Measurement of Stress Optic Coefficient for Thermal Barrier Coating Based on Terahertz Time-Domain Spectrum

Abstract

:1. Introduction

2. Materials and Experiments

3. Models and Methods

3.1. Model of Stress Measurement

3.2. Model of Refractive Index Measurement

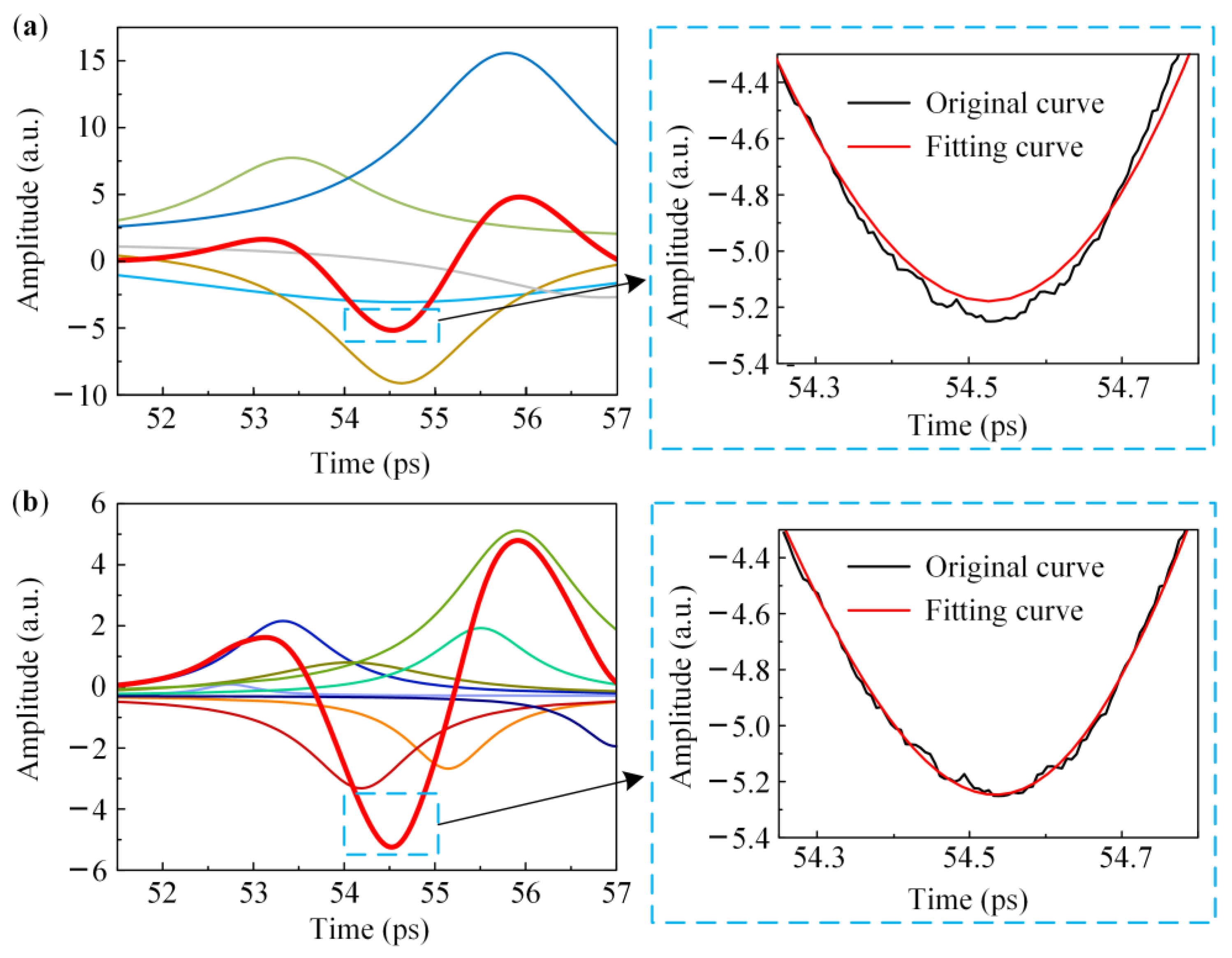

3.3. Data Processing Methods

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, D.R.; Fan, X.L.; Sun, Y.L. The stresses and cracks in thermal barrier coating system: A review. Chin. J. Solid Mech. 2016, 37, 477–517. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–899. [Google Scholar] [CrossRef] [Green Version]

- Schulz, U.; Leyens, C.; Fritscher, K. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef] [PubMed]

- Eldridge, J.I.; Bencic, T.J.; Spuckler, C.M. Delamination-indicating thermal barrier coatings using YSZ: Eu sublayers. J. Am. Ceram. Soc. 2006, 89, 3246–3251. [Google Scholar] [CrossRef]

