Functional Thin Films Synthesized from Liquid Precursors by Combining Mist Chambers and Atmospheric-Pressure Plasma Polymerization

Abstract

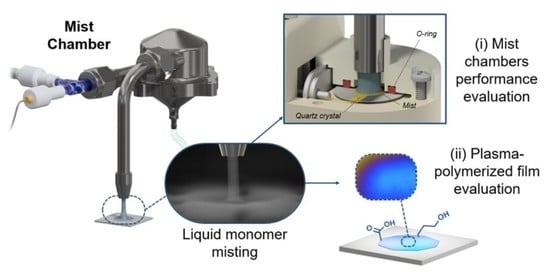

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

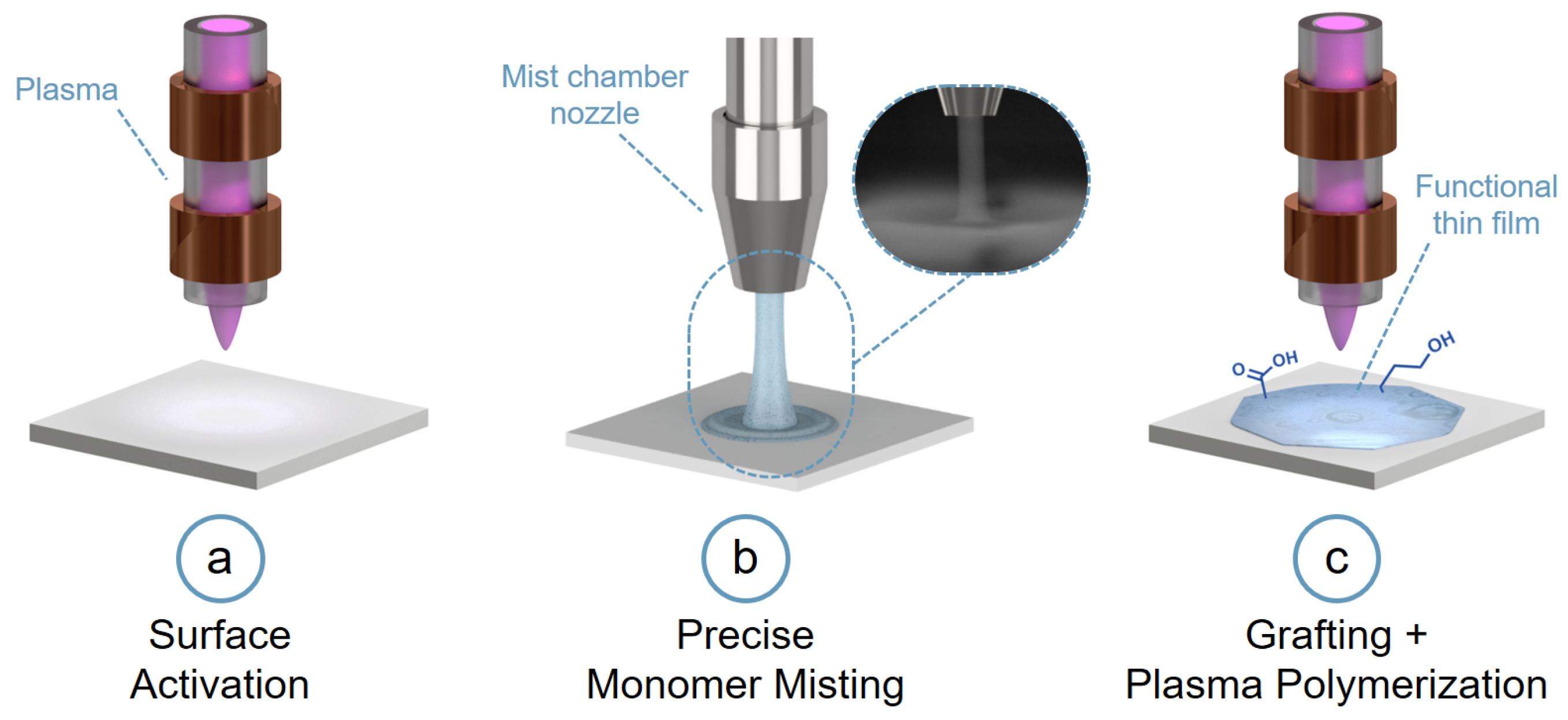

