Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

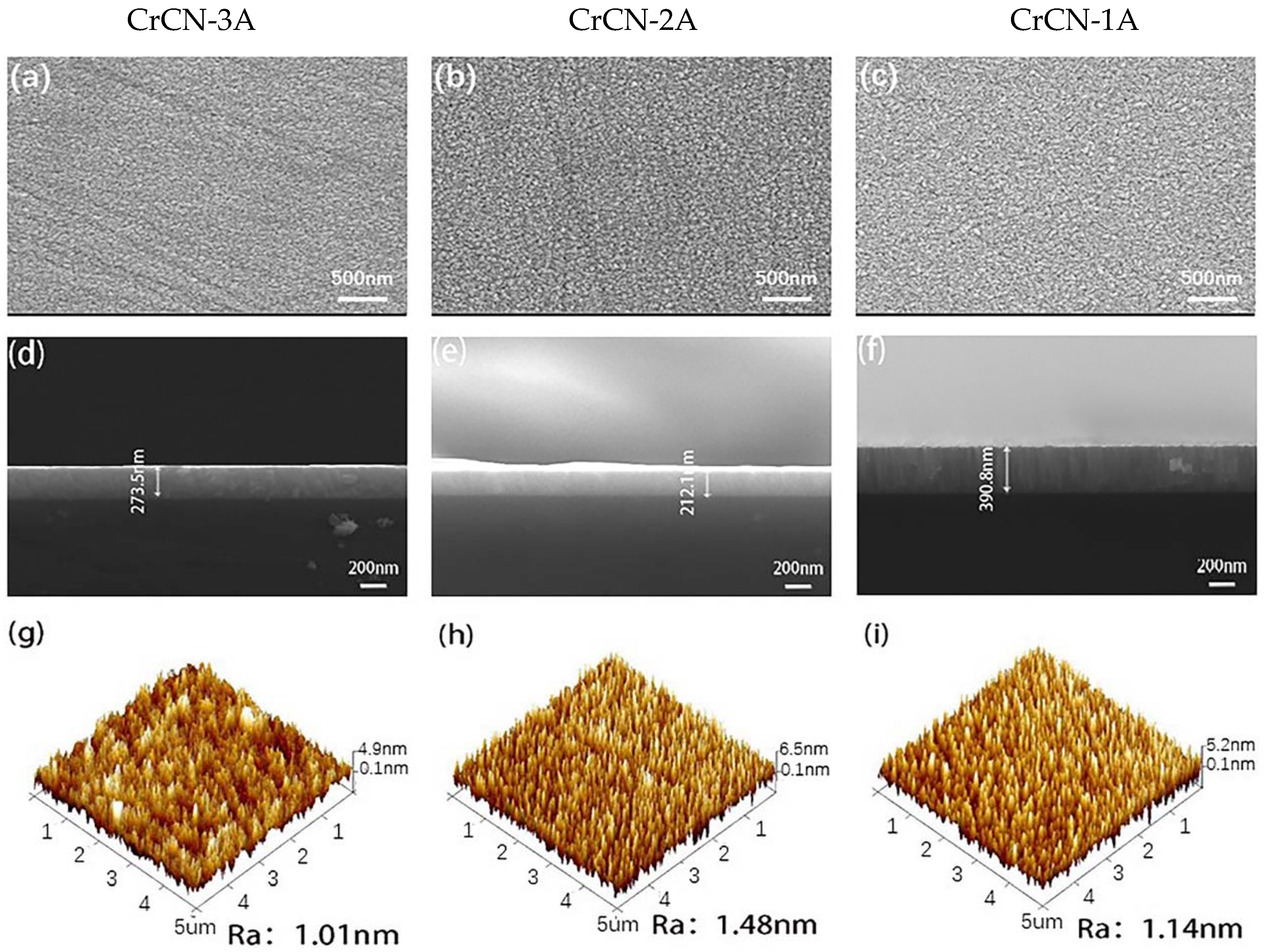

3.1. Characterization of CrCN Coatings

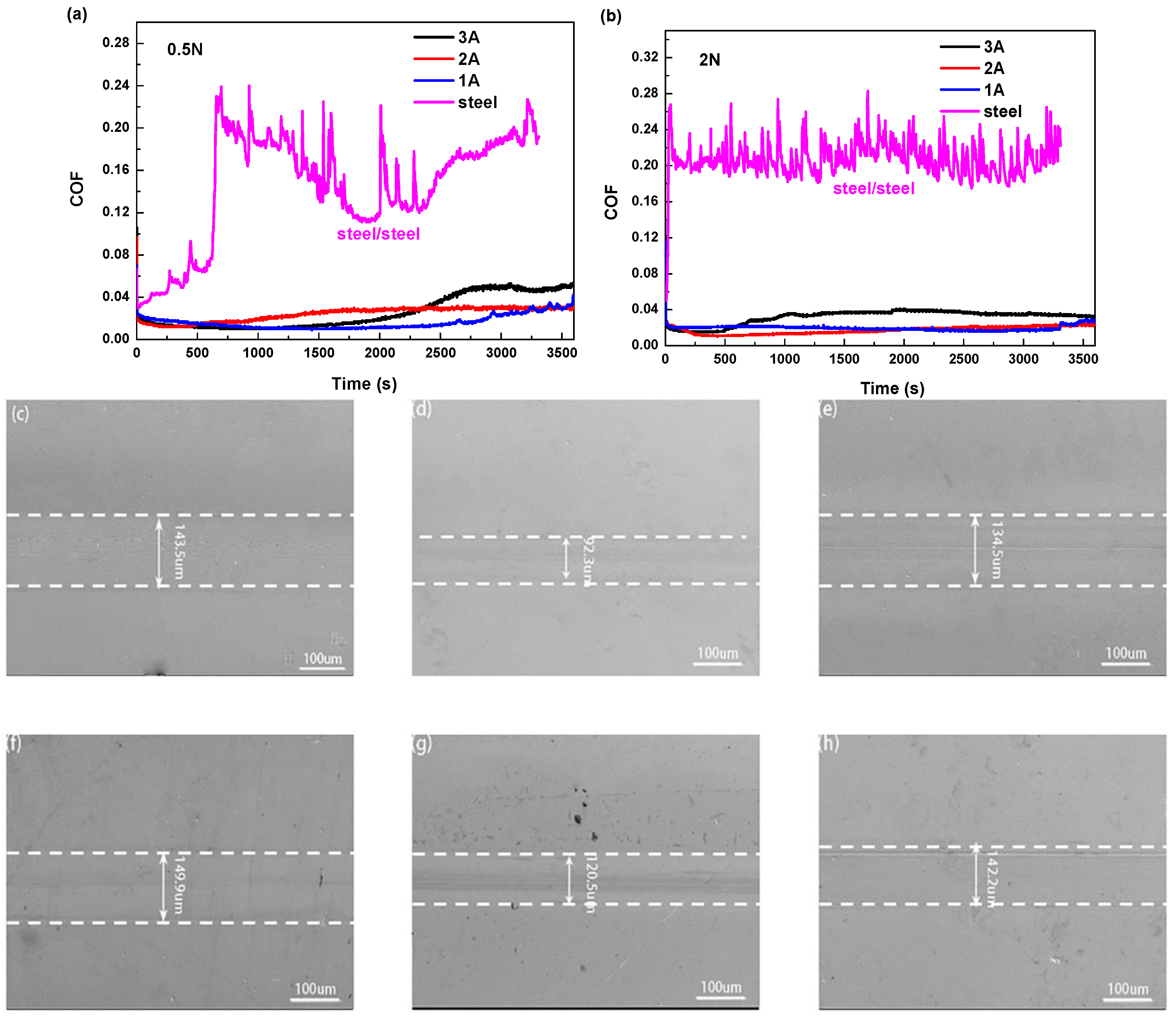

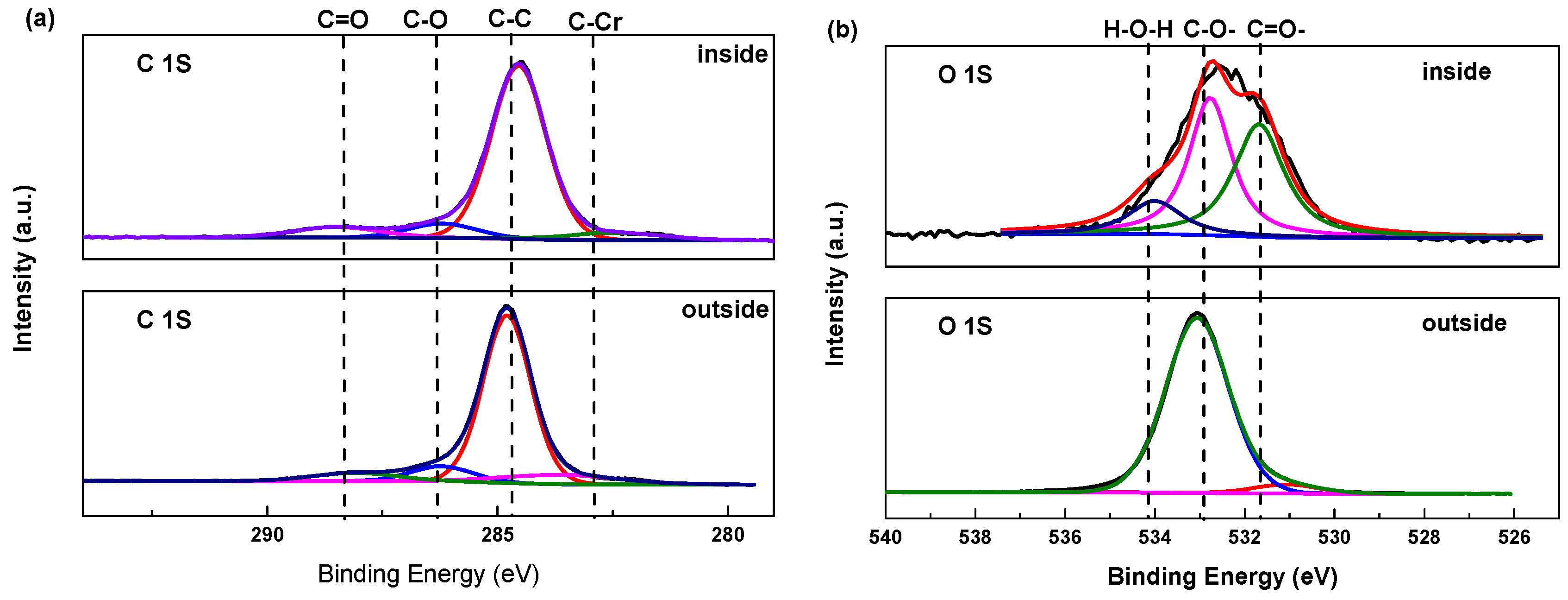

3.2. Tribological Performance of CrCN Coating under Glycerol Lubrication

4. Conclusions

- (1)

- By changing the deposition current of the C target, it can be found that the surface of CrCN-2A coating is the densest with highest hardness up to 17.87 GPa.

- (2)

- CrCN-2A coating showed excellent lubrication performance, as indicated by a more stable low coefficient of friction and the lowest wear.

- (3)

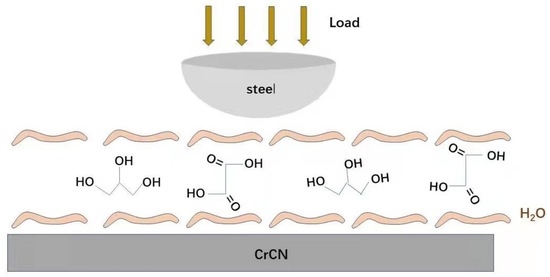

