Effect of the Post-Deposition Thermal Treatment on the Mechanical Properties of a Compositionally Modulated CrAlSiN-AlSiN Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Characterization Methods

3. Results and Discussion

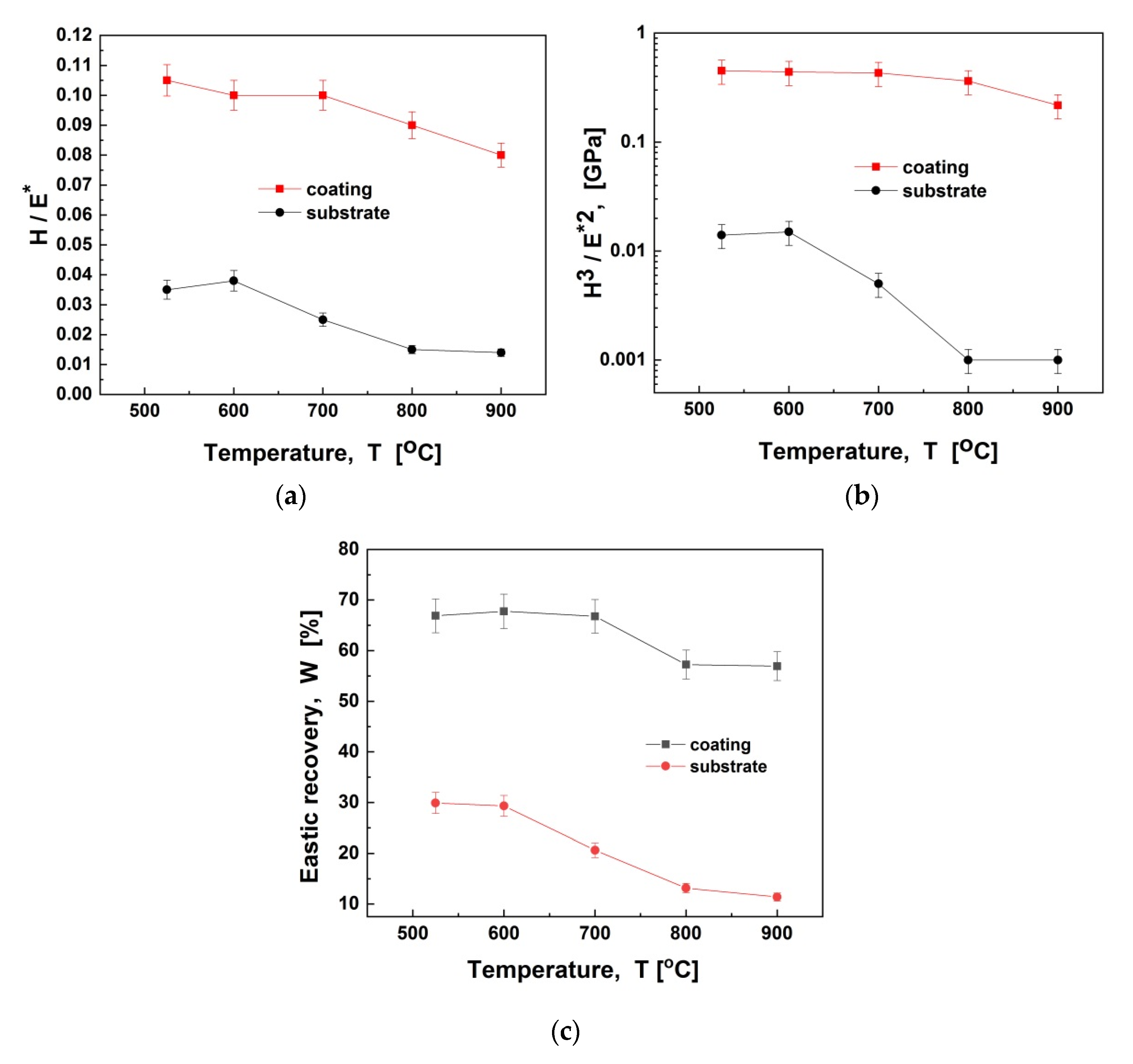

3.1. Mechanical Properties

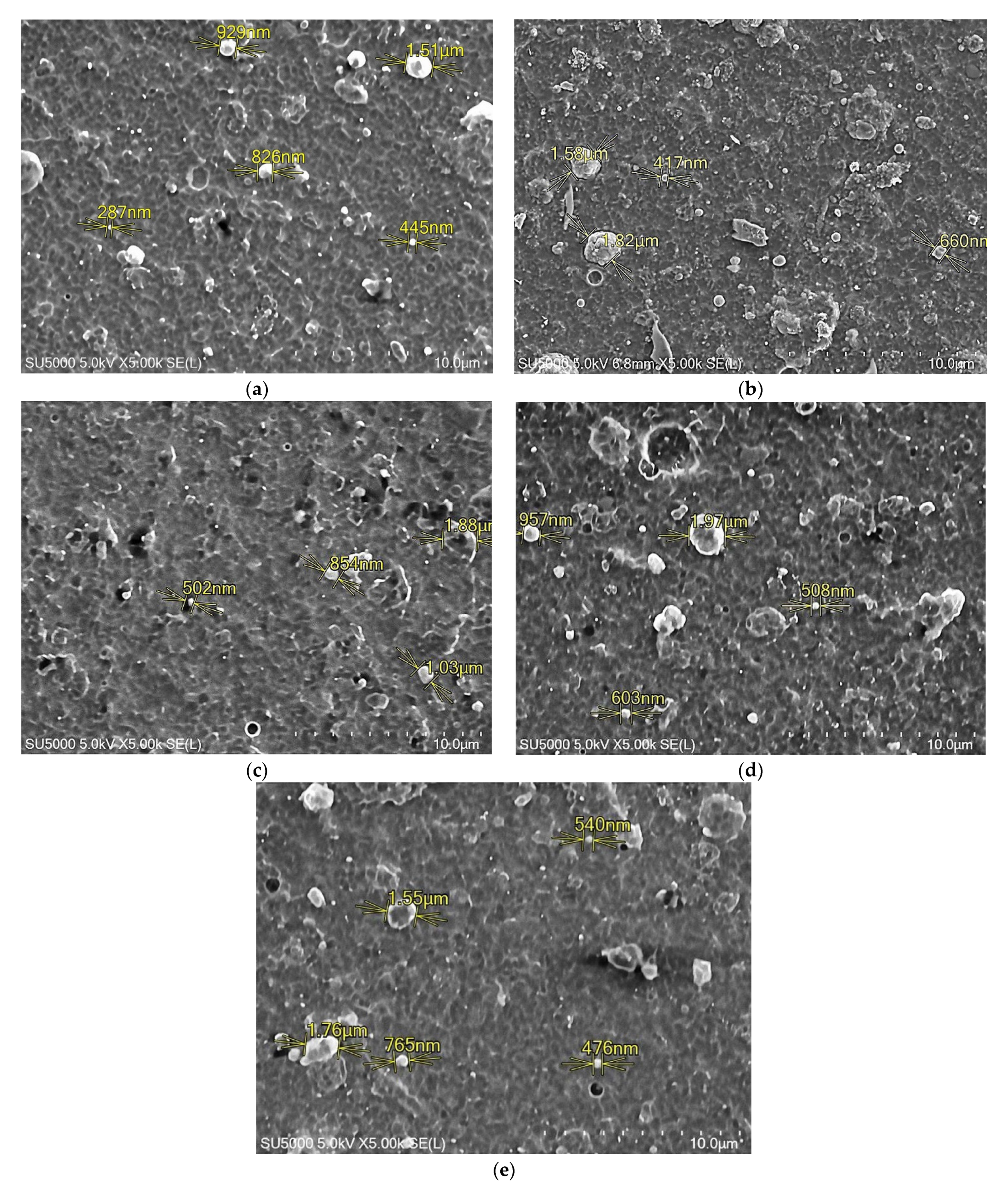

3.2. Surface Morphology and Composition

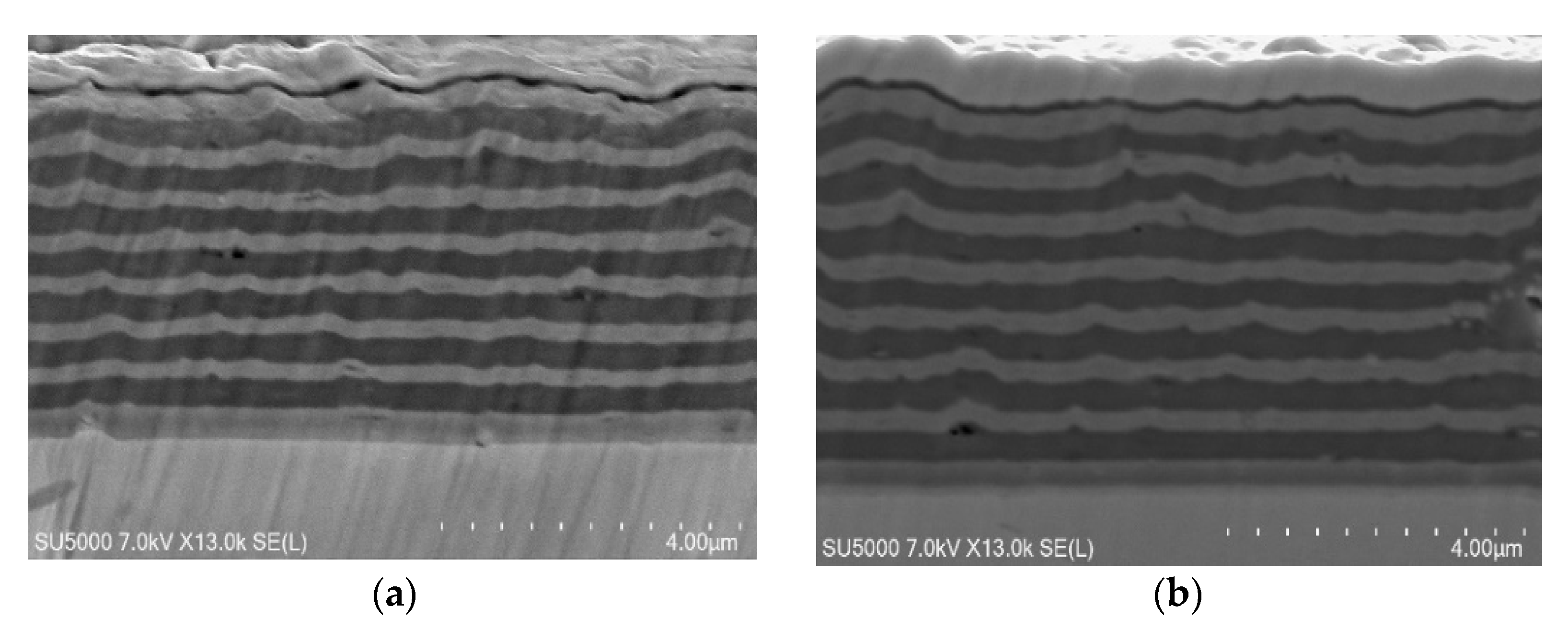

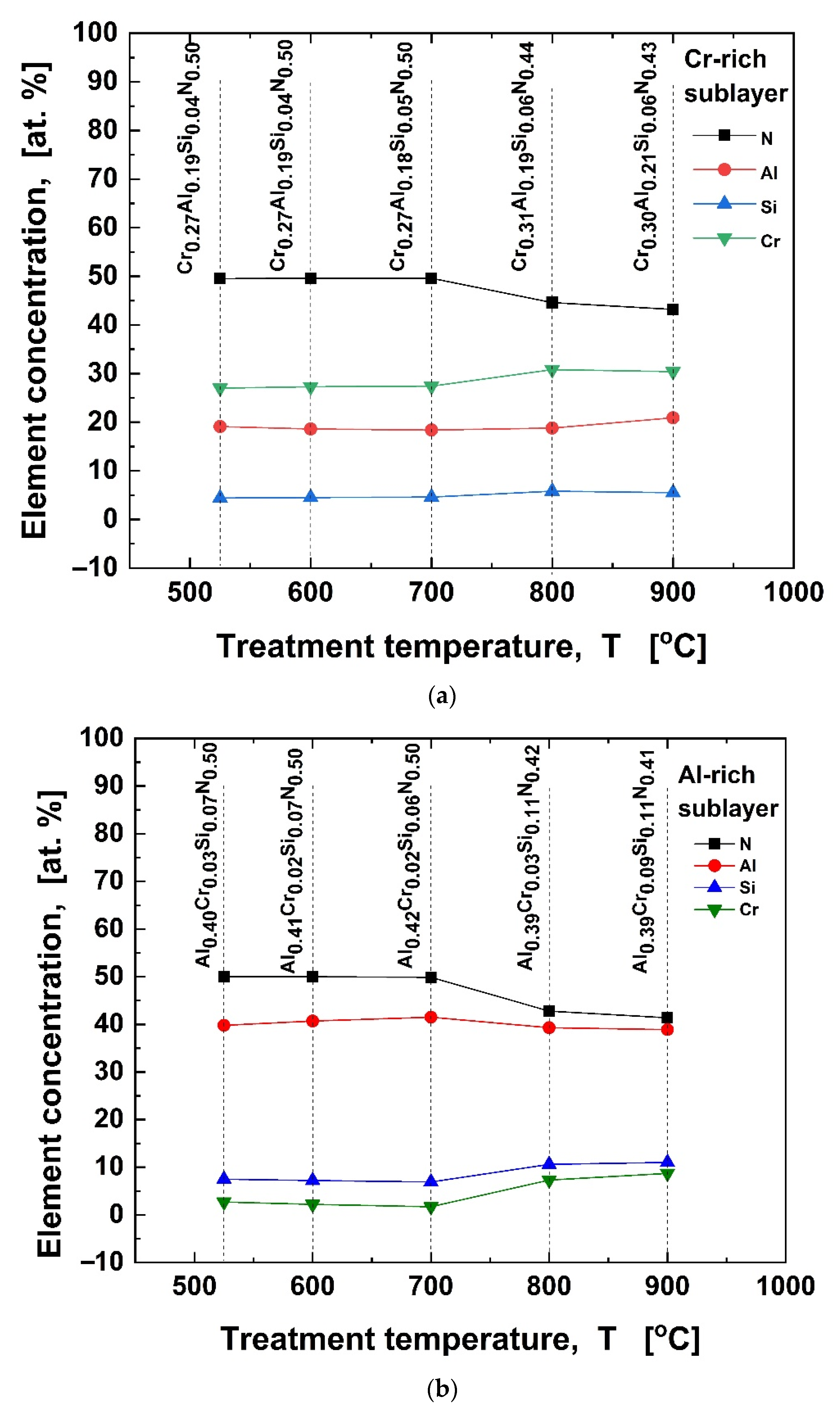

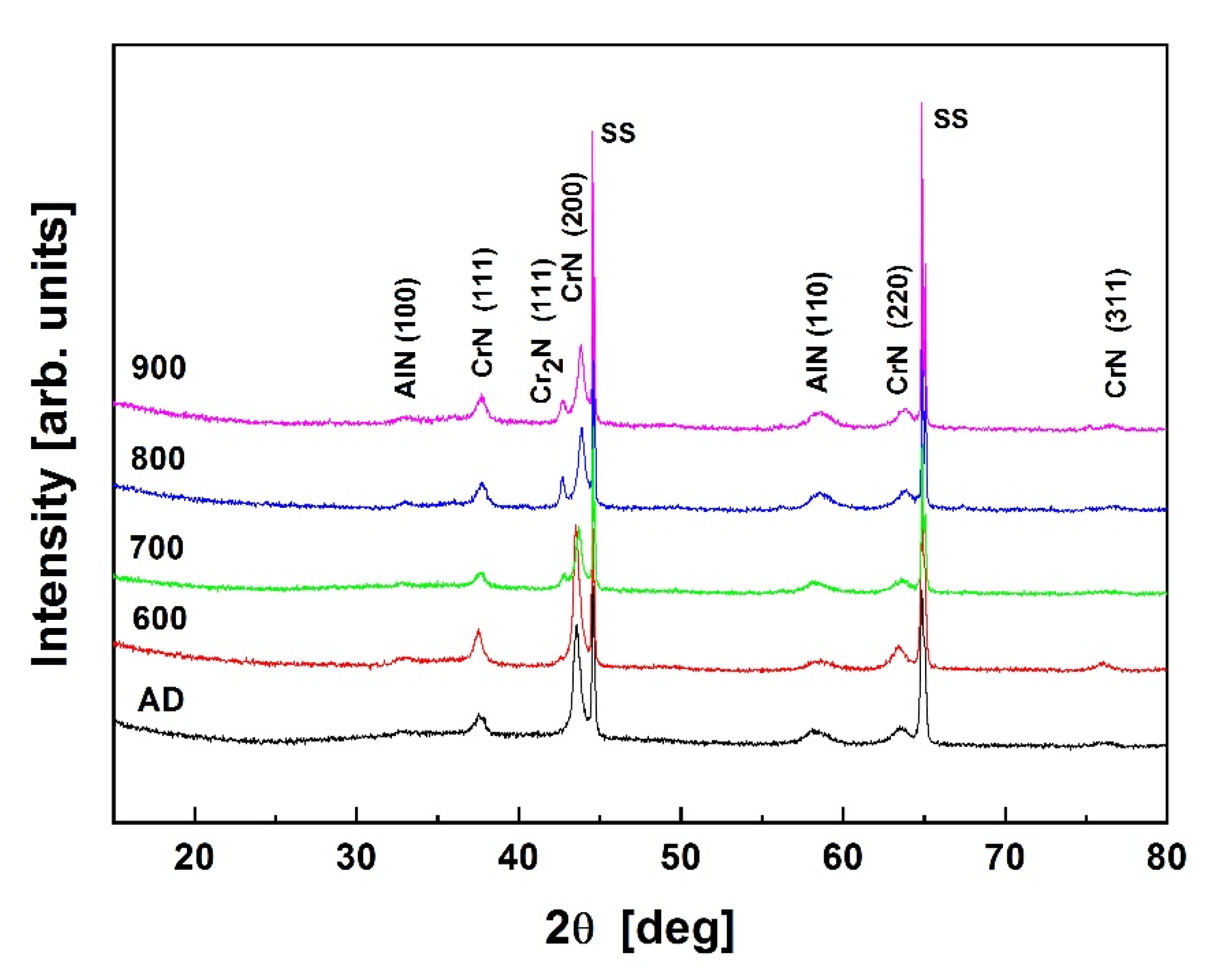

3.3. Coating Composition and Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Warcholinski, L.; Gilewich, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D. Structure and Properties of AlCrN Coatings Deposited Using Cathodic Arc Evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Wu, L.; Qiu, L.; Du, Y.; Zeng, F.; Lu, Q.; Tan, Z. Structure