2.2. Mist Generation

2.3. Plasma-Induced Synthesis of pp Films

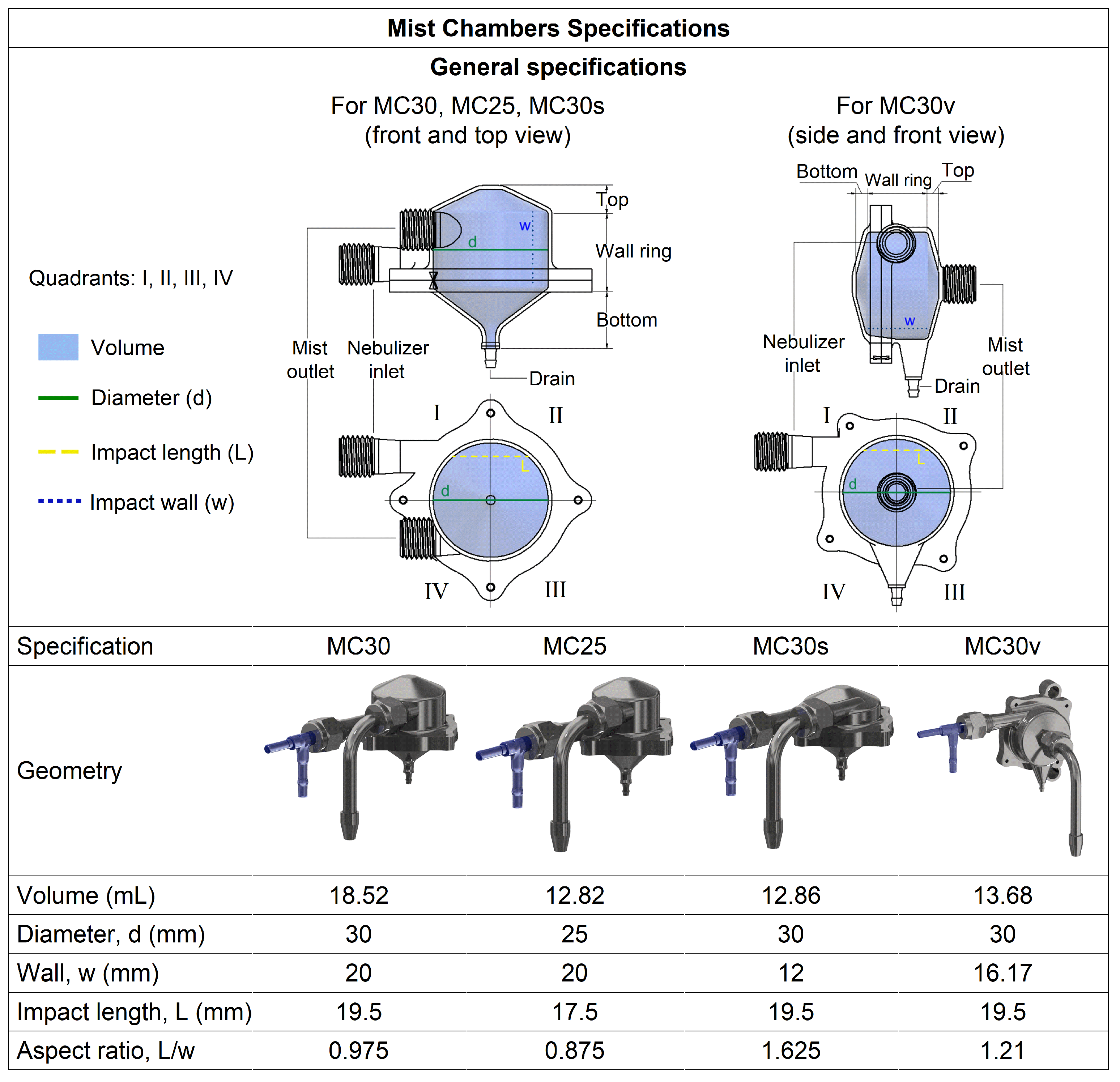

2.4. Design and Manufacturing of the Mist Chambers

2.5. Plasma-Electrolytic Polishing

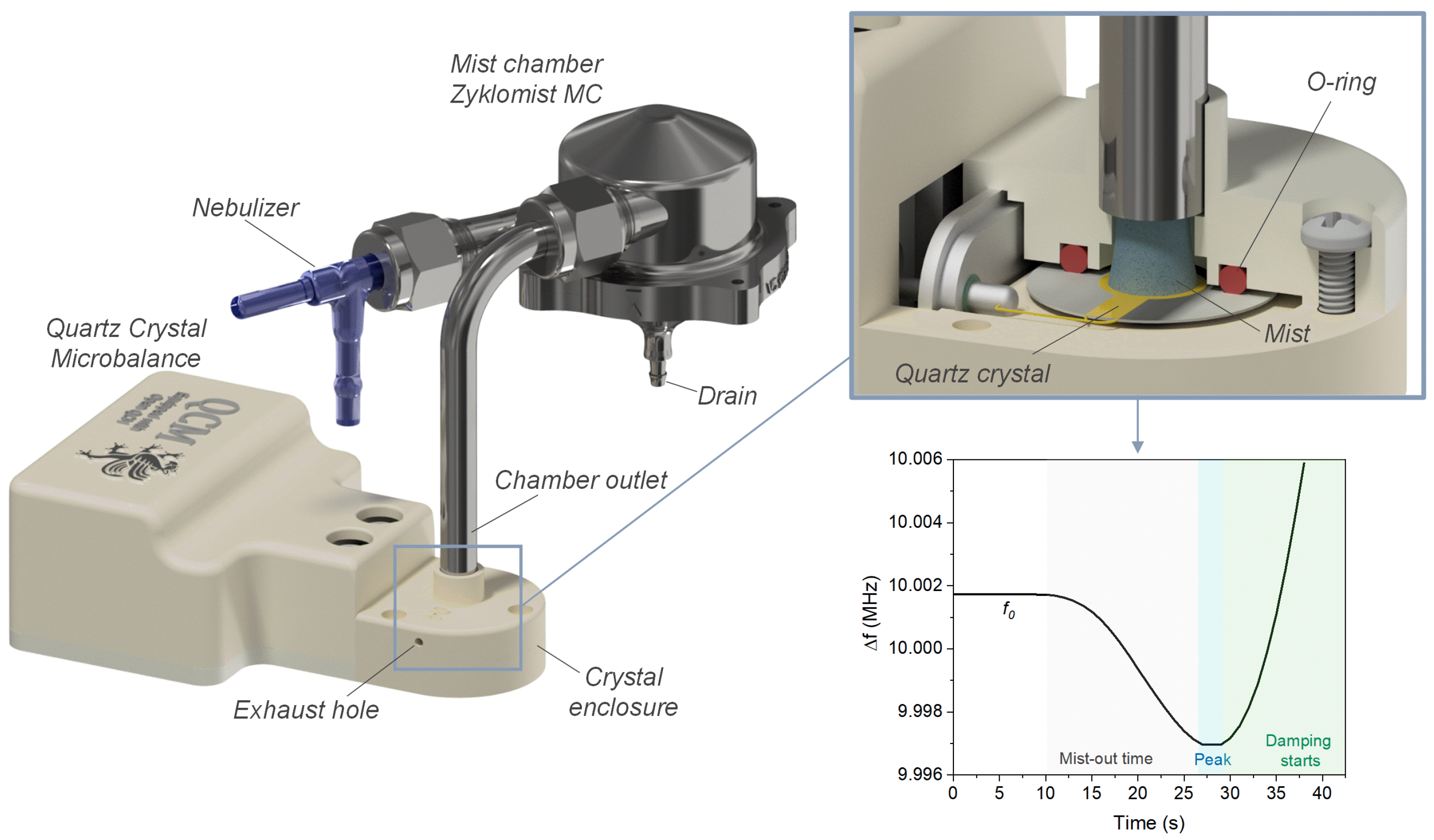

2.6. Quartz Crystal Microbalance

2.7. Atomic Force Microscopy

