A Modeling and Experimental Study on the Growth of VCSEL Materials Using an 8 × 6 Inch Planetary MOCVD Reactor

Abstract

1. Introduction

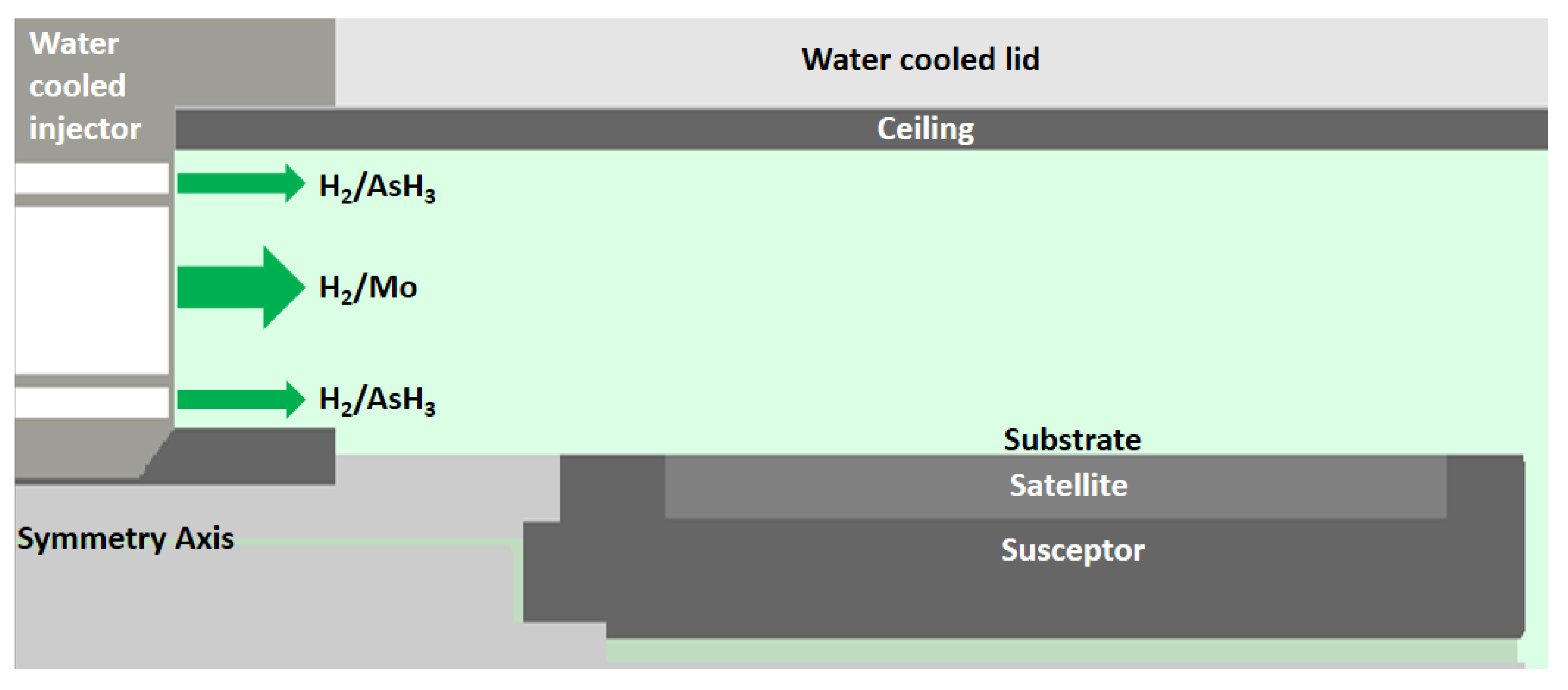

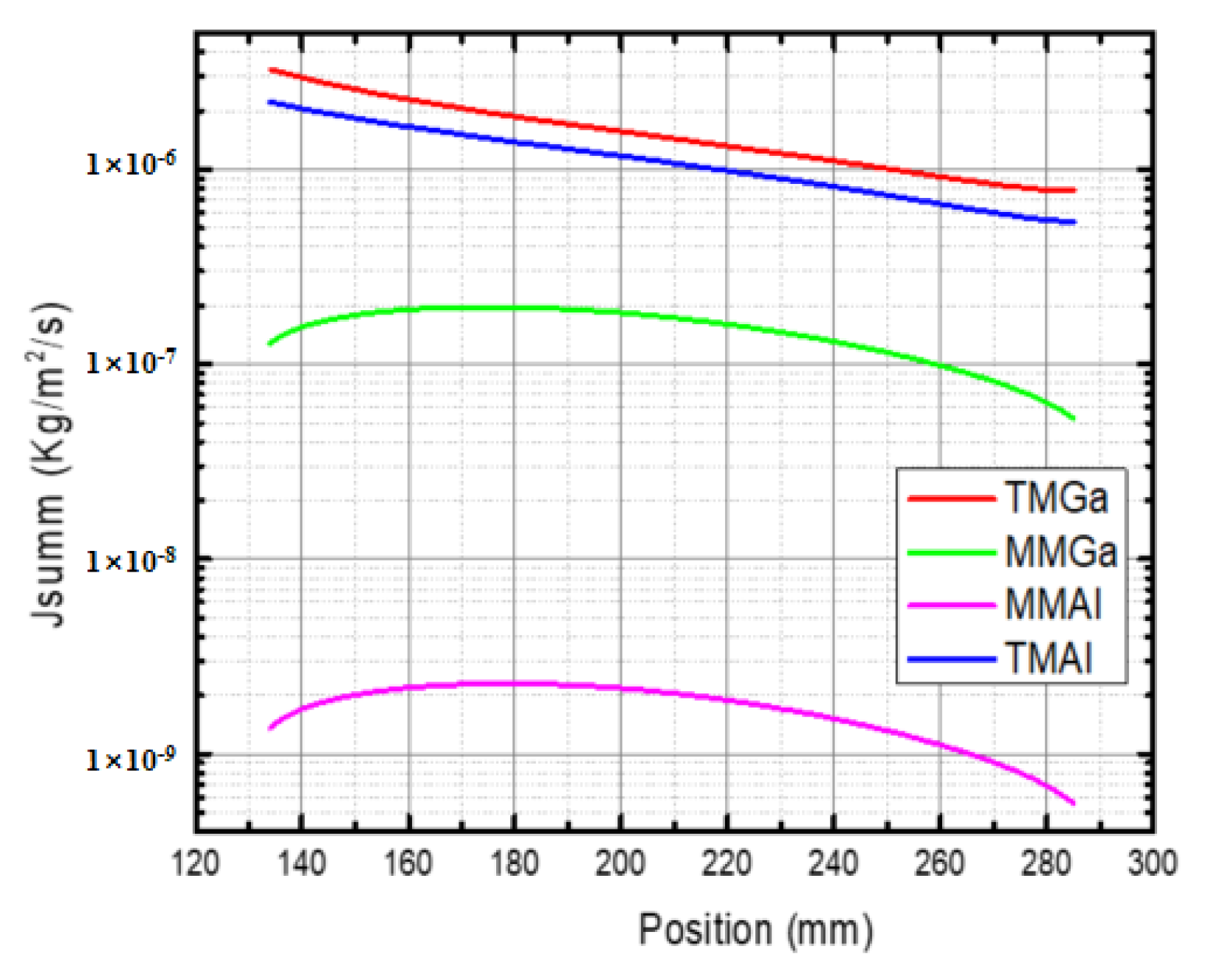

2. Model

3. Experimental

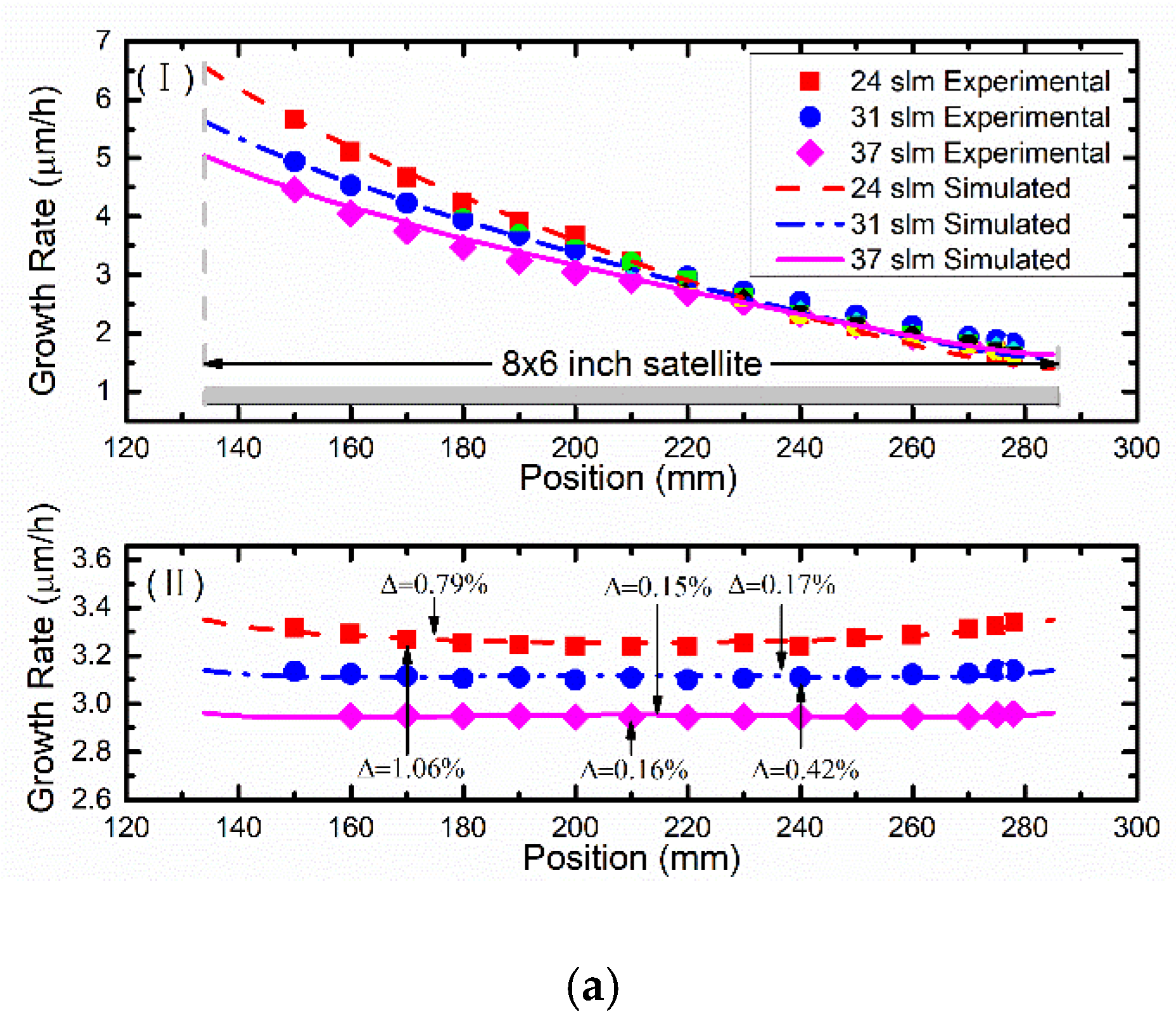

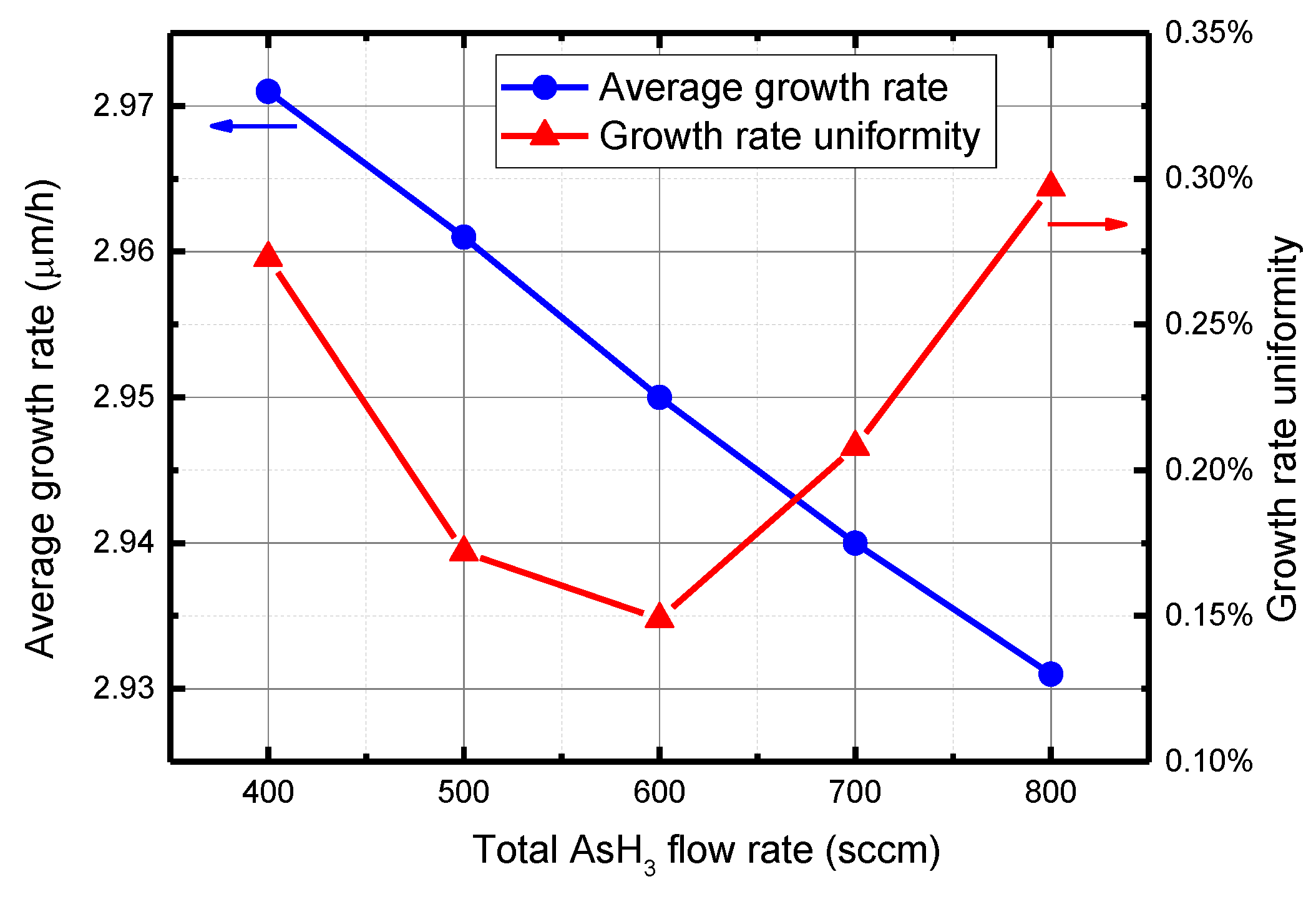

4. Results and Discussion

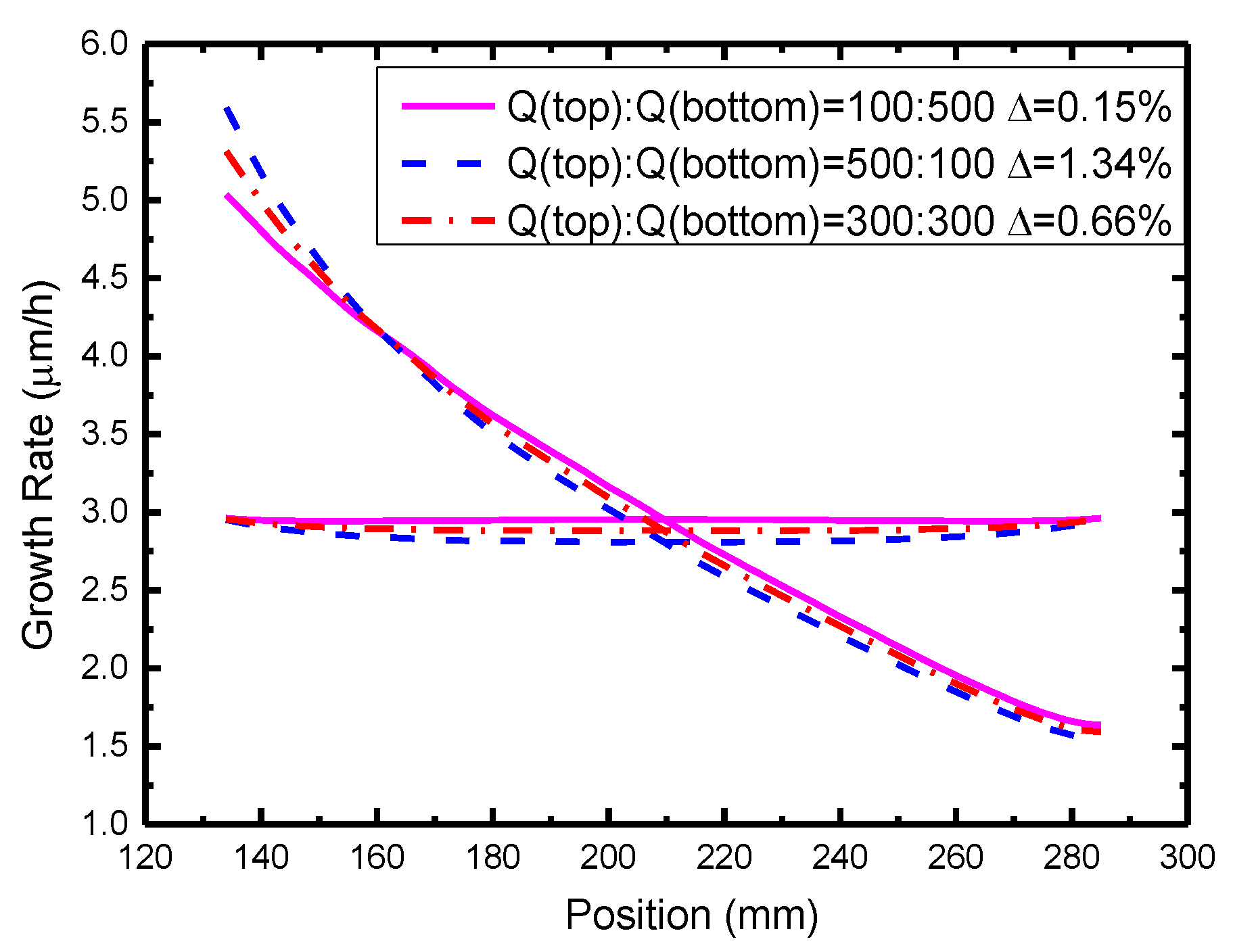

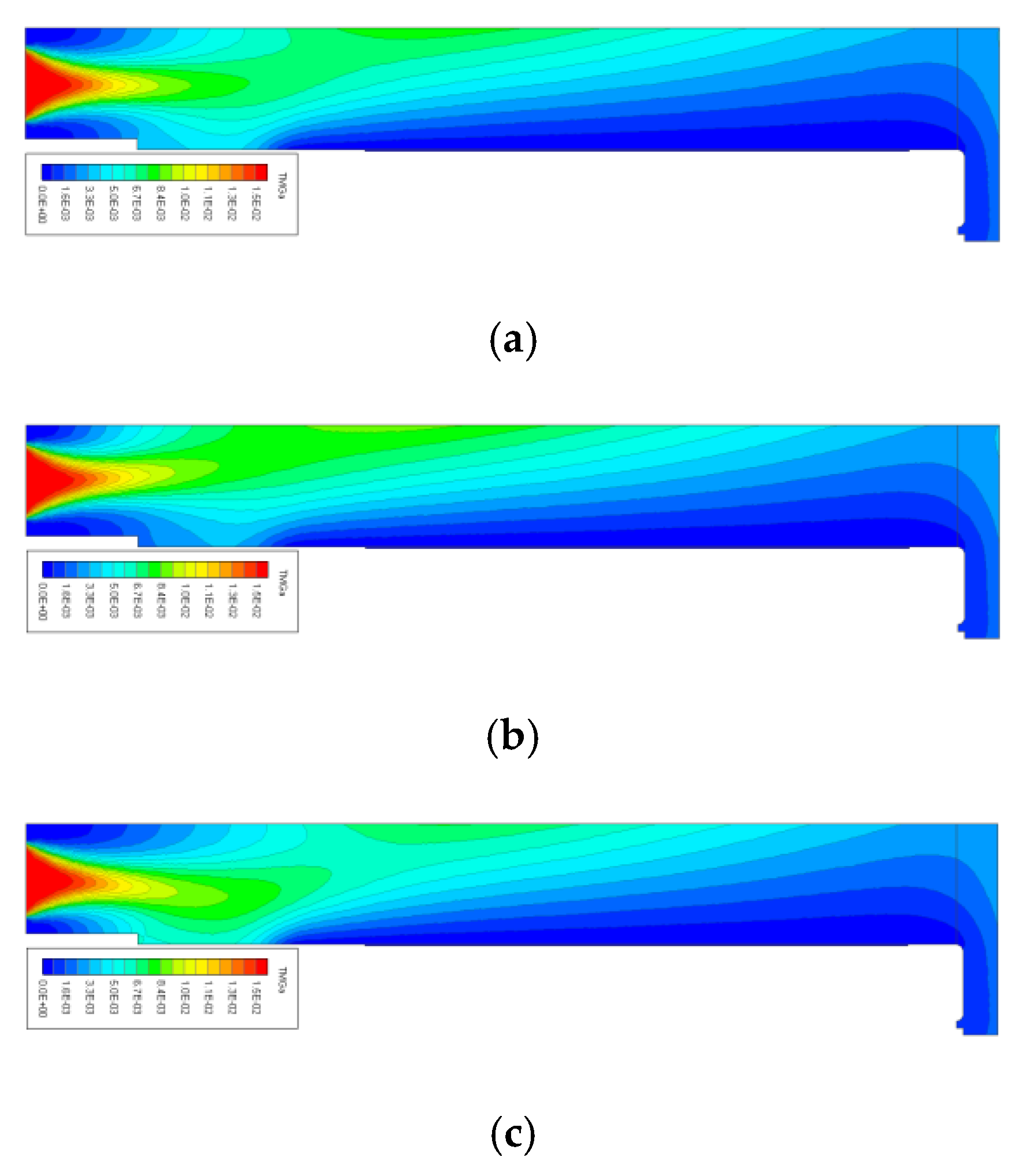

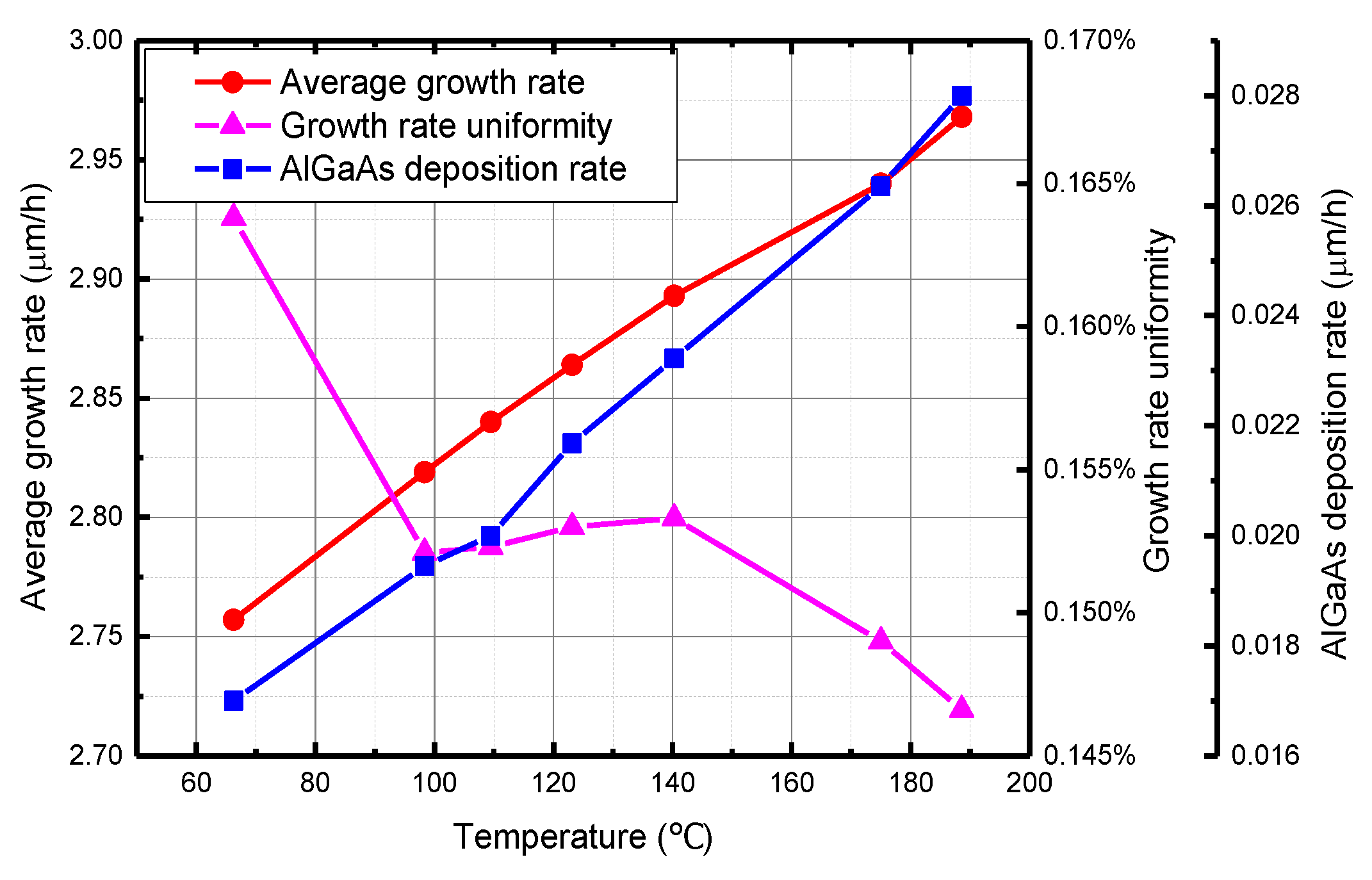

4.1. Growth Rate Uniformity

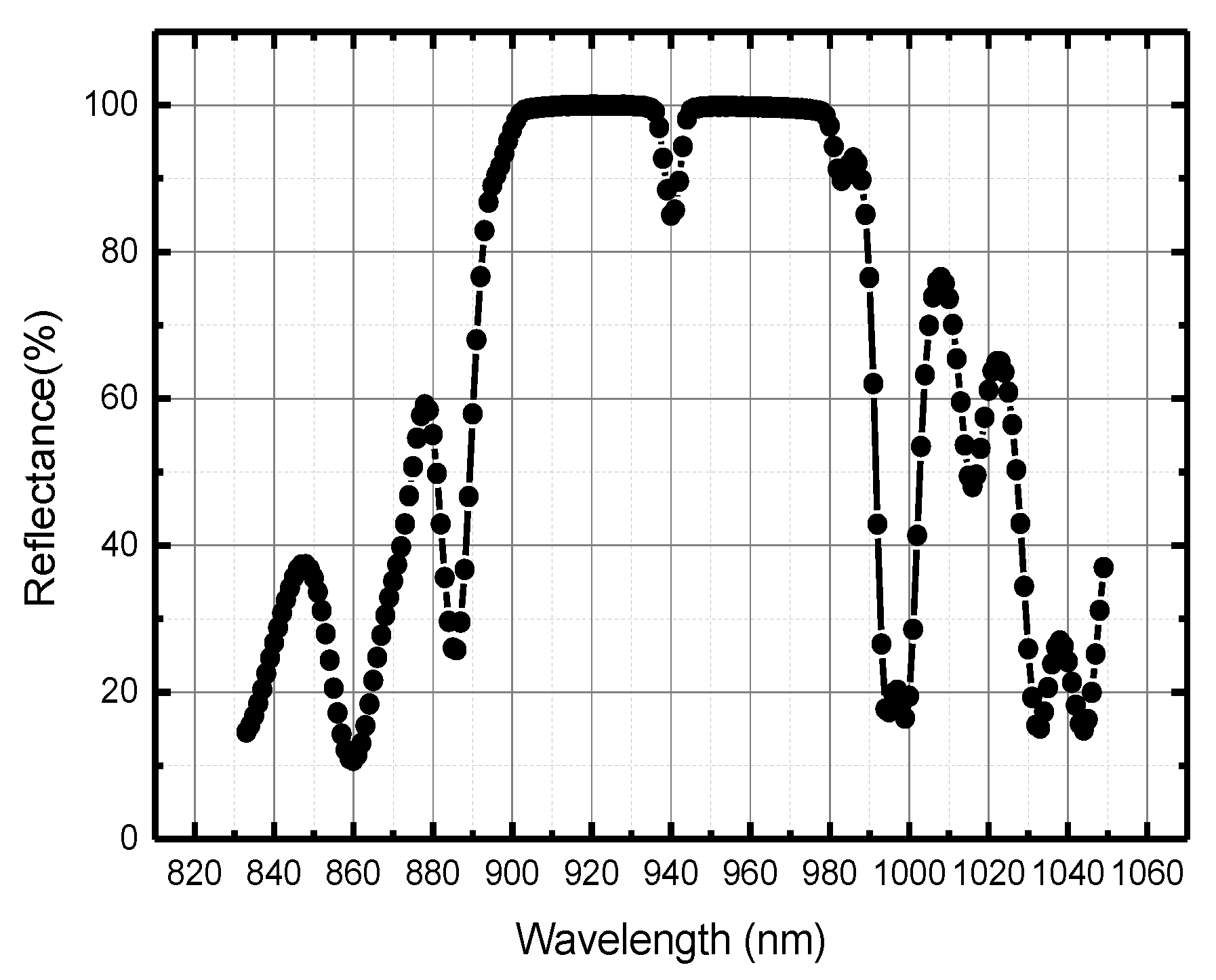

