Microencapsulation for Functional Textile Coatings with Emphasis on Biodegradability—A Systematic Review

Abstract

1. Motivation and Research Questions

2. Publication Trends in Microencapsulation for Textiles

3. Microcapsules in Functional Textile Products

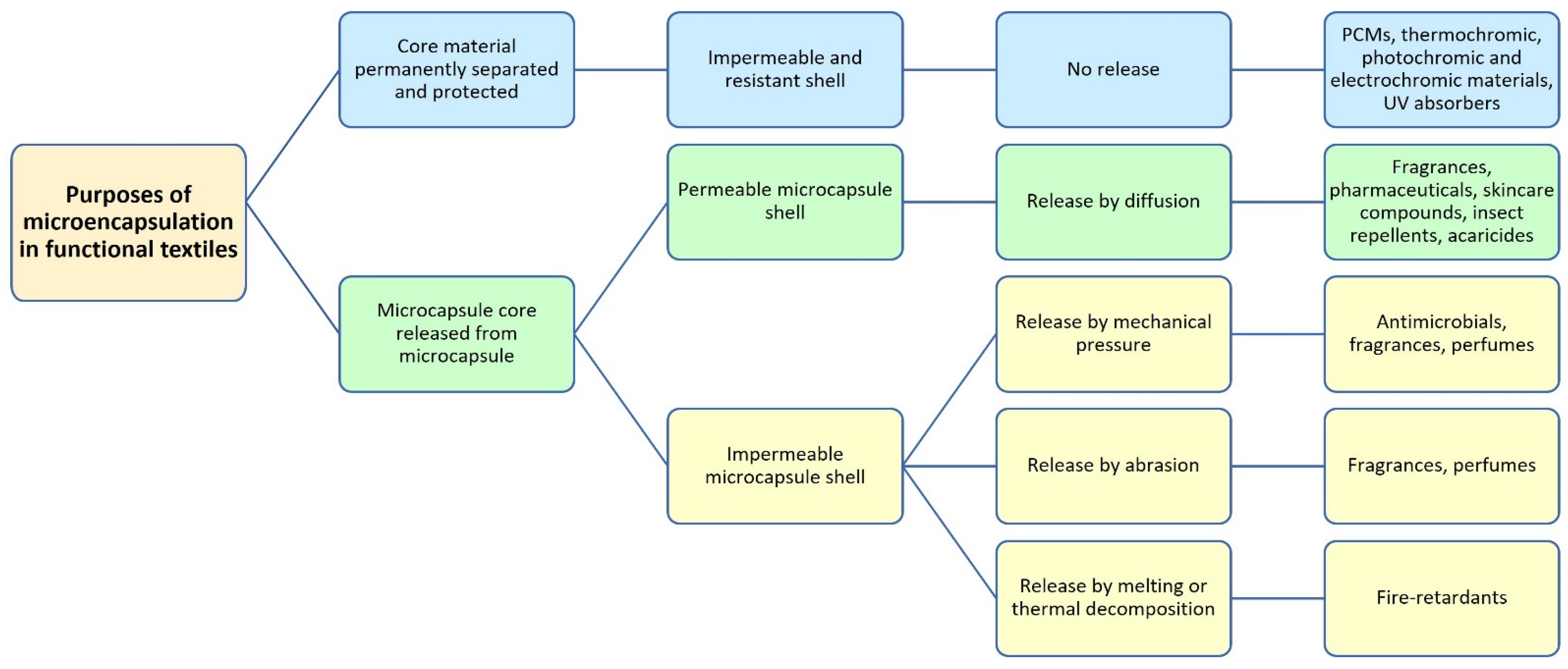

4. Purposes and Effects of Microencapsulation in Functional Textiles

- Permanent protection or separation of a core material for the life of the product. Such long-life microcapsules provide localized activity by permanently confining the liquid core within the mechanically resistant shell, as in PCMs for active thermal regulation or colour-changing textiles with electrochromic, photochromic and thermochromic materials.

- Targeted release of the core under planned conditions that trigger the opening of the shell. When temporary isolation and rapid, targeted release of active components from the core is envisaged, microcapsules with impermeable shells burst open by mechanical pressure, abrasion, melting or thermal decomposition. Until release, the active components in the microcapsule core remain separated from the reactive components (leuco dyes and colour developers), converted from a liquid to a solid state and protected against evaporation (essential oils) or protected against environmental influences and oxidation (essential oils, lipids and vitamins).

- Long-lasting, gradual release by diffusion through the permeable microcapsule shell. This principle is used in long-lasting perfumed textiles, in insect repellent fabrics and in sustained-release medical and cosmetic textiles.

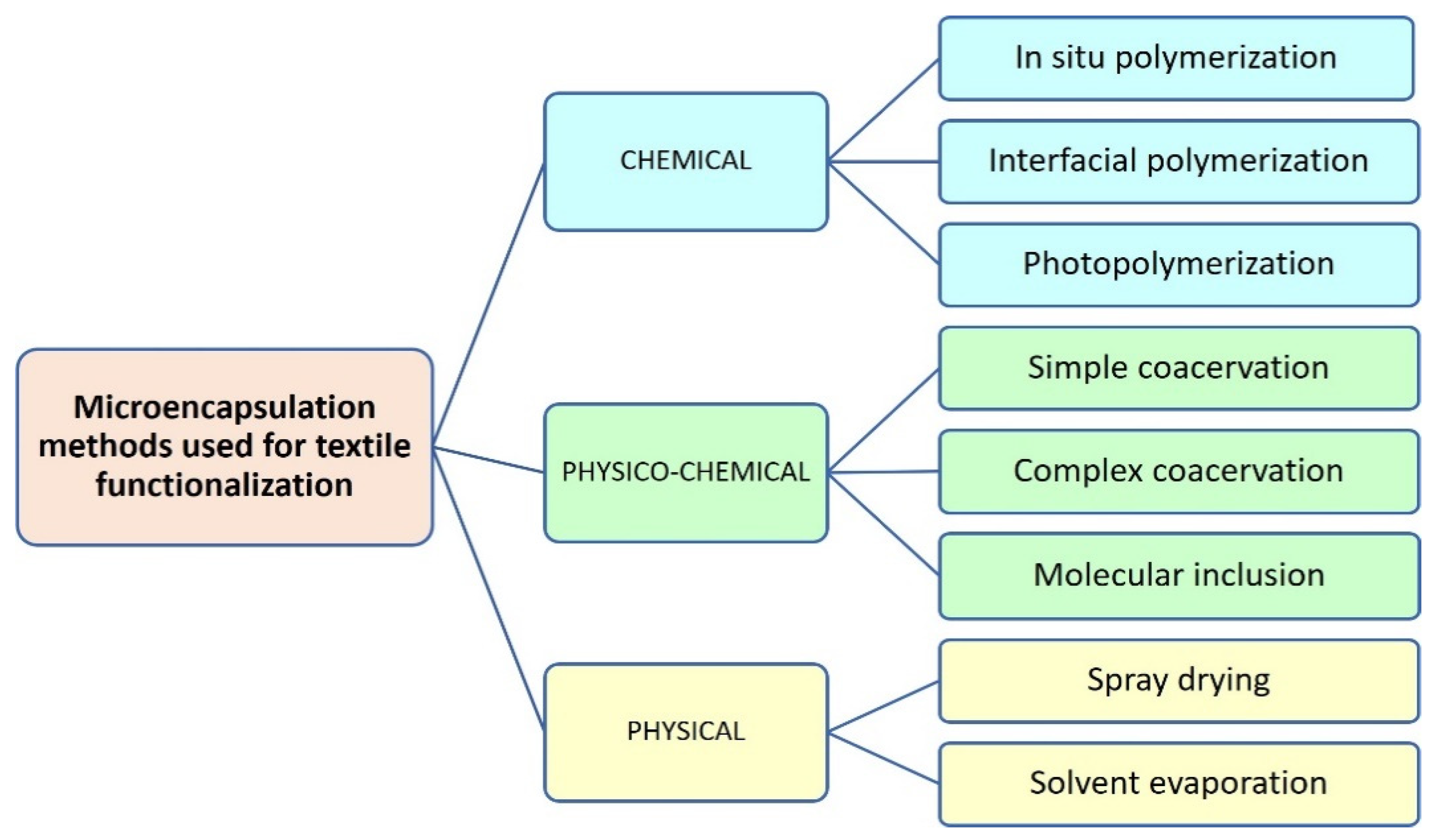

5. Microencapsulation Methods for Functional Textiles

5.1. Chemical Microencapsulation Methods for Functional Textiles

5.1.1. In Situ Polymerization Microencapsulation

5.1.2. Interfacial Polymerization Microencapsulation

5.2. Physico-Chemical Microencapsulation Methods for Functional Textiles

5.2.1. Coacervation

5.2.2. Molecular Inclusion with Cyclodextrins

5.3. Physical Microencapsulation Methods for Functional Textiles

6. Microcapsule Coating Formulations and Technologies

6.1. Formulation Composition

- Chitosan gel [144].

6.2. Durability of Coatings

6.3. Coating Techniques

- exhaustion [150];

7. Biodegradable Functional Textiles Containing Microcapsules

7.1. Biodegradability of Synthetic Materials

7.1.1. Melamine-Formaldehyde Resins

7.1.2. Polyurethane and Polyester-Polyurethane

7.1.3. Nylon/Polyamides

7.1.4. Polyesters

7.2. Biodegradable Polymers

7.3. Biodegradability Testing

- 21701:2019 Textiles—Test method for accelerated hydrolysis of textile materials and biodegradation under controlled composting conditions of the resulting hydrolysate,

- ISO 11721-1:2001 Textiles—Determination of resistance of cellulose-containing textiles to micro-organisms—Soil burial test—Part 1: Assessment of rot-retardant finishing,

- ISO 11721-2:2003 Textiles—Determination of the resistance of cellulose-containing textiles to micro-organisms—Soil burial test—Part 2: Identification of long-term resistance of a rot retardant finish,

- AATCC TM30: 2013 Antifungal activity, assessment on textile materials: Mildew and rot resistance of textile materials, Test 1 soil burial,

- ASTM D 5988-18 Standard test method for determining aerobic biodegradation of plastic materials in soil)

7.4. Biodegradable Microcapsules for Functional Textiles

7.5. Opportunities for Further Research

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fanger, G.O. Microencapsulation: A Brief History and Introduction. In Microencapsulation—Processes and Applications; Vandegaer, J.E., Ed.; Plenum Press: New York, NY, USA; London, UK, 1974; pp. 1–20. ISBN 978-1-4684-0739-6. [Google Scholar]

- Versic, R.J.; Barrett, K. Green the Father of Microencapsulation. Bioencapsul. Innov. 2013, 2–3. [Google Scholar]

- Urbas, R.; Milošević, R.; Kašiković, N.; Pavlović, Ž.; Stankovič Elesini, U. Microcapsules Application in Graphic Arts Industry: A review on the state-of-the-art. Iran. Polym. J. 2017, 26, 541–561. [Google Scholar] [CrossRef]

- Huang, K.; Yuan, Y.; Baojun, X. A Critical Review on the Microencapsulation of Bioactive Compounds and Their Application. Food Rev. Int. 2021, 1–41. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and Applications. Compr. Rev. Food Sci. Food Saf. 2016, 15, 143–182. [Google Scholar] [CrossRef] [PubMed]

- Podgornik Boh, B.; Starešinič, M. Microencapsulation Technology and Applications in Added–Value Functional Textiles. In Microencapsulation: Innovative Applications; Giamberini, M., Fernandez Prieto, S., Tylkowski, B., Eds.; De Gruyter: Berlin, Germany; München, Germany; Boston, MA, USA, 2015; pp. 37–76. ISBN 9783110331875. [Google Scholar] [CrossRef]

- Abdul Aziz, F.R.; Jai, J.; Raslan, R.; Subuki, I. Microencapsulation of Essential Oils Application in Textile: A Review. Adv. Mat. Res. 2015, 1113, 346–351. [Google Scholar] [CrossRef]

- Poncelet, D.; Boh, B. Microcapsules Deliver. Chem. Ind. 2008, 72, 23–25. [Google Scholar]

- Boh, B.; Sajovic, I.; Voda, K. Microcapsule Applications: Patent and Literature Analysis. In Microcapsule Patents and Products; The MML Series; Arshady, R., Boh, B., Eds.; CITUS: London, UK, 2003; Volume 6, pp. 85–156. ISBN 0953218767. [Google Scholar]

- Clarivate. Web of Science. Available online: https://www.webofknowledge.com (accessed on 18 August 2021).

