Fire Performance of Intumescent Waterborne Coatings with Encapsulated APP for Wood Constructions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

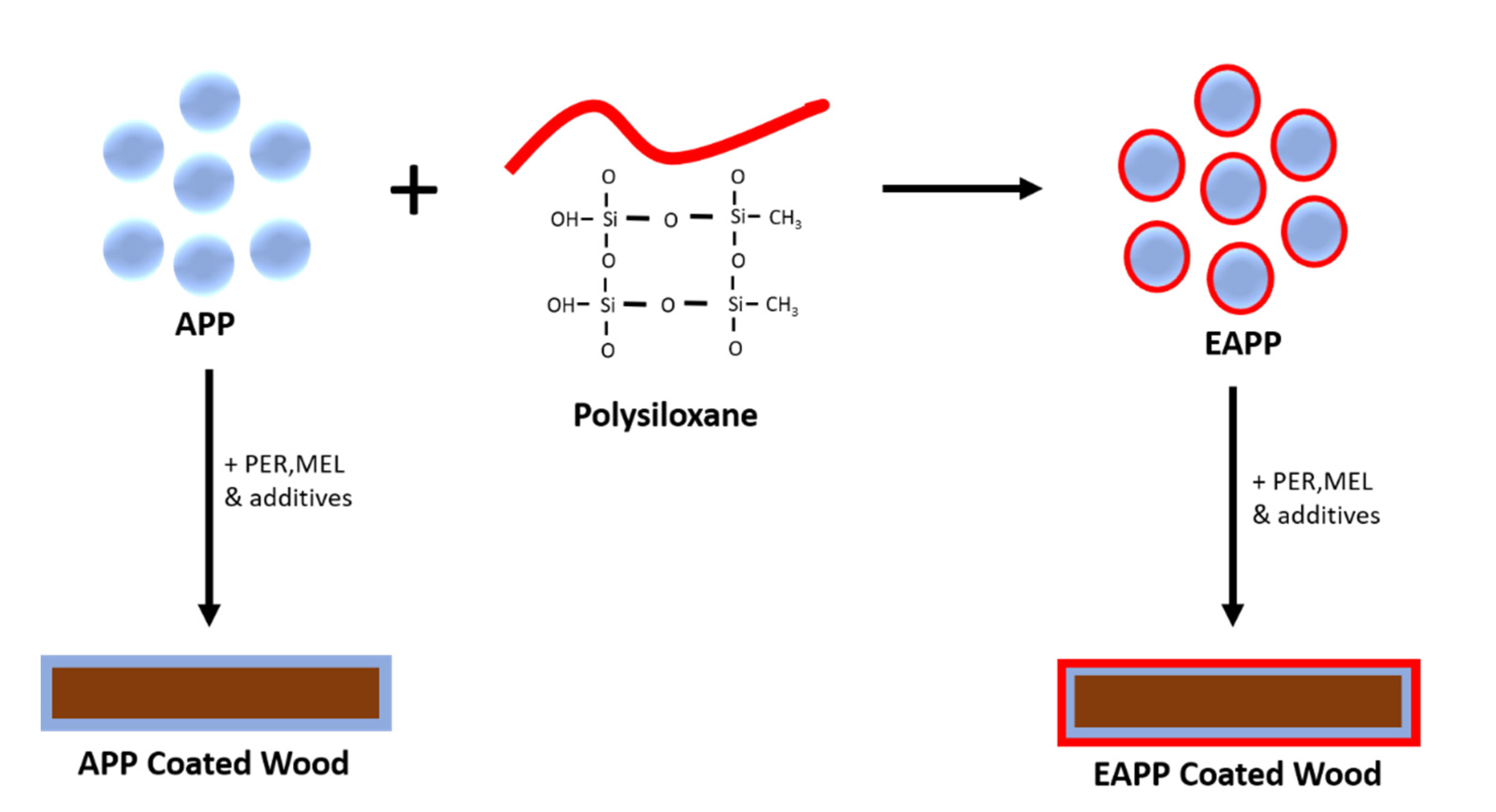

2.1.1. Preparation of Intumescent Powder Blend

2.1.2. Preparation of Intumescent Waterborne Coating

2.1.3. Preparation of Water Based Epoxy Primer

2.1.4. Wood Sample Preparation

2.1.5. Coating Deposition

2.2. Methods

2.2.1. X-ray Fluorescence (XRF) Analysis

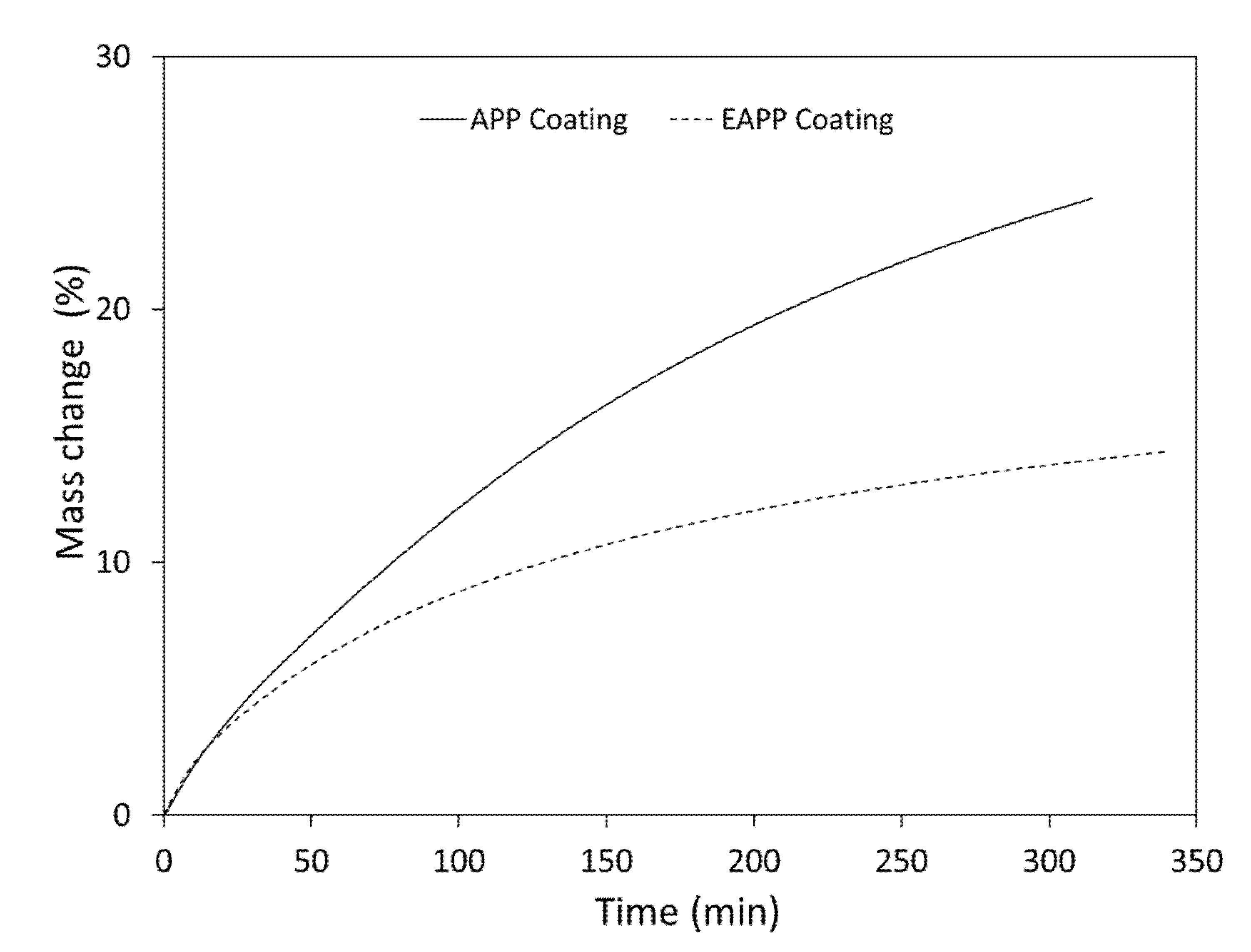

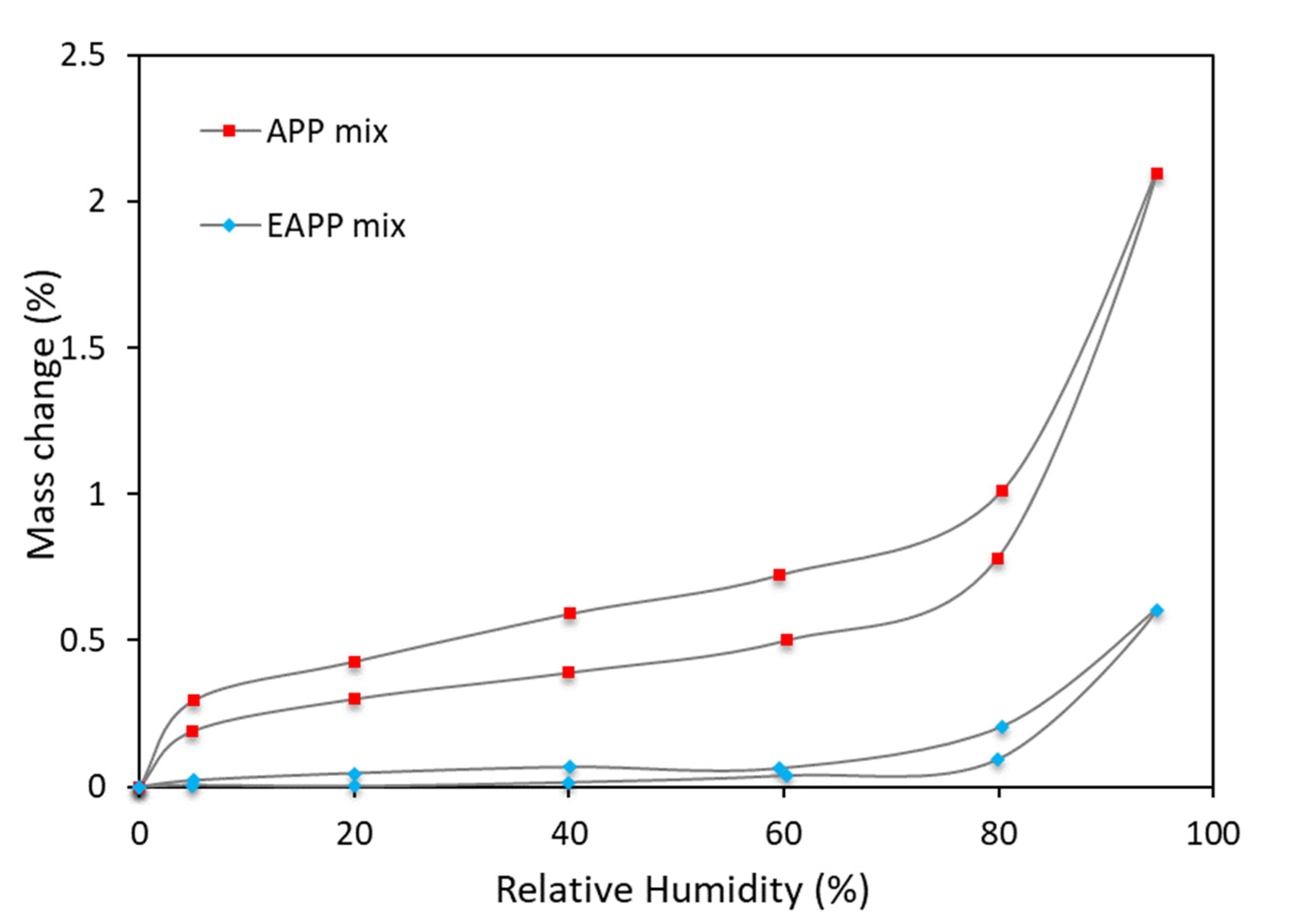

2.2.2. Dynamic Vapor Sorption Isotherm and Water Uptake

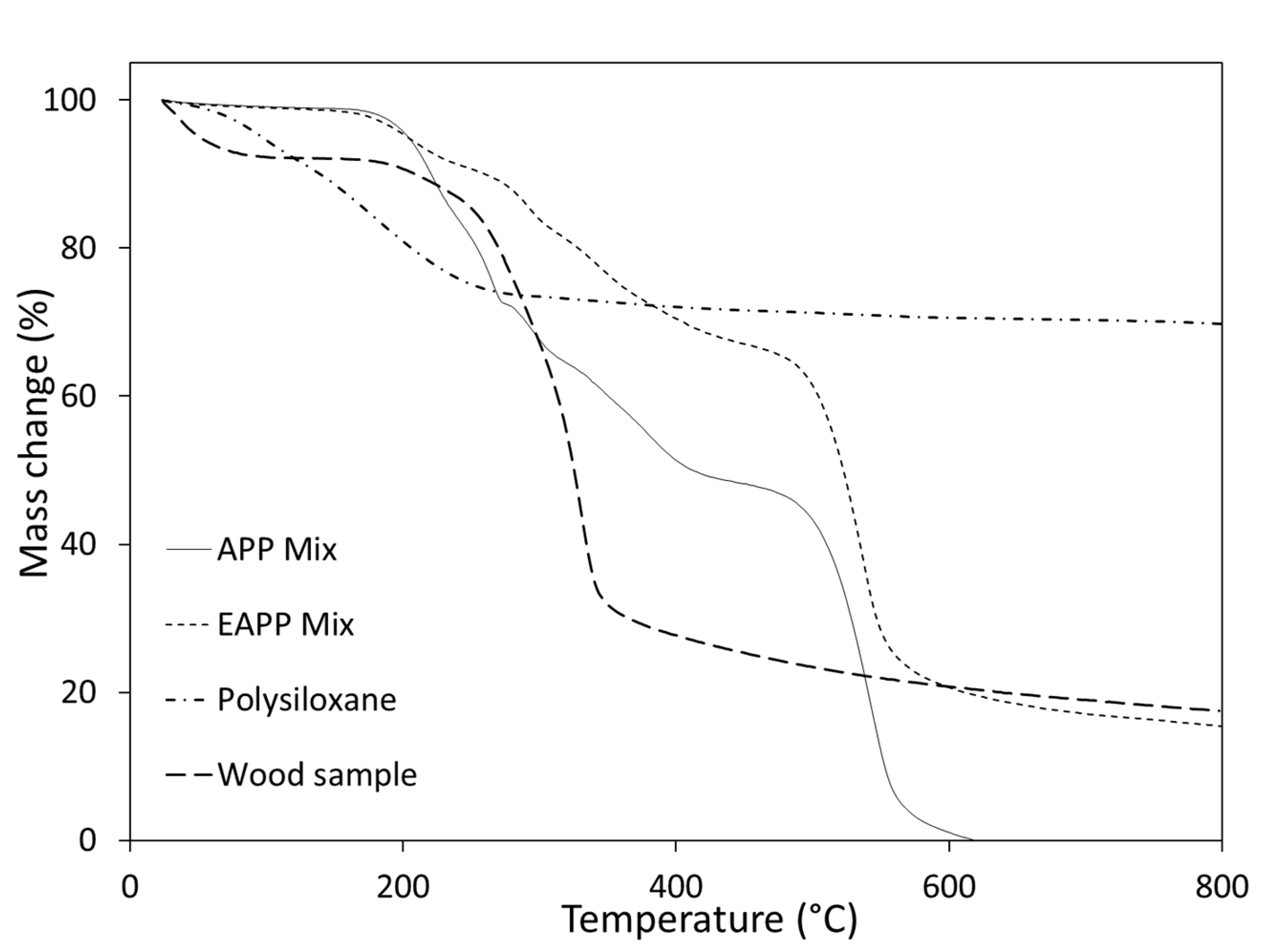

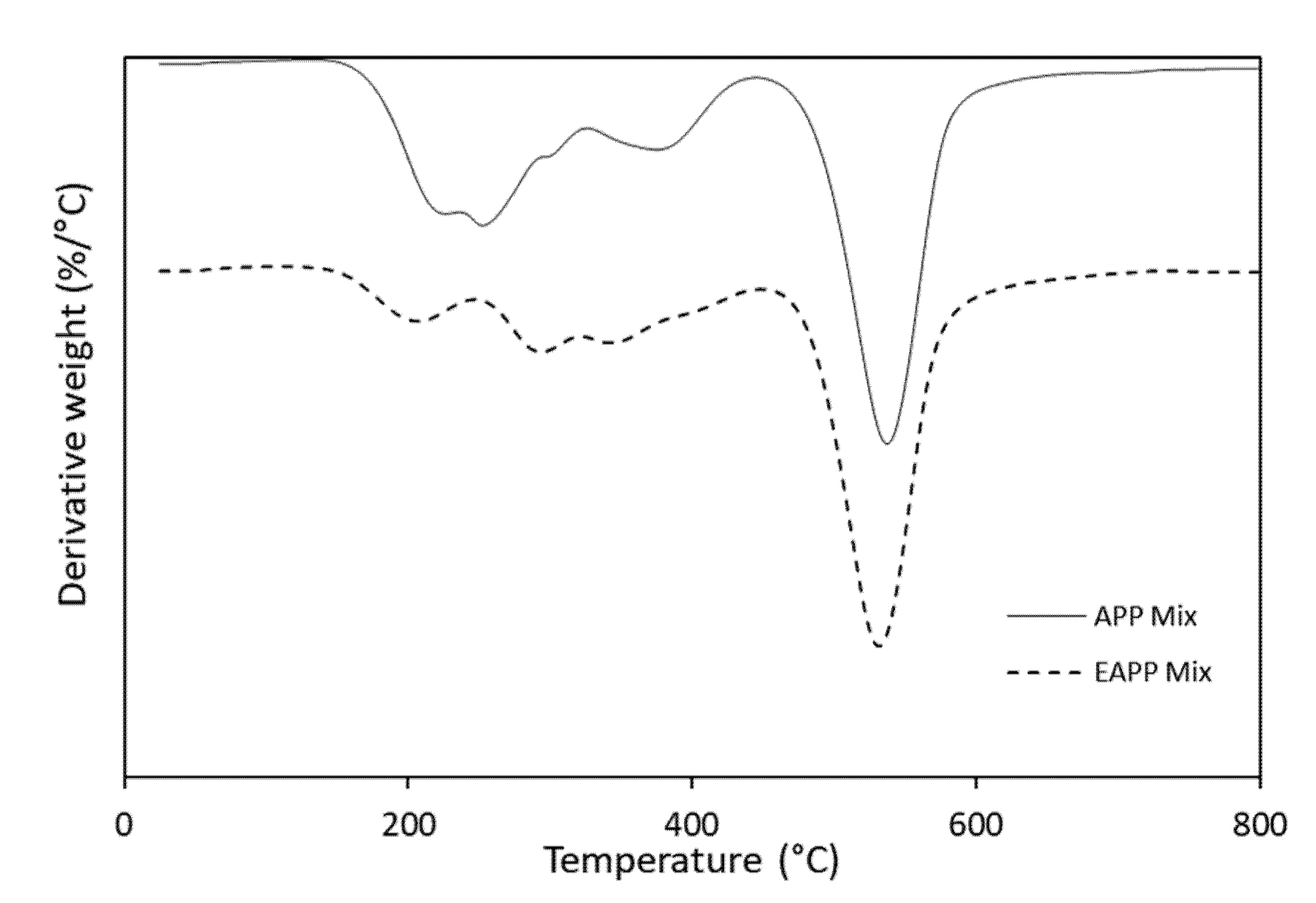

2.2.3. Thermogravimetric and Differential Thermogravimetric Analysis (TG/DTG)

2.2.4. Fourier Transform-Infrared (FTIR) Spectroscopy

2.2.5. Accelerated Aging Tests

2.2.6. Cone Calorimeter Test

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grześkowiak, W. Effectiveness of new wood fire retardants using a cone calorimeter. J. Fire Sci. 2017, 35, 565–576. [Google Scholar] [CrossRef]

