Integration of Fluorescent, NV-Rich Nanodiamond Particles with AFM Cantilevers by Focused Ion Beam for Hybrid Optical and Micromechanical Devices

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Preparation of NV-Rich Nanodiamond Particles

2.2. Preparation of NV-Rich Nanodiamond Particles

2.3. Preparation of NV-Rich Nanodiamond Particles

3. Results

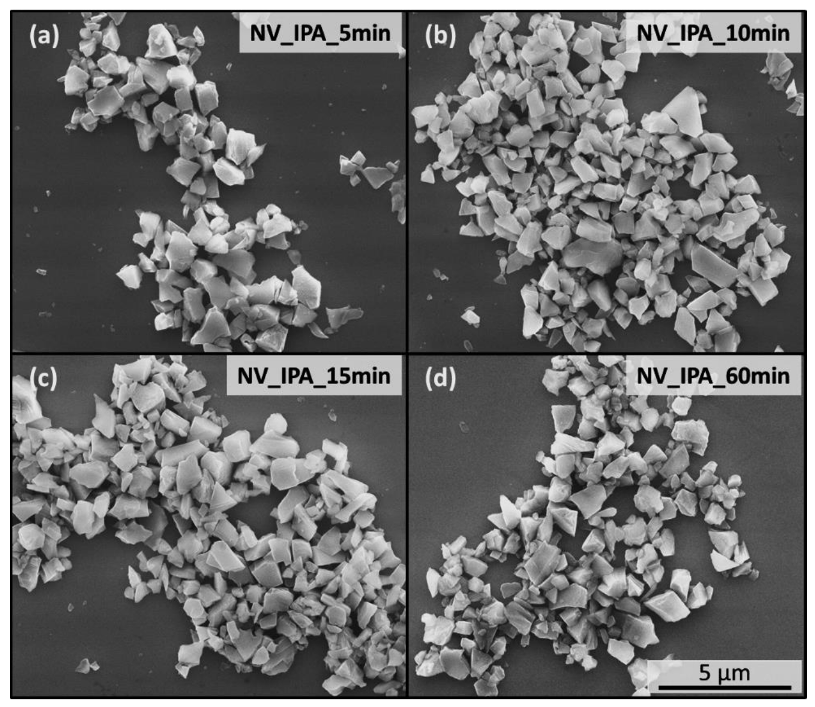

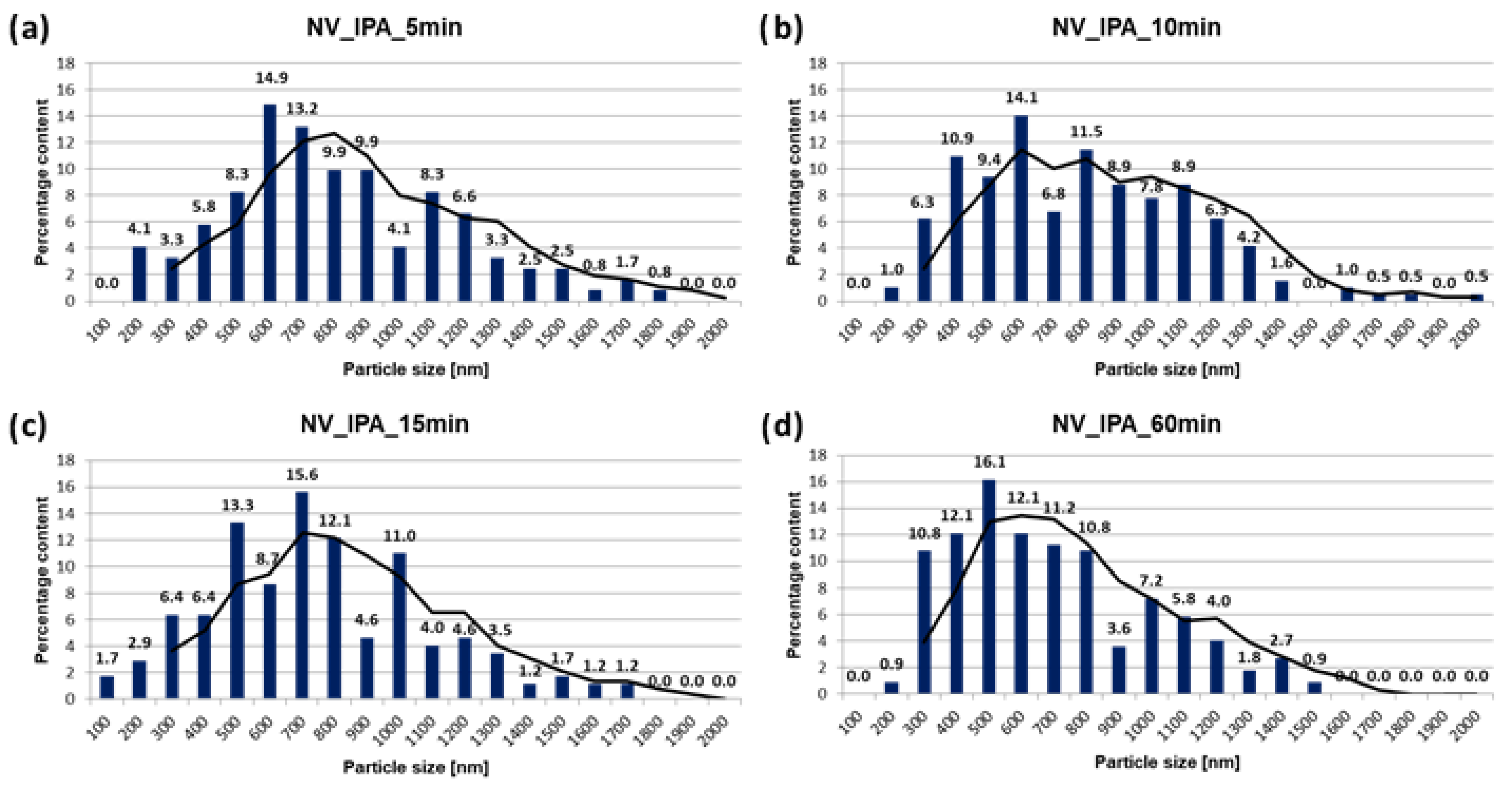