and Mechanical Properties of PVD and CVD TiAlSiN Coatings Deposited on Cemented Carbide. Crystals 2021, 11, 598. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Chang, C.P.; Wang, D.Y.; Yang, S.M.; Wu, W. High temperature oxidation resistance of CrAlSiN coatings synthesized by a cathodic arc deposition process. J. Alloy. Compd. 2008, 461, 336–341. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, S.-S.; Deng, X.; Liu, J.-Y.; Wang, Z.-P.; Qu, Z. Cutting Performance and Wear Behavior of TiAlN- and TiAlSiN-Coated Carbide Tools During Dry Milling of Ti-6Al-4V. Acta Metall. Sin. Engl. Lett. 2020, 33, 459–470. [Google Scholar] [CrossRef] [Green Version]

- Getachew, B.A.; Wang, T.-G. Effect of Modulation Period on the Structure and Properties AlTiN/AlTiSiN Multilayers. Intern. J. Eng. Res. Tech. 2020, 9, 62–68. Available online: https://www.ijert.org/volume-09-issue-06-june-2020 (accessed on 9 June 2020).

- Bouamerene, M.S.; Nouveau, C.; Aknouche, H.; Zerizer, A.; Almani, T.D.; Challali, M.O. A Study of Cr/CrN and Cr/CrN/CrAlN Multilayer Coatings for Permanent Mold Castings of Aluminum Alloys: Wear and Soldering Tendency. J. Mater. Eng. Struct. 2021, 8, 83–94. Available online: https://hal.archives-ouvertes.fr/hal-03274564/document (accessed on 31 October 2020).

- Li, G.; Lu, W.; Liu, S.; Li, C.; Zhou, Y.; Wang, Q. Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy. Compos. Part B 2021, 211, 108620. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials 2019, 12, 795. [Google Scholar] [CrossRef] [Green Version]