- Kaboorani, A.; Auclair, N.; Riedl, B.; Landry, V. Physical and morphological properties of UV-cured cellulose nanocrystal (CNC) based nanocomposite coatings for wood furniture. Prog. Org. Coatings 2016, 93, 17–22. [Google Scholar] [CrossRef]

- White, R.H. Use of Coatings To Improve Fire Resistance of Wood. In Fire Resistive Coatings: The Need for Standards; ASTM International: West Conshohocken, PA, USA, 1983; pp. 24–39. [Google Scholar] [CrossRef]

- Lowden, L.; Hull, T. Flammability behaviour of wood and a review of the methods for its reduction. Fire Sci. Rev. 2013, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Goldsmith, F.P. Fire Retardant Coatings: An Evaluation of Fire Retardant Coatings as a Means of Protecting Wood Panels; University of British Columbia Library: Vancouver, BC, Canada, 2011. [Google Scholar]

- Mariappan, T. Recent developments of intumescent fire protection coatings for structural steel: A review. J. Fire Sci. 2016, 34, 120–163. [Google Scholar] [CrossRef]

- Sun, F.C.; Fu, J.H.; Peng, Y.X.; Jiao, X.M.; Liu, H.; Du, F.P.; Zhang, Y.F. Dual-functional intumescent fire-retardant/self-healing water-based plywood coatings. Prog. Org. Coatings 2021, 154, 106187. [Google Scholar] [CrossRef]