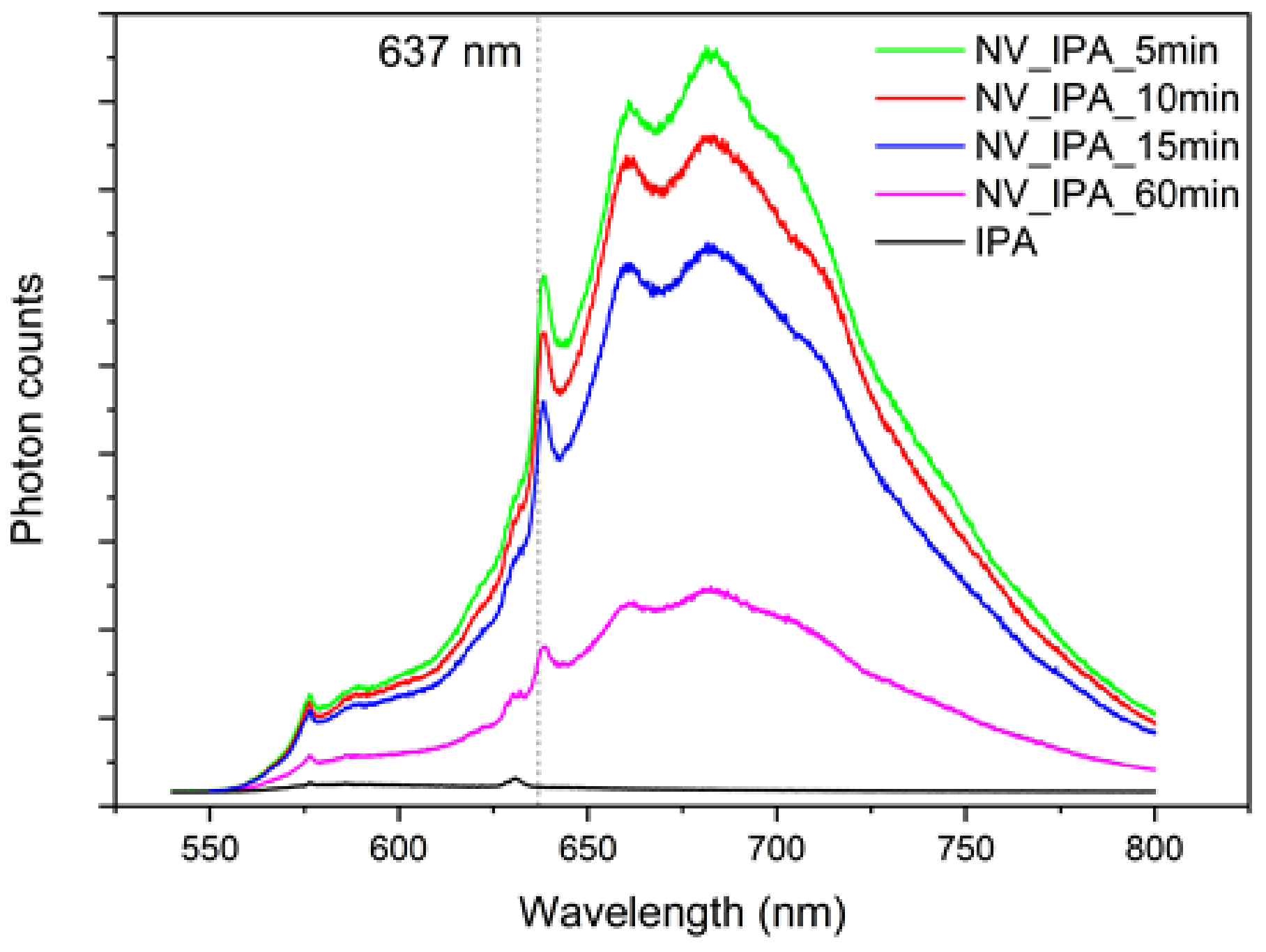

3.1. NV-Rich Nano diamond Particle Parameters

3.2. NV-Rich Nanodiamond Particle Parameters

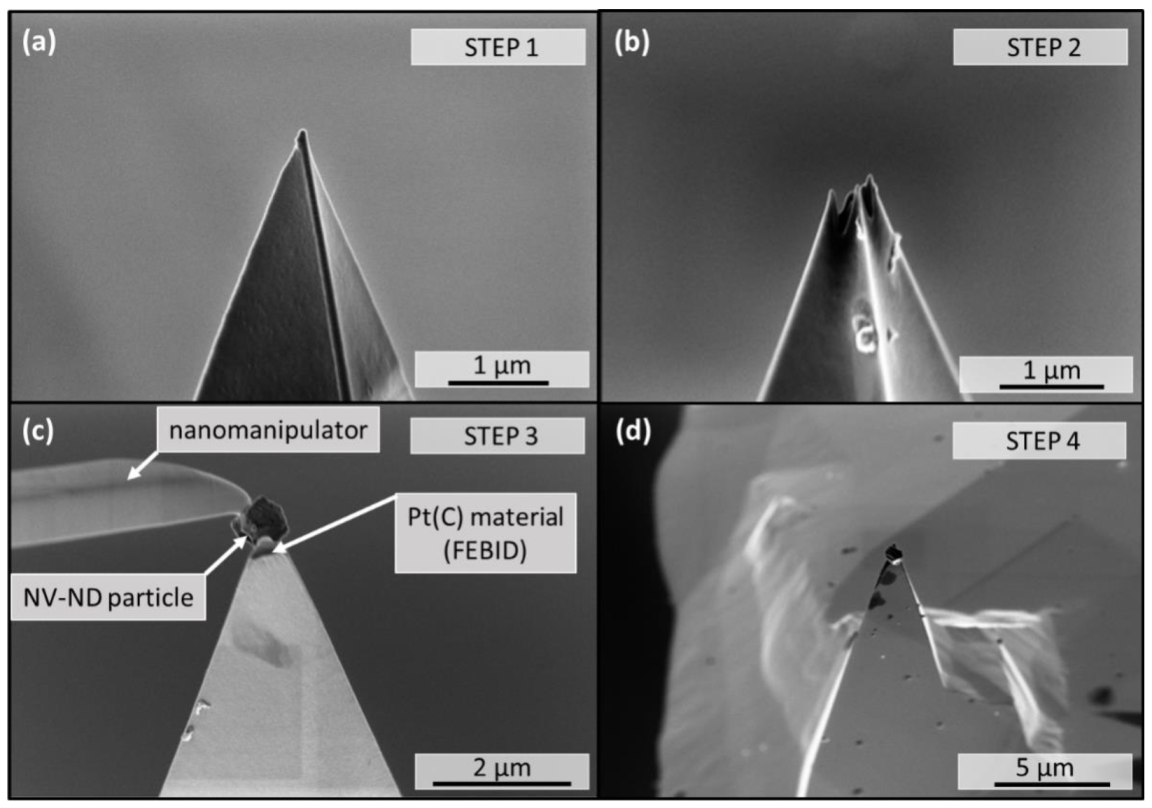