- Kawate, M.; Hashimoto, A.K.; Suzuki, T. Oxidation resistance of Cr1-XAlXN and Ti1-XAlXN films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- Carneiro, E.; Castro, J.D.; Marques, S.M.; Cavaleiro, A.; Carvalho, S. REACH regulation challenge: Development of alternative coatings to hexavalent chromium for milling applications. Surf. Coat. Technol. 2021, 418, 127271. [Google Scholar] [CrossRef]

- Horník, J.; Krum, S.; Tondl, D.; Puchnin, M.; Sachr, P.; Cvrcek, L. Multilayer coatings Ti/TiN, Cr/CrN and W/WN deposited by magnetron sputtering for improvement of adhesion to base materials. Acta Polytech. 2015, 55, 388–392. [Google Scholar] [CrossRef] [Green Version]

- Wieciński, P.; Smolik, J.; Garbacz, H.; Kurzydłowski, K.J. Thermal stability and corrosion resistance of Cr/CrN multilayer coatings on Ti6Al4V alloy. Solid State Phenom. 2015, 237, 47–53. [Google Scholar] [CrossRef]

- Samim, P.M.; Fattah-Alhosseini, A.; Elmkhah, H.; Imantalab, O. Structure and corrosion behavior of ZrN/CrN nano-multilayer coating deposited on AISI 304 stainless steel by CAE-PVD technique. J. Asian Ceram. Soc. 2020, 8, 460–469. [Google Scholar] [CrossRef] [Green Version]

- Illana, A.; Almandoz, E.; Fuentes, G.G.; Pérez, F.J.; Mato, S. Comparative study of CrAlSiN monolayer and CrN/AlSiN superlattice multilayer coatings: Behavior at high temperature in steam atmosphere. J. Alloy. Compd. 2019, 778, 652–661. [Google Scholar] [CrossRef]

- Liu, H.; Feng, Y.; Li, P.; Shi, X.; Zhu, H.; Shu, J.; Huang, Q.; Ge, F.; Huang, F. Enhanced plasticity of the oxide scales by in-situ formed Cr2O3/Cr heterostructures for Cr-based coatings on Zr alloy in 1200 °C steam. Corros. Sci. 2021, 184, 109361. [Google Scholar] [CrossRef]