2.8. Ellipsometry

2.9. FT-IR Spectroscopy

3. Results and Discussion

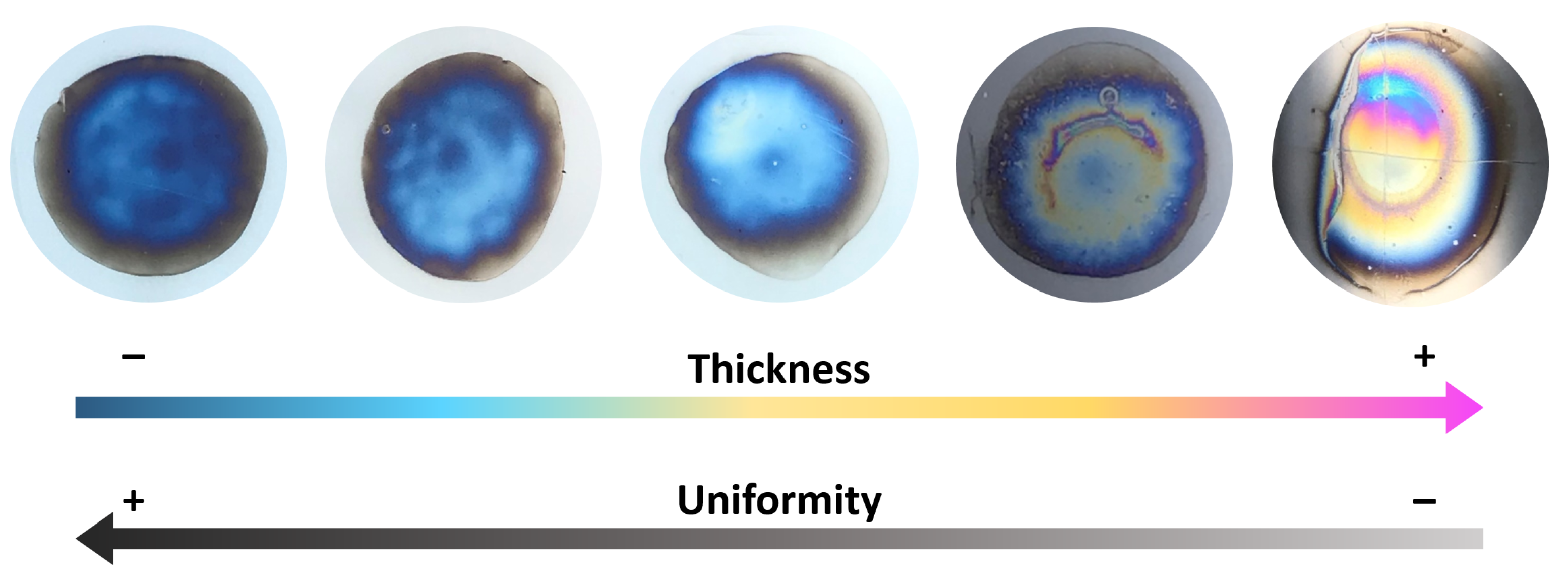

3.1. Design and Manufacturing of Mist Chambers

3.2. Surface Treatment of the Mist Chambers: Plasma-Electrolytic Polishing

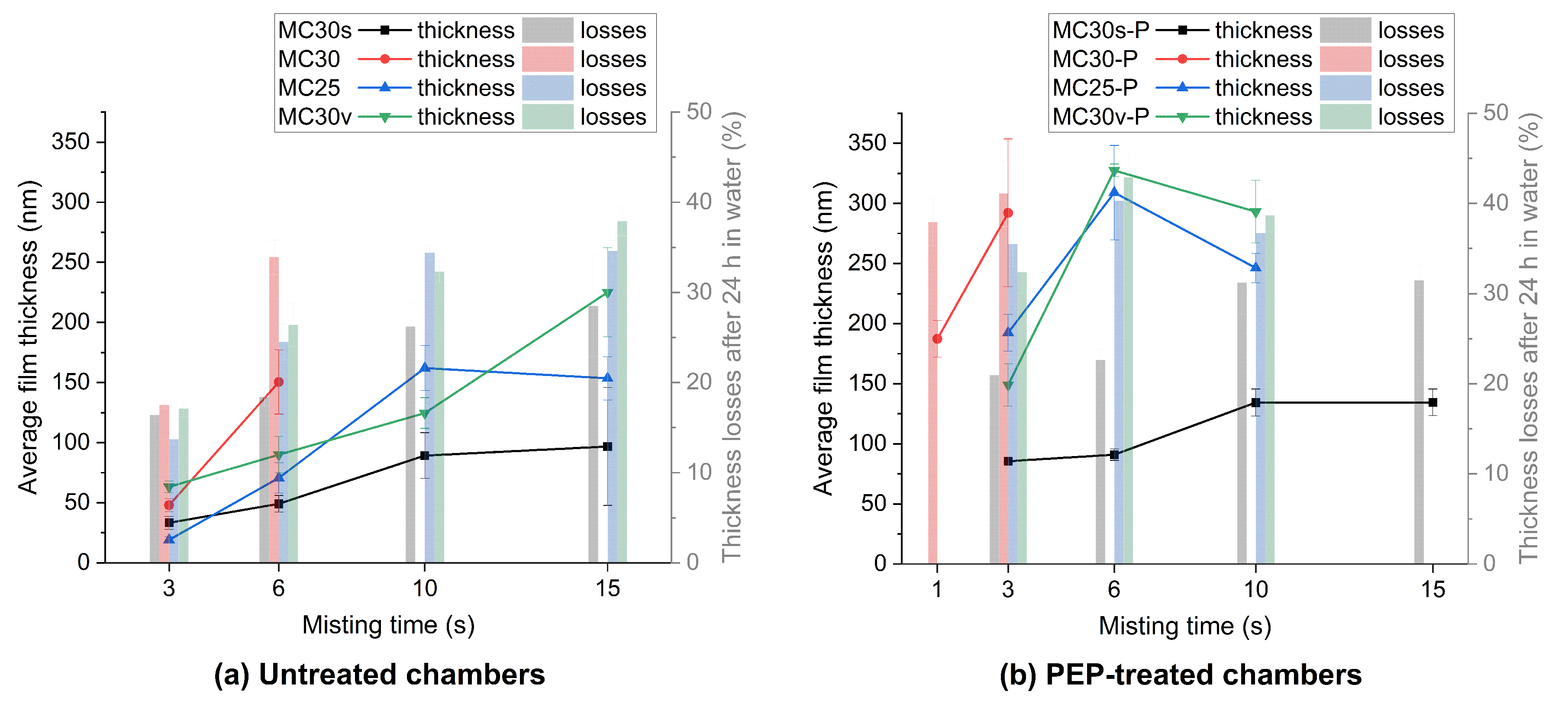