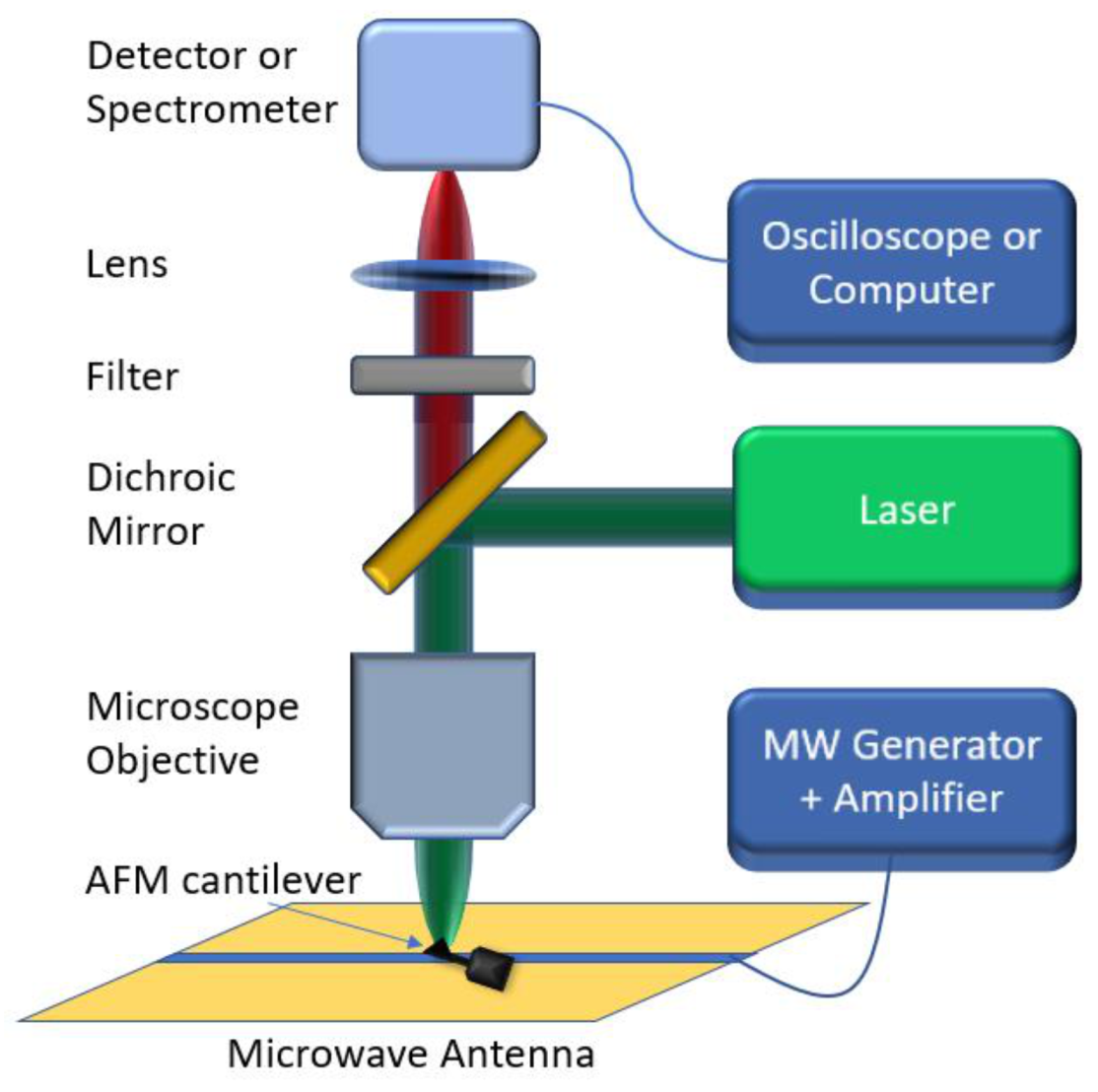

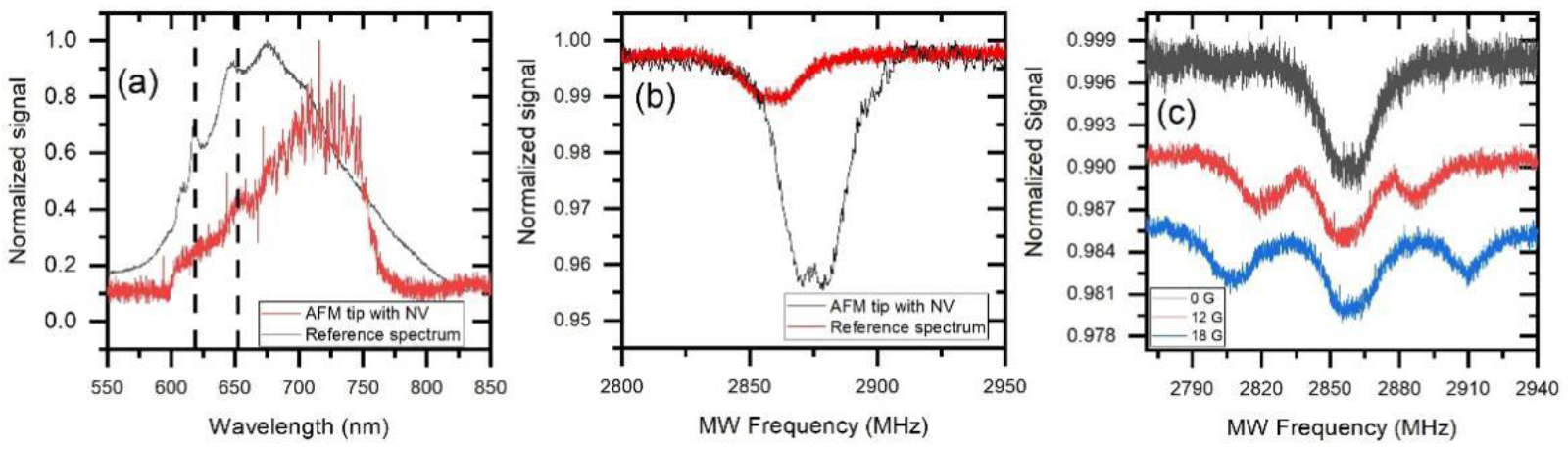

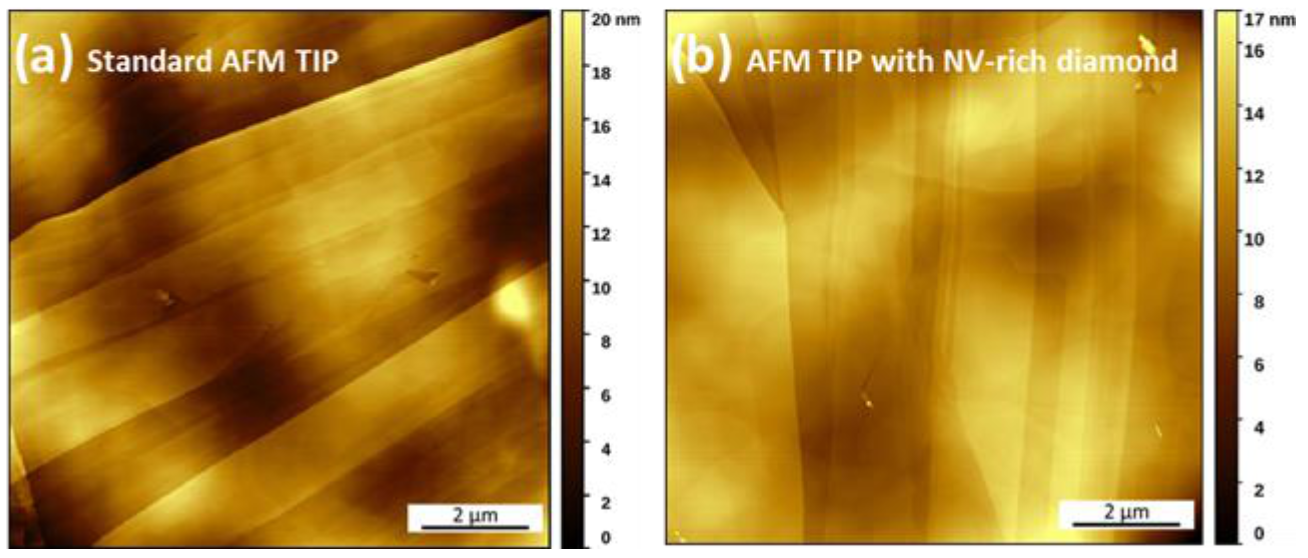

3.3. AFM Cantilevers with NV-Rich Nanodiamond Particle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, S.; Grinolds, M.S.; Pham, L.M.; Sage, D.L.; Luan, L.; Walsworth, R.L.; Yacoby, A. Nanoscale magnetometry with NV centers in diamond. MRS Bull. 2013, 38, 155–161. [Google Scholar] [CrossRef] [Green Version]