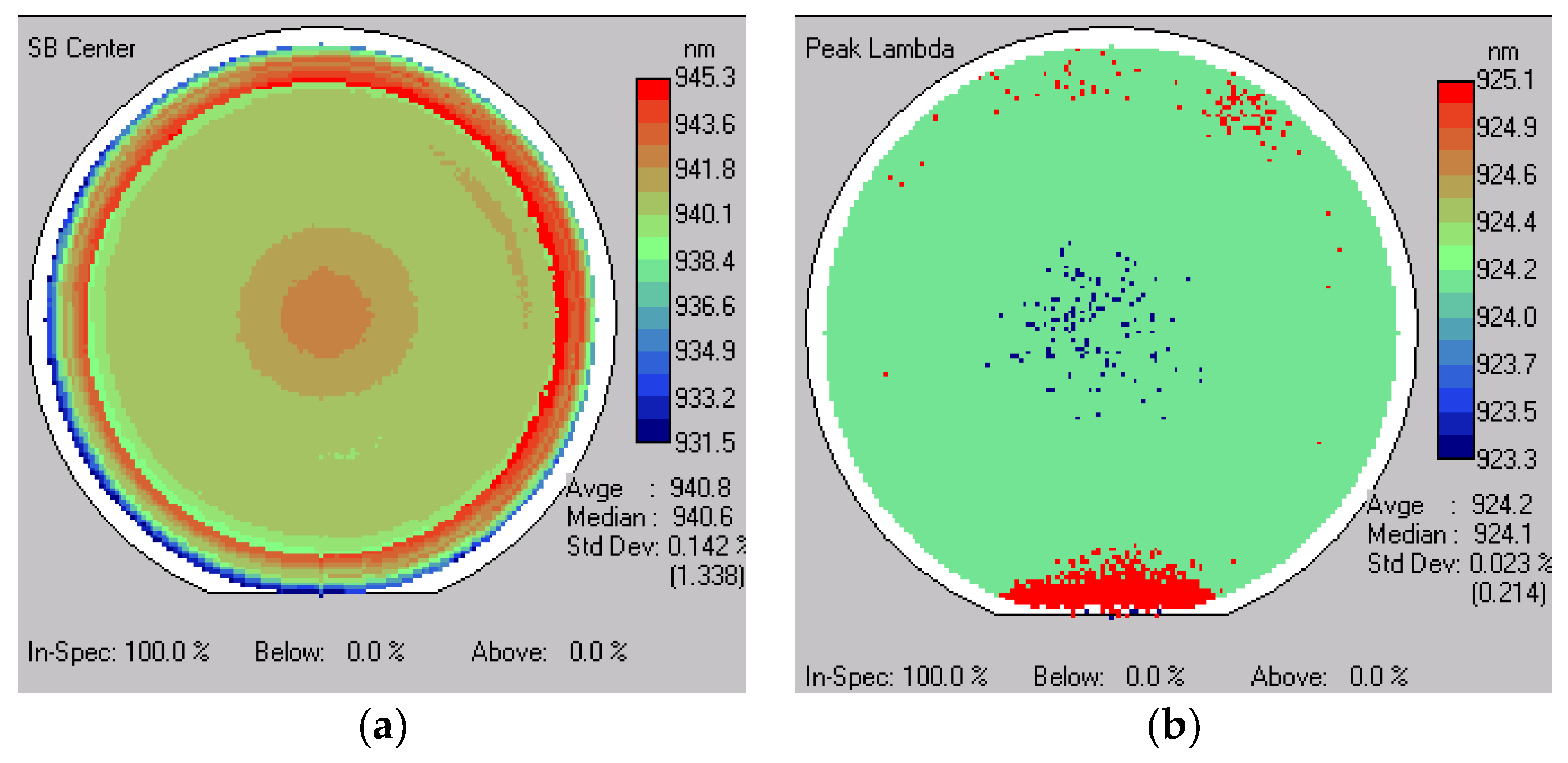

4.2. Performance of VCSEL

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, Z.; Wang, L.; Zhao, Z.; Shu, S.; Hou, G.; Lu, H.; Tian, S.; Tong, C.; Wang, L. Broad-area laser diodes with on-chip combined angled cavity. Chin. Opt. Lett. 2017, 15, 081402. [Google Scholar]

- Wang, T.; Wang, L.; Shu, S.; Tian, S.; Zhao, Z.; Tong, C.; Wang, L. Suppression of far-field blooming in high-power broad-area diode lasers by optimizing gain distribution. Chin. Opt. Lett. 2017, 15, 071404. [Google Scholar] [CrossRef]