- Aziz, H.; Ahmad, F. Effects from nano-titanium oxide on the thermal resistance of an intumescent fire retardant coating for structural applications. Prog. Org. Coatings 2016, 101, 431–439. [Google Scholar] [CrossRef]

- Eremina, T.; Korolchenko, D. Fire protection of building constructions with the use of fire-retardant intumescent compositions. Buildings 2020, 10, 185. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, C.L.; Zhao, J.; Wang, J.S.; Chen, L.; Wang, Y.Z. An efficiently halogen-free flame-retardant long-glass-fiber-reinforced polypropylene system. Polym. Degrad. Stab. 2011, 96, 363–370. [Google Scholar] [CrossRef]

- Alongi, J.; Han, Z.; Bourbigot, S. Intumescence: Tradition versus novelty. A comprehensive review. Prog. Polym. Sci. 2014, 51, 28–73. [Google Scholar] [CrossRef]

- Bellayer, S.; Jimenez, M.; Barrau, S.; Bourbigot, S. Fire retardant sol-gel coatings for flexible polyurethane foams. RSC Adv. 2016, 6, 28543–28554. [Google Scholar] [CrossRef]

- Deng, C.L.; Du, S.L.; Zhao, J.; Shen, Z.Q.; Deng, C.; Wang, Y.Z. An intumescent flame retardant polypropylene system with simultaneously improved flame retardancy and water resistance. Polym. Degrad. Stab. 2014, 108, 97–107. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, M.; Arora, S. Thermal degradation and flammability studies of wood coated with fly ash intumescent composites. J. Indian Acad. Wood Sci. 2013, 10, 125–133. [Google Scholar] [CrossRef]

- Popescu, C.M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products—An overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Sheng, H.; Shi, Y.; Hu, W.; Hong, N.; Zeng, W.; Ge, H.; Yu, X.; Song, L.; Hu, Y. Recent advances for microencapsulation of flame retardant. Polym. Degrad. Stab. 2015, 113, 96–109. [Google Scholar] [CrossRef]

- Idumah, C.I. Emerging advancements in flame retardancy of polypropylene nanocomposites. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Kazanci, B.; Cellat, K.; Paksoy, H. Preparation, characterization, and thermal properties of novel fire-resistant microencapsulated phase change materials based on paraffin and a polystyrene shell. RSC Adv. 2020, 10, 24134–24144. [Google Scholar] [CrossRef]