- Sanchéz, J.E.; Sanchéz, O.M.; Ipaz, L.; Aperador, W.; Caicedo, J.C.; Amaya, C.; Landaverde, M.A.H.; Beltran, F.E.; Munoz-Saldana, M.; Zambrano, G. Mechanical, tribological, and electrochemical behavior of Cr1_x AlxN coatings deposited by r.f. reactive magnetron co-sputtering method. Appl. Surf. Sci. 2010, 256, 2380–2387. [Google Scholar] [CrossRef]

- Brizuela, M.; Garcia-Luis, A.; Braceras, I.; Oñate, J.I.; Sánchez-López, J.C.; Martínez- Martínez, D.; Lopez-Cartes, C.; Fernandez, A. Magnetron sputtering of Cr(Al)N coatings: Mechanical and tribological study. Surf. Coat. Technol. 2005, 200, 192–197. [Google Scholar] [CrossRef]

- Zheng, K.; Liu, P.; Li, W.; Ma, F.; Liu, X.; Chen, X. Investigation on microstructure and properties of CrAlN/AlON nanomultilayers. Appl. Surf. Sci. 2011, 257, 9583–9586. [Google Scholar] [CrossRef]

- Nose, M.; Kawabata, T.; Watanuki, T.; Ueda, S.; Fujii, K.; Matsuda, K.; Ikeno, S. Mechanical properties and oxidation resistance of CrAlN/BN nanocomposite coatings prepared by reactive dc and rf co-sputtering. Surf. Coat. Technol. 2011, 205, 533–537. [Google Scholar] [CrossRef]

- Li, P.; Chen, L.; Wang, S.Q.; Yang, B.; Du, Y.; Li, J.; Wu, M.J. Microstructure, mechanical and thermal properties of TiAlN/CrAlN multilayer coatings. Int. J. Refract. Met. Hard Mater. 2013, 40, 51–57. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Zhao, Y.; Ma, F.; Liu, X.; Chen, X.; He, D. Structure, mechanical properties and thermal stability of CrAlN/ZrO2 nanomultilayers deposited by magnetron sputtering. J. Alloy. Compd. 2013, 562, 5–10. [Google Scholar] [CrossRef]

- Qiua, Y.; Zhang, S.; Leed, J.-W.; Li, B.; Wang, Y.; Zhao, D. Self-lubricating CrAlN/VN multilayer coatings at room temperature. Appl. Surf. Sci. 2013, 279, 189–196. [Google Scholar] [CrossRef]

- Kim, Y.J.; Byun, T.J.; Han, J.G. Bilayer period dependence of CrN/CrAl nanoscale multilayer thin films. Superlattices Microstruct. 2009, 45, 73–79. [Google Scholar] [CrossRef]

- Beliardouh, N.E.; Bouzid, K.; Nouveau, C.; Tlili, B.; Walock, M.J. Tribological and electrochemical performances of Cr/CrN and Cr/CrN/CrAlN multilayer coatings deposited by RF magnetron sputtering. Tribol. Int. 2015, 82, 443–452. Available online: http://hdl.handle.net/10985/10069 (accessed on 24 March 2014). [CrossRef] [Green Version]

- Fan, Q.; Liang, Y.; Wu, Z.; Liu, Y.; Wang, T. Microstructure and Properties of CrAlSiN Coatings Deposited by HiPIMS and Direct-Current Magnetron Sputtering. Coatings 2019, 9, 512. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.-F.; Huang, C.-H.; Lin, C.-Y.; Yang, F.-C.; Chang, C.-L. Effects of Substrate Rotation Speed on Structure and Adhesion Properties of CrN/CrAlSiN Multilayer Coatings Prepared Using High-Power Impulse Magnetron Sputtering. Coatings 2020, 10, 742. [Google Scholar] [CrossRef]

- Wang, R.; Mei, H.; Zhang, T.; Wang, Q. Influence and V addition on the microstructure, mechanical, oxidation and tribological properties of AlCrSiN coatings. Surf. Coat. Technol. 2021, 407, 126767. [Google Scholar] [CrossRef]

- Dai, W.; Wang, Q.; Kim, K.-H.; Kwon, S.-H. Al2O3/CrAlSiN multilayer coating deposited using hybrid magnetron sputtering and atomic layer deposition. Ceram. Int. 2019, 45, 11335–11341. [Google Scholar] [CrossRef]

- Punnet, C.; Valleti, K.; Gopal, A.V. Low Friction Coefficient Nanocomposite CrAlSiN/ Cradient-CrAlSiCN Coatings for High Speed/Dry Machining Applications. J. Manuf. Sci. Eng. 2021, 143, 081013. [Google Scholar] [CrossRef]