- Appel, P.; Neu, E.; Ganzhorn, M.; Barfuss, A.; Batzer, M.; Gratz, M.; Tschöpe, A.; Maletinsky, P. Fabrication of All Diamond Scanning Probes for Nanoscale Magnetometry. Rev. Sci. Instrum. 2016, 87, 063703. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Degen, A. Scanning magnetic field microscope with a diamond single-spin sensor. ACS Appl. Phys. Lett. 2008, 92, 243111. [Google Scholar] [CrossRef] [Green Version]

- Taylor, J.M.; Cappellaro, P.; Childress, L.; Jiang, L.; Budker, D.; Hemmer, P.R.; Yacoby, A.; Walsworth, R.; Lukin, M.D. High-sensitivity diamond magnetometer with nanoscale resolution. Nat. Phys. 2008, 4, 810–816. [Google Scholar] [CrossRef]

- Maze, J.R.; Stanwix, P.L.; Hodges, J.S.; Hong, S.; Taylor, J.M.; Cappellaro, P.; Jiang, L.; Gurudev Dutt, M.V.; Togan, E.; Zibrov, A.S.; et al. Nanoscale magnetic sensing with an individual electronic spin in diamond. Nature 2008, 455, 644–647. [Google Scholar] [CrossRef]

- Rondin, L.; Tetienne, J.-P.; Spinicelli, P.; Dal Savio, C.; Karrai, K.; Dantelle, G.; Thiaville, A.; Rohart, S.; Roch, J.-F.; Jacques, V. Nanoscale magnetic field mapping with a single spin scanning probe magnetometer. Appl. Phys. Lett. 2012, 100, 153118. [Google Scholar] [CrossRef] [Green Version]

- Rondin, L.; Tetienne, J.-P.; Rohart, S.; Thiaville, A.; Hingant, T.; Spinicelli, P.; Roch, J.-F.; Jacques, V. Stray-field imaging of magnetic vortices with a single diamond spin. Nat. Commun. 2013, 4, 2279. [Google Scholar] [CrossRef]

- Pelz, J.P.; Koch, R.H. Tip-Related Artifacts in Scanning Tunneling Potentiometry. Phys. Rev. B 1990, 41, 1212–1215. [Google Scholar] [CrossRef]

- Westra, K.L.; Mitchell, A.W.; Thomson, D.J. Tip Artifacts in Atomic Force Microscope Imaging of Thin Film Surfaces. J. Appl. Phys. 1993, 74, 3608–3610. [Google Scholar] [CrossRef]

- Bao, G.W.; Li, S.F. Characterization of Atomic Force Microscopy (AFM) Tip Shapes by Scanning Hydrothermally Deposited ZnO Thin Films. Talanta 1998, 45, 751–757. [Google Scholar] [CrossRef]

- Cui, S.; Kim, T.-H.; Ham, U. Influence of the Tip Shape on Scanning Tunneling Luminescence Spectra: Implications for Nanomaterial Characterization. ACS Appl. Nano Mater. 2021, 4, 29–32. [Google Scholar] [CrossRef]

- Hartmann, U. Magnetic Force Microscopy. Adv. Mater. 1990, 2, 550–552. [Google Scholar] [CrossRef]

- Ruggeri, F.S.; Šneideris, T.; Vendruscolo, M.; Knowles, T.P.J. Atomic Force Microscopy for Single Molecule Characterisation of Protein Aggregation. Arch. Biochem. Biophys. 2019, 664, 134–148. [Google Scholar] [CrossRef]

- Canet-Ferrer, J.; Coronado, E.; Forment-Aliaga, A.; Pinilla-Cienfuegos, E. Correction of the Tip Convolution Effects in the Imaging of Nanostructures Studied through Scanning Force Microscopy. Nanotechnology 2014, 25, 395703. [Google Scholar] [CrossRef]

- Giessibl, F.J. Advances in Atomic Force Microscopy. Rev. Mod. Phys. 2003, 75, 949–983. [Google Scholar] [CrossRef] [Green Version]

- Bogdanowicz, R.; Sobaszek, M.; Ficek, M.; Kopiec, D.; Moczała, M.; Orłowska, K.; Sawczak, M.; Gotszalk, T. Fabrication and Characterization of Boron-Doped Nanocrystalline Diamond-Coated MEMS Probes. Appl. Phys. A 2016, 122, 270. [Google Scholar] [CrossRef] [Green Version]

- Shibata, T.; Unno, K.; Makino, E.; Shimada, S. Fabrication and Characterization of Diamond AFM Probe Integrated with PZT Thin Film Sensor and Actuator. Sens. Actuators A Phys. 2004, 114, 398–405. [Google Scholar] [CrossRef]