- Huang, Z.; Ruan, B.; Wu, J.; Ma, N.; Jiang, T.; Tsai, F.C. High-efficiency ammonium polyphosphate intumescent encapsulated polypropylene flame retardant. J. Appl. Polym. Sci. 2021, 138, 50413. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-retardant surface treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Tang, G.; Shi, Y.; Hu, W.; Lu, H.; Song, L.; Hu, Y. Preparation of silane precursor microencapsulated intumescent flame retardant and its enhancement on the properties of ethylene–vinyl acetate copolymer cable. Compos. Sci. Technol. 2012, 72, 1042–1048. [Google Scholar] [CrossRef]

- Qiu, J.; Lai, X.; Li, H.; Gao, J.; Zeng, X.; Liao, X. Facile fabrication of a novel polyborosiloxane-decorated layered double hydroxide for remarkably reducing fire hazard of silicone rubber. Compos. Part B Eng. 2019, 175, 107068. [Google Scholar] [CrossRef]

- Xu, B.; Wu, X.; Ma, W.; Qian, L.; Xin, F.; Qiu, Y. Synthesis and characterization of a novel organic-inorganic hybrid char-forming agent and its flame-retardant application in polypropylene composites. J. Anal. Appl. Pyrolysis 2018, 134, 231–242. [Google Scholar] [CrossRef]

- Wilke, A.; Langfeld, K.; Ulmer, B.; Andrievici, V.; Hörold, A.; Limbach, P.; Bastian, M.; Schartel, B. Halogen-free multicomponent flame retardant thermoplastic styrene–ethylene–butylene–styrene elastomers based on ammonium polyphosphate–expandable graphite synergy. Ind. Eng. Chem. Res. 2017, 56, 8251–8263. [Google Scholar] [CrossRef]

- Ran, G.; Liu, X.; Guo, J.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Improving the flame retardancy and water resistance of polylactic acid by introducing polyborosiloxane microencapsulated ammonium polyphosphate. Compos. Part B Eng. 2019, 173, 106772. [Google Scholar] [CrossRef]

- Liu, X.; Sun, J.; Zhang, S.; Guo, J.; Tang, W.; Li, H.; Gu, X. Effects of carboxymethyl chitosan microencapsulated melamine polyphosphate on the flame retardancy and water resistance of thermoplastic polyurethane. Polym. Degrad. Stab. 2019, 160, 168–176. [Google Scholar] [CrossRef]

- Jia, Y.-W.; Zhao, X.; Fu, T.; Li, D.-F.; Guo, Y.; Wang, X.-L.; Wang, Y.-Z. Synergy effect between quaternary phosphonium ionic liquid and ammonium polyphosphate toward flame retardant PLA with improved toughness. Compos. Part B Eng. 2020, 197, 108192. [Google Scholar] [CrossRef]

- Hoang, D.T.; Schorr, D.; Landry, V.; Blanchet, P.; Vanslambrouck, S.; Dagenais, C. Preparation and characterisation of flame retardant encapsulated with functionalised silica-based shell. J. Microencapsul. 2018, 35, 428–438. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Jiang, Y.; Meng, Y.; Li, Y.; Han, Z.; Liu, X.; Li, H.; Sun, J.; Fei, B.; Gu, X.; et al. The encapsulation of intumescent flame retardants by poly-siloxane for thermoplastic polyolefin: Fire safety and water resistance. Polym. Degrad. Stab. 2021, 188, 109561. [Google Scholar] [CrossRef]

- Li, R.-M.; Deng, C.; Deng, C.-L.; Dong, L.-P.; Di, H.-W.; Wang, Y.-Z. An efficient method to improve simultaneously the water resistance, flame retardancy and mechanical properties of POE intumescent flame-retardant systems. RSC Adv. 2015, 5, 16328–16339. [Google Scholar] [CrossRef]

- Liu, Z.; Dai, M.; Zhang, Y.; Gao, X.; Zhang, Q. Preparation and performances of novel waterborne intumescent fire retardant coatings. Prog. Org. Coatings 2016, 95, 100–106. [Google Scholar] [CrossRef]

- Shen, M.Y.; Chen, W.J.; Kuan, C.F.; Kuan, H.C.; Yang, J.M.; Chiang, C.L. Preparation, characterization of microencapsulated ammonium polyphosphate and its flame retardancy in polyurethane composites. Mater. Chem. Phys. 2016, 173, 205–212. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Jiang, Y.; Lawrence, M. Modification of hemp shiv properties using water-repellent sol–gel coatings. J. Sol-Gel Sci. Technol. 2018, 86, 187–197. [Google Scholar] [CrossRef] [Green Version]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Jiang, Y. Resilient hemp shiv aggregates with engineered hygroscopic properties for the building industry. Constr. Build. Mater. 2019, 212, 247–253. [Google Scholar] [CrossRef] [Green Version]

- Camino, G.; Grassie, N.; McNeill, I.C. Influence of the fire retardant, ammonium polyphosphate, on the thermal degradation of poly(methyl methacrylate). J. Polym. Sci. Polym. Chem. Ed. 1978, 16, 95–106. [Google Scholar] [CrossRef]

- Ni, J.; Chen, L.; Zhao, K.; Hu, Y.; Song, L. Preparation of gel-silica/ammonium polyphosphate core-shell flame retardant and properties of polyurethane composites. Polym. Adv. Technol. 2011, 22, 1824–1831. [Google Scholar] [CrossRef]

- Wu, K.; Wang, Z.; Hu, Y. Microencapsulated ammonium polyphosphate with urea–melamine–formaldehyde shell: Preparation, characterization, and its flame retardance in polypropylene. Polym. Adv. Technol. 2008, 19, 1118–1125. [Google Scholar] [CrossRef]

- Gao, S.; Li, B.; Bai, P.; Zhang, S. Effect of polysiloxane and silane-modified SiO2 on a novel intumescent flame retardant polypropylene system. Polym. Adv. Technol. 2011, 22, 2609–2616. [Google Scholar] [CrossRef]