- It can be found that in the steel/steel friction pair, glycerol does not show excellent lubricating performance. Meanwhile, in the steel/CrCN system, the lowest friction coefficient under glycerol lubrication is only 0.01. This is mainly due to the fact that the degradation of glycerol generates the fluid lubricating layer during the friction process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruden, A.; Restrepo-Parra, E.; Paladines, A.U.; Sequeda, F. Corrosion resistance of CrN thin films produced by DC magnetron sputtering. Appl. Surf. Sci. 2013, 270, 150–156. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Jiang, X.; Chen, J. Improving tribological performance of CrN coatings in seawater by structure design. Tribol. Int. 2015, 82, 78–88. [Google Scholar] [CrossRef]

- Chang, Z.; Wan, X.; Pei, Z.; Gong, J.; Sun, C. Microstructure and mechanical properties of CrN coating deposited by arc ion plating on Ti6Al4V substrate. Surf. Coat. Technol. 2011, 205, 4690–4696. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuklinski, Z.; Myslinski, P. Hard CrCN/CrN multilayer coatings for tribological applications. Surf. Coat. Technol. 2010, 204, 2289–2293. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Leyland, A.; Matthewsb, A. Impact wear and abrasion resistance of CrN, AlCrN and AlTiN PVD coatings. Surf. Coat. Technol. 2013, 215, 170–177. [Google Scholar] [CrossRef]

- Shan, L.; Zhang, Y.; Wang, Y.; Li, J.; Jiang, X.; Chen, J. Corrosion and wear behaviors of PVD CrN and CrSiN coatings in seawater. Trans. Nonferrous Met. Soc. China 2016, 26, 175–184. [Google Scholar] [CrossRef]