- European Patent Office. Espacenet Patent Search. Available online: https://worldwide.espacenet.com/ (accessed on 18 August 2021).

- Rani, S.; Goel, A. Microencapsulation Technology in Textiles: A Review Study. Pharma Innov. J. 2021, SP–10, 660–663. Available online: https://www.thepharmajournal.com/archives/2021/vol10issue5S/PartJ/S-10-5-64-493.pdf (accessed on 18 August 2021).

- Nadi, A.; Boukhriss, A.; Bentis, A.; Jabrane, E.; Gmouh, S. Evolution in the Surface Modification of Textiles: A Review. Text. Prog. 2018, 50, 67–108. [Google Scholar] [CrossRef]

- Boh Podgornik, B.; Starešinič, M. Microencapsulation Technology and Applications in Added–Value Functional Textiles. Phys. Sci. Rev. 2016, 1, 20150003. [Google Scholar] [CrossRef]

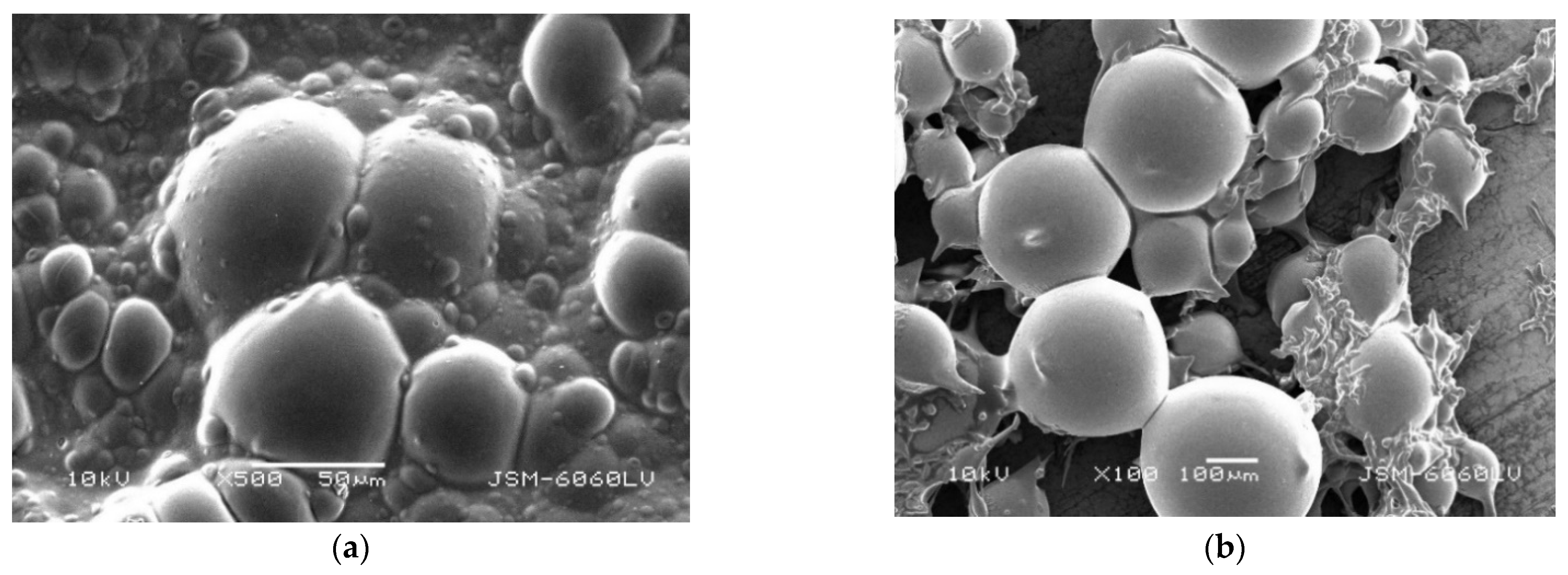

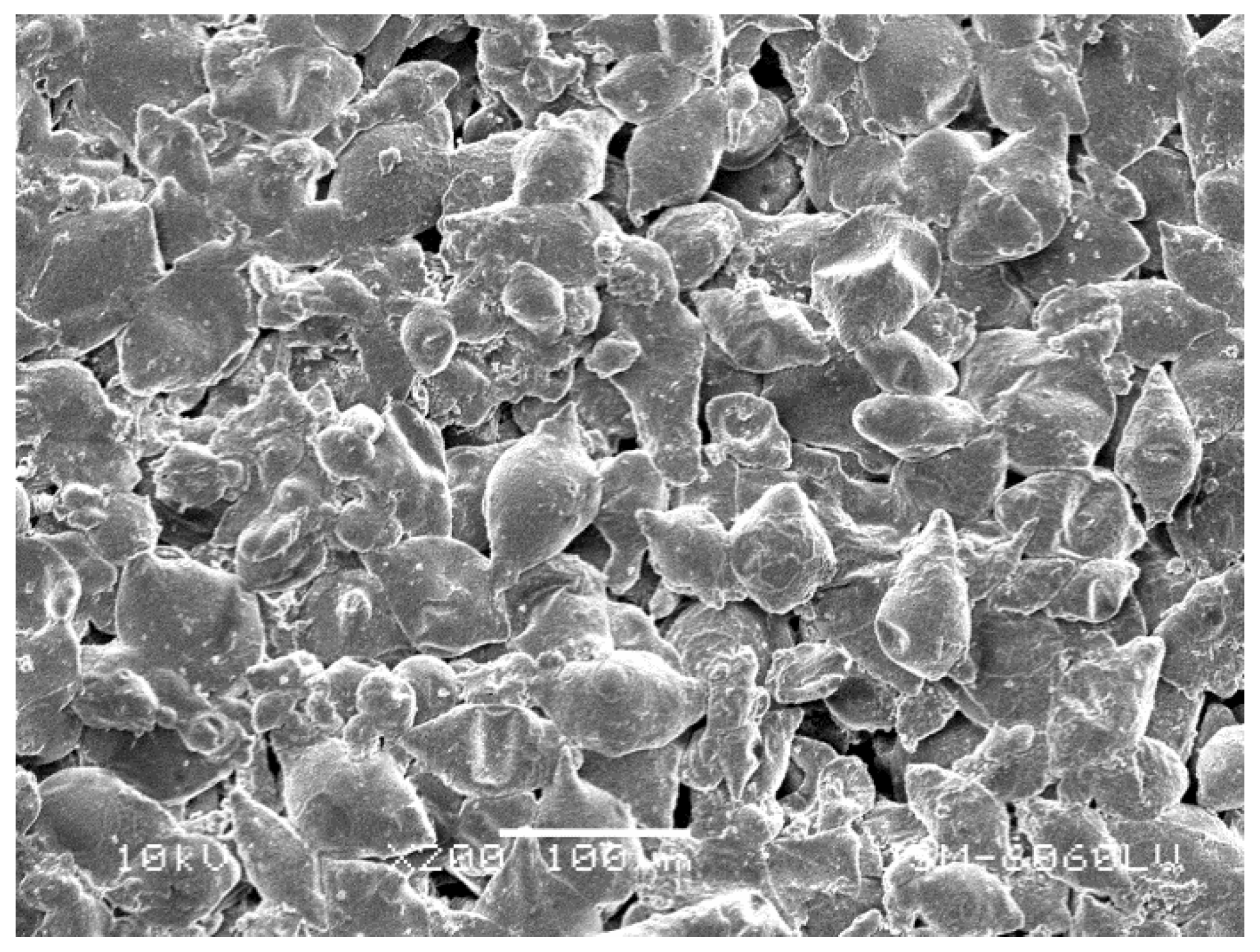

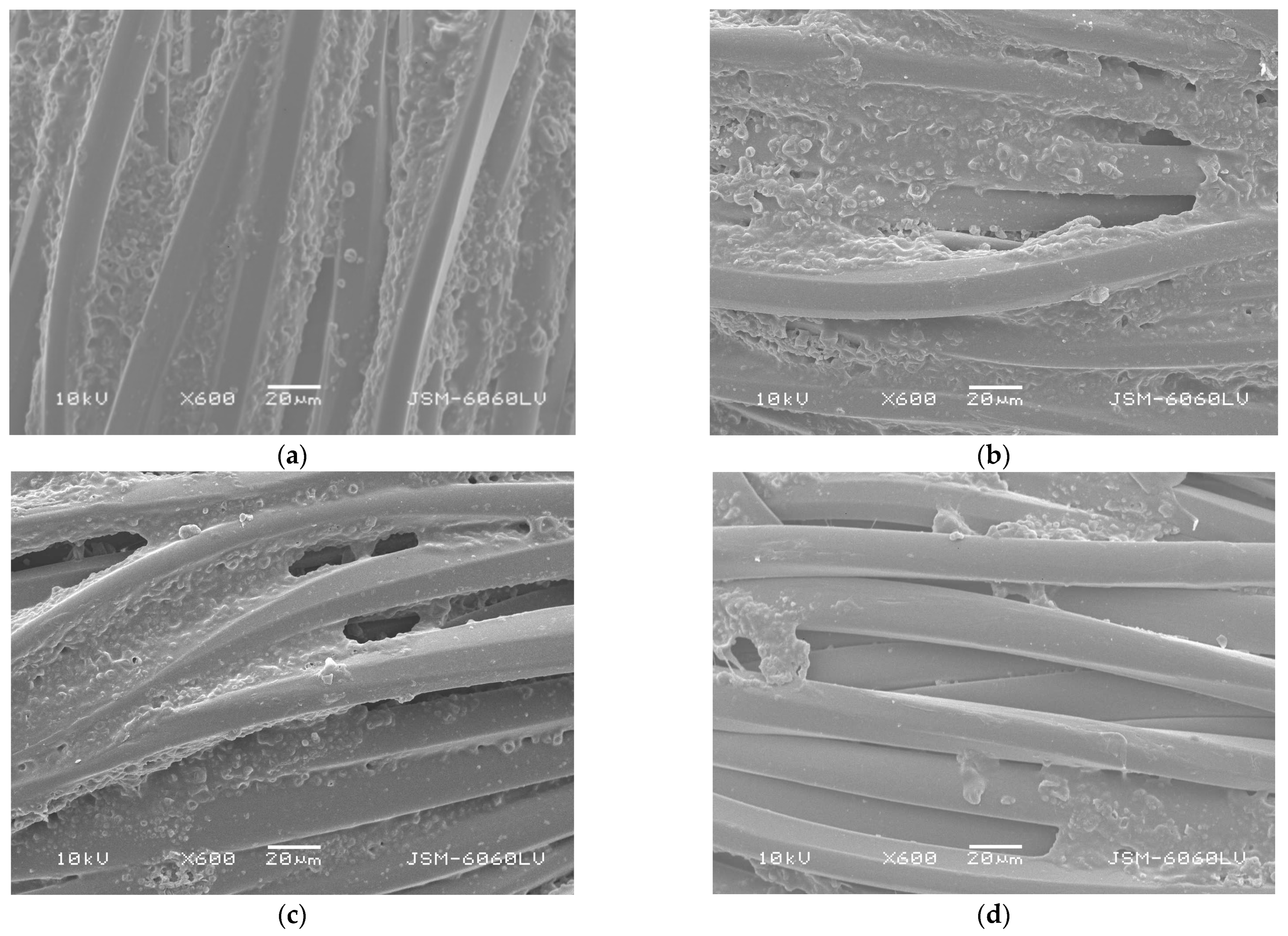

- Starešinič, M.; Šumiga, B.; Boh, B. Microencapsulation for Textile Applications and Use of SEM Image Analysis for Visualisation of Microcapsules. Tekstilec 2011, 54, 80–103. Available online: http://www.tekstilec.si/wp-content/uploads/2011/04/Microcapsulation-for-Textile-Application-and-Use-of-SEM-Image-Analysis-for-Visualisation-of-Microcapsules.pdf (accessed on 19 August 2021).