- Lin, H.; Yan, H.; Liu, B.; Wei, L.; Xu, B. The influence of KH-550 on properties of ammonium polyphosphate and polypropylene flame retardant composites. Polym. Degrad. Stab. 2011, 96, 1382–1388. [Google Scholar] [CrossRef]

| Component | Chemical Composition | Average Particle Size (µm) | Content Wt.% Solids (%) |

|---|---|---|---|

| Ammonium polyphosphate (APP) | (NH4PO3)n (n > 1000) crystalline form II 31% w/w P content 14% w/w N content | ≤15 µm | 100 |

| Melamine (MEL) | 1,3,5-Triazine-2,4,6-triamine | ≤40 µm | 100 |

| Pentaerythritol (PER) | 2,2-Bis(hydroxymethyl)1,3-propanediol | ≤40 µm | ≥98 |

| Binder ECO VAE401 | vinyl acetate-ethylene copolymer | 54–58 | |

| Prime pigment KRNOS2310 | Titanium dioxide | ≥0.1 | 95–100% TiO2 1–5% Al(OH)3 |

| Coalescent agent | 2-methoxy-1-methylethyl acetate | - | >99 |

| Wetting and Dispersing agent BYK2010 | Aqueous emulsion of a structured acrylate copolymer with pigment-affinic groups. | - | - |

| Defoaming agentBYK022 | Mixture of foam-destroying polysiloxanes and hydrophobic solids in polyglycol | - | - |

| Microencapsulated APP (EAPP) | APP encapsulated by polysiloxane | 10 ± 2 | - |

| Sample | Description |

|---|---|

| APP Mix | APP, MEL and PER |

| EAPP Mix | Microencapsulated APP, MEL and PER |

| APP Coating | APP mix + dispersing agent, pigment, defoaming agent, binder, coalescent agent and water |

| EAPP Coating | EAPP mix + dispersing agent, pigment, defoaming agent, binder, coalescent agent and water |

| APP Coated Wood | Wood samples coated with APP Coating |

| EAPP Coated Wood | Wood samples coated with EAPP Coating |

| Aged APP Coated Wood | Wood samples coated with APP Coating after weathering |

| Aged EAPP Coated Wood | Wood samples coated with EAPP Coating after weathering |