- Kolaklieva, L.; Kakanakov, R.; Stefanov, P.; Kovacheva, D.; Atanasova, G.; Russev, S.; Chitanov, V.; Cholakova, T.; Bahchedjiev, C. Mechanical and Structural Properties of Nanocomposite CrAlSiN–AlSiN Coating with Periodically Modulated Composition. Coatings 2020, 10, 41. [Google Scholar] [CrossRef] [Green Version]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C. Measurement of Thin Film Mechanical Properties Using Nanoindentation. MRS Bull. 1992, 17, 28–33. [Google Scholar] [CrossRef]

- Drnovsec, A.; Vo, H.i.T.; Figueiredo, M.R.; Kolozsvari, S.; Hosemann, P.; Franz, R. High temperature fracture toughness of single-layer CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2021, 409, 126909. [Google Scholar] [CrossRef]

- Ho, W.-Y.; Hsu, C.-H.; Chen, C.-W.; Wang, D.-Y. Characteristics of PVD-CrAlSiN films after post-coat heat treatments in nitrogen atmosphere. Appl. Surf. Sci. 2011, 257, 3770–3775. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Leynad, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Sun, S.Q.; Ye, Y.W.; Wang, Y.X.; Liu, M.Q.; Liu, X.; Li, J.L.; Wang, L.P. Structure and tribological performances of CrAlSiN coatings with different Si percentages in seawater. Tribol. Int. 2017, 115, 591–599. [Google Scholar] [CrossRef]

- Drnovšek, A.; de Figueiredo, M.R.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Wang, Q.; Li, M. A superhard CrAlSiN superlattice coating deposited by a multi-arc ion plating: II—Thermal stability and oxidation resistance. Surf. Coat. Technol. 2013, 214, 153–159. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chiu, W.-T.; Hung, J.-P. Mechanical properties and high temperature oxidation of CrAlSiN/TiVN hard coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2016, 303, 18–24. [Google Scholar] [CrossRef]

- Pulugurtha, S.R.; Bhat, D.G.; Gordon, M.H.; Shultz, J.; Staia, M.; Joshi, S.V.; Govindarajan, S. Mechanical and tribological properties of compositionally graded CrAlN films deposited by AC reactive magnetron sputtering. Surf. Coat. Technol. 2007, 202, 1160–1166. [Google Scholar] [CrossRef]

- Wan, X.S.; Zhao, S.S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr–N coatings deposited by arc ion plating. Surf. Coat. Technol. 2010, 204, 1800–1810. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, T.; Yun, J.M.; Chang, K.M.; Wang, Q.; Kim, K.H. Microstructure, Mechanical, Oxidation and Corrosion Properties of the Cr-Al-Si-N Coatings Deposited by a Hybrid Sputtering System. Coatings 2017, 7, 119. [Google Scholar] [CrossRef] [Green Version]

- Li, B.-S.; Wang, T.-G.; Ding, J.; Cai, Y.; Shi, J.; Zhang, X. Influence of N2/Ar Flow Ratio on Microstructure and Properties of the AlCrSiN Coatings Deposited by High-Power Impulse Magnetron Sputtering. Coatings 2018, 8, 3. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.F.; Yan, W.Q.; Chen, L.; Liao, B.; Hua, Q.S.; Zhang, X. A hard yet tough CrAlSiN nanocomposite coating for blades deposited by filtered cathode vacuum arc. Surf. Interfaces 2021, 25, 101156. [Google Scholar] [CrossRef]

- Gahlin, R.; Bromark, M.; Hedenqvist, P.; Hogmark, S.; Hakansson, G. Properties of TiN and CrN coatings deposited at low temperature using reactive arc-evaporation. Surf. Coat. Technol. 1995, 76, 174–180. [Google Scholar] [CrossRef]

- Münz, W.D.; Hurkmans, T.; Keiren, G.; Trinh, T. Comparison of TiAlN coatings grown by unbalanced magnetron and arc bond sputtering techniques. J. Vac. Sci. Technol. A 1993, 11, 2583–2589. [Google Scholar] [CrossRef]

- Veprek, S.; Männling, H.-D.; Jilek, M.; Holubar, P. Avoiding the high-temperature decomposition and softening of (Al1−xTix)N coatings by the formation of stable superhard nc-(Al1−xTix)N/a-Si3N4 nanocomposite. Mater. Sci. Eng. 2004, A366, 202–205. [Google Scholar] [CrossRef]

- Chen, C.-S.; Liu, C.-P.; Tsao, C.-Y.A. Influence of growth temperature on microstructure and mechanical properties of nanocrystalline zirconium carbide films. Thin Solid Films 2005, 479, 130–136. [Google Scholar] [CrossRef]