- Guo, H.B.; Kuroda, S.; Murakami, H. Microstructures and properties of plasma-sprayed segmented thermal barrier coatings. J. Am. Ceram. Soc. 2006, 89, 1432–1439. [Google Scholar] [CrossRef]

- Nychka, A.; Clarke, D.R. Damage quantification in TBCs by photo-stimulated luminescence spectroscopy. Surf. Coat. Technol. 2001, 146, 110–116. [Google Scholar] [CrossRef]

- Jiang, P.; Fan, X.L.; Sun, Y.L. Competition mechanism of interfacial cracks in thermal barrier coating system. Mater. Des. 2017, 132, 559–566. [Google Scholar] [CrossRef] [Green Version]

- Jiang, P.; Fan, X.L.; Sun, Y.L. Bending-driven failure mechanism and modelling of double-ceramic-layer thermal barrier coating system. Int. J. Solids Struct. 2017, 130, 11–20. [Google Scholar] [CrossRef]

- Miller, R.A. Oxidation-based model for thermal barrier coating life. J. Am. Ceram. Soc. 2010, 67, 517–521. [Google Scholar] [CrossRef]

- Widjaja, S.; Limarga, A.M.; Yip, T.H. Modeling of residual stresses in a plasma-sprayed zirconia/alumina functionally graded-thermal barrier coating. Thin Solid Film. 2003, 434, 216–227. [Google Scholar] [CrossRef]

- Kuroda, S.; Fukushima, T.; Kitahara, S. Generation mechanisms of residual stresses in plasma-sprayed coatings. Vacuum 1990, 41, 1297–1299. [Google Scholar] [CrossRef]

- Matejícek, J.; Sampath, S.; Dubsky, J. X-ray residual stress measurement in metallic and ceramic plasma sprayed coatings. J. Therm. Spray Technol. 1998, 7, 489–496. [Google Scholar] [CrossRef]

- Totemeier, T.C.; Wright, J.K. Residual stress determination in thermally sprayed coatings—A comparison of curvature models and X-ray techniques. Surf. Coat. Technol. 2006, 200, 3955–3962. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Microstructure and indentation mechanical properties of plasma sprayed nano-bimodal and conventional ZrO2-8 wt.% Y2O3 thermal barrier coatings. Vacuum 2012, 86, 1174–1185. [Google Scholar] [CrossRef]

- Jordan, D.W.; Faber, K.T. X-ray residual stress analysis of a ceramic thermal barrier coating undergoing thermal cycling. Thin Solid Film. 1993, 235, 137–141. [Google Scholar] [CrossRef]

- Mao, W.G.; Chen, Q.; Dai, C.Y.; Yang, L.; Zhou, Y.C.; Lu, C. Effects of piezo-spectroscopic coefficients of 8 wt.% Y2O3 stabilized ZrO2 on residual stress measurement of thermal barrier coatings by Raman spectroscopy. Surf. Coat. Technol. 2010, 204, 3573–3577. [Google Scholar] [CrossRef] [Green Version]

- Loechelt, G.H.; Cave, N.G.; Menendez, J. Measuring the tensor nature of stress in silicon using polarized off-axis Raman spectroscopy. Appl. Phys. Lett. 1995, 66, 3639–3641. [Google Scholar] [CrossRef]

- Fu, D.H.; He, X.Y.; Ma, L.L.; Xing, H.D.; Meng, T.; Chang, Y.; Qiu, W. The 2-axis stress component decoupling of {100} c-Si by using oblique backscattering micro-Raman spectroscopy. Sci. China Phys. Mech. 2020, 63, 10460. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, C.L.; Huang, F.X.; Wang, C.J.; Zhao, S.M.; Cui, X.Q.; Li, F.F. Residual stress inspection by Eu3+ photoluminescence piezo-spectroscopy: An application in thermal barrier coatings. J. Appl. Phys. 2013, 114, 073502. [Google Scholar] [CrossRef]

- Zhao, S.M.; Ren, Z.M.; Zhao, Y.; Xu, J.Y.; Zou, B.L.; Hui, Y.; Zhu, L.; Zhou, X.; Cao, X.Q. The application of Eu3+ photoluminescence piezo-spectroscopy in the LaMgAl11O19/8YSZ:Eu double-ceramic-layer coating system. J. Eur. Ceram. Soc. 2015, 35, 249–257. [Google Scholar] [CrossRef]

- Jiang, P.; Fan, X.L.; Sun, Y.L.; Wang, H.T.; Su, L.C.; Wang, T.J. Thermal-cycle dependent residual stress within the crack-susceptible zone in thermal barrier coating system. J. Am. Ceram. Soc. 2018, 101, 4256–4261. [Google Scholar] [CrossRef]