| Test Sample | Elemental Composition (%) | Si/P | ||

|---|---|---|---|---|

| Si | O | P | ||

| 1 | 20.63 | 68.48 | 10.89 | 1.90 |

| 2 | 21.21 | 68.40 | 10.39 | 2.04 |

| 3 | 21.09 | 68.42 | 10.50 | 2.01 |

| 4 | 21.32 | 68.38 | 10.30 | 2.07 |

| Steps | Ingredients | Batch (wt.%) | |

|---|---|---|---|

| APP Coating | EAPP Coating | ||

| Step 1 (10 min, 800 rpm) | Water | 20.00 | 40.91 |

| Dispersing agent (Byk-2010) | 1.21 | 1.83 | |

| Step 2 (30 min, 2500 rpm) | TiO2 Pigment | 4.00 | 6.06 |

| Intumescent Blend | 44.16 | 15.39 | |

| Water | 7.00 | - | |

| Defoaming agent (Byk-022) | 0.88 | 1.34 | |

| Step 3 (20 min, 1700 rpm) | Binder | 20.75 | 31.44 |

| Coalescent agent | 2.00 | 3.03 | |

| - | Total | 100.00 | 100.00 |

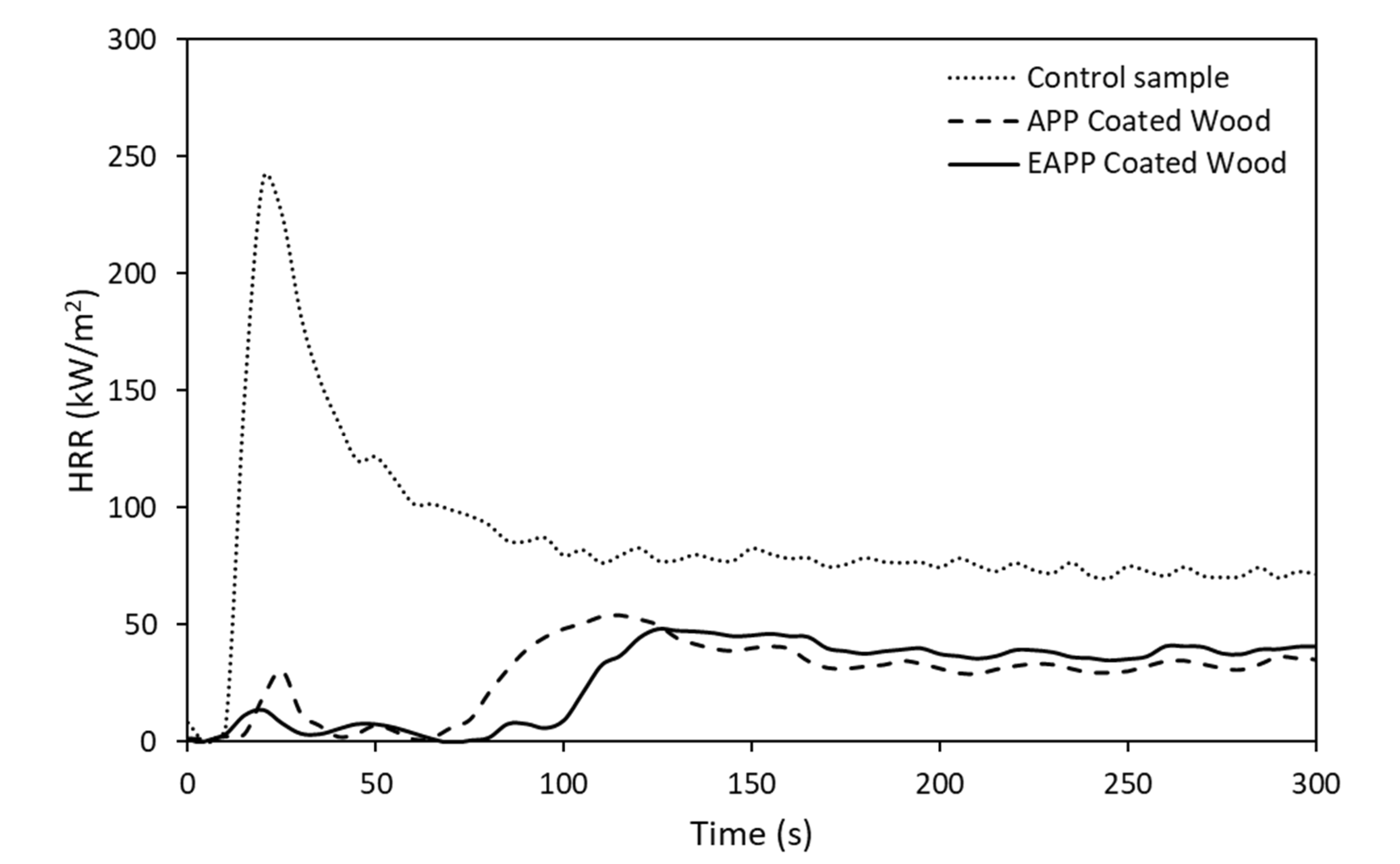

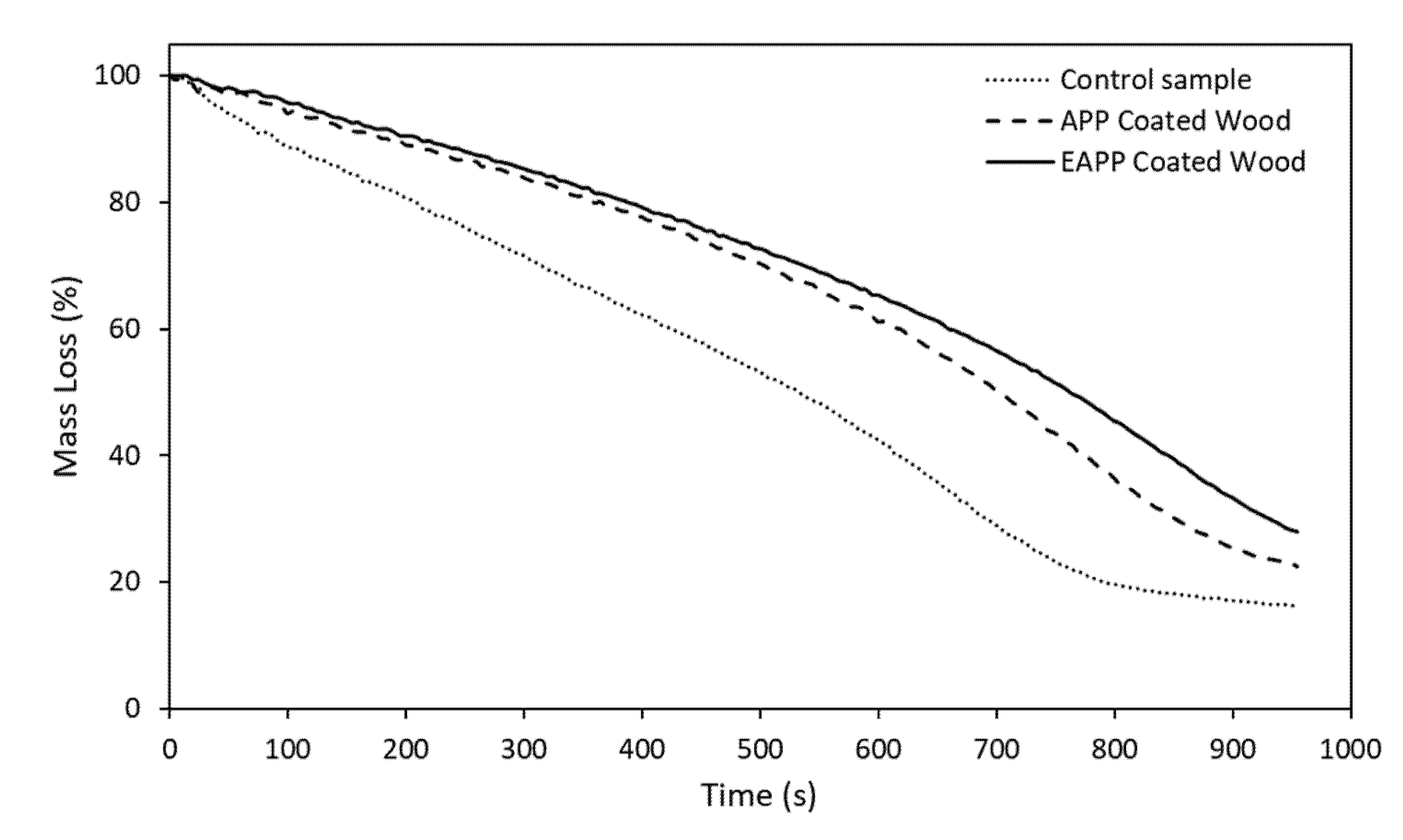

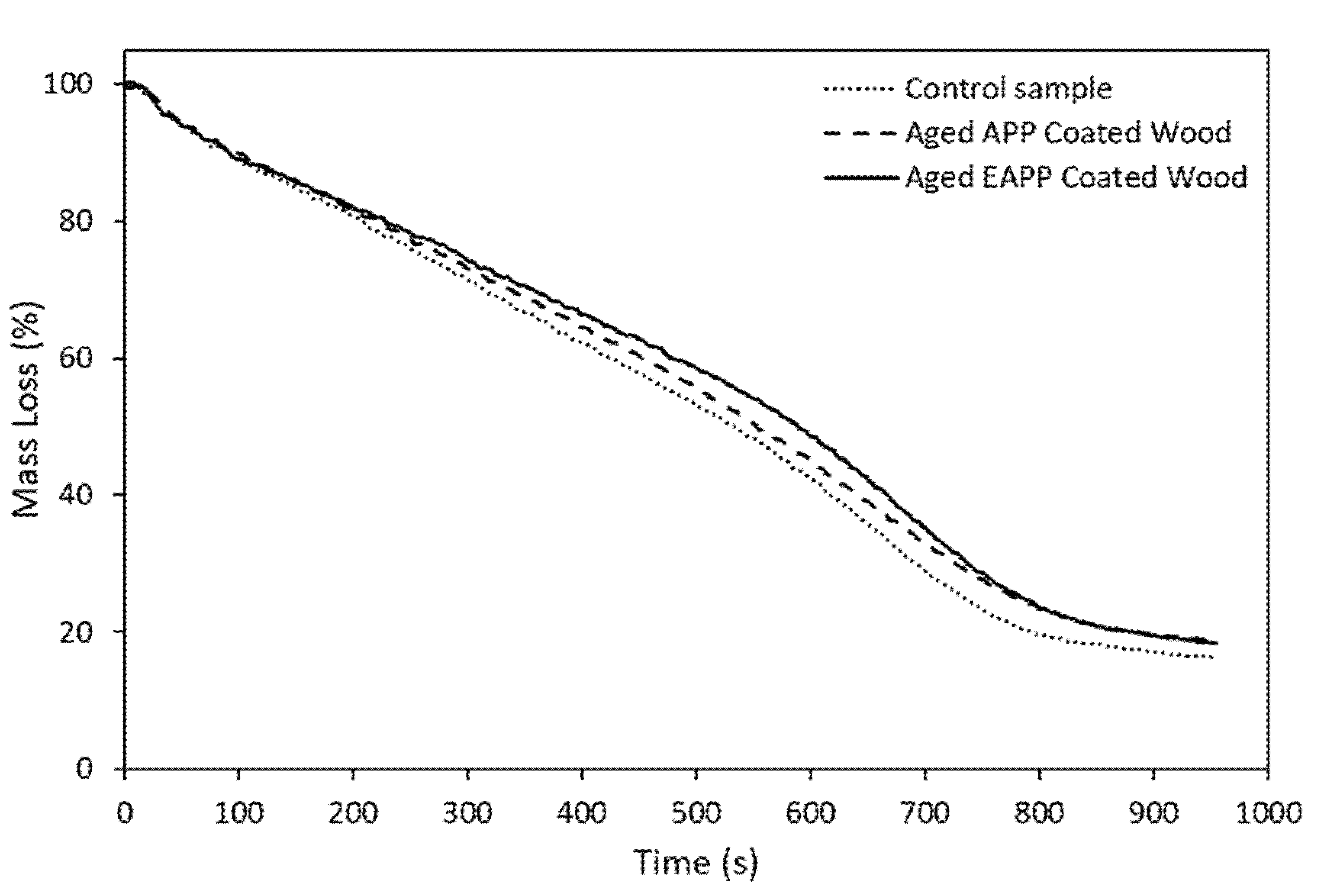

| Flammability Traits | Control Sample | APP Coated Wood | EAPP Coated Wood | Aged APP Coated Wood | Aged EAPP Coated Wood |

|---|---|---|---|---|---|

| Tign (s) | 10 ± 2 | 50 ± 5 | 65 ± 5 | 10 ± 2 | 10 ± 2 |

| HRR in 180 s (kW/m2) | 95.64 ± 4.11 | 28.52 ± 1.46 | 26.36 ± 0.56 | 83.35 ± 2.91 | 85.77 ± 1.33 |

| HRR in 300 s (kW/m2) | 86.90 ± 3.23 | 30.62 ± 1.18 | 28.78 ± 0.81 | 77.46 ± 2.74 | 76.08 ± 0.62 |

| HRRmax (kW/m2) | 240.01 ± 9.21 | 54.16 ± 2.27 | 48.15 ± 2.73 | 186.19 ± 6.21 | 187.09 ± 3.45 |

| MLR (g/s) | 0.064 ± 0.004 | 0.056 ± 0.002 | 0.041 ± 0.001 | 0.057 ± 0.003 | 0.053 ± 0.001 |

| THR (MJ/m2) | 83.59 ± 2.19 | 60.59 ± 1.91 | 55.49 ± 0.89 | 74.81 ± 2.12 | 68.70 ± 1.56 |

| Time HRRmax (s) | 20 ± 2 | 115 ± 5 | 125 ± 5 | 20 ± 2 | 20 ± 2 |

| Wavenumber (cm−1) | Vibration | Source |

|---|---|---|