- Ocepek, B.; Forte–Tavčer, P. Microencapsulation in Textiles. Tekstilec 2008, 51, 216–230. Available online: http://www.tekstilec.si/wp-content/uploads/2008/09/Mikrokapsuliranje-na-podro%C4%8Dju-tekstilstva.pdf (accessed on 19 August 2021).

- Boh, B.; Knez, E.; Starešinič, M. Microcapsules in Textile Industry. In Microcapsule Patents and Products; The MML Series; Arshady, R., Boh, B., Eds.; CITUS: London, UK, 2003; Volume 6, pp. 235–269. ISBN 0953218767. [Google Scholar]

- Nelson, G. Application of Microencapsulation in Textiles. Int. J. Pharm. 2002, 242, 55–62. [Google Scholar] [CrossRef]

- Zhao, F.; Rao, B.; Xue, W.; Wang, F.; Li, C.; Lao, J.; Wang, L. The Development of Eco–Friendly Dye Microcapsules for Wool Fabric Dyeing Application. J. Polym. Environ. 2019, 27, 1202–1211. [Google Scholar] [CrossRef]

- Nelson, G. Microencapsulated Colourants for Technical Textile Application. In Advances in the Dyeing and Finishing of Technical Textiles; Woodhead Publishing: Oxford, UK; Cambridge, UK; Philadelphia, PA, USA; New Delhi, India, 2013; pp. 78–104. [Google Scholar] [CrossRef]

- She, F.Y.; Qi, D.M.; Chen, Z.J.; Shao, J.Z.; Yang, L. Preparation of Organic Pigment Microcapsules and its Application in Pigment Printing of Silk Fabric. Adv. Mater. Res. 2012, 441, 145–149. [Google Scholar] [CrossRef]

- Shi, M.; Lu, B.; Li, X.; Jin, Y.; Ge, M. Thermochromic Luminescent Fiber Based on Yellow Thermochromic Microcapsules: Preparation, Properties, and Potential Application Areas. Cellulose 2021, 28, 5005–5018. [Google Scholar] [CrossRef]

- Tözüm, M.S.; Alay Aksoy, S.; Alkan, C. Manufacturing Surface Active Shell and Bisphenol A Free Thermochromic Acrylic Microcapsules for Textile Applications. Int. J. Energy Res. 2021, 45, 7018–7037. [Google Scholar] [CrossRef]

- Tözüm, M.S.; Alkan, C.; Alay Aksoy, S. Preparation of Poly (Methyl Methacrylate-Co-Ethylene Glycol Dimethacrylate-Co-Glycidyl Methacrylate) Walled Thermochromic Microcapsules and Their Application to Cotton Fabrics. J. Appl. Polym. Sci. 2020, 137, 48815. [Google Scholar] [CrossRef]

- Wu, Z.; Ma, X.; Zheng, X.; Yang, W.; Meng, Q.; Zheng, Z. Synthesis and Characterization of Thermochromic Energy–Storage Microcapsule and Application to Fabric. J. Text. Inst. 2014, 105, 398–405. [Google Scholar] [CrossRef]

- Hozić, N.; Kert, M. Influence of Different Colourants on Properties of Cotton Fabric, Printed with Microcapsules of Photochromic Dye. Tekstilec 2019, 62, 208–218. [Google Scholar] [CrossRef]

- Fan, F.; Wu, Y. Photochromic Properties of Color-Matching, Double-Shelled Microcapsules Covalently Bonded onto Cotton Fabric and Applications to Outdoor Clothing. J. Appl. Polym. Sci. 2017, 134, 44698. [Google Scholar] [CrossRef]

- Kert, M.; Gorjanc, M. The Study of Colour Fastness of Commercial Microencapsulated Photoresponsive Dye Applied on Cotton, Cotton/Polyester and Polyester Fabric Using a Pad-Dry-Cure Process. Color. Technol. 2017, 133, 491–497. [Google Scholar] [CrossRef]

- Fan, F.; Zhang, W.; Wang, C. Covalent Bonding and Photochromic Properties of Double–Shell Polyurethane–Chitosan Microcapsules Crosslinked onto Cotton Fabric. Cellulose 2015, 22, 1427–1438. [Google Scholar] [CrossRef]

- Sheng, M.; Zhang, L.; Jiang, S.; Yang, L.; Zaaboul, F.; Fu, S. Bioinspired Electro–Responsive Multispectral Controllable Dye–Doped Liquid Crystal Yolk–Shell Microcapsules for Advanced Textiles. ACS Appl. Mater. Interfaces 2021, 13, 13586–13595. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Jiang, X.; Cui, P.; Sheng, M.; Gong, X.; Zhang, L.; Fu, S. Multicolor and Multistage Response Electrochromic Color–Memory Wearable Smart Textile and Flexible Display. ACS Appl. Mater. Interfaces 2021, 13, 12313–12321. [Google Scholar] [CrossRef] [PubMed]

- Sheng, M.; Zhang, L.; Wang, D.; Li, M.; Li, L.; West, J.L.; Fu, S. Fabrication of Dye–Doped Liquid Crystal Microcapsules for Electro–Stimulated Responsive Smart Textiles. Dye. Pigment. 2018, 158, 1–11. [Google Scholar] [CrossRef]

- Li, Y.; Wang, B.; Sui, X.; Xie, R.; Xu, H.; Zhang, L.; Zhong, Y.; Mao, Z. Durable Flame Retardant and Antibacterial Finishing on Cotton Fabrics with Cyclotriphosphazene/Polydopamine/Silver Nanoparticles Hybrid Coatings. Appl. Surf. Sci. 2018, 435, 1337–1343. [Google Scholar] [CrossRef]

- Golja, B.; Šumiga, B.; Boh, B.; Medved, J.; Pušič, T.; Forte Tavcer, P. Application of Flame Retardant Microcapsules to Polyester and Cotton Fabrics. Mater. Tehnol. 2014, 48, 105–111. Available online: http://mit.imt.si/izvodi/mit141/golja.pdf (accessed on 19 August 2021).

- Lin, M.; Yang, Y.; Xi, P.; Chen, S.L. Microencapsulation of Water-Soluble Flame Retardant Containing Organophosphorus and its Application on Fabric. J. Appl. Polym. Sci. 2006, 102, 4915–4920. [Google Scholar] [CrossRef]

- Giraud, S.; Bourbigot, S.; Rochery, M.; Vroman, I.; Tighzert, L.; Delobel, R.; Poutch, F. Flame Retarded Polyurea with Microencapsulated Ammonium Phosphate for Textile Coating. Polym. Degrad. Stab. 2005, 88, 106–113. [Google Scholar] [CrossRef]

- Li, J.; Zhu, X.; Wang, H.; Lin, P.; Jia, L.; Li, L.; Chen, Y. Synthesis and Properties of Multifunctional Microencapsulated Phase Change Material for Intelligent Textiles. J. Mater. Sci. 2021, 56, 2176–2191. [Google Scholar] [CrossRef]

- Larciprete, M.C.; Paoloni, S.; Cesarini, G.; Sibilia, C.; Rubežienė, V.; Sankauskaitė, A. Thermo–Regulating Properties of Textiles with Incorporated Microencapsulated Phase Change Materials. MRS Adv. 2020, 5, 1023–1028. [Google Scholar] [CrossRef]

- Skurkytė-Papievienė, V.; Abraitienė, A.; Sankauskaitė, A.; Rubežienė, V.; Dubinskaitė, K. Enhancement of Thermal Properties of Bio–Based Microcapsules Intended for Textile Applications. Open Chem. 2020, 18, 669–680. [Google Scholar] [CrossRef]

- Zhang, G.; Cai, C.; Wang, Y.; Liu, G.; Zhou, L.; Yao, J.; Zhu, G. Preparation and Evaluation of Thermo–Regulating Bamboo Fabric Treated by Microencapsulated Phase Change Materials. Text. Res. J. 2019, 89, 3387–3393. [Google Scholar] [CrossRef]

- Chen, X.; Wu, B.; Fan, Y.; Duan, X.; Yang, M. Temperature Adjusting Performance of Thermoregulated Woven Fabric Finished with Phase–Change Microcapsule in Low–Temperature Environment. J. Eng. Fibers Fabr. 2019, 14, 1–10. [Google Scholar] [CrossRef]

- Saraç, E.G.; Öner, E.; Kahraman, M.V. Microencapsulated Organic Coconut Oil as a Natural Phase Change Material for Thermo–Regulating Cellulosic Fabrics. Cellulose 2019, 26, 8939–8950. [Google Scholar] [CrossRef]

- Geng, X.; Li, W.; Wang, Y.; Lu, J.; Wang, J.; Wang, N.; Li, X.; Zhang, X. Reversible Thermochromic Microencapsulated Phase Change Materials for Thermal Energy Storage Application in Thermal Protective Clothing. Appl. Energy 2018, 217, 281–294. [Google Scholar] [CrossRef]

- Benmoussa, D.; Molnar, K.; Hannache, H.; Cherkaoui, O. Development of Thermo–Regulating Fabric Using Microcapsules of Phase Change Material. Mol. Cryst. Liq. Cryst. 2016, 627, 163–169. [Google Scholar] [CrossRef]

- Keyan, K.; Ramachandran, T.; Shamugasundaram, O.L.; Balasubramaniam, M.; Ragavendra, T. Microencapsulation of PCMs in Textiles: A Review. J. Text. Appar. Technol. Manag. 2012, 7, 1–10. Available online: https://ojs.cnr.ncsu.edu/index.php/JTATM/article/viewFile/2414/1412 (accessed on 20 August 2021).