- Schlögl, M.; Paulitsch, J.; Keckes, J.; Mayrhofer, P.H. Influence of AlN layers on mechanical properties and thermal stability of Cr-based nitride coatings. Thin Solid Films 2013, 531, 113–118. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Microstructure, mechanical and tribological properties of Cr1−xAlxN films deposited by pulsed-closed field unbalanced magnetron sputtering (P-CFUBMS). Surf. Coat. Technol. 2006, 201, 4329–4334. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings—Structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- NORAN Instruments. Energy-Dispersive X-ray Microanalysis—An Introduction; NORAN Instruments: Middleton, WI, USA; Kevex Instruments Inc.: San Carlos, CA, USA, 1999; Available online: https://www.epfl.ch/research/facilities/cime/wp-content/uploads/2019/02/Introduction-to-EDS.pdf (accessed on 5 February 2019).

- Chen, H.W.; Chan, Y.C.; Lee, J.W.; Duh, J.G. Oxidation behavior of Si-doped nanocomposite CrAlSiN coatings. Surf. Coat. Technol. 2010, 205, 1189–1194. [Google Scholar] [CrossRef]

| Treatment Temperature | Feature | Element Concentration, at.% | |||

|---|---|---|---|---|---|

| N | Al | Si | Cr | ||

| As-deposited | matrix | 49.5 | 17.7 | 6.4 | 26.4 |

| macroparticle | 45.9 | 17.6 | 6.9 | 29.6 | |

| crater | 32.7 | 33.4 | 6.4 | 27.5 | |

| 600 °C | matrix | 49.9 | 18.3 | 4.8 | 27.0 |

| macroparticle | 41.3 | 21.8 | 5.5 | 31.4 | |

| crater | 38.5 | 41.7 | 8.7 | 11.1 | |

| 700 °C | matrix | 49.9 | 18.9 | 5.0 | 26.9 |

| macroparticle | 37.7 | 23.8 | 5.7 | 32.8 | |

| crater | 34.6 | 34.0 | 7.3 | 24.1 | |

| 800 °C | matrix | 48.2 | 19.6 | 4.8 | 27.4 |

| macroparticle | 40.3 | 16.4 | 9.2 | 34.1 | |

| crater | 36.5 | 33.7 | 6.8 | 23.0 | |

| 900 °C | matrix | 44.6 | 18.0 | 6.8 | 30.6 |

| macroparticle | 40.2 | 19.2 | 7.7 | 32.9 | |

| crater | 33.6 | 32.7 | 7.4 | 26.3 | |

| Diameter [µm] | D1 Inner | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 Outer |

| Test #1 | 461.81 | 493.22 | 536.81 | 574.19 | 601.20 | 634.75 | 664.50 | 694.09 | 730.61 |

| Layer th. [µm] | Total | LT 1–2 | LT 2–3 | LT 3–4 | LT 4–5 | LT 5–6 | LT 6–7 | LT 7–8 | LT 8–9 |

| Test #1 | 4.008 | 0.375 | 0.561 | 0.519 | 0.397 | 0.519 | 0.483 | 0.503 | 0.651 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolaklieva, L.; Kakanakov, R.; Kovacheva, D.; Chitanov, V.; Cholakova, T.; Bahchedjiev, C.; Kolchev, S. Effect of the Post-Deposition Thermal Treatment on the Mechanical Properties of a Compositionally Modulated CrAlSiN-AlSiN Coating. Coatings 2021, 11, 1311. https://doi.org/10.3390/coatings11111311

Kolaklieva L, Kakanakov R, Kovacheva D, Chitanov V, Cholakova T, Bahchedjiev C, Kolchev S. Effect of the Post-Deposition Thermal Treatment on the Mechanical Properties of a Compositionally Modulated CrAlSiN-AlSiN Coating. Coatings. 2021; 11(11):1311. https://doi.org/10.3390/coatings11111311

Chicago/Turabian StyleKolaklieva, Lilyana, Roumen Kakanakov, Daniela Kovacheva, Vasiliy Chitanov, Tetyana Cholakova, Christo Bahchedjiev, and Stefan Kolchev. 2021. "Effect of the Post-Deposition Thermal Treatment on the Mechanical Properties of a Compositionally Modulated CrAlSiN-AlSiN Coating" Coatings 11, no. 11: 1311. https://doi.org/10.3390/coatings11111311

APA StyleKolaklieva, L., Kakanakov, R., Kovacheva, D., Chitanov, V., Cholakova, T., Bahchedjiev, C., & Kolchev, S. (2021). Effect of the Post-Deposition Thermal Treatment on the Mechanical Properties of a Compositionally Modulated CrAlSiN-AlSiN Coating. Coatings, 11(11), 1311. https://doi.org/10.3390/coatings11111311