- Bao, L.; Kim, N.H.; Mawst, L.J.; Elkin, N.N.; Troshchieva, V.N.; Vysotsky, D.V.; Napartovich, A.P. Near-diffraction-limited coherent emission from large aperture antiguided vertical-cavity surface-emitting laser arrays. Appl. Phys. Lett. 2004, 84, 320–322. [Google Scholar] [CrossRef]

- Mereuta, A.; Sirbu, A.; Caliman, A.; Suruceanu, G.; Iakovlev, V.; Mickvic, Z.; Kapon, E. Fabrication and performance of 1.3-μm 10-Gb/s CWDM wafer-fused VCSELs grown by MOVPE. J. Cryst. Growth. 2015, 414, 210–214. [Google Scholar] [CrossRef]

- Yoon, J.; Jo, S.; Chun, I.S.; Jung, I.; Kim, H.-S.; Meitl, M.; Menard, E.; Li, X.; Coleman, J.J.; Paik, U.; et al. GaAs photovoltaics and optoelectronics using releasable multilayer epitaxial assemblies. Nature 2010, 465, 329–333. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Shin, H.B.; Lee, W.H.; Jung, S.H.; Kim, C.Z.; Kim, H.; Lee, Y.T.; Kang, H.K. 1080 nm InGaAs laser power converters grown by MOCVD using InAlGaAs metamorphic buffer layers. Sol. Energy Mat. Sol. Cells 2019, 200, 109984. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, H.S.; Yao, Q.X.; Yan, H.; Gan, Z.Y. Species transport and chemical reaction in a MOCVD reactor and their influence on the GaN growth uniformity. J. Cryst. Growth. 2016, 454, 87–95. [Google Scholar] [CrossRef]

- Li, Z.; Jiao, T.; Hu, D.; Lv, Y.; Li, W.; Dong, X.; Zhang, B. Study on β-Ga2O3 Films Grown with Various VI/III Ratios by MOCVD. Coatings 2019, 9, 281. [Google Scholar] [CrossRef]

- Hu, C.K.; Chen, C.J.; Wei, T.C.; Li, T.T.; Huang, C.Y.; Chao, C.L.; Lin, Y.J. Numerical verification of gallium nitride thin-film growth in a large MOCVD reactor. Coatings 2017, 7, 112. [Google Scholar] [CrossRef]

- Su, J.; Armour, E.; Lee, S.M.; Arif, R.; Papasouliotis, G.D. Uniform growth of III-nitrides on 200 mm silicon substrates using a single wafer rotating disk MOCVD reactor. Phys. Status Solidi A. 2016, 213, 856–860. [Google Scholar] [CrossRef]

- Kadinski, L.; Merai, V.; Parekh, A.; Ramer, J.; Armour, E.A.; Stall, R.; Gurary, A.; Galyukov, A.; Makarov, Y. Computational analysis of GaN/InGaN deposition in MOCVD vertical rotating disk reactors. J. Cryst. Growth 2004, 261, 175–181. [Google Scholar] [CrossRef]

- Schmitz, D.A.; Habermann, S.; Hofeldt, J.; Brien, D.; Schineller, B.; Heuken, M. Application of Advanced Planetary Reactor® Technology for Production of III-V Compound Semiconductor Materials for CPV on 6 ″Ge Wafers. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 000546–000551. [Google Scholar]

- Black, L.R.; Clark, I.O.; Fox, B.A.; Jesser, W.A. MOCVD of GaAs in a horizontal reactor: Modeling and growth. J. Cryst. Growth 1991, 109, 241–245. [Google Scholar] [CrossRef]