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Thermoregulating Response of Cotton Fabric Containing Microencapsulated Phase Change Materials. Thermochim. Acta 2010, 506, 82–93. [Google Scholar] [CrossRef]

- Hu, L.; Li, X.; Ding, L.; Chen, L.; Zhu, X.; Mao, Z.; Feng, X.; Sui, X.; Wang, B. Flexible Textiles with Polypyrrole Deposited Phase Change Microcapsules for Efficient Photothermal Energy Conversion and Storage. Sol. Energy Mater. Sol. Cells 2021, 224, 110985. [Google Scholar] [CrossRef]

- Geng, X.; Gao, Y.; Wang, N.; Han, N.; Zhang, X.; Li, W. Intelligent Adjustment of Light–to–Thermal Energy Conversion Efficiency of Thermo–Regulated Fabric Containing Reversible Thermochromic MicroPCMs. Chem. Eng. J. 2021, 408, 127276. [Google Scholar] [CrossRef]

- Tong, W.; Tong, A. Solar–Absorbing Metamaterial Microencapsulation of Phase Change Materials for Thermo–Regulating Textiles. Int. J. Smart Nano Mater. 2015, 6, 105–112. [Google Scholar] [CrossRef]

- Pargai, D.; Jahan, S. Application of Vitis vinifera Microcapsules on Cotton Fabric: A Potential to Prevent UV–Induced Skin Problems. J. Nat. Fibers 2020, 17, 412–426. [Google Scholar] [CrossRef]

- Geethadevi, R.; Maheshwari, V. Long–lasting UV Protection and Mosquito Repellent Finish on Bamboo/Tencel Blended Fabric with Microencapsulated Essential Oil. Indian J. Fibre Text. Res. 2015, 40, 175–179. Available online: http://op.niscair.res.in/index.php/IJFTR/article/view/4631/309 (accessed on 23 August 2021).

- Hong, S.A.; Kim, I.Y.; Kim, H.R.; Song, W.S. Manufacture of UV Absorbers and UV Protection Fabrics Using Microcapsules. Fibers Polym. 2011, 12, 491–498. [Google Scholar] [CrossRef]

- Atiénzar-Navarro, R.; Bonet-Aracil, M.A.R.I.L.É.S.; Gisbert-Payá, J.; del Rey, R.; Picó, R. Sound Absorption of Textile Fabrics Doped with Microcapsules. Appl. Acoust. 2020, 164, 107285. [Google Scholar] [CrossRef]

- Wang, W.; Liang, Y.; Yang, Z.; Zhang, W.; Wang, S. Construction of Ultraviolet Protection, Thermal Insulation, Superhydrophobic and Aromatic Textile with Al–Doped ZnO–Embedded Lemon Microcapsule Coatings. Text. Res. J. 2019, 89, 3860–3870. [Google Scholar] [CrossRef]

- He, Z.; Bao, B.; Fan, J.; Wang, W.; Yu, D. Photochromic Cotton Fabric Based on Microcapsule Technology with Anti–Fouling Properties. Colloids Surf. A Physicochem. Eng. Asp. 2020, 594, 124661. [Google Scholar] [CrossRef]

- Khattab, T.A.; Fouda, M.M.; Abdelrahman, M.S.; Othman, S.I.; Bin–Jumah, M.; Alqaraawi, M.A.; Al Fassam, H.; Allam, A.A. Co–Encapsulation of Enzyme and Tricyanofuran Hydrazone into Alginate Microcapsules Incorporated onto Cotton Fabric as a Biosensor for Colorimetric Recognition of Urea. React. Funct. Polym. 2019, 142, 199–206. [Google Scholar] [CrossRef]

- Hassan, M.M.; Sunderland, M. Antimicrobial and Insect–Resist Wool Fabrics by Coating with Microencapsulated Antimicrobial and Insect–Resist Agents. Prog. Org. Coat. 2015, 85, 221–229. [Google Scholar] [CrossRef]

- Kim, J.R. Eucalyptus Oil–Loaded Microcapsules Grafted to Cotton Fabrics for Acaricidal Effect against Dermatophagoides farinae. J. Microencapsul. 2017, 34, 262–269. [Google Scholar] [CrossRef] [PubMed]

- Eyupoglu, S.; Kut, D.; Girisgin, A.O.; Eyupoglu, C.; Ozuicli, M.; Dayioglu, H.; Civan, M.; Aydin, L. Investigation of the Bee–Repellent Properties of Cotton Fabrics Treated with Microencapsulated Essential Oils. Tex. Res. J. 2019, 89, 1417–1435. [Google Scholar] [CrossRef]

- Miro Specos, M.M.; García, J.J.; Tornesello, J.; Marino, P.; Vecchia, M.D.; Tesoriero, M.D.; Hermida, L.G. Microencapsulated Citronella Oil for Mosquito Repellent Finishing of Cotton Textiles. Trans. R. Soc. Trop. Med. Hyg. 2010, 104, 653–658. [Google Scholar] [CrossRef] [PubMed]

- Miro Specos, M.M.; Garcia, J.J.; Gutierrez, A.C.; Hermida, L.G. Application of Microencapsulated Biopesticides to Improve Repellent Finishing of Cotton Fabrics. J. Text. Inst. 2017, 108, 1454–1460. [Google Scholar] [CrossRef]

- Yao, T.T.; Wang, L.K.; Cheng, J.L.; Hu, Y.Z.; Zhao, J.H.; Zhu, G.N. Optimization of Pyrethroid and Repellent on Fabrics against Stegomyia albopicta (= Aedes albopictus) Using a Microencapsulation Technique. Med. Vet. Entomol. 2015, 29, 37–43. [Google Scholar] [CrossRef]

- Mertgenç, C.; Enginar, H.; Yılmaz, H. Microencapsulation of Fragrance with Polyurethane—Urea and Application on Different Fabrics. Iran. J. Sci. Technol. Trans. A Sci. 2021, 45, 1–11. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, W.; Chen, Y.; Zhang, S.; Wang, W. The Aromatic Properties of Polyurea–Encapsulated Lavender Oil Microcapsule and their Application in Cotton Fabrics. J. Nanosci. Nanotechnol. 2019, 19, 4147–4153. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.; Martins, I.M.; Barreiro, M.F.; Dias, M.M.; Rodrigues, A.E. Functionalized Textiles with PUU/Limonene Microcapsules: Effect of Finishing Methods on Fragrance Release. J. Text. Inst. 2017, 108, 361–367. [Google Scholar] [CrossRef]

- Zhao, D.; Jiao, X.; Zhang, M.; Ye, K.; Shi, X.; Lu, X.; Shea, K.J. Preparation of High Encapsulation Efficiency Fragrance Microcapsules and Their Application in Textiles. RSC Adv. 2016, 6, 80924–80933. [Google Scholar] [CrossRef]

- He, Y.; Bowen, J.; Andrews, J.W.; Liu, M.; Smets, J.; Zhang, Z. Adhesion of Perfume–Filled Microcapsules to Model Fabric Surfaces. J. Microencapsul. 2014, 31, 430–439. [Google Scholar] [CrossRef]

- Mercadé-Prieto, R.; Pan, X.; Fernández-González, A.; Zhang, Z.; Bakalis, S. Quantification of Microcapsules Deposited in Cotton Fabrics Before and After Abrasion Using Fluorescence Microscopy. Ind. Eng. Chem. Res. 2012, 51, 16741–16749. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M. Micro/Nanoencapsulation of Essential Oils and Fragrances: Focus on Perfumed, Antimicrobial, Mosquito–Repellent and Medical Textiles. J. Microencapsul. 2016, 33, 497–510. [Google Scholar] [CrossRef]

- Bouaziz, A.; Dridi, D.; Gargoubi, S.; Zouari, A.; Majdoub, H.; Boudokhane, C.; Bartegi, A. Study on the Grafting of Chitosan–Essential Oil Microcapsules onto Cellulosic Fibers to Obtain Bio Functional Material. Coatings 2021, 11, 637. [Google Scholar] [CrossRef]

- Julaeha, E.; Puspita, S.; Eddy, D.R.; Wahyudi, T.; Nurzaman, M.; Nugraha, J.; Herlina, T.; Al Anshori, J. Microencapsulation of Lime (Citrus aurantifolia) Oil for Antibacterial Finishing of Cotton Fabric. RSC Adv. 2021, 11, 1743–1749. [Google Scholar] [CrossRef]

- Beşen, B.S. Tea Tree Oil/Ethyl Cellulose Microcapsule Loaded Antimicrobial Textiles. AATCC J. Res. 2020, 7, 1–6. [Google Scholar] [CrossRef]

- Sharkawy, A.; Fernandes, I.P.; Barreiro, M.F.; Rodrigues, A.E.; Shoeib, T. Aroma–Loaded Microcapsules with Antibacterial Activity for Eco–Friendly Textile Application: Synthesis, Characterization, Release, and Green Grafting. Ind. Eng. Chem. Res. 2017, 56, 5516–5526. [Google Scholar] [CrossRef]

- Panisello, C.; Peña, B.; Gilabert Oriol, G.; Constantí, M.; Gumí, T.; Garcia–Valls, R. Polysulfone/Vanillin Microcapsules for Antibacterial and Aromatic Finishing of Fabrics. Ind. Eng. Chem. Res. 2013, 52, 9995–10003. [Google Scholar] [CrossRef]

- Ocepek, B.; Boh, B.; Šumiga, B.; Forte Tavčer, P. Printing of Antimicrobial Microcapsules on Textiles. Color. Technol. 2012, 128, 95–102. [Google Scholar] [CrossRef]

- Jo, Y.K.; Heo, S.J.; Peredo, A.P.; Mauck, R.L.; Dodge, G.R.; Lee, D. Stretch–Responsive Adhesive Microcapsules for Strain–Regulated Antibiotic Release from Fabric Wound Dressings. Biomater. Sci. 2021, 9, 5136–5143. [Google Scholar] [CrossRef]

- Mendes, S.; Catarino, A.; Zille, A.; Fernandes, N.; Bezerra, F.M. Vehiculation of Methyl Salicylate from Microcapsules Supported on Textile Matrix. Materials 2021, 14, 1087. [Google Scholar] [CrossRef]

- Volmajer Valh, J.; Peršin, Z.; Vončina, B.; Vrezner, K.; Tušek, L.; Fras Zemljič, L. Microencapsulation of Cannabidiol in Liposomes as Coating for Cellulose for Potential Advanced Sanitary Material. Coatings 2021, 11, 3. [Google Scholar] [CrossRef]

- Beşen, B.S.; Balcı, O.; Güneşoğlu, C.; Orhan, M.; Somuncuoğlu, E.İ.; Tatlı, İ.İ. Obtaining Medical Textiles Including Microcapsules of the Ozonated Vegetable Oils. Fibers Polym. 2017, 18, 1079–1090. [Google Scholar] [CrossRef]

- Wijesirigunawardana, P.B.; Perera, B.G.K. Development of a Cotton Smart Textile with Medicinal Properties Using Lime Oil Microcapsules. Acta Chim. Slov. 2018, 65, 150–159. [Google Scholar] [CrossRef]

- Massella, D.; Giraud, S.; Guan, J.; Ferri, A.; Salaün, F. Textiles for Health: A Review of Textile Fabrics Treated with Chitosan Microcapsules. Environ. Chem. Lett. 2019, 17, 1787–1800. [Google Scholar] [CrossRef]

- Ripoll, L.; Bordes, C.; Etheve, S.; Elaissari, A.; Fessi, H. Cosmeto–Textile from Formulation to Characterization: An Overview. e-Polymers 2010, 10, 040. [Google Scholar] [CrossRef]