- Nordin, M.; Larsson, M.; Hogmark, S. Mechanical and tribological properties of multilayered PVD TiNrCrN. Wear 1999, 232, 221–225. [Google Scholar] [CrossRef]

- Mendibide, C.; Steyer, P.; Fontaine, J.; Goudeau, P. Improvement of the tribological behaviour of PVD nanostratified TiN/CrN coatings—An explanation. Surf. Coat. Technol. 2006, 201, 4119–4124. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.; Xie, Z. Structure and mechanical properties of graded Cr/CrN/CrTiN coatings synthesized by close field unbalanced magnetron sputtering. Surf. Coat. Technol. 2017, 309, 779–789. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R.; Pandey, A.C. Nanoindentation study of magnetron-sputtered CrN and CrSiN coatings. Mater. Des. 2011, 32, 2628–2634. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Comparison study on structure of Si and Cu doping CrN films by reactive sputtering. Appl. Surf. Sci. 2011, 257, 5595–5600. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Yan, J. Evaluating mechanical properties and crack resistance of CrN, CrTiN, CrAlN and CrTiAlN coatings by nanoindentation and scratch tests. Surf. Coat. Technol. 2016, 285, 203–213. [Google Scholar] [CrossRef]

- Zhou, F.; Ma, Q.; Zhang, M. Comparison of tribological properties of CrN, CrTiN and CrTiBN coatings sliding against SiC and SUS440C balls in water. Appl. Phys. A 2020, 126, 796. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Zhou, S.; Wang, Y.; Wang, C.; Wang, Y.; Sui, Y.; Lan, J.; Xue, Q. Improvement in the tribocorrosion performance of CrCN coating by multilayered design for marine protective application. Appl. Surf. Sci. 2020, 528, 147061. [Google Scholar] [CrossRef]

- Tong, C.; Lee, J.; Kuo, C.; Huang, S.; Chan, Y.; Chen, H.; Duh, J. Effects of carbon content on the microstructure and mechanical property of cathodic arc evaporation deposited CrCN thin films. Surf. Coat. Technol. 2013, 231, 482–486. [Google Scholar] [CrossRef]

- Huang, S.; Tong, C.; Hsieh, T.; Lee, J. Microstructure and mechanical properties evaluation of cathodic arc deposited CrCN/ZrCN multilayer coatings. J. Alloys Compd. 2019, 803, 1005–1015. [Google Scholar] [CrossRef]

- Fuentes, G.; Díaz de Cerio, M.; García, J.; Martínez, R.; Bueno, R.; Rodríguez, R.; Rico, M.; Montalá, F.; Qin, Y. Gradient CrCN cathodic arc PVD coatings. Thin Solid Film. 2009, 517, 5894–5899. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B. Tribological properties of CrCN/CrN multilayer coatings. Tribol. Int. 2014, 80, 34–40. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Ding, X.; Zhou, Z.; Wang, C.; Zhang, W.; Li, L.; Lee, S. Microstructure and water-lubricated friction and wear properties of CrN (C) coatings with different carbon contents. Appl. Surf. Sci. 2013, 268, 579–587. [Google Scholar] [CrossRef]

- Guan, J.J.; Wang, H.Q.; Qin, L.Z.; Liao, B.; Liang, H.; Li, B. Phase transitions of doped carbon in CrCN coatings with modified mechanical and tribological properties via filtered cathodic vacuum arc deposition. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 397, 86–91. [Google Scholar] [CrossRef]

- Hu, P.; Jiang, B. Study on tribological property of CrCN coating based on magnetron sputtering plating technique. Vacuum 2011, 85, 994–998. [Google Scholar]

- Mandrino, D.; Podgornik, B. XPS investigations of tribofilms formed on CrN coatings. Appl. Surf. Sci. 2017, 396, 554–559. [Google Scholar] [CrossRef]

- Podgornik, B.; Sedlaček, M.; Mandrino, D. Performance of CrN coatings under boundary lubrication. Tribol. Int. 2016, 96, 247–257. [Google Scholar] [CrossRef]

- Wu, X.; Yue, B.; Su, Y.; Wang, Q.; Huang, Q.; Wang, Q.; Cai, H. Pollution characteristics of polycyclic aromatic hydrocarbons in common used mineral oils and their transformation during oil regeneration. J. Environ. Sci. 2017, 56, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Habchi, W.; Matta, C.; Joly-Pottuz, L.; De Barros, M.; Martin, J.; Vergne, P. Full film, boundary lubrication and tribochemistry in steel circular contacts lubricated with glycerol. Tribol. Lett. 2011, 42, 351. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Martin, J.; Bouchet, M.; Belin, M. Anomalous low friction under boundary lubrication of steel surfaces by polyols. Tribol. Lett. 2009, 34, 21–29. [Google Scholar] [CrossRef]