3.3. Performance Evaluation

3.3.1. Mist-Out Time and Misted Mass Transport Rate

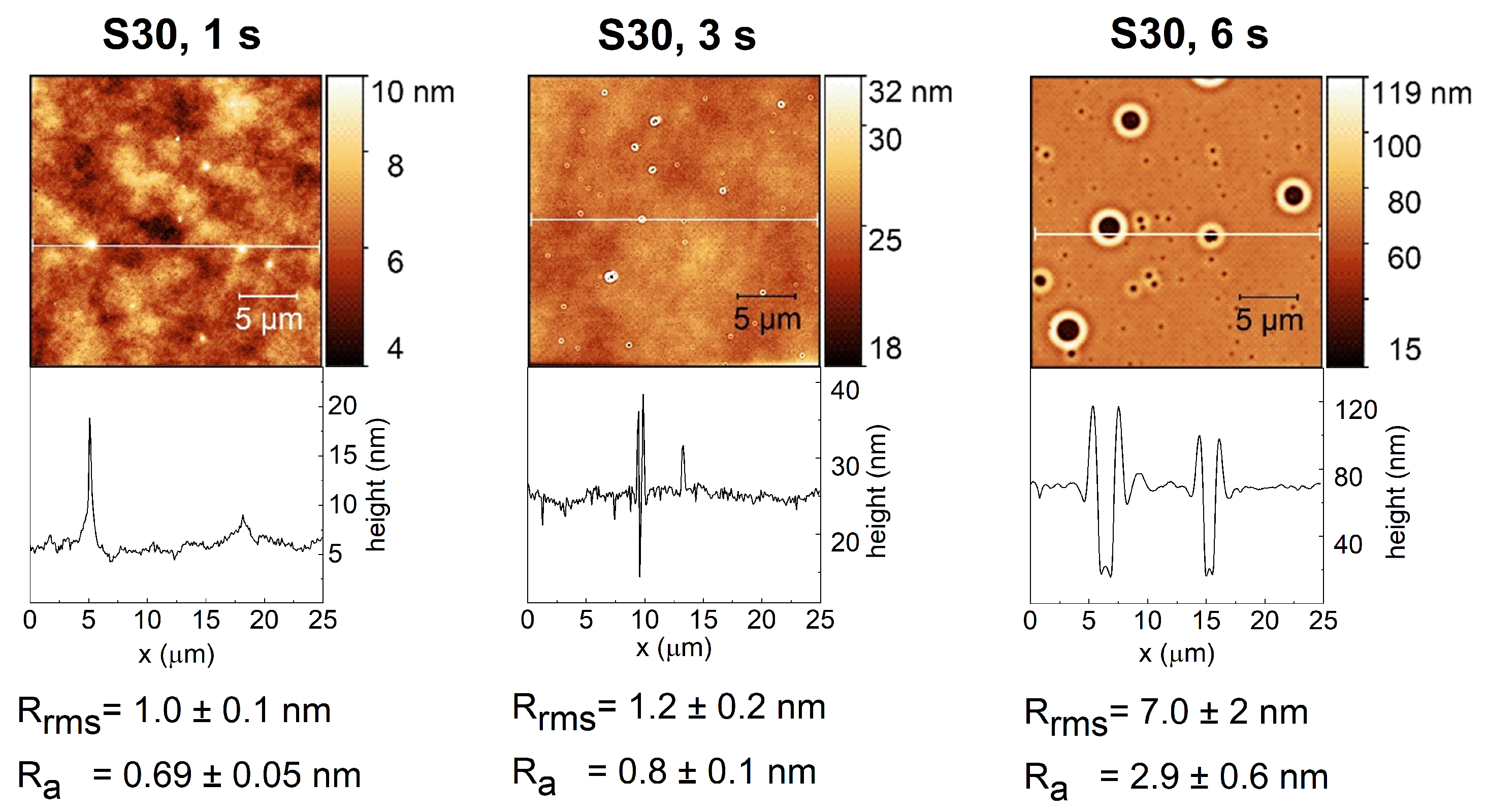

3.3.2. Plasma-Polymerized Films

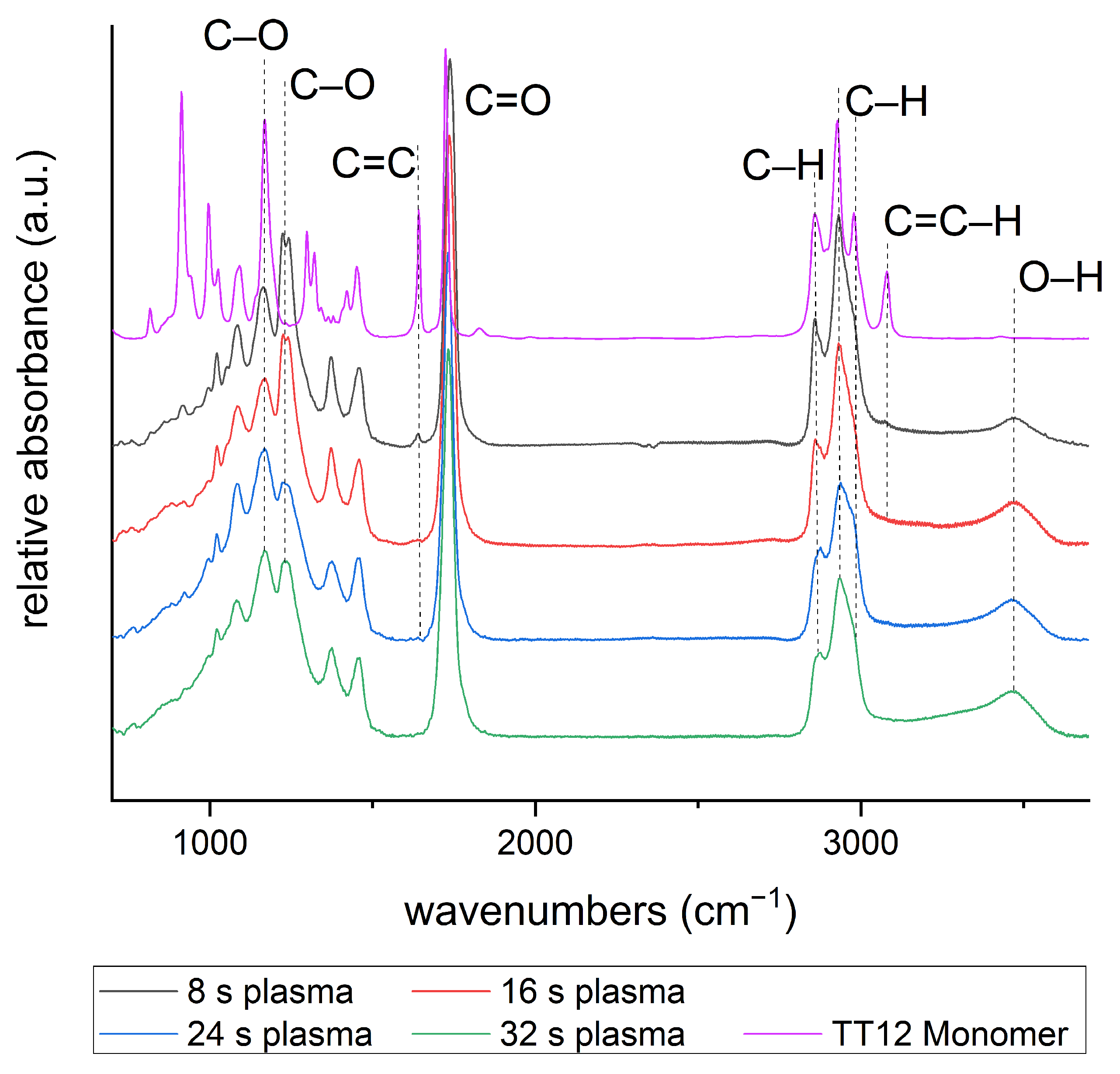

3.4. Influence of Misting Conditions and Plasma Polymerization Time on the Degree of Monomer Conversion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martin, P.M. Deposition Technologies: An Overview. In Handbook of Deposition Technologies for Films and Coatings, 3rd ed.; Martin, P.M., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; pp. 1–31. [Google Scholar] [CrossRef]