- Stan, M.S.; Chirila, L.; Popescu, A.; Radulescu, D.M.; Radulescu, D.E.; Dinischiotu, A. Essential oil microcapsules immobilized on textiles and certain induced effects. Materials 2019, 12, 2029. [Google Scholar] [CrossRef]

- Azizi, N.; Chevalier, Y.; Majdoub, M. Isosorbide–Based Microcapsules for Cosmeto–Textiles. Ind. Crops Prod. 2014, 52, 150–157. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Yuen, M.C.W.; Kan, C.W.; Cheuk, K.K.L.; Chui, C.H.; Lam, K.H. Cosmetic Textiles with Biological Benefits: Gelatin Microcapsules Containing Vitamin C. Int. J. Mol. Med. 2009, 24, 411–419. [Google Scholar] [CrossRef]

- Xu, C.; Hu, J.; Chen, Y.; Yang, Q.; Zhang, Y.; Wang, C.; Chen, K. Rapid Synthesis of Strawberry Microcapsules via Pickering Emulsion Photopolymerization for use in Multifunctional Fabric Coatings. Prog. Org. Coat. 2021, 152, 106110. [Google Scholar] [CrossRef]

- Singh, N.; Sheikh, J. Multifunctional Linen Fabric Obtained through Finishing with Chitosan–Gelatin Microcapsules Loaded with Cinnamon Oil. J. Nat. Fibers 2021, 1–11. [Google Scholar] [CrossRef]

- Chen, K.; Zhou, J.; Hu, J.; Zhang, J.; Heng, T.; Xu, C.; Yu, K. Preparation of pH–Responsive Dual–Compartmental Microcapsules via Pickering Emulsion and Their Application in Multifunctional Textiles. ACS Appl. Mater. Interfaces 2020, 13, 1234–1244. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Xu, C.; Zhou, J.; Zhao, R.; Gao, Q.; Wang, C. Multifunctional Fabric Coatings with Slow–Releasing Fragrance and UV Resistant Properties from Ethyl Cellulose/Silica Hybrid Microcapsules. Carbohydr. Polym. 2020, 232, 115821. [Google Scholar] [CrossRef]

- Valle, J.A.B.; Valle, R.D.C.S.C.; Bierhalz, A.C.K.; Bezerra, F.M.; Hernandez, A.L.; Lis Arias, M.J. Chitosan Microcapsules: Methods of The Production and Use in the Textile Finishing. J. Appl. Polym. Sci. 2021, 138, 50482. [Google Scholar] [CrossRef]

- Bah, M.G.; Bilal, H.M.; Wang, J. Fabrication and Application of Complex Microcapsules: A Review. Soft Matter 2020, 16, 570–590. [Google Scholar] [CrossRef]

- Ozkan, G.; Franco, P.; De Marco, I.; Xiao, J.; Capanoglu, E. A Review of Microencapsulation Methods for food Antioxidants: Principles, Advantages, Drawbacks and Applications. Food Chem. 2019, 272, 494–506. [Google Scholar] [CrossRef] [PubMed]

- Suganya, V.; Anuradha, V. Microencapsulation and Nanoencapsulation: A Review. Int. J. Pharm. Clin. Res 2017, 9, 233–239. [Google Scholar] [CrossRef]

- Kaushik, P.; Dowling, K.; Barrow, C.J.; Adhikari, B. Microencapsulation of Omega–3 Fatty Acids: A Review of Microencapsulation and Characterization Methods. J. Funct. Foods 2015, 19, 868–881. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A Review of Microencapsulation Methods of Phase Change Materials (PCMs) as a Thermal Energy Storage (TES) Medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Golja, B.; Tavčer, P.F. Textile Functionalisation by Printing Fragrant, Antimicrobial and Flame–Retardant Microcapsules. Tekstilec 2016, 59, 278–288. [Google Scholar] [CrossRef]

- Erkan, G.; Sariişik, M.; Pazarlioğlu, N.K. The Microencapsulation of Terbinafine via In Situ Polymerization of Melamine-Formaldehyde and Their Application to Cotton Fabric. J. Appl. Polym. Sci. 2010, 118, 3707–3714. [Google Scholar] [CrossRef]

- Palanikkumaran, M.; Gupta, K.K.; Agrawal, A.K.; Jassal, M. Highly Stable Hexamethylolmelamine Microcapsules Containing N-Octadecane Prepared by In Situ Encapsulation. J. Appl. Polym. Sci. 2009, 114, 2997–3002. [Google Scholar] [CrossRef]

- Stanković Elesini, U.; Leskovšek, M.; Bernik, S.; Šumiga, B.; Urbas, R. Influence of Co–Current Spray Drying Conditions on Agglomeration of Melamine–Formaldehyde Microcapsules. Dry. Technol. 2016, 34, 1510–1520. [Google Scholar] [CrossRef]

- Zhao, H.; Fei, X.; Cao, L.; Zhang, B.; Liu, X. Relation Between the Particle Size and Release Characteristics of Aromatic Melamine Microcapsules in Functional Textile Applications. RSC Adv. 2019, 9, 25225–25231. [Google Scholar] [CrossRef]

- Stanković Elesini, U.; Švarc, J.; Šumiga, B.; Urbas, R. Melamine Formaldehyde Microcapsules with Fragrance Core Material: Preparation, Properties, and End Use. Text. Res. J. 2017, 87, 2435–2448. [Google Scholar] [CrossRef]

- Golja, B.; Šumiga, B.; Forte Tavčer, P. Fragrant Finishing of Cotton with Microcapsules: Comparison between Printing and Impregnation. Color. Technol. 2013, 129, 338–346. [Google Scholar] [CrossRef]

- Skurkyte–Papieviene, V.; Abraitiene, A.; Sankauskaite, A.; Rubeziene, V.; Baltusnikaite–Guzaitiene, J. Enhancement of the Thermal Performance of the Paraffin–Based Microcapsules Intended for Textile Applications. Polymers 2021, 13, 1120. [Google Scholar] [CrossRef]

- Topbas, O.; Sariisik, A.M.; Erkan, G.; Ek, O. Photochromic Microcapsules by Coacervation and In Situ Polymerization Methods for Product–Marking Applications. Iran. Polym. J. 2020, 29, 117–132. [Google Scholar] [CrossRef]

- Wang, S.; Ding, H.; Zhao, Y.; Li, Y.; Wang, W. Fabrication of Protective Textile with N–doped TiO2 Embedded Citral Microcapsule Coating and Its Air Purification Properties. Fibers Polym. 2020, 21, 334–342. [Google Scholar] [CrossRef]

- Rodrigues, S.N.; Fernandes, I.; Martins, I.M.; Mata, V.G.; Barreiro, F.; Rodrigues, A.E. Microencapsulation of Limonene for Textile Application. Ind. Eng. Chem. Res. 2008, 47, 4142–4147. [Google Scholar] [CrossRef]

- Azizi, N.; Abdelkader, M.B.; Chevalier, Y.; Majdoub, M. New β–Cyclodextrin–Based Microcapsules for Textiles Uses. Fibers Polym. 2019, 20, 683–689. [Google Scholar] [CrossRef]

- Boh, B.; Šumiga, B. In Situ Polymerisation Microcapsules. Available online: https://bioencapsulation.net/group/300_literature/320_newsletters/Bioencap_innov_2013_03.pdf (accessed on 24 August 2021).

- Šumiga, B.; Knez, E.; Vrtačnik, M.; Ferk Savec, V.; Starešinic, M.; Boh, B. Production of Melamine–Formaldehyde PCM Microcapsules with Ammonia Scavenger Used for Residual Formaldehyde Reduction. Acta Chim. Slov. 2011, 58, 14–25. [Google Scholar]

- Alič, B.; Šebenik, U.; Krajnc, M. Differential Scanning Calorimetric Examination of Melamine–Formaldehyde Microcapsules Containing Decane. J. Appl. Polym. Sci. 2011, 119, 3687–3695. [Google Scholar] [CrossRef]

- Yuan, H.; Li, G.; Yang, L.; Yan, X.; Yang, D. Development of Melamine–Formaldehyde Resin Microcapsules with Low Formaldehyde Emission Suited for Seed Treatment. Colloids Surf. B Biointerfaces 2015, 128, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Paiva, N.T.; Henriques, A.; Cruz, P.; Ferra, J.M.; Carvalho, L.H.; Magalhães, F.D. Production of Melamine Fortified Urea-Formaldehyde Resins with Low Formaldehyde Emission. J. Appl. Polym. Sci. 2012, 124, 2311–2317. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.X.; Wang, X.C.; Niu, J.J. Preparation and Characterization of Microencapsulated Phase Change Material with Low Remnant Formaldehyde Content. Mater. Chem. Phys. 2007, 106, 437–442. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Wang, X.; Wu, S.; Zhang, X. Effects of Ammonium Chloride and Heat Treatment on Residual Formaldehyde Contents of Melamine–Formaldehyde Microcapsules. Colloid Polym. Sci. 2007, 285, 1691–1697. [Google Scholar] [CrossRef]

- Perignon, C.; Ongmayeb, G.; Neufeld, R.; Frere, Y.; Poncelet, D. Microencapsulation by Interfacial Polymerisation: Membrane Formation and Structure. J. Microencapsul. 2015, 32, 1–15. [Google Scholar] [CrossRef]

- Fiedler, J.O.; Carmona, Ó.G.; Carmona, C.G.; Lis, M.J.; Plath, A.M.S.; Samulewski, R.B.; Bezerra, F.M. Application of Aloe vera Microcapsules in Cotton Nonwovens to Obtain Biofunctional Textiles. J. Text. Inst. 2019, 111, 68–74. [Google Scholar] [CrossRef]

- Sharma, R.; Goel, A. Development of Insect Repellent Finish by a Simple Coacervation Microencapsulation Technique. Int. J. Cloth. Sci. Technol. 2018, 30, 152–158. [Google Scholar] [CrossRef]

- Turan, N.Y.; Turker, E.; Insaatci, Ö. Microparticles Loaded with Propolis to Make Antibacterial Cotton. Cellulose 2021, 28, 4469–4483. [Google Scholar] [CrossRef]

- Demirbağ, S.; Aksoy, S.A. Encapsulation of Phase Change Materials by Complex Coacervation to Improve Thermal Performances and Flame Retardant Properties of the Cotton Fabrics. Fibers Polym. 2016, 17, 408–417. [Google Scholar] [CrossRef]

- Deveci, S.S.; Basal, G. Preparation of PCM Microcapsules by Complex Coacervation of Silk Fibroin and Chitosan. Colloid Polym. Sci. 2009, 287, 1455–1467. [Google Scholar] [CrossRef]

- Xiao, Z.; Xu, W.; Ma, J.; Zhao, Y.; Niu, Y.; Kou, X.; Ke, Q. Double–Encapsulated Microcapsules for the Adsorption to Cotton Fabrics. Coatings 2021, 11, 426. [Google Scholar] [CrossRef]

- Lis, M.J.; García Carmona, Ó.; García Carmona, C.; Maestá Bezerra, F. Inclusion Complexes of Citronella Oil with β–Cyclodextrin for Controlled Release in Biofunctional Textiles. Polymers 2018, 10, 1324. [Google Scholar] [CrossRef] [PubMed]