| ~3300 | O–H | Polysiloxane encapsulation, wood |

| 2930–2950 | C–H vibration | Binder |

| 1732 | C=O stretch in unconjugated ketone, carbonyl and ester groups | Binder |

| 1675 | C=C stretch (weak) | Lignin in wood |

| 1510 | Aromatic skeletal vibrations C=C | Lignin in wood |

| 1430 | CH2 bending | Polysiloxane encapsulation, binder |

| 1373 | CH bending | Binder |

| 1231 | C–O–C | Binder |

| 1070 | C–O stretching | Cellulose, hemicellulose in wood |

| 1050 | Si–O–Si | Polysiloxane encapsulation |

| 1020 | C–C | Binder |

| 896 | C–O–C glycosidic stretch | Polysaccharides in wood |

| 893 | Si–OH stretching | Polysiloxane encapsulation |

| 798 | Si–CH3 stretching | Polysiloxane encapsulation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, A.; Landry, V.; Blanchet, P.; Hoang, D.-T.; Dagenais, C. Fire Performance of Intumescent Waterborne Coatings with Encapsulated APP for Wood Constructions. Coatings 2021, 11, 1272. https://doi.org/10.3390/coatings11111272

Hussain A, Landry V, Blanchet P, Hoang D-T, Dagenais C. Fire Performance of Intumescent Waterborne Coatings with Encapsulated APP for Wood Constructions. Coatings. 2021; 11(11):1272. https://doi.org/10.3390/coatings11111272

Chicago/Turabian StyleHussain, Atif, Véronic Landry, Pierre Blanchet, Doan-Trang Hoang, and Christian Dagenais. 2021. "Fire Performance of Intumescent Waterborne Coatings with Encapsulated APP for Wood Constructions" Coatings 11, no. 11: 1272. https://doi.org/10.3390/coatings11111272

APA StyleHussain, A., Landry, V., Blanchet, P., Hoang, D.-T., & Dagenais, C. (2021). Fire Performance of Intumescent Waterborne Coatings with Encapsulated APP for Wood Constructions. Coatings, 11(11), 1272. https://doi.org/10.3390/coatings11111272