- Kim, J.T.; Choudhury, U.; Jeong, H.-H.; Fischer, P. Nanodiamonds That Swim. Adv. Mater. 2017, 29, 1701024. [Google Scholar] [CrossRef]

- Zhou, T.X.; Stöhr, R.J.; Yacoby, A. Scanning Diamond NV Center Probes Compatible with Conventional AFM Technology. Appl. Phys. Lett. 2017, 111, 163106. [Google Scholar] [CrossRef]

- Choi, S.; Leong, V.; Alagappan, G.; Krivitsky, L. Enhancing Optical Readout from Diamond AFM Tips for Quantum Nanosensing. ACS Photonics 2018, 5, 4244–4248. [Google Scholar] [CrossRef] [Green Version]

- Głowacki, M.J.; Gardas, M.; Ficek, M.; Sawczak, M.; Bogdanowicz, R. Preparation of Fluorescent Nanodiamond Suspensions Using Bead-Assisted Ultrasonic Disintegration. In Proceedings of the 12th Conference on Integrated Optics: Sensors, Sensing Structures, and Methods, Szczyrk-Gliwice, Poland, 3 March 2017; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10455, p. 104550E. [Google Scholar]

- Thorman, R.M.; TP, R.K.; Fairbrother, D.H.; Ingólfsson, O. The Role of Low-Energy Electrons in Focused Electron Beam Induced Deposition: Four Case Studies of Representative Precursors. Beilstein J. Nanotechnol. 2015, 6, 1904–1926. [Google Scholar] [CrossRef] [Green Version]

- Świadkowski, B.; Majstrzyk, W.; Kunicki, P.; Sierakowski, A.; Gotszalk, T. Near-Zero Contact Force Atomic Force Microscopy Investigations Using Active Electromagnetic Cantilevers. Nanotechnology 2020, 31, 425706. [Google Scholar] [CrossRef]

- Kreibig, U.; Quinten, M. OPTICAL MATERIALS | Heterogeneous Materials. In Encyclopedia of Modern Optics; Guenther, R.D., Ed.; Elsevier: Oxford, UK, 2005; pp. 446–460. ISBN 978-0-12-369395-2. [Google Scholar]

- Manson, N.B.; Hedges, M.; Barson, M.S.J.; Ahlefeldt, R.; Doherty, M.W.; Abe, H.; Ohshima, T.; Sellars, M.J. NV––N+ Pair Centre in 1b Diamond. New J. Phys. 2018, 20, 113037. [Google Scholar] [CrossRef]

- Wojciechowski, A.M.; Nakonieczna, P.; Mrózek, M.; Sycz, K.; Kruk, A.; Ficek, M.; Głowacki, M.; Bogdanowicz, R.; Gawlik, W. Optical Magnetometry Based on Nanodiamonds with Nitrogen-Vacancy Color Centers. Materials 2019, 12, 2951. [Google Scholar] [CrossRef] [Green Version]

- Shenderova, O.; Nunn, N. Chapter 2—Production and purification of nanodiamonds. In Nanodiamonds; Arnault, J.-C., Ed.; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 25–56. ISBN 978-0-323-43029-6. [Google Scholar]

- Białobrzeska, W.; Głowacki, J.M.; Janik, M.; Ficek, M.; Pyrchla, K.; Sawczak, M.; Bogdanowicz, R.; Malinowska, N.; Żołędowska, S.; Nidzworski, D. Quantitative fluorescent determination of DNA—Ochratoxin a interactions supported by nitrogen-vacancy rich nanodiamonds. J. Mol. Liq. 2021, 342, 117338. [Google Scholar] [CrossRef]

- Chipaux, M.; Tallaire, A.; Achard, J.; Pezzagna, S.; Meijer, J.; Jacques, V.; Roch, J.-F.; Debuisschert, T. Magnetic Imaging with an Ensemble of Nitrogen-Vacancy Centers in Diamond. Eur. Phys. J. D 2015, 69, 166. [Google Scholar] [CrossRef] [Green Version]

- Glenn, D.R.; Lee, K.; Park, H.; Weissleder, R.; Yacoby, A.; Lukin, M.D.; Lee, H.; Walsworth, R.L.; Connolly, C.B. Single-Cell Magnetic Imaging Using a Quantum Diamond Microscope. Nat. Methods 2015, 12, 736–738. [Google Scholar] [CrossRef]

- Chen, X.-D.; Dong, C.-H.; Sun, F.-W.; Zou, C.-L.; Cui, J.-M.; Han, Z.-F.; Guo, G.-C. Temperature Dependent Energy Level Shifts of Nitrogen-Vacancy Centers in Diamond. Appl. Phys. Lett. 2011, 99, 161903. [Google Scholar] [CrossRef]