- Mihailiasa, M.; Caldera, F.; Li, J.; Peila, R.; Ferri, A.; Trotta, F. Preparation of Functionalized Cotton Fabrics by Means of Melatonin Loaded β–Cyclodextrin Nanosponges. Carbohydr. Polym. 2016, 142, 24–30. [Google Scholar] [CrossRef]

- Timilsena, Y.P.; Akanbi, T.O.; Khalid, N.; Adhikari, B.; Barrow, C.J. Complex Coacervation: Principles, Mechanisms and Applications in Microencapsulation. Int. J. Biol. Macromol. 2019, 121, 1276–1286. [Google Scholar] [CrossRef]

- Challa, R.; Ahuja, A.; Ali, J.; Khar, R.K. Cyclodextrins in Drug Delivery: An Updated Review. AAPS PharmSciTech 2005, 6, E329–E357. [Google Scholar] [CrossRef] [PubMed]

- Wadhwa, G.; Kumar, S.; Chhabra, L.; Mahant, S.; Rao, R. Essential Oil–Cyclodextrin Complexes: An Updated Review. J. Incl. Phenom. Macrocycl. Chem. 2017, 89, 39–58. [Google Scholar] [CrossRef]

- Marcillo–Parra, V.; Tupuna–Yerovi, D.S.; González, Z.; Ruales, J. Encapsulation of Bioactive Compounds from Fruit and Vegetable By–Products for Food Application—A Review. Trends Food Sci. Technol. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Geranpour, M.; Assadpour, E.; Jafari, S.M. Recent Advances in the Spray Drying Encapsulation of Essential Fatty Acids and Functional Oils. Trends Food Sci. Technol. 2020, 102, 71–90. [Google Scholar] [CrossRef]

- Carvalho, I.T.; Estevinho, B.N.; Santos, L. Application of Microencapsulated Essential Oils in Cosmetic and Personal Healthcare Products—A Review. Int. J. Cosmet. Sci. 2016, 38, 109–119. [Google Scholar] [CrossRef] [PubMed]

- Yingngam, B.; Kacha, W.; Rungseevijitprapa, W.; Sudta, P.; Prasitpuriprecha, C.; Brantner, A. Response Surface Optimization of Spray–Dried Citronella Oil Microcapsules with Reduced Volatility and Irritation for Cosmetic Textile Uses. Powder Technol. 2019, 355, 372–385. [Google Scholar] [CrossRef]

- Yang, Z.; Zeng, Z.; Xiao, Z.; Ji, H. Preparation and Controllable Release of Chitosan/Vanillin Microcapsules and their Application to Cotton Fabric. Flavour Fragr. J. 2014, 29, 114–120. [Google Scholar] [CrossRef]

- Brlek, I.; Ludaš, A.; Sutlović, A. Synthesis and Spectrophotometric Analysis of Microcapsules Containing Immortelle Essential Oil. Molecules 2021, 26, 2390. [Google Scholar] [CrossRef] [PubMed]

- Erkan, G.; Sarıışık, M. Antifungal Microcapsules of Ethyl Cellulose by Solvent Evaporation and their Application to Cotton Fabric. Fibres Text. East. Eur. 2015, 23, 125–130. [Google Scholar] [CrossRef][Green Version]

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Application of Contact Angle Measurement to the Manufacture of Textiles Containing Microcapsules. Text. Res. J. 2009, 79, 1202–1212. [Google Scholar] [CrossRef]

- López, A.; Lis, M.J.; Maesta Bezerra, F.; Vilaseca, M.; Vallés, B.; Prieto, R.; Simó, M. Production and Evaluation of Antimicrobial Microcapsules with Essential Oils Using Complex Coacervation. J. Biomed. Sci. Eng. 2019, 12, 377–390. [Google Scholar] [CrossRef]

- Singh, N.; Sheikh, J. Sustainable Development of Mosquito-Repellent, Flame-Retardant, Antibacterial, Fragrant and Antioxidant Linen Using Microcapsules Containing Thymus Vulgaris Oil in In-Situ Generated Chitosan-Phosphate. Cellulose 2021, 28, 2599–2614. [Google Scholar] [CrossRef]

- Bhatt, L.; Singh, S.S.J. Comparative Analysis of Lemongrass Oil Application on Textile Substate Through Microencapsulation and Exhaust Method. Int. J. Adv. Res. Sci. Eng. 2018, 7, 313–320. [Google Scholar]

- Hui, P.C.; Wang, W.; Kan, C.; Ng, F.S.; Wat, E.; Zhang, V.X.; Chan, C.; Lau, C.B.; Leung, P. Microencapsulation of Traditional Chinese Herbs—Pentaherbs Extracts and Potential Application in Healthcare Textiles. Colloid Surface B Biointerfaces 2013, 111, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Abdelkader, M.B.; Azizi, N.; Baffoun, A.; Chevalier, Y.; Majdoub, M. New Microcapsules Based on Isosorbide for Cosmetotextile: Preparation And Characterization. Ind. Crops Prod. 2018, 123, 591–599. [Google Scholar] [CrossRef]

- Salaün, F. Microencapsulation as An Effective Tool for the Design of Functional Textiles. In Advances in Textile Engineering; Trans Tech Publications Ltd.: Bäch, Switzerland, 2019. [Google Scholar]

- Abdelkader, M.B.; Azizi, N.; Baffoun, A.; Chevalier, Y.; Majdoub, M. Fragrant Microcapsules Based on β-Cyclodextrin For Cosmetotextile Application. J. Renew. Mater. 2019, 7, 1347–1362. [Google Scholar] [CrossRef]

- Arias, M.J.L.; López, A.; Vilaseca, M.; Vallès, B.; Prieto, R.; Simó, M.; Valle, J.A.B.; Valle, R.D.C.S.C.; Bezerra, F.M.; Bellalta, J.P. Influence of Chitosan Characteristics in the Microencapsulation of Essential Oils. J. Biomed. Sci. Eng. 2021, 14, 119–129. [Google Scholar] [CrossRef]

- Bezerra, F.M.; Lis, M.; García Carmona, O.; García Carmona, C.; Moisés, M.P.; Zanin, G.M.; Moraes, F.F. Assessment of the Delivery of Citronella Oil from Microcapsules Supported on Wool Fabrics. Powder Technol. 2019, 343, 775–782. [Google Scholar] [CrossRef]

- Ferrándiz, M.; Capablanca, L.; García, D.; Bonet, M.A. Application of Antimicrobial Microcapsules on Agrotextiles. J. Agric. Chem. Environ. 2017, 6, 62–82. [Google Scholar] [CrossRef]

- Khodary, M.M.M.; El-Rafie, H.M.; Abdel Salam, H.M.; El-Rafie, M.H. Imparting Eco-Friendly Antibacterial and Anti-Inflammatory Finishing by Microencapsulation Technique for Cotton Fabric. Int. Des. J. 2017, 7, 131–140. [Google Scholar] [CrossRef]

- Soo, P.M. Method for Producing Coated Fabric Having Antibacterial Activity Removing Bad Smell and Giving Off Forest Fragrance and the Coated Fabric Produced by the Method. Korean Patent KR20020059050A, 12 July 2002. [Google Scholar]

- Soo, P.M. Producing Method of Coated Fabric Changing Its Color According to Temperature Variation and Having Excellent Washing Resistance and the Coated Fabric Produced by the Method. Korean Patent KR20020059049A, 12 July 2002. [Google Scholar]

- Zhao, H.; Fei, X.; Cao, L.; Zhang, B.; Liu, X. The Fabrication of Fragrance Microcapsules and Their Sustained and Broken Release Behavior. Materials 2019, 12, 393. [Google Scholar] [CrossRef] [PubMed]

- Kert, M.; Krkoč, V.; Gorjanc, M. Influence of Optical Brightening Agent Concentration on Properties of Cotton Fabric Coated with Photochromic Microcapsules Using A Pad-Dry-Cure Process. Polymers 2019, 11, 1919. [Google Scholar] [CrossRef] [PubMed]

- Sannapapamma, K.J.; Malligawad Lokanath, H.; Naikwadi, S. Antimicrobial and Aroma Finishing of Organic Cotton Knits Using Vetiver Oil Microcapsules for Health Care Textiles. Inter. J. Mater. Text. Eng. 2018, 12, 82–91. [Google Scholar] [CrossRef]

- Yuqing, C.; Kuanjun, F.; Yawei, S. Colored Polymer Microsphere Ink for Inkjet. Printing. Patent CN105504990A, 20 April 2016. [Google Scholar]

- Lam, P.L.; Li, L.; Yuen, C.W.M.; Gambari, R.; Wong, R.S.M.; Chui, C.H.; Lam, K.H. Effects of Multiple Washing on Cotton Fabrics Containing Berberine Microcapsules with Anti-Staphylococcus Aureus Activity. J. Microencapsul. 2013, 30, 143–150. [Google Scholar] [CrossRef] [PubMed]

- Fei, B.; Xin, J.H. N, N-diethyl-m-toluamide–Containing Microcapsules for Bio-Cloth Finishing. Am. J. Trop. Med. Hyg. 2007, 77, 52–57. [Google Scholar] [CrossRef]

- Stankovič Elesini, U.; Knez, E.; Leskovšek, M. Vgrajevanje Mikrokapsul v Tekstilna Vlakna. Tekstilec 2004, 47, 175–184. [Google Scholar]

- Leskovšek, M.; Jedrinović, G.; Stankovič Elesini, U. Properties of Polypropylene Fibres with Incorporated Microcapsules. Acta Chim. Slov. 2004, 51, 699–715. [Google Scholar]

- Gao, X.Y.; Han, N.; Zhang, X.X.; Yu, W.Y. Melt-Processable Acrylonitrile–Methyl Acrylate Copolymers and Melt-Spun Fibers Containing MicroPCMs. J. Mater. Sci. 2009, 44, 5877–5884. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wang, X.C.; Tao, X.M.; Yick, K.L. Energy Storage Polymer/MicroPCMs Blended Chips and Thermo-Regulated Fibers. J. Mater. Sci. 2005, 40, 3729–3734. [Google Scholar] [CrossRef]

- Zhang, X.X.; Wang, X.C.; Tao, X.M.; Yick, K.L. Structures and Properties of Wet Spun Thermo-Regulated Polyacrylonitrile-Vinylidene Chloride Fibers. Text. Res. J. 2006, 76, 351–359. [Google Scholar] [CrossRef]

- Kim, J.; Cho, G. Thermal Storage/Release, Durability, and Temperature Sensing Properties of Thermostatic Fabrics Treated with Octadecane-Containing Microcapsules. Text. Res. J. 2002, 72, 1093–1098. [Google Scholar] [CrossRef]

- Koo, K.; Choe, J.; Park, Y. The Application of PCMMcs and SiC by Commercially Direct Dual-Complex Coating on Textile Polymer. Appl. Surf. Sci. 2009, 255, 8313–8318. [Google Scholar] [CrossRef]

- Koo, K.; Park, Y.; Choe, J.; Kim, E. The Application of Microencapsulated Phase-Change Materials to Nylon Fabric Using Direct Dual Coating Method. J. Appl. Polym. Sci. 2008, 108, 2337–2344. [Google Scholar] [CrossRef]

- Sanchez, P.; Sanchez-Fernandez, M.V.; Romero, A.; Rodriguez, J.F.; Sanchez-Silva, L. Development of Thermo-Regulating Textiles Using Paraffin Wax Microcapsules. Thermochim. Acta 2010, 498, 16–21. [Google Scholar] [CrossRef]