- Brien, D.; Dauelsberg, M.; Christiansen, K.; Hofeldt, J.; Deufel, M.; Heuken, M. Modelling and simulation of MOVPE of GaAs-based compound semiconductors in production scale Planetary Reactors. J. Cryst. Growth 2007, 303, 330–333. [Google Scholar] [CrossRef]

- Martin, C.; Dauelsberg, M.; Protzmann, H.; Boyd, A.R.; Thrush, E.J.; Heuken, M.; Talalaev, R.A.; Yakovlev, E.V.; Kondratyev, A.V. Modelling of group-III nitride MOVPE in the closed coupled showerhead reactor and Planetary Reactor®. J. Cryst. Growth 2007, 303, 318–322. [Google Scholar] [CrossRef]

- STR Group, Modeling of Crystal Growth and Devices. Available online: http://www.str-soft.com/ (accessed on 17 October 2019).

- Parikh, R.P.; Adomaitis, R.A. An overview of gallium nitride growth chemistry and its effect on reactor design: Application to a planetary radial-flow CVD system. J. Cryst. Growth 2006, 286, 259–278. [Google Scholar] [CrossRef]

- Yakovlev, E.V.; Shpolyanskiy, Y.A.; Talalaev, R.A.; Karpov, S.Y.; Makarov, Y.N.; Bergunde, T.; Lowry, S.A. Detailed Modeling of Metal Organic Vapor Phase Epitaxy of III-V Ternary Compounds in Production-Scale AIX 2400G3 Planetary Reactor. In Fundamental Gas.-Phase and Surface Chemistry of Vapor-Phase Deposition II and Process. Control., Diagnostics and Modeling in Semiconductor Manufacturing IV: Proceedings of the International Symposium; Swihart, M.T., Allendorf, M.D., Meyyappan, M., Eds.; The Electrochemical Society: Atlantic, NJ, USA, 2001; Volume 2001–2013, pp. 292–300. [Google Scholar]

- Mountziaris, T.J.; Kalyanasundaram, S.; Ingle, N.K. A reaction-transport model of GaAs growth by metalorganic chemical vapor deposition using trimethyl-gallium and tertiary-butyl-arsine. J. Cryst. Growth 1993, 131, 283–299. [Google Scholar] [CrossRef]

- Clayton, A.; Irvine, S. The kinetics of parasitic growth in GaAs MOVPE. J. Cryst. Growth 2007, 300, 277–283. [Google Scholar] [CrossRef]

- Bergunde, T.; Dauelsberg, M.; Kadinski, L.; Makarov, Y.N.; Weyers, M.; Schmitz, D.; Strauch, G.; Jürgensen, H. Heat transfer and mass transport in a multiwafer MOVPE reactor: Modelling and experimental studies. J. Cryst. Growth 1997, 170, 66–71. [Google Scholar] [CrossRef]

| Chemical Formula | Abbreviation |

|---|---|

| Ga(CH3)3 | TMGa |

| Al(CH3)3 | TMAl |

| GaCH3 | MMGa |

| AlCH3 | MMAl |

| Gas-Phase Reactions | A (s−1) | E (kcal/mol) | Ref. | |

|---|---|---|---|---|

| G1 | TMGa -> MMGa + 2CH3 * | 3.47 × 1015 | 59.5 | [18] |

| G2 | TMAl -> MMAl + 2CH3 * | 3.47 × 1015 | 66.0 | [18] |

| Surface Reactions | Ref. | |

|---|---|---|

| S1 | TMGa + AsH3 <-> GaAs(s) + 3CH4 | [18,19] |

| S2 | TMAl + AsH3 <-> AlAs(s) + 3CH4 | [18] |

| S3 | MMGa + AsH3 <-> GaAs(s) + CH4 + H2 | [18,19] |

| S4 | MMAl + AsH3 <-> AlAs(s) + CH4 + H2 | [18] |

| S5 | 2AsH3 <-> As2 + 3H2 | [18,19] |

| S6 | 4AsH3 <-> As4 + 6H2 | [18,19] |

| S7 | 2CH3 + H2 <-> 2CH4 | [18,19] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gou, Y.; Wang, J.; Cheng, Y.; Guo, Y.; Xiao, X.; Zhou, S. A Modeling and Experimental Study on the Growth of VCSEL Materials Using an 8 × 6 Inch Planetary MOCVD Reactor. Coatings 2020, 10, 797. https://doi.org/10.3390/coatings10080797

Gou Y, Wang J, Cheng Y, Guo Y, Xiao X, Zhou S. A Modeling and Experimental Study on the Growth of VCSEL Materials Using an 8 × 6 Inch Planetary MOCVD Reactor. Coatings. 2020; 10(8):797. https://doi.org/10.3390/coatings10080797

Chicago/Turabian StyleGou, Yudan, Jun Wang, Yang Cheng, Yintao Guo, Xiao Xiao, and Shouhuan Zhou. 2020. "A Modeling and Experimental Study on the Growth of VCSEL Materials Using an 8 × 6 Inch Planetary MOCVD Reactor" Coatings 10, no. 8: 797. https://doi.org/10.3390/coatings10080797

APA StyleGou, Y., Wang, J., Cheng, Y., Guo, Y., Xiao, X., & Zhou, S. (2020). A Modeling and Experimental Study on the Growth of VCSEL Materials Using an 8 × 6 Inch Planetary MOCVD Reactor. Coatings, 10(8), 797. https://doi.org/10.3390/coatings10080797