- Doherty, M.W.; Acosta, V.M.; Jarmola, A.; Barson, M.S.J.; Manson, N.B.; Budker, D.; Hollenberg, L.C.L. Temperature Shifts of the Resonances of the NV– Center in Diamond. Phys. Rev. B 2014, 90, 041201. [Google Scholar] [CrossRef] [Green Version]

- Guo, M.; Wang, M.; Wang, P.; Wu, D.; Ye, X.; Yu, P.; Huang, Y.; Shi, F.; Wang, Y.; Du, J. A Flexible Nitrogen-Vacancy Center Probe for Scanning Magnetometry. Rev. Sci. Instrum. 2021, 92, 055001. [Google Scholar] [CrossRef] [PubMed]

- Orzechowska, Z.; Mrózek, M.; Gawlik, W.; Wojciechowski, A. Preparation and characterization of AFM tips with nitrogen-vacancy and nitrogen-vacancy-nitrogen color centers. Photonics Lett. Pol. 2021, 13, 28. [Google Scholar] [CrossRef]

- Lang, H.P.; Berger, R.; Battiston, F.; Ramseyer, J.-P.; Meyer, E.; Andreoli, C.; Brugger, J.; Vettiger, P.; Despont, M.; Mezzacasa, T.; et al. A Chemical Sensor Based on a Micromechanical Cantilever Array for the Identification of Gases and Vapors. Appl. Phys. A 1998, 66, S61–S64. [Google Scholar] [CrossRef] [Green Version]

| Name of the Suspension | Mass of the NV-Rich Nanodiamond Particles | Volume of Isopropyl Alcohol | Time of Active Operation of Ultrasounds |

|---|---|---|---|

| NV_IPA_5min | 0.01 g | 10 mL | 5 min |

| NV_IPA_10min | 0.01 g | 10 mL | 10 min |

| NV_IPA_15min | 0.01 g | 10 mL | 15 min |

| NV_IPA_60min | 0.01 g | 10 mL | 60 min |

| Tip | fr before Experiment (Hz) | fr after Experiment (Hz) | Frequency Difference (Hz) |

|---|---|---|---|

| PPP-EFM | 63,598 | 63,573 | 25 |

| PPP-NCLPt#1 | 167,262 | 167,319 | −57 |

| PPP-NCLPt#2 | 159,863 | 159,855 | 8 |

| PPP-NCLPt#3 | 163,726 | 163,705 | 21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ficek, M.; Głowacki, M.J.; Gajewski, K.; Kunicki, P.; Gacka, E.; Sycz, K.; Mrózek, M.; Wojciechowski, A.M.; Gotszalk, T.P.; Gawlik, W.; et al. Integration of Fluorescent, NV-Rich Nanodiamond Particles with AFM Cantilevers by Focused Ion Beam for Hybrid Optical and Micromechanical Devices. Coatings 2021, 11, 1332. https://doi.org/10.3390/coatings11111332

Ficek M, Głowacki MJ, Gajewski K, Kunicki P, Gacka E, Sycz K, Mrózek M, Wojciechowski AM, Gotszalk TP, Gawlik W, et al. Integration of Fluorescent, NV-Rich Nanodiamond Particles with AFM Cantilevers by Focused Ion Beam for Hybrid Optical and Micromechanical Devices. Coatings. 2021; 11(11):1332. https://doi.org/10.3390/coatings11111332

Chicago/Turabian StyleFicek, Mateusz, Maciej J. Głowacki, Krzysztof Gajewski, Piotr Kunicki, Ewelina Gacka, Krystian Sycz, Mariusz Mrózek, Adam M. Wojciechowski, Teodor P. Gotszalk, Wojciech Gawlik, and et al. 2021. "Integration of Fluorescent, NV-Rich Nanodiamond Particles with AFM Cantilevers by Focused Ion Beam for Hybrid Optical and Micromechanical Devices" Coatings 11, no. 11: 1332. https://doi.org/10.3390/coatings11111332

APA StyleFicek, M., Głowacki, M. J., Gajewski, K., Kunicki, P., Gacka, E., Sycz, K., Mrózek, M., Wojciechowski, A. M., Gotszalk, T. P., Gawlik, W., & Bogdanowicz, R. (2021). Integration of Fluorescent, NV-Rich Nanodiamond Particles with AFM Cantilevers by Focused Ion Beam for Hybrid Optical and Micromechanical Devices. Coatings, 11(11), 1332. https://doi.org/10.3390/coatings11111332