- Sánchez-Silva, L.; Rodríguez, J.F.; Romero, A.; Sánchez, P. Preparation of Coated Thermo-Regulating Textiles Using Rubitherm-RT31 Microcapsules. J. Appl. Polym. Sci. 2012, 124, 4809–4818. [Google Scholar] [CrossRef]

- Pak, A.R.; Park, J.H.; Lee, S.G. Blowing Properties and Functionality of Thermoplastic Polyester Film Using Thermally Expandable Microcapsules. Polymers 2019, 11, 1652. [Google Scholar] [CrossRef] [PubMed]

- Otake, Y.; Kobayashi, T.; Asabe, H.; Murakami, N.; Ono, K. Biodegradation of Low-Density Polyethylene, Polystyrene, Polyvinyl Chloride, and Urea Formaldehyde Resin Buried Under Soil for Over 32 Years. J. Appl. Polym. Sci. 1995, 56, 1789–1796. [Google Scholar] [CrossRef]

- Danso, D.; Chow, J.; Streit, W.R. Plastics: Environmental and Biotechnological Perspectives on Microbial Degradation. Appl. Environ. Microbiol. 2019, 85, e01095-19. [Google Scholar] [CrossRef] [PubMed]

- El-Sayed, W.S.; El-Baz, A.F.; Othman, A.M. Biodegradation of Melamine Formaldehyde by Micrococcus sp. Strain MF-1 Isolated from Aminoplastic Wastewater Effluent. Int. Biodeterior. Biodegrad. 2006, 57, 75–81. [Google Scholar] [CrossRef]

- Nakajima-Kambe, T.; Shigeno-Akutsu, Y.; Nomura, N.; Onuma, F.; Nakahara, T. Microbial Degradation of Polyurethane, Polyester Polyurethanes and Polyether Polyurethanes. Appl. Microbiol. Biotechnol. 1999, 51, 134–140. [Google Scholar] [CrossRef]

- Ibrahim, I.N.; Maraqa, A.; Hameed, K.M.; Saadoun, I.M.; Maswadeh, H.M. Assessment of Potential Plastic-Degrading Fungi in Jordanian Habitats. Turk. J. Biol. 2011, 35, 551–557. [Google Scholar] [CrossRef]

- Khan, S.; Nadir, S.; Shah, Z.U.; Shah, A.A.; Karunarathna, S.C.; Xu, J.; Khan, A.; Munir, S.; Hasan, F. Biodegradation of Polyester Polyurethane by Aspergillus Tubingensis. Environ. Pollut. 2017, 225, 469–480. [Google Scholar] [CrossRef]

- Khan, S.; Nadir, S.; Dong, Y.; Schaefer, D.A.; Mortimer, P.E.; Gui, H.; Khan, A.; Yu, M.; Iqbal, S.; Sheng, J.; et al. Biodegradation of Polyester Polyurethane by Aspergillus Flavus G10. bioRxiv 2020. [Google Scholar] [CrossRef]

- Brunner, I.; Fischer, M.; Rüthi, J.; Stierli, B.; Frey, B. Ability of Fungi Isolated from Plastic Debris Floating in the Shoreline of A Lake to Degrade Plastics. PLoS ONE 2018, 13, e0202047. [Google Scholar] [CrossRef]

- Russell, J.R.; Huang, J.; Anand, P.; Kucera, K.; Sandoval, A.G.; Dantzler, K.W.; Hickman, D.; Jee, J.; Kimovec, F.M.; Koppstein, D.; et al. Biodegradation of Polyester Polyurethane by Endophytic Fungi. Appl. Environ. Microbiol. 2011, 77, 6076–6084. [Google Scholar] [CrossRef]

- Deguchi, T.; Kakezawa, M.; Nishida, T. Nylon Biodegradation by Lignin-Degrading Fungi. Appl. Environ. Microbiol. 1997, 63, 329–331. [Google Scholar] [CrossRef] [PubMed]

- Negoro, S. Biodegradation of Nylon Oligomers. Appl. Microbiol. Biotechnol. 2000, 54, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Sudhakar, M.; Priyadarshini, C.; Doble, M.; Murthy, P.S.; Venkatesan, R. Marine Bacteria Mediated Degradation of Nylon 66 and 6. Int. Biodeterior. Biodegr. 2007, 60, 144–151. [Google Scholar] [CrossRef]

- Kim, D.Y.; Rhee, Y.H. Biodegradation of Microbial and Synthetic Polyesters by Fungi. Appl. Microbiol. Biotechnol. 2003, 61, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Müller, R.J.; Kleeberg, I.; Deckwer, W.D. Biodegradation of Polyesters Containing Aromatic Constituents. J. Biotechnol. 2001, 86, 87–95. [Google Scholar] [CrossRef]

- Liu, J.; Willfor, S.; Xu, C. A Review of Bioactive Plant Polysaccharides: Biological Activities, Functionalization, and Biomedical Applications. Bioact. Carbohydr. Diet. Fibre 2015, 5, 31–41. [Google Scholar] [CrossRef]

- Park, C.H.; Kang, Y.K.; Im, S.S.I. Biodegradability of Cellulose Fabrics. J. Appl. Polym. Sci. 2004, 94, 248–253. [Google Scholar] [CrossRef]

- Yin, G.Z.; Yang, X.M. Biodegradable Polymers: A Cure for the Planet, But A Long Way to Go. J. Polym. Res. 2020, 27, 38. [Google Scholar] [CrossRef]

- Amin, M.; Abadi, G.; Katas, H. Purification, Characterization and Comparative Studies of Spray-Dried Bacterial Cellulose Microparticles. Carbohydr. Polym. 2014, 99, 181–185. [Google Scholar] [CrossRef]

- Gupta, B.S. Manufacture, Types and Properties of Biotextiles for Medical Applications. In Biotextiles as Medical Implants; Elsevier: Oxford, UK; Cambridge, UK; Philadelphia, PA, USA; New Delhi, India, 2013; pp. 3–47. [Google Scholar] [CrossRef]

- Smith, S.; Ozturk, M.; Frey, M. Soil Biodegradation of Cotton Fabrics Treated with Common Finish. Cellulose 2021, 28, 4485–4494. [Google Scholar] [CrossRef]

- Malis, D.; Jeršek, B.; Tomšič, B.; Štular, D.; Golja, B.; Kapun, G.; Simončič, B. Antibacterial Activity and Biodegradation of Cellulose Fiber Blends with Incorporated ZnO. Materials 2019, 12, 3399. [Google Scholar] [CrossRef]

- Sülar, V.; Devrim, G. Biodegradation Behaviour of Different Textile Fibres: Visual, Morphological, Structural Properties and Soil Analyses. Fibres Text. East. Eur. 2019, 27, 100–111. [Google Scholar] [CrossRef]

- Milošević, M.; Krkobabić, A.; Radoiči, M.; Šaponjić, Z.; Radetić, T.; Radetić, M. Biodegradation of Cotton and Cotton/Polyester Fabrics Impregnated with Ag/TiO2 Nanoparticles in Soil. Carbohydr. Polym. 2017, 158, 77–84. [Google Scholar] [CrossRef]

- Arshad, K.; Skrifvars, M.; Vivod, V.; Valh, J.; Voncina, B. Biodegradation of Natural Textile Materials in Soil. Tekstilec 2014, 57, 118–132. [Google Scholar] [CrossRef]

- Klemenčič, D.; Simončič, B.; Tomšič, B.; Orel, B. Biodegradation of Silver Functionalised Cellulose Fibres. Carbohydr. Polym. 2010, 80, 426–435. [Google Scholar] [CrossRef]

- Tomšič, B.; Simončič, B.; Orel, B.; Vilčnik, A.; Spreizer, H. Biodegradability of Cellulose Fabric Modified by Imidazolidinone. Carbohydr. Polym. 2007, 69, 478–488. [Google Scholar] [CrossRef]

- Salerno-Kochan, R.; Szostak-Kotowa, J. Biodegradation of Cellulose Textiles. Fibres Text. East. Eur. 2001, 9, 69–72. [Google Scholar]

- Dridi, D.; Bouaziz, A.; Gargoubi, S.; Zouari, A.; B’chir, F.; Bartegi, A.; Majdoub, H.; Boudokhane, C. Enhanced Antibacterial Efficiency of Cellulosic Fibers: Microencapsulation and Green Grafting Strategies. Coatings 2021, 11, 980. [Google Scholar] [CrossRef]

- Gaytán, I.; Burelo, M.; Loza-Tavera, H. Current Status on the Biodegradability of Acrylic Polymers: Microorganisms, Enzymes and Metabolic Pathways Involved. Appl. Microbiol. Biotechnol. 2021, 105, 991–1006. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; WU, B.; Fu, X.; Wang, R.; Lei, J. Preparation of Biodegradable Microcapsules Through and Organic Solvent-Free Interfacial Polymerization Method. Polym. Adv. Technol. 2019, 30, 483–488. [Google Scholar] [CrossRef]

- de Carvalho Arjona, J.; das Graças Silva-Valenzuela, M.; Wang, S.H.; Valenzuela-Diaz, F.R. Biodegradable Nanocomposite Microcapsules for Controlled Release of Urea. Polymers 2021, 13, 722. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Fei, J.; Cui, Y.; Yang, Y.; Gao, L.; Li, J. pH-Responsive Polysaccharide Microcapsules Through Covalent Bonding Assembly. Chem. Commun. 2011, 47, 1175–1177. [Google Scholar] [CrossRef]

- Maesta Bezerra, F.; Carmona, O.C.; Carmona, C.G.; Lis, M.J.; de Moraes, F.F. Controlled Release of Microencapsulated Citronella Essential Oil on Cotton and Polyester Matrices. Cellulose 2016, 23, 1459–1470. [Google Scholar] [CrossRef]

- Ryu, S.J.; Bae, H.S. Properties Analysis of Crosslinked Chitosan Microcapsules by Multiple Emulsification Method. Fash. Text. 2021, 8, 9. [Google Scholar] [CrossRef]

- Liu, X.; Lou, Y. Preparation of Microencapsulated Phase Change Materials by the Sol-Gel Process and Its Application on Textiles. Fibres Text. East. Eur. 2015, 23, 63–67. [Google Scholar]

- Microcapsule Market. Available online: https://www.marketsandmarkets.com/Market-Reports/microcapsule-market-24415649.html?gclid=EAIaIQobChMI4dvb-4ra8wIVXUaRBR0srQuhEAAYASAAEgLwsfD_BwE (accessed on 21 October 2021).

- Meticulous Market Research. Available online: https://www.globenewswire.com/news-release/2021/06/24/2252620/0/en/Microencapsulation-Market-Worth-17-31-billion-by-2027-Growing-at-a-CAGR-of-11-7-from-2020-Exclusive-Report-by-Meticulous-Research.html (accessed on 21 October 2021).