- Fan, W.H.; Burnett, A.; Upadhya, P.C. Far-Infrared spectroscopic characterization of explosives for security applications using broadband terahertz time-domain spectroscopy. Appl. Spectrosc. 2007, 61, 638–643. [Google Scholar] [CrossRef]

- Kojima, S.; Tsumura, N.; Kitahara, H. Terahertz time domain spectroscopy of phonon-polaritons in ferroelectric lithium niobate crystals. Jpn. J. Appl. Phys. 2002, 41, 7033–7037. [Google Scholar] [CrossRef]

- Cogdill, R.P.; Forcht, R.N.; Shen, Y. Comparison of terahertz pulse imaging and near-infrared spectroscopy for rapid, non-destructive analysis of tablet coating thickness and uniformity. Pharm. Innov. 2007, 2, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.N.; Chen, J.; Zhou, Z.K. THz time-domain spectroscopy technology. Laser Optoelectron. Prog. 2005, 42, 35–38. (In Chinese) [Google Scholar]

- Zhong, S.C. Progress in terahertz nondestructive testing: A review. Front. Mech. Eng. 2019, 14, 273–281. [Google Scholar] [CrossRef]

- Song, W.; Li, L.A.; Wang, Z.Y. Experimental verification of the uniaxial stress-optic law in the terahertz frequency regime. Opt. Lasers Eng. 2007, 52, 174–177. [Google Scholar] [CrossRef]

- Shuai, S.; Zhang, G.; Shi, W. Optically pumped gas terahertz fiber laser based on gold-coated quartz hollow-core fiber. Appl. Opt. 2019, 58, 2828–2831. [Google Scholar] [CrossRef]

- Chen, C.C.; Lee, D.J.; Pollock, T. Pulsed-terahertz reflectometry for health monitoring of ceramic thermal barrier coatings. Opt. Express 2010, 18, 3477–3486. [Google Scholar] [CrossRef]

- Watanabe, M.; Kuroda, S.; Yamawaki, H. Terahertz dielectric properties of plasma-sprayed thermal-barrier coatings. Surf. Coat. Technol. 2011, 205, 4620–4626. [Google Scholar] [CrossRef]

- Schemmel, P.; Diederich, G.; Moore, A.J. Direct stress optic coefficients for YTZP ceramic and PTFE at GHz frequencies. Opt. Express 2016, 24, 8110–8119. [Google Scholar] [CrossRef] [PubMed]

- Schemmel, P.; Diederich, G.; Moore, A.J. Measurement of direct strain optic coefficient of YSZ thermal barrier coatings at GHz frequencies. Opt. Express 2017, 24, 19968–19980. [Google Scholar] [CrossRef] [PubMed]

- Fukuchi, T.; Fuse, N.; Okada, M. Measurement of refractive index and thickness of topcoat of thermal barrier coating by reflection measurement of terahertz waves. Electr. Commun. Jpn. 2013, 96, 37–45. [Google Scholar] [CrossRef]

| Method | Stress Optical Coefficient c1 (GPa) | Linear Goodness of Fit |

|---|---|---|

| Unimodal fitting method | 0.2844 ± 0.0132 | 0.9728 |

| Multimodal fitting method | 0.3131 ± 0.0166 | 0.9648 |

| Barycenter method | 0.3180 ± 0.0091 | 0.9894 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhang, Y.; Lu, N.; Wang, Z.; Qiu, W. Measurement of Stress Optic Coefficient for Thermal Barrier Coating Based on Terahertz Time-Domain Spectrum. Coatings 2021, 11, 1265. https://doi.org/10.3390/coatings11101265

Wang Z, Zhang Y, Lu N, Wang Z, Qiu W. Measurement of Stress Optic Coefficient for Thermal Barrier Coating Based on Terahertz Time-Domain Spectrum. Coatings. 2021; 11(10):1265. https://doi.org/10.3390/coatings11101265

Chicago/Turabian StyleWang, Zong, Yanheng Zhang, Ning Lu, Zhiyong Wang, and Wei Qiu. 2021. "Measurement of Stress Optic Coefficient for Thermal Barrier Coating Based on Terahertz Time-Domain Spectrum" Coatings 11, no. 10: 1265. https://doi.org/10.3390/coatings11101265

APA StyleWang, Z., Zhang, Y., Lu, N., Wang, Z., & Qiu, W. (2021). Measurement of Stress Optic Coefficient for Thermal Barrier Coating Based on Terahertz Time-Domain Spectrum. Coatings, 11(10), 1265. https://doi.org/10.3390/coatings11101265