- Jilani, A.; Abdel-wahab, M.S.; Hammad, A.H. Advance Deposition Techniques for Thin Film and Coating. In Modern Technologies for Creating the Thin-film Systems and Coatings; Nikitenkov, N.N., Ed.; IntechOpen: London, UK, 2017; pp. 137–149. [Google Scholar] [CrossRef] [Green Version]

- Rossnagel, S.M. Thin film deposition with physical vapor deposition and related technologies. J. Vac. Sci. Technol. A Vacuum Surfaces Film. 2003, 21, S74–S87. [Google Scholar] [CrossRef]

- Martinu, L.; Zabeida, O.; Klemberg-Sapieha, J. Plasma-Enhanced Chemical Vapor Deposition of Functional Coatings. In Handbook of Deposition Technologies for Films and Coatings, 3rd ed.; Martin, P.M., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; pp. 392–465. [Google Scholar] [CrossRef]

- Cameron, D. Introduction to Films and Coatings: Technology and Recent Development. In Comprehensive Materials Processing, 1st ed.; Hashmi, S., Batalha, G.F., Tyne, C.J.V., Yilbas, B., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 4, p. 1. [Google Scholar] [CrossRef]

- Setsuhara, Y. Plasma Sources in Thin Film Deposition. In Comprehensive Materials Processing, 1st ed.; Hashmi, S., Batalha, G.F., Tyne, C.J.V., Yilbas, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 4, pp. 307–324. [Google Scholar] [CrossRef]

- Vasudev, M.C.; Anderson, K.D.; Bunning, T.J.; Tsukruk, V.V.; Naik, R.R. Exploration of Plasma-Enhanced Chemical Vapor Deposition as a Method for Thin-Film Fabrication with Biological Applications. ACS Appl. Mater. Interfaces 2013, 5, 3983–3994. [Google Scholar] [CrossRef] [PubMed]

- Massines, F.; Sarra-Bournet, C.; Fanelli, F.; Naude, N.; Gherardi, N. Atmospheric Pressure Low Temperature Direct Plasma Technology: Status and Challenges for Thin Film Deposition. PLasma Process. Polym. 2012, 9, 1041–1073. [Google Scholar] [CrossRef]

- Merche, D.; Vandencasteele, N.; Reniers, F. Atmospheric plasmas for thin film deposition: A critical review. Thin Solid Film. 2012, 520, 4219–4236. [Google Scholar] [CrossRef]

- Tatoulian, M.; Arefi-Khonsari, F.; Borra, J.P. Deposition of organic coatings at atmospheric pressure from liquid precursors. Plasma Process. Polym. 2007, 4, 360–369. [Google Scholar] [CrossRef]

- Schäfer, J.; Fricke, K.; Mika, F.; Pokorná, Z.; Zajíčková, L.; Foest, R. Liquid assisted plasma enhanced chemical vapour deposition with a non-thermal plasma jet at atmospheric pressure. Thin Solid Film. 2017, 630, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Palumbo, F.; Porto, C.L.; Fracassi, F.; Favia, P. Recent Advancements in the Use of Aerosol-Assisted Atmospheric Pressure Plasma Deposition. Coatings 2020, 10, 440. [Google Scholar] [CrossRef]

- Makhneva, E.; Barillas, L.; Weltmann, K.D.; Fricke, K. Stability of oxygen-rich plasma-polymerized coatings in aqueous environment. Biointerphases 2020, 15, 061001. [Google Scholar] [CrossRef]

- Makhneva, E.; Barillas, L.; Farka, Z.; Pastucha, M.; Skládal, P.; Weltmann, K.D.; Fricke, K. Functional Plasma Polymerized Surfaces for Biosensing. ACS Appl. Mater. Interfaces 2020, 12, 17100–17112. [Google Scholar] [CrossRef]

- Boscher, N.D.; Duday, D.; Heier, P.; Heinze, K.; Hilt, F.; Choquet, P. Plasma polymer membranes for immobilising metalloporphyrins. Plasma Process. Polym. 2013, 10, 336–344. [Google Scholar] [CrossRef]

- Makhlouf, A.S.H. Current and advanced coating technologies for industrial applications. In Nanocoatings and Ultra-Thin Films; Makhlouf, A.S.H., Tiginyanu, I., Eds.; Woodhead Publishing: Sawston, UK, 2011; pp. 3–23. [Google Scholar] [CrossRef]

- Tao, R.; Ning, H.; Chen, J.; Zou, J.; Fang, Z.; Yang, C.; Zhou, Y.; Zhang, J.; Yao, R.; Peng, J. Inkjet Printed Electrodes in Thin Film Transistors. IEEE J. Electron Devices Soc. 2018, 6, 774–790. [Google Scholar] [CrossRef]

- Shi, Y.; Osada, M.; Ebina, Y.; Sasaki, T. Single Droplet Assembly for Two-Dimensional Nanosheet Tiling. ACS Nano 2020, 14, 15216–15226. [Google Scholar] [CrossRef] [PubMed]