- Deng, H.; Wei, R.; Luo, W.; Hu, L.; Li, B.; Shi, H. Microplastic Pollution in Water and Sediment in a Textile Industrial Area. Environ. Pollut. 2020, 258, 113658. [Google Scholar] [CrossRef]

- Acharya, S.; Rumi, S.S.; Hu, Y.; Abidi, N. Microfibers from Synthetic Textiles as A Major Source of Microplastics in the Environment: A review. Text. Res. J. 2021, 91, 2136–2156. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Acierno, D. Eco-Sustainability of the Textile Production: Waste Recoveryand Current Recycling in The Composites World. Polymers 2021, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Bhardwaj, R.; Jassal, S.; Goyal, T.; Khullar, A.; Gupta, N. Application of Enzymes for An Eco-Friendly Approach To Textile Processing. Environ. Sci. Pollut. Res. 2021, 1–11. [Google Scholar] [CrossRef]

- Hashem, M.; El-Bisi, M.; Sharaf, S.; Refaie, R. Pre-Cationization of Cotton Fabrics: An Effective Alternative Tool for Activation of Hydrogen Peroxide Bleaching Process. Carbohyd. Polym. 2010, 79, 533–540. [Google Scholar] [CrossRef]

- Kert, M.; Forte Tavčer, P.; Hladnik, A.; Spasić, K.; Puač, N.; Petrović, Z.L.; Gorjanc, M. Application of Fragrance Microcapsules onto Cotton Fabric after Treatment with Oxygen and Nitrogen Plasma. Coatings 2021, 11, 1181. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Khan, A.M.; Ahmad, M.; Sarfraz, M. Effectiveness of Silica Based Sol-Gel Microencapsulation Method for Odorants and Flavors Leading to Sustainable Environment. Front. Chem. 2015, 3, 42. [Google Scholar] [CrossRef] [PubMed]

| Shell Materials | Core Materials | Functional Textiles | Ref. No. |

|---|---|---|---|

| In situ Polymerization Method | |||

| Melamine-formaldehyde polymer. | Sage, rosemary and lavender essential oils in isopropyl myristate. Antimicrobial triclosan. Fire retardant triphenyl phosphate. | Cotton woven fabrics with fragrant, antimicrobial, or flame-retardant functionalisation. | [96] |

| – | Antifungal pharmaceutical agent terbinafine. | Antifungal cotton fabrics. | [97] |

| from prepolymer, with Sodium lauryl sulphate emulsifier. | PCM n-octadecane. | Cellulose-polyester fabrics with improved thermoregulation. | [98] |

| from partially methylated trimethylolmelamine prepolymer, with styrene maleic anhydride copolymer modifier. | Thermochromic PCM composition: crystal violet lactone dye, bisphenol A developer, tetradecanol solvent. | Thermal protective clothing. | [43] |

| – | Paraffinic PCM Rubitherm®RT27. | Microcapsules incorporated in melt spinning of polypropylene textile fibres. | [99] |

| – | Rose essential oil. | Fragranced textiles. | [100] |

| with polyacrylic polymer modifier. | Male and female fragrance oils. | Fragranced textiles–scented bow-ties. | [101] |

| – | Lavender, rosemary and sage essential oils. | Fragrant cotton textiles. | [102] |

| with sodium salt of styrene maleic anhydride copolymer and sodium polyacrylate modifiers. | Thermochromic PCM mixture. | Non-woven functional thermochromic textiles with improved thermal regulation. | [48] |

| modified with multiwall carbon nanotubes and poly (3,4-ethylenedioxyoxy-thiophene) poly (styrene sulphonate). | PCM paraffin with MP 30–32°C. | 3D warp-knitted spacer fabrics from polyethylene terephthalate (PET) and elastane, with improved thermal properties. | [103] |

| Melamine-urea-formaldehyde polymer from prepolymer. Tween 20 emulsifier. | Photochromic dyes in ethyl acetate. | Cotton fabrics with reversible photochromic response. | [104] |

| Interfacial Polymerization Method | |||

| Polyurea from hexamethylene diisocyanate and guanidine carbonate. N-TiO2 particles loaded on the shell surface. | Citral fragrance. | Fragranced and photocatalytic bifunctional cotton textiles for air purification and personal protection. | [105] |

| Polyurethane–urea polymer from isocyanate/PEG-400/polyamine. | Methyl cedryl ketone fragrance. | Fragranced cotton, Polyester and silk textiles. | [63] |

| from hexamethylene diisocyanate, polyethylene glycol, thylenediamine, hydrazine. | Limonene oil. | Wool-polyester perfumed Textiles. | [106] |

| Bio-polyurethane composed of β-cyclodextrin and 4,4′-methylenebis(phenyl isocyanate). | Neroline perfume. | Perfumed polyamide knitted textiles. | [107] |

| Photopolymerization method | |||

| Hexanediol diacrylate/modified TiO2. Perfluorooctyltriethoxysilane and UV absorber Tinuvin grafted on TiO2 nanoparticles. | Osmanthus fragrance oil. | Multifunctional cotton textiles with fragranced, superhydrophobic and UV protective properties. | [86] |

| Shell Materials | Core Materials | Functional Textile | Ref. No. |

|---|---|---|---|

| Simple Coacervation | |||

| Chitosan. | Cinnamon essential oil. | Antimicrobial woven cotton fabrics. | [70] |

| Ethyl cellulose. | Photochromic dyes in ethyl acetate. | Cotton fabrics with reversible photochromic response. | [104] |

| Corn starch, formaldehyde cross-linked. | Aloe vera oil. | Cotton nonwoven bandages for treatment of burned skin. | [116] |

| Gum acacia, formaldehyde cross-linked. | Eucalyptus oil and cedarwood oil as insect repellent. | Insect repelling woven fabrics. | [117] |

| Complex Coacervation | |||

| Gelatin and gum Arabic, glutaraldehyde cross-linked. | Citronella essential oil. | Mosquito repellent cotton fabrics. | [60] |

| – | Methyl salicylate pharmaceutical. | Cotton and polyamide Jersey knitted pharmaceutical textiles. | [77] |

| – | Propolis emulsion in rice oil. | Antimicrobial cotton textiles. | [118] |

| Chitosan-gum Arabic, tannic acid cross-linked. | Limonene and vanillin. | Antibacterial cotton textiles. | [73] |

| Gelatine and sodium alginate, glutaraldehyde cross-linked. Hydrophilic bentonite nano-particles doped on shell. | n-eicosane PCM. | Cotton textiles with improved thermal stability and flame-retardant properties. | [119] |

| Silk fibroin andchitosan. | n-eicosane PCM. | Thermoregulated textiles. | [120] |

| Molecular Inclusion | |||

| Epichlorohydrin modified β-cyclodextrin. | Indigo dye and lavender essential oil. | Bifunctional coloured and fragranced cotton textiles. | [121] |

| β-cyclodextrin. | Citronella oil. | Woven cotton and spun polyester textiles with insect repellent activity. | [122] |

| Hyper cross-linked β-cyclodextrins. | Melatonin sleep hormone. | Knitted cotton biofunctional fabrics. | [123] |

| Shell Materials | Core Materials | Functional Textile | Ref. No. |

|---|---|---|---|

| Spray Drying | |||

| Acacia gum. | Citronella oil. | Nonwoven cosmetic textiles. | [130] |

| Chitosan. | Vanillin. | Fragranced cotton fabric. | [131] |

| Emulsification and Solvent Evaporation | |||

| Soy lecithin and cholesterol. | Reactive dye vinylsulfone azonaphthalene. | Wool textile dyeing. | [19] |

| Poly-lactic acid. | Phase change material capric acid. Thermal conductivity enhancer carbon nanotubes. | 3D polyester knitted fabric with enhanced thermal properties. | [39] |

| Ethyl cellulose. | Immortelle essential oil. | Cosmetic and medical textiles. | [132] |

| – | Antifungal pharmaceuticals terbinafine and ketoconazole. | Antifungal cotton fabrics. | [133] |

| Shell Materials | Core Materials | Coating Composition Additives | Application Method | Functional Textile | Ref. No. |

|---|---|---|---|---|---|

| Simple Coacervation | |||||

| Chitosan. | Cinnamon essential oil. | Dimethylol dihydroxy ethylene urea. | Pad-pre-dry-cure. | Antimicrobial cotton woven fabric. | [70] |

| Cinnamon and clove essential oil. | Citric acid, monosodium phosphate. | Immersion-dry-cure. | Antimicrobial cotton fabric. | [192] | |

| Mypro gum or sodium alginate. | Extract of Pelargonium hortorum. | Citric acid or commercial binder | Pad-dry-cure. | Antimicrobial and anti-inflammatory cotton woven fabric. | [145] |

| Complex Coacervation | |||||

| Chitosan, gum Arabic. | Vanillin or limonene essential oil. | Citric acid and sodium phosphate monobasic monohydrate. | Immersion-dry-cure. | Antimicrobial cotton fabric. | [73] |

| Lavender essential oil. | Citric acid and sodium phosphate monobasic monohydrate. | Pad-dry. | Antimicrobial cotton fabric. | [135] | |

| Gelatine, gum Arabic | Propolis, rice oil. | Acrylate binder. | Pad-dry. | Antimicrobial cotton fabric. | [118] |

| Methyl salicylate. | Citric acid and sodium hypophosphite. | Pad-dry-cure. | Anti-inflammatory and analgesic cotton and polyamide knitwear. | [77] | |

| Citronella essential oil. | – | Pad-dry. | Insect/Mosquito repellent cotton and polyester fabric. | [197] | |

| Gelatine, alginate. | C. aurantifolia essential oil. | Citric acid | Pad-dry-cure. | Antimicrobial cotton fabric. | [71] |

| Molecular Inclusion | |||||

| Epichlorohydrin modified β-cyclodextrin. | Lavender essential oil, indigo powder. | – | Immersion-freeze dried | Bifunctional dyed and fragranced cotton woven fabric. | [121] |

| Emulsification and Solvent Evaporation | |||||

| Soy lecithin, cholesterol. | Reactive dye (vinylsulphone azonaphthalene). | Acetic acid, sodium sulphate. | Dyeing. | Dyed wool fabric | [19] |

| Polylactic acid. | Bio based PCM, (capric acid, multiwall carbon nanotube). | – | Screen printing. | Thermo-regulated 3D polyester knitwear. | [39] |

| Emulsification and Crosslinking | |||||

| Chitosan. | Basil oil. | Acrylic binder. | Immersion-drying. | Antimicrobial Tencel/ polyurethane fabric. | [198] |

| Spray-Drying | |||||

| Chitosan. | Vanillin essential oil. | Citric acid and sodium hypophosphite. | Immersion-dry-cure. | Fragranced cotton fabric. | [131] |

| SOL-GEL | |||||

| Tetraethoxy-silane—TEOS. | Paraffin PCM. | – | Pad-dry-cure. | Thermo-regulated cotton fabric. | [199] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boh Podgornik, B.; Šandrić, S.; Kert, M. Microencapsulation for Functional Textile Coatings with Emphasis on Biodegradability—A Systematic Review. Coatings 2021, 11, 1371. https://doi.org/10.3390/coatings11111371

Boh Podgornik B, Šandrić S, Kert M. Microencapsulation for Functional Textile Coatings with Emphasis on Biodegradability—A Systematic Review. Coatings. 2021; 11(11):1371. https://doi.org/10.3390/coatings11111371

Chicago/Turabian StyleBoh Podgornik, Bojana, Stipana Šandrić, and Mateja Kert. 2021. "Microencapsulation for Functional Textile Coatings with Emphasis on Biodegradability—A Systematic Review" Coatings 11, no. 11: 1371. https://doi.org/10.3390/coatings11111371

APA StyleBoh Podgornik, B., Šandrić, S., & Kert, M. (2021). Microencapsulation for Functional Textile Coatings with Emphasis on Biodegradability—A Systematic Review. Coatings, 11(11), 1371. https://doi.org/10.3390/coatings11111371