |

| Mo/Zr [92] | 1–200 nm | Incoherent at T = 1–200 nm |

| Zr/Nb [93] | 6 and 27 nm | Incoherent at T = 27 nm and semi-coherent at T = 6 nm |

| Ti/Ta [94] | 2.5–80 nm | Coherent at T ≤ 7.5 nm |

| Ti/Zr [77] | 5–150 nm | Coherent at T = 5–50 nm and semi-coherent at T = 50–150 nm |

| Al/Ti [95] | 1–90 nm | Coherent at T ≤ 9 nm |

| Metallic Nanolayers | Irradiation Miscibility | Substrate | Radiation Source | First Layer | Base Pressure |

|---|---|---|---|---|---|

| Cu/Nb [2] | Immiscible | Sapphire (120) | He ion | Nb | |

| Cu/V [5] | Immiscible | Si (100) | He ion | 5.0 × 10−1 Pa | |

| Cu/Mo [103] | Immiscible | Si (100) | He ion | ||

| Cu/W [4] | Immiscible | SiO2 | He ion | Cu | 3.6 × 10−1 Pa |

| Cu/Fe [104] | Nearly Immiscible | Si (100) | Xe ion | Cu | 6.8 × 10−1 Pa |

| Cu/Ru [81] | Immiscible | Si (111) | Cu ion | Ru | 1.2 Pa |

| Cu/Ni [102] | Miscible | Needle-shaped Mo | Kr ion | Cu | 2.7 × 10−1 Pa |

| Cu/Co [76] | Immiscible | Si (100) | He ion | ||

| Cu/Ta [105] | Immiscible | Si (100) | He ion | Ta | 1.3–3.3 × 10−1 Pa |

| Cu/Zr [84] | Miscible | Si (100) | He ion | 1.3–3.3 × 10−1 Pa | |

| Co/Pd [106] | Miscible | SiO2 | Ga ion | Pd | 2.7 Pa |

| Co/W [107] | Nearly Immiscible | Si (100) | Au ion | 5.3 × 10−2 Pa | |

| Co/Pt [108] | Miscible | Float Glass | Si ion | Co | |

| Co/Ag [109] | Miscible | NaCl | Ar ion | Ag | |

| Ag/V [74] | Immiscible | Si (100) | He ion | V | 5.0 × 10−1 Pa |

| Ag/Ni [110] | Immiscible | Si (111) | Kr ion | 5.0 × 10−1 Pa | |

| Al/Nb [57] | Miscible | SiO2 | He ion | Al | |

| Al/Ti [111] | Miscible | Si (100) | Ar ion | 1.0 × 10−1 Pa | |

| Al/Ni [67] | Miscible | MgO (220) | Ni ion | Ni | 4.0 × 10−2 Pa |

| Fe/Ni [112] | Miscible | Si | Fe ion | ||

| Fe/W [3] | Miscible | SiO2 | He ion | ||

| Fe/Ti [113] | Miscible | Si (100) | Ar ion | 3.0 × 10−1 Pa | |

| Cr/W [114] | Miscible | Si | Xe ion | 3.0 × 10−1 Pa | |

| Mo/Zr [92] | Immiscible | Si (100) | Xe ion | 1.3–3.3 × 10−1 Pa | |

| Zr/Nb [93] | Immiscible | Si (110) | H ion | 2.5 × 10−1 Pa | |

| Ti/Ta [115] | Miscible | Si | Ar ion | Ti | 1.0 × 10−1 Pa |

| Ti/Zr [77] | Miscible | Si (100) | He ion | Zr | 5.3 × 10−1 Pa |

| Ti/Mg [116] | Immiscible | Si (100) | Cu ion | Ti | 1.3 × 10−1 Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, J.; Li, J.; Jian, J.; He, J.; Chen, H.; Leng, X.; Liu, X. Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors. Coatings 2021, 11, 1468. https://doi.org/10.3390/coatings11121468

Ni J, Li J, Jian J, He J, Chen H, Leng X, Liu X. Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors. Coatings. 2021; 11(12):1468. https://doi.org/10.3390/coatings11121468

Chicago/Turabian StyleNi, Jinyang, Jin Li, Jie Jian, Jianchao He, Hongsheng Chen, Xuesong Leng, and Xiangli Liu. 2021. "Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors" Coatings 11, no. 12: 1468. https://doi.org/10.3390/coatings11121468

APA StyleNi, J., Li, J., Jian, J., He, J., Chen, H., Leng, X., & Liu, X. (2021). Recent Studies on the Fabrication of Multilayer Films by Magnetron Sputtering and Their Irradiation Behaviors. Coatings, 11(12), 1468. https://doi.org/10.3390/coatings11121468