- Jaworek, A. Electrospray droplet sources for thin film deposition. J. Mater. Sci. 2007, 42, 266–297. [Google Scholar] [CrossRef]

- Sharp, B.L. Pneumatic nebulisers and spray chambers for inductively coupled plasma spectrometry: A review. Part 1. Nebulisers. J. Anal. At. Spectrom. 1988, 3, 613–652. [Google Scholar] [CrossRef]

- Sharp, B.L. Pneumatic nebulisers and spray chambers for inductively coupled plasma spectrometry: A review. Part 2. Spray Chambers. J. Anal. At. Spectrom. 1988, 3, 939–963. [Google Scholar] [CrossRef]

- Schaldach, G.; Berger, L.; Razilov, I.; Berndt, H. Characterization of a cyclone spray chamber for ICP spectrometry by computer simulation. J. Anal. At. Spectrom. 2002, 17, 334–344. [Google Scholar] [CrossRef]

- Todolí, J.L.; Mermet, J.M. Specifications of a Sample Introduction System to be Used with an ICP. In Liquid Sample Introduction in ICP Spectrometry, 1st ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; pp. 3–15. [Google Scholar] [CrossRef]

- Todolí, J.L.; Mermet, J.M. Spray Chamber Design. In Liquid Sample Introduction in ICP Spectrometry, 1st ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; pp. 77–118. [Google Scholar] [CrossRef]

- Sharp, B.L.; O’Connor, C. Aerosol Generation and Sample Transport. In Inductively Coupled Plasma Spectrometry and its Applications, 1st ed.; Hill, S., Ed.; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2007; pp. 98–133. [Google Scholar] [CrossRef]

- Hidalgo, S.; Barillas, L.; Weltmann, K.D.; Fricke, K. Influence of the design of a mist chamber for the deposition of nanometric thin liquid films—Proof-of-concept. Tecnol. Marcha 2020, 33, 130–142. [Google Scholar] [CrossRef]

- Wu, C.Y.; Zhang, Q.; Li, Y.; Switt, R.; Matta, S. Aerosol Transport—Inertia. Available online: https://aerosol.ees.ufl.edu/aerosol_trans/section09_c.html (accessed on 25 March 2021).

- Schäfer, J.; Foest, R.; Quade, A.; Ohl, A.; Weltmann, K.D. Local deposition of SiOx plasma polymer films by a miniaturized atmospheric pressure plasma jet (APPJ). J. Phys. D Appl. Phys. 2008, 41, 194010. [Google Scholar] [CrossRef] [Green Version]

- An, S.; Foest, R.; Fricke, K.; Riemer, H.; Fröhlich, M.; Quade, A.; Schäfer, J.; Weltmann, K.D.; Kersten, H. Pretreatment of cutting tools by plasma electrolytic polishing (PEP) for enhanced adhesion of hard coatings. Surf. Coatings Technol. 2021, 405, 126504. [Google Scholar] [CrossRef]

- Sauerbrey, G. Verwendung von Schwingquarzen zur Wägung dünner Schichten und zur Mikrowägung. Z. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Thompson, D.F. Rapid production of cyclonic spray chambers for inductively coupled plasma applications using low cost 3D printer technology. J. Anal. At. Spectrom. 2014, 29, 2262–2266. [Google Scholar] [CrossRef]

- Schaldach, G.; Berndt, H.; Sharp, B.L. An application of computational fluid dynamics (CFD) to the characterisation and optimisation of a cyclonic spray chamber for ICP-AES. J. Anal. At. Spectrom. 2003, 18, 742–750. [Google Scholar] [CrossRef]

- Todolí, J.L.; Mermet, J.M. Influence of the spray chamber design for vapor-based liquid sample introduction at room temperature in ICP-AES. J. Anal. At. Spectrom. 2002, 17, 211–218. [Google Scholar] [CrossRef]

- Taylor, K.A.; Sharp, B.L.; Lewis, D.J.; Crews, H.M. Design and characterisation of a microconcentric nebuliser interface for capillary electrophoresis-inductively coupled plasma mass spectrometry. J. Anal. At. Spectrom. 1998, 13, 1095–1100. [Google Scholar] [CrossRef]

- PFA Cyclonic Spray Chamber for ICP-OES and ICP-MS (Data Sheet). Available online: https://www.savillex.com/Image/GetDocument/en/56 (accessed on 13 March 2021).

- Masone, J.; Brennan, R.; Fornadel, A. Improved Washout with the Glass Expansion Helix CT Cyclonic Spray Chamber. Available online: https://www.geicp.com/site/images/application_notes/ (accessed on 15 October 2020).

- Product Design Focus: Inert Spray Chambers—Glass Expansion Newsletter Issue 26,2011. Available online: https://www.geicp.com/site/GE_Newsletter/GlassExpansionNewsOct11.pdf (accessed on 15 October 2020).