- Shi, Y.; Minami, L.; Grahn, M.; Björling, M.; Larsson, R. Boundary and elastohydrodynamic lubrication studies of glycerol aqueous solutions as green lubricants. Tribol. Int. 2014, 69, 39–45. [Google Scholar] [CrossRef]

- Kuzharov, A.A.; Luk’Yanov, B.S.; Kuzharov, A.S. Tribochemical transformations of glycerol. J. Frict. Wear 2016, 37, 337–345. [Google Scholar] [CrossRef]

- Fu, X.; Cao, L.; Qi, C.; Wan, Y.; Xu, H. Ultralow friction of PVD TiN coating in the presence of glycerol as a green lubricant. Ceram. Int. 2020, 46, 24302–24311. [Google Scholar] [CrossRef]

- Ma, Q.; He, T.; Khan, A.M.; Wang, Q.; Chung, Y. Achieving macroscale liquid superlubricity using glycerol aqueous solutions. Tribol. Int. 2021, 160, 107006. [Google Scholar] [CrossRef]

- Pakala, M.; Lin, R.Y. Reactive sputter deposition of chromium nitride coatings. Surf. Coat. Technol. 1996, 81, 233–239. [Google Scholar] [CrossRef]

- Raza, H.A.; Shafiq, M.; Naeem, M.; Naz, M.Y.; Díaz-Guillén, J.C.; Lopez-Badillo, C.M. Cathodic cage plasma pre-treatment of TiN-coated AISI-304 stainless steel for enhancement of mechanical strength and wear resistance. J. Mater. Eng. Perform. 2019, 28, 20–32. [Google Scholar] [CrossRef]

- Dowson, D.; Jin, Z.M. Metal-on-metal hip joint tribology. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2006, 220, 107–118. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.M.; Dowson, D.; Fisher, J. Analysis of fluid film lubrication in artificial hip joint replacements with surfaces of high elastic modulus. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1997, 211, 247–256. [Google Scholar] [CrossRef]

- Long, Y.; Bouchet, M.I.D.B.; Lubrecht, T.; Onodera, T.; Martin, J.M. Superlubricity of glycerol by self-sustained chemical polishing. Sci. Rep. 2019, 9, 6286. [Google Scholar] [CrossRef] [PubMed]

- Bühler, W.; Dinjus, E.; Ederer, H.J.; Kruse, A.; Mas, C. Ionic reactions and pyrolysis of glycerol as competing reaction pathways in near- and supercritical water. J. Supercrit. Fluids 2002, 22, 37–53. [Google Scholar] [CrossRef]

- Martin, J.M.; Bouchet, M.I.D.B.; Matta, C.; Zhang, Q.; Goddard, W.A.; Okuda, S.; Takumaru, S. Gas-phase lubrication of ta-C by glycerol and hydrogen peroxide. Experimental and computer modeling. J. Phys. Chem. C 2010, 114, 5003–5011. [Google Scholar] [CrossRef]

| Samples | N2 Flow /sccm | Ar Flow /sccm | Working Pressure /Pa | Target Current /A |

Bias Voltage /V | Deposition Temperature /°C | Deposition Time /min | |

|---|---|---|---|---|---|---|---|---|

| Cr | C | |||||||

| CrCN-1A | 55 | 25 | 0.5 | 7 | 1 | −50 | 400 | 120 |

| CrCN-2A | 55 | 25 | 0.5 | 7 | 2 | −50 | 400 | 120 |

| CrCN-3A | 55 | 25 | 0.5 | 7 | 3 | −50 | 400 | 120 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, N.; Gao, J.; Xu, L.; Wan, Y.; Li, R. Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication. Coatings 2021, 11, 1155. https://doi.org/10.3390/coatings11101155

Liu N, Gao J, Xu L, Wan Y, Li R. Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication. Coatings. 2021; 11(10):1155. https://doi.org/10.3390/coatings11101155

Chicago/Turabian StyleLiu, Naiyu, Jianguo Gao, Luyao Xu, Yong Wan, and Ruichuan Li. 2021. "Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication" Coatings 11, no. 10: 1155. https://doi.org/10.3390/coatings11101155

APA StyleLiu, N., Gao, J., Xu, L., Wan, Y., & Li, R. (2021). Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication. Coatings, 11(10), 1155. https://doi.org/10.3390/coatings11101155