- Jeon, T.J.; Hwang, T.W.; Yun, H.J.; VanTyne, C.J.; Moon, Y.H. Control of porosity in parts produced by a direct laser melting process. Appl. Sci. 2018, 8, 2573. [Google Scholar] [CrossRef] [Green Version]

- Yasa, E.; Kruth, J.P. Microstructural investigation of Selective Laser Melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Matras, A. Research and Optimization of Surface Roughness in Milling of SLM Semi-Finished Parts Manufactured by Using the Different Laser Scanning Speed. Materials 2019, 13, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hong, M.H.; Min, B.K.; Kwon, T.Y. The influence of process parameters on the surface roughness of a 3d-printed Co-Cr dental alloy produced via selective laser melting. Appl. Sci. 2016, 6, 401. [Google Scholar] [CrossRef] [Green Version]

- Alekseev, Y.G.; Kosobutsky, A.A.; Korolev, A.Y.; Niss, V.S.; Kucheryavy, V.D.; Povzhik, A.A. Features of the processes of dimensional processing of metal products by the electrolyte-plasma method. Litye. Metall. 2005, 4, 188–195. [Google Scholar]

- Adamson, J.; Hughes, S.; Azzopardi, D.; McAughey, J.; Gaça, M.D. Real-time assessment of cigarette smoke particle deposition. Chem. Cent. J. 2012, 6, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Weindl, P.; Lenz, A.G.; Mayer, P.; Krebs, T.; Schmid, O. Quartz crystal microbalances (QCM) are suitable for real-time dosimetry in nanotoxicological studies using VITROCELL®Cloud cell exposure systems. Part. Fibre Toxicol. 2020, 17, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Shih, W.P.; Chen, C.S.; Dai, C.A. A Miniature system for separating aerosol particles and measuring mass concentrations. Sensors 2010, 10, 3641–3654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Edvardsson, M. QCM-D in Relation to Other QCMs: What Are the Differences, and Does It Matter Which One to Use? 2018. Available online: https://www.biolinscientific.com/measurements/qcm-d (accessed on 21 February 2021).

- Quartz Crystal Microbalance (QCM). Available online: https://www.nanoscience.com/techniques/quartz-crystal-microbalance/ (accessed on 19 October 2021).

| Mist Chamber | Tmist (s) | Wtot (g/s) | ||||

|---|---|---|---|---|---|---|

| Untreated | PEP-Treated | Untreated | PEP-Treated | |||

| MC30s | 158.85 ± 1.0 | 121.97 ± 5.8 | −23.2% | 0.03915 ± 0.001 | 0.05063 ± 0.002 | 29.3% |

| MC30 | 41.72 ± 1.0 | 17.74 ± 1.0 | −57.5% | 0.1375 ± 0.001 | 0.31282 ± 0.006 | 127.5% |

| MC25 | 60.42 ± 3.5 | 21.29 ± 3.0 | −64.8% | 0.10301 ± 0.012 | 0.2807 ± 0.020 | 172.5% |

| MC30v | 56.36 ± 6.9 | 18.65 ± 3.5 | −66.9% | 0.10762 ± 0.013 | 0.30499 ± 0.040 | 183.4% |

| Conditions (Pump Speed, Misting Time) | Wtot (g/s) | Thickness of pp Film (Measured by Ellipsometry) | Mass of pp Film (Measured by QCM) | ||||

|---|---|---|---|---|---|---|---|

| As-Deposited (nm) | After 24 h in Water (nm) | Thickness Loss (%) | As-Deposited Mass (g) | Mass Loss after 24 h in Water (g) | Mass Loss (%) | ||

| S10, 1 s | 0.00854 | N/A | N/A | N/A | N/A | N/A | N/A |

| S10, 3 s | 0.01894 | N/A | N/A | N/A | 0.25 ± 0.05 | 0.02 ± 0.00 | 8.32 |

| S10, 6 s | 0.03214 | 28.40 ± 0.86 | 23.49 ± 0.99 | 17.29 | 1.04 ± 0.16 | 0.20 ± 0.02 | 19.61 |

| S30, 1 s | 0.02362 | 17.48 ± 1.09 | 15.13 ± 0.91 | 13.41 | 0.59 ± 0.07 | 0.08 ± 0.01 | 13.91 |

| S30, 3 s | 0.05358 | 68.63 ± 3.10 | 52.07 ± 2.10 | 24.14 | 1.99 ± 0.05 | 0.50 ± 0.02 | 25.09 |

| S30, 6 s | 0.11946 | 146.02 ± 6.93 | 98.89 ± 3.66 | 32.28 | 3.56 ± 0.22 | 1.29 ± 0.11 | 36.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barillas, L.; Makhneva, E.; An, S.; Fricke, K. Functional Thin Films Synthesized from Liquid Precursors by Combining Mist Chambers and Atmospheric-Pressure Plasma Polymerization. Coatings 2021, 11, 1336. https://doi.org/10.3390/coatings11111336

Barillas L, Makhneva E, An S, Fricke K. Functional Thin Films Synthesized from Liquid Precursors by Combining Mist Chambers and Atmospheric-Pressure Plasma Polymerization. Coatings. 2021; 11(11):1336. https://doi.org/10.3390/coatings11111336

Chicago/Turabian StyleBarillas, Laura, Ekaterina Makhneva, Sehoon An, and Katja Fricke. 2021. "Functional Thin Films Synthesized from Liquid Precursors by Combining Mist Chambers and Atmospheric-Pressure Plasma Polymerization" Coatings 11, no. 11: 1336. https://doi.org/10.3390/coatings11111336

APA StyleBarillas, L., Makhneva, E., An, S., & Fricke, K. (2021). Functional Thin Films Synthesized from Liquid Precursors by Combining Mist Chambers and Atmospheric-Pressure Plasma Polymerization. Coatings, 11(11), 1336. https://doi.org/10.3